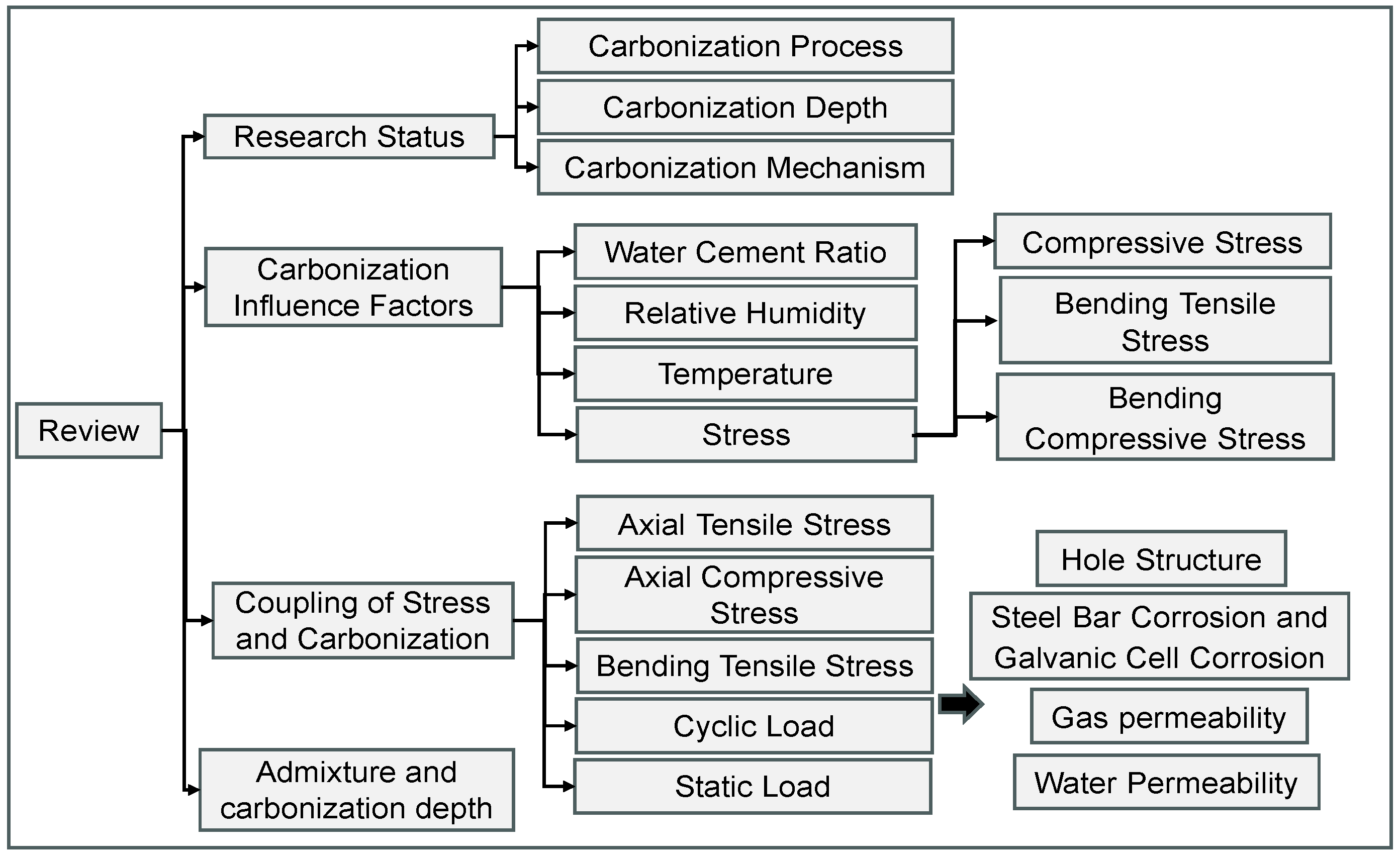

Coupling Effects of Stress and Carbonation on Concrete Durability: A Review

Abstract

1. Introduction

2. Research Status and Main Point of View

2.1. Research Status of the Concrete Carbonization Process

2.2. The Current Status of Research on the Impact of Concrete Stress on Carbonation Depth

2.3. Carbonization Mechanism of Concrete

3. Factors Affecting Carbonation of Concrete

3.1. Effect of Water-Cement Ratio on Concrete Carbonation

3.2. Effect of Relative Humidity on Concrete Carbonization

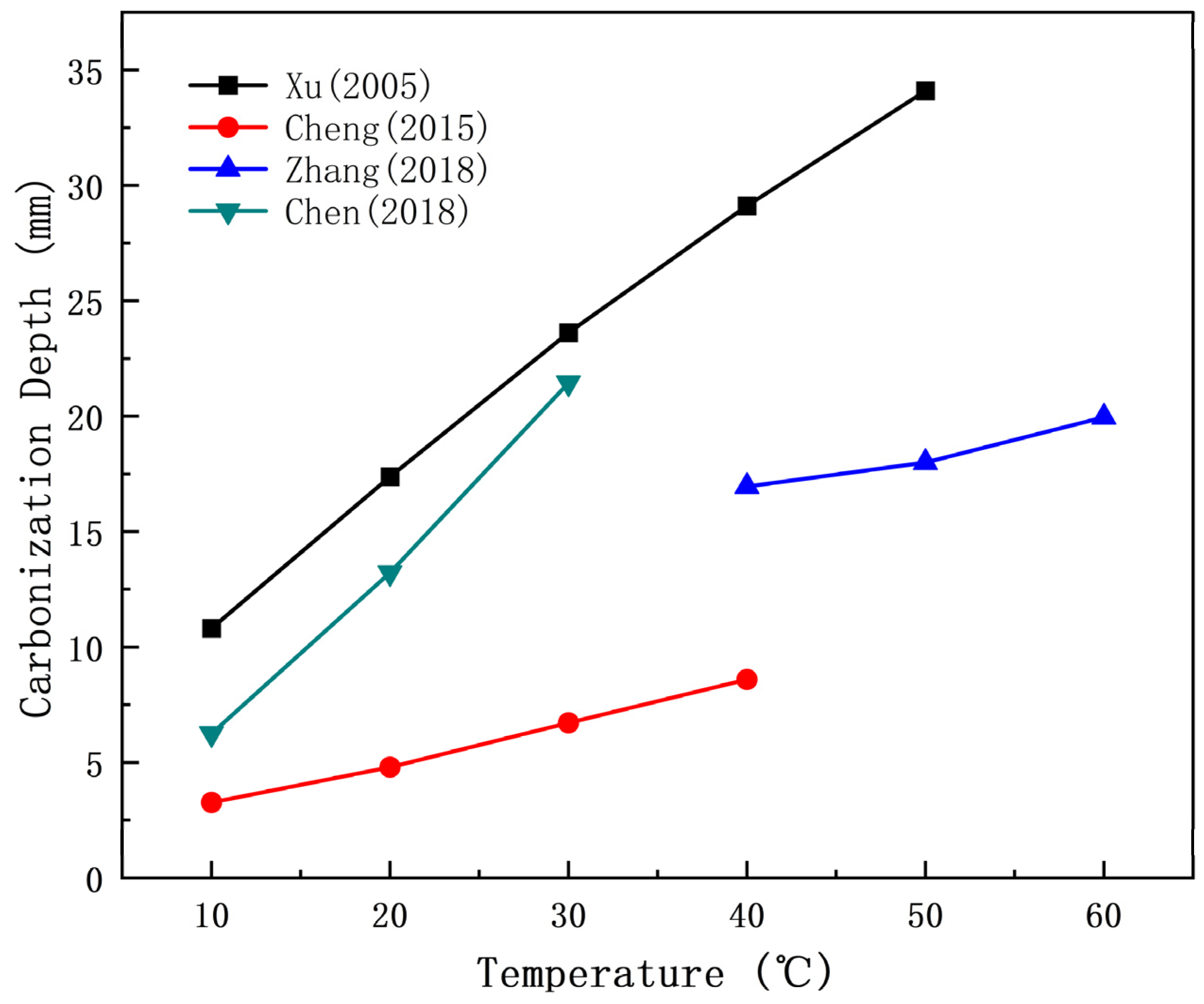

3.3. Effect of Temperature on Carbonization

3.4. Effect of Stress on Concrete Carbonization

- CD: concrete carbonization depth; σs: tensile stress of concrete; CD0: carbonation depth at 20 cm of the concrete sample without bending load; hσs/d: effective tensile stress;

- η = 1.6175; kRh: Influence coefficient of environmental relative humidity; kT: environmental temperature influence coefficient;

