Tensile Properties of Ex-Situ Ti-TiC Metal Matrix Composites Manufactured by Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

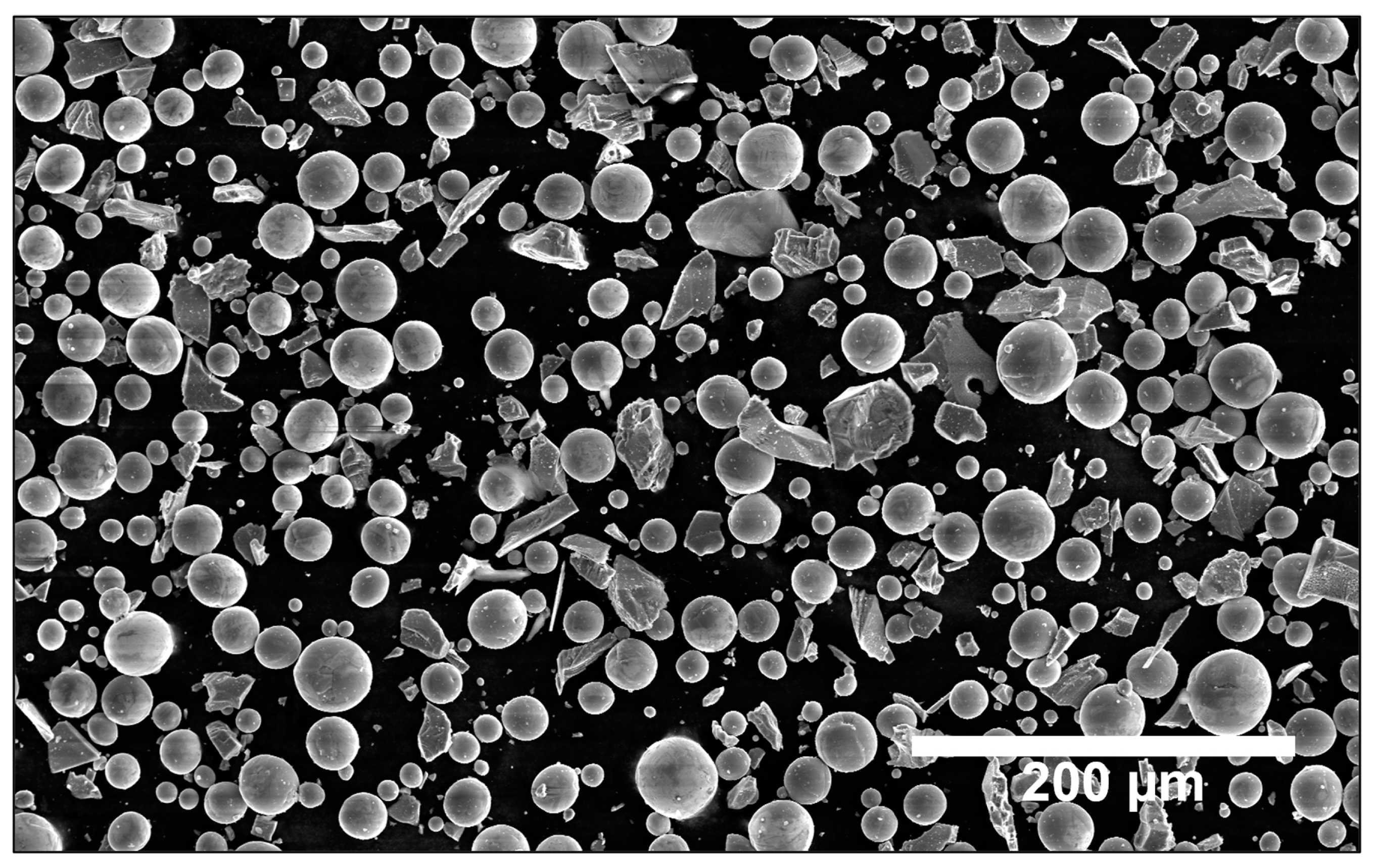

