MXene/Bacterial Cellulose Hybrid Materials for Sustainable Soft Electronics

Abstract

1. Introduction

2. Materials and Methods

2.1. Bacterial Cellulose Production and Processing

2.2. MXene Synthesis

2.3. Morphology, Structure and Chemical Composition Analysis

- CI—crystalline index [%]

- —intensity of the (002) peak at 22.6°

- —intensity of diffraction function minimum between 16.8° and 22.6°

- —coherent domain size [nm]

- K—shape factor (0.9)

- —X-ray wavelength [nm]

- —FWHM of reflection measured in 2

- —Bragg angle [°]

- d—d-spacing [nm]

- n—diffraction order (0.9)

2.4. Mechanical Properties

2.5. Viscoelastic Properties

2.6. Electrical Properties

- Rs—sheet resistance [/cm]

- C—geometrical correction factor;

- V—voltage drop [V]

- I—applied current [A]

- — electrical conductivity [S]

- l—length of sample [cm]

- R—measured resistance []

- A—cross-sectional surface area [cm2]

2.7. Sensitivity Properties

- R—measured resistance []

- —initial resistance of the sensor []

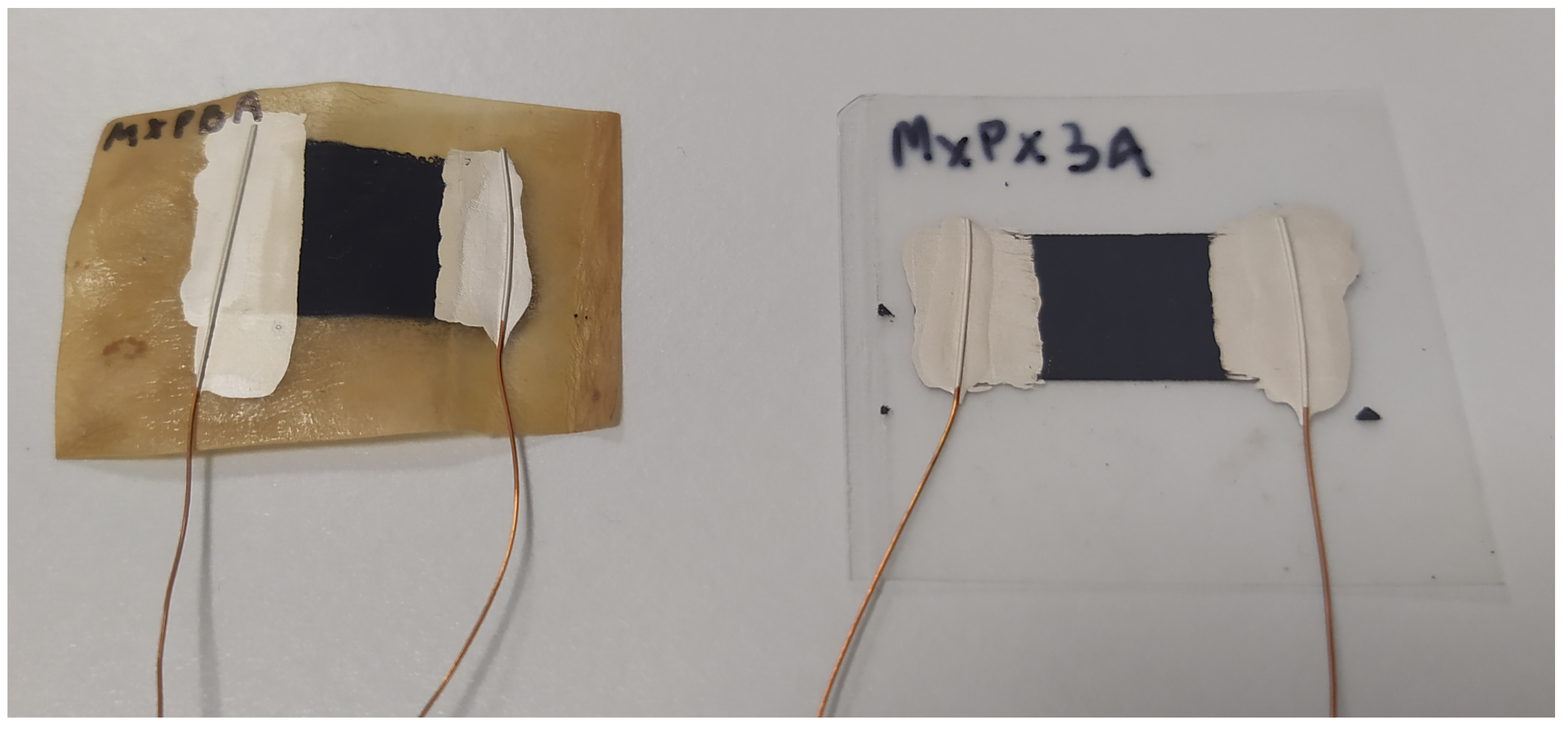

