1. Introduction

Airports have been hot targets of military attacks owing to their large footprint, obvious targets, and prominent military status, which can effectively neutralize the enemy’s capability to conduct air operations [

1]. Mainly composed of a surface layer, a base layer, and a compacted soil layer, the airport runway is a typical layered structure [

2]. Although some studies proved that asphalt concrete surfaces could absorb the impact energy [

3], the concrete pavements is widely used in the airports due to the fact that the high temperature and aircraft load generated by takeoffs of jet airplanes can damage and deteriorate asphalt surfaces [

4].

Calcareous sand is a sediment primarily composed of the skeletal remains of marine organisms [

5], with calcium carbonate accounting for over 97% of its weight [

6]. It is widely found in the coral reefs of the Nansha Islands in the South China Sea, and is characterized by high intragranular porosity [

7], significant particle angularity [

8], irregular shape, and a tendency to break easily [

9]. Moreover, calcareous sand exhibits higher apparent cohesion than quartz sand, and demonstrates considerable load-bearing capacity after compaction [

10], making it an ideal backfilling material for the subgrade of airport runways in marine engineering. Additionally, due to the remote location of the South China Sea islands, using calcareous sand as a foundation material for island construction projects effectively reduces transportation costs and minimizes the reliance on expensive imported materials [