- x represents the depth of carbonization

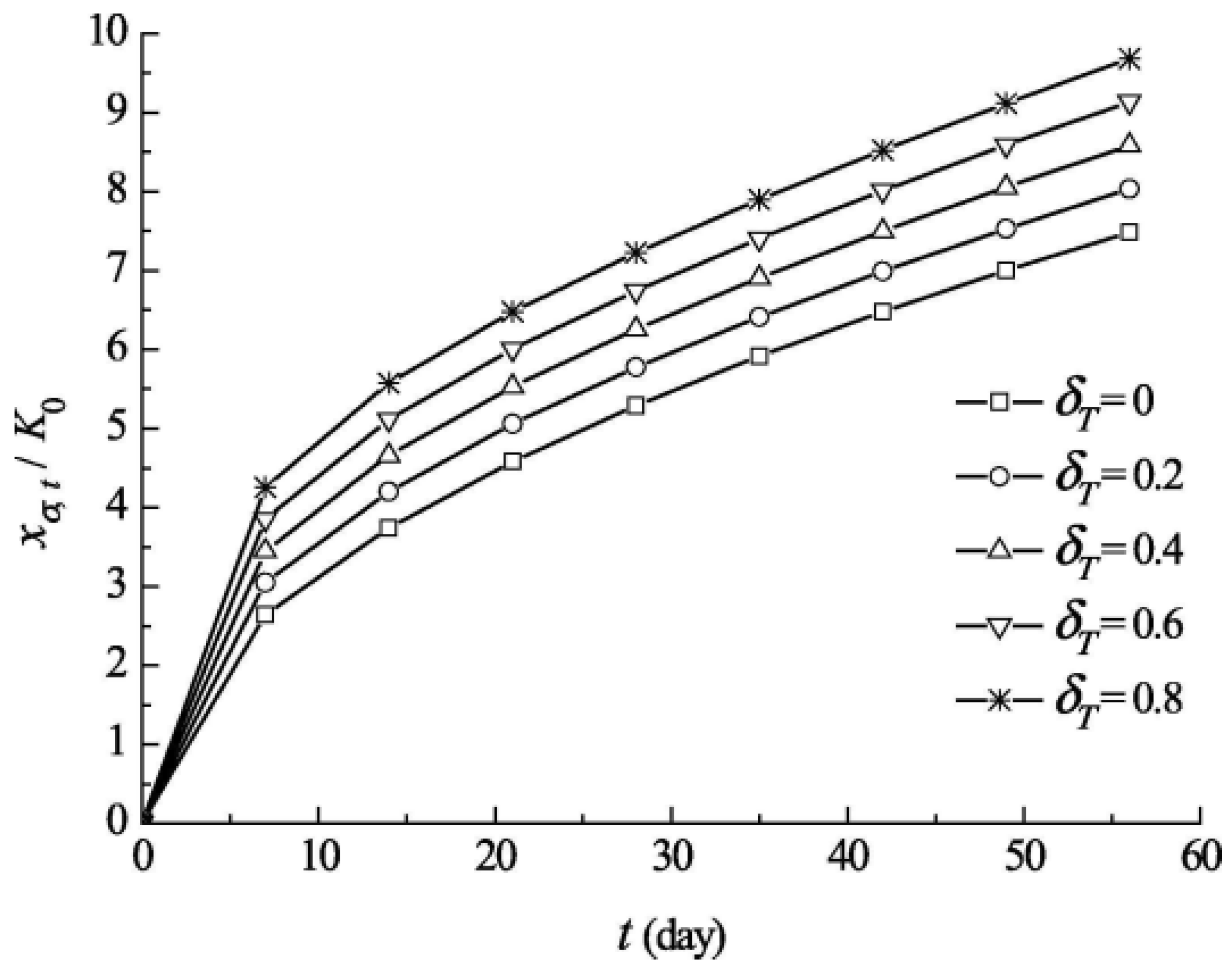

- xσ: carbonization depth of concrete under stress: carbonation depth under zero stress: tensile stress ratio;

- The application range of St is 0~0.8; The application range of Sc is 0~0.3.

- xi is the carbonization depth under the combined action of freeze-thaw carbonization, xk is the concrete carbonization depth of pure carbonization.

