High-Performance Concrete from Rubber and Shell Waste Materials: Experimental and Computational Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

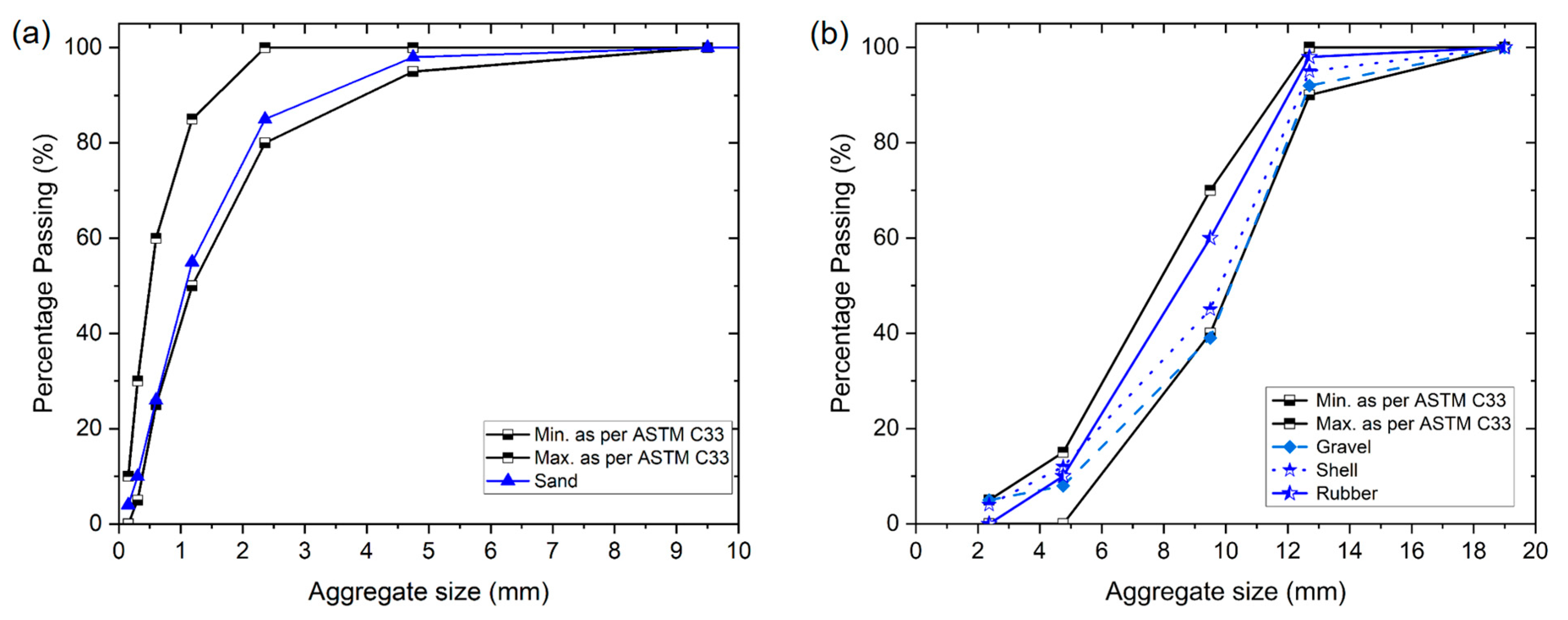

2.2. Measure Gradation, Density, and Absorption of Aggregates

2.3. Mix Design and Sample Preparation

2.4. Mechanical Testing

2.5. Computational Simulation

3. Results and Discussion

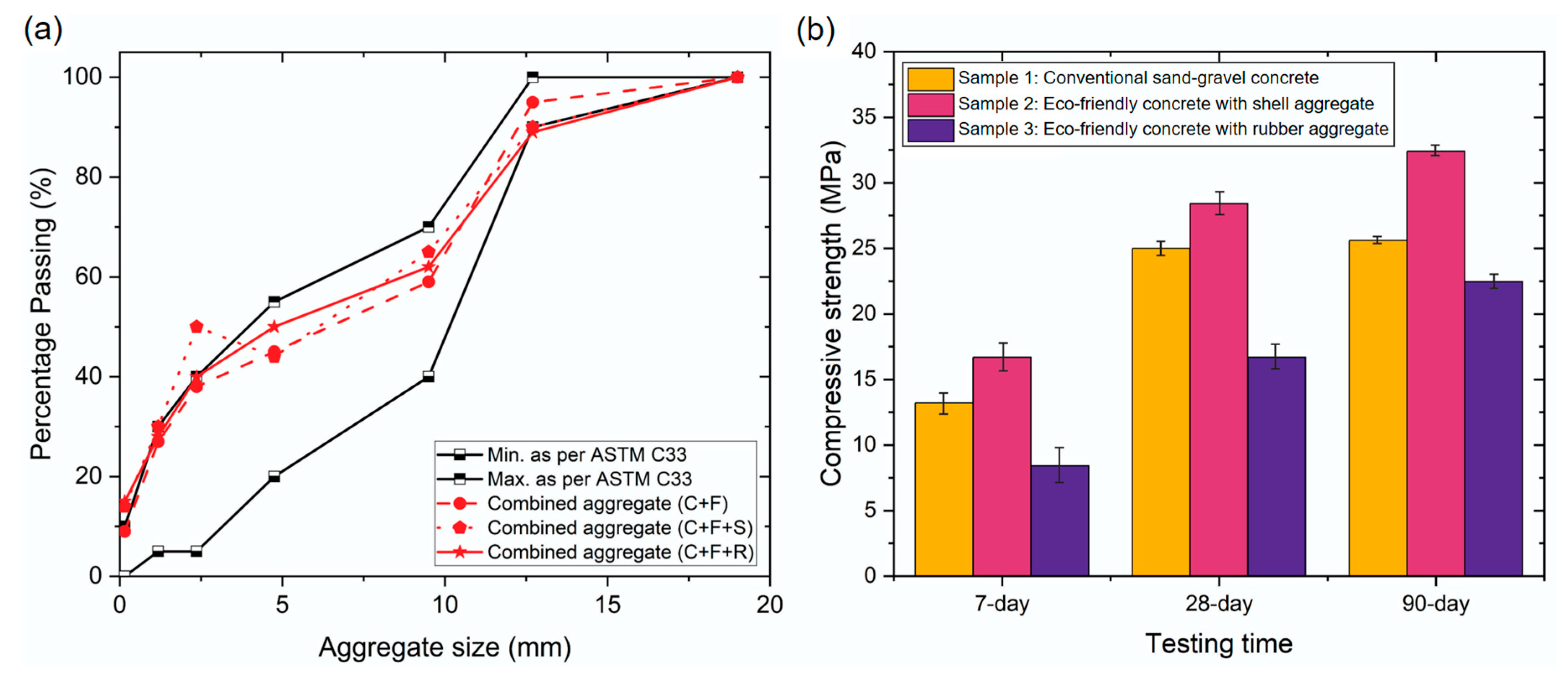

3.1. Physical Characterization and Workability of Sustainable Concrete

3.2. Compressive Strength of Sustainable Structural Concrete Containing Seashells vs. Rubber

3.3. Failure Behavior of Concrete Compression Samples