2.8. Flexible MX/BC and MX/PET Device Fabrication

3. Results and Discussion

3.1. Structural and Morphological Properties

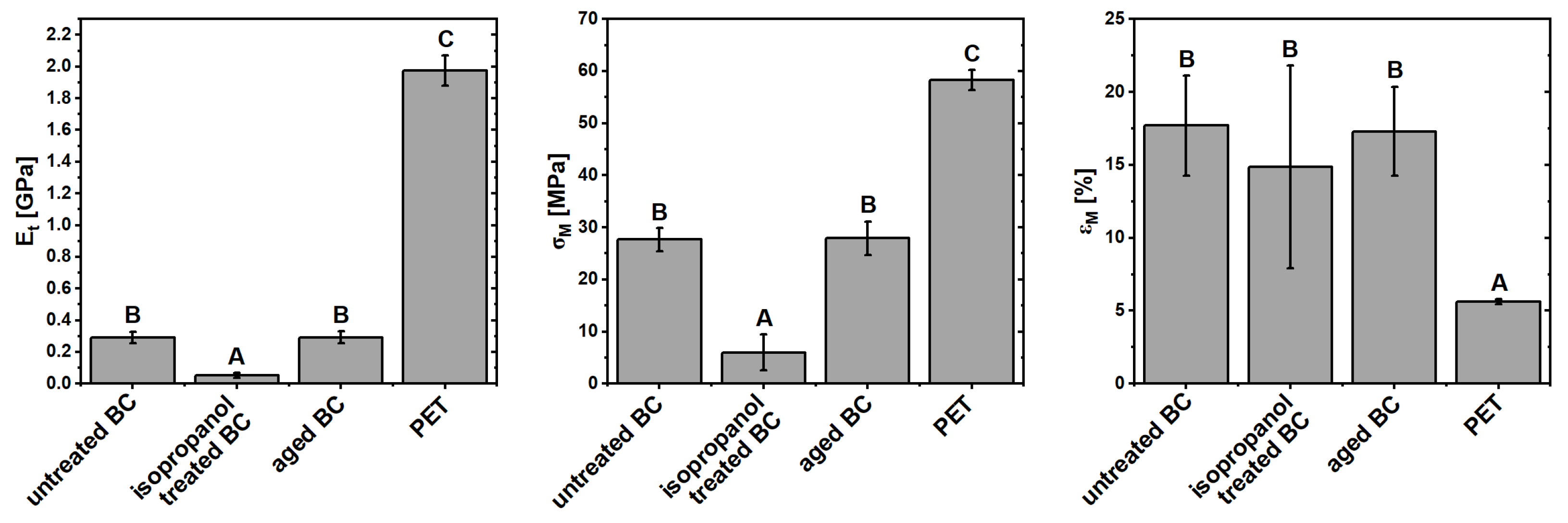

3.2. Mechanical Properties

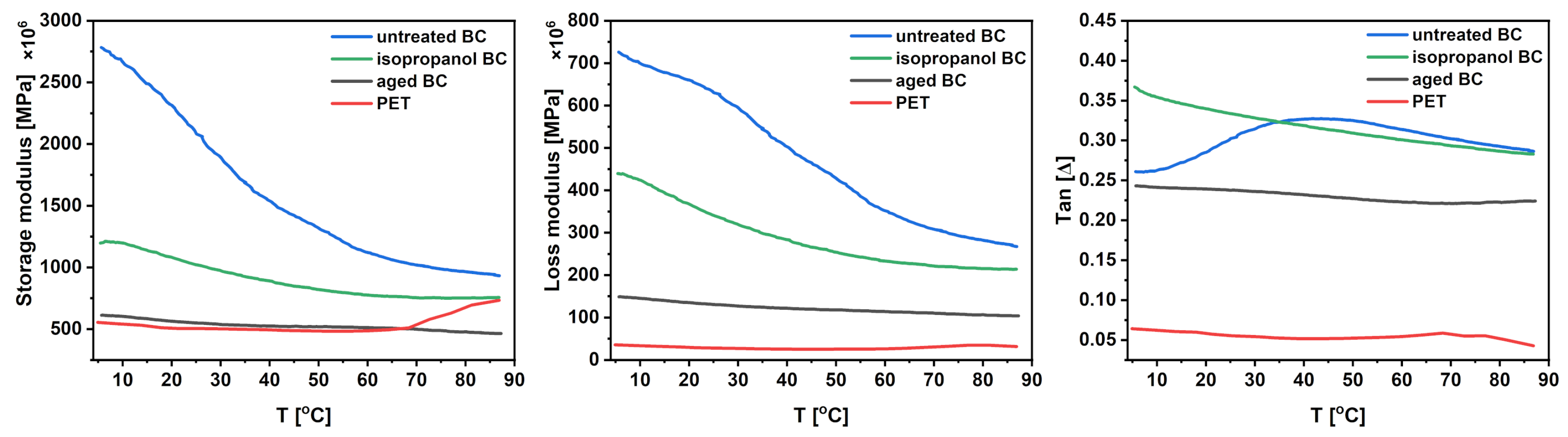

3.3. Viscoelastic Properties

3.4. Electrical Properties

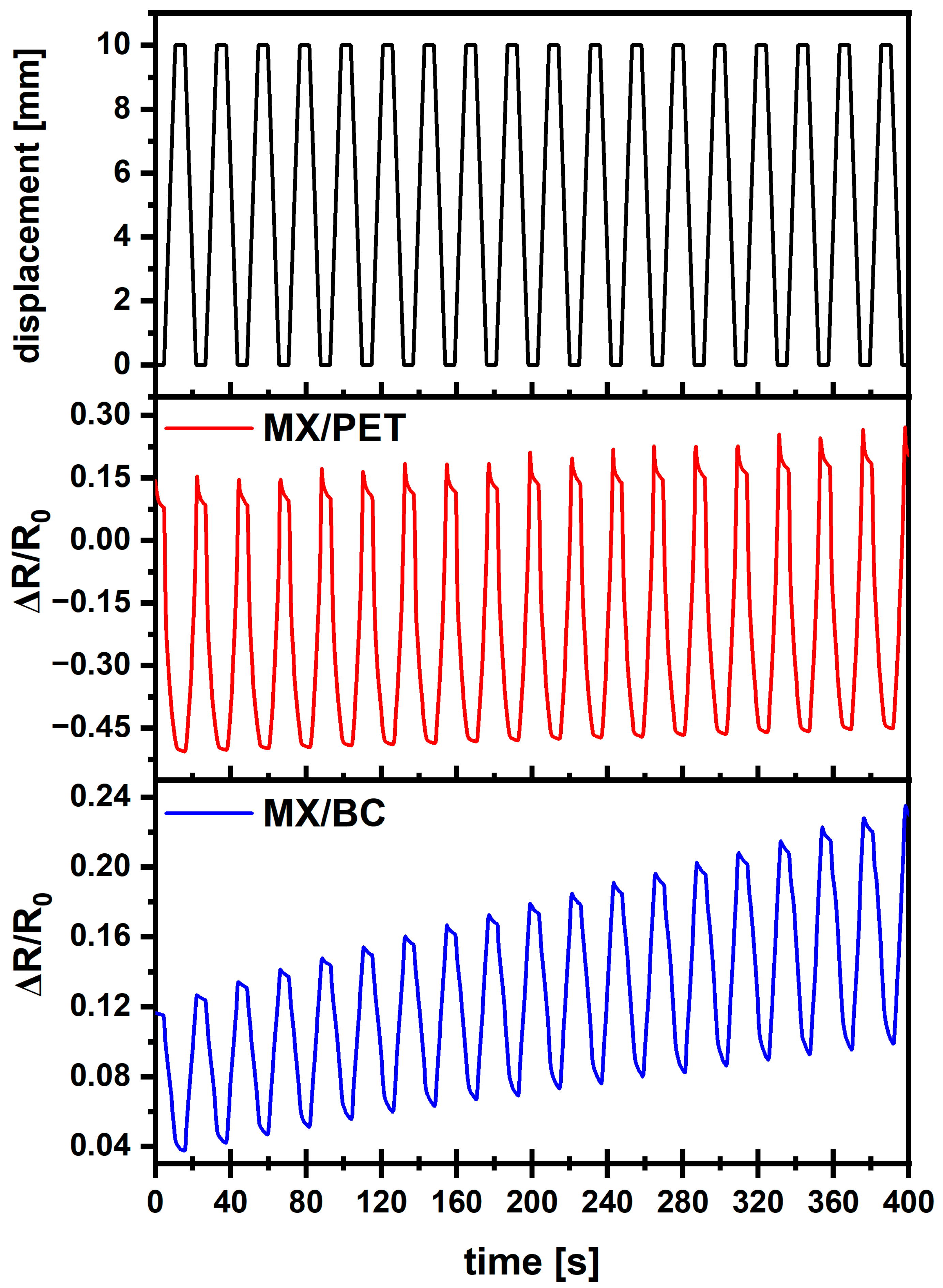

3.5. Sensitivity Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shahabuddin, M.; Uddin, M.N.; Chowdhury, J.I.; Ahmed, S.F.; Uddin, M.N.; Mofijur, M.; Uddin, M.A. A review of the recent development, challenges, and opportunities of electronic waste (e-waste). Int. J. Environ. Sci. Technol. 2023, 20, 4513–4520. [Google Scholar] [CrossRef]

- Zhu, J.; Wen, H.; Zhang, H.; Huang, P.; Liu, L.; Hu, H. Recent advances in biodegradable electronics- from fundament to the next-generation multi-functional, medical and environmental device. Sustain. Mater. Technol. 2023, 35, e00530. [Google Scholar] [CrossRef]