3.4.1. Effect of Compressive Stress on Concrete Carbonization

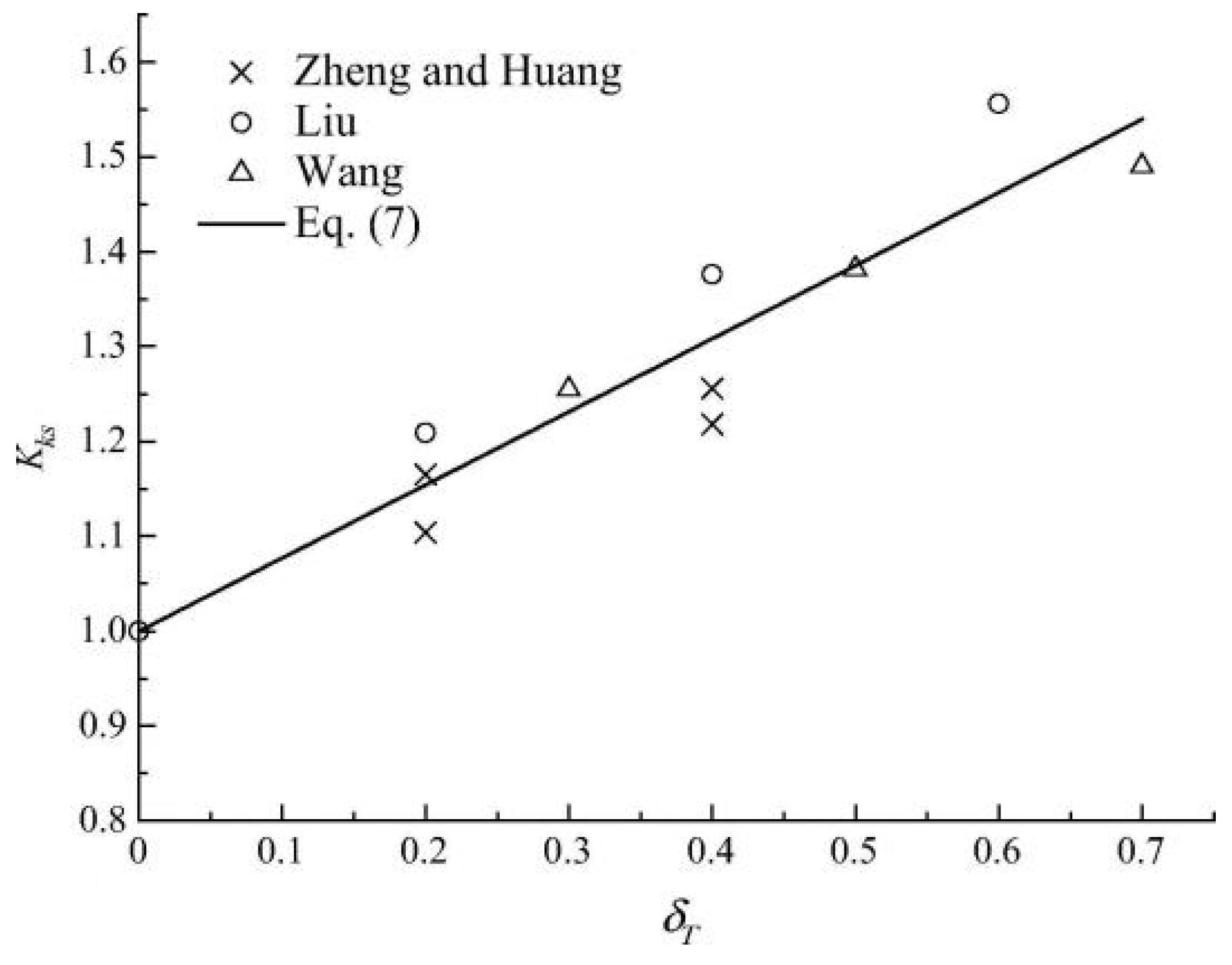

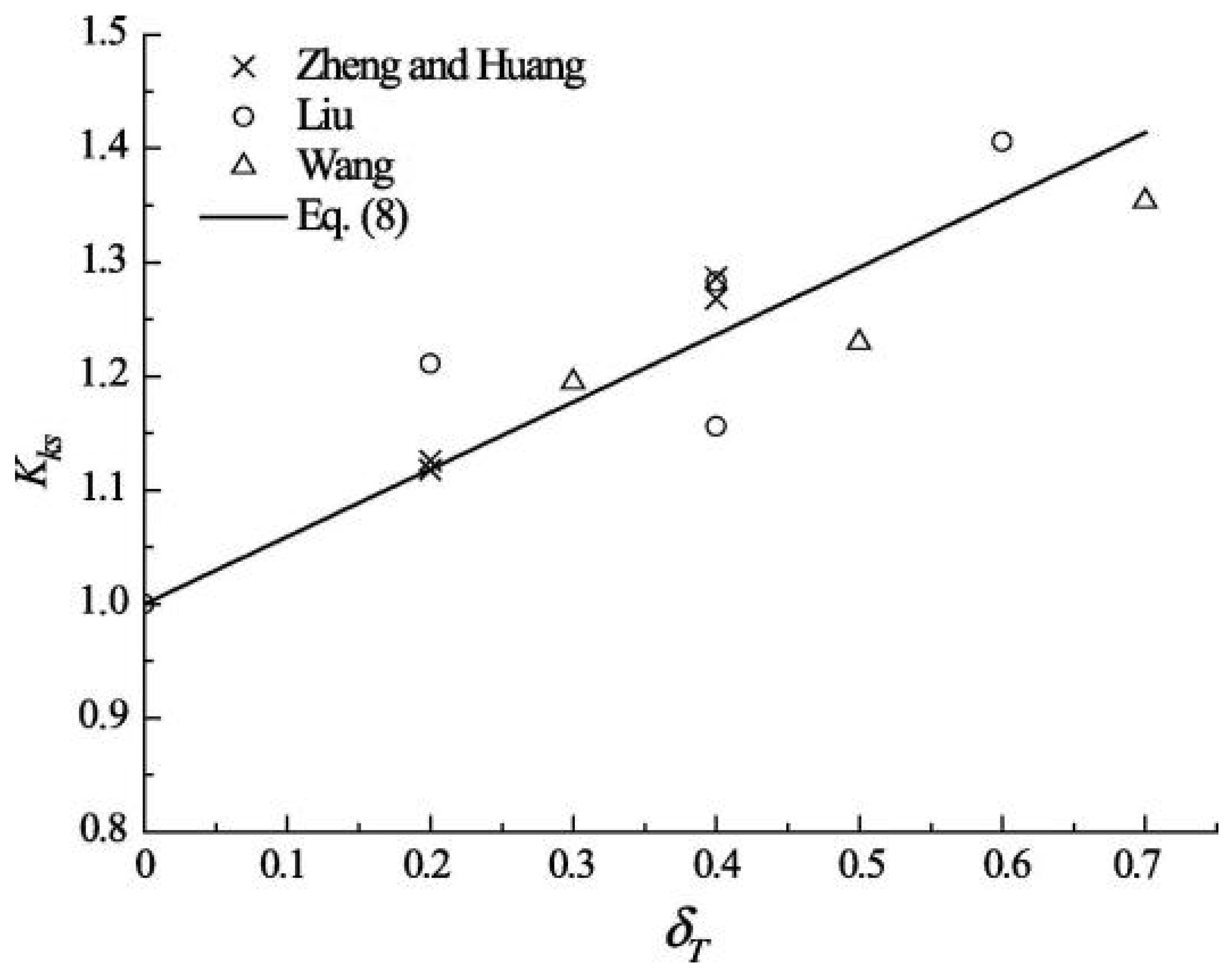

3.4.2. Effect of Flexural Tensile Stress on Concrete Carbonization

3.4.3. Effect of Bending Compressive Stress on Concrete Carbonization

4. Effect of Coupling Effect of Stress and Carbonization on the Durability of Concrete

4.1. Coupling of Tensile Stress and Carbonization

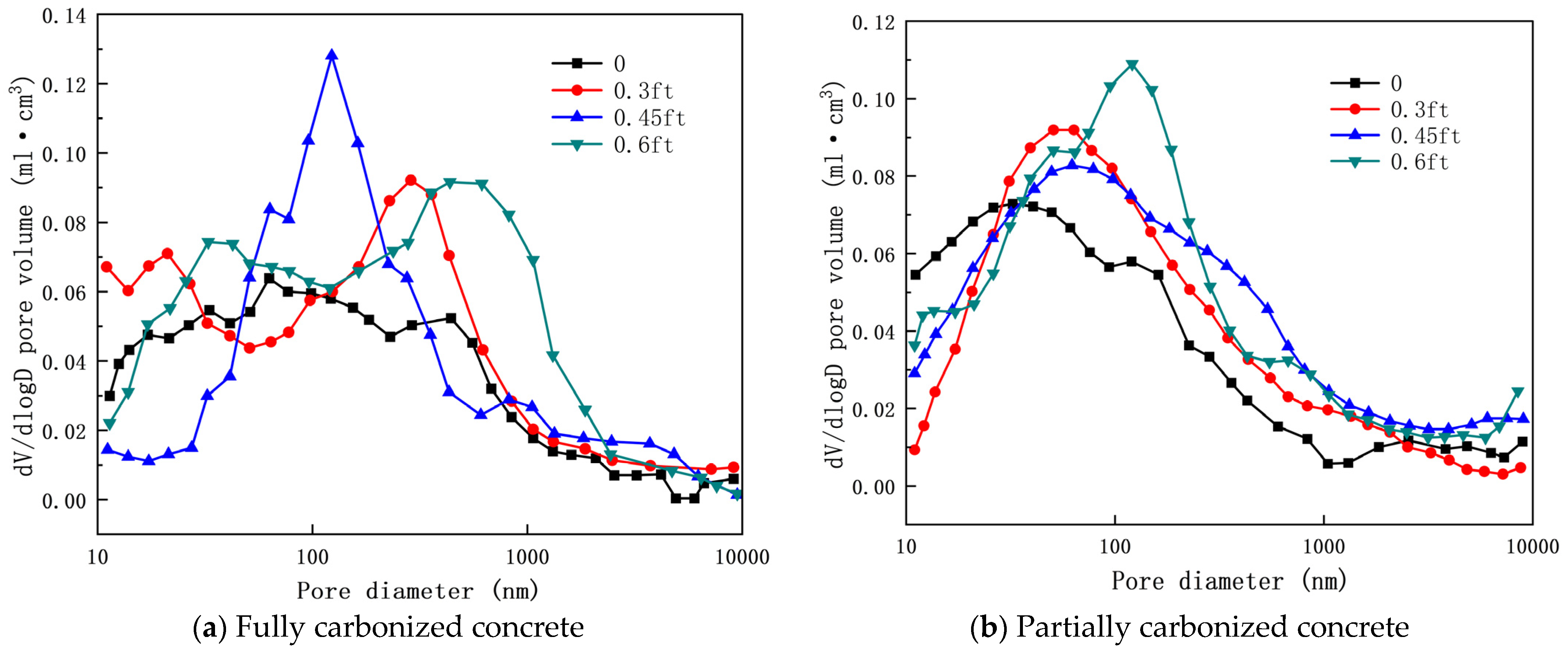

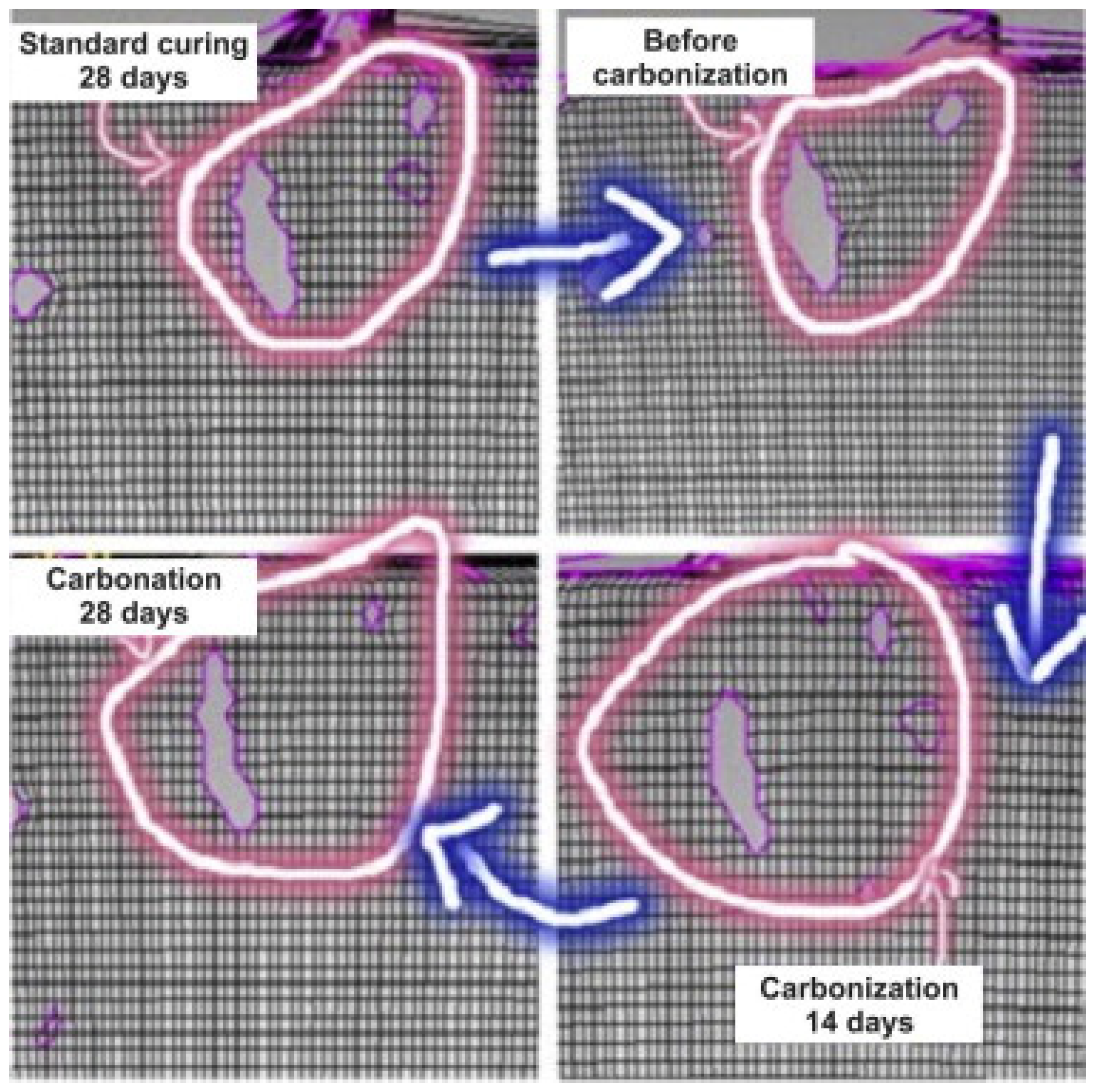

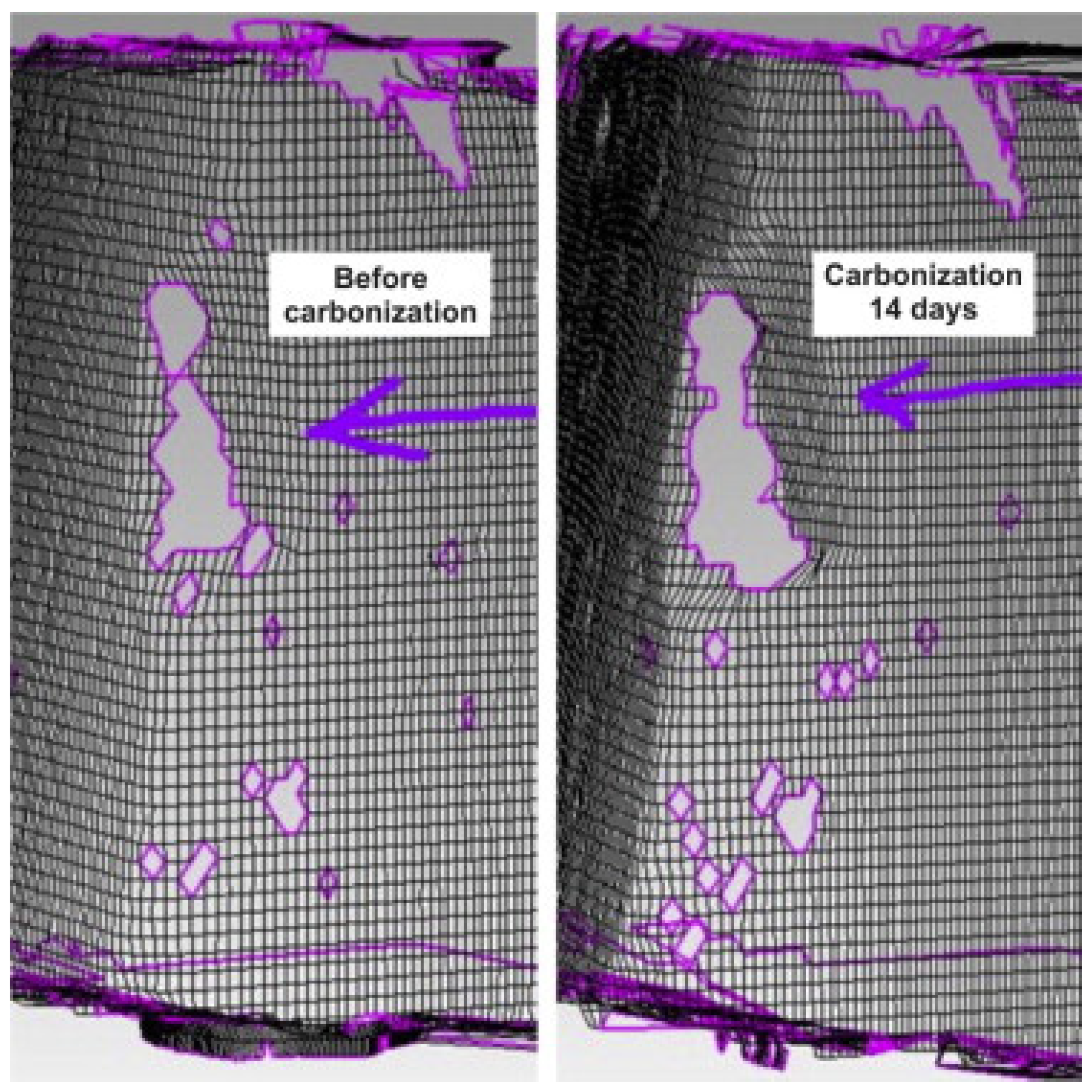

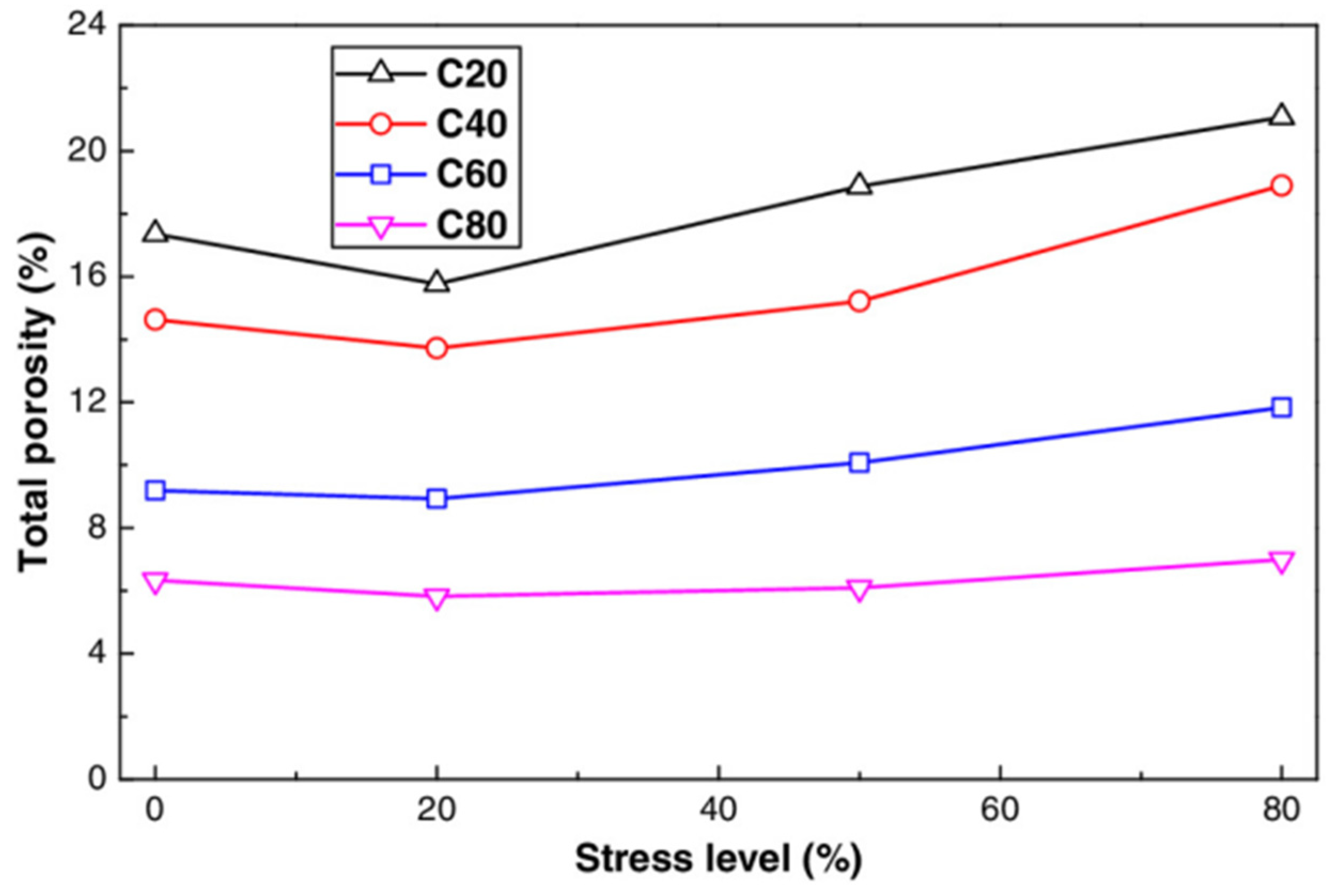

4.1.1. Pore Structure Changes of OPC Under the Coupling Effect of Tensile Stress and Carbonization

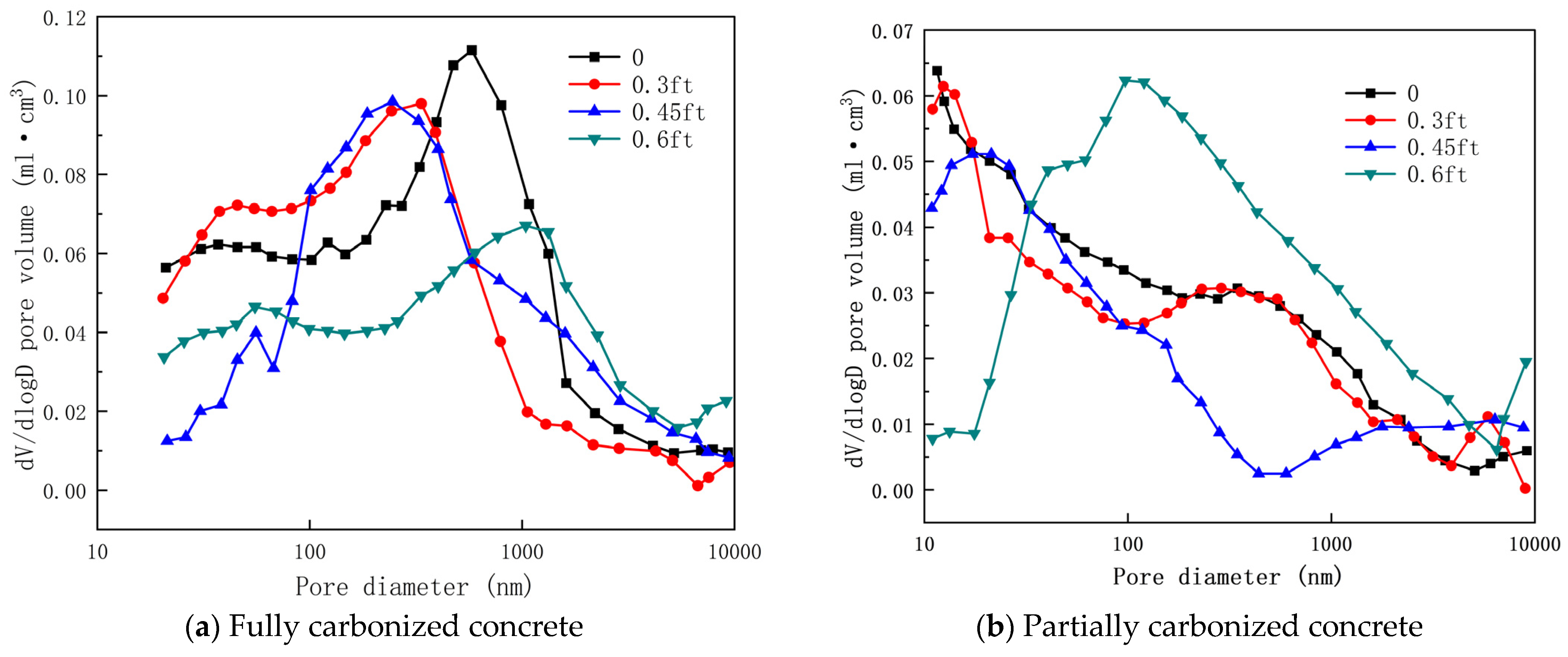

4.1.2. Pore Structure Changes of PSC Under the Coupling Effect of Tensile Stress and Carbonization

4.2. Coupling of Axial Compression and Carbonization

4.2.1. Steel Bar Corrosion and Galvanic Cell Corrosion

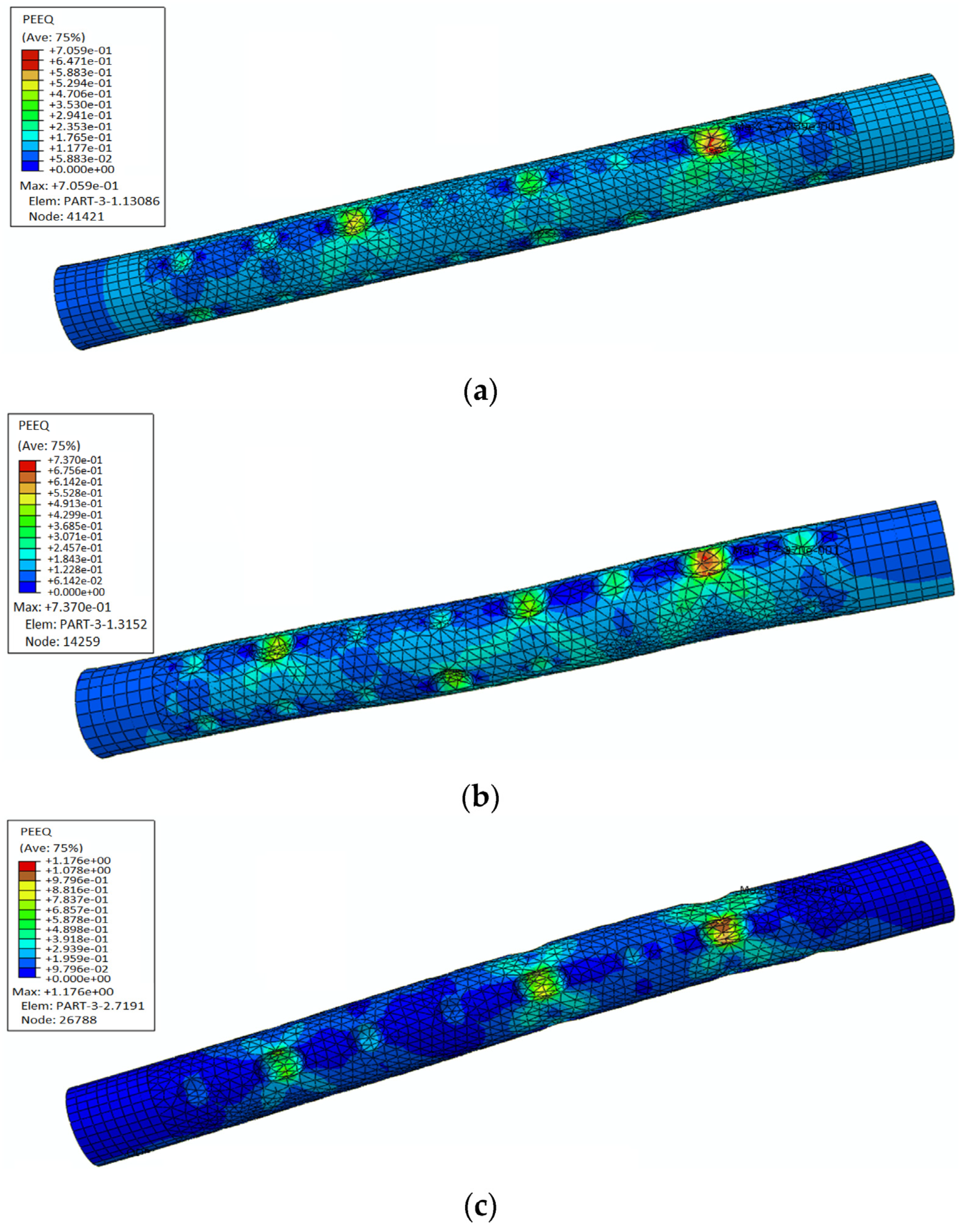

4.2.2. Influence of Coupling Effect of Axial Compression Load and Carbonization on Gas Permeability

4.2.3. Influence of Axial Compression Load and Carbonization Coupling on Water Permeability

4.3. Coupling of Bending Load and Carbonization

Influence of Flexural Tensile Stress and Carbonization Time Coupling Effect on Concrete Durability

4.4. Coupling of Cyclic Load and Carbonized Concrete

4.5. Steel Bar Corrosion Under the Coupling Effect of Static Load and Carbonization

5. Impact of Various Additives on the Carbonation Depth of Concrete

6. Discussions

- Literature Screening: We prioritized the screening process based on relevance. Initially, we selected highly relevant studies and organized them according to their impact factor, journal ranking, and publication date, ensuring that the cited works were high-quality and closely related to our topic. Additionally, we conducted supplementary searches using targeted keywords for specific research areas that require further exploration.

- Content Summary: As a review paper, we focused on synthesizing and distilling different studies’ experimental processes and findings, including model proposals and validations. We also examined modifications to these models and presented contrasting perspectives on similar issues, thereby allowing readers to gain a more comprehensive understanding.

- Data Visualization: For figures, we recreated graphs using data extracted from various studies to enhance clarity. We made every effort to maintain visual clarity and data accuracy, particularly for 3D graphs where data extraction presented challenges.

