Influence of Internal Architecture and Ink Formulation on the Thermal Behavior of 3D-Printed Cementitious Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

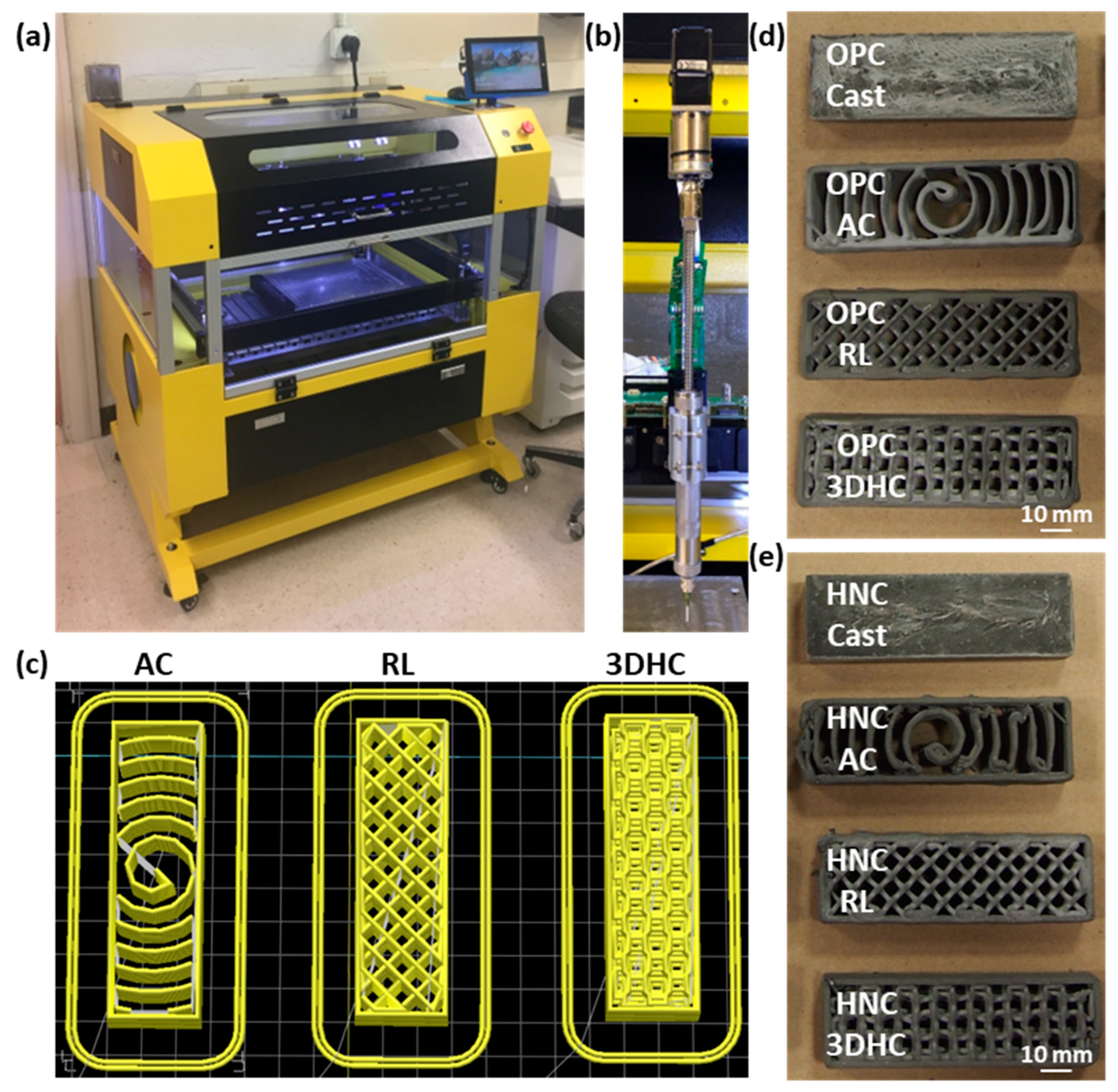

2.2. Architected Cement Composite Preparation

2.2.1. Cement Ink Design

2.2.2. Three-Dimensional Printed and Cast Cement Beam Fabrication

2.3. Thermal Measurements

2.4. Analytical Model for Heat Transfer in the 3D-Printed and Cast Cement Beams

3. Results and Discussion

3.1. Thermal Imaging and Temperature Evolution

3.2. Temperature Profiles from Analytical Modeling

3.3. Apparent Thermal Conductivity

4. Conclusions

- -

- The internal architectures had a greater impact on thermal behavior than HNC, reducing apparent thermal conductivity by up to 75%, while HNC incorporation reduced it by up to 14%.

- -

- The following clear progression was observed for internal architectures in order of decreasing apparent thermal conductivity, regardless of the cement ink used: cast, RL, 3DHC, and AC, with air voids and fewer direct conduction pathways resulting in reduced conductivity.

- -

- Distinct thermal behaviors were observed among the internal architectures: the RL architecture facilitated heat transfer, exhibiting 10–15% higher apparent thermal conductivity than the 3DHC architecture and a 35–40% higher apparent thermal conductivity than the AC architecture. The 3DHC architecture retained heat, while the unbridged air voids in the AC architecture disrupted heat flow.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. The Future of Cooling: Opportunities for Energy-Efficient Air Conditioning; IEA: Paris, France, 2018. [Google Scholar]

- Chung, S.-Y.; Abd Elrahman, M.; Stephan, D. Investigation of the effects of anisotropic pores on material properties of insulating concrete using computed tomography and probabilistic methods. Energy Build. 2016, 125, 122–129. [Google Scholar] [CrossRef]

