Optimization Conditions for High-Power AlGaN/InGaN/GaN/AlGaN High-Electron-Mobility Transistor Grown on SiC Substrate

Abstract

1. Introduction

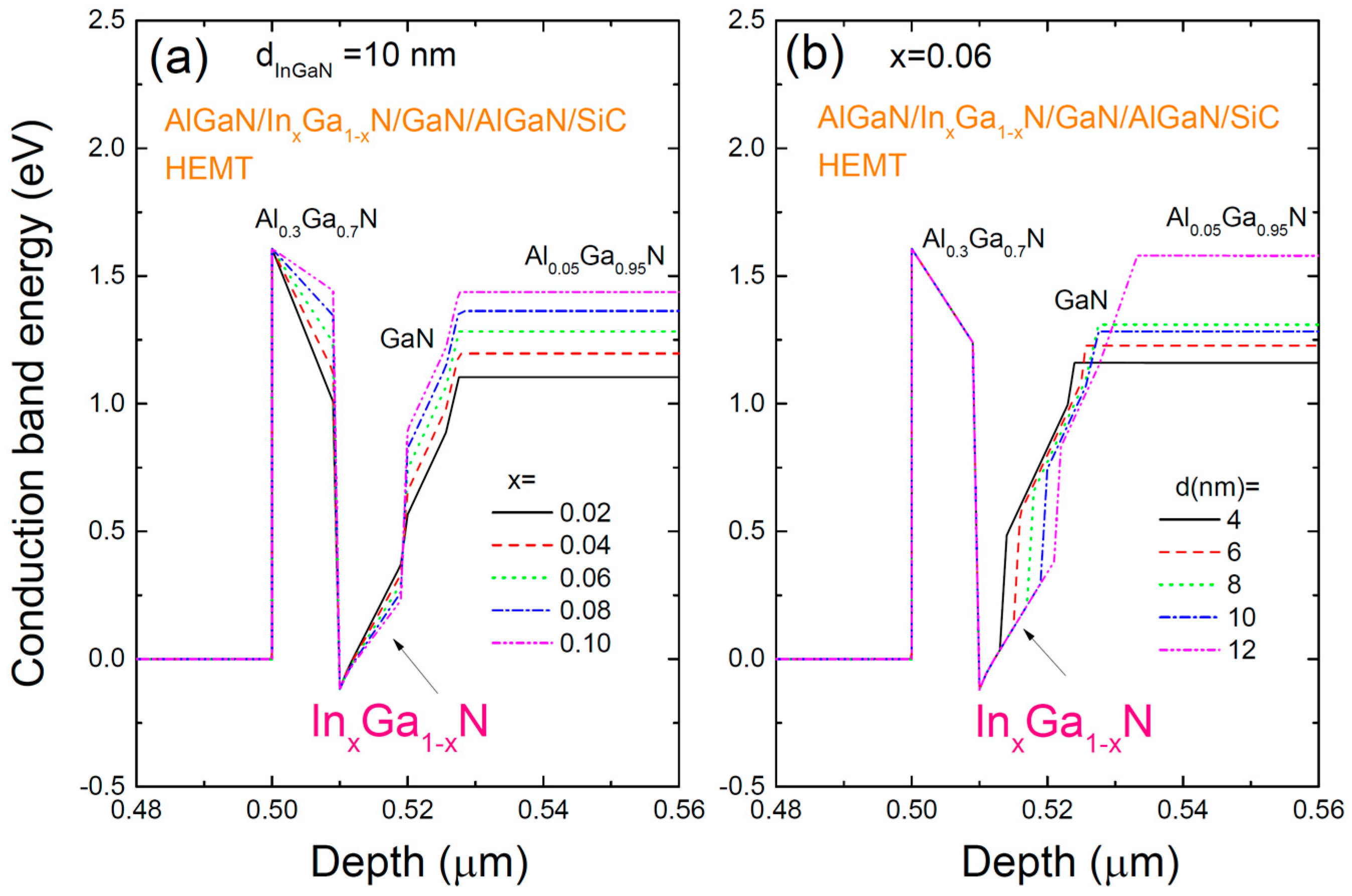

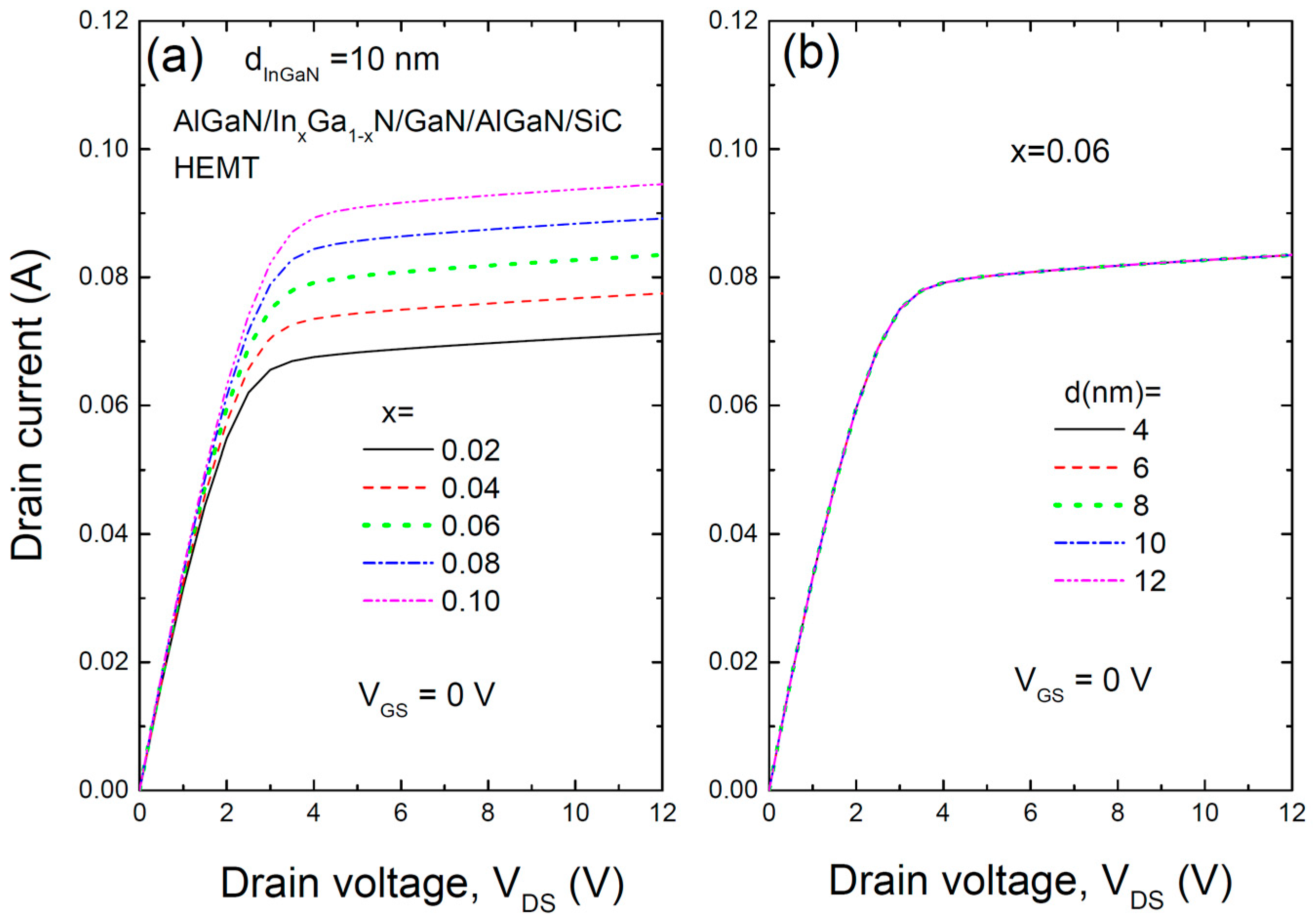

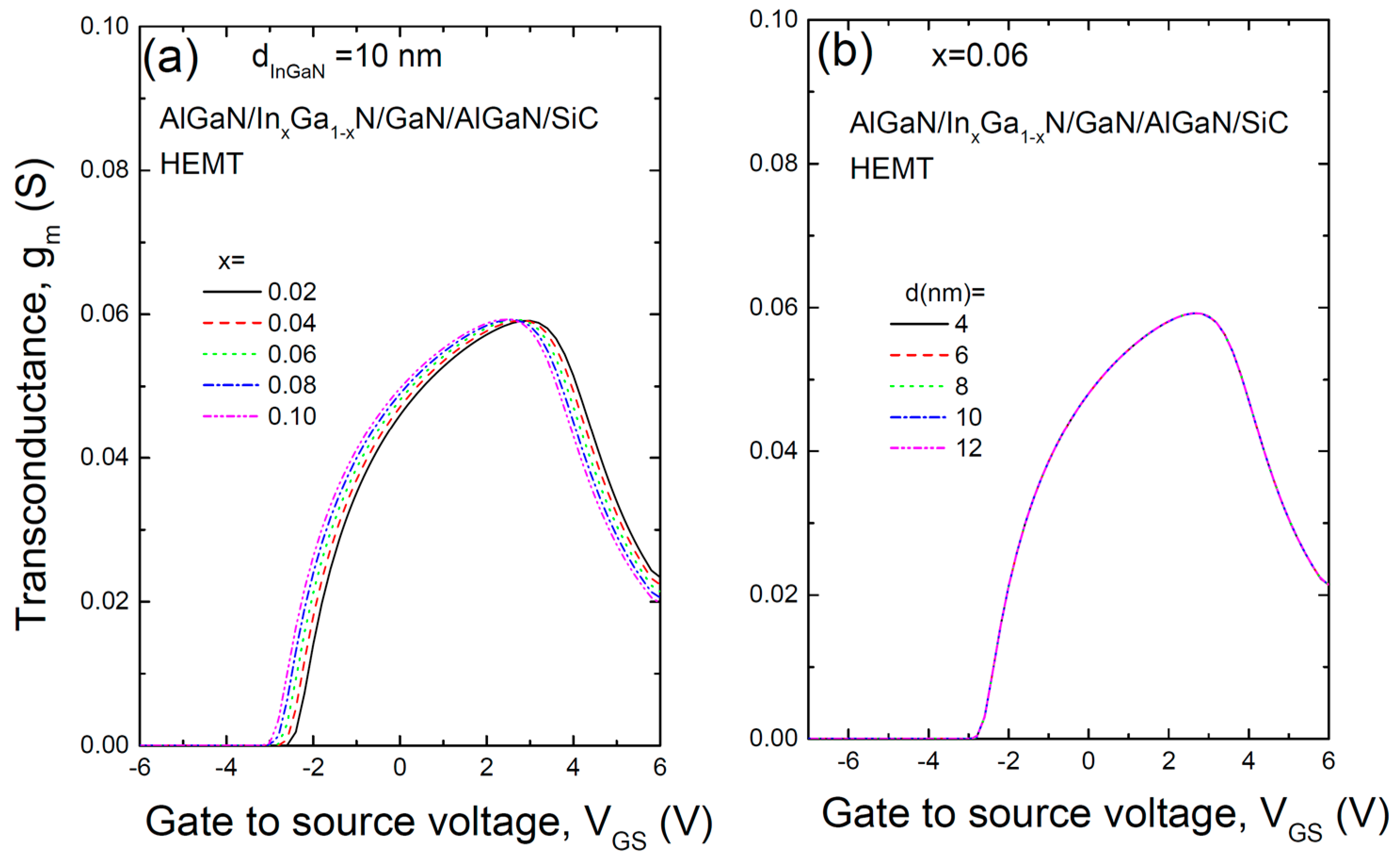

2. Methods

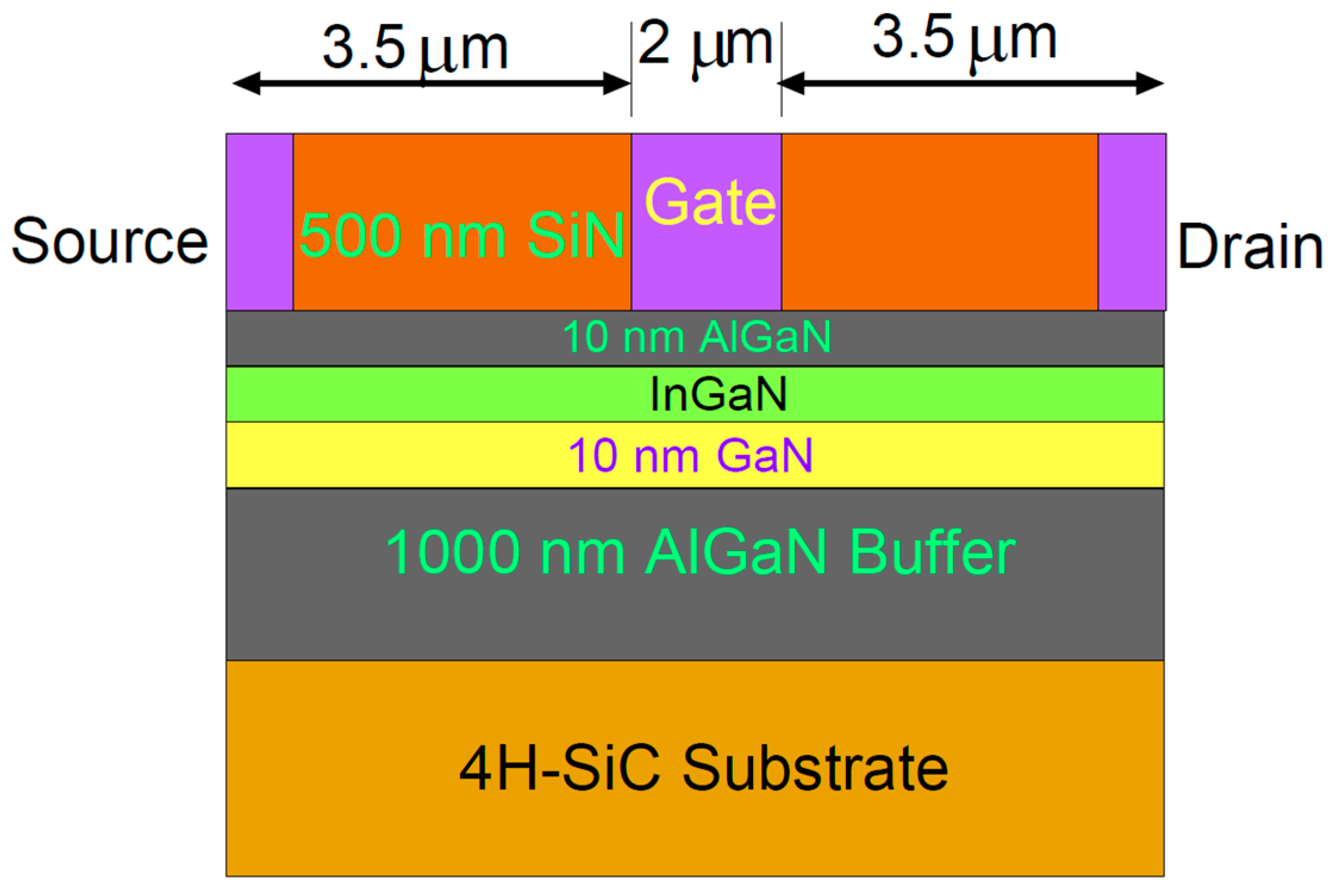

- A silicon carbide (4H-SiC) substrate was used as the base material due to its high thermal conductivity and ability to handle high power.

- A 1 µm thick Al0.05Ga0.95N back-barrier layer was deposited on top of the substrate.

- A 10 nm thick GaN layer was used to form the primary channel for electron transport.

- The InGaN layer, whose thickness and composition were varied in the simulation, was placed on top of the GaN layer.

- A 10 nm thick Al0.3Ga0.7N barrier layer was used to control electron confinement in the channel region.

- A 500 nm thick silicon nitride (SiN) passivation layer was deposited to reduce surface states and prevent surface-related traps.

- Shockley–Read–Hall (SRH) recombination to model the carrier recombination processes;

- Mobility models accounting for temperature and electric field dependence;

- Bandgap-narrowing effects in the presence of high doping concentrations.