- Selection of Representative Studies: For findings reported across multiple studies, we selected representative papers for detailed discussion, while other supporting studies were referenced but not elaborated upon.

- The increasing trend of utilizing mineral admixtures to partially replace Portland cement for CO2 emission reduction, yet the carbonation behavior of such concrete under stress conditions is not fully understood;

- The dynamics of CO2 transport vary significantly under stress, necessitating investigation into the coupling effects between load and carbonation;

- Existing prediction models for carbonation depth often fail to integrate the chemical factors from the carbonation reaction with physical stress factors; a comprehensive approach should include CO2 transport rates and carbonate content to improve predictive accuracy under load;

- Accelerated carbonation tests frequently employ CO2 concentrations significantly higher than those found in natural environments, raising questions about the applicability of these models to real-world scenarios and highlighting the need for more effective testing devices for rapid carbonation assessments.

- Development of standardized testing protocols for carbonation assessment that can be universally applied across studies, ensuring consistency and comparability of results;

- Implementation of innovative modeling techniques incorporating multi-physics simulations to better understand the coupled effects of environmental factors and mechanical stresses on carbonation processes;

- Exploration of real-time monitoring technologies to track carbonation progression in situ, providing valuable data for predicting service life and durability;

- Investigation into the long-term effects of varying loading conditions on the carbonation behavior of concrete containing different mineral admixtures to establish comprehensive guidelines for sustainable concrete design.

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lan, X.; Tans, P.; Thoning, K.W. Trends in globally-averaged CO2 determined from NOAA Global Monitoring Laboratory measurements. Version 2023, 3, 2023. [Google Scholar] [CrossRef]

- Friedlingstein, P.; O’sullivan, M.; Jones, M.W.; Andrew, R.M.; Gregor, L.; Hauck, J.; Le Quéré, C.; Luijkx, I.T.; Olsen, A.; Peters, G.P.; et al. Global carbon budget 2021. Earth Syst. Sci. Data 2022, 14, 481–519. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2021: The Physical Science Basis; Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2021. [Google Scholar]

