Strain Rate Sensitivity of Low Carbon Threaded Steel Rods of Grade 4.6

Abstract

1. Introduction

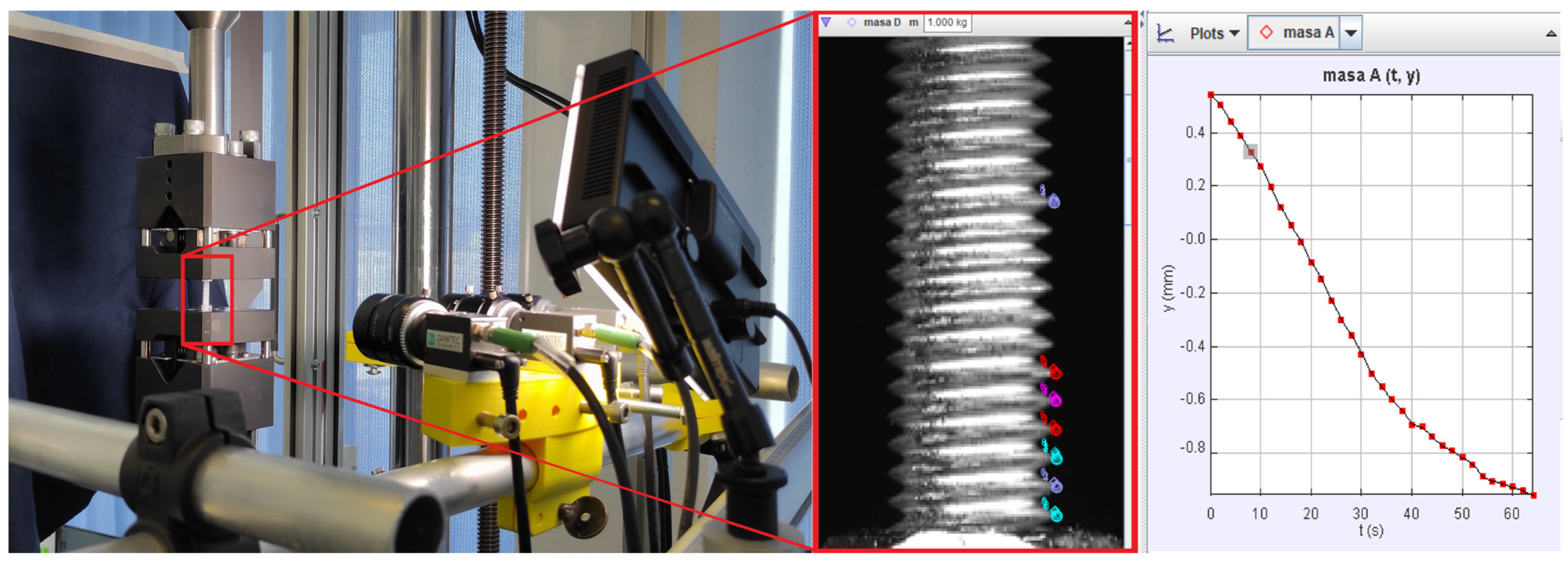

2. Experiments and Methods

2.1. Tests

2.2. Material

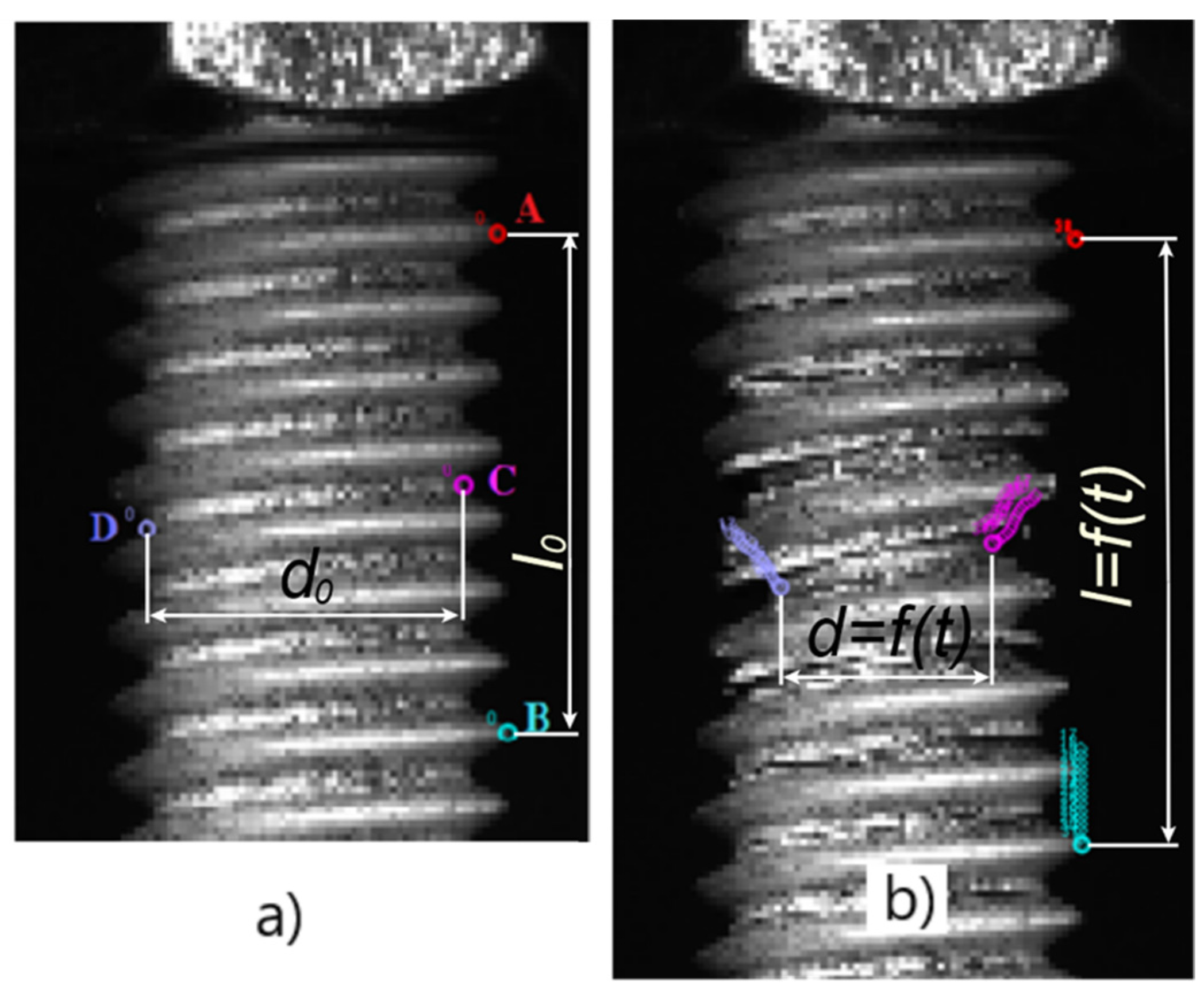

2.3. Video Analysis

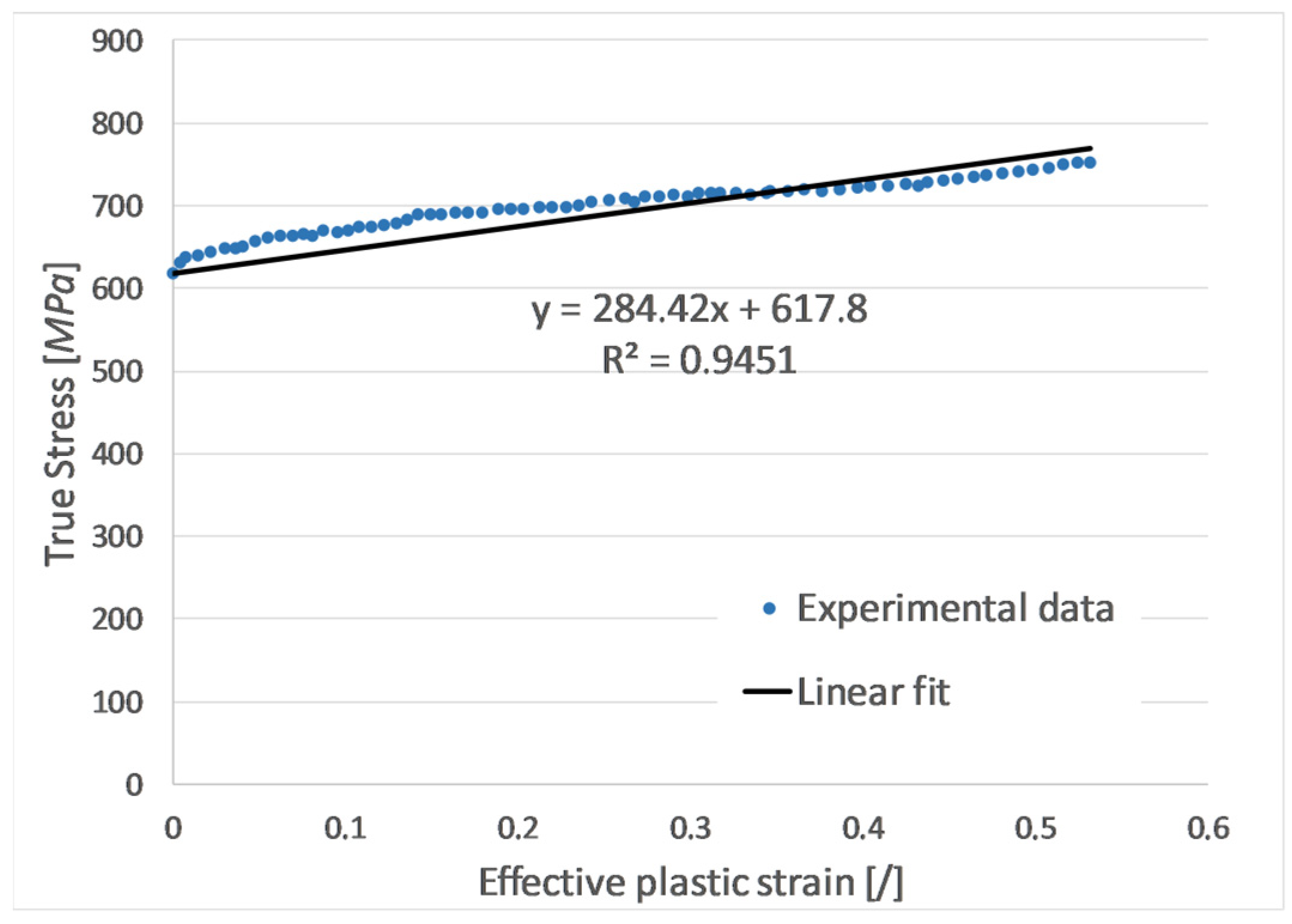

2.4. Material Characterization

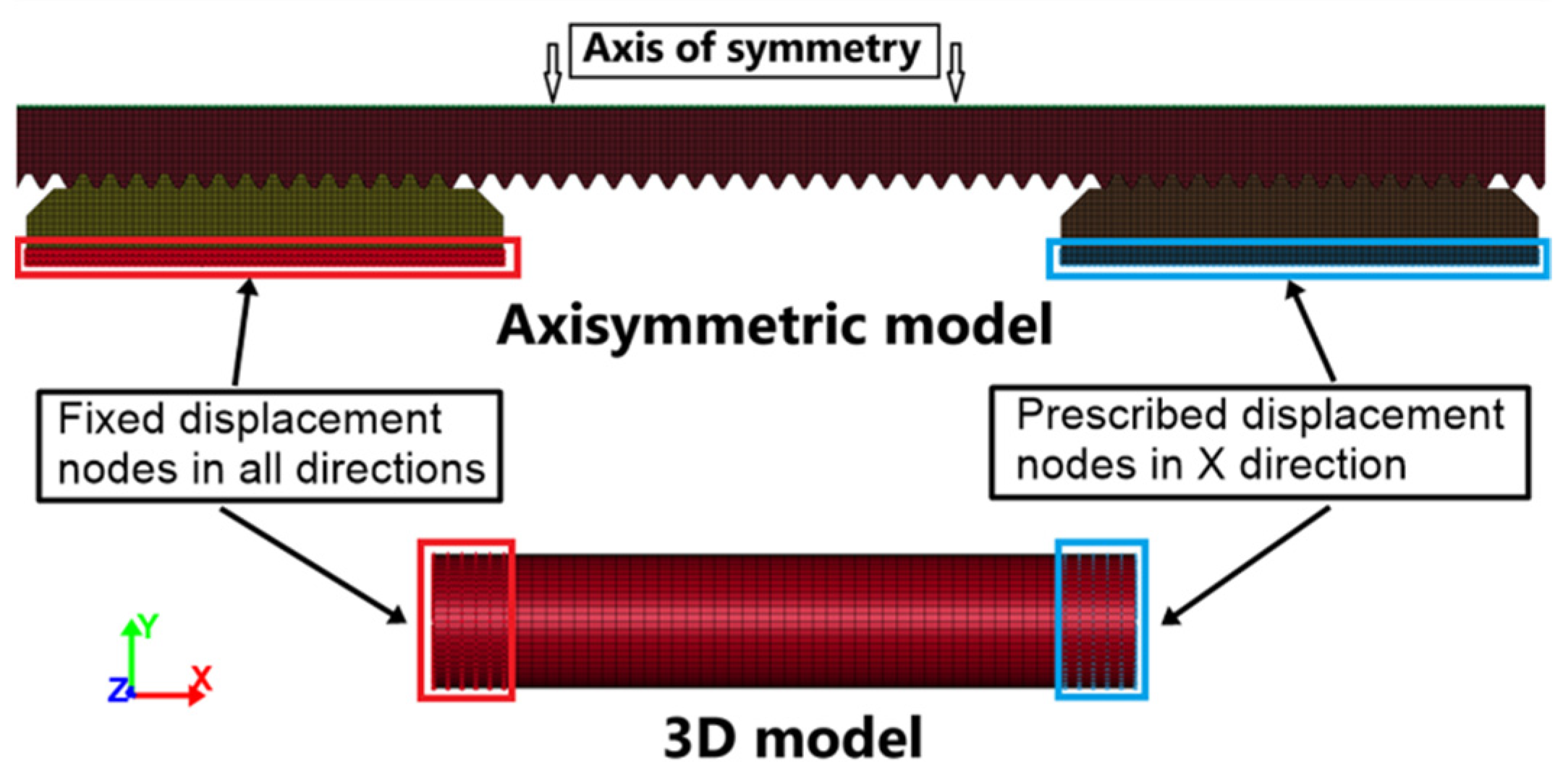

2.5. Material Parameters Identification

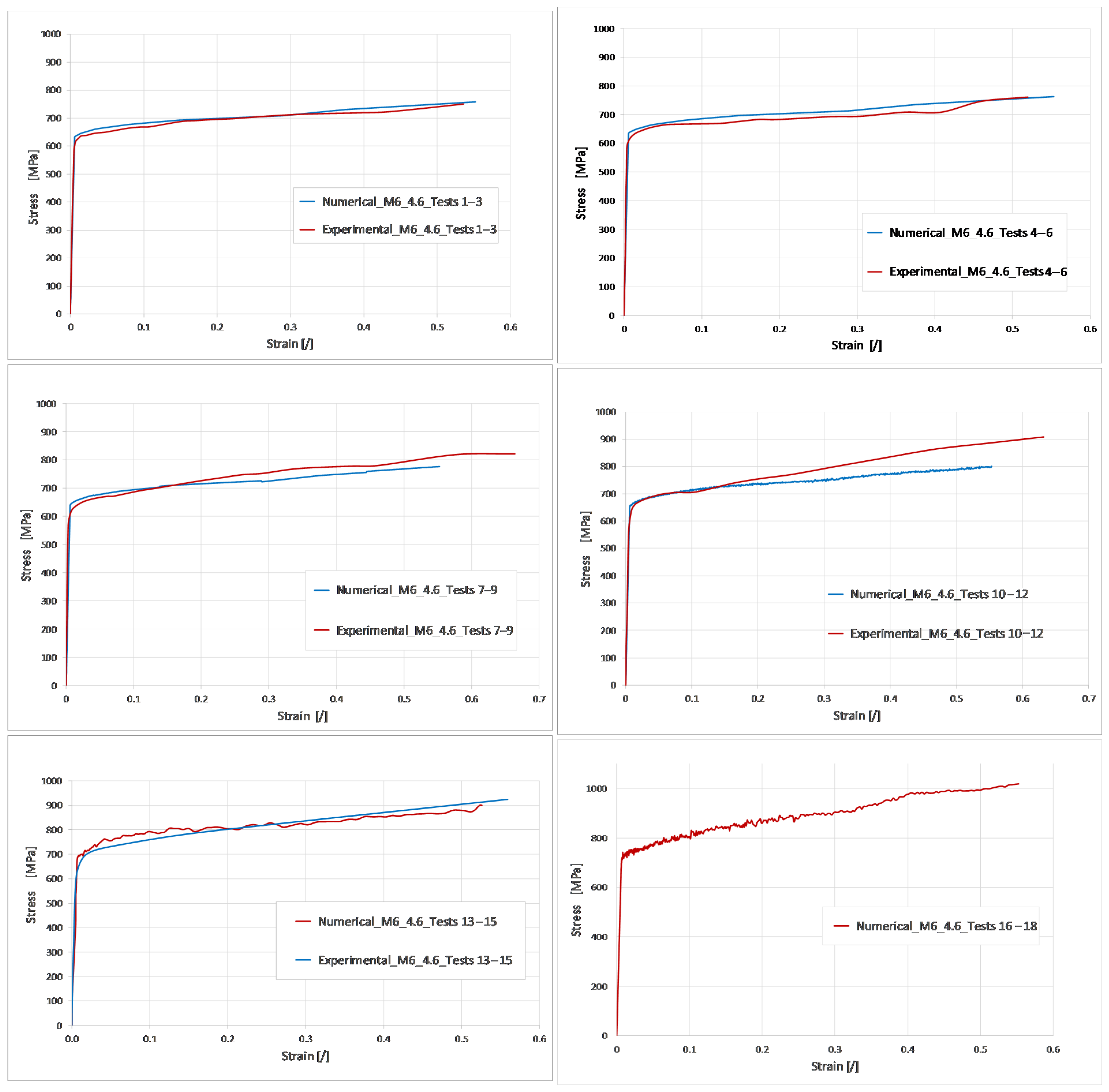

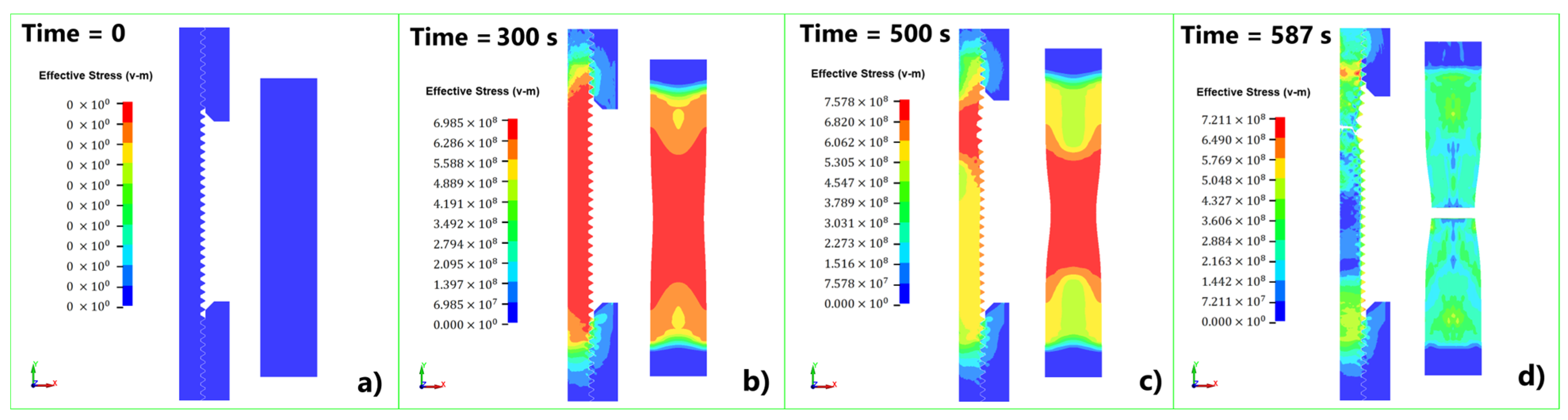

2.6. Model Validation

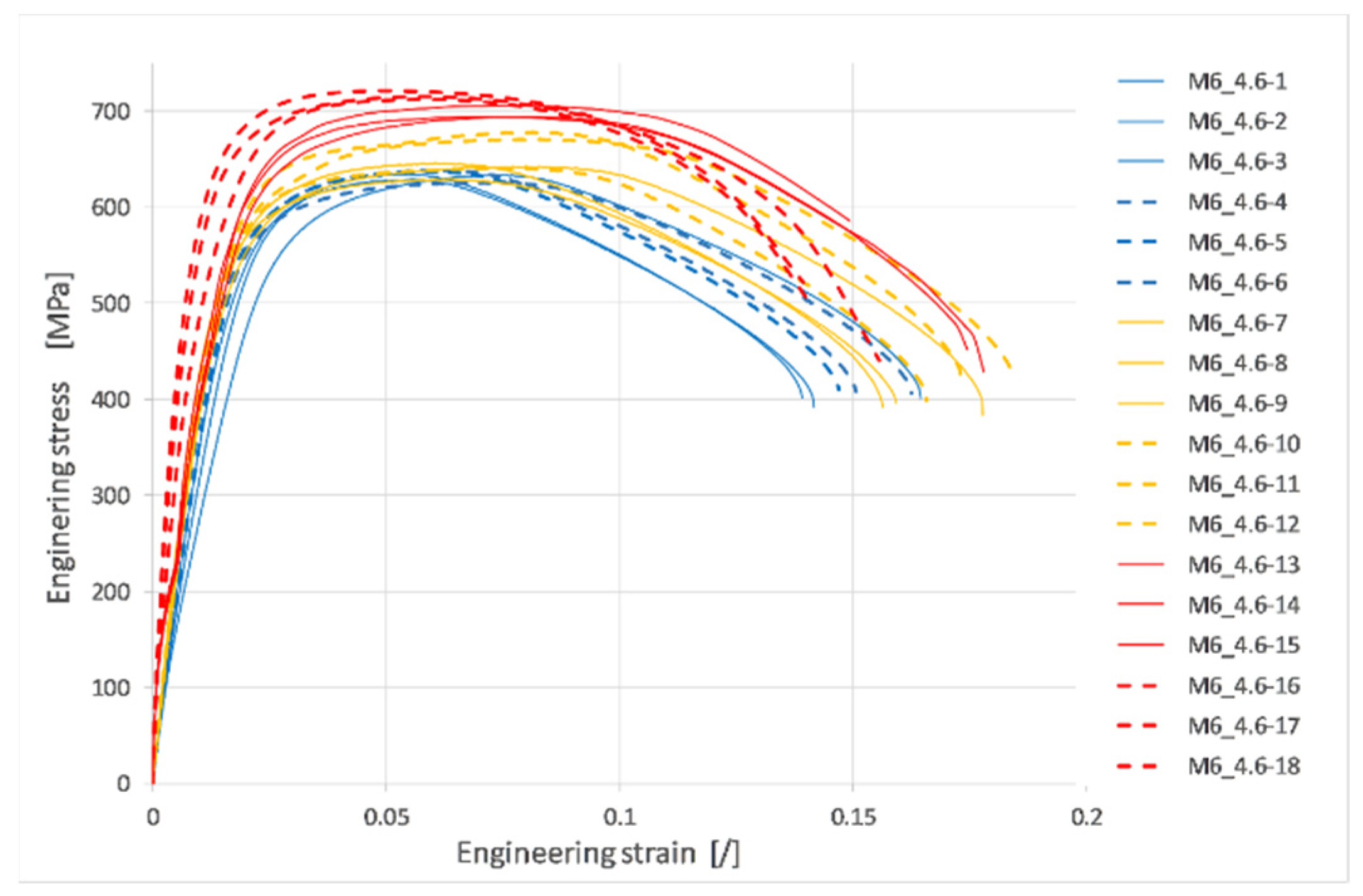

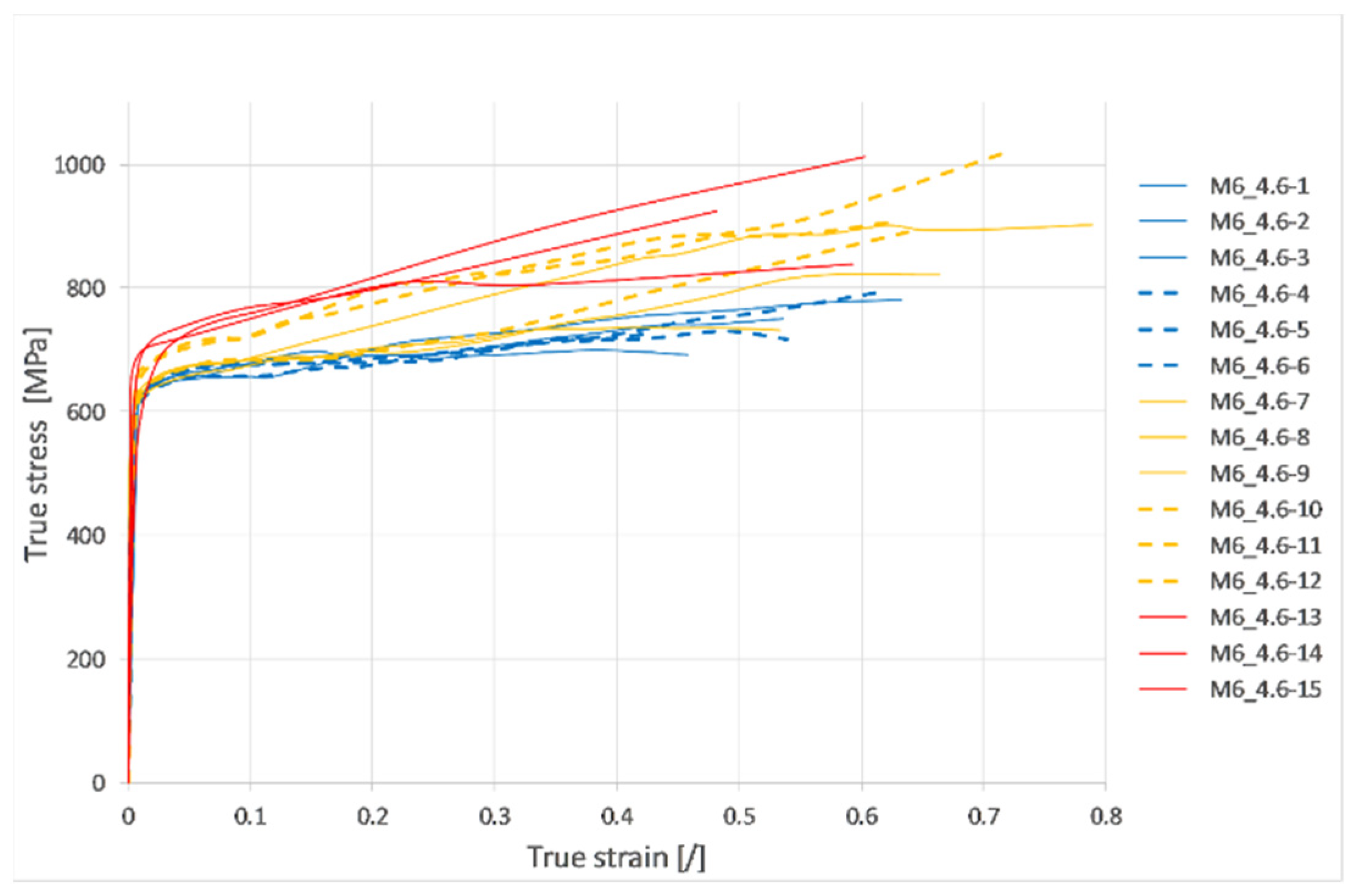

3. Results and Discussion