- Liu, H.J.; Chen, Z.C.; Liang, Y.Y.; Chang, Y.C. Design of biodegradable gelatin resistive memory with remarkable performance. Org. Electron. 2024, 125, 106979. [Google Scholar] [CrossRef]

- Carrasco-Pena, A.; Catania, F.; Haller, M.; Nippa, M.; Canterella, G.; Münzenrieder, N. Flexible Thin-Film Temperature Sensors on Gelatin-Based Biodegradable Substrates for the Development of Green Electronics. In Proceedings of the 2023 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Boston, MA, USA, 9–12 July 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Ko, G.J.; Kang, H.; Han, W.B.; Dutta, A.; Shin, J.W.; Jang, T.M.; Han, S.; Lim, J.H.; Eom, C.H.; Choi, S.J.; et al. Materials and Designs for Extremely Efficient Encapsulation of Soft, Biodegradable Electronics. Adv. Funct. Mater. 2024, 34, 2403427. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Saha, N.; Ngwabebhoh, F.A.; Zandraa, O.; Saha, T.; Saha, P. Kombucha-derived bacterial cellulose from diverse wastes: A prudent leather alternative. Cellulose 2021, 28, 9335–9353. [Google Scholar] [CrossRef]

- Avcioglu, N.H. Bacterial cellulose: Recent progress in production and industrial applications. World J. Microbiol. Biotechnol. 2022, 38, 86. [Google Scholar] [CrossRef]

- Laavanya, D.; Shirkole, S.; Balasubramanian, P. Current challenges, applications and future perspectives of SCOBY cellulose of Kombucha fermentation. J. Clean. Prod. 2021, 295, 126454. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- McKenna, B.A.; Mikkelsen, D.; Wehr, J.B.; Gidley, M.J.; Menzies, N.W. Mechanical and structural properties of native and alkali-treated bacterial cellulose produced by Gluconacetobacter xylinus strain ATCC 53524. Cellulose 2009, 16, 1047–1055. [Google Scholar] [CrossRef]

- Avcioglu, N.H.; Birben, M.; Seyis Bilkay, I. Optimization and physicochemical characterization of enhanced microbial cellulose production with a new Kombucha consortium. Process. Biochem. 2021, 108, 60–68. [Google Scholar] [CrossRef]

- Choi, S.M.; Shin, E.J. The nanofication and functionalization of bacterial cellulose and its applications. Nanomaterials 2020, 10, 406. [Google Scholar] [CrossRef] [PubMed]