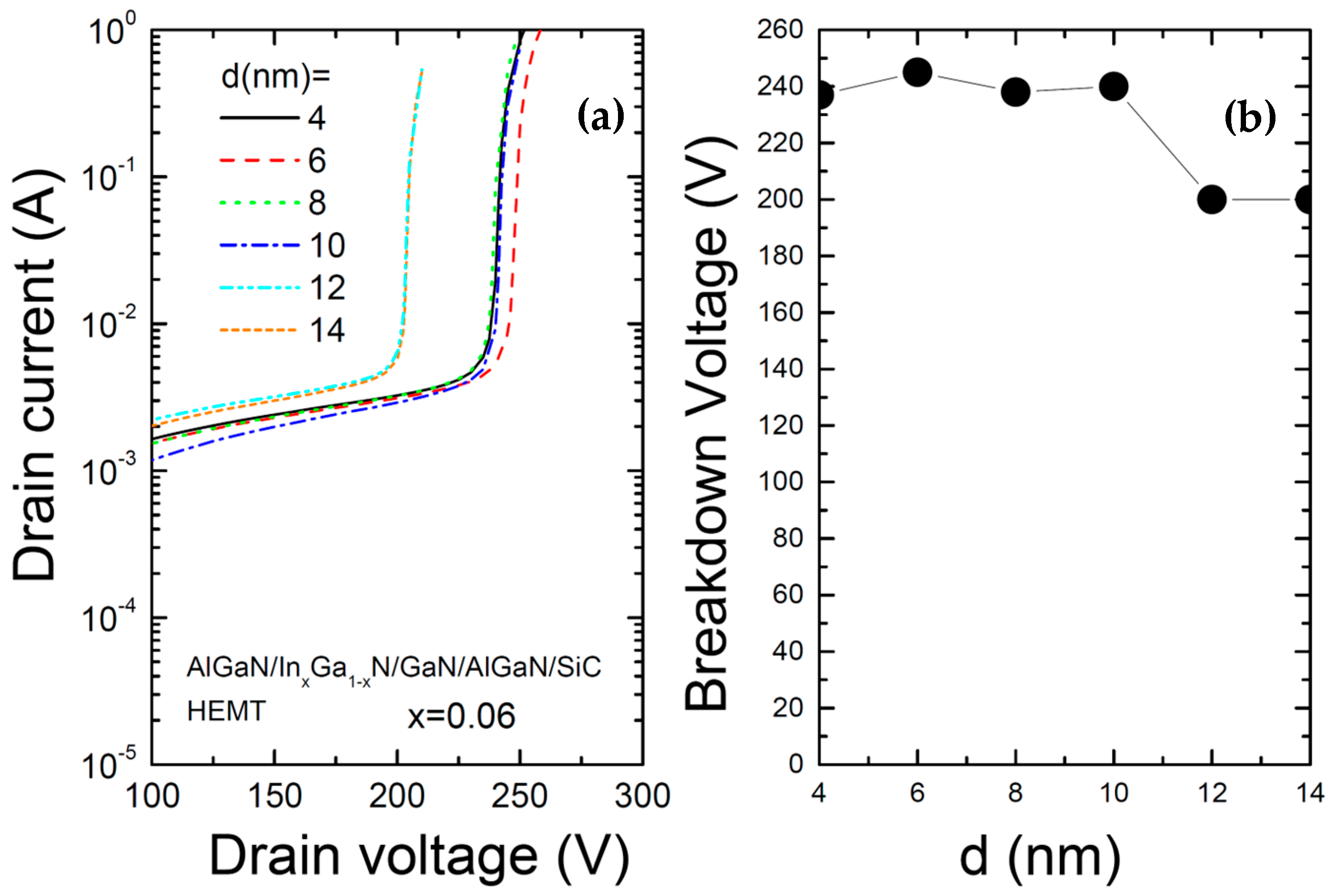

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Murugapandiyan, P.; Kalva, S.R.K.; Rajyalakshmi, V.; Princy, B.A.; Tarauni, Y.U.; Fletcher, A.; Wasim, M. A Comparative Analysis of GaN and InGaN/GaN Coupling Channel HEMTs on Silicon Carbide Substrate for High Linear RF Applications. Micro Nanostruct. 2023, 177, 207545. [Google Scholar] [CrossRef]

- Sun, S.; Xie, X.; Zhang, P.; Zhao, Z.; Wei, J.; Luo, X. Improvement of Single Event Transients Effect for a Novel AlGaN/GaN HEMT with Enhanced Breakdown Voltage. J. Sci. Adv. Mater. Devices 2024, 9, 100692. [Google Scholar] [CrossRef]

- Kandpal, J.; Kumar, A. A Comprehensive Study on AlGaN/GaN-Based HEMT for High-Speed. Int. J. High Speed Electron. Syst. 2024, 33, 2450001. [Google Scholar] [CrossRef]

- Murugapandiyan, P.; Sri Rama Krishna, K.; Revathy, A.; Fletcher, A. Enhancement Mode AlGaN/GaN MISHEMT on Ultra-Wide Band Gap β-Ga2O3 Substrate for RF and Power Electronics. J. Electron. Mater. 2024, 53, 2973–2987. [Google Scholar] [CrossRef]

- Natarajan, R.; Murugapandiyan, P.; Vigneshwari, N.; Mohanbabu, A.; Karthikeyan, S.; Ravi, S. Investigation of Different Buffer Layer Impact on AlN/GaN/AlGaN HEMT Using Silicon Carbide Substrate for High-Speed RF Applications. Micro Nanostruct. 2024, 189, 207815. [Google Scholar] [CrossRef]