3.4. Overall Elastic Properties of Constituents from Nanoscale Testing

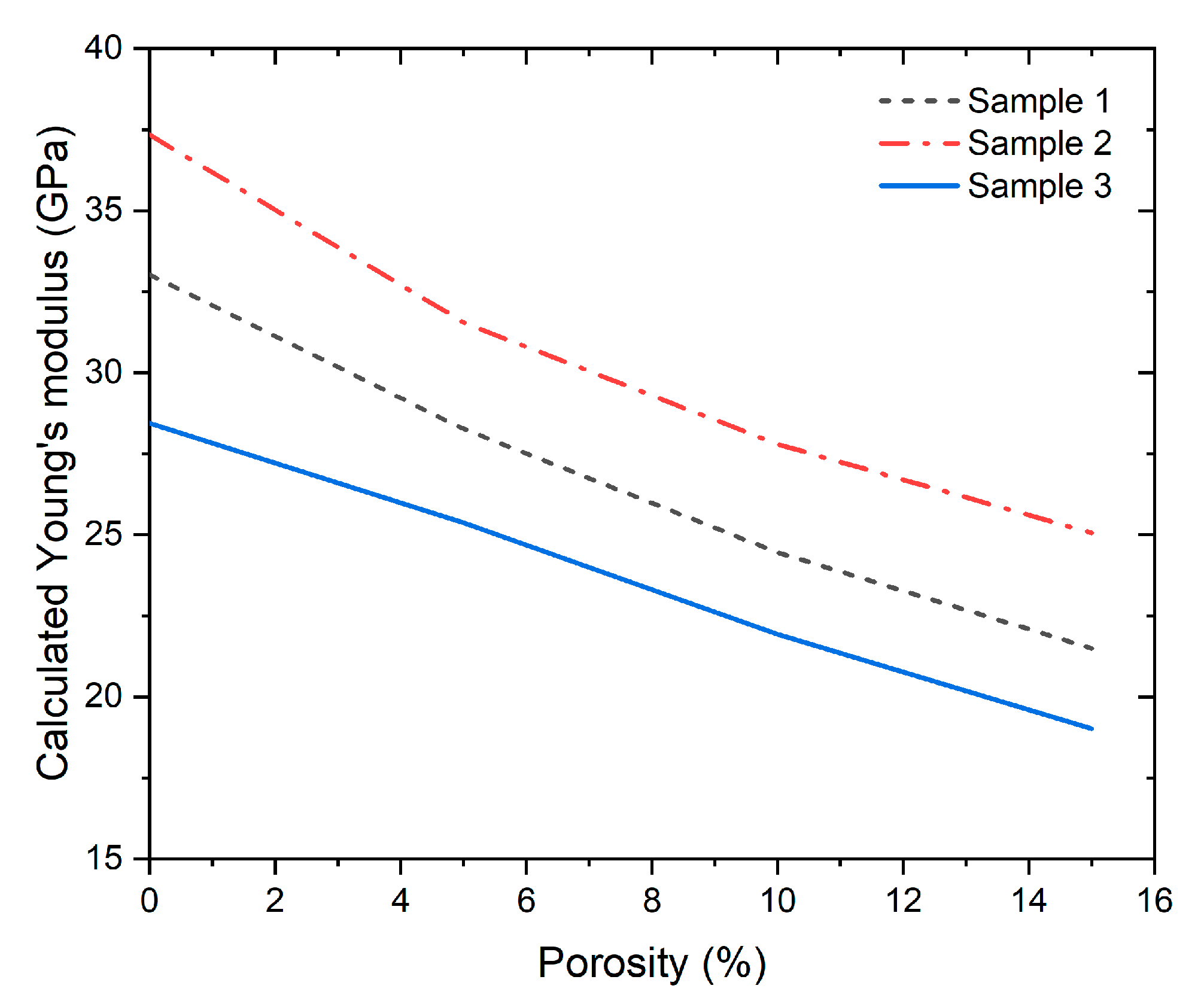

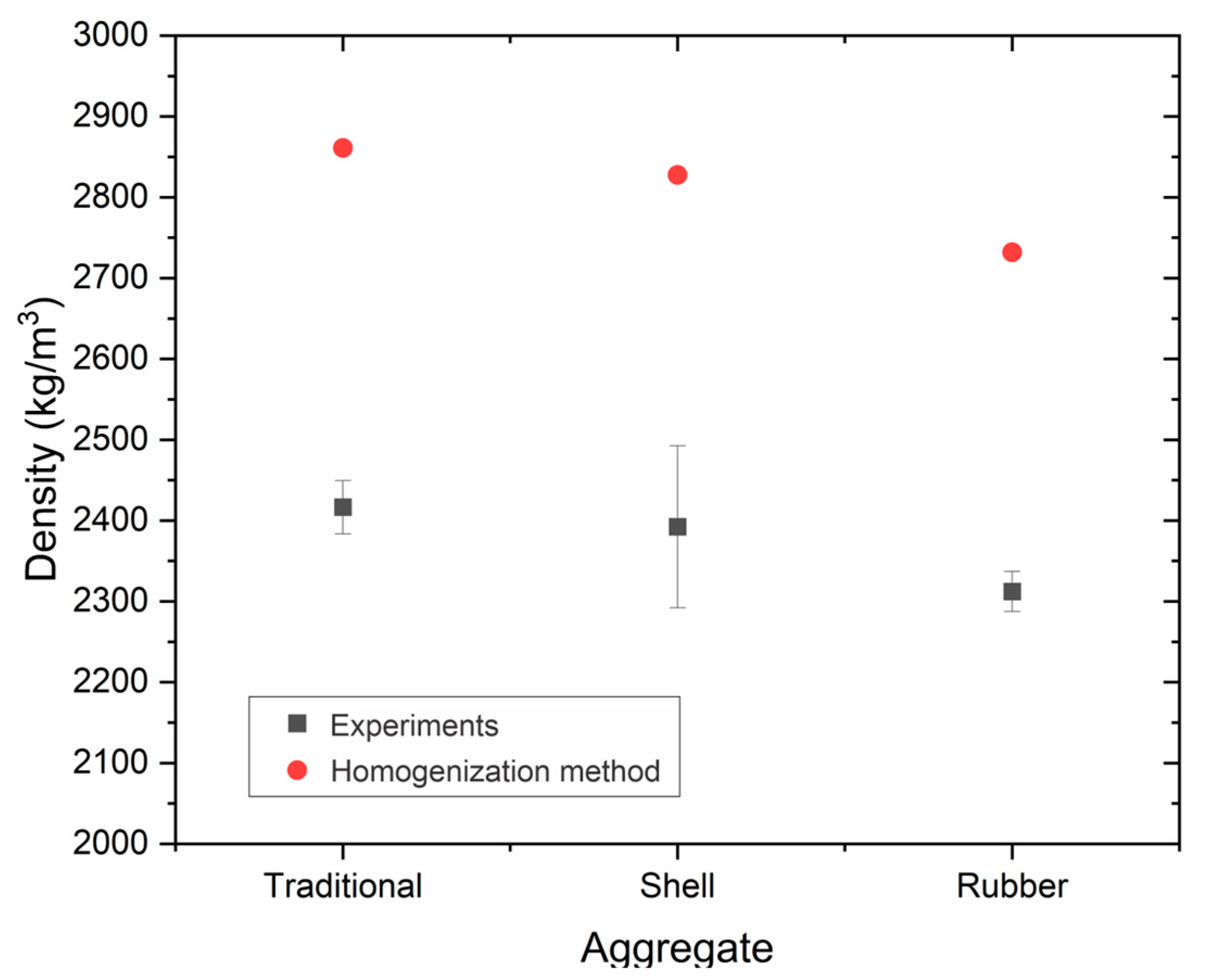

3.5. Predicting Concrete Behavior from Homogenized Representative Volume Elements

3.6. Compressive Stress-Strain Relationship

3.7. Finite Element-Based Computational Simulation of Axial Compression of Sustainable Concrete

3.8. Correlating Density, Porosity, and Strength of Sustainable High-Strength Structural Concrete

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.; Lei, J.; Wang, Q.; Xu, S.; Zhou, Y. Mechanical and vegetative