Application of a 3D-Printed Part with Conformal Cooling in High-Pressure Die Casting Mould and Evaluation of Stress State During Exploitation

Abstract

1. Introduction

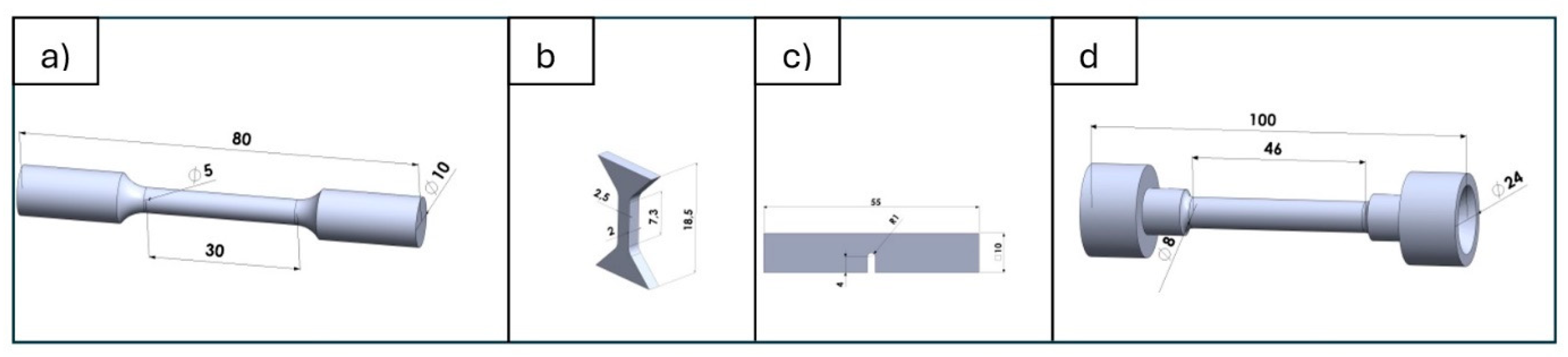

2. Materials and Methods

3. Results

3.1. Research and Determination of the Properties of 1.2709 (Maraging) Steel Obtained Through Additive Manufacturing Technology Necessary for Numerical Calculations