- Shanbhag, A.; Grandpierron, F.; Harrouche, K.; Medjdoub, F. Physical Insights of Thin AlGaN Back Barrier for Millimeter-Wave High Voltage AlN/GaN on SiC HEMTs. Appl. Phys. Lett. 2023, 123, 142102. [Google Scholar] [CrossRef]

- Mounika, B.; Ajayan, J.; Bhattacharya, S.; Nirmal, D.; Sreenivasulu, V.B.; Kumari, N.A. Investigation on Effect of AlN Barrier Thickness and Lateral Scalability of Fe-Doped Recessed T-Gate AlN/GaN/SiC HEMT with Polarization-Graded Back Barrier for Future RF Electronic Applications. Microelectron. J. 2023, 140, 105923. [Google Scholar] [CrossRef]

- Said, N.; Harrouche, K.; Medjdoub, F.; Labat, N.; Tartarin, J.G.; Malbert, N. Role of AlGaN Back-Barrier in Enhancing the Robustness of Ultra-Thin AlN/GaN HEMT for mmWave Applications. Microelectron. Reliab. 2023, 150, 115110. [Google Scholar] [CrossRef]

- Garg, T.; Kale, S. A Novel p-GaN HEMT with AlInN/AlN/GaN Double Heterostructure and InAlGaN Back-Barrier. Microelectron. Reliab. 2023, 145, 114998. [Google Scholar] [CrossRef]

- Binola, I.V.K.J.; Franklin, S.A.; Gifta, G.; Prajoon, P.; Nirmal, D. Revolutionizing Fe Doped Back Barrier AlGaN/GaN HEMTs: Unveiling the Remarkable 1700V Breakdown Voltage Milestone. Microelectron. J. 2024, 147, 106158. [Google Scholar]

- SILVACO International. ATLAS User’s Manual; Device Simulation Software: Santa Clara, CA, USA, 2016. [Google Scholar]

- Lee, M.-W.; Lin, Y.-C.; Hsu, H.-T.; Gamiz, F.; Chang, E.-Y. Improvement of AlGaN/GaN HEMTs Linearity Using Etched-Fin Gate Structure for Ka Band Applications. Micromachines 2023, 14, 931. [Google Scholar] [CrossRef] [PubMed]

- Jena, D.; Das, S.; Baral, B.; Mohapatra, E.; Dash, T. Linearity Improvement in Graded Channel AlGaN/GaN HEMTs for High-Speed Applications. Phys. Scr. 2023, 98, 105936. [Google Scholar] [CrossRef]

- Lee, H.-C.; Lee, C.-C.; Lee, H.-J.; Lee, W.-Y.; Chuang, W.-C. Improving GaN-Based HEMTs Performance by Gate Recess Technique. In Proceedings of the 2020 IEEE Eurasia Conference on IOT, Communication and Engineering (ECICE), Yunlin, Taiwan, 27–30 October 2020; pp. 133–135. [Google Scholar]

- Egorkin, V.; Zaitsev, A.; Garmash, V.; Zagidullina, O.; Negencev, A. Digital Circuits Based on GaN HEMTs with Threshold Voltage Adjusted by Fluorine Plasma Treatment. In Proceedings of the 2017 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), St. Petersburg and Moscow, Russia, 1–3 February 2017; pp. 1131–1134. [Google Scholar]

- Jia, M.; Hou, B.; Yang, L.; Jia, F.; Niu, X.; Du, J.; Chang, Q.; Zhang, M.; Wu, M.; Zhang, X.; et al. High VTH and Improved Gate Reliability in P-GaN Gate HEMTs with Oxidation Interlayer. IEEE Electron. Device Lett. 2023, 44, 1404–1407. [Google Scholar] [CrossRef]

- Li, W.; Tao, L.; Wang, L.; Zhang, X.; Li, X.; Chen, X. High Threshold Voltage GaN HEMT with Mixed Conductive Channel. In Proceedings of the 2020 21st International Conference on Electronic Packaging Technology (ICEPT), Guangzhou, China, 12–15 August 2020; pp. 1–4. [Google Scholar]

- Xu, K. Silicon Electro-Optic Micro-Modulator Fabricated in Standard CMOS Technology as Components for All Silicon Monolithic Integrated Optoelectronic Systems. J. Micromech. Microeng. 2021, 31, 054001. [Google Scholar] [CrossRef]