performance of ecological concrete with nutrient aggregates. Case Stud. Constr. Mater. Case Stud. Constr. Mater. 2024, 20, e03210. [Google Scholar] [CrossRef]

- Valenzuela, M.; Leiva, J.; Salas, A.; Ciudad, G.; Cárdenas, J.P.; Oñate, A.; Hunter, R.; Attia, S.; Tuninetti, V. CEBs with GRC: Fabrication, characterization, modeling, and correlation with microstructural fracture features. Mater. Today Commun. 2023, 37, 107028. [Google Scholar] [CrossRef]

- Valenzuela, M.; Ciudad, G.; Cárdenas, J.P.; Medina, C.; Salas, A.; Oñate, A.; Pincheira, G.; Attia, S.; Tuninetti, V. Towards the development of performance-efficient compressed earth blocks from industrial and agro-industrial by-products. Renew. Sustain. Energy Rev. 2024, 194, 114323. [Google Scholar] [CrossRef]

- Akhtar, N.; Ahmad, T.; Husain, D.; Majdi, A.; Alam, T.; Husain, N.; Wayal, A.K.S. Ecological footprint and economic assessment of conventional and geopolymer concrete for sustainable construction. J. Clean. Prod. 2022, 380, 134910. [Google Scholar] [CrossRef]

- Lei, J.; Yang, Y.; Chen, X. Mechanics and permeability properties of ecological concrete mixed with recycled engineering muck particles. J. Build. Eng. 2024, 91, 109560. [Google Scholar] [CrossRef]

