Hybrid Functional ITO/Silver Nanowire Transparent Conductive Electrodes for Enhanced Output Efficiency of Ultraviolet GaN-Based Light-Emitting Diodes

Abstract

1. Introduction

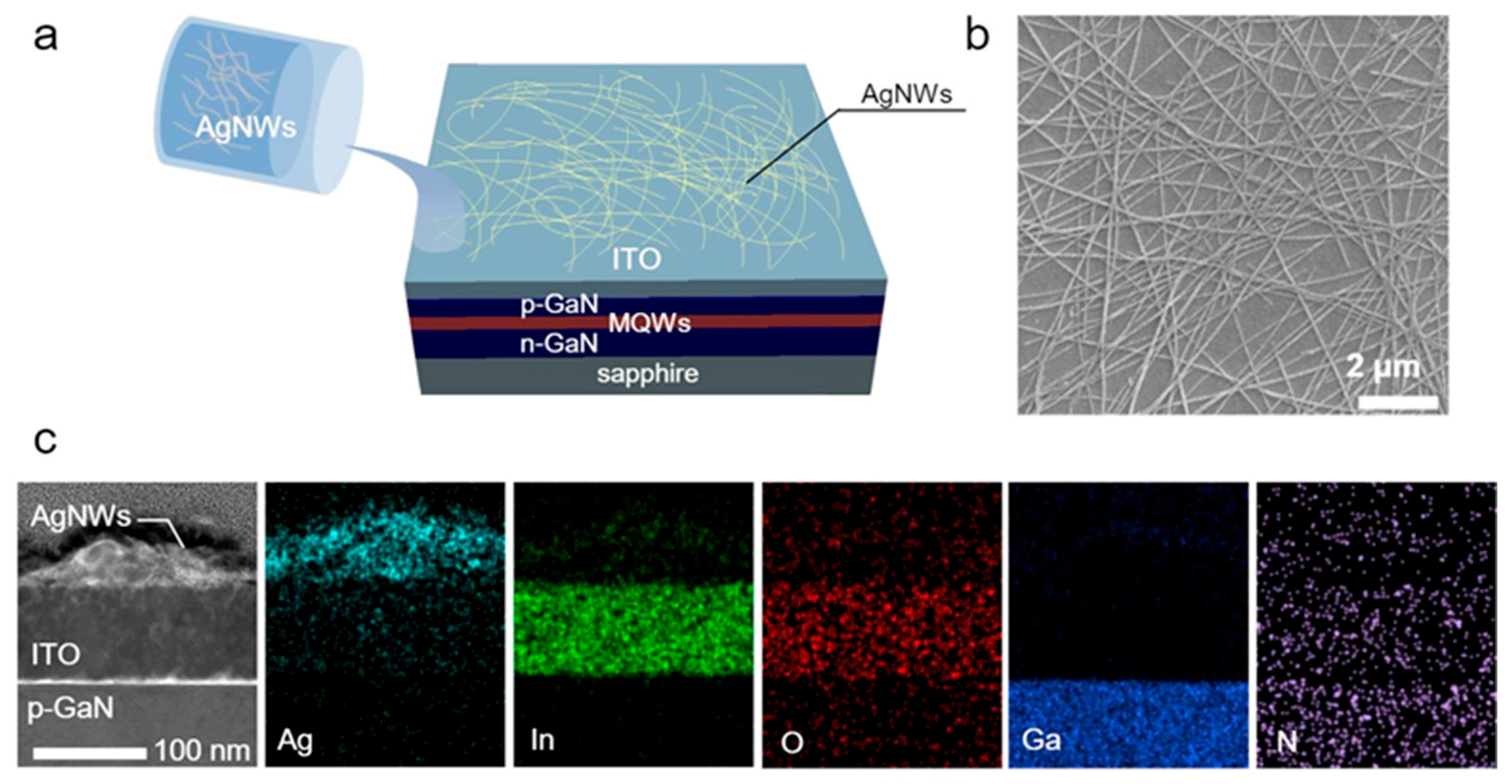

2. Materials and Methods

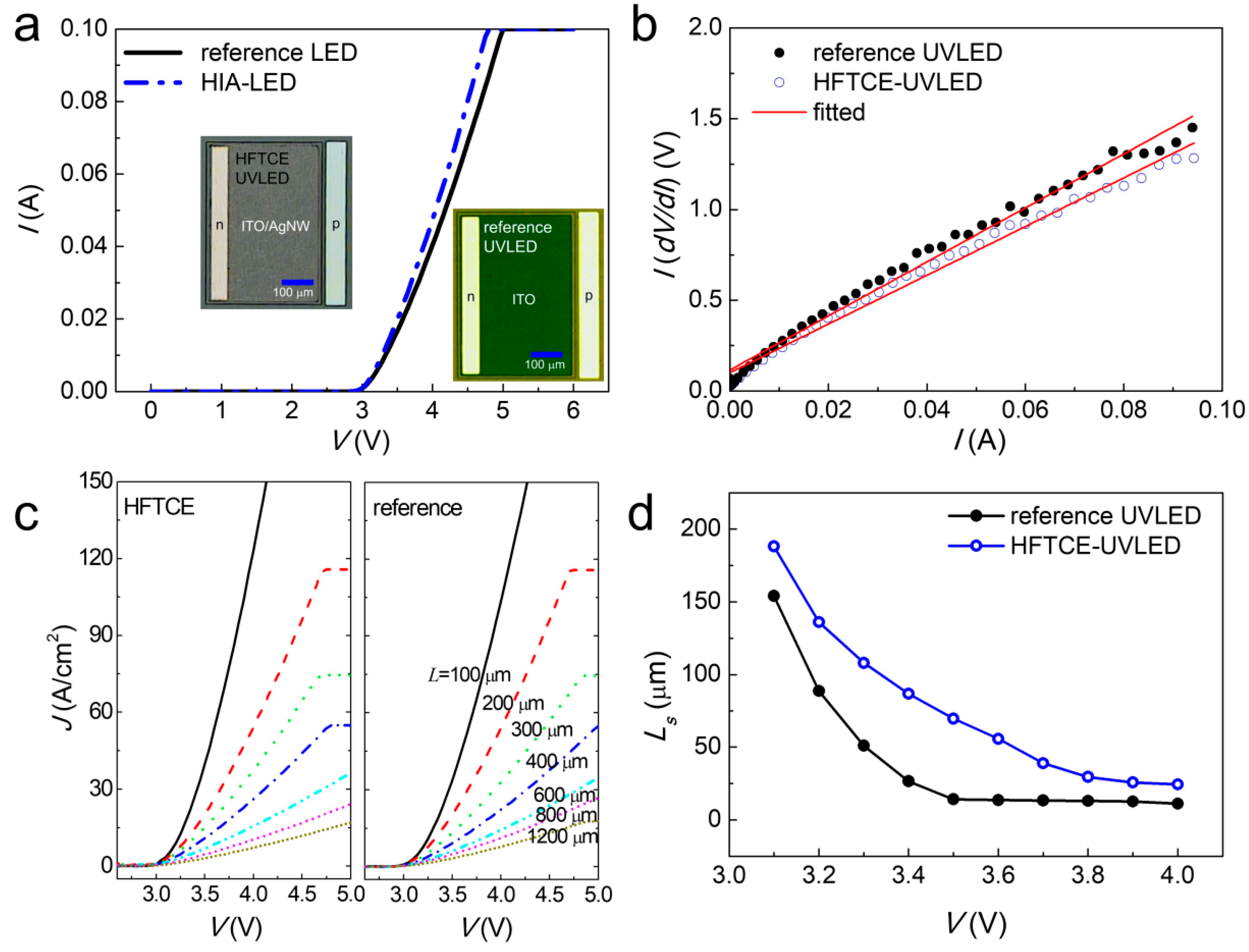

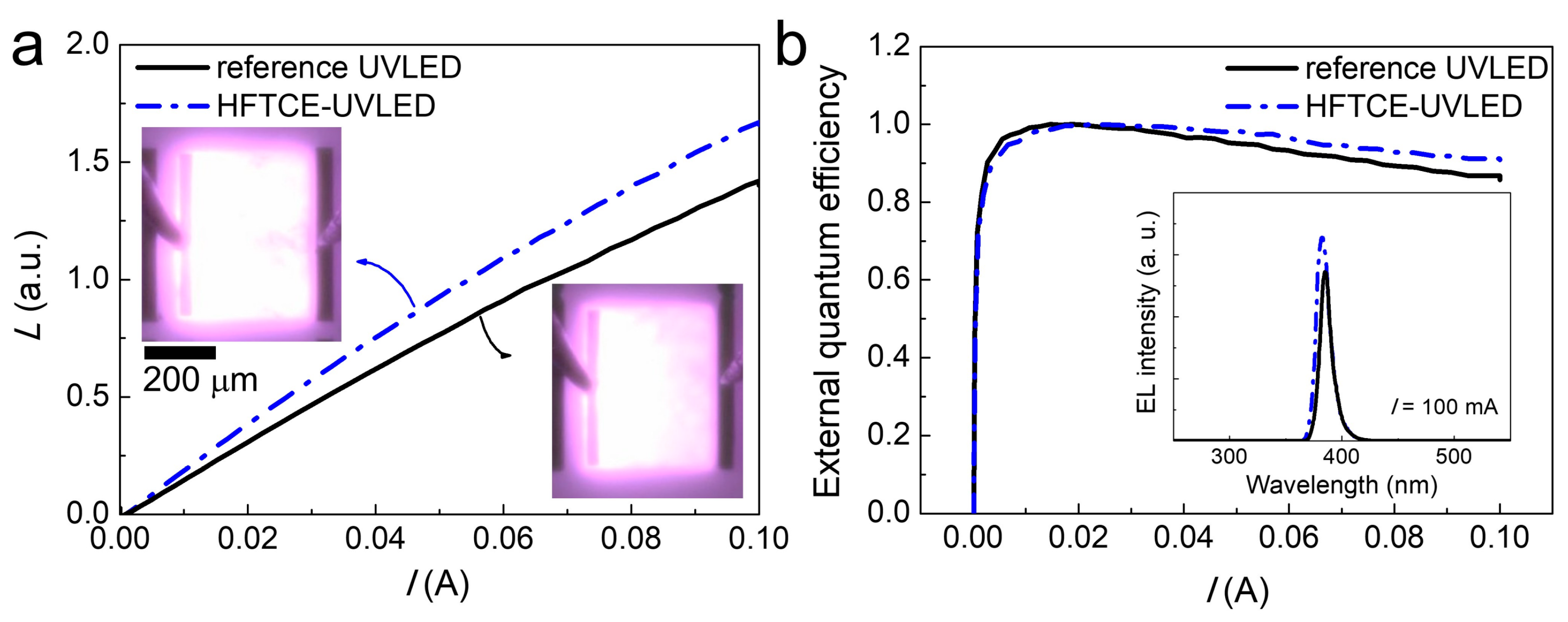

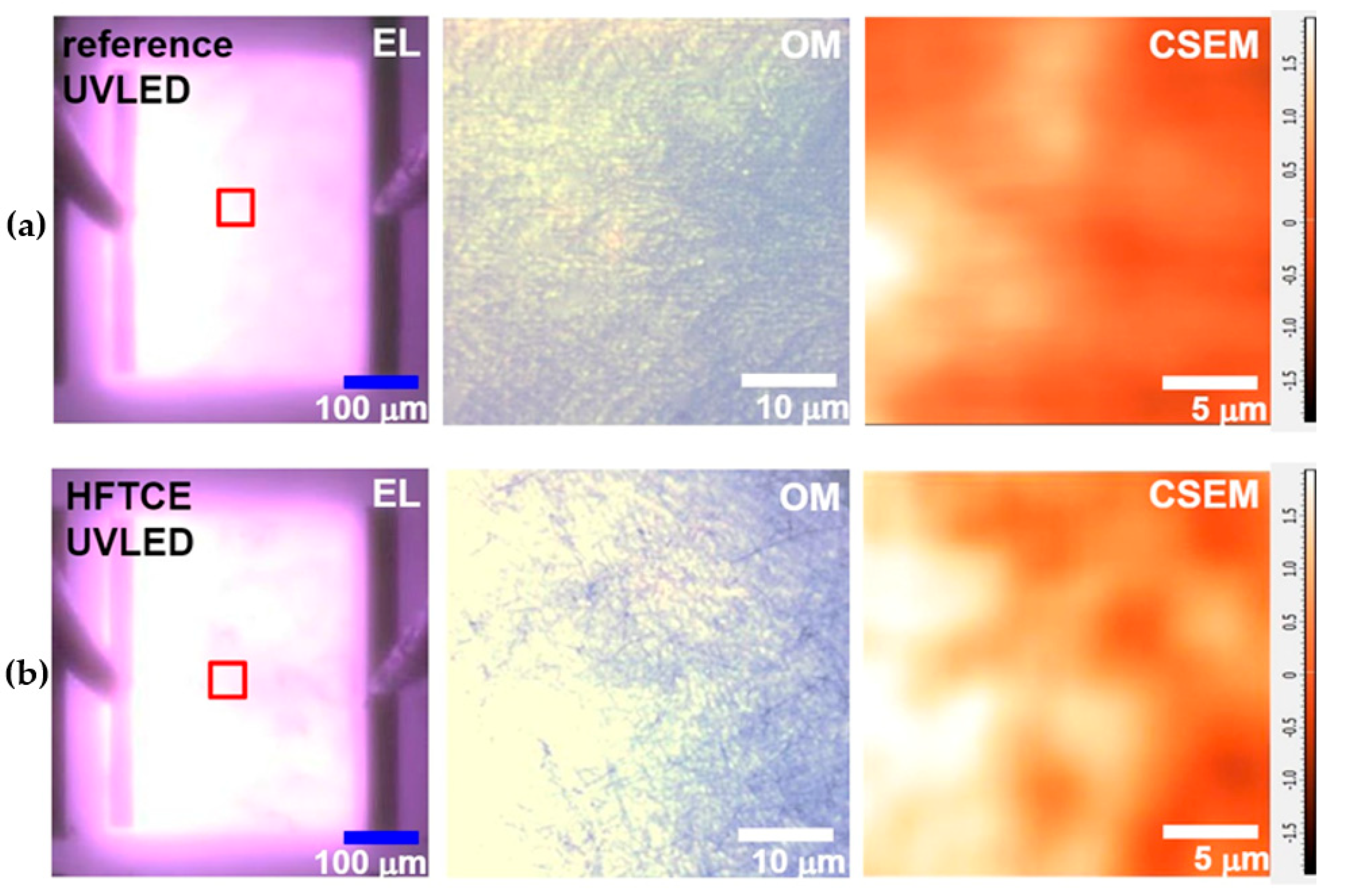

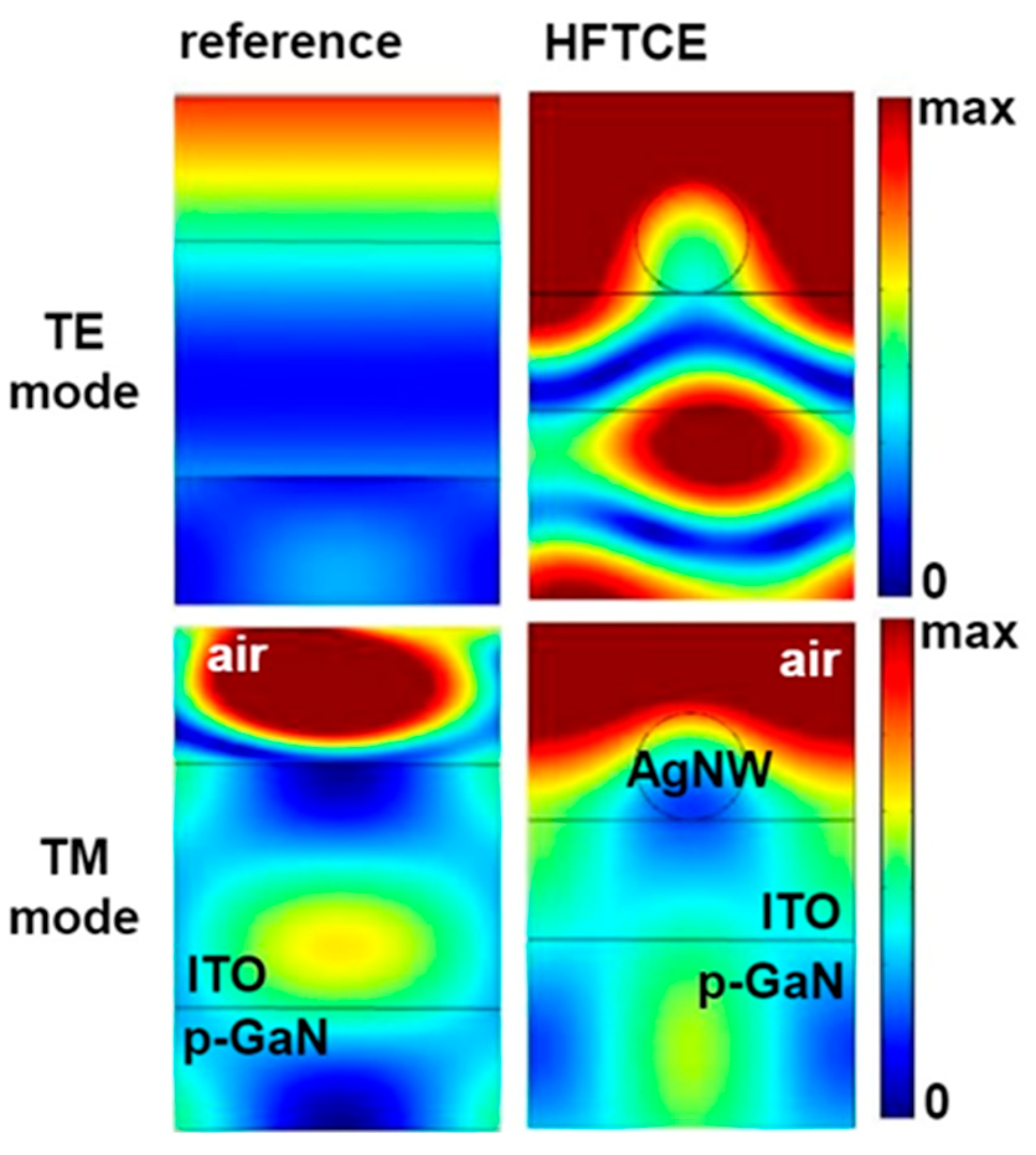

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, J.O.; Ha, J.-S.; Seong, T.-Y. Ohmic-Contact Technology for GaN-Based Light-Emitting Diodes: Role of P-Type Contact. IEEE Trans. Electron. Devices 2010, 57, 42–59. [Google Scholar] [CrossRef]