3.1. True Stress–Strain Curves

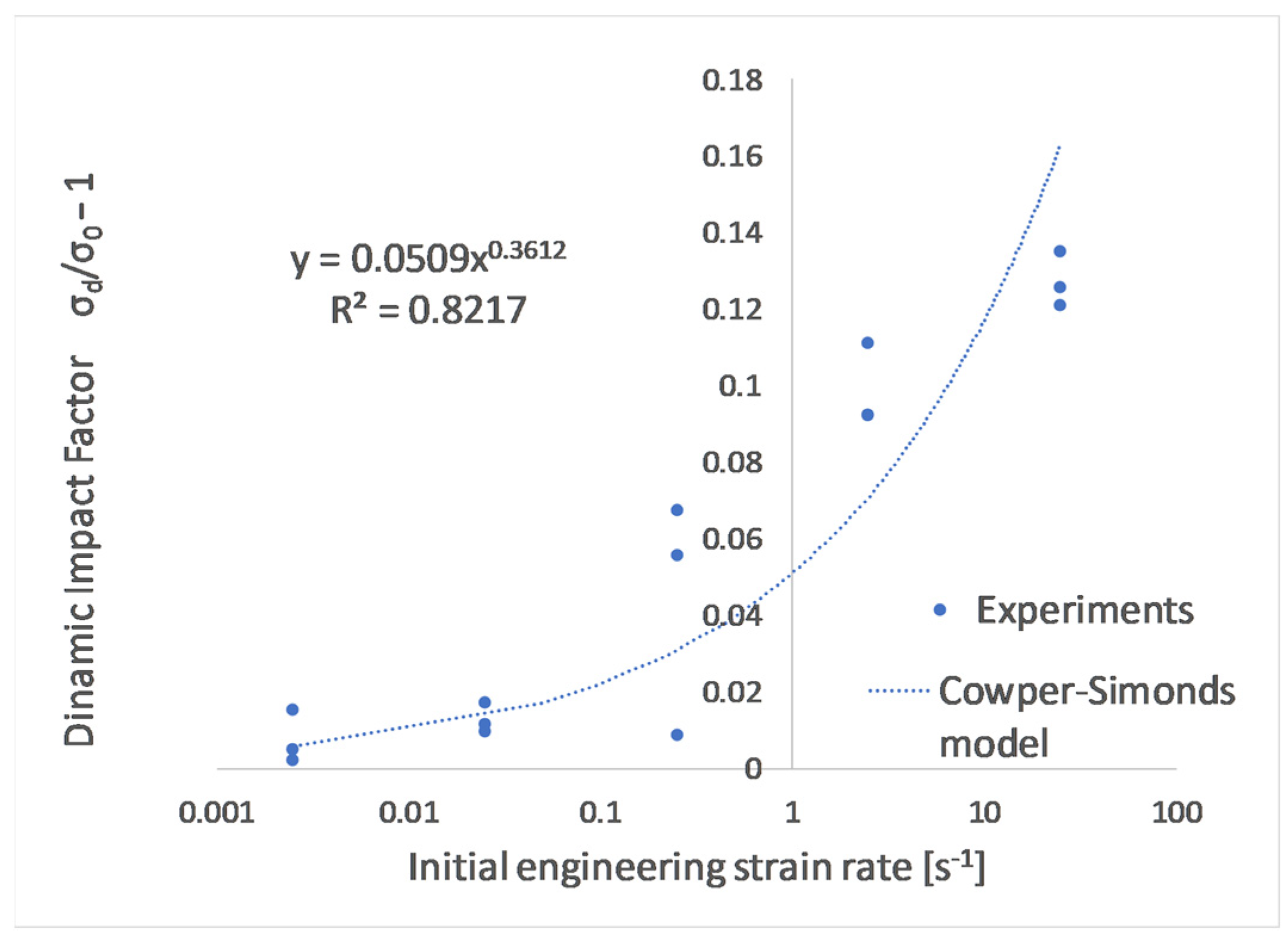

3.2. Cowper–Symonds Materials Parameters Identification

4. Validation Study

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Warren, M.; Antoniou, A.; Stewart, L. A review of experimentation and computational modeling of dynamic bolt fracture. J. Constr. Steel Res. 2022, 194, 107293. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, F.; Zhang, D.; Yu, Y.; Li, L.; Guo, X. Failure mechanisms of bolted flanges in aero-engine casings subjected to impact loading. Chin. J. Aeronaut. 2021, 34, 125–144. [Google Scholar] [CrossRef]