- Ran, T.; Pang, J.; Yu, J. Performance of Rubber Concrete Containing Polypropylene and Basalt Fibers under Coupled Sulfate Attack and Freeze–Thaw Conditions: An Experimental Evaluation. Polymers 2023, 15, 2066. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, C.; Zhao, Y.; Bi, J.; Shen, M.; Deng, X. Study on the effect of wood admixture on the physical and mechanical properties of corn cob ecological recycled concrete. J. Build. Eng. 2024, 88, 109116. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, J.; Liu, J.; Bie, Y.; Hu, Q. Sustainable ecological pervious concrete (SEPC) based on modified corn-cob coarse aggregate: Crushing morphology, strength, pore properties, and durability. J. Build. Eng. 2024, 88, 136194. [Google Scholar] [CrossRef]

- Viejo, I.; Esteves, L.P.; Laspalas, M.; Bielsa, J.M. Numerical modelling of porous cement-based materials by superabsorbent polymers. Cem. Concr. Res. 2016, 90, 184–193. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, M.; Meng, X.; Liu, A.; Duo, L. Waste rubber—Black pollution reframed as a global issue: Ecological challenges and sustainability initiatives. Environ. Pollut. 2024, 356, 124291. [Google Scholar] [CrossRef]

- Kong, J.; Cong, G.; Ni, S.; Sun, J.; Guo, C.; Chen, M.; Quan, H. Recycling of waste oyster shell and recycled aggregate in the porous ecological concrete used for artificial reefs. Constr. Build. Mater. 2022, 323, 126447. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Hernandez, J. Conceptualization, modeling and environmental impact assessment of a natural rubber techno-ecological system with nutrient, water and energy integration. J. Clean. Prod. 2018, 185, 707–722. [Google Scholar] [CrossRef]

- Zerin, N.; Rasul, M.; Jahirul, M.; Sayem, A. End-of-life tyre conversion to energy: A review on pyrolysis and activated carbon production processes and their challenges. Sci. Total. Environ. 2023, 905, 166981. [Google Scholar] [CrossRef] [PubMed]

- Kan, T.; Strezov, V.; Evans, T. Fuel production from pyrolysis of natural and synthetic rubbers. Fuel 2017, 191, 403–410. [Google Scholar] [CrossRef]

- Han, W.; Jiang, C.; Wang, J.; Chen, H. Enhancement of heat transfer during rubber pyrolysis process. J. Clean. Prod. 2022, 348, 131363. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Chiaia, B.; Gorino, A. Ecological and mechanical assessment of lightweight fiber-reinforced concrete made with rubber or expanded clay aggregates. Constr. Build. Mater. 2016, 127, 692–701. [Google Scholar] [CrossRef]

- Aziz, P.L.; Abdulkadir, M.R. Mechanical Properties and Flexural Strength of Reinforced Concrete Beams Containing Waste Material as Partial Replacement for Coarse Aggregates. Int. J. Concr. Struct. Mater. 2022, 16, 56. [Google Scholar] [CrossRef]

- Abbas, S.; Fatima, A.; Kazmi, S.M.S.; Munir, M.J.; Ali, S.; Rizvi, M.A. Effect of Particle Sizes and Dosages of Rubber Waste on the Mechanical Properties of Rubberized Concrete Composite. Appl. Sci. 2022, 12, 8460. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Baharom, S.; Baghban, M.H.; Nehdi, M.L.; Faridmehr, I.; Huseien, G.F.; Algaifi, H.A.; Ismail, M. Systematic Experimental Assessment of POFA Concrete Incorporating Waste Tire Rubber Aggregate. Polymers 2022, 14, 2294. [Google Scholar] [CrossRef] [PubMed]

- Eissa, M.; Habib, A.; AL Houri, A.; Alibrahim, B. Recent efforts on investigating the effects of recycled rubber content on the mechanical properties of structural concrete. Discov. Civ. Eng. 2024, 1, 16. [Google Scholar] [CrossRef]

- Lakhiar, M.T.; Kong, S.Y.; Bai, Y.; Susilawati, S.; Zahidi, I.; Paul, S.C.; Raghunandan, M.E. Thermal and Mechanical Properties of Concrete Incorporating Silica Fume and Waste Rubber Powder. Polymers 2022, 14, 4858. [Google Scholar] [CrossRef] [PubMed]

- Yoon, G.-L.; Kim, B.-T.; Kim, B.-O.; Han, S.-H. Chemical–mechanical characteristics of crushed oyster-shell. Waste Manag. 2003, 23, 825–834. [Google Scholar] [CrossRef]