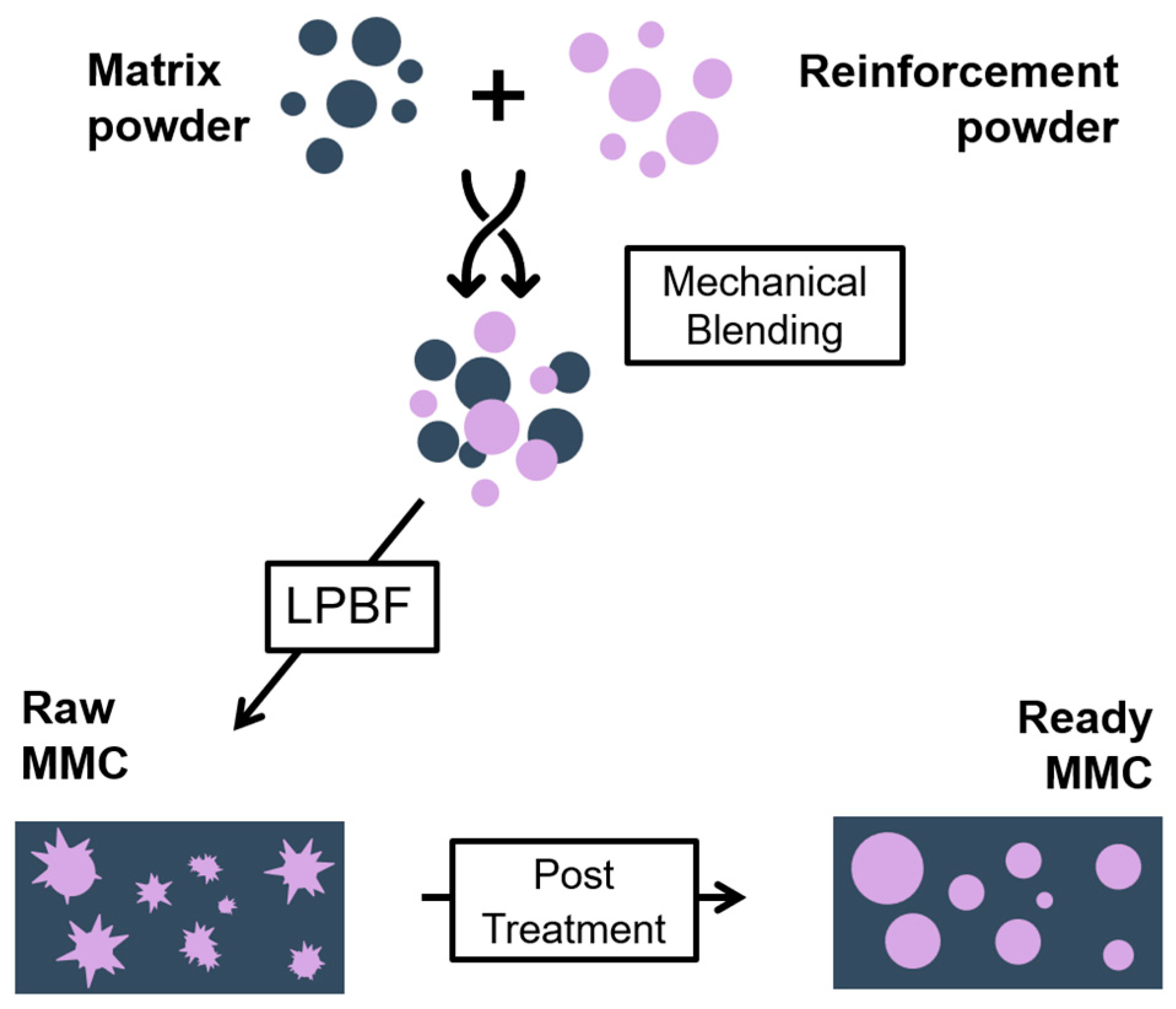

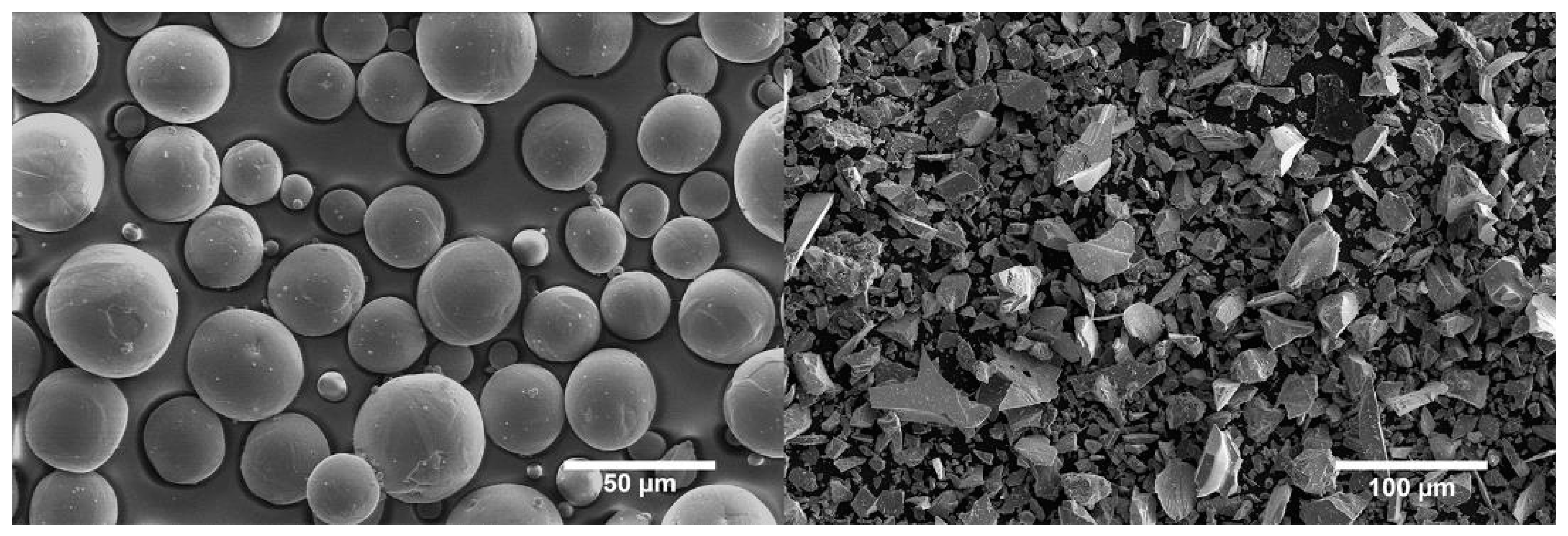

2.1. Powder Preparation

2.2. Laser Powder Bed Fusion Processing and Heat Treatment

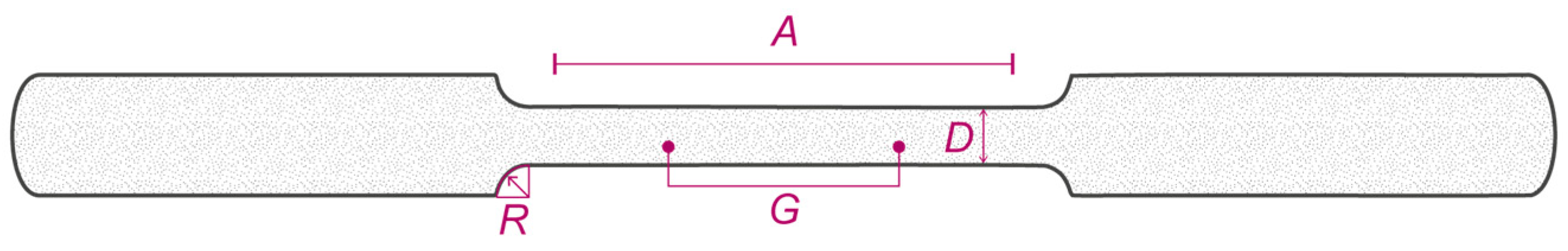