- Fransplass, H.; Langseth, M.; Hopperstad, O.S. Tensile behaviour of threaded steel fasteners at elevated rates of strain. Int. J. Mech. Sci. 2011, 53, 946–957. [Google Scholar] [CrossRef]

- Mouritz, A.P. Failure mechanisms of mild steel bolts under different tensile loading rates. Int. J. Impact Eng. 1994, 15, 311–324. [Google Scholar] [CrossRef]

- Fransplass, H.; Langseth, M.; Hopperstad, O.S. Numerical study of the tensile behaviour of threaded steel fasteners at elevated rates of strain. Int. J. Impact Eng. 2013, 54, 19–30. [Google Scholar] [CrossRef]

- Schauwecker, F.; Moncayo, D.; Middendorf, P. Characterization of high-strength bolts and the numerical representation method for an efficient crash analysis. Eng. Fail. Anal. 2022, 137, 106249. [Google Scholar] [CrossRef]

- Trajkovski, J.; Kunc, R.; Pepel, V.; Prebil, I. Flow and fracture behavior of high-strength armor steel PROTAC 500. Mater. Des. 2015, 66 Pt A, 37–45. [Google Scholar] [CrossRef]

- Cowper, G.; Symonds, P. Strain Hardening and Strain-Rate Effects in the Impact Loading of Cantilever Beam; Brown University Division of Applied Mathematics: Providence, RI, USA, 1957. [Google Scholar]

- Mahalle, G.; Kotkunde, N.; Gupta, A.K.; Singh, S.K. Cowper-symonds strain hardening model for flow behaviour of inconel 718 alloy. Mater. Today Proc. 2019, 18, 2796–2801. [Google Scholar] [CrossRef]