- Palacios, T.; Chakraborty, A.; Rajan, S.; Heikman, S.; Keller, S.; Mishra, U.K. Influence of the Dynamic Access Resistance in the gₘ and fₜ Linearity of AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2005, 52, 2117–2123. [Google Scholar] [CrossRef]

- DiSanto, D.W.; Bolognesi, C.R. At-Bias Extraction of Access Parasitic Resistances in AlGaN/GaN HEMTs: Impact on Device Linearity and Channel Electron Velocity. IEEE Trans. Electron Devices 2006, 53, 2914–2919. [Google Scholar] [CrossRef]

- Mishra, U.K.; Parikh, P.; Wu, Y.-F. AlGaN/GaN HEMTs—An Overview of Device Operation and Applications. Proc. IEEE 2002, 90, 1022–1031. [Google Scholar] [CrossRef]

- Meneghesso, G.; Verzellesi, G.; Zanoni, E.; Chini, A.; Rampazzo, F.; Tazzoli, A.; Mishra, U.K.; Yu, E.T.; Longo, M. Reliability of GaN High-Electron-Mobility Transistors: State of the Art and Perspectives. IEEE Trans. Device Mater. Reliab. 2008, 8, 332–343. [Google Scholar] [CrossRef]

- Mohapatra, R.; Dutta, P. Improvement of Transconductance and Cut-off Frequency in In0.1Ga0.9N Back-Barrier-Based Double-Channel Al0.3Ga0.7N/GaN High Electron Mobility Transistor by Enhancing the Drain Source Contact Length Ratio. Pramana—J. Phys. 2020, 94, 5. [Google Scholar] [CrossRef]

- Liao, S.Y.; Lu, C.C.; Chang, T.; Huang, C.F.; Cheng, C.H.; Chang, L.B. Gate Length Scaling Effect on High-Electron Mobility Transistors Devices Using AlGaN/GaN and AlInN/AlN/GaN Heterostructures. J. Nanosci. Nanotechnol. 2014, 14, 6243–6246. [Google Scholar] [CrossRef]

- Du, C.; Ye, R.; Cai, X.; Duan, X.; Liu, H.; Zhang, Y.; Qiu, G.; Mi, M. A Review on GaN HEMTs: Nonlinear Mechanisms and Improvement Methods. J. Semicond. 2023, 44, 121801. [Google Scholar] [CrossRef]

- Liu, A.C.; Huang, Y.W.; Chen, H.C.; Kuo, H.C. Improvement Performance of p-GaN Gate High-Electron-Mobility Transistors with GaN/AlN/AlGaN Barrier Structure. Micromachines 2024, 15, 517. [Google Scholar] [CrossRef] [PubMed]

- Selberherr, S. Analysis and Simulation of Semiconductor Devices; Springer: New York, NY, USA, 1984. [Google Scholar]

- Hatakeyama, T.; Watanabe, T.; Shinohe, T.; Kojima, K.; Arai, K.; Sano, N. Impact ionization coefficients of 4H silicon carbide. Appl. Phys. Lett. 2004, 85, 1380–1382. [Google Scholar] [CrossRef]

- Hansch, W.; Selberherr, S. MINIMOS 3: A MOSFET Simulator That Includes Energy Balance. IEEE Trans. Electron Devices 1987, 34, 1074–1078. [Google Scholar] [CrossRef]

- Akturk, A.; Goldsman, N.; Aslam, S.; Sigwarth, J.; Herrero, F. Comparison of 4H-SiC impact ionization models using experiments and self-consistent simulations. J. Appl. Phys. 2008, 104, 026101. [Google Scholar] [CrossRef]

- Stefanakis, D.; Makris, N.; Zekentes, K.; Tassis, D. Comparison of Impact Ionization Models for 4H-SiC Along the <0001> Direction, Through Breakdown Voltage Simulations at Room Temperature. IEEE Trans. Electron Devices 2021, 68, 2078–2083. [Google Scholar]

- Mishra, U.K.; Shen, L.; Kazior, T.E.; Wu, Y.-F. GaN-Based RF Power Devices and Amplifiers. Proc. IEEE 2008, 96, 287–305. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Kapolnek, D.; Ibbetson, J.P.; Parikh, P.; Keller, B.P.; Mishra, U.K. Very-High Power Density AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2001, 48, 586–590. [Google Scholar]

- Han, X.; Li, D.; Yuan, H.; Sun, X.; Liu, X.; Wang, X.; Zhu, Q.; Wang, Z. Dislocation Scattering in a Two-Dimensional Electron Gas of an AlxGa1−xN/GaN Heterostructure. Phys. Status Solidi B 2004, 241, 2989–2994. [Google Scholar] [CrossRef]