- Amobonye, A.; Lalung, J.; Awasthi, M.K.; Pillai, S. Fungal mycelium as leather alternative: A sustainable biogenic material for the fashion industry. Sustain. Mater. Technol. 2023, 38, e00724. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Saha, N.; Ngwabebhoh, F.A.; Zandraa, O.; Saha, T.; Saha, P. Silane-modified kombucha-derived cellulose/polyurethane/polylactic acid biocomposites for prospective application as leather alternative. Sustain. Mater. Technol. 2023, 36, e00611. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, X.; Shen, Y.; Yoshino, K.; Feng, W. A mechanically strong, flexible and conductive film based on bacterial cellulose/graphene nanocomposite. Carbohydr. Polym. 2012, 87, 644–649. [Google Scholar] [CrossRef]

- Horue, M.; Silva, J.M.; Berti, I.R.; Brandão, L.R.; Barud, H.d.S.; Castro, G.R. Bacterial Cellulose-Based Materials as Dressings for Wound Healing. Pharmaceutics 2023, 15, 424. [Google Scholar] [CrossRef] [PubMed]

- Gebrekrstos, A.; Orasugh, J.T.; Muzata, T.S.; Ray, S.S. Cellulose-Based Sustainable Composites: A Review of Systems for Applications in EMI Shielding and Sensors. Macromol. Mater. Eng. 2022, 307, 2200185. [Google Scholar] [CrossRef]

- Adamatzky, A.; Tarabella, G.; Phillips, N.; Chiolerio, A.; D’Angelo, P.; Nikolaidou, A.; Sirakoulis, G.C. Kombucha electronics: Electronic circuits on kombucha mats. Sci. Rep. 2023, 13, 9367. [Google Scholar] [CrossRef]

- Wang, S.; Li, T.; Chen, C.; Kong, W.; Zhu, S.; Dai, J.; Diaz, A.J.; Hitz, E.; Solares, S.D.; Li, T.; et al. Transparent, Anisotropic Biofilm with Aligned Bacterial Cellulose Nanofibers. Adv. Funct. Mater. 2018, 28, 1707491. [Google Scholar] [CrossRef]

- Naguib, M.; Barsoum, M.W.; Gogotsi, Y. Ten Years of Progress in the Synthesis and Development of MXenes. Adv. Mater. 2021, 33, 2103393. [Google Scholar] [CrossRef]

- Nashim, A.; Parida, K. A Glimpse on the plethora of applications of prodigious material MXene. Sustain. Mater. Technol. 2022, 32, e00439. [Google Scholar] [CrossRef]

- Li, Y.; Lai, M.; Hu, M.; Zhao, S.; Liu, B.; Kai, J.J. Insights into electronic and magnetic properties of MXenes: From a fundamental perspective. Sustain. Mater. Technol. 2022, 34, e00516. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Nanocrystals Produced by Exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef] [PubMed]

- Ling, Z.; Ren, C.E.; Zhao, M.Q.; Yang, J.; Giammarco, J.M.; Qiu, J.; Barsoum, M.W.; Gogotsi, Y. Flexible and conductive MXene films and nanocomposites with high capacitance. Proc. Natl. Acad. Sci. USA 2014, 111, 16676–16681. [Google Scholar] [CrossRef]

- Lipatov, A.; Lu, H.; Alhabeb, M.; Anasori, B.; Gruverman, A.; Gogotsi, Y.; Sinitskii, A. Elastic properties of 2D Ti 3 C 2 T x MXene monolayers and bilayers. Sci. Adv. 2018, 4, eaat0491. [Google Scholar] [CrossRef]

- Srivatsa, S.; Belthangadi, P.; Ekambaram, S.; Pai, M.; Sen, P.; Uhl, T.; Kumar, S.; Grabowski, K.; Nayak, M.M. Dynamic response study of Ti 3 C 2 -MXene films to shockwave and impact forces. RSC Adv. 2020, 10, 29147–29155. [Google Scholar] [CrossRef] [PubMed]

- Sarycheva, A.; Polemi, A.; Liu, Y.; Dandekar, K.; Anasori, B.; Gogotsi, Y. 2D titanium carbide (MXene) for wireless communication. Sci. Adv. 2018, 4, 1–9. [Google Scholar] [CrossRef]

- Raza, A.; Qumar, U.; Rafi, A.A.; Ikram, M. MXene-based nanocomposites for solar energy harvesting. Sustain. Mater. Technol. 2022, 33, e00462. [Google Scholar] [CrossRef]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Hong, S.M.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef]