- Peruzzi, A.d.P.; Rossignolo, J.A.; Kahn, H. Air-entrained concrete: Relationship between thermal conductivity and pore distribution analyzed by X-ray tomography. J. Civ. Eng. Archit. 2018, 12, 507–517. [Google Scholar] [CrossRef]

- Kim, H.-K.; Jeon, J.; Lee, H.-K. Workability, and mechanical, acoustic and thermal properties of lightweight aggregate concrete with a high volume of entrained air. Constr. Build. Mater. 2012, 29, 193–200. [Google Scholar] [CrossRef]

- Hossain, M.A. Mechanical and thermal performance of cement mortar incorporating super absorbent polymer (SAP). Civ. Eng. J. 2020, 6, 2231–2244. [Google Scholar]

- Jeong, Y.-W.; Koh, T.-H.; Youm, K.-S.; Moon, J. Experimental evaluation of thermal performance and durability of thermally-enhanced concretes. Appl. Sci. 2017, 7, 811. [Google Scholar] [CrossRef]

- Samson, G.; Phelipot-Mardelé, A.; Lanos, C. A review of thermomechanical properties of lightweight concrete. Mag. Concr. Res. 2017, 69, 201–216. [Google Scholar] [CrossRef]

- Zeng, Q.; Fang, R.; Li, H.; Peng, Y.; Wang, J. Tailoring the thermal and mechanical properties of lightweight cement-based composites by macro and micro fillers. Cem. Concr. Compos. 2019, 102, 169–184. [Google Scholar] [CrossRef]

- Zeng, Q.; Mao, T.; Li, H.; Peng, Y. Thermally insulating lightweight cement-based composites incorporating glass beads and nano-silica aerogels for sustainably energy-saving buildings. Energy Build. 2018, 174, 97–110. [Google Scholar] [CrossRef]

- Thompson, B.R.; Horozov, T.S.; Stoyanov, S.D.; Paunov, V.N. Hierarchically porous composites fabricated by hydrogel templating and viscous trapping techniques. Mater. Des. 2018, 137, 384–393. [Google Scholar] [CrossRef]