- Etheridge, D.M.; Steele, L.P.; Langenfelds, R.L.; Francey, R.J.; Barnola, J.M.; Morgan, V.I. Atmospheric CO2 over the last 1000 years measured in air from glacial ice. J. Geophys. Res. 1996, 101, 4115–4128. [Google Scholar] [CrossRef]

- Marcott, S.A.; Shakun, J.D.; Clark, P.U.; Mix, A.C. A reconstruction of regional and global temperature for the past 11,000 years. Science 2013, 339, 1198–1201. [Google Scholar] [CrossRef] [PubMed]

- Ciais, P.; Sabine, C.; Bala, G.; Bopp, L.; Brovkin, V.; House, J.I. Carbon and other biogeochemical cycles. In Climate Change 2013: The Physical Science Basis; Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change Change; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- IPCC. Climate Change 2014: Mitigation of Climate Change; Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Chang, H.; Wang, Y.; Wang, X.; Liu, J.; Zhang, H. Effects of carbonation on phase compositionof Metakaolin-blended cement pastes. Constr. Build. Mater. 2022, 324, 126639. [Google Scholar] [CrossRef]

- Zhang, M.Z. Multiscale Lattice Boltzmann-Finite Element Modelling of Transportproperties in Cement-Based Materials. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2013. [Google Scholar]

- Koch, G.H.; Brongers, M.P.; Thompson, N.G.; Virmani, Y.P.; Payer, J.H. Corrosion Cost and Preventive Strategies in the United States; NACE International Houston: Houston, TX, USA, 2001. [Google Scholar]

- Hou, B.; Li, X.; Ma, X.; Du, C.; Zhang, D.; Zheng, M.; Xu, W.; Lu, D.; Ma, F. The cost of corrosion in China. NPJ Mater. Degrad. 2017, 1, 4. [Google Scholar] [CrossRef]

- Wang, J.; Xu, L.; Li, M.; He, H.; Wang, Y.; Xiang, D.; Lin, S.; Zhong, Y.; Zhao, H. Effect of pre-carbonation on the properties of cementpaste subjected to high temperatures. J. Build. Eng. 2022, 51, 104337. [Google Scholar] [CrossRef]

- Liu, P.; Yu, Z.W.; Chen, Y. Carbonation depth model and carbonated acceleration rateof concrete under different environment. Cem. Concr. Compos. 2020, 114, 103736. [Google Scholar] [CrossRef]

- Thiery, M.; Villain, G.; Dangla, P.; Platret, G. Investigation of the carbonation front shape oncementitious materials: Effects of the chemical kinetics. Cem. Concr. Res. 2007, 37, 1047–1058. [Google Scholar] [CrossRef]

- Hui, G.U.; Quan-wang, L.I.; Guan-jie, H.O.U. Updating Method for Durability Models of Concrete Structures in Carbonation Environment. Eng. Mech. 2021, 38, 113–121. [Google Scholar]