- Neha, V.; Kumari, V.; Gupta, M.; Saxena, M. Temperature-Based Analysis of 3-Step Field Plate AlGaN/GaN HEMT Using Numerical Simulation. Superlattices Microstruct. 2019, 3, 154–164. [Google Scholar] [CrossRef]

- Huque, M.; Eliza, S.A.; Rahman, T.; Huq, H.; Islam, S. Temperature-Dependent Analytical Model for Current-Voltage Characteristics of AlGaN/GaN Power HEMT. Solid State Electron. 2009, 53, 238–244. [Google Scholar] [CrossRef]

- Liu, K.; Wang, C.; Zheng, X.; Ma, X.; Huang, Z.; He, Y.; Li, A.; Zhao, Y.; Mao, W.; Hao, Y. High-Temperature Characteristics of p-GaN HEMTs with Enhanced Threshold Voltage Stability. Solid State Electron. 2021, 183, 108109. [Google Scholar] [CrossRef]

- Dai, P.; Wang, S.; Lu, H. Research on the Reliability of Threshold Voltage Based on GaN High-Electron-Mobility Transistors. Micromachines 2024, 15, 321. [Google Scholar] [CrossRef]

- Huang, H.; Li, F.; Sun, Z.; Cao, Y. Model Development for Threshold Voltage Stability Dependent on High Temperature Operations in Wide-Bandgap GaN-Based HEMT Power Devices. Micromachines 2018, 9, 658. [Google Scholar] [CrossRef] [PubMed]

- Sehra, K.; Kumari, V.; Nath, V.; Gupta, M.; Rawal, D.S.; Saxena, M. Comparison of Linearity and Intermodulation Distortion Metrics for T- and Pi-Gate HEMT. In Proceedings of the 2019 International Conference on Electrical, Electronics and Computer Engineering (UPCON), Aligarh, India, 8–10 November 2019; p. 8980221. [Google Scholar]

- Sarkar, A. Investigation of the Forward Gate Leakage Current in pGaN/AlGaN/GaN HEMTs through TCAD Simulations. Jpn. J. Appl. Phys. 2024, 63, 074503. [Google Scholar] [CrossRef]

- Chen, X.; Zhong, Y.; Yan, S.; Guo, X.; Gao, H.; Sun, X.; Wang, H.; Li, F.-M.; Zhou, Y.; Feng, M.; et al. Enhanced Breakdown Voltage and Dynamic Performance of GaN HEMTs with AlN/GaN Superlattice Buffer. J. Phys. D Appl. Phys. 2023, 56, 154503. [Google Scholar] [CrossRef]

- Ma, M.; Cao, Y.; Lv, H.; Wang, Z.; Zhang, X.; Chen, C.; Wu, L.; Lv, L.; Zheng, X.; Tian, W.; et al. Effect of Acceptor Traps in GaN Buffer Layer on Breakdown Performance of AlGaN/GaN HEMTs. Micromachines 2022, 14, 79. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, H.; Liao, Y.; Xu, Y.; Yan, F.; Ji, X. Degradation Prediction of GaN HEMTs under Hot-Electron Stress Based on ML-TCAD Approach. Electronics 2022, 11, 3582. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, B.; Park, S.-H. Optimization Conditions for High-Power AlGaN/InGaN/GaN/AlGaN High-Electron-Mobility Transistor Grown on SiC Substrate. Materials 2024, 17, 5515. https://doi.org/10.3390/ma17225515

Kim B, Park S-H. Optimization Conditions for High-Power AlGaN/InGaN/GaN/AlGaN High-Electron-Mobility Transistor Grown on SiC Substrate. Materials. 2024; 17(22):5515. https://doi.org/10.3390/ma17225515

Chicago/Turabian StyleKim, Bonghwan, and Seung-Hwan Park. 2024. "Optimization Conditions for High-Power AlGaN/InGaN/GaN/AlGaN High-Electron-Mobility Transistor Grown on SiC Substrate" Materials 17, no. 22: 5515. https://doi.org/10.3390/ma17225515

APA StyleKim, B., & Park, S.-H. (2024). Optimization Conditions for High-Power AlGaN/InGaN/GaN/AlGaN High-Electron-Mobility Transistor Grown on SiC Substrate. Materials, 17(22), 5515. https://doi.org/10.3390/ma17225515