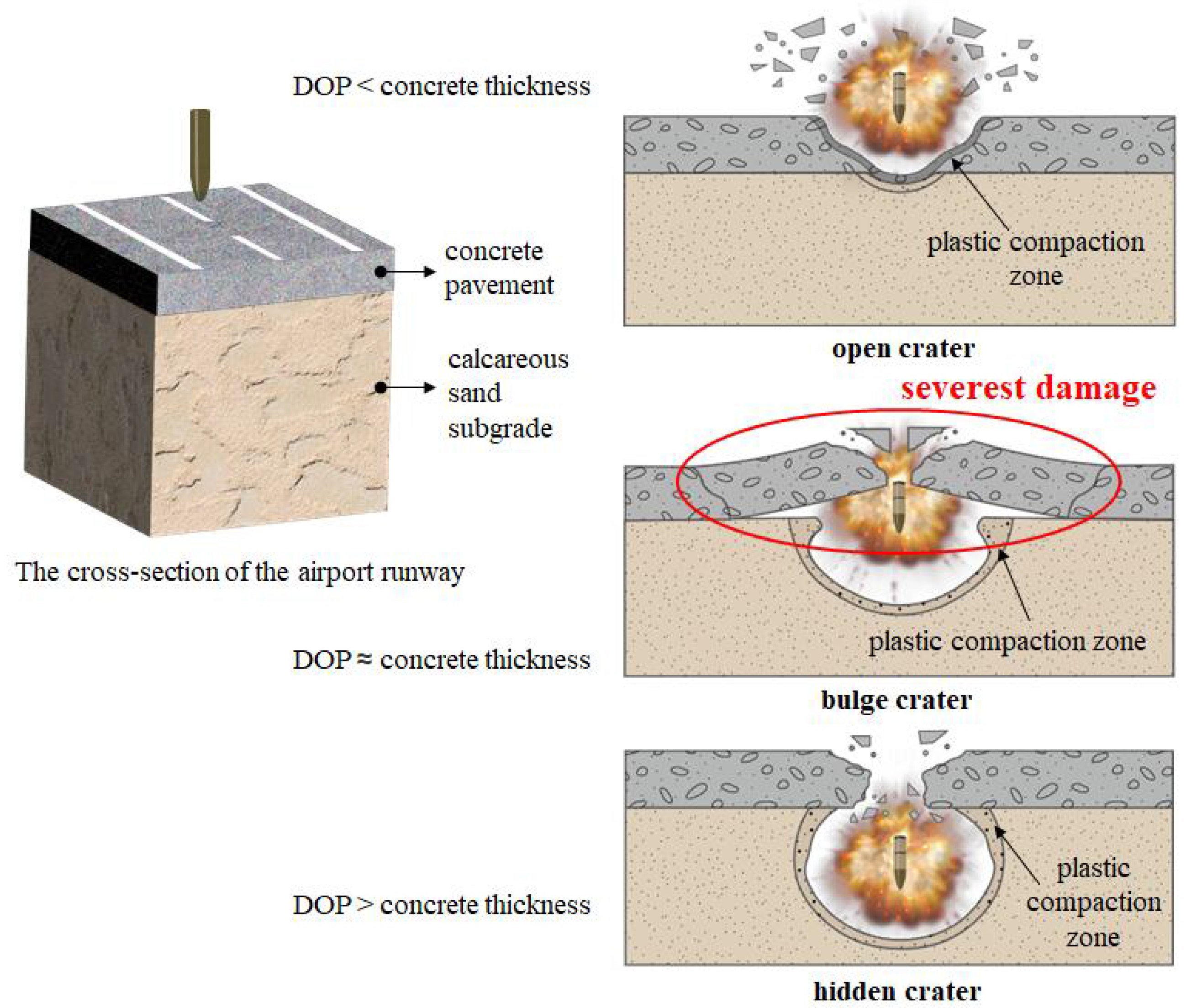

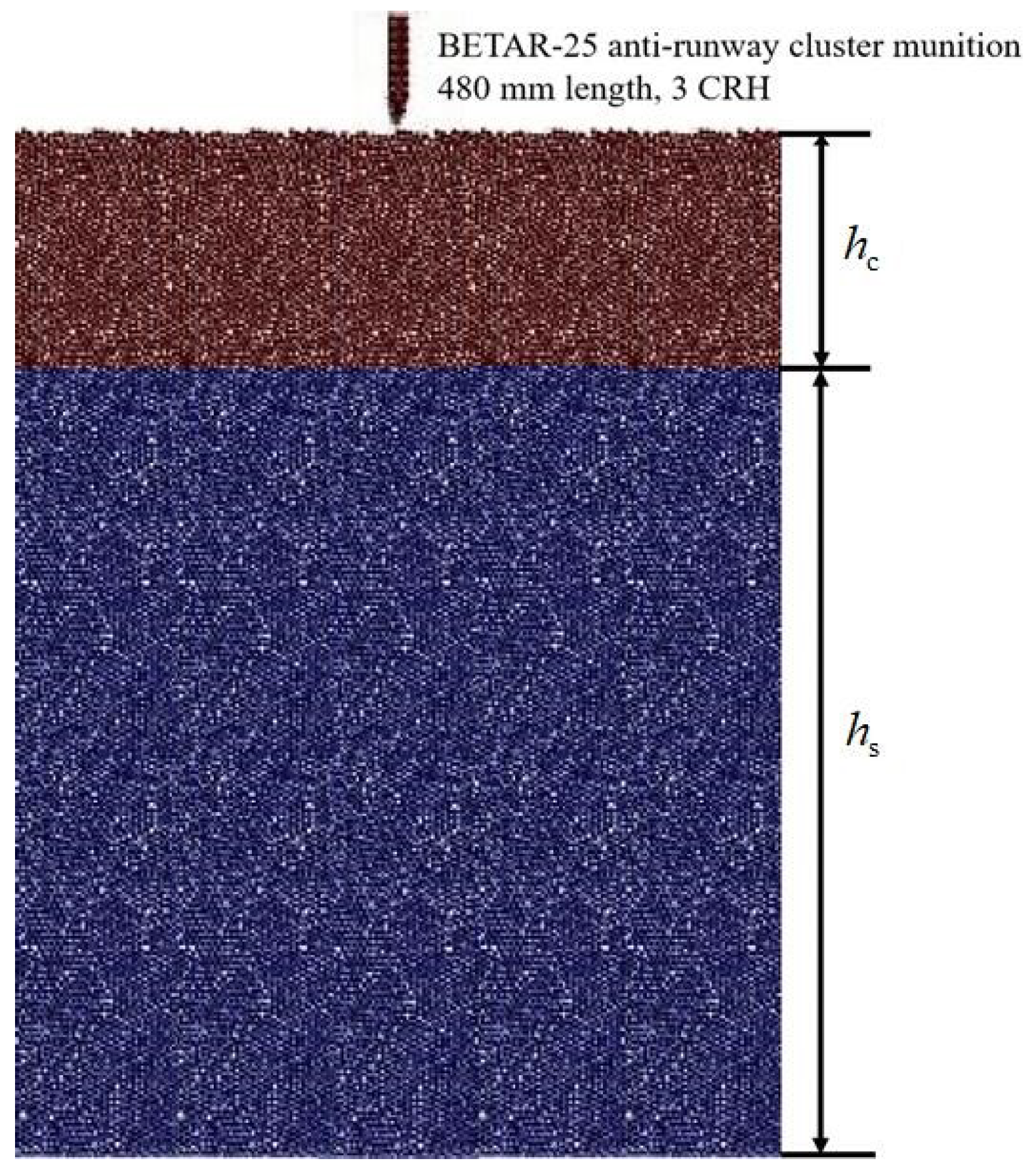

11]. It is believed that the reef island airport with calcareous sand subgrade runway pavement structure is vulnerable to cluster munitions, whereby the projectile penetrate to a certain depth with detonation, as shown in

Figure 1. The first stage damage composed of penetration is critical for the second stage internal explosion, which needs to be comprehensively studied for damage evaluation and munition optimization. In recent decades, extensive research has been conducted on the damage caused by various weapons to airport runways [

12]. However, currently, the use of cluster munitions to create multiple craters on the runways, achieving the blockade of airports, has become the primary attacking strategy [

13]. Based on the analysis of the crater characterization, and the mechanism of implosion in the runways obtained from the experiments and simulations, the damage modes of implosion in airfield runways can be classified into three categories: open crater mode, bulge crater mode, and hidden crater mode [

14], as shown in

Figure 1. In particular, for anti-runway munitions, the bulge crater, caused by explosion near interface, is the severest damage of the above three destruction modes, creating a relatively long blockade of the runway and being the most difficult and time-consuming to repair. Hence, the critical striking velocity corresponding to the interface location DOP is deemed to be the optimal penetration scenario. The gap between the literature and this work lies in the fact that the few attempts have been made to study reef island runway penetration. The critical striking velocity of projectile to penetrate to the interface of pavement and subgrade has not been reported yet. The purpose of this study aggregates to the state-of-the-art of the reef island runway pavement damage is to optimize the striking velocity to realize the proper penetration depth for the subsequent internal explosion. Such novelty not only benefits the cluster munitions attack strategy, but also promotes runway structure protection design.

The destructive effect and impact resistance performance of airport runways structured with multi-layer pavements under impacting loads have been a significant area of research. Han et al. conducted the field penetration and blast tests on airport pavements subjected to blast loading from a cluster bomb unit and assessed the condition of damage by numerical simulation, suggesting the rapid hardening high-strength concrete for the damaged concrete pavements repair [

15]. Wu et al. developed a new muti-layer pavement system consisting of asphalt concrete layer reinforced with geogrid, high strength concrete layer, and engineered cementitious composites layer, and the system was compared with conventional concrete pavements through field blast tests and numerical modeling, revealing that the new multi-layer pavement had better blast resistance [

3]. Zha et al. used the finite element simulation to compare the damage contours and dynamic responses of the anti-blasting asphalt pavement with a reinforced concrete layer and the conventional asphalt pavement, which showed that the additional reinforced concrete layer improved the blast resistance performance by about 20% [

16]. To investigate the damage of scaled-down target of the airport runway, Wei et al. carried out experiment and numerical simulation to analyze the destructive effect of static explosion of charge after penetration and explosion of prefabricated hole, which showed that the crater size produced by the former explosion mode was obviously larger than that produced by the latter under the same explosion depth and explosive charge [

17]. A three-dimensional graphics processing unit (GPU)-accelerated smoothed particle hydrodynamics (SPH) method was developed by Chen et al. [

18], and was applied to the simulation of soil fragmentation and fracture propagation of the concrete-soil multilayered medium subjected to underground explosion involving millions of particles [

19]. Comparing with the experimental data, the SPH model was able to reproduce the damage pattern of concrete slabs with different depths of explosives burial. Although the dynamic impact responses of airport runway with multi-layer pavements have been extensively studied through experiments and numerical simulation, there is still a knowledge gap in the research on pavement structures with calcareous sand as the subgrade, which hinders the development of island infrastructure engineering.

As the pavement structure surface layer, the mechanical properties of concrete have attracted wide attention [

20], and the dynamic mechanical response of concrete panel or plate under the impactive loading conditions has been extensively studied [

21]. Feng et al. obtained data on penetration depth, crater size, and net axial resistance through ballistic penetration tests and subsequent static deep indentation tests, and conducted numerical simulations using lattice discrete particle model [

22]. Similarly, Liu et al. conducted experimental research and theoretical analysis on projectile penetration in concrete targets, examining destruction parameters such as ballistic depth and crater area [

23]. The experiments and numerical simulations of the structural behavior of full-scale reinforced concrete slabs under blast loading were conducted by Castedo et al. [

24], finding that the addition of steel fibers or polypropylene fibers to concrete slabs could effectively improve the tensile strength and blast resistance compared to simple reinforced concrete slabs. Feng et al. introduced the impact resistance theory to establish a semi-empirical analytical model for projectile perforation on steel–concrete–steel sandwich panels and an analytical model for perforation on steel–concrete panels, respectively, to predict the residual velocities and the target damage patterns [

25], analyzing the dynamic response of the projectile on concrete–steel panels of different thicknesses [

26]. The fiber reinforced concrete runway pavement proposed by Ali et al. [

27] proved much better than the normal concrete pavement, and the researchers came up with finite element model to analyze the performance of improved concrete runway pavement under impact loading based on the results of drop weight impact test. However, adding fibers is not the sole method for enhancing the impact resistance of airport runways. Rubberized concrete also offered high impact resistance, and increased the ductility of runway pavements, as highlighted by Ferretti and Bignozzi [

28]. Hardened steel ovoid nose projectiles with 19 mm diameter and three caliber-radius-head of 0.5 and 1 kg mass and 11.8 and 23.7 length-to-diameter ratios were used to impact the plain and reinforced concrete targets, in conjunction with numerical simulations in order to find out the behavior of the concrete against the impact loading, as well as to explore the length-to-diameter ratio of the projectile effect on the ballistic performance [

29].