- Noh, H.G.; Lee, K.; Kang, B.S.; Kim, J. Inverse parameter estimation of the Cowper-Symonds material model for electromagnetic free bulge forming. Int. J. Precis. Eng. Manuf. 2016, 17, 1483–1492. [Google Scholar] [CrossRef]

- Škrlec, A.; Kocjan, T.; Nagode, M.; Klemenc, J. Modelling a Response of Complex-Phase Steel at High Strain Rates. Materials 2024, 17, 2302. [Google Scholar] [CrossRef]

- Škrlec, A.; Panić, B.; Nagode, M.; Klemenc, J. Estimating the Cowper–Symonds Parameters for High-Strength Steel Using DIC Combined with Integral Measures of Deviation. Metals 2024, 14, 992. [Google Scholar] [CrossRef]

- Yang, S.; Zhu, Y.; Zhang, R.; Zhao, Y.; Yang, H. Rate-dependent behaviour of high-strength steel bolts. J. Constr. Steel Res. 2024, 215, 108560. [Google Scholar] [CrossRef]

- Johnson, G.R. Materials characterization for computations involving severe dynamic loading. In Proceedings of the Army Symposium on Solid Mechanics, Cape Cod, MA, USA, 30 September–2 October 1980. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Borovinšek, M.; Vesenjak, M.; Ren, Z. Improving the crashworthiness of reinforced wooden road safety barrier using simulations of pre-stressed bolt connections with failure. Eng. Fail. Anal. 2013, 35, 625–635. [Google Scholar] [CrossRef]

- ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2009.

- ISO 898; Mechanical and Physical Properties for Metric Fasteners Made of Carbon Steel and Alloy Steel—Part 1: Bolts, Screws and Studs with Specified Property Classes—Coarse Thread and Fine Pitch Thread. ISO: Geneva, Switzerland, 2013.

- Brown, D.; Christian, W. Simulating what you see: Combining computer modeling with video Modeling. In Proceedings of the Mptl 16—Hsci 2011, Ljubljana, Slovenia, 15–17 September 2011. [Google Scholar]

- Tracker. 2024. Available online: https://physlets.org/tracker/ (accessed on 2 December 2024).