- Xiao, P.; Yifeng, Z.; Peng, W.; Dan, L. Estimation of thermal conduction in hollow-glass-beads-filled cement-based composites by variational asymptotic homogenization method. Appl. Therm. Eng. 2019, 161, 114191. [Google Scholar] [CrossRef]

- Lu, J.; Jiang, J.; Lu, Z.; Li, J.; Niu, Y.; Yang, Y. Pore structure and hardened properties of aerogel/cement composites based on nanosilica and surface modification. Constr. Build. Mater. 2020, 245, 118434. [Google Scholar] [CrossRef]

- Záleská, M.; Pokorný, J.; Pavlíková, M.; Pavlík, Z. Thermal properties of light-weight concrete with waste polypropylene aggregate. AIP Conf. Proc. 2017, 1866, 040043. [Google Scholar]

- Xie, Y.; Li, J.; Lu, Z.; Jiang, J.; Niu, Y. Effects of bentonite slurry on air-void structure and properties of foamed concrete. Constr. Build. Mater. 2018, 179, 207–219. [Google Scholar] [CrossRef]

- Zhao, Z.; Qu, X.; Li, F.; Wei, J. Effects of steel slag and silica fume additions on compressive strength and thermal properties of lime-fly ash pastes. Constr. Build. Mater. 2018, 183, 439–450. [Google Scholar] [CrossRef]

- Ali, K.; Qureshi, M.I.; Saleem, S.; Khan, S.U. Effect of waste electronic plastic and silica fume on mechanical properties and thermal performance of concrete. Constr. Build. Mater. 2021, 285, 122952. [Google Scholar] [CrossRef]

- Bentz, D.P.; Peltz, M.A.; Duran-Herrera, A.; Valdez, P.; Juarez, C. Thermal properties of high-volume fly ash mortars and concretes. J. Build. Phys. 2011, 34, 263–275. [Google Scholar] [CrossRef]

- Vásquez-Molina, D.; Mejía-Arcila, J.M.; Gutiérrez, R.M.-d. Mechanical and thermal performance of a geopolymeric and hybrid material based on fly ash. Dyna 2016, 83, 216–223. [Google Scholar] [CrossRef]

- Sharma, R.; Jang, J.-G.; Hu, J.-W. Phase-change materials in concrete: Opportunities and challenges for sustainable construction and building materials. Materials 2022, 15, 335. [Google Scholar] [CrossRef]

- Korniejenko, K.; Nykiel, M.; Choinska, M.; Jexembayeva, A.; Konkanov, M.; Aruova, L. An Overview of Phase Change Materials and Their Applications in Pavement. Energies 2024, 17, 2292. [Google Scholar] [CrossRef]

- Marais, H.; Christen, H.; Cho, S.; De Villiers, W.; Van Zijl, G. Computational assessment of thermal performance of 3D printed concrete wall structures with cavities. J. Build. Eng. 2021, 41, 102431. [Google Scholar] [CrossRef]

- Ayegba, B.O.; Egbe, K.-J.I.; Matin Nazar, A.; Huang, M.; Hariri-Ardebili, M.A. Resource Efficiency and Thermal Comfort of 3D Printable Concrete Building Envelopes Optimized by Performance Enhancing Insulation: A Numerical Study. Energies 2022, 15, 1069. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Gatheeshgar, P.; Upasiri, I.; Poologanathan, K.; Nagaratnam, B.; Rajanayagam, H.; Navaratnam, S. Numerical Study of Fire and Energy Performance of Innovative Light-Weight 3D Printed Concrete Wall Configurations in Modular Building System. Sustainability 2021, 13, 2314. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Upasiri, I.; Nagaratnam, B.; Poologanathan, K.; Gatheeshgar, P.; Tsavdaridis, K.D.; Nuwanthika, D. Finite Element Modelling to Predict the Fire Performance of Bio-Inspired 3D-Printed Concrete Wall Panels Exposed to Realistic Fire. Buildings 2022, 12, 111. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Upasiri, I.; Gatheeshgar, P.; Poologanathan, K.; Nagaratnam, B.; Santos, P.; Rajanayagam, H. Energy Performance of 3D-Printed Concrete Walls: A Numerical Study. Buildings 2021, 11, 432. [Google Scholar] [CrossRef]