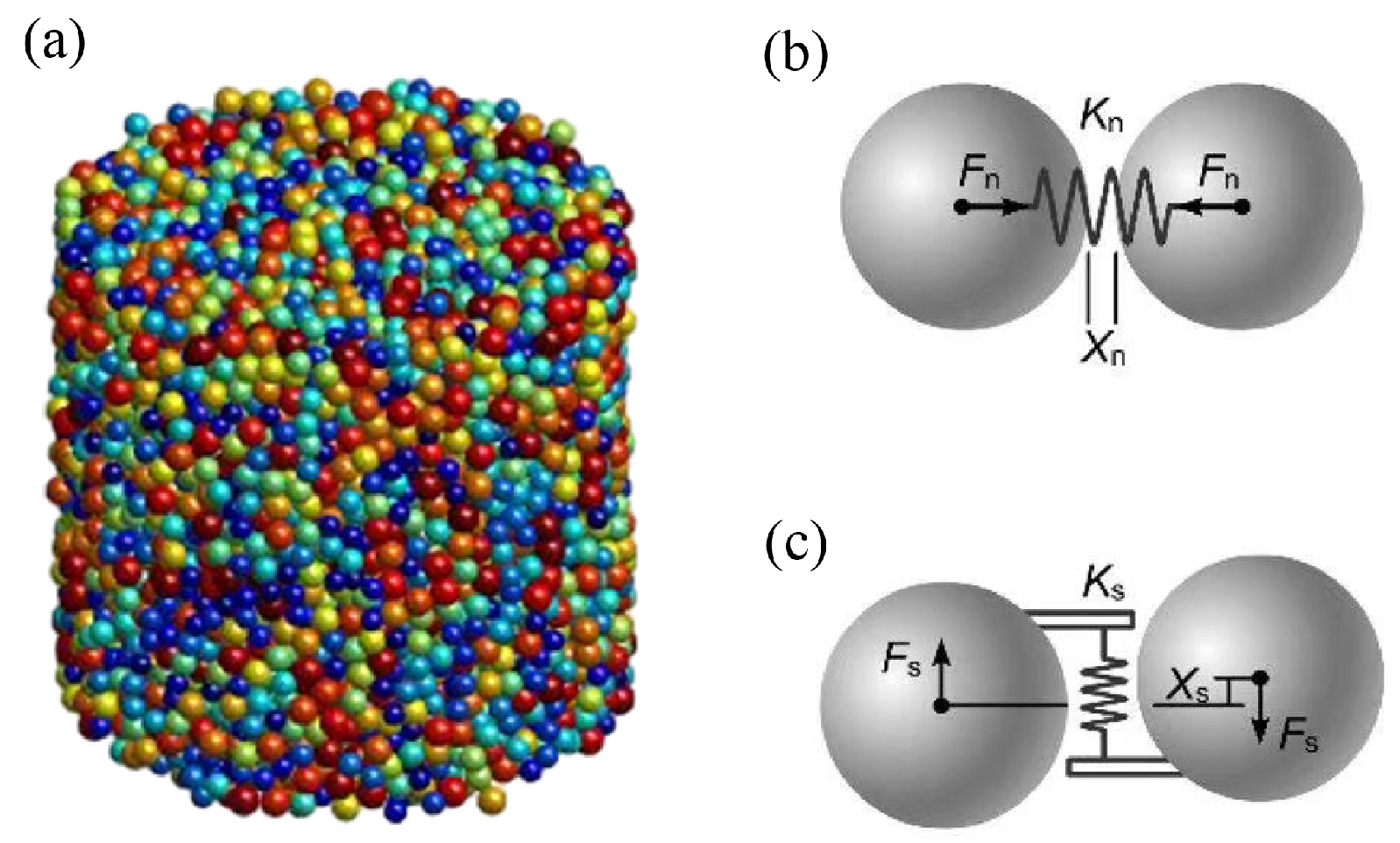

The Discrete Element Method (DEM) has been widely adopted to quantitatively analyze the deformation and damage processes occurring in concrete or geotechnical materials under both macro and micro mechanical regimes [

30]. The unique advantage of DEM is that it is independent of numerical mesh, and allows large deformation and fracture of particles from the microscopic layer without deformation constraints [

31], which is suitable for dealing with discontinuous problems [

32]. Geng et al. applied DEM to analyze the infiltration distribution changes of tailing slopes and tailing landslides in different rainy seasons by constructing discrete units with specific elastic modulus and strength properties with the combination of the conversion formulas for the discrete units and numerical simulation experiments, realizing the automatic modeling of the discrete units [

33]. Mechtcherine and Shyshko presented a numerical approach based on DEM to establish a link between the yield stress of the simulated concrete and the model parameters as a parametric reference for modeling the behavior of fresh concrete in different working processes, which showed that the numerical analysis agreed well with the final shape of the concrete in the slump-flow test [

34]. DEM can also be used to study the physical process of impact-induced rock fragmentation in rockfall analysis [

35]. A normal impact fragmentation model of synthetic spherical rock block under different impact loading rates was carried out by Shen et al. [

36], which could reproduce the whole process of rock fragmentation under the impact, being in good agreement with the experimental observations. Huan et al. used matDEM1.60 software to develop an asteroid impact sampling model under microgravity conditions to explore the effects of the initial impact velocity and projectile shape on the internal characteristics of regolith and ejecta after impact, verifying the feasibility of discrete element simulation of the impact process [

37]. The Lattice Discrete Particle Model (LDPM) was proposed to simulate concrete at the aggregate level and characterize the formation and evolution of cracks in concrete under loading, investigating the structural size and geometry effect on the strength and fracture process of concrete, which was proved to have a good agreement with experimental data and performed well in the prediction of splitting test results [

38]. Therefore, it is advisable to apply DEM to model and investigate the dynamic responses of the airport runways with concrete and calcareous sand layers with matDEM as an effective tool.