- Xu, S.; Cai, S.; Zhang, C.; Fang, L.; Bian, C.; Zou, X.; Fu, D. A novel environmentally-friendly filler of the asphalt mastic: Organic modified waste shells. J. Clean. Prod. 2024, 470, 143333. [Google Scholar] [CrossRef]

- Oh, S.-E.; Chung, S.-Y.; Kim, K.; Han, S.-H. Comparative analysis of the effects of waste shell aggregates on the material properties of cement mortars. Constr. Build. Mater. 2024, 412, 134887. [Google Scholar] [CrossRef]

- Caroscio, L.; De Pascale, B.; Tataranni, P.; Chiavetta, C.; Lantieri, C.; Bonoli, A. Preliminary study on the application of waste bivalve shells as biofiller for the production of asphalt concrete. Clean. Eng. Technol. 2024, 20, 100743. [Google Scholar] [CrossRef]

- Ramasubramani, R.; Nareshbabu, A.; Sudarsan, J.; Nithiyanantham, S. Feasibility of cockle seashell waste as an additive material to concrete as a green concrete initiative to promote sustainability. J. Build. Pathol. Rehabil. 2022, 7, 93. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, D.; Yu, X.; Liu, R.; Liao, Y. Properties of Cementitious Materials Utilizing Seashells as Aggregate or Cement: Prospects and Challenges. Materials 2024, 17, 1222. [Google Scholar] [CrossRef]

- Kuo, W.-T.; Wang, H.-Y.; Shu, C.-Y.; Su, D.-S. Engineering properties of controlled low-strength materials containing waste oyster shells. Constr. Build. Mater. 2013, 46, 128–133. [Google Scholar] [CrossRef]

- Safi, B.; Saidi, M.; Daoui, A.; Bellal, A.; Mechekak, A.; Toumi, K. The use of seashells as a fine aggregate (by sand substitution) in self-compacting mortar (SCM). Constr. Build. Mater. 2015, 78, 430–438. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Boutouil, M.; Sebaibi, N.; Leleyter, L.; Baraud, F. Valorization of seashell by-products in pervious concrete pavers. Constr. Build. Mater. 2013, 49, 151–160. [Google Scholar] [CrossRef]

- Cuadrado-Rica, H.; Sebaibi, N.; Boutouil, M.; Boudart, B. Properties of ordinary concretes incorporating crushed queen scallop shells. Mater. Struct. 2015, 49, 1805–1816. [Google Scholar] [CrossRef]

- Olivia, M.; Mifshella, A.A.; Darmayanti, L. Mechanical Properties of Seashell Concrete. Procedia Eng. 2015, 125, 760–764. [Google Scholar] [CrossRef]

- Wang, J.; Liu, E. Upcycling waste seashells with cement: Rheology and early-age properties of Portland cement paste. Resour. Conserv. Recycl. 2020, 155, 104680. [Google Scholar] [CrossRef]

- Topić Popović, N.; Lorencin, V.; Strunjak-Perović, I.; Čož-Rakovac, R. Shell Waste Management and Utilization: Mitigating Organic Pollution and Enhancing Sustainability. Appl. Sci. 2023, 13, 623. [Google Scholar] [CrossRef]

- ASTM C150/C150M-24; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM C128-22; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- ASTM C127-24; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM C33/C33M-23; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- ASTM C192/C192M-19; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM C39/C39M-24; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- Tuninetti, V.; Jaramillo, A.F.; Riu, G.; Rojas-Ulloa, C.; Znaidi, A.; Medina, C.; Mateo, A.M.; Roa, J.J. Experimental Correlation of Mechanical Properties of the Ti-6Al-4V Alloy at Different Length Scales. Metals 2021, 11, 104. [Google Scholar] [CrossRef]

- Rojas-Ulloa, C.; Bouffioux, C.; Jaramillo, A.F.; García-Herrera, C.M.; Hussain, T.; Duchêne, L.; Riu, G.; Roa, J.J.; Flores, P.; Habraken, A.M.; et al. Nanomechanical Characterization of the Deformation Response of Orthotropic Ti–6Al–4V. Adv. Eng. Mater. 2021, 23, 2001341. [Google Scholar] [CrossRef]