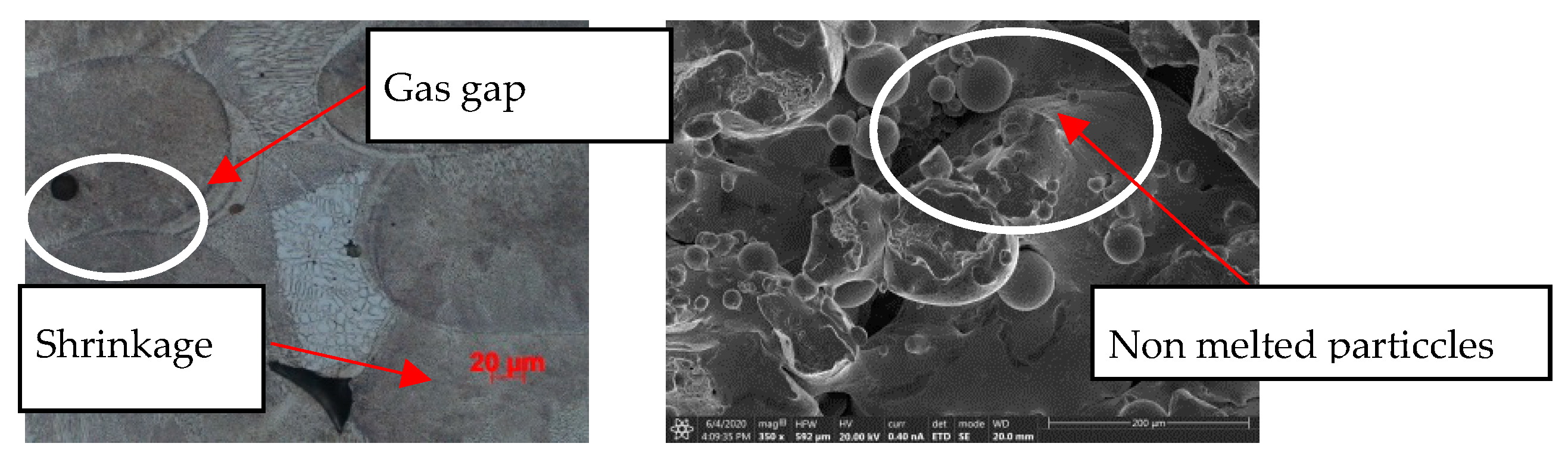

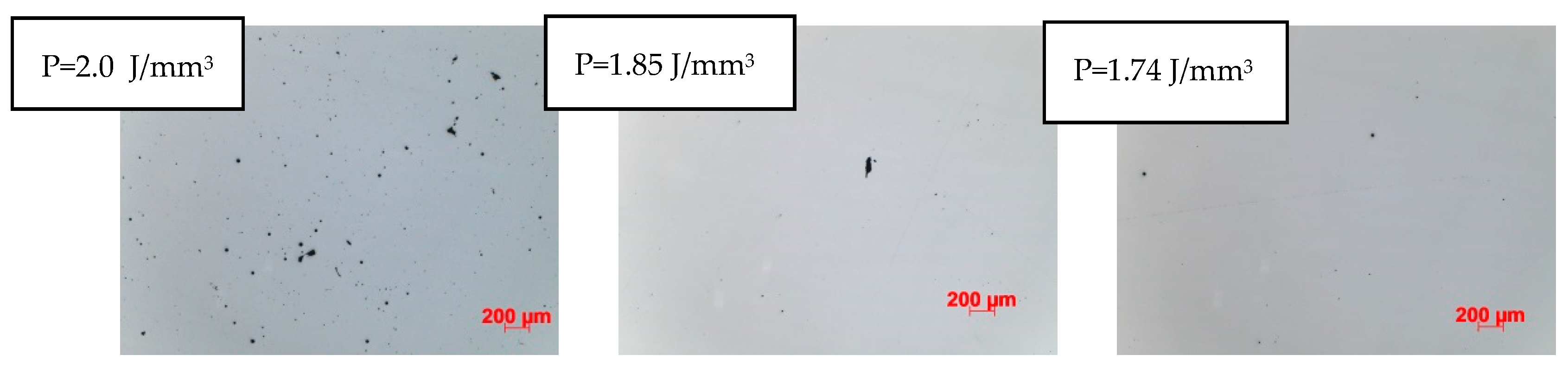

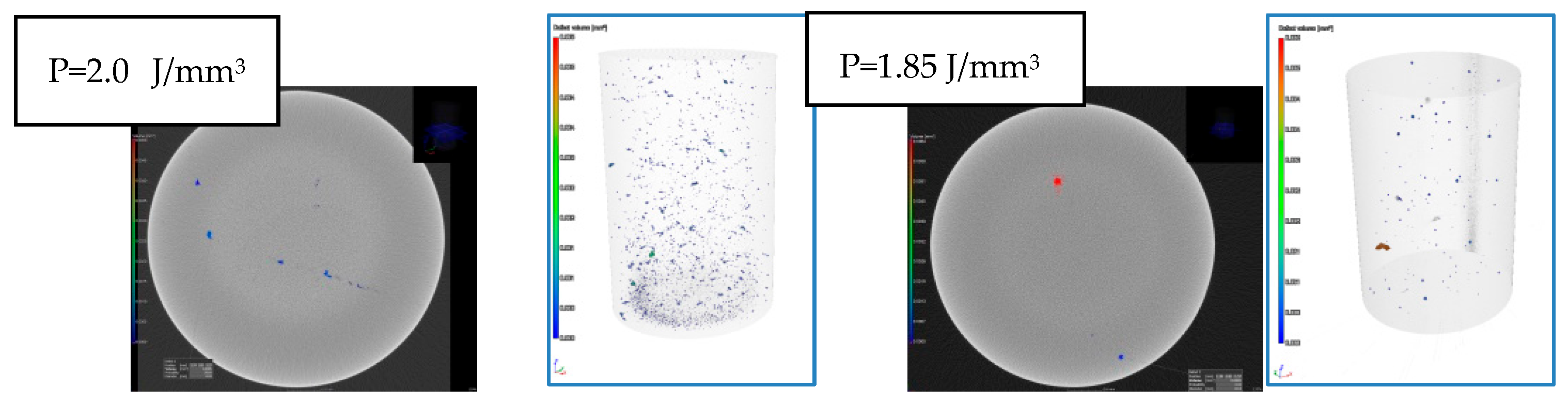

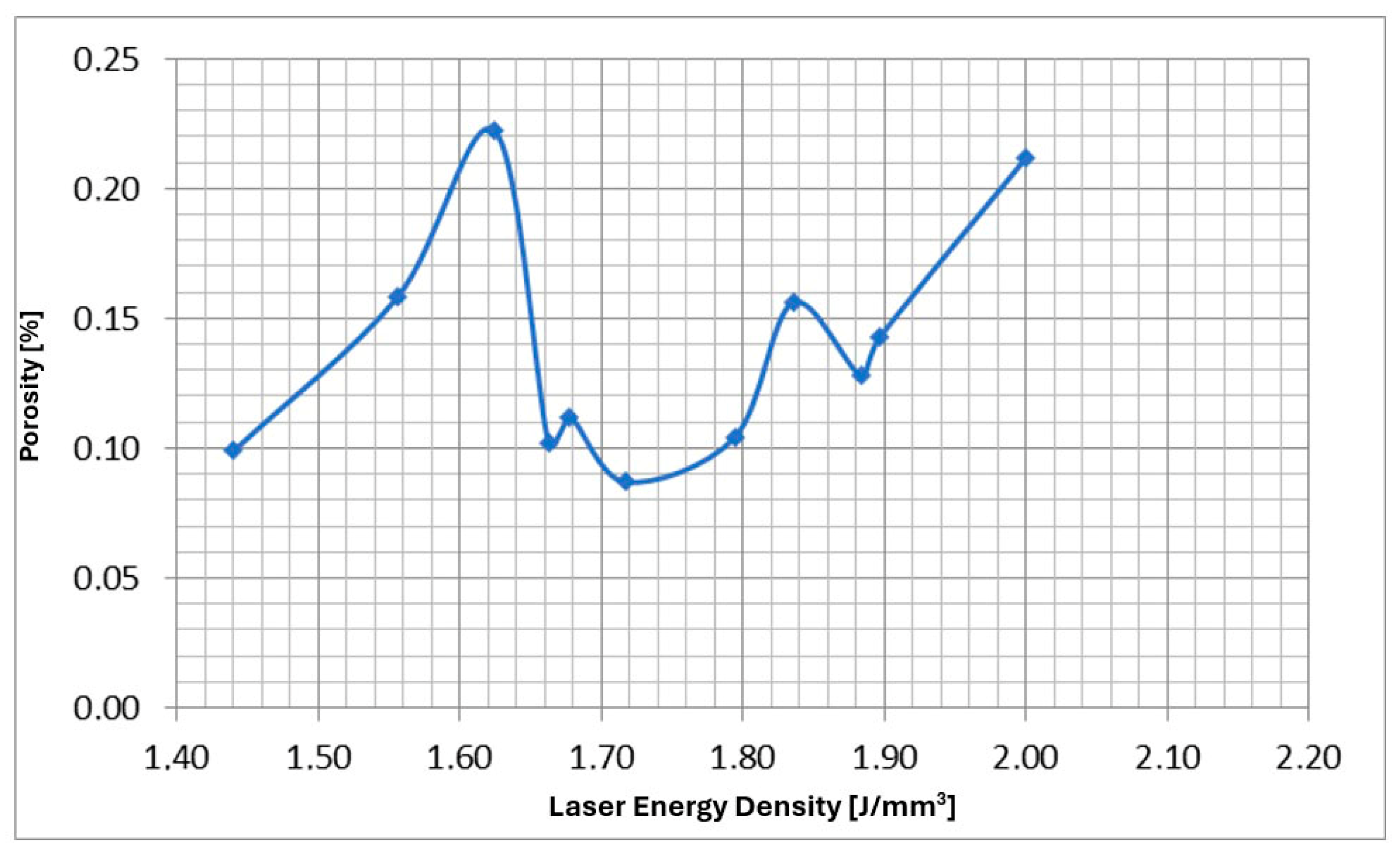

3.1.1. Determination of Printer Parameters to Achieve Minimal Porosity

- shrinkage—transition from liquid to solid phase,

- gaseous—entrapment of shielding gas as bubbles,

- incompletely melted powder.