- Chen, J.; Brewer, W.D. Ohmic Contacts on p-GaN. Adv. Electron. Mater. 2015, 1, 1500113. [Google Scholar] [CrossRef]

- Margalith, T.; Buchinski, O.; Cohen, D.A.; Abare, A.C.; Hansen, M.; DenBaars, S.P.; Coldren, L.A. Indium Tin Oxide Contacts to Gallium Nitride Optoelectronic Devices. Appl. Phys. Lett. 1999, 74, 3930–3932. [Google Scholar] [CrossRef]

- Chang, K.-M.; Chu, J.-Y.; Cheng, C.-C. Investigation of Indium-Tin-Oxide Ohmic Contact to p-GaN and Its Application to High-Brightness GaN-Based Light-Emitting Diodes. Solid-State Electron. 2005, 49, 1381–1386. [Google Scholar] [CrossRef]

- Zahir, N.; Talik, N.A.; Harun, H.N.; Kamarundzaman, A.; Tunmee, S.; Nakajima, H.; Chanlek, N.; Shuhaimi, A.; Majid, W.H.A. Improved Performance of InGaN/GaN LED by Optimizing the Properties of the Bulk and Interface of ITO on p-GaN. Appl. Surf. Sci. 2021, 540, 148406. [Google Scholar] [CrossRef]

- Lee, K.; Wu, Z.; Chen, Z.; Ren, F.; Pearton, S.J.; Rinzler, A.G. Single Wall Carbon Nanotubes for P-type Ohmic Contacts to GaN Light-Emitting Diodes. Nano Lett. 2004, 4, 911–914. [Google Scholar] [CrossRef]