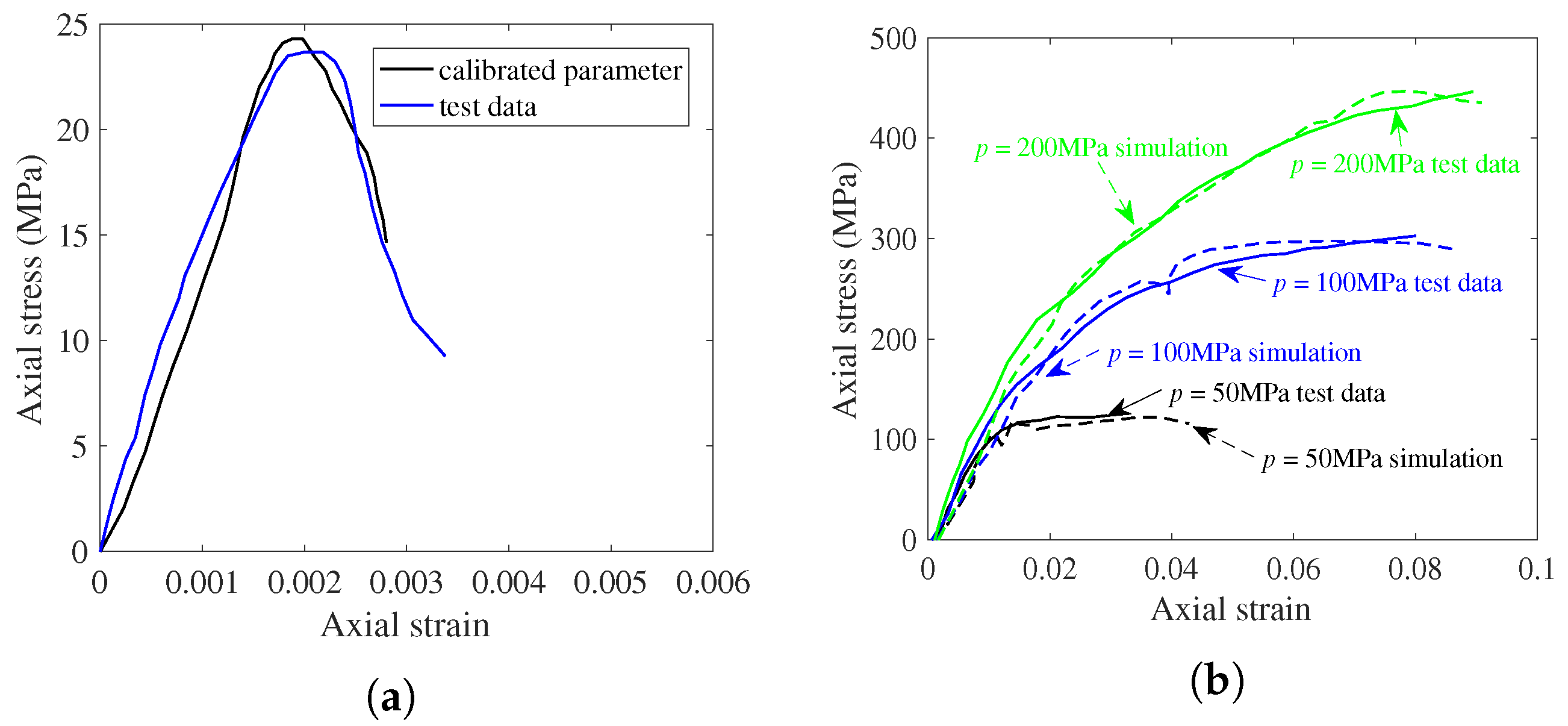

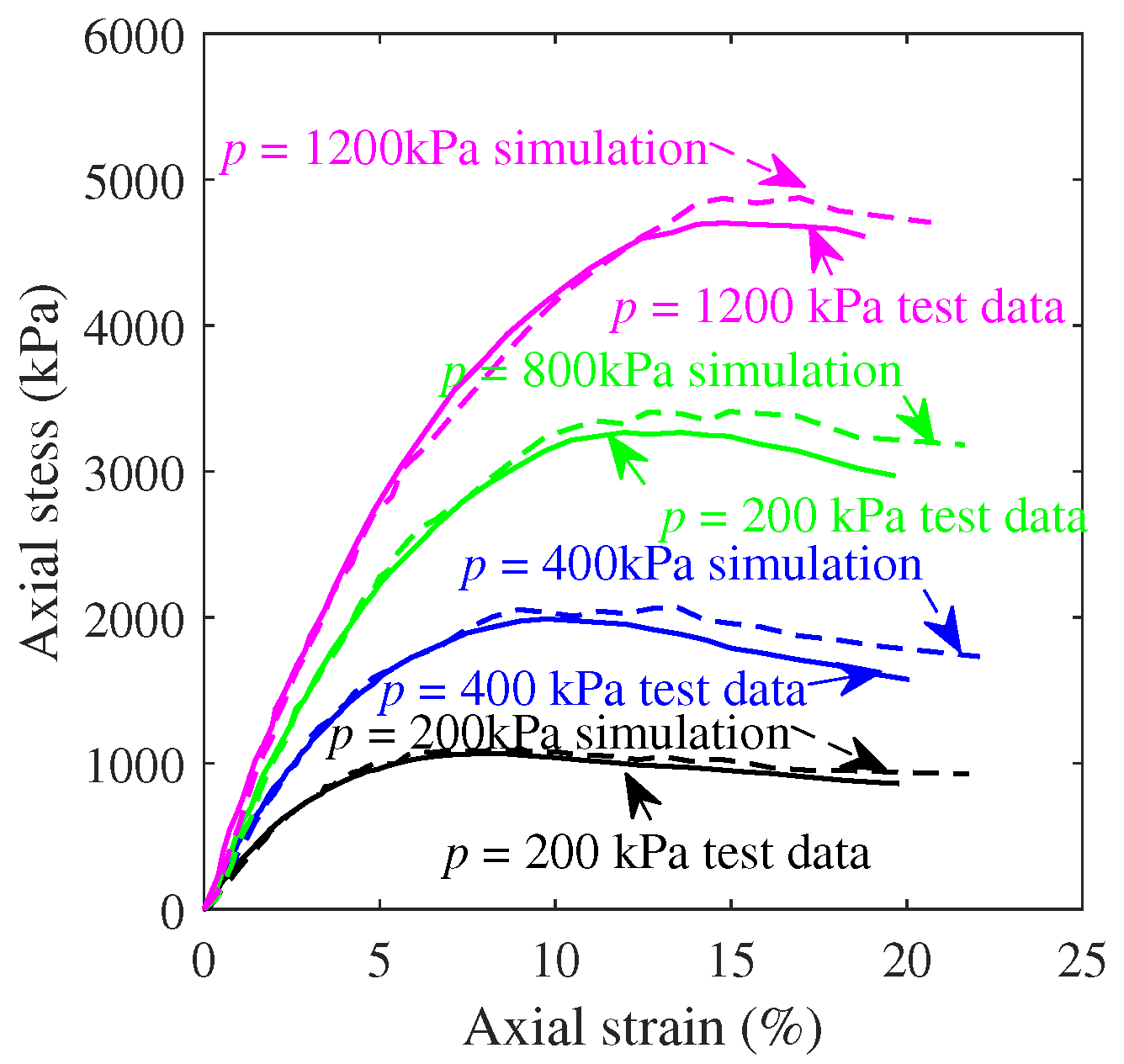

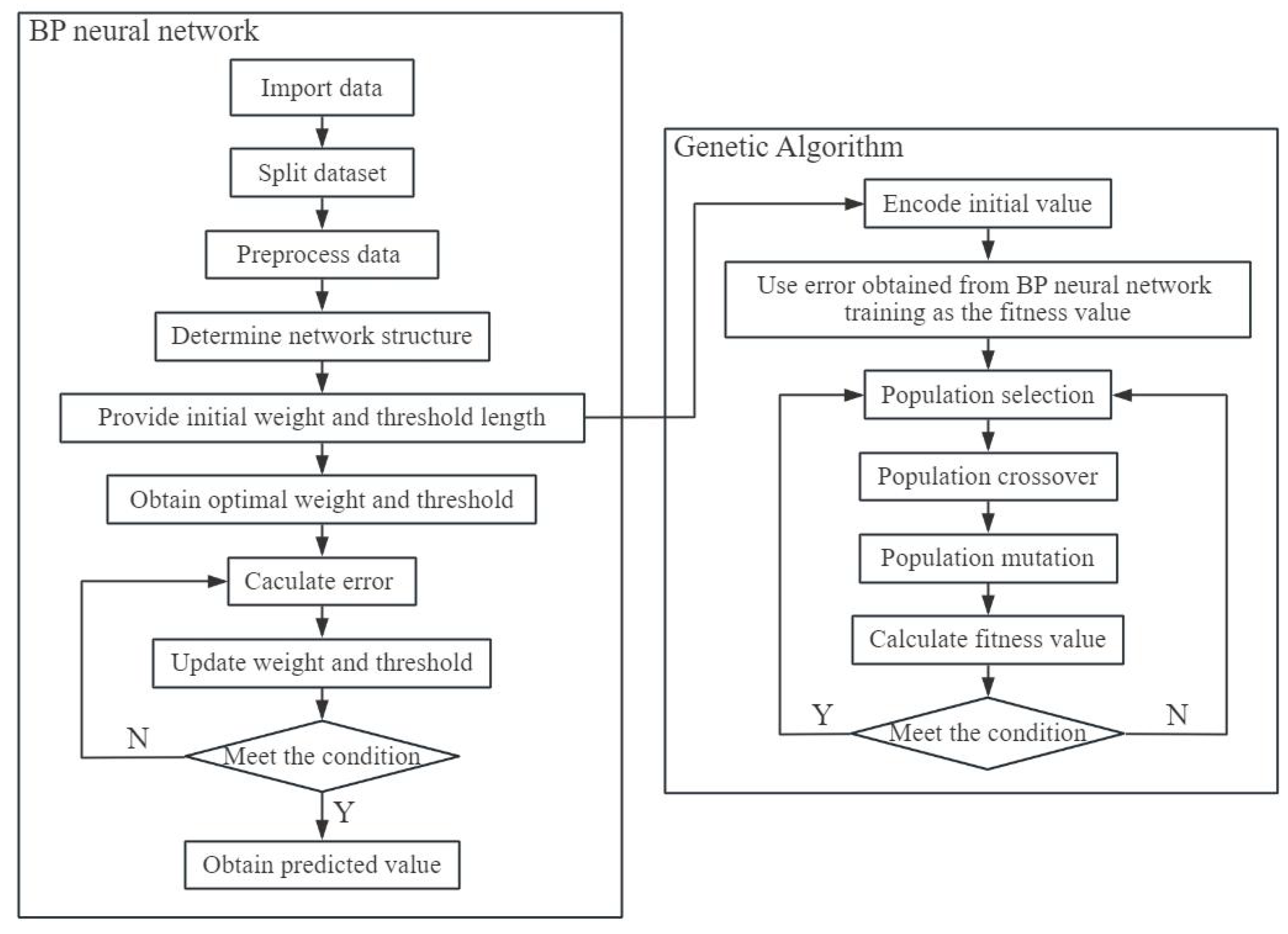

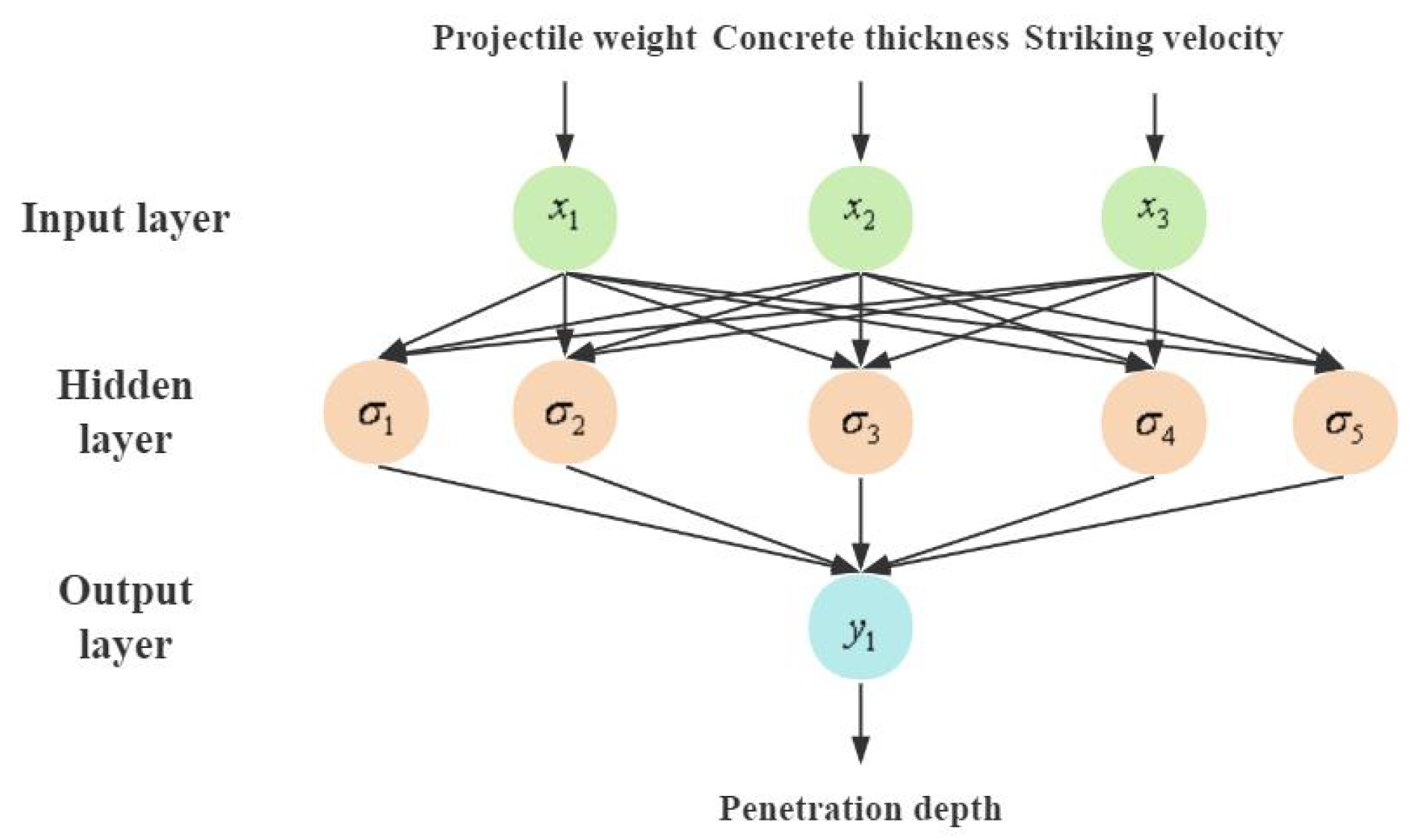

In order to assess the damage effects of reef island airport runway pavements under projectile penetration, this paper adopted DEM simulation to numerically model the penetration of rigid projectiles into runway pavements with calcareous sand subgrade. The material parameters were calibrated with uniaxial compression and triaxial compression tests for subsequent penetration model validation. Furthermore, the penetration depth of airport runway structures with concrete pavement and calcareous sand base were numerically evaluated. Combining with back-propagation (BP) neural network and genetic algorithm, the critical velocity of