- Ji, B.; Fan, S.; Ma, X.; Hu, K.; Wang, L.; Luan, C.; Deng, J.; Cheng, L.; Zhang, L. Electromagnetic shielding behavior of heat-treated Ti3C2TX MXene accompanied by structural and phase changes. Carbon 2020, 165, 150–162. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, P.; Soomro, R.A.; Zhu, Q.; Xu, B. Advances in the Synthesis of 2D MXenes. Adv. Mater. 2021, 33, 2103148. [Google Scholar] [CrossRef]

- Zhan, X.; Si, C.; Zhou, J.; Sun, Z. MXene and MXene-based composites: Synthesis, properties and environment-related applications. Nanoscale Horizons 2020, 5, 235–258. [Google Scholar] [CrossRef]

- Huang, K.; Li, Z.; Lin, J.; Han, G.; Huang, P. Two-dimensional transition metal carbides and nitrides (MXenes) for biomedical applications. Chem. Soc. Rev. 2018, 47, 5109–5124. [Google Scholar] [CrossRef] [PubMed]

- Iravani, S.; Nazarzadeh Zare, E.; Makvandi, P. Multifunctional MXene-Based Platforms for Soft and Bone Tissue Regeneration and Engineering. ACS Biomater. Sci. Eng. 2024, 10, 1892–1909. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liang, C.; Zhang, Y. Functional characteristics and clinical applications of mxene nanoparticles in wound healing. Chin. J. Tissue Eng. Res. 2024, 28, 2739–2746. [Google Scholar] [CrossRef]

- Wu, J.; Li, T.; Zhao, Q.; Wen, X.; Liu, L.; Duan, J. Flexible wood-based composite for solar water evaporation and waste heat power generation. Sustain. Mater. Technol. 2024, 40, e00950. [Google Scholar] [CrossRef]

- Huang, C.; Xiao, M.; Li, Z.; Fu, Z.; Shi, R. Bioinspired breathable biodegradable bioelastomer-based flexible wearable electronics for high-sensitivity human-interactive sensing. Chem. Eng. J. 2024, 486, 150013. [Google Scholar] [CrossRef]

- Zhang, W.; Ji, X.X.; Ma, M.G. Emerging MXene/cellulose composites: Design strategies and diverse applications. Chem. Eng. J. 2023, 458, 141402. [Google Scholar] [CrossRef]

- Yamada, S. Biodegradable Mg-Mo2C MXene Air Batteries for Transient Energy Storage. ACS Appl. Mater. Interfaces 2024, 16, 14759–14769. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for Synthesis and Processing of Two-Dimensional Titanium Carbide (Ti 3 C 2 T x MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. Opportunity for new developments in all phases of textile manufacturing. Literature Cited An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Technical Report. Apparel Manuf. 1952, 43, 15. [Google Scholar]

- Schwanninger, M.; Rodrigues, J.; Pereira, H.; Hinterstoisser, B. Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib. Spectrosc. 2004, 36, 23–40. [Google Scholar] [CrossRef]

- Szcześniak, L.; Rachocki, A.; Tritt-Goc, J. Glass transition temperature and thermal decomposition of cellulose powder. Cellulose 2008, 15, 445–451. [Google Scholar] [CrossRef]

- Marcuello, C.; Foulon, L.; Chabbert, B.; Aguié-Béghin, V.; Molinari, M. Atomic force microscopy reveals how relative humidity impacts the Young’s modulus of lignocellulosic polymers and their adhesion with cellulose nanocrystals at the nanoscale. Int. J. Biol. Macromol. 2020, 147, 1064–1075. [Google Scholar] [CrossRef] [PubMed]

- Cichosz, S.; Masek, A. IR Study on Cellulose with the Varied Moisture Contents: Insight into the Supramolecular Structure. Materials 2020, 13, 4573. [Google Scholar] [CrossRef] [PubMed]

- Habib, T.; Zhao, X.; Shah, S.A.; Chen, Y.; Sun, W.; An, H.; Lutkenhaus, J.L.; Radovic, M.; Green, M.J. Oxidation stability of Ti3C2Tx MXene nanosheets in solvents and composite films. npj 2D Mater. Appl. 2019, 3, 8. [Google Scholar] [CrossRef]

- Gutsul, O.; Szabo, O.; Kumar, N.; Pfeifer, R.; Dzurnak, B.; Sasitharan, K.; Slobodyan, V.; Kromka, A.; Rezek, B. Electrical properties of MXene thin films prepared from non-aqueous polar aprotic solvents. J. Mater. Res. 2023, 38, 3227–3237. [Google Scholar] [CrossRef]