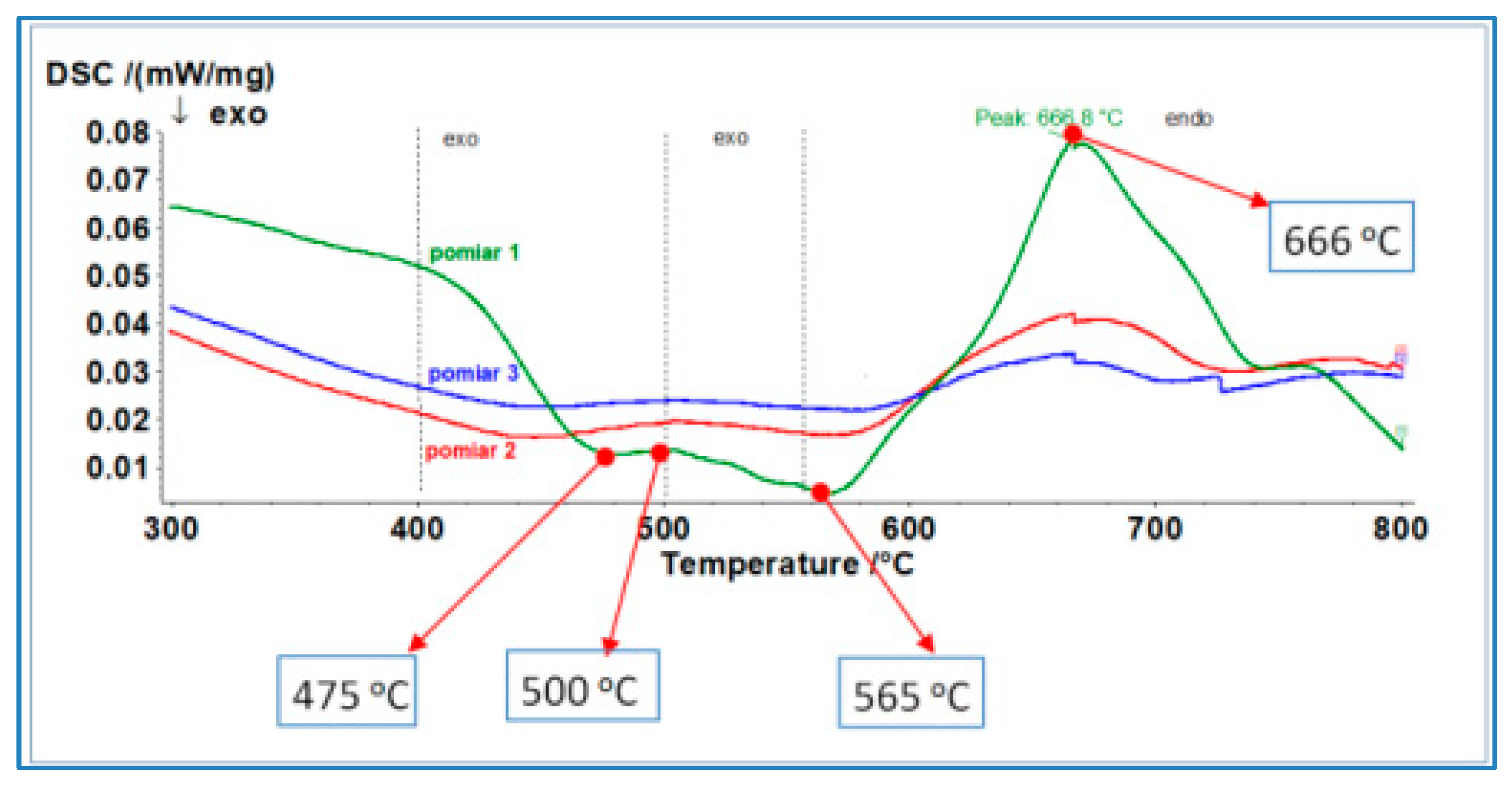

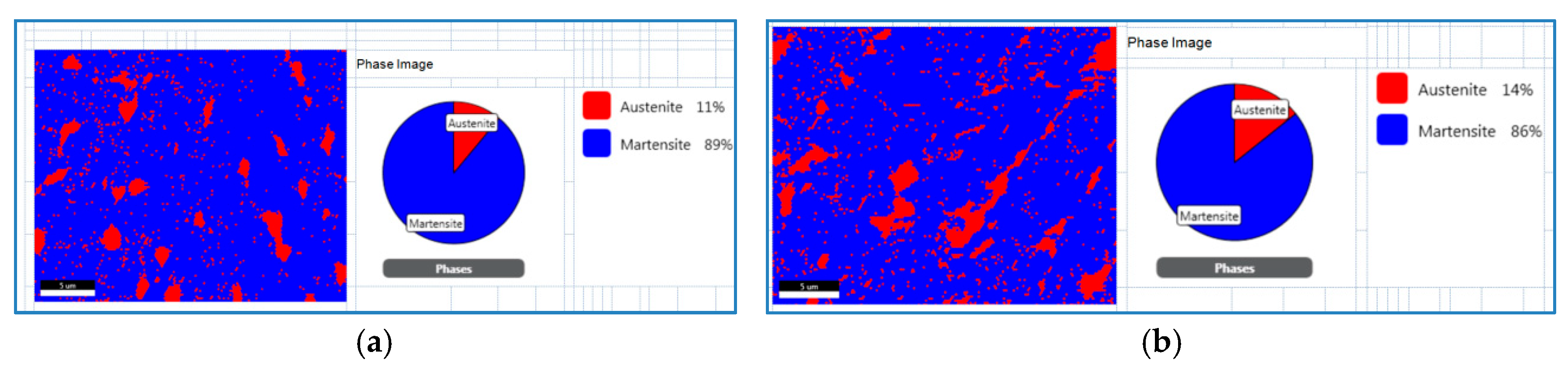

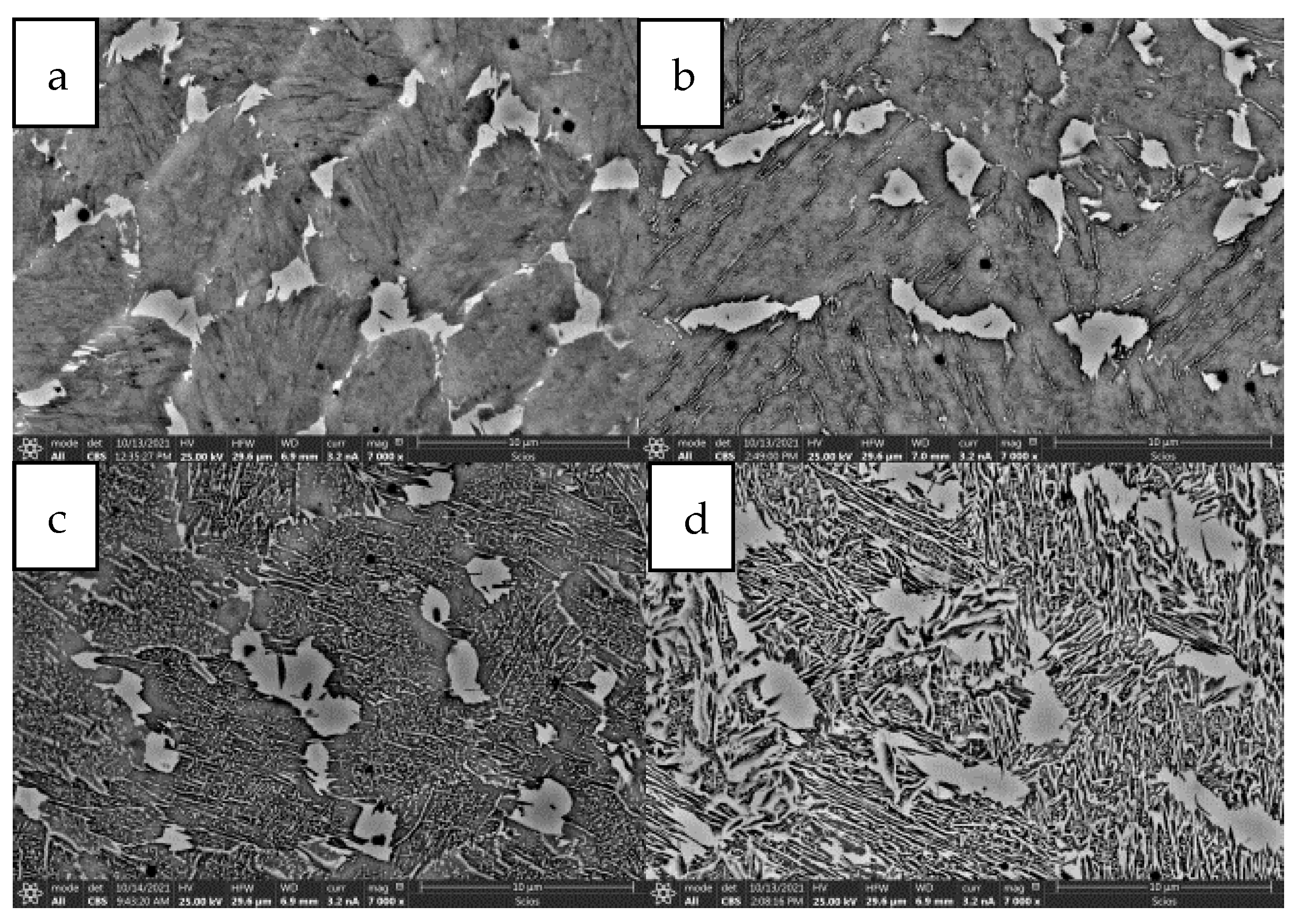

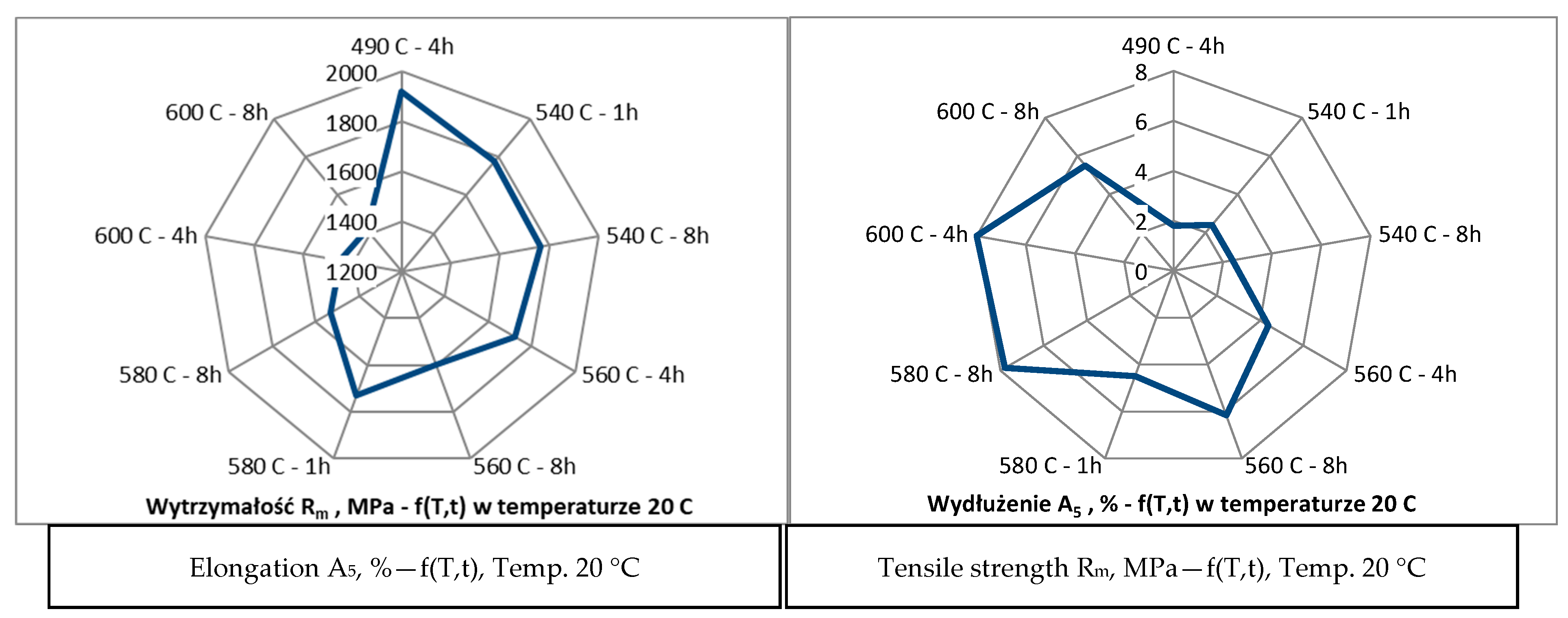

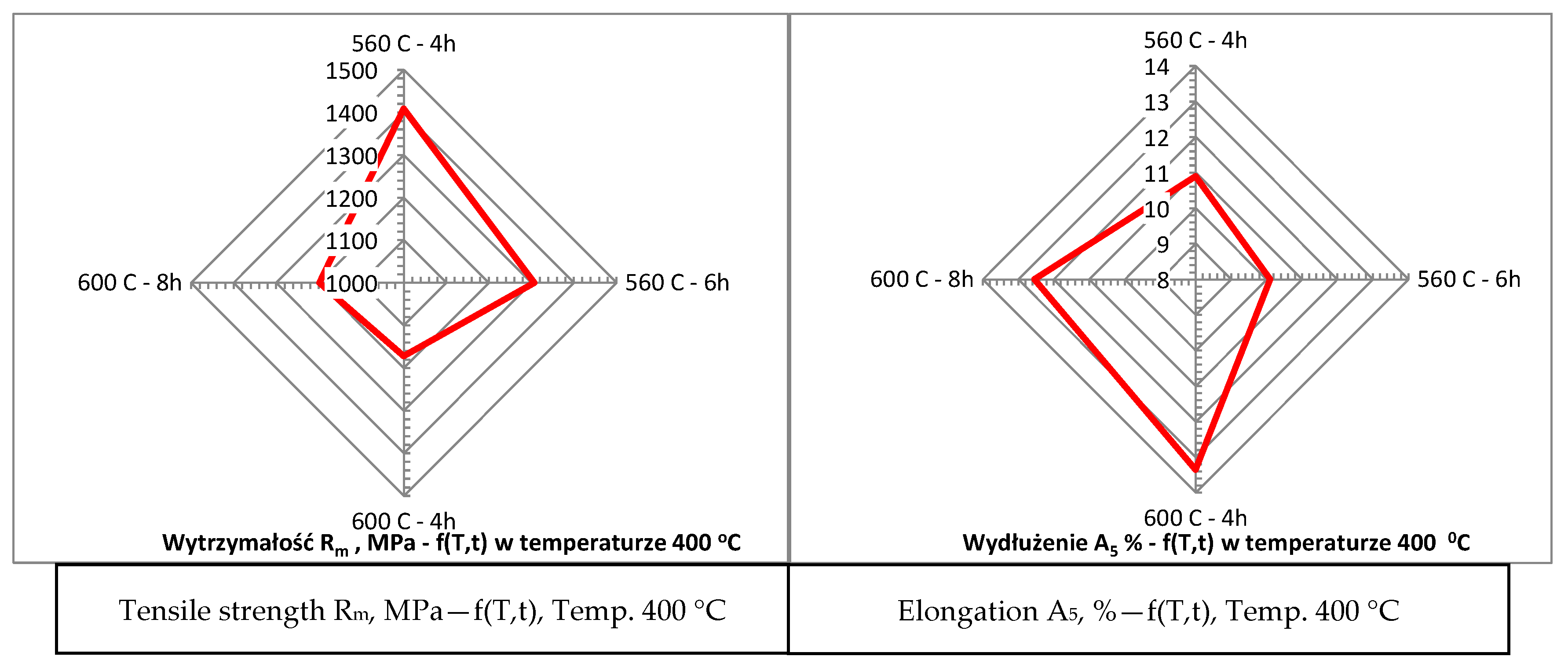

3.1.2. Determination of Heat Treatment Parameters

- average hardness: 46 ± 2 HRC,

- tensile strength (Rm): approximately 1600 ± 50 MPa,

- elongation (A5): approximately 10 ± 1.5%.