airport runway penetration was predicted via intelligent optimization of pavement penetration. The results may shed some light on damage assessment, as well as anti-airfield runway cluster munitions design.

3. Results of Pavement Structure Penetration Simulations

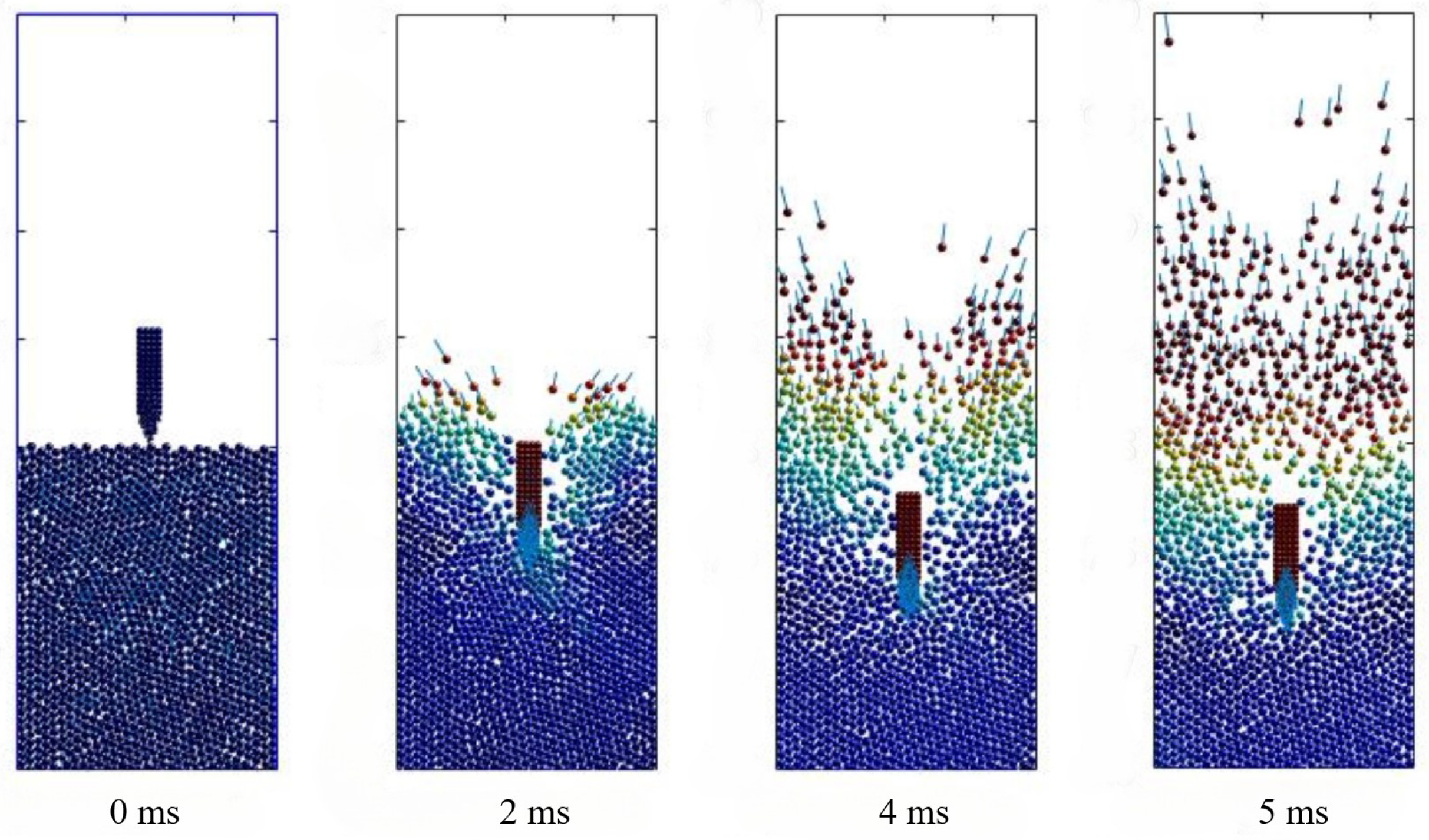

Given the specific characteristics of the reef island airport runway, the penetration process is divided into two distinct phases: the concrete penetration phase and the calcareous sand penetration phase. In this section, the previously validated DEM model was employed to conduct numerical simulations of runway pavement penetration with various striking velocities and concrete thicknesses, with the aim of providing a comprehensive assessment of the airport runway structure under impact.