- Paul, S.C.; Panda, B.; Huang, Y.; Garg, A.; Peng, X. An empirical model design for evaluation and estimation of carbonation depth in concrete. Measurement 2018, 124, 205–210. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Ta, V.L.; Bonnet, S.; Kiesse, T.S.; Ventura, A. A new meta-model to calculate carbonation frontdepth within concrete structures. Constr. Build. Mater. 2016, 129, 172–181. [Google Scholar] [CrossRef]

- Peter, M.A.; Muntean, A.; Meier, S.A.; Böhm, M. Competition of several carbonation reactionsin concrete: A parametric study. Cem. Concr. Res. 2008, 38, 1385–1393. [Google Scholar] [CrossRef]

- Fang, Y.; Chang, J. Microstructure changes of waste hydrated cement paste induced byaccelerated carbonation. Constr. Build. Mater. 2015, 76, 360–365. [Google Scholar] [CrossRef]

- Andrade, C.; Turrero, M.J. Assessment of corrosion of steel reinforcement in concrete structures exposed to carbon dioxide. Corros. Sci. 2018, 140, 76–83. [Google Scholar]

- Stewart, M.G.; Wang, X.; Nguyen, M.N. Climate change impact and risks of concrete infrastructure deterioration. Eng. Struct. 2011, 33, 1326–1337. [Google Scholar] [CrossRef]

- Wang, X.-Y. Effects of Crack and Climate Change on Service Life of Concrete Subjected to Carbonation. Appl. Sci. 2018, 8, 572. [Google Scholar] [CrossRef]

- Tighe, S.L.; Lutz, J. Case study of concrete carbonation in residential buildings: Analysis and implications for safety. J. Build. Perform. 2020, 11, 189–198. [Google Scholar]

- Lollini, F.; Redaelli, E.; Bertolini, L. Corrosion assessment of reinforced concrete elements of Torre Velasca in Milan. Case Stud. Constr. Mater. 2016, 4, 55–61. [Google Scholar] [CrossRef][Green Version]

- Ghosh, P.; Tran, D. Modeling of carbonation-induced corrosion in prestressed concrete structures under various load conditions. Materials 2022, 15, 567. [Google Scholar]

- Lei, B.; Li, W.; Li, Z.; Wang, G.; Sun, Z. Effect of Cyclic Loading Deterioration on Concrete Durability: Water Absorption, Freeze-Thaw, and Carbonation. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef]

- GB/T 50476-2019; Design Standard for Durability of Concrete Structures. Ministry of Housing and Urban-Rural Development: Beijing, China, 2019.

- GB/T 51355-2019; Evaluation Standard for Durability of Existing Concrete Structures. Ministry of Housing and Urban-Rural Development: Beijing, China, 2019.

- SL 775-2018; Specification for Durability Assessment of Hydraulic Concrete Structures. China Water Conservancy and Hydropower Press: Beijing, China, 2018.

- Ishida, T.; Li, C.H. Modeling of Carbonation Based on Thermo-Hygro Physics with Strong Coupling of Mass Transport and Equilibrium in Micro-Pore Structure of Concrete. J. Adv. Concr. Technol. 2008, 6, 303–316. [Google Scholar] [CrossRef]

- Ruan, X.; Pan, Z.C. Mesoscopic simulation method of concrete carbonation process. Struct. Infrastruct. Eng. 2012, 8, 99–110. [Google Scholar] [CrossRef]

- Talukdar, S.; Banthia, N.; Grace, J.R. Carbonation in concrete infrastructure in the context of global climate change—Part 1: Experimental results and model development. Cem. Concr. Compos. 2012, 34, 924–930. [Google Scholar] [CrossRef]

- Cui, H.; Tang, W.; Liu, W.; Dong, Z.; Xing, F. Experimental study on effects of CO2 concentrations on concrete carbonation and diffusion mechanisms. Constr. Build. Mater. 2015, 93, 522–527. [Google Scholar] [CrossRef]

- Li, G.; Dong, L.; Bai, Z.; Lei, M.; Du, J.M. Predicting carbonation depth for concrete with organic film coatings combined with ageing effects. Constr. Build. Mater. 2017, 142, 59–65. [Google Scholar] [CrossRef]

- Jiang, C.; Huang, Q.; Gu, X.; Zhang, W. Experimental investigation on carbonation in fatigue-damaged concrete. Cem. Concr. Res. 2017, 99, 38–52. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, P.; Yu, Z. Effects of Environmental Factors on Concrete Carbonation Depth and Compressive Strength. Materials 2018, 11, 2167. [Google Scholar] [CrossRef]

- Zhou, S.; Lv, H.; Wu, Y. Degradation behavior of concrete under corrosive coal mine environment. Int. J. Min. Sci. Technol. 2019, 29, 307–312. [Google Scholar] [CrossRef]

- Zhang, J.S.; Cheng, M.; Zhu, J.H. Carbonation depth model and prediction of hybrid fiber fly ash concrete. Adv. Civ. Eng. 2020, 2020, 9863963. [Google Scholar] [CrossRef]

- Huo, Z.; Wang, L.; Huang, Y. Predicting carbonation depth of concrete using a hybrid ensemble model. J. Build. Eng. 2023, 76, 107320. [Google Scholar] [CrossRef]

- Tian, H.; Yongxu, G.P.L.J.L.; Yu, W. Experimental study on carbonization of forced concrete Specimens. J. Tongji Univ. 2010, 38, 200–204. [Google Scholar]

- Zheng, J.L.; Huang, L.P. Experimental study on carbonization of self-compacting concrete under tensile and compressive stress. J. Constr. Mater. 2013, 16, 115–120. [Google Scholar]

- Ruan, X.; Chen, X.L.A. Two-dimensional numerical simulation of carbonization process considering stress state. J. Tongji Univ. 2013, 41, 191–196. [Google Scholar]

- Jiang, C.; Gu, X.; Zhang, W.; Zou, W. Modeling of carbonation in tensile zone of plain concrete beams damaged by cyclic loading. Constr. Build. Mater. 2015, 77, 479–488. [Google Scholar] [CrossRef]

- Sun, J.; Lu, L. Coupled effect of axially distributed load and carbonization on permeability of concrete. Constr. Build. Mater. 2015, 79, 9–13. [Google Scholar] [CrossRef]

- Yan, L.; Luo, X.-y.; Shi, Y. Study on carbonated concrete mechanical property and constitutive relation under cyclic load. J. Hunan Univ. 2016, 43, 43–50. [Google Scholar]

- Liu, Y.; Ren, J.; Li, Z.X.; Gao, Q.L.; Zhao, S.L. Experimental study on carbonation properties of concrete based on bending load damage. Fresenius Environ. Bull. 2019, 28, 10021–10028. [Google Scholar]

- Liu, Y.; Ren, J.; Li, Z.; Gao, Q.; Zhao, S. Carbonization Resistance of Reinforced Concrete under Bending Load. Frat. Integrità Strutt. 2019, 13, 714–724. [Google Scholar] [CrossRef]

- Miao, Y.-Y.; Niu, D.-T.; Cheng, N. Durability of concrete under the combined action of carbonization and fatigue loading of vehicles. Sci. Adv. Mater. 2019, 11, 1781–1787. [Google Scholar] [CrossRef]

- Cao, D.; Liu, J.; Zhou, Y.; Ge, W.; Zhang, X. Experimental Study on the Effect of Freeze-Thaw Cycles on Axial Tension and Compression Performance of Concrete after Complete Carbonization. Adv. Civ. Eng. 2021, 2021, 8111436. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, S.; Qu, Y.; Liu, K.; Jia, L. Research on Mechanical and Carbonization Properties of Hybrid Fiber Iron Tailings Concrete Based on Deep Learning. J. Adv. Concr. Technol. 2022, 2022, 3475679. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Feng, Y.; Shen, J.; Sun, G.; Shi, J. Experimental and simulation study on chloride diffusion in unsaturated concrete under the coupled effect of carbonation and loading. Structures 2022, 43, 1356–1368. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, S.; Quan, X.; Qu, Y.; Mo, Z.; Lin, C. Carbonation Resistance and Pore Structure of Mixed-Fiber-Reinforced Concrete Conta.ining Fine Aggregates of Iron Ore Tailings. Materials 2022, 15, 8992. [Google Scholar] [CrossRef] [PubMed]

- Long, J.; Peng, Z.; Feng, H.; Yang, A. Study of Carbonation-depth Prediction of Unsaturated Concrete Considering Carbonation-produced Water. Jordan J. Civ. Eng. 2023, 17, 83–96. [Google Scholar] [CrossRef]

- Wang, H.; Zong, Q.; Wang, H. Mechanical properties and crushing mechanism of axially carbonated mortar under impact loading. Case Stud. Constr. Mater. 2023, 19, 02315. [Google Scholar] [CrossRef]

- Ma, H.-W.; Yu, Y.-F.; Liang, C.-F.; He, Z.-H.; Zhao, J.-X. Research progress on Carbonization Performance of concrete under Different stress states. Concr. Cem. Prod. 2019, 6, 20–24. [Google Scholar]

- Liu, L.; Wang, Y.; Zhang, D. Concrete carbonation depth and water cement ratio with time change rule of the experimental study. Sci. Technol. Innov. Her. 2009, 11, 54–56. [Google Scholar]

- Yang, S.; Jin, W. Study on the Correlation between Carbonization performance and Gas Permeability of Concrete. Concrete 2018, 6, 13–17. [Google Scholar]

- Wang, Y.H.; Dong, H. Effect of water-cement ratio on properties of sulphoaluminate cement based high performance concrete. Bulk Cem. 2022, 2, 17–19. [Google Scholar]

- Liu, L.-M. Water cement ratio on recycled aggregate concrete carbonization performance test study. J. Inn. Mong. Highw. Transp. 2016, 2, 36–38. [Google Scholar]

- Niu, D.; Yang, R.; Lv, Y. Performance degradation of concrete under the action of SO2 and CO2. Mater. Rev. 2014, 1–15. Available online: http://kns.cnki.net/kcms/detail/50.1078.TB.20240415.1357.019.html (accessed on 3 November 2024).