- average hardness: 40 to 43 HRC,

- tensile strength (Rm): approximately 1050 ± 50 MPa,

- elongation (A5): approximately 2.5 ± 2%.

3.1.3. Development of a Database of Thermophysical Properties for the MAGMA5 Program

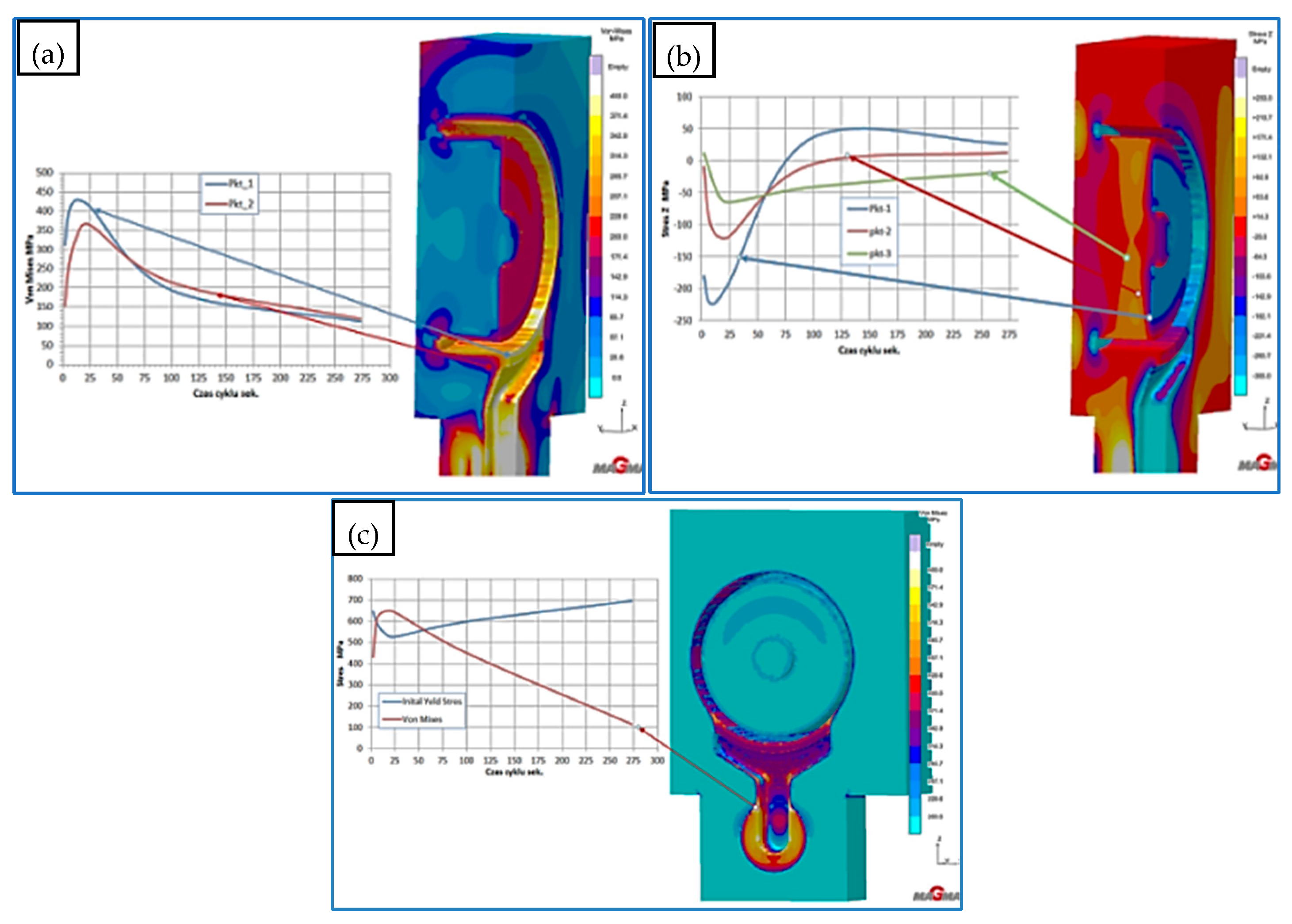

3.2. Stress Analysis in a Working Die Made of Hot-Working Construction Steel X40CrMoV5_1