The model of projectile penetration into airport runway pavement structure is depicted as

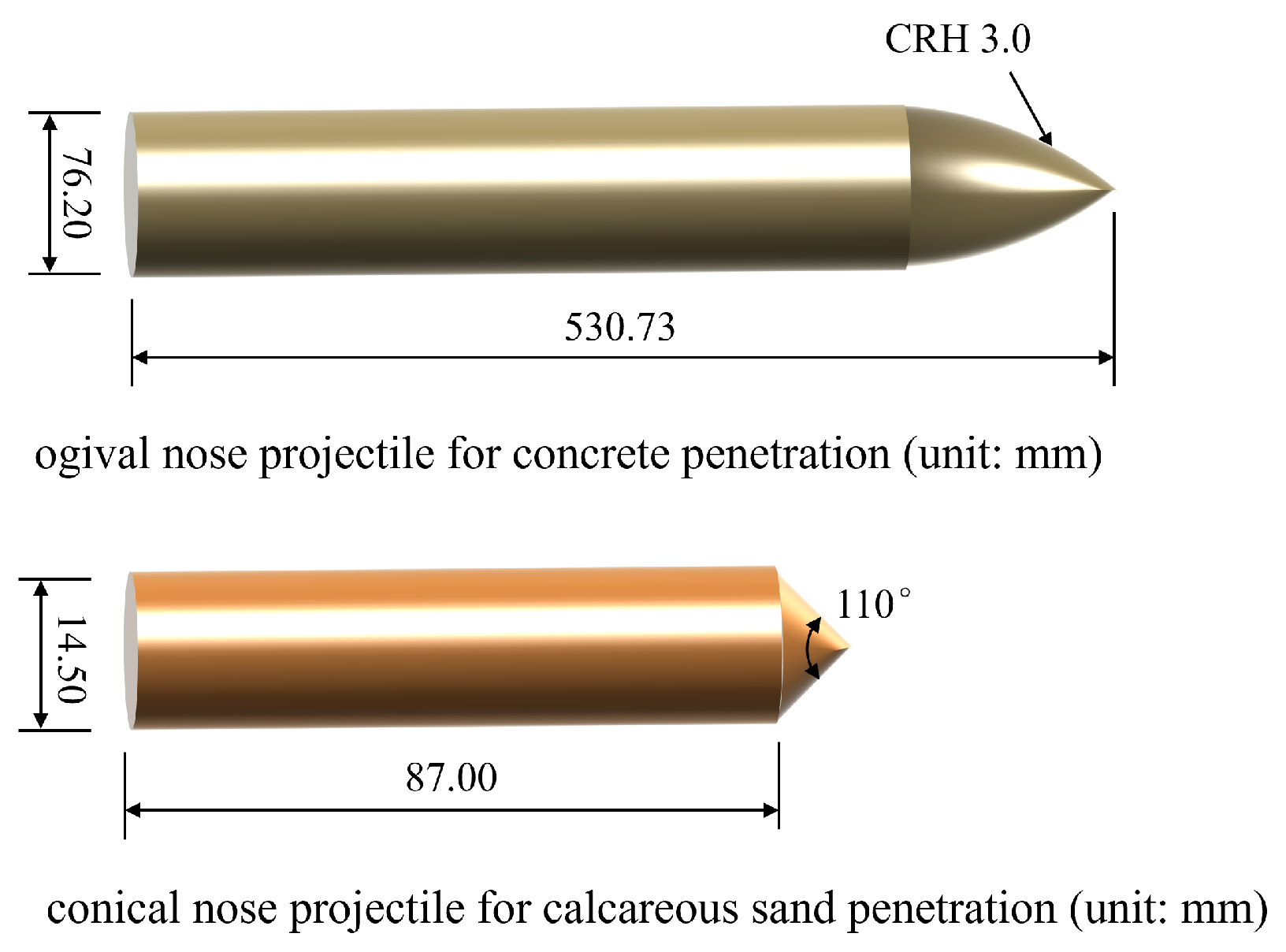

Figure 10. In this paper, the Russian-made BETAR-25 anti-runway cluster munition was selected for numerical simulation, with ogival nose projectile body with a total weight of 9–13 kg, a diameter of 76 mm, 3.0 CRH, and an overall length of 480 mm [

50]. With striking velocity of 170 m/s–280 m/s, the projectile is supposed to impact the target with normal penetration.

The reef island airport runway model was constructed as a two-layer composite structure with a concrete layer for the surface and a calcareous sand layer for the base, measuring 1.8 m × 1.8 m area, with lateral constraints. The model particles were randomly generated using Fuller’s coefficient 0.5 in the range of aggregate particle size of 5–15 mm.