- Yang, S.; Wi, S.; Park, J.H.; Cho, H.M.; Kim, S. Novel proposal to overcome insulation limitations due to nonlinear structures using 3D printing: Hybrid heat-storage system. Energy Build. 2019, 197, 177–187. [Google Scholar] [CrossRef]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-scale 3D printing of ultra-high performance concrete–a new processing route for architects and builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef]

- Alghamdi, H.; Neithalath, N. Synthesis and characterization of 3D-printable geopolymeric foams for thermally efficient building envelope materials. Cem. Concr. Compos. 2019, 104, 103377. [Google Scholar] [CrossRef]

- Ma, G.; Ruhan, A.; Xie, P.; Pan, Z.; Wang, L.; Hower, J.C. 3D-printable aerogel-incorporated concrete: Anisotropy influence on physical, mechanical, and thermal insulation properties. Constr. Build. Mater. 2022, 323, 126551. [Google Scholar] [CrossRef]

- de Rubeis, T. 3D-Printed Blocks: Thermal Performance Analysis and Opportunities for Insulating Materials. Sustainability 2022, 14, 1077. [Google Scholar] [CrossRef]

- Sovetova, M.; Calautit, J.K. Thermal and energy efficiency in 3D-printed Buildings: Review of geometric Design, materials and printing processes. Energy Build. 2024, 323, 114731. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Muthukrishnan, S.; Sanjayan, J.; Pasupathy, K. Concrete 3D printing of lightweight elements using hollow-core extrusion of filaments. Cem. Concr. Compos. 2021, 123, 104220. [Google Scholar] [CrossRef]

- Kawashima, S.; Wang, K.; Ferron, R.D.; Kim, J.H.; Tregger, N.; Shah, S. A review of the effect of nanoclays on the fresh and hardened properties of cement-based materials. Cem. Concr. Res. 2021, 147, 106502. [Google Scholar] [CrossRef]

- Qian, Y.; Ma, S.; Kawashima, S.; De Schutter, G. Rheological characterization of the viscoelastic solid-like properties of fresh cement pastes with nanoclay addition. Theor. Appl. Fract. Mech. 2019, 103, 102262. [Google Scholar] [CrossRef]

- Kaushik, S.; Sonebi, M.; Amato, G.; Perrot, A.; Das, U.K. Influence of nanoclay on the fresh and rheological behaviour of 3D printing mortar. Mater. Today Proc. 2022, 58, 1063–1068. [Google Scholar] [CrossRef]

- Pan, T.; Jiang, Y.; He, H.; Wang, Y.; Yin, K. Effect of Structural Build-Up on Interlayer Bond Strength of 3D Printed Cement Mortars. Materials 2021, 14, 236. [Google Scholar] [CrossRef]

- Natanzi, A.S.; McNally, C. Characterising Concrete Mixes for 3D Printing. In Second RILEM International Conference on Concrete and Digital Fabrication, Proceedings of the Digital Concrete 2020, Eindhoven, The Netherlands, 6–8 July 2020; Springer: Cham, Switzerland, 2020; pp. 83–92. [Google Scholar]

- Panda, B.; Unluer, C.; Tan, M.J. Extrusion and rheology characterization of geopolymer nanocomposites used in 3D printing. Compos. Part B Eng. 2019, 176, 107290. [Google Scholar] [CrossRef]