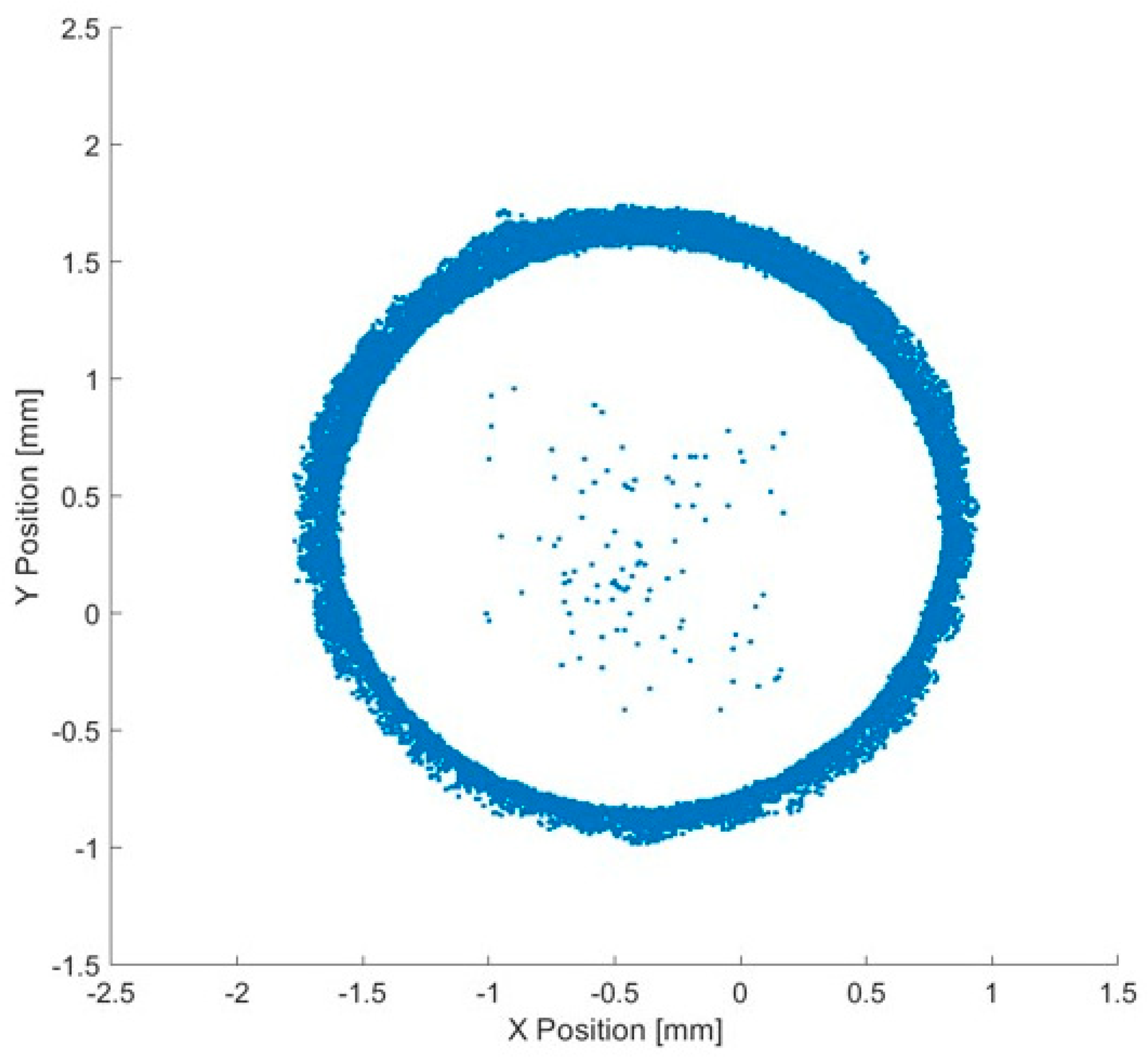

2.3. Microstructural and Mechanical Characterization

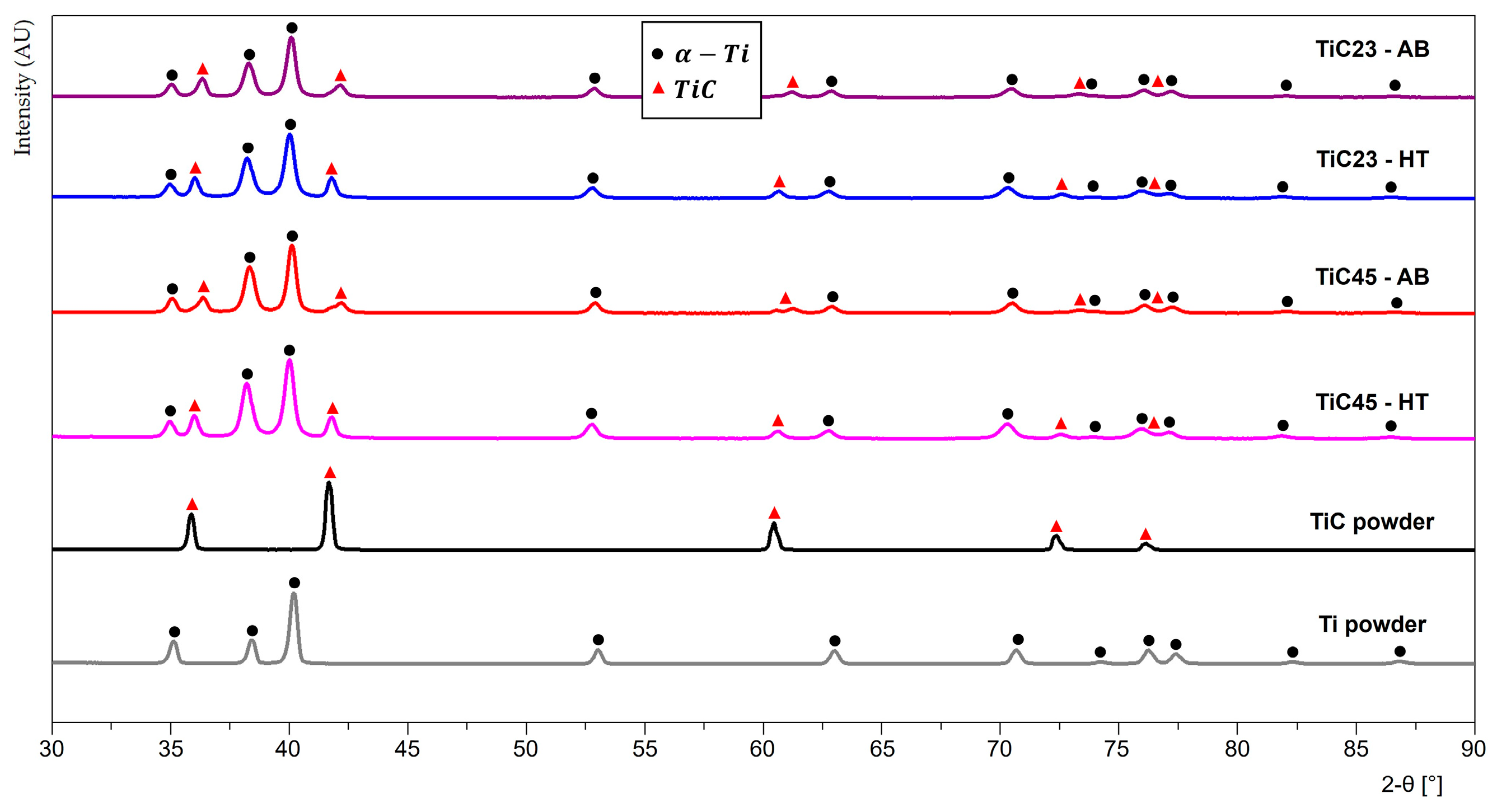

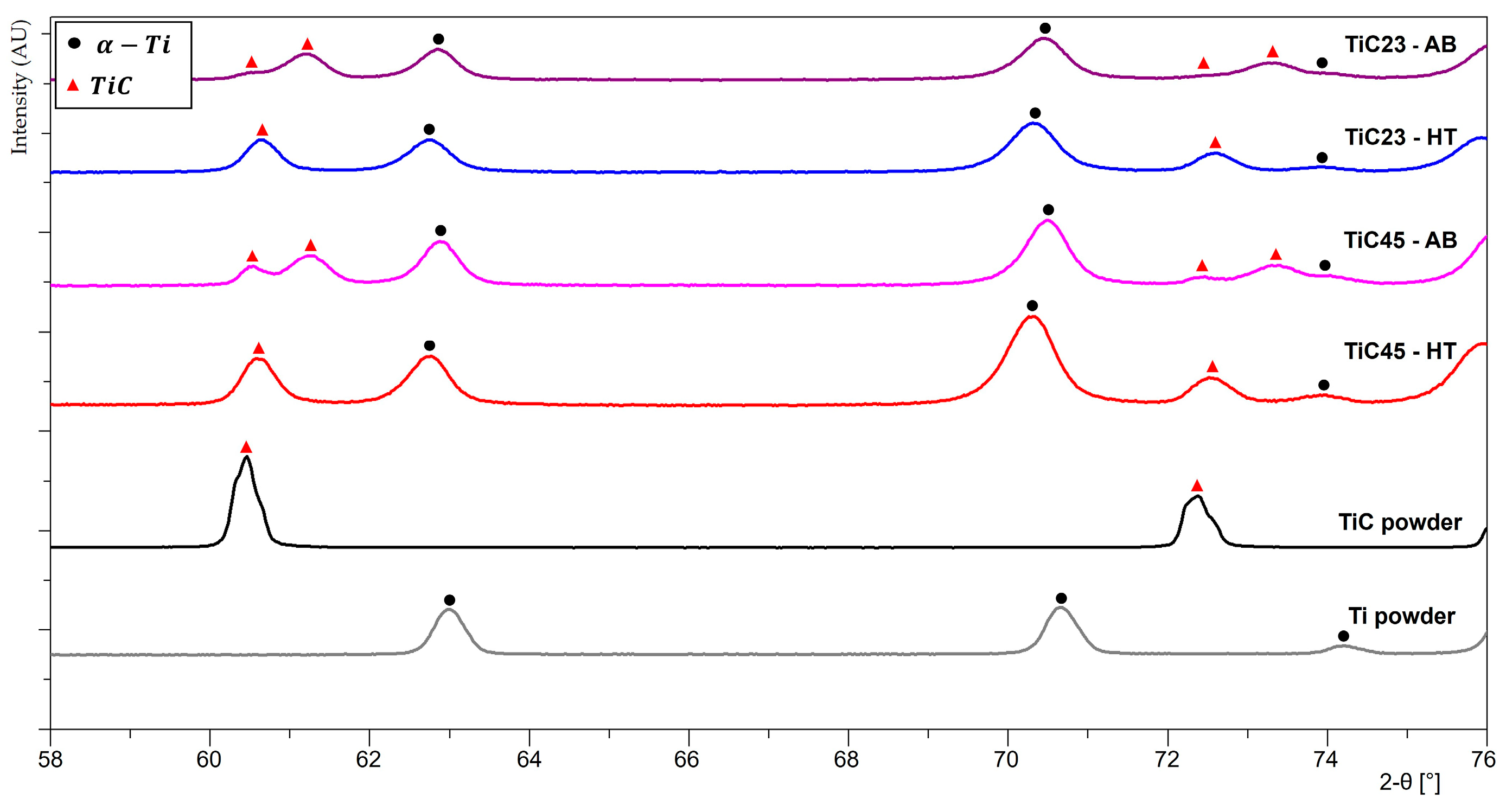

3. Results and Discussion