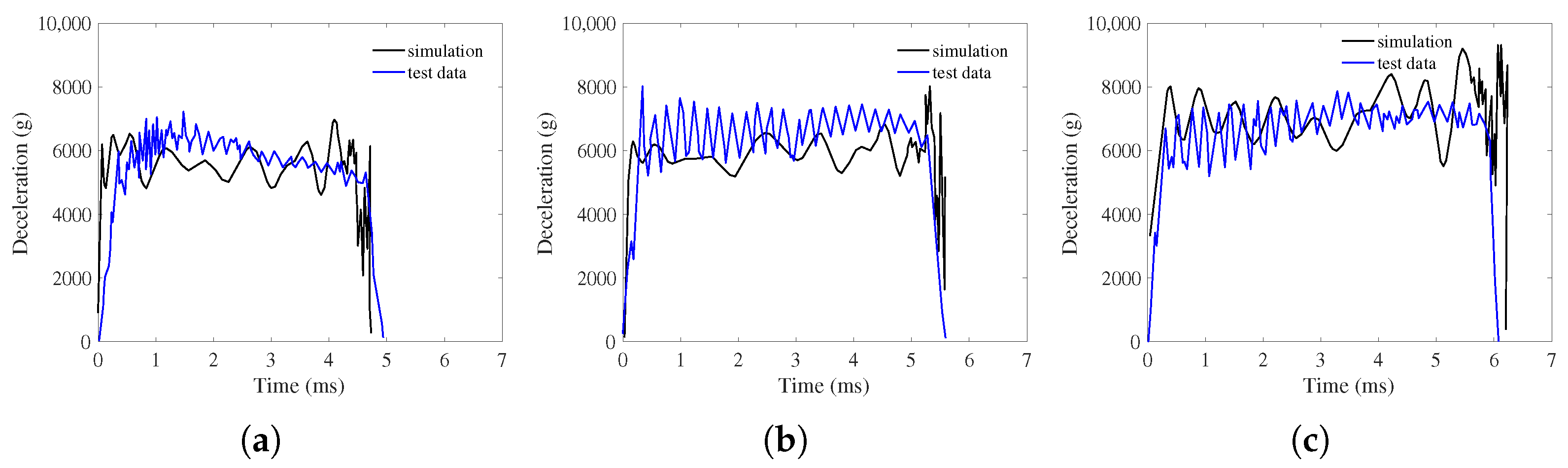

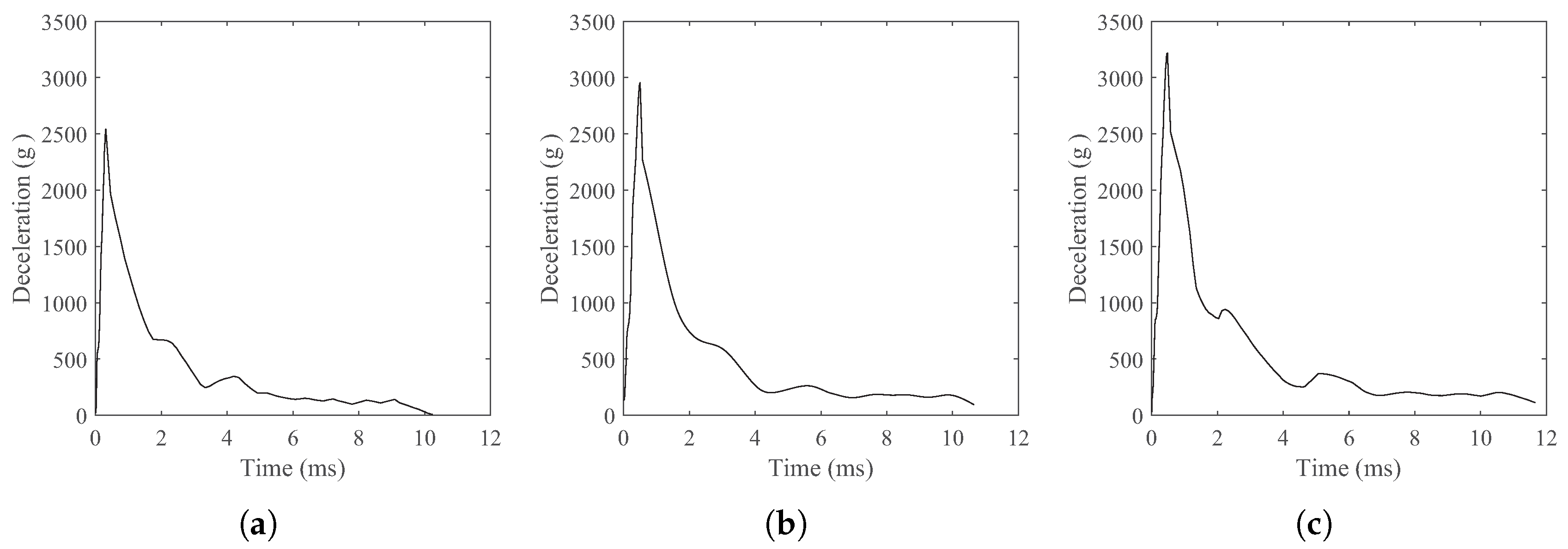

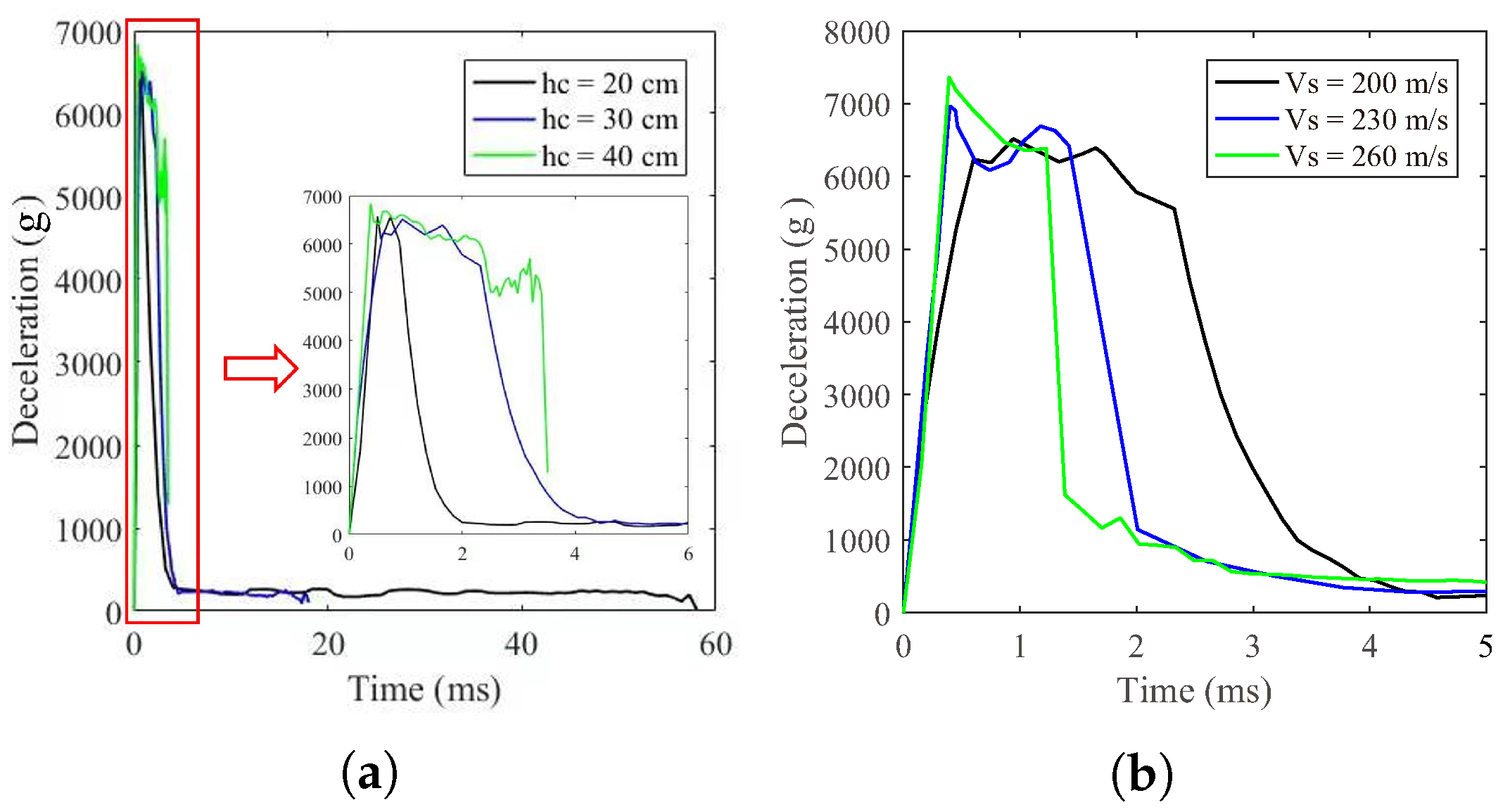

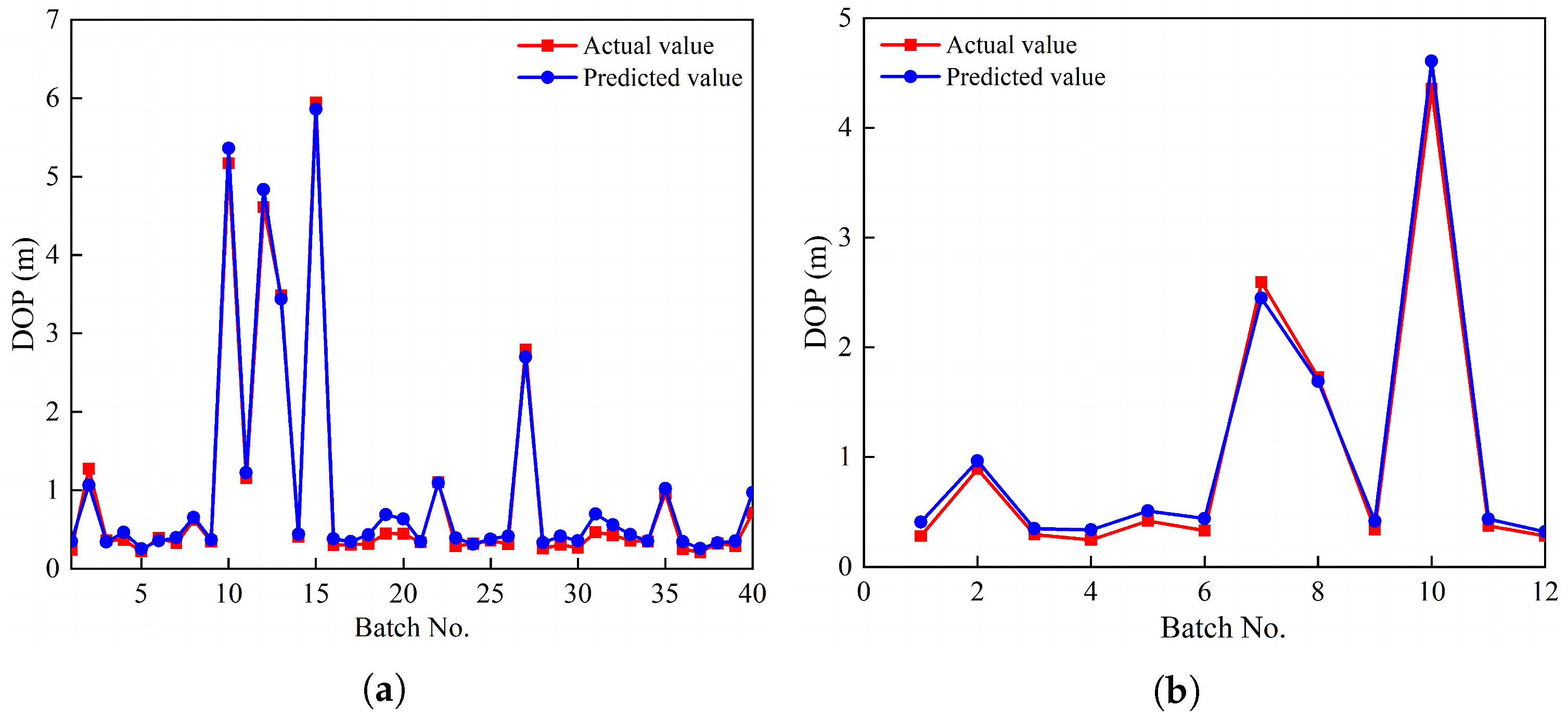

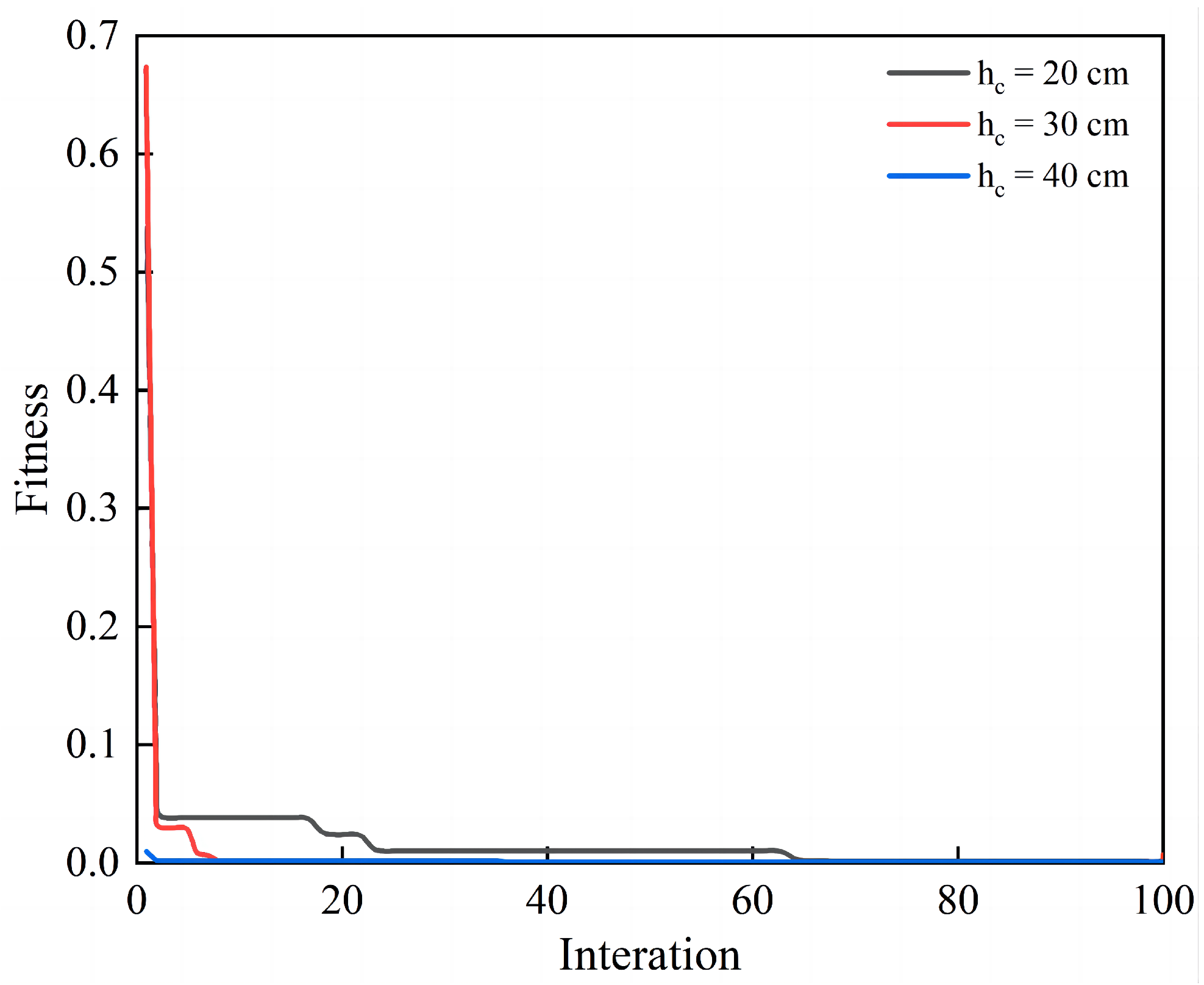

Table 5 shows the simulation results of DOP of various velocities of projectile and thickness of concrete layer. Among all of the results, three representative striking velocities (200 m/s, 230 m/s and 260 m/s), as well as three different concrete thickness (20 cm, 30 cm, 40 cm), have been selected and plotted in

Figure 11 with three different colors. During the surface concrete layer penetration phase, the velocity of the projectile into the concrete decreased while the deceleration initially increased. As the resistance reached its maximum value, the deceleration also peaked and was maintained in a short plateau period with slight fluctuations. However, as the projectile penetrated deeper, it was subjected to the resistance, leading to the decline of velocities and decelerations. After entering the calcareous sand layer, which offered significantly lower resistance than concrete, the reduction in velocities slowed down. In addition, when the projectile navigated through the pit-opening stage in the calcareous sand layer, the deceleration rose slightly, and after the pit-opening stage, the resistance acting on the projectile head became smaller due to the degradation of the tensile stress between the surface of the projectile body and the calcareous sand particles [

45]. On the other hand, the lower striking velocities further reduced the resistant force. These two main factors both contribute to the decrease in the deceleration at a low rate and the stabilization with slight fluctuations.

Since the impact velocity and mass of the projectile were constant, the peak of the deceleration curves remained almost unchanged, regardless of the target thickness, although thicker targets led to longer penetration durations. However, the projectile was unable to penetrate the concrete layer at a thickness of 40 cm. Variations in striking velocities resulted in changes to peak deceleration, with higher velocities producing greater peak deceleration values and shorter penetration durations.