- Sonebi, M.; Dedenis, M.; Amziane, S.; Abdalqader, A.; Perrot, A. Effect of Red Mud, Nanoclay, and Natural Fiber on Fresh and Rheological Properties of Three-Dimensional Concrete Printing. ACI Mater. J. 2021, 118, 97–110. [Google Scholar]

- Zhang, Y.; Zhang, Y.; Liu, G.; Yang, Y.; Wu, M.; Pang, B. Fresh properties of a novel 3D printing concrete ink. Constr. Build. Mater. 2018, 174, 263–271. [Google Scholar] [CrossRef]

- Sajadi, S.M.; Boul, P.J.; Thaemlitz, C.; Meiyazhagan, A.K.; Puthirath, A.B.; Tiwary, C.S.; Rahman, M.M.; Ajayan, P.M. Direct ink writing of cement structures modified with nanoscale Additive. Adv. Eng. Mater. 2019, 21, 1801380. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.; Low, I.M. Characteristics of nanoclay and calcined nanoclay-cement nanocomposites. Compos. Part B Eng. 2015, 78, 174–184. [Google Scholar] [CrossRef]

- Farzadnia, N.; Ali, A.A.A.; Demirboga, R.; Anwar, M.P. Effect of halloysite nanoclay on mechanical properties, thermal behavior and microstructure of cement mortars. Cem. Concr. Res. 2013, 48, 97–104. [Google Scholar] [CrossRef]

- Allalou, S.; Kheribet, R.; Benmounah, A. Effects of calcined halloysite nano-clay on the mechanical properties and microstructure of low-clinker cement mortar. Case Stud. Constr. Mater. 2019, 10, e00213. [Google Scholar] [CrossRef]

- Wang, W.-C. Compressive strength and thermal conductivity of concrete with nanoclay under Various High-Temperatures. Constr. Build. Mater. 2017, 147, 305–311. [Google Scholar] [CrossRef]

- Cho, J.; Waetzig, G.R.; Udayakantha, M.; Hong, C.Y.; Banerjee, S. Incorporation of hydroxyethylcellulose-functionalized halloysite as a means of decreasing the thermal conductivity of oilwell cement. Sci. Rep. 2018, 8, 16149. [Google Scholar] [CrossRef]

- Udayakantha, M.; Cho, J.; Liu, K.-W.; Mukhopadhyay, A.; Gupta, S.; Hong, C.Y.; Banerjee, S. An evaluation of the reduction of heat loss enabled by halloysite modification of oilwell cement. Eng. Res. Express 2019, 1, 025028. [Google Scholar] [CrossRef]

- Haw, T.T.; Hart, F.; Rashidi, A.; Pasbakhsh, P. Sustainable cementitious composites reinforced with metakaolin and halloysite nanotubes for construction and building applications. Appl. Clay Sci. 2020, 188, 105533. [Google Scholar] [CrossRef]

- Liu, H.; Jin, J.; Yu, Y.; Liu, H.; Liu, S.; Shen, J.; Xia, X.; Ji, H. Influence of halloysite nanotube on hydration products and mechanical properties of oil well cement slurries with nano-silica. Constr. Build. Mater. 2020, 247, 118545. [Google Scholar] [CrossRef]

- Kosson, M.T. Chemo-Mechanical and Thermal Behavior of 3D Printed Cement Composites. Ph.D. Thesis, Vanderbilt University, Nashville, TN, USA, 2022. [Google Scholar]

- BASF. MasterGlenium 7700; Data Sheet; BASF: Ludwigshafen, Germany, 2018. [Google Scholar]

- BASF. MasterMatrix UW 450; Data Sheet; BASF: Ludwigshafen, Germany, 2018. [Google Scholar]

- BASF. MasterMatrix VMA 362; Data Sheet; BASF: Ludwigshafen, Germany, 2019. [Google Scholar]

- Singh, T.; Shrivastava, S.; Ber, H.S. Analysis of unsteady heat conduction through short fin with applicability of quasi theory. Int. J. Mech. Eng. Robot. Res. 2013, 2, 269–283. [Google Scholar]

- Spakovszky, Z.S. 18.2 Heat Transfer From a Fin. Available online: https://web.mit.edu/16.unified/www/FALL/thermodynamics/notes/node128.html (accessed on 26 April 2022).