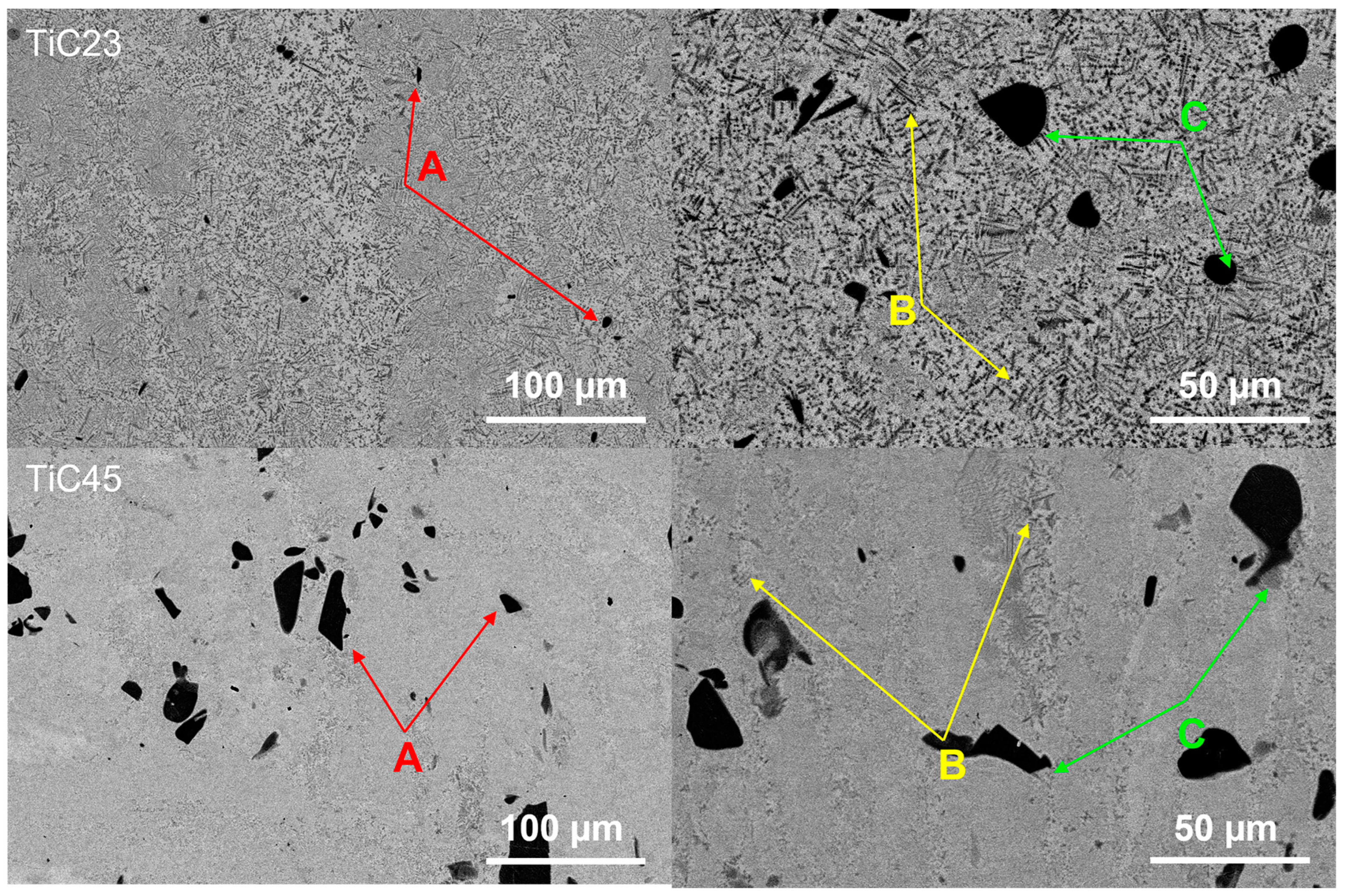

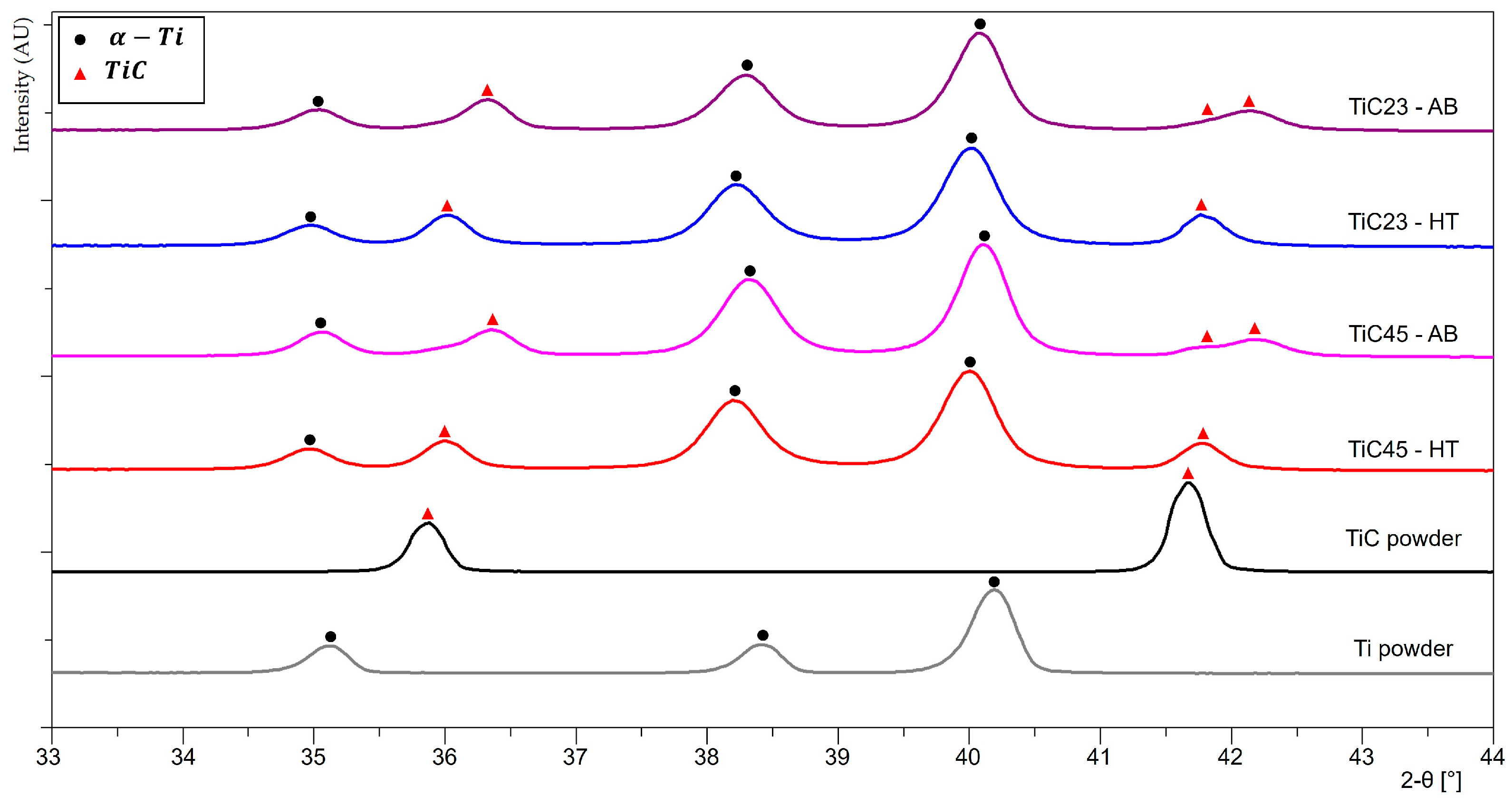

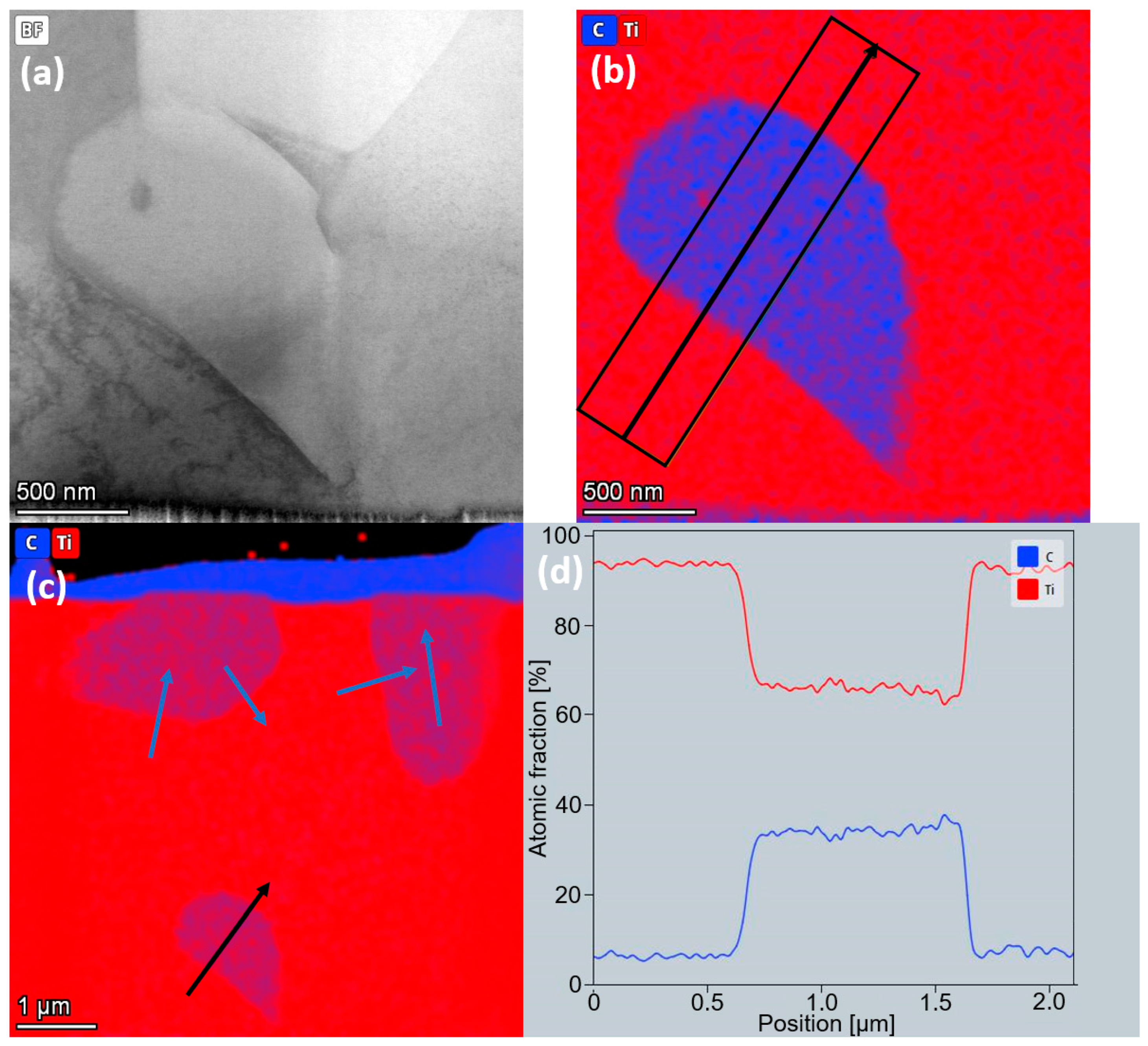

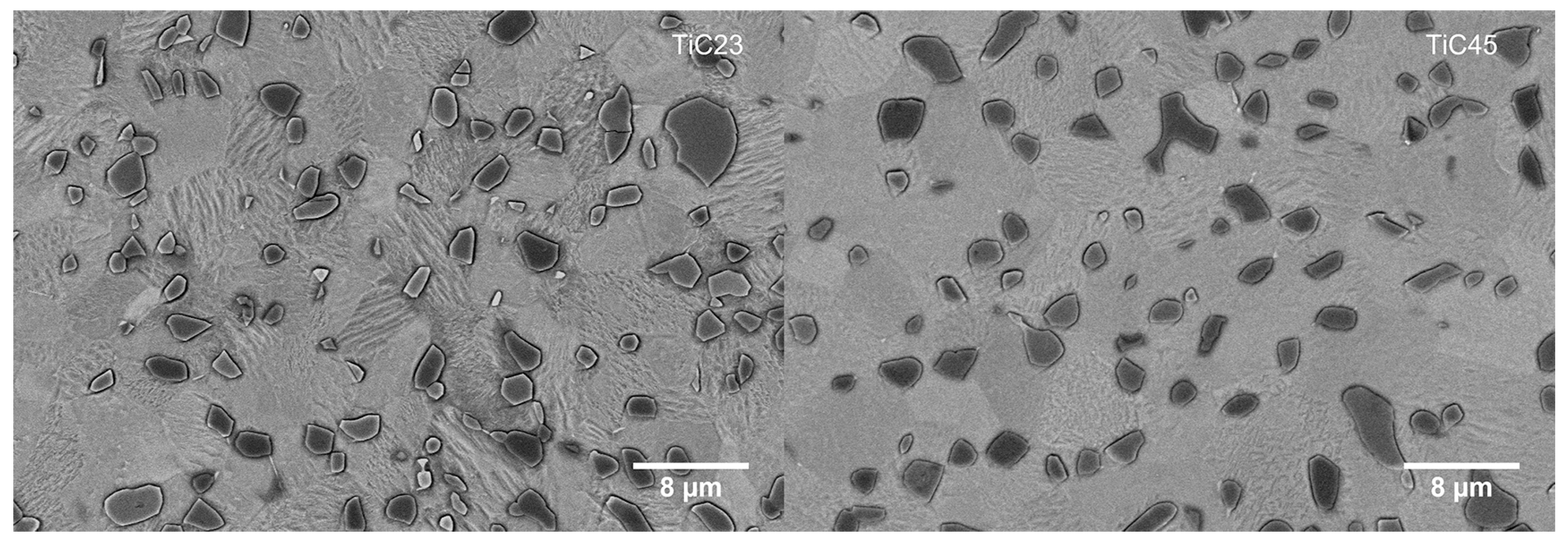