- Moustafa, A.; ElGawady, M.A. Mechanical properties of high strength concrete with scrap tire rubber. Constr. Build. Mater. 2015, 93, 249–256. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Kalla, P.; Cseteneyi, L. Strength, abrasion and permeation characteristics of cement concrete containing discarded rubber fine aggregates. Constr. Build. Mater. 2014, 59, 204–212. [Google Scholar] [CrossRef]

- Li, G.; Wang, Z.; Leung, C.K.; Tang, S.; Pan, J.; Huang, W.; Chen, E. Properties of rubberized concrete modified by using silane coupling agent and carboxylated SBR. J. Clean. Prod. 2016, 112, 797–807. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K. Hardened properties of concrete mixtures containing pre-coated crumb rubber and silica fume. J. Clean. Prod. 2014, 82, 125–131. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Özturan, T. Properties of rubberized concretes containing silica fume. Cem. Concr. Res. 2004, 34, 2309–2317. [Google Scholar] [CrossRef]

- Alsaif, A.; Alharbi, Y.R. Strength, durability and shrinkage behaviours of steel fiber reinforced rubberized concrete. Constr. Build. Mater. 2022, 345, 128295. [Google Scholar] [CrossRef]

- Yung, W.H.; Yung, L.C.; Hua, L.H. A study of the durability properties of waste tire rubber applied to self-compacting concrete. Constr. Build. Mater. 2013, 41, 665–672. [Google Scholar] [CrossRef]

- Youssf, O.; ElGawady, M.A.; Mills, J.E.; Ma, X. An experimental investigation of crumb rubber concrete confined by fibre reinforced polymer tubes. Constr. Build. Mater. 2014, 53, 522–532. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Alhoubi, Y. Experimental Investigation of Recycled Fine Aggregate from Demolition Waste in Concrete. Sustainability 2022, 14, 10787. [Google Scholar] [CrossRef]

- Xiong, G.; Al-Deen, S.; Guan, X.; Qin, Q.; Zhang, C. Economic and Environmental Benefit Analysis between Crumb Rubber Concrete and Ordinary Portland Cement Concrete. Sustainability 2024, 16, 4758. [Google Scholar] [CrossRef]

- Shetty, P.P.; Rao, A.U.; Pai, B.H.V.; Kamath, M.V. Performance of High-Strength Concrete with the Effects of Seashell Powder as Binder Replacement and Waste Glass Powder as Fine Aggregate. J. Compos. Sci. 2023, 7, 92. [Google Scholar] [CrossRef]

- Lógó, B.A.; Vásárhelyi, B. Estimation of the Poisson’s Rate of the Intact Rock in the Function of the Rigidity. Period. Polytech. Civ. Eng. 2019, 63, 1030–1037. [Google Scholar] [CrossRef]

- Molina, O.; Vilarrasa, V.; Zeidouni, M. Geologic Carbon Storage for Shale Gas Recovery. Energy Procedia 2017, 114, 5748–5760. [Google Scholar] [CrossRef]

- Deng, Z.; Chen, L.; Li, L. Comparative nanoindentation study of biogenic and geological calcite. J. Mech. Behav. Biomed. Mater. 2022, 137, 105538. [Google Scholar] [CrossRef]

- Merkel, C.; Deuschle, J.; Griesshaber, E.; Enders, S.; Steinhauser, E.; Hochleitner, R.; Brand, U.; Schmahl, W.W. Mechanical properties of modern calcite- (Mergerlia truncata) and phosphate-shelled brachiopods (Discradisca stella and Lingula anatina) determined by nanoindentation. J. Struct. Biol. 2009, 168, 396–408. [Google Scholar] [CrossRef]

- Liu, J.; Tran, P. Cement mortar containing crumb rubber coated with geopolymer: From microstructural properties to compressive strength. Constr. Build. Mater. 2023, 383, 131284. [Google Scholar] [CrossRef]

- Martínez-Tong, D.; Najar, A.; Soccio, M.; Nogales, A.; Bitinis, N.; López-Manchado, M.; Ezquerra, T. Quantitative mapping of mechanical properties in polylactic acid/natural rubber/organoclay bionanocomposites as revealed by nanoindentation with atomic force microscopy. Compos. Sci. Technol. 2014, 104, 34–39. [Google Scholar] [CrossRef]

- Chung, S.-Y.; Sikora, P.; Rucinska, T.; Stephan, D.; Elrahman, M.A. Comparison of the pore size distributions of concretes with different air-entraining admixture dosages using 2D and 3D imaging approaches. Mater. Charact. 2020, 162, 110182. [Google Scholar] [CrossRef]