- Joshi, J.H.; Kanchan, D.K.; Joshi, M.J.; Jethva, H.O.; Parikh, K.D. Dielectric relaxation, complex impedance and modulus spectroscopic studies of mix phase rod like cobalt sulfide nanoparticles. Mater. Res. Bull. 2017, 93, 63–73. [Google Scholar] [CrossRef]

| Sample | d-Spacing [nm] | [nm] |

|---|---|---|

| untreated BC | d101 = 0.53 d10i = 0.46 d002 = 0.35 | 5.64 |

| isoprop. BC | d101 = 0.53 d10i = 0.46 d002 = 0.35 | 3.38 |

| MAX | d002 = 0.81 d006 = 0.20 | 40.21 |

| MXene | d002 = 1.48 | 29.77 |

| Sample | Et [MPa] | σM [MPa] | ϵM [%] |

|---|---|---|---|

| untreated BC | 289 ± 36 | 27.6 ± 2.2 | 17.7 ± 3.4 |

| isopropanol BC | 53 ± 17 | 6.0 ± 3.4 | 14.9 ± 6.9 |

| aged BC | 293 ± 37 | 27.9 ± 3.2 | 17.3 ± 3.0 |

| PET | 1976 ± 96 | 58.3 ± 1.9 | 5.6 ± 0.2 |

| Sample | E′at 25 °C | E′ at 85 °C | E′ | E″ at 25 °C | E″ at 85 °C | E″ |

|---|---|---|---|---|---|---|

| [MPa] | [MPa] | Change | [MPa] | [MPa] | Change | |

| untreated BC | 2100 | 950 | −55% | 630 | 273 | −57% |

| isopropanol BC | 1300 | 760 | −42% | 342 | 214 | −37% |

| aged BC | 550 | 470 | −15% | 131 | 105 | −21% |

| PET | 505 | 734 | +45% | 28 | 31 | +12% |

| Substrate | Thickness [μm] | Sheet Resistance | Conductivity | Resistivity |

|---|---|---|---|---|

| (Substrate + MXene) | [·cm−1] | [S·sq−1] | [·cm] | |

| BC (dry) | 130 + 0 | n.m | n.m | n.m |

| BC (humid) | 130 + 0 | 2.4 ± 1.1 (×107) | 3.2 ± 0.1 (×10−6) | 3.2 ± 0.1 (×106) |

| BC (dry) | 130 + 10 | 2733 ± 1321 | 0.45 ± 0.27 | 2.73 ± 1.32 |

| PET | 70 + 20 | 156 ± 5 | 3.21 ± 0.10 | 0.31 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guziewicz, W.; Srivatsa, S.; Zambrzycki, M.; Dziadek, M.; Szatkowski, P.; Szymczak, P.; Berent, K.; Marciszko-Wiąckowska, M.; Radecka, M.; Kołodziejczyk, A.; et al. MXene/Bacterial Cellulose Hybrid Materials for Sustainable Soft Electronics. Materials 2024, 17, 5513. https://doi.org/10.3390/ma17225513

Guziewicz W, Srivatsa S, Zambrzycki M, Dziadek M, Szatkowski P, Szymczak P, Berent K, Marciszko-Wiąckowska M, Radecka M, Kołodziejczyk A, et al. MXene/Bacterial Cellulose Hybrid Materials for Sustainable Soft Electronics. Materials. 2024; 17(22):5513. https://doi.org/10.3390/ma17225513

Chicago/Turabian StyleGuziewicz, Wojciech, Shreyas Srivatsa, Marcel Zambrzycki, Michał Dziadek, Piotr Szatkowski, Patryk Szymczak, Katarzyna Berent, Marianna Marciszko-Wiąckowska, Marta Radecka, Agata Kołodziejczyk, and et al. 2024. "MXene/Bacterial Cellulose Hybrid Materials for Sustainable Soft Electronics" Materials 17, no. 22: 5513. https://doi.org/10.3390/ma17225513

APA StyleGuziewicz, W., Srivatsa, S., Zambrzycki, M., Dziadek, M., Szatkowski, P., Szymczak, P., Berent, K., Marciszko-Wiąckowska, M., Radecka, M., Kołodziejczyk, A., & Uhl, T. (2024). MXene/Bacterial Cellulose Hybrid Materials for Sustainable Soft Electronics. Materials, 17(22), 5513. https://doi.org/10.3390/ma17225513