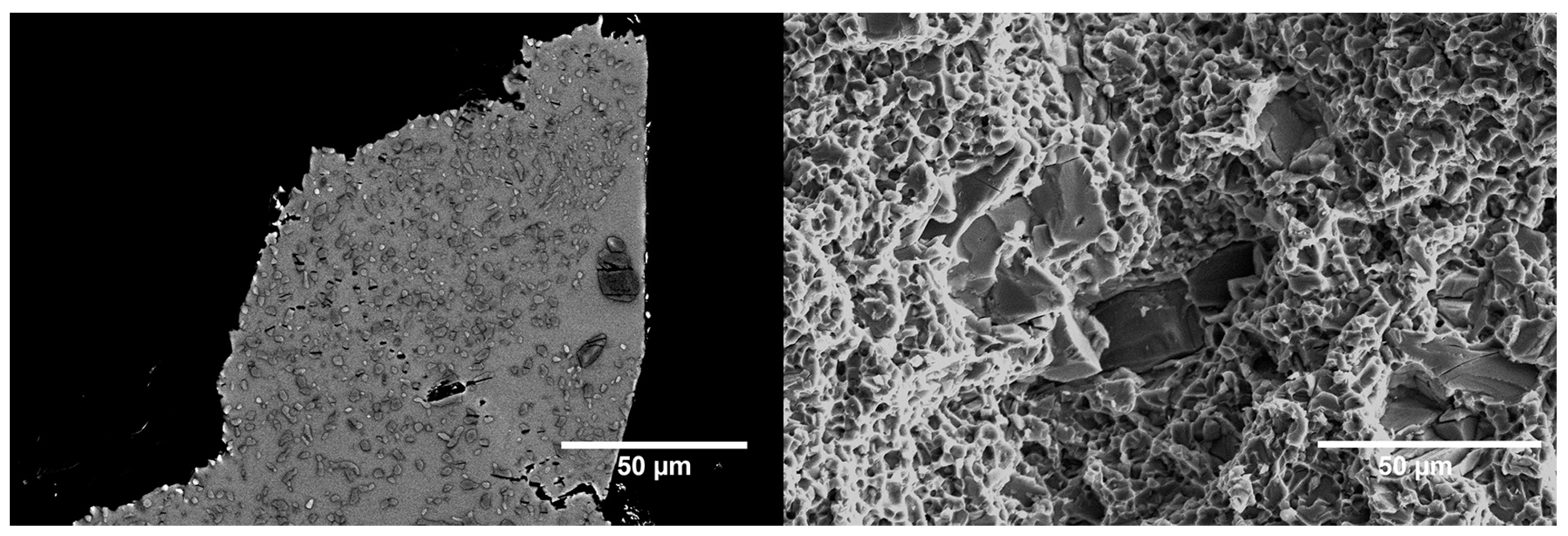

3.1. As-Built MMCs Microstructure

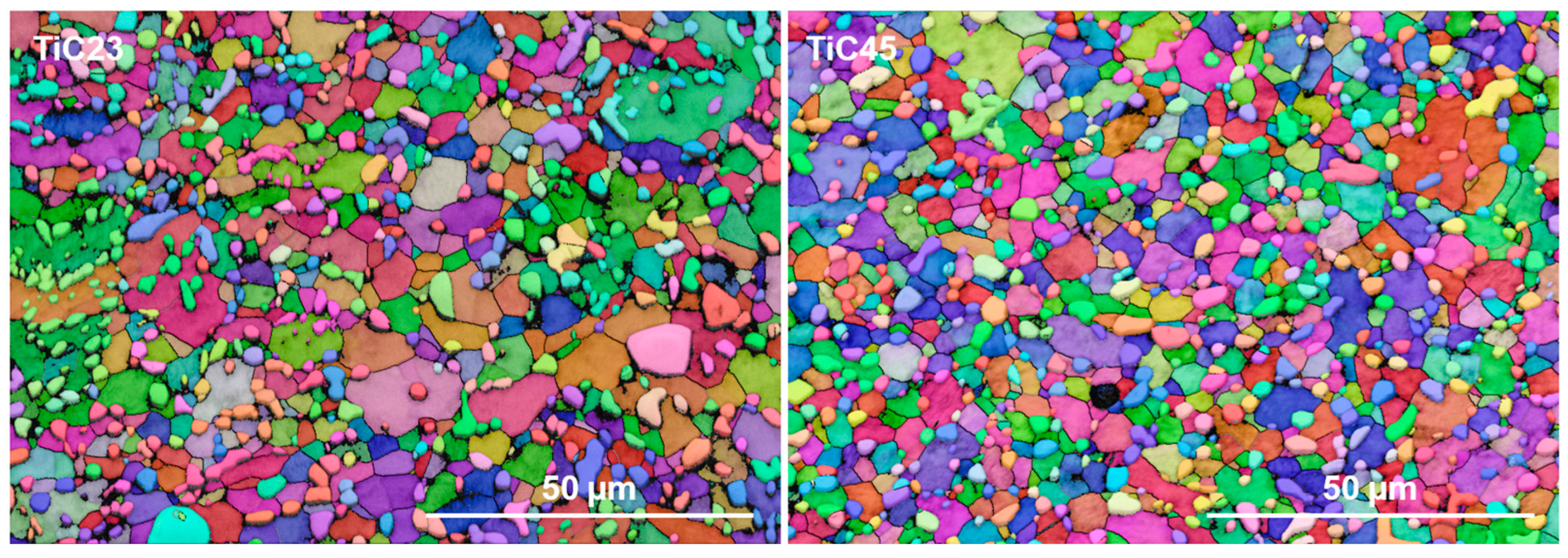

3.2. Heat-Treated Microstructure

3.3. Density Characterization

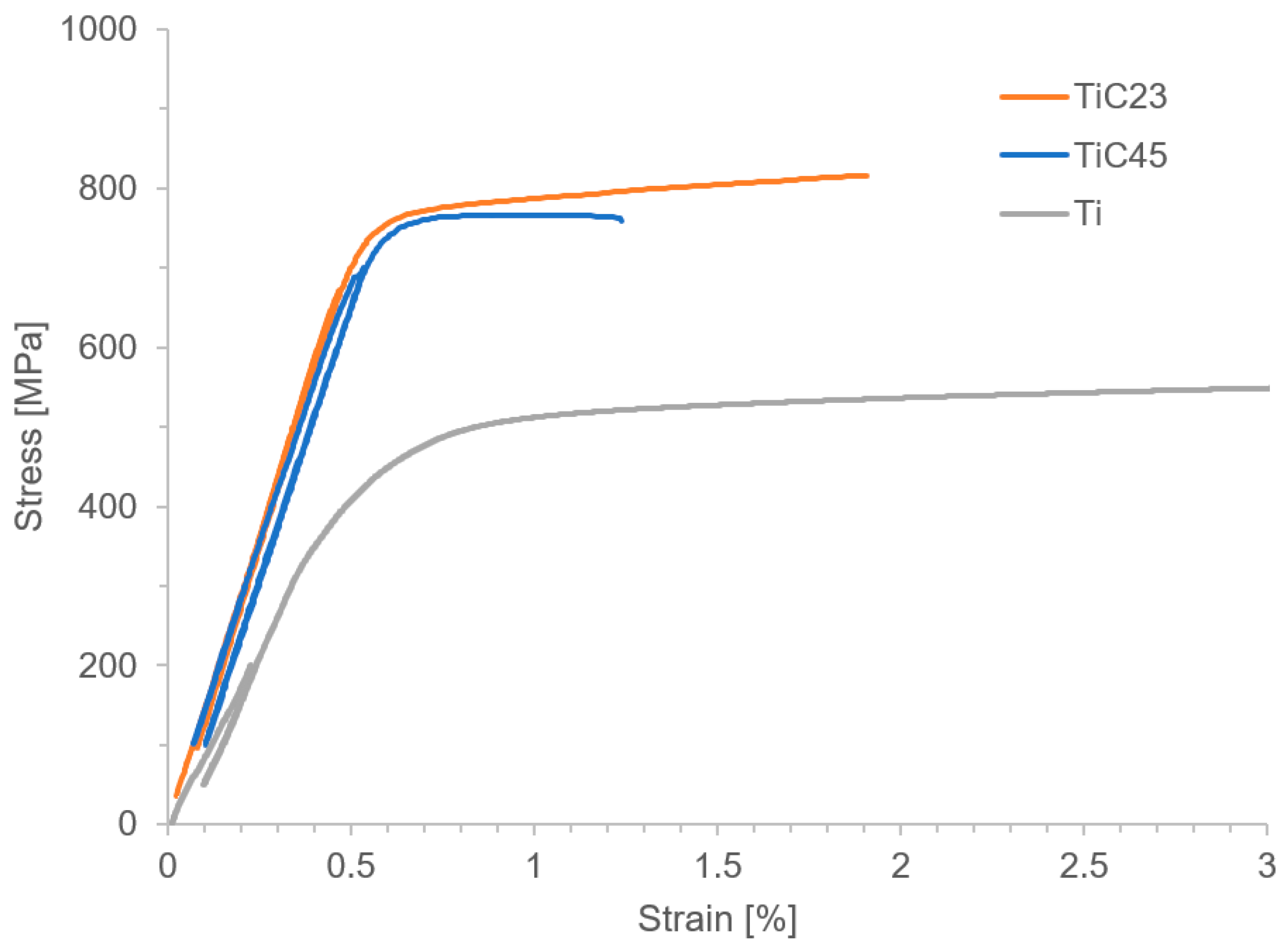

3.4. Mechanical Properties

4. Conclusions

- A density > 99% is achieved with the lowest reinforcement particle sizes, while a density >98% is achieved with the other one.