- Ji, Y.; Zhao, G.; Fan, Z. A Study on Similarity of Concrete Carbonization Area. J. Huaihai Inst. Technol. 2002, 11, 60–63. [Google Scholar]

- Du, Y.; Huang, C. Study on Prediction Model for Carbonization Area Depth of High Volume Fly Ash Concrete. J. Yangtze River Sci. Res. Inst. 2011, 28, 68–71. [Google Scholar]

- Jiang, Q. Concrete Carbonization Area Database and Concrete Carbonization Area Analysis; Climbing Project—Prediction Models for Steel Corrosion and Concrete Freeze-thaw Damage; Annual Research Report; Tsinghua University Press: Beijing, China, 1997. [Google Scholar]

- Yang, L. Research on Depth Model of Concrete Carbonization and Its Influencing Factors. Ph.D. Thesis, Liaoning Technical University, Fuxin, China, 2017. [Google Scholar]

- Zhang, X.; Chen, T.; Yang, J.; Chen, J. Analysis of Influence Factors on Strength and Durability for Different Kinds of Self-compacting Lightweight Concretes. Bull. Chin. Ceram. Soc. 2019, 38, 39–45. [Google Scholar]

- Loo, Y.; Chin, M.; Tam, C. Carbonization Area Prediction Model for Accelerated Carbonization Area Testing of Concrete. Mag. Concr. Res. 1994, 46, 191–200. [Google Scholar] [CrossRef]

- Gong, L. Concrete Multi-factor Carbonization Area Equation and Application. Concrete 1985, 6, 10–16. [Google Scholar]

- Niu, D. Durability and Life Prediction of Concrete Structures; Science Press: Beijing, China, 2002. [Google Scholar]

- Xu, D. Study on carbonization rate of concrete under environmental and climatic conditions. West China Explor. Eng. 2005, 10, 147–149. [Google Scholar]

- Yu, B.; Cheng, D.; Yang, L. Quantification and durability analysis of Carbonization effect on Concrete Structure. Chin. J. Civ. Eng. 2015, 48, 51–59. [Google Scholar]

- Zhang, J.; He, S.; Xie, N.; Chen, X.; Guo, Y. Durability Experimental Study on the Heat-Supplying Tunnel Lining Structure under Thermal-Mechanical Coupling. IOP Conf. Ser. Mater. Sci. Eng. 2018, 452, 022104. [Google Scholar] [CrossRef]

- Castel, A.; Franois, R.; Arliguie, G. Effect of loading on carbonation penetration in reinforced concrete elements. Cem. Concr. Res. 1999, 29, 561–565. [Google Scholar] [CrossRef]

- Yongming, T.; Zhitao, L.V. Experimental Study on carbonization of concrete under Stress. J. Southeast. Univ. 2003, 33, 573–576. [Google Scholar]

- CECS 220:2007; Standard for Durability Assessment of Concrete Structures. China Architecture & Building Press: Beijing, China, 2007.

- Wang, J.; Ng, P.L.; Su, H.; Chen, J.; Du, J. Effect of Concrete Stress States on Carbonation Depth of Concrete. J. Civ. Eng. Manag. 2019, 25, 518–530. [Google Scholar] [CrossRef]

- Xu, C.; Cao, S.; Fan, S.; Liu, Q. Unified prediction model of concrete neutral depth under multiple factors. J. Southeast Univ. 2014, 44, 363–368. [Google Scholar] [CrossRef]

- Sun, X.; Hu, D.; Zhang, L.; Chen, F.; Zha, B. Considering the effects of freezing and thawing and stress experimental study on carbonization of concrete component. J. Silic. Bull. 2020, 33, 1115–1125. [Google Scholar]

- Wan, X.M.; Wittmann, F.H.; Zhao, T.J.; Fan, H. Chloride content and pH value in the pore solution of concrete under carbonation. J. Zhejiang Univ. 2013, 14, 71–78. [Google Scholar] [CrossRef]

- Tang, J.; Wu, J.; Zou, Z.; Yue, A.; Mueller, A. Influence of axial loading and carbonation age on the carbonation resistance of recycled aggregate concrete. Constr. Build. Mater. 2018, 173, 707717. [Google Scholar] [CrossRef]

- Zhang, D.; Lv, Z. Modem prestressed concrete structure durability research status and characteristics. Ind. Constr. 2000, 11, 1–4. [Google Scholar] [CrossRef]

- Shi, Q. Experimental Study on Carbonation Durability of Concrete Under Stress State. Ph.D. Thesis, Central South University, Changsha, China, 2008; pp. 14–15. [Google Scholar]

- Wu, Y. Test of Carbonation and Chloride Ion Erosion Ofprestressed Concrete Members. Ph.D. Thesis, Tongji University, Shanghai, China, 2009; pp. 50–55. [Google Scholar]

- Wang, M. Carbonation and Chloride Ion Erosion Test and Theoretical Analysis of Steamed Prestressed Concrete. Ph.D. Thesis, Central South University, Changsha, China, 2012; pp. 14–16. [Google Scholar]

- Luo, X.; Zou, H.; Shi, Q. The durability of concrete carbonization test under different stress state study. J. Nat. Disasters 2012, 21, 194–199. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Sun, W.; Chen, S.; Guo, F.; Zhao, Q. 1D and 2D carbonation of fly ash concrete under flexural stress. J. Southeast Univ. 2007, 37, 118–122. [Google Scholar]

- Liu, W. Research on the Carbonation of Fly Ash Concrete Under the Action of Bending Load and Environment. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2008; pp. 29–31. [Google Scholar]

- Wang, J.-H.; Jiang, H.-D. Research on neutralization of steel fiber self-compacting concrete under multi-factor action. J. Nanjing Univ. Aeronaut. Astronsuol. 2013, 45, 260–265. [Google Scholar] [CrossRef]

- Yang, L.; Pan, H.; Zhu, Y.; Wu, Z. Experimental study of concrete’s carbonization resistance under combined action of factors. J. Build. Mater. 2008, 11, 345–348. [Google Scholar]

- Cai, C. Investigation and experimental study on the Relationship between surface carbonization and stress corrosion of aged concrete. Coagulation 2007, 6, 4–6. [Google Scholar]

- Luo, L.; Wu, X. Preliminary study on mechanical properties of concrete subjected to stress corrosion. J. Nanchang Hydraul. Eng. 1994, 13, 13–16. [Google Scholar]

- Zhang, C. Research on Prediction Model of Concrete Deterioration Process and Carbonation Depth under Coupling Effect of Stress and Carbonation. Ph.D. Thesis, China Building Materials Science Research Institute, Beijing, China, 2022. [Google Scholar]

- Wang, Q.; Niu, D. Corrosion of steel bars caused by carbonization; Durability Design and Construction of Concrete Structures. In Proceedings of the Science and Technology Forum on Safety and Durability of Civil Structure Engineering, Beijing, China, 15–17 October 2004. [Google Scholar]

- Marcotte, T.D.; Hansson, C.M. Corrosion products that form on steel within cement paste. Mater. Struct. 2018, 40, 325–340. [Google Scholar] [CrossRef]

- Liang, C.; Liu, T.; Xiao, J.; Zou, D.; Cui, C. Effect of reinforcement and its corrosion on damping of concrete Members. Eng. Mech. 2017, 34, 101–107. [Google Scholar]

- Zheng, Y.-Y.; Xu, Y.-D. Research progress on rust swelling and cracking of concrete protective layer. Concrete 2015, 6, 26–31. [Google Scholar]

- Zhang, C.; Shi, X.; Wang, L.; Yao, Y. Investigation on the air permeability and pore structure of concrete subjected to carbonation under compressive stress. Materials 2022, 15, 4775. [Google Scholar] [CrossRef]

- Wang, J.; Su, H.; Du, J. Influence of Coupled Effects between Flexural Tensile Stress and Carbonation Time on the Carbonation Depth of Concrete. Constr. Build. Mater. 2018, 190, 439–451. [Google Scholar] [CrossRef]

- Saito, M.; Imai, S. Direct tensile fatigue of concrete by the use of friction grips. ACI J. 1984, 80, 431–438. [Google Scholar]

- Xu, Y. The corrosion characteristics and tensile behavior of reinforcement under coupled carbonation and static loading. Materials 2015, 8, 8561–8577. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Chao, J.; Xianglin, G. Effect of carbonization on microporous characteristics and water absorption performance of concrete. J. Tongji Univ. 2024, 52, 567–573. [Google Scholar]

- Nayak, D.K.; Abhilash, P.P.; Singh, R.; Kumar, R.; Kumar, V. Fly ash for sustainable construction: A review of fly ash concrete and its beneficial use case studies. Clean. Mater. 2022, 6, 100143. [Google Scholar] [CrossRef]

- Sereewatthanawut, I.; Panwisawas, C.; Ngamkhanong, C. Effects of extended mixing processes on fresh, hardened and durable properties of cement systems incorporating fly ash. Sci. Rep. 2023, 13, 6091. [Google Scholar] [CrossRef]

- Liu, H.; Ma, H.; Liu, N.; Wu, B.; Yang, H.; Yang, W. Desert sand and fly ash on the properties of concrete carbonation resistance influence. J. Silic. Bull. 2017, 4, 3823–3828+3847. [Google Scholar]

- Chen, Z.; Hu, Y.; Zhao, Y.; Yu, B. Multi-factor calculation model of concrete carbonation depth based on material parameters in standard carbonation environment. Silic. Bull. 2019, 38, 1681–1687+1693. [Google Scholar]

- Bai, H.; Fan, Y.; Li, Y.; Dai, D. Regeneration of micro powder and mineral admixtures on the properties of concrete carbonation resistance impact study. J. Silic. Bull. 2020, 33, 2628–2633. [Google Scholar]