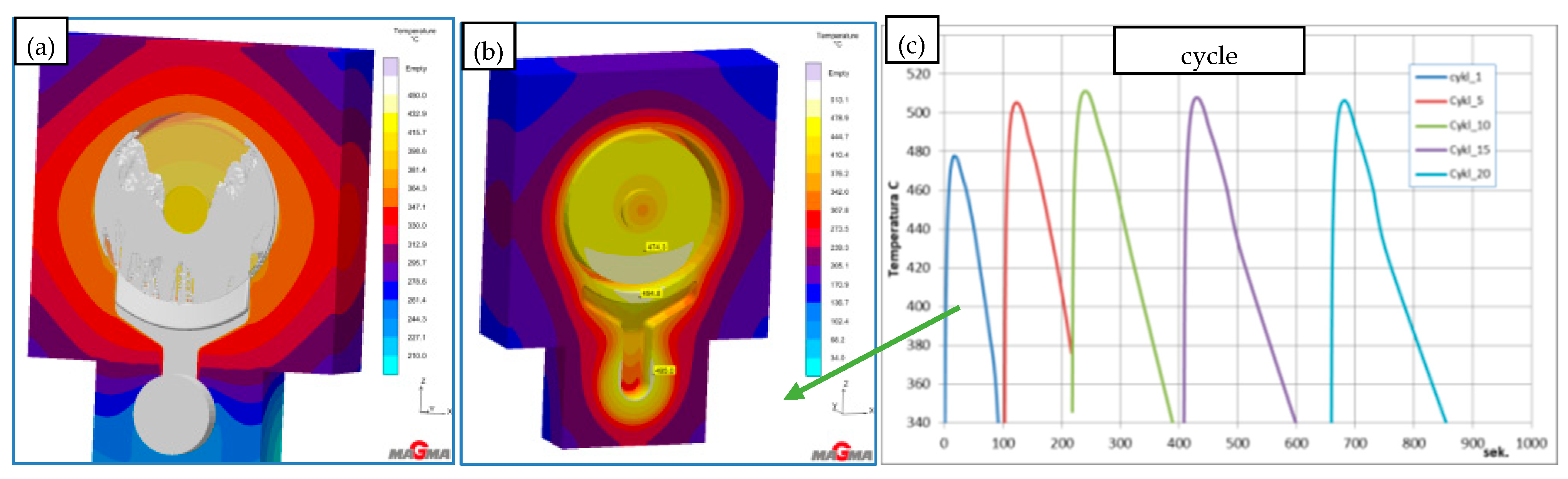

3.2.1. The HPDC Die Mould During Operation

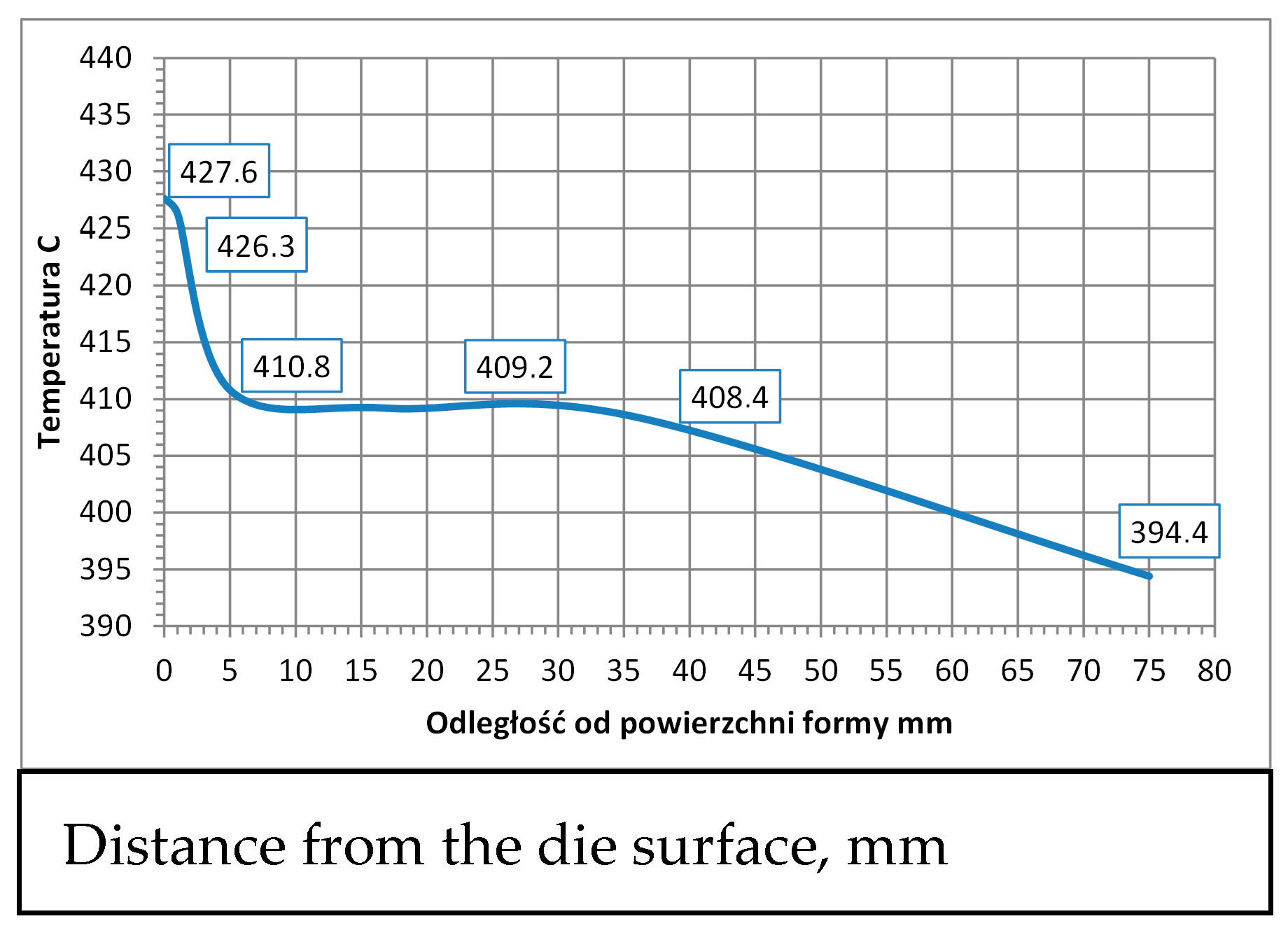

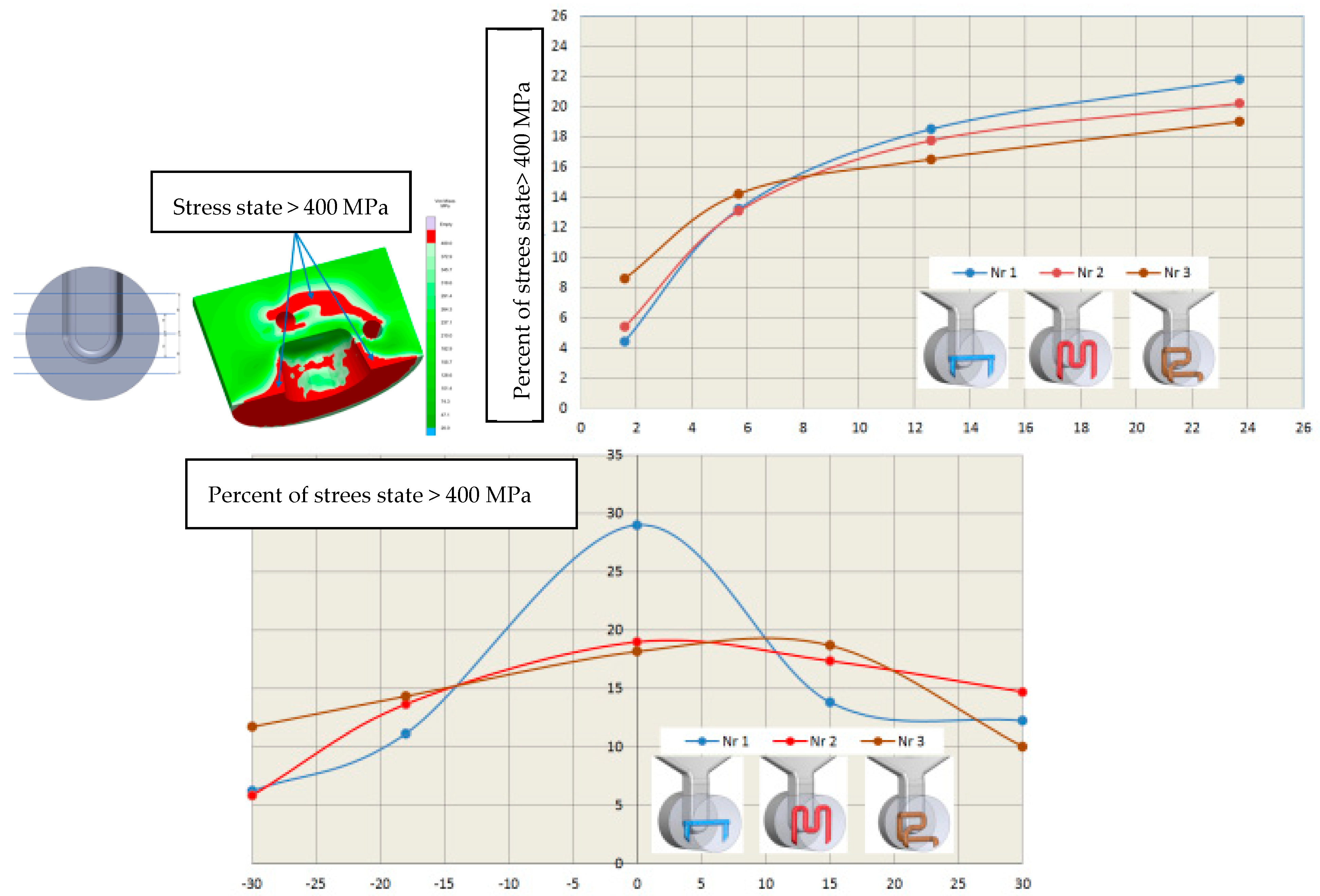

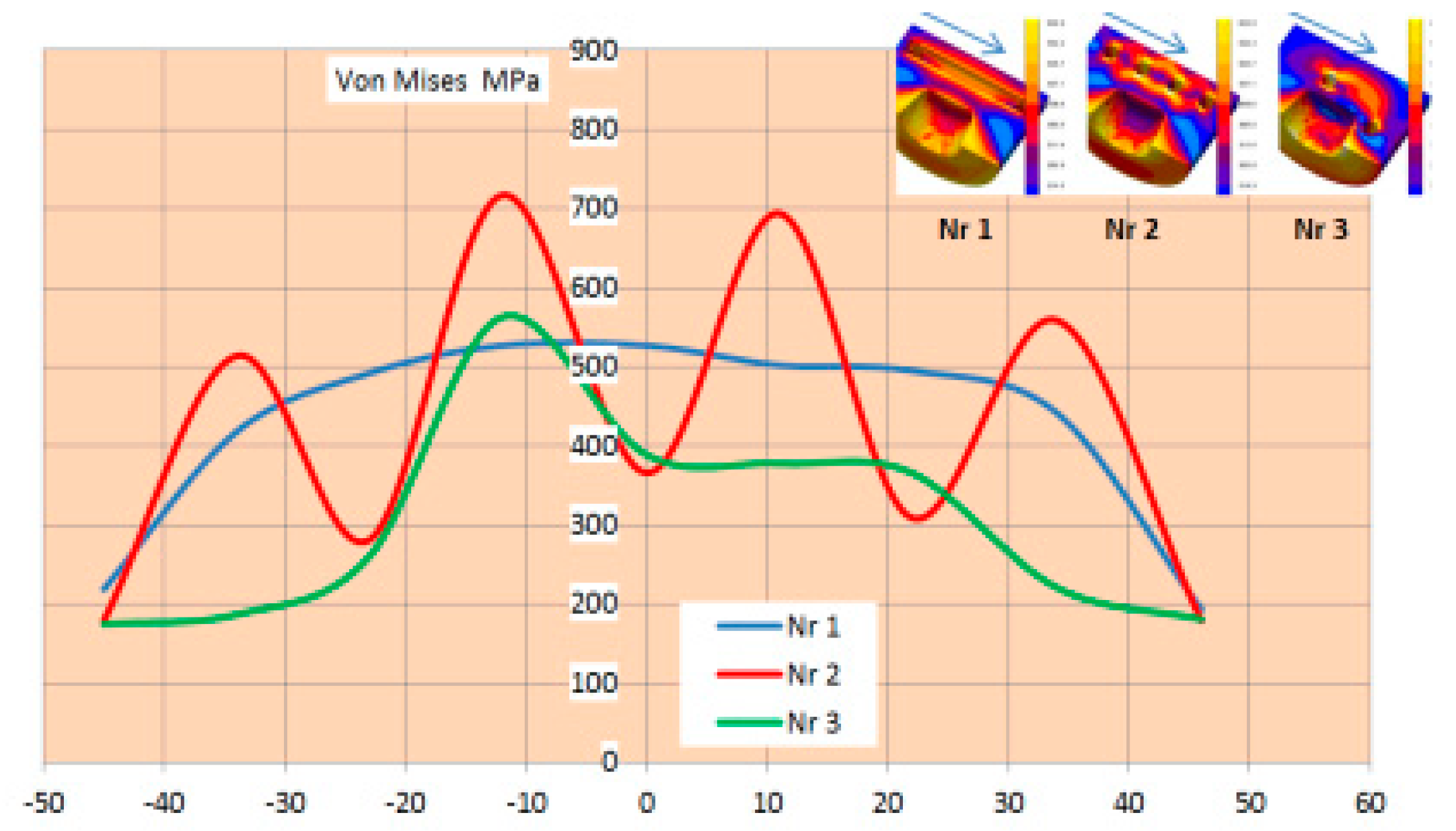

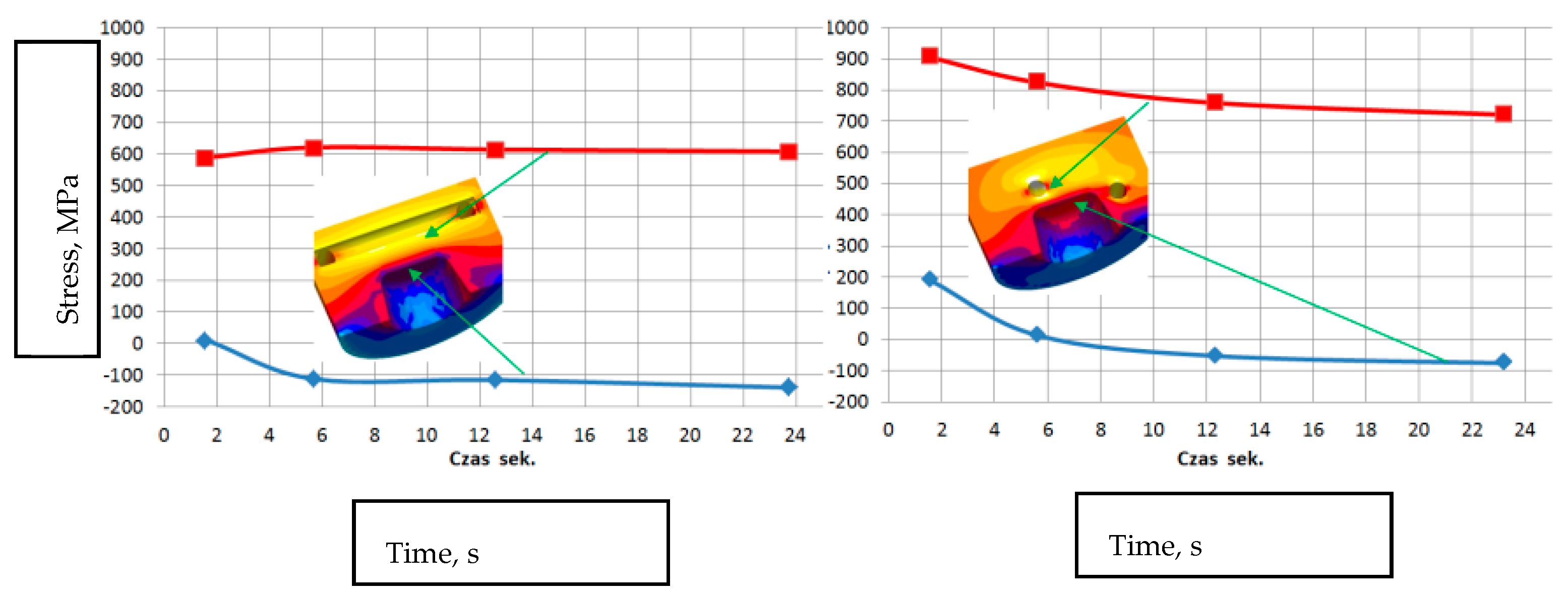

3.2.2. Stress Analysis in a Working Mould with Structural Elements with Simple and Conformal Cooling Made Using Additive Manufacturing from 18Ni300 Powder

4. Summary and Conclusions

- For the assumed boundary conditions, printing parameters were determined to allow for achieving the minimum porosity in the printed material.