- Lienhard, J.H., V; Lienhard, J.H., IV. A Heat Transfer Textbook, 6th ed.; Phlogiston Press: Cambridge, MA, USA, 2024. [Google Scholar]

- Anwajler, B.; Szołomicki, J.; Noszczyk, P.; Baryś, M. The Potential of 3D Printing in Thermal Insulating Composite Materials—Experimental Determination of the Impact of the Geometry on Thermal Resistance. Materials 2024, 17, 1202. [Google Scholar] [CrossRef]

- Bentz, D.P. Transient plane source measurements of the thermal properties of hydrating cement pastes. Mater. Struct. 2007, 40, 1073–1080. [Google Scholar] [CrossRef]

- DeArmitt, C. Halloysite Clay Nanotubes: Introduction to Halloysite Filler. Available online: https://phantomplastics.com/functional-fillers/halloysite-filler-gives-unique-properties-to-plastics-and-coatings/ (accessed on 19 October 2024).

- Zhang, T.; Zhang, X.; Zhang, S.; Wang, L.; Yu, D.; Wang, W. 3D Printing-Assisted Honeycomb-Structured Bricklike Aerogels Applied for Infrared Stealth with Good Thermal Management. ACS Appl. Polym. Mater. 2024. [Google Scholar] [CrossRef]

- Güngör, Ş. Experimental investigations on the thermal performance of additively manufactured porous topologies. Dokuz Eylül Üniversitesi Mühendislik Fakültesi Fen Ve Mühendislik Derg. 2023, 25, 761–767. [Google Scholar] [CrossRef]

| Ink Type | OPC | HNC | Water | VMA 362 | Glenium 7700 | UW 450 |

|---|---|---|---|---|---|---|

| OPC Ink | 100 g | - | 30 g | 0.90 g | 0.35 g | 1.00 g |

| HNC Ink | 95 g | 5 g | 30 g | 0.90 g | 0.35 g | 1.00 g |

| Architecture Type | ||||

|---|---|---|---|---|

| Ink Type | Cast | RL | 3DHC | AC |

| OPC | 0.1362 ± 0.0081 | 0.0456 ± 0.0020 | 0.0408 ± 0.0013 | 0.0329 ± 0.0013 |

| HNC | 0.1251 ± 0.0070 | 0.0443 ± 0.0018 | 0.0385 ± 0.0005 | 0.0282 ± 0.0020 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosson, M.; Brown, L.; Thorne, G.; Sanchez, F. Influence of Internal Architecture and Ink Formulation on the Thermal Behavior of 3D-Printed Cementitious Materials. Materials 2024, 17, 5736. https://doi.org/10.3390/ma17235736

Kosson M, Brown L, Thorne G, Sanchez F. Influence of Internal Architecture and Ink Formulation on the Thermal Behavior of 3D-Printed Cementitious Materials. Materials. 2024; 17(23):5736. https://doi.org/10.3390/ma17235736

Chicago/Turabian StyleKosson, Michael, Lesa Brown, Garrett Thorne, and Florence Sanchez. 2024. "Influence of Internal Architecture and Ink Formulation on the Thermal Behavior of 3D-Printed Cementitious Materials" Materials 17, no. 23: 5736. https://doi.org/10.3390/ma17235736

APA StyleKosson, M., Brown, L., Thorne, G., & Sanchez, F. (2024). Influence of Internal Architecture and Ink Formulation on the Thermal Behavior of 3D-Printed Cementitious Materials. Materials, 17(23), 5736. https://doi.org/10.3390/ma17235736