- Huang, Q.; Zhu, X.; Liu, D.; Zhao, L.; Zhao, M. Modification of water absorption and pore structure of high-volume fly ash cement pastes by incorporating nanosilica. J. Build. Eng. 2021, 33, 101638. [Google Scholar] [CrossRef]

- Win, T.T.; Prasittisopin, L.; Jongvivatsakul, P.; Likitlersuang, S. Investigating the synergistic effect of graphene nanoplatelets and fly ash on the mechanical properties and microstructure of calcium aluminate cement composites. J. Build. Eng. 2023, 78, 107710. [Google Scholar] [CrossRef]

| Concrete | FA (%) | Water Ash Ratio | Carbonization Depth (mm) | References | ||||

|---|---|---|---|---|---|---|---|---|

| 3 d | 7 d | 14 d | 28 d | 60 d | ||||

| OPC | 0 | 0.45 | 0.12 | 0.41 | 0.48 | 0.68 | [58] | |

| 15 | 0.45 | 0.92 | 1.45 | 1.78 | 2.35 | |||

| 30 | 0.35 | 0.74 | 1.13 | 1.56 | 1.85 | |||

| 0.45 | 1.67 | 2.78 | 3.55 | 4.38 | ||||

| 0.55 | 2.89 | 4.02 | 5.89 | 7.75 | ||||

| OPC | 20 | 0.4 | 0.1 | 0.2 | 0.3 | 0.4 | [57] | |

| 0.45 | 3 | 3.4 | 4.3 | 4.8 | ||||

| 0.5 | 12.3 | 17.1 | 25.3 | 30 | ||||

| 0.55 | 8.8 | 10.8 | 15.3 | 17.2 | ||||

| 30 | 0.4 | 0.6 | 0.9 | 2.2 | 4.3 | |||

| 0.45 | 4.6 | 5.3 | 5.9 | 6.4 | ||||

| 0.5 | 8.3 | 8.7 | 9.5 | 11.6 | ||||

| 0.55 | 9.6 | 12.9 | 14.2 | 14.5 | ||||

| 40 | 0.45 | 8.6 | 12.1 | 13.3 | 17.8 | |||

| 0.5 | 9.9 | 14.8 | 15.3 | 17.3 | ||||

| 0.55 | 12.2 | 15.8 | 18.5 | 27.3 | ||||

| 50 | 0.5 | 11.8 | 15 | 18.9 | 27.6 | |||

| 0.55 | 14.8 | 18.8 | 21.1 | 25.6 | ||||

| 60 | 0.5 | 30 | 33.2 | 50 | 50 | |||

| 0.55 | 30 | 50 | 50 | 50 | ||||

| PSC | 0 | 0.35 | 0 | 0 | 0 | 0 | [57] | |

| 0.4 | 0 | 0 | 0 | 0 | ||||

| 0.45 | 0.5 | 1.9 | 2.9 | 3.8 | ||||

| 0.5 | 3.1 | 4.5 | 4.6 | 4.8 | ||||

| 20 | 0.4 | 4.1 | 4.5 | 5.1 | 5.7 | |||

| 0.45 | 7.3 | 8.7 | 9.5 | 10.1 | ||||

| 0.5 | 9.7 | 11.1 | 11.7 | 12.9 | ||||

| 40 | 0.4 | 6.8 | 7.7 | 8.3 | 8.8 | |||

| 0.45 | 7.6 | 9.7 | 10.6 | 12.1 | ||||

| 0.5 | 10.3 | 11.6 | 13.3 | 15.2 | ||||

| PSC | 7 | 0.33 | 4.7 | 5.3 | 5.8 | 6.4 | [59] | |

| 0.35 | 5.9 | 6.5 | 7.1 | 7.6 | ||||

| 0.38 | 7.6 | 8.8 | 10.3 | 11.4 | ||||

| 0.49 | 8.8 | 11.6 | 14.1 | 18 | ||||

| OPC | 0 | 0.4 | 0 | 2.4 | 2.9 | 3.3 | [60] | |

| 0.5 | 3.1 | 3.9 | 3.9 | 8 | ||||

| 0.6 | 3.2 | 9.1 | 10.9 | 16 | ||||

| Researcher | Compressive Stress | Carbonation Depth (mm) | References |

|---|---|---|---|

| Zhang | 0 | 25.45 | [81] |

| 0.3 | 23.2 | ||

| 0.5 | 22.5 | ||

| 0.7 | 19.95 | ||

| Shi | 0 | 14.72 | [82] |

| 0.15 | 13.56 | ||

| 0.3 | 12.7 | ||

| 0.45 | 11.6 | ||

| 0.6 | 10.4 | ||

| 0.75 | 7.9 | ||

| Wu | 0 | 6.57 | [83] |

| 0.05 | 5.71 | ||

| 0.3 | 2.75 | ||

| 0.5 | 1.35 | ||

| Wang | 0 | 2.71 | [84] |

| 0.2 | 2.35 | ||

| 0.35 | 2.21 | ||

| 0.5 | 1.92 | ||

| Luo | 0 | 11.85 | [85] |

| 0.15 | 10.1 | ||

| 0.3 | 8.75 | ||

| 0.45 | 7.06 | ||

| 0.6 | 5.21 | ||

| 0.75 | 1.36 | ||

| Sun | 0 | 4.16 | [78] |

| 0.3 | 3.91 | ||

| 0.5 | 3.7 | ||

| Zhang | 0 | 17 | [72] |

| 0.25 | 16 | ||

| 0.5 | 15.01 | ||

| 0.75 | 15.61 | ||

| Xu | 0 | 1 | [77] |

| 0.1 | 0.87 | ||

| 0.3 | 0.78 |

| Researcher | Tensile Stress | Carbonation Depth (mm) | References |

|---|---|---|---|

| Zhang | 0 | 29 | [81] |

| 0.3 | 29.6 | ||

| 0.5 | 30.2 | ||

| 0.7 | 31 | ||

| Shi | 0 | 14.72 | [82] |

| 0.15 | 15.1 | ||

| 0.3 | 15.82 | ||

| 0.45 | 16.76 | ||

| 0.6 | 17.9 | ||

| 0.75 | 19.1 | ||

| Wu | 0 | 6.22 | [83] |

| 0.05 | 6.89 | ||

| 0.3 | 7.28 | ||

| 0.5 | 7.93 | ||

| Zhang | 0 | 8.5 | [86] |

| 0.2 | 9.1 | ||

| 0.35 | 10 | ||

| 0.5 | 11.4 | ||

| 0.65 | 12.8 | ||

| 0.8 | 14 | ||

| Liu | 0 | 1.12 | [87] |

| 0.2 | 1.59 | ||

| 0.4 | 2.16 | ||

| 0.6 | 2.56 | ||

| Wang | 0 | 2.71 | [84] |

| 0.3 | 2.87 | ||

| 0.5 | 3.12 | ||

| 0.7 | 3.42 | ||

| Luo | 0 | 11.86 | [85] |

| 0.15 | 12.41 | ||

| 0.3 | 13.54 | ||

| 0.45 | 15 | ||

| 0.6 | 16.8 | ||

| 0.75 | 18.57 | ||

| Sun | 0 | 4.20 | [78] |

| 0.15 | 4.59 | ||

| 0.3 | 4.89 | ||

| Zhang | 0 | 16.96 | [72] |

| 0.25 | 19.08 | ||

| 0.5 | 20.17 | ||

| 0.75 | 24 | ||

| Wang | 0.2 | 3.73 | [88] |

| 0.4 | 4.04 | ||

| 0.6 | 4.38 | ||

| Liu | 0 | 4.74 | [48] |

| 0.2 | 4.56 | ||

| 0.4 | 4.01 | ||

| 0.6 | 3.55 | ||

| Xu | 0 | 1 | [77] |

| 0.2 | 1.23 | ||

| 0.4 | 1.62 | ||

| 0.6 | 1.65 | ||

| 0.8 | 1.69 |

| Researcher | Compressive Stress | Carbonation Depth (mm) | References |

|---|---|---|---|

| Liu | 0 | 1.75 | [87] |

| 0.2 | 1.64 | ||

| 0.4 | 1.59 | ||

| 0.6 | 1.35 | ||

| Wang | 0.2 | 1.91 | [88] |

| 0.4 | 1.95 | ||

| 0.6 | 1.57 | ||

| Liu | 0 | 4.5 | [48] |

| 0.2 | 5.99 | ||

| 0.4 | 7.32 | ||

| 0.6 | 8.86 |

| Concrete | Compressive Stress Level | ||||

|---|---|---|---|---|---|

| 20% | 40% | 50% | 60% | 80% | |

| C20 | 23.26 | 17.58 | 15.32 | 12.99 | 10.82 |

| C40 | 31.38 | 24.26 | 17.15 | 15.33 | 12.32 |

| C60 | 40.43 | 32.49 | 24.87 | 21.01 | 19.32 |

| C80 | 65.34 | 50.65 | 46.57 | 43.18 | 40.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Sun, C.; Qu, J. Coupling Effects of Stress and Carbonation on Concrete Durability: A Review. Materials 2024, 17, 5438. https://doi.org/10.3390/ma17225438

Liu Z, Sun C, Qu J. Coupling Effects of Stress and Carbonation on Concrete Durability: A Review. Materials. 2024; 17(22):5438. https://doi.org/10.3390/ma17225438

Chicago/Turabian StyleLiu, Zhixin, Chaochao Sun, and Jili Qu. 2024. "Coupling Effects of Stress and Carbonation on Concrete Durability: A Review" Materials 17, no. 22: 5438. https://doi.org/10.3390/ma17225438

APA StyleLiu, Z., Sun, C., & Qu, J. (2024). Coupling Effects of Stress and Carbonation on Concrete Durability: A Review. Materials, 17(22), 5438. https://doi.org/10.3390/ma17225438