- Bridgman, P.W. Studies in Large Plastic Flow and Fracture; Harvard University Press: Cambridge, MA, USA; London, UK, 1964. [Google Scholar] [CrossRef]

- Majzoobi, G.H.; Freshteh-Saniee, F.; Faraj Zadeh Khosroshahi, S.; Beik Mohammadloo, H. Determination of materials parameters under dynamic loading. Part I: Experiments and simulations. Comput. Mater. Sci. 2010, 49, 192–200. [Google Scholar] [CrossRef]

- Majzoobi, G.H.; Khosroshahi, S.F.Z.; Mohammadloo, H.B. Determination of materials parameters under dynamic loading: Part II: Optimization. Comput. Mater. Sci. 2010, 49, 201–208. [Google Scholar] [CrossRef]

- Borvik, T.; Hopperstad, O.S.; Berstad, T.; Langseth, M. A computational model of viscoplasticity and ductile damage for impact and penetration. Eur. J. Mech. A/Solids 2001, 20, 685–712. [Google Scholar] [CrossRef]

- Hernandez, C.; Maranon, A.; Ashcroft, I.A.; Casas-Rodriguez, J.P. An inverse problem for the characterization of dynamic material model parameters from a single SHPB test. Procedia Eng. 2011, 10, 1603–1608. [Google Scholar] [CrossRef]

- Milani, A.S.; Dabboussi, W.; Nemes, J.A.; Abeyaratne, R.C. An improved multi-objective identification of Johnson-Cook material parameters. Int. J. Impact Eng. 2009, 36, 294–302. [Google Scholar] [CrossRef]

- Škrlec, A.; Klemenc, J. Parameter identification for a Cowper-Symonds material model using a genetic algorithm combined with a response surface. Eng. Comput. 2017, 34, 921–940. [Google Scholar] [CrossRef]

- Stronge, W.J.; Yu, T.X. Dynamic plastic deformation in strain hardening and strain-softening cantilevers. Int. J. Solids Struct. 1989, 25, 769–782. [Google Scholar] [CrossRef]

- Jones, N. Influence of strain-hardening and strain-rate sensitivity on the permanent deformation of impulsively loaded rigid-plastic beams. Int. J. Mech. Sci. 1967, 9, 777–796. [Google Scholar] [CrossRef]

| Sample No. | File Name | Head Speed | Engineering Strain Rate | Acquisition Sampling | DIC Sampling |

|---|---|---|---|---|---|

| 4.6_xx | [mm/s] | [s−1] | [Hz] | [Hz] | |

| 1 | 4.6_01 | 0.005 | 0.00025 | 5 | 0.1 |

| 2 | 4.6_02 | 0.005 | 0.00025 | 5 | 0.1 |

| 3 | 4.6_03 | 0.005 | 0.00025 | 5 | 0.1 |

| 4 | 4.6_04 | 0.05 | 0.0025 | 50 | 1 |

| 5 | 4.6_05 | 0.05 | 0.0025 | 50 | 1 |

| 6 | 4.6_06 | 0.05 | 0.0025 | 50 | 1 |

| 7 | 4.6_07 | 0.5 | 0.025 | 500 | 10 |

| 8 | 4.6_08 | 0.5 | 0.025 | 500 | 10 |

| 9 | 4.6_09 | 0.5 | 0.025 | 500 | 10 |

| 10 | 4.6_10 | 5 | 0.25 | 5000 | 100 |

| 11 | 4.6_11 | 5 | 0.25 | 5000 | 100 |

| 12 | 4.6_12 | 5 | 0.25 | 5000 | 100 |

| 13 | 4.6_13 | 50 | 2.5 | 50,000 | 250 |

| 14 | 4.6_14 | 50 | 2.5 | 50,000 | 250 |

| 15 | 4.6_15 | 50 | 2.5 | 50,000 | 250 |

| 16 | 4.6_16 | 500 | 25 | 200,000 | / |

| 17 | 4.6_17 | 500 | 25 | 200,000 | / |

| 18 | 4.6_18 | 500 | 25 | 200,000 | / |

| Strength Class or Grade | Material and Heat Treatment | Chemical Composition (Analysis of the Product) % | Min. Hardening Temperature °C | ||||

|---|---|---|---|---|---|---|---|

| C | P | S | B | ||||

| Min | Max | Max | Max | Max | |||

| 4.6 | Carbon steel | - | 0.55 | 0.050 | 0.060 | Not specified | - |

| Class/Grade | Material | Proof Stress | Yield Strength (Min.) | Tensile Strength (Min.) | Core Hardness (Rockwell) |

|---|---|---|---|---|---|

| 4.6 | Low- or medium-carbon steel | 225 MPa | 240 MPa | 400 MPa | B67-95 |

| Effective Plastic Strain [/] | Effective Stress [MPa] |

|---|---|

| 0.0000 | 617.8 |

| 0.0033 | 631.6 |

| 0.0112 | 643.5 |

| 0.0310 | 658.7 |

| 0.0760 | 674.5 |

| 0.1445 | 689.8 |

| 0.2872 | 705.6 |

| 0.3725 | 727.5 |

| 0.5263 | 751.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trajkovski, J.; Kunc, R. Strain Rate Sensitivity of Low Carbon Threaded Steel Rods of Grade 4.6. Materials 2024, 17, 6228. https://doi.org/10.3390/ma17246228

Trajkovski J, Kunc R. Strain Rate Sensitivity of Low Carbon Threaded Steel Rods of Grade 4.6. Materials. 2024; 17(24):6228. https://doi.org/10.3390/ma17246228

Chicago/Turabian StyleTrajkovski, Jovan, and Robert Kunc. 2024. "Strain Rate Sensitivity of Low Carbon Threaded Steel Rods of Grade 4.6" Materials 17, no. 24: 6228. https://doi.org/10.3390/ma17246228

APA StyleTrajkovski, J., & Kunc, R. (2024). Strain Rate Sensitivity of Low Carbon Threaded Steel Rods of Grade 4.6. Materials, 17(24), 6228. https://doi.org/10.3390/ma17246228