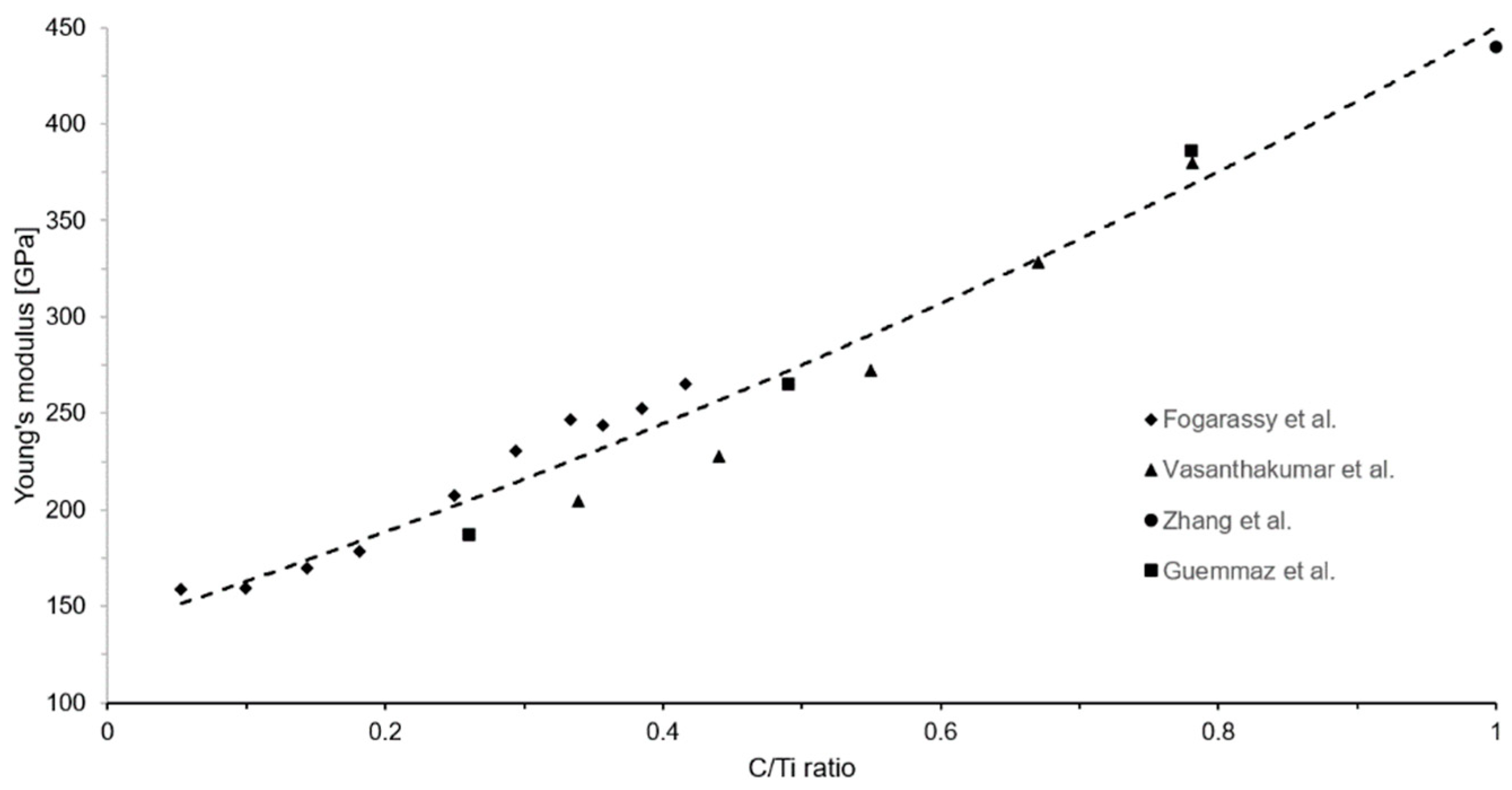

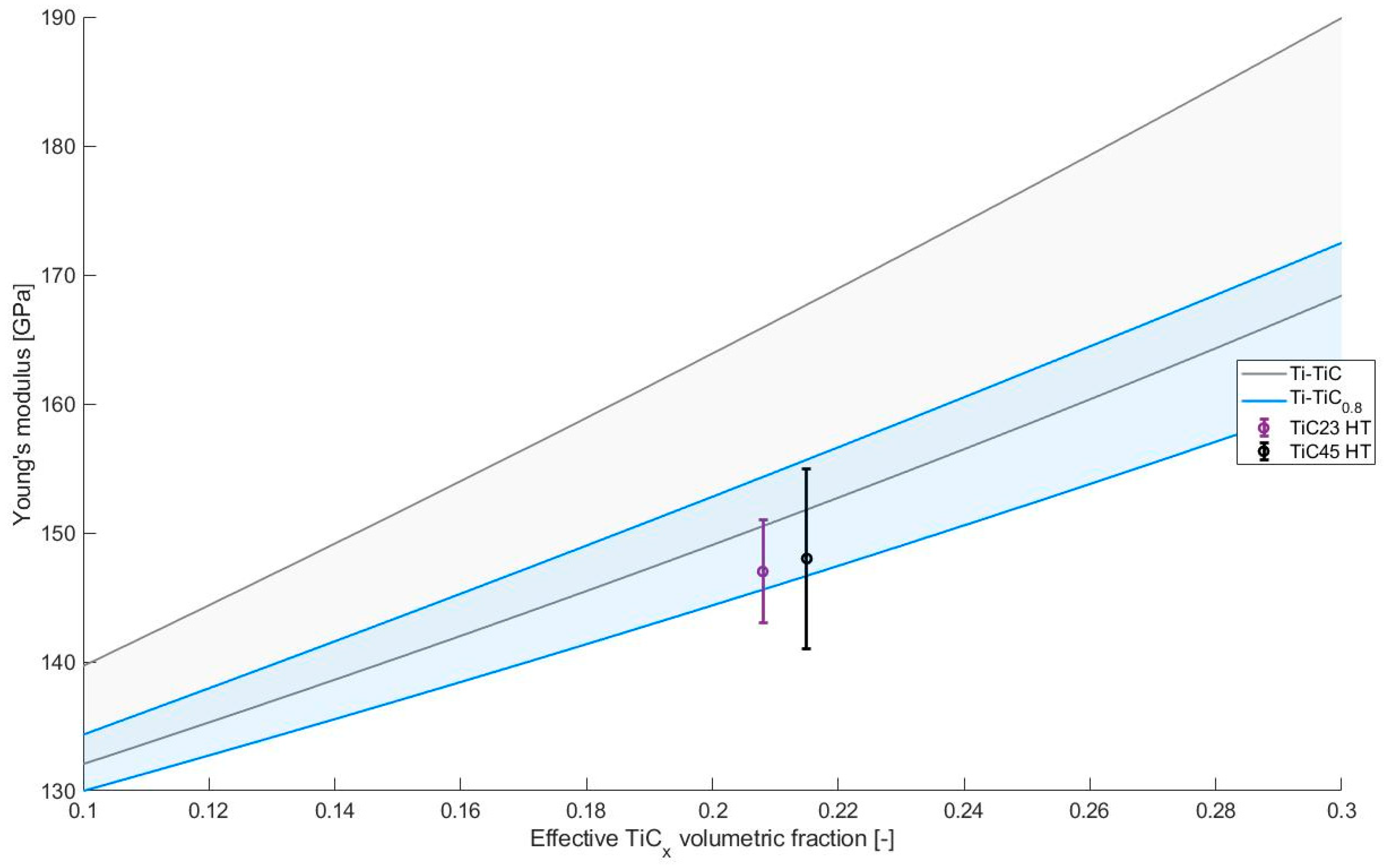

- A drastic evolution of the reinforcement content (12 vol% to 21 vol%) and C/Ti ratio (0.98 to 0.8) is observed following LPBF and heat treatment. The effect of the variation of TiC elastic properties and volumetric fraction on composite elastic properties is discussed.

- Young’s moduli of both MMCs are 26% higher (149 GPa) than the one of Ti grade 2.

- The fracture strain after heat treatment is more than twice the one observed in as-built conditions thanks to the conversion of dendritic TiCx into equiaxed TiCx.

- The elastic modulus is not affected by the heat treatment. It is proposed that the decrease in TiC’s elastic modulus induced by the reduction in the C/Ti ratio is compensated by the increase in the TiCx volumetric fraction.

- Lower particle sizes are shown to be beneficial for both density and mechanical properties and are correlated to a lower fraction of un-dissolved TiC particles. In addition, ductility increase after heat treatment is more pronounced for the latter.

- Fracture up to 1.7% is achieved after heat treatment and for lower particle size distribution. The value is 30% higher than previously reported for Ti-based MMCs produced by LPBF with a similar elastic modulus. This improvement demonstrates the potential of heat-treated Ti-TiC and is a first step in enabling its use in stiffness-driven applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Ti [wt%] | C [wt%] | O [wt%] | H [wt%] | N [wt%] | Fe [wt%] | Other [wt%] | |

|---|---|---|---|---|---|---|---|

| Ti grade 2 | balance | 0.01 | 0.14 | 0.002 | 0.01 | 0.02 | <0.2 |

| TiC | balance | 19.6 | 0.5 | - | - | 0.2 | <0.01 |

| ASTM E8 [mm] | Effective Dimensions [mm] | |

|---|---|---|

| G—Gauge length | 10 ± 0.1 | 10 |

| D—Diameter | 2.5±0.1 | 2.5 |

| R—Radius of filler, min | 2 | 2 |

| A—Length of reduced parallel section, min | 16 | 25 |

References

- Bartolomeu, F.; Michael, G.; Filipe, S.S.; Georgina, M. Mechanical Properties of Ti6Al4V Fabricated by Laser Powder Bed Fusion: A Review Focused on the Processing and Microstructural Parameters Influence on the Final Properties. Metals 2022, 12, 986. [Google Scholar] [CrossRef]

- Chandran, K.S.R.; Panda, K.B.; Sahay, S.S. TiBw-reinforced Ti composites: Processing, properties, application prospects, and research needs. JOM 2004, 56, 42–48. [Google Scholar] [CrossRef]

- Lagos, M.A.; Agote, I.; Atxaga, G.; Adarraga, O.; Pambaguian, L. Fabrication and characterisation of Titanium Matrix Composites obtained using a combination of Self propagating High temperature Synthesis and Spark Plasma Sintering. Mater. Sci. Eng. A 2016, 655, 44–49. [Google Scholar] [CrossRef]