- Studies on the impact of the heat treatment on the mechanical properties allowed for determining the most favorable process recipe.

- Numerical analysis of the operation process of the diffuser element, working in a pressure mould, enabled the design of optimal part parameters.

- Numerical analysis of the stresses arising during operation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuo, C.-C.; You, Z.-Y.; Chang, S.-J.; Liao, J.-D.; Yu, S.-T.; Zeng, R.-T. Development of green conformal cooling channels for rapid tooling. Int. J. Adv. Manuf. Technol. 2020, 111, 109–125. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, K.-M.; Yu, K.-M.; Wang, C.; Zhang, Y. Automatic design of conformal cooling circuits for rapid tooling. Comput. Aided Des. 2011, 43, 1001–1010. [Google Scholar] [CrossRef]

- Ferreira, J.C.; Mateus, A. Studies of rapid soft tooling with conformal cooling channels for plastic injection moulding. J. Mater. Process. Technol. 2003, 142, 508–516. [Google Scholar] [CrossRef]

- Au, K.M.; Yu, K.M. Variable Distance Adjustment for Conformal Cooling Channel Design in Rapid Tool. J. Manuf. Sci. Eng.-Trans. Asme 2014, 136, 044501. [Google Scholar] [CrossRef]

- Meyer, R. Euro-u Rapid 2002. In Proceedings of the International User’s Conference on Rapid Prototyping & Rapid Tooling & Rapid Manufacturing, Frankfurt, Germany, 2–3 December 2002. [Google Scholar]

- Kürnsteiner, P.; Wilms, M.B.; Weisheit, A.; Barriobero-Vila, P.; Jägle, E.A.; Raabe, D. Massive nanoprecipitation in an Fe-19Ni-xAl maraging steel triggered by the intrinsic heat treatment during laser metal deposition. Acta Mater. 2017, 129, 52–60. [Google Scholar] [CrossRef]

- Kempen, K.; Yasa, E.; Thijs, L.; Kruth, J.P.; Van Humbeeck, J. Microstructure and mechanical properties of Selective Laser Melted 18Ni-300 steel. Phys. Procedia 2011, 12, 255–263. [Google Scholar] [CrossRef]

- Mutua, J.; Nakata, S.; Onda, T.; Chen, Z.-C. Optimization of selective laser melting parameters and influence of post heat treatment on microstructure and mechanical properties of maraging steel. Mater. Des. 2018, 139, 486–497. [Google Scholar] [CrossRef]

- Jägle, E.A.; Sheng, Z.; Kürnsteiner, P.; Ocylok, S.; Weisheit, A.; Raabe, D. Comparison of Maraging Steel Micro- and Nanostructure Produced Conventionally and by Laser Additive Manufacturing. Materials 2017, 10, 8. [Google Scholar] [CrossRef] [PubMed]

- Jägle, E.A.; Choi, P.P.; Van Humbeeck, J.; Raabe, D. Precipitation and austenite reversion behavior of a maraging steel produced by selective laser melting. Mater. Res. Soc. 2014, 29, 2072–2079. [Google Scholar] [CrossRef]

- Bai, Y.; Yang, Y.; Wang, D.; Zhang, M. Influence mechanism of parameters process and mechanical properties evolution mechanism of maraging steel 300 by selective laser melti. Mater. Sci. Eng. A 2017, 703, 116–123. [Google Scholar] [CrossRef]

- „UDDEHOLM DIEVAR®” Edition 9, 06.2015. Available online: https://www.uddeholm.com/us/en-us/products/uddeholm-dievar/ (accessed on 25 November 2024).

| Aging | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Temperature °C | 490 | 540 | 540 | 560 | 560 | 580 | 580 | 600 | 600 |

| Time/h | 6 | 1 | 8 | 4 | 8 | 1 | 8 | 4 | 8 |

| C | Si | Mn | P | Cr | Mo | V | Co | Cu | Al. | Ti | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| X40CrMoV5_1 | 0.4 | 1.0 | 0.4 | 0.035 | 5.0 | 1.0 | 0.3 | ||||

| Dievar | 0.4 | 0.2 | 0.5 | 0.01 | 5.1 | 2.2 | 0.6 | 0.02 | 0.05 | 0.02 | 0.002 |

| Temperature (°C) | Thermal Conductivity (W/mK) | Density (kg/m3) | Young’s Modulus (MPa) | Thermal Expansion Coefficient (1/°C) | Yield Strength Rp0.2 (MPa) |

|---|---|---|---|---|---|

| X40CrMoV5_1—MAGMA Database | |||||

| 20 | 25.0 | 7830 | 216,691 | 1.03 × 10−5 | 1391 |

| 200 | 27.4 | 7776 | 206,100 | 1.24 × 10−5 | 1366 |

| 400 | 27.3 | 7711 | 189,300 | 1.30 × 10−5 | 1168 |

| 600 | 26.4 | 7644 | 165,700 | 1.00 × 10−5 | 650 |

| 1.2709 maraging steel from 18Ni300 powder—own research | |||||

| 20 | 18.2 | 7977 | 213,400 | 1.03 × 10−5 | 1673 |

| 200 | 13.9 | 8176 | 195,900 | 1.11 × 10−5 | 1463 |

| 400 | 16.9 | 8078 | 179,500 | 1.36 × 10−5 | 1220 |

| 600 | 1.35 × 10−5 | 780 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Małysza, M.; Żuczek, R.; Wilk-Kołodziejczyk, D.; Jaśkowiec, K.; Bitka, A.; Głowacki, M.; Zięba, Ł.; Pysz, S. Application of a 3D-Printed Part with Conformal Cooling in High-Pressure Die Casting Mould and Evaluation of Stress State During Exploitation. Materials 2024, 17, 5988. https://doi.org/10.3390/ma17235988

Małysza M, Żuczek R, Wilk-Kołodziejczyk D, Jaśkowiec K, Bitka A, Głowacki M, Zięba Ł, Pysz S. Application of a 3D-Printed Part with Conformal Cooling in High-Pressure Die Casting Mould and Evaluation of Stress State During Exploitation. Materials. 2024; 17(23):5988. https://doi.org/10.3390/ma17235988

Chicago/Turabian StyleMałysza, Marcin, Robert Żuczek, Dorota Wilk-Kołodziejczyk, Krzysztof Jaśkowiec, Adam Bitka, Mirosław Głowacki, Łukasz Zięba, and Stanisław Pysz. 2024. "Application of a 3D-Printed Part with Conformal Cooling in High-Pressure Die Casting Mould and Evaluation of Stress State During Exploitation" Materials 17, no. 23: 5988. https://doi.org/10.3390/ma17235988

APA StyleMałysza, M., Żuczek, R., Wilk-Kołodziejczyk, D., Jaśkowiec, K., Bitka, A., Głowacki, M., Zięba, Ł., & Pysz, S. (2024). Application of a 3D-Printed Part with Conformal Cooling in High-Pressure Die Casting Mould and Evaluation of Stress State During Exploitation. Materials, 17(23), 5988. https://doi.org/10.3390/ma17235988