- Chen, Y.; Çopuroğlu, O.; Rodriguez, C.R.; Filho, F.F.d.M.; Schlangen, E. Characterization of air-void systems in 3D printed cementitious materials using optical image scanning and X-ray computed tomography. Mater. Charact. 2021, 173, 110948. [Google Scholar] [CrossRef]

- Carrara, P.; Kruse, R.; Bentz, D.; Lunardelli, M.; Leusmann, T.; Varady, P.; De Lorenzis, L. Improved mesoscale segmentation of concrete from 3D X-ray images using contrast enhancers. Cem. Concr. Compos. 2018, 93, 30–42. [Google Scholar] [CrossRef]

- du Plessis, A.; Boshoff, W.P. A review of X-ray computed tomography of concrete and asphalt construction materials. Constr. Build. Mater. 2018, 199, 637–651. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. The relationship between porosity and strength for porous concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar] [CrossRef]

- Howiacki, T.; Sieńko, R.; Bednarski, Ł. Structural concrete measurements: New distributed approach for standard specimens. Measurement 2024, 235, 115003. [Google Scholar] [CrossRef]

- Ojeda, J.M.P.; Cayatopa-Calderón, B.A.; Huatangari, L.Q.; Tineo, J.L.P.; Pino, M.E.M.; Pintado, W.R. Convolutional Neural Network for Predicting Failure Type in Concrete Cylinders During Compression Testing. Civ. Eng. J. 2023, 9, 2105–2119. [Google Scholar] [CrossRef]

- Ma, G.; Wu, C. Crack type analysis and damage evaluation of BFRP-repaired pre-damaged concrete cylinders using acoustic emission technique. Constr. Build. Mater. 2023, 362, 129674. [Google Scholar] [CrossRef]

- Li, P.; Chen, Y.; Yuan, F. Stress-strain behavior of ECC-GFRP spiral confined concrete cylinders. J. Build. Eng. 2023, 63, 105473. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, B.; Qian, Z.; Yu, J.; Shi, T.; Fan, Y.; Zhou, Y.; Ning, Y.; Zhou, X. State-of-the art on preparation, performance, and ecological applications of planting concrete. Case Stud. Constr. Mater. 2024, 20, e03131. [Google Scholar] [CrossRef]

| Materials | Water Absorption (%) | Loose Unit Weight (kg/m3) | Sample 1 (C + F) (%) | Sample 2 (C + F + S) (%) | Sample 3 (C + F + R) (%) |

|---|---|---|---|---|---|

| Sand (F) | 2.3 | 1695 | 40 | 30 | 35 |

| Gravel (C) | 1.9 | 1691 | 60 | 55 | 55 |

| Shells (S) | 1.3 | 1459 | -- | 15 | -- |

| Rubber (R) | 0.7 | 552 | -- | -- | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miranda, A.; Muñoz, R.; Aedo, C.; Bustos, F.; Tuninetti, V.; Valenzuela, M.; Medina, C.; Oñate, A. High-Performance Concrete from Rubber and Shell Waste Materials: Experimental and Computational Analysis. Materials 2024, 17, 5516. https://doi.org/10.3390/ma17225516

Miranda A, Muñoz R, Aedo C, Bustos F, Tuninetti V, Valenzuela M, Medina C, Oñate A. High-Performance Concrete from Rubber and Shell Waste Materials: Experimental and Computational Analysis. Materials. 2024; 17(22):5516. https://doi.org/10.3390/ma17225516

Chicago/Turabian StyleMiranda, Alejandra, Ricardo Muñoz, Cristopher Aedo, Flavia Bustos, Víctor Tuninetti, Marian Valenzuela, Carlos Medina, and Angelo Oñate. 2024. "High-Performance Concrete from Rubber and Shell Waste Materials: Experimental and Computational Analysis" Materials 17, no. 22: 5516. https://doi.org/10.3390/ma17225516

APA StyleMiranda, A., Muñoz, R., Aedo, C., Bustos, F., Tuninetti, V., Valenzuela, M., Medina, C., & Oñate, A. (2024). High-Performance Concrete from Rubber and Shell Waste Materials: Experimental and Computational Analysis. Materials, 17(22), 5516. https://doi.org/10.3390/ma17225516