- Kim, M.-K.; Fang, Y.; Kim, J.; Kim, T.; Zhang, Y.; Jeong, W.; Suhr, J. Strategies and Outlook on Metal Matrix Composites Produced Using Laser Powder Bed Fusion: A Review. Metals 2023, 13, 1658. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review. Int. J. Mach. Tools Manuf. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Hayat, M.D.; Singh, H.; He, Z.; Cao, P. Titanium metal matrix composites: An overview. Compos. Part A Appl. Sci. Manuf. 2019, 121, 418–438. [Google Scholar] [CrossRef]

- Xi, L.; Ding, K.; Gu, D.; Guo, S.; Cao, M.; Zhuang, J.; Lin, K.; Okulov, I.; Sarac, B.; Eckert, J.; et al. Interfacial structure and wear properties of selective laser melted Ti/(TiC + TiN) composites with high content of reinforcements. J. Alloys Compd. 2021, 870, 159436. [Google Scholar] [CrossRef]

- Radhakrishnan, M.; Hassan, M.; Long, B.; Otazu, D.; Lienert, T.; Anderoglu, O. Microstructures and properties of Ti/TiC composites fabricated by laser-directed energy deposition. Addit. Manuf. 2021, 46, 102198. [Google Scholar] [CrossRef]

- Gu, D.; Meng, G.; Li, C.; Meiners, W.; Poprawe, R. Selective laser melting of TiC/Ti bulk nanocomposites: Influence of nanoscale reinforcement. Scr. Mater. 2012, 67, 185–188. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.-C.; Meiners, W.; Wissenbach, K.; Poprawe, R. Nanocrystalline TiC reinforced Ti matrix bulk-form nanocomposites by Selective Laser Melting (SLM): Densification, growth mechanism and wear behavior. Compos. Sci. Technol. 2011, 71, 1612–1620. [Google Scholar] [CrossRef]

- Yan, Q.; Chen, B.; Li, J. Super-high-strength graphene/titanium composites fabricated by selective laser melting. Carbon 2021, 174, 451–462. [Google Scholar] [CrossRef]

- Andrieux, J.; Gardiola, B.; Dezellus, O. Synthesis of Ti matrix composites reinforced with TiC particles: In situ synchrotron X-Ray diffraction and modeling. J. Mater. Sci. 2018, 53, 9533–9544. [Google Scholar] [CrossRef]

- Roger, J.; Gardiola, B.; Andrieux, J.; Viala, J.-C.; Dezellus, O. Synthesis of Ti matrix composites reinforced with TiC particles: Thermodynamic equilibrium and change in microstructure. J. Mater. Sci. 2016, 52, 4129–4141. Available online: https://link.springer.com/article/10.1007/s10853-016-0677-y (accessed on 24 November 2020). [CrossRef]

- Lin, Y.; Zee, R.H.; Chin, B.A. In situ formation of three-dimensional TiC reinforcements in Ti-TiC composites. Met. Trans. A 1991, 22, 859–865. [Google Scholar] [CrossRef]

- Kurlov, A.S.; Gusev, A.I. High-energy milling of nonstoichiometric carbides: Effect of nonstoichiometry on particle size of nanopowders. J. Alloys Compd. 2014, 582, 108–118. [Google Scholar] [CrossRef]

- E28 Committee. Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Lin, P.; Wang, J. Effect of TiC particle size on the microstructure and tensile properties of TiCp/Ti6Al4V composites fabricated by laser melting deposition. Opt. Laser Technol. 2018, 105, 195–206. [Google Scholar] [CrossRef]

- Haase, F.; Siemers, C.; Rösler, J. Laser powder bed fusion (LPBF) of commercially pure titanium and alloy development for the LPBF process. Front. Bioeng. Biotechnol. 2023, 11, 1260925. [Google Scholar] [CrossRef]

- Szkliniarz, A.; Szkliniarz, W. Carbon in Commercially Pure Titanium. Materials 2023, 16, 711. [Google Scholar] [CrossRef]

- Fogarassy, Z.; Oláh, N.; Cora, I.; Horváth, Z.E.; Csanádi, T.; Sulyok, A.; Balázsi, K. The structural and mechanical characterization of TiC and TiC/Ti thin films grown by DC magnetron sputtering. J. Eur. Ceram. Soc. 2018, 38, 2886–2892. [Google Scholar] [CrossRef]

- Vasanthakumar, K.; Bakshi, S.R. Effect of C/Ti ratio on densification, microstructure and mechanical properties of TiCx prepared by reactive spark plasma sintering. Ceram. Int. 2018, 44, 484–494. [Google Scholar] [CrossRef]

- Guemmaz, M.; Mosser, A.; Boudoukha, L.; Grob, J.J.; Raiser, D.; Sens, J.C. Ion beam synthesis of non-stoichiometric titanium carbide: Composition structure and nanoindentation studies. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1996, 111, 263–270. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, H.; Li, X.; Wang, Z.; Dong, X. First-principles study on the stability and mechanical properties of TiCxN1−x. J. Mater. Sci. 2023, 58, 4474–4486. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 1963, 11, 127–140. [Google Scholar] [CrossRef]

| Hatching Region | Contour | General Parameters | |||

|---|---|---|---|---|---|

| VED [J/mm3] | Hatching distance [µm] | VED [J/mm3] | Layer thickness [µm] | Contour distance [µm] | Contour number [-] |

| 166.7 | 40 | 52 | 30 | 30 | 1 |

| Parameters | TiC45 AB | TiC23 AB | TiC45 HT | TiC23 HT |

|---|---|---|---|---|

| [Å] | 2.957 | 2.956 | 2.961 | 2.961 |

| [Å] | 4.698 | 4.698 | 4.707 | 4.706 |

| [-] | 1.589 | 1.589 | 1.590 | 1.589 |

| [Å] | 4.279 | 4.282 | 4.319 | 4.318 |

| * [Å] | 4.295 | 4.308 | 4.324 | 4.326 |

| [-] | 0.45 | 0.55 | 0.76 | 0.81 |

| [Å] | 4.321 | 4.310 | x | x |

| * [Å] | 4.326 | 4.326 | x | x |

| [-] | 1.00 | 1.00 | x | x |

| Sample | Sample Density [%] | Hatching Density [%] |

|---|---|---|

| TiC23 | 99.5 | 99.9 |

| TiC45 | 98.8 | 99.1 |

| TiC45 AB | TiC45 HT | TiC23 AB | TiC23 HT | Ti | |

|---|---|---|---|---|---|

| E300 [GPa] | 153 ± 4 | 148 ± 7 | 149 ± 17 | 147 ± 4 | 117 ± 7 |

| E700 [GPa] | - | 149 ± 9 | - | 149 ± 3 | - |

| YS [MPa] | - | 700 ± 74 | - | 806 ± 20 | 512 ± 6 |

| UTS [MPa] | 668 ± 21 | 752 ± 11 | 778 ± 15 | 827 ± 9 | 576 ± 4 |

| e [%] | 0.5 ± 0.0 | 1.3 ± 0.1 | 0.7 ± 0.1 | 1.7 ± 0.2 | 29.3 ± 3.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bernard, G.; Pejchal, V.; Sereda, O.; Logé, R.E. Tensile Properties of Ex-Situ Ti-TiC Metal Matrix Composites Manufactured by Laser Powder Bed Fusion. Materials 2024, 17, 5613. https://doi.org/10.3390/ma17225613

Bernard G, Pejchal V, Sereda O, Logé RE. Tensile Properties of Ex-Situ Ti-TiC Metal Matrix Composites Manufactured by Laser Powder Bed Fusion. Materials. 2024; 17(22):5613. https://doi.org/10.3390/ma17225613

Chicago/Turabian StyleBernard, Gaëtan, Vaclav Pejchal, Olha Sereda, and Roland E. Logé. 2024. "Tensile Properties of Ex-Situ Ti-TiC Metal Matrix Composites Manufactured by Laser Powder Bed Fusion" Materials 17, no. 22: 5613. https://doi.org/10.3390/ma17225613

APA StyleBernard, G., Pejchal, V., Sereda, O., & Logé, R. E. (2024). Tensile Properties of Ex-Situ Ti-TiC Metal Matrix Composites Manufactured by Laser Powder Bed Fusion. Materials, 17(22), 5613. https://doi.org/10.3390/ma17225613