- Jo, G.; Choe, M.; Kim, J.H.; Park, W.; Lee, S.; Kim, W.K.; Park, S.J.; Hong, B.H.; Kahng, Y.H.; Lee, T. Large-Scale Patterned Multi-Layer Graphene Films as Transparent Conducting Electrodes for GaN Light-Emitting Diodes. Nanotechnology 2010, 21, 175201. [Google Scholar] [CrossRef]

- Geim, A.K. Graphene: Status and Prospects. Science 2009, 324, 1530–1534. [Google Scholar] [CrossRef]

- Jeon, D.-W.; Choi, W.M.; Shin, H.-J.; Yoon, S.-M.; Choi, J.-Y.; Jang, L.-W.; Lee, I.-H. Nanopillar InGaN/GaN Light Emitting Diodes Integrated with Homogeneous Multilayer Graphene Electrodes. J. Mater. Chem. 2011, 21, 17688–17692. [Google Scholar] [CrossRef]

- Kim, B.-J.; Lee, C.; Jung, Y.; Baik, K.H.; Mastro, M.A.; Hite, J.K.; Eddy, C.R.; Kim, J. Large-Area Transparent Conductive Few-Layer Graphene Electrode in GaN-Based Ultra-Violet Light-Emitting Diodes. Appl. Phys. Lett. 2011, 99, 143101. [Google Scholar] [CrossRef]

- Zhang, H.; Mischke, J.; Mertin, W.; Bacher, G. Graphene as a Transparent Conductive Electrode in GaN-Based LEDs. Materials 2022, 15, 2203. [Google Scholar] [CrossRef] [PubMed]

- Choe, M.; Cho, C.-Y.; Shim, J.-P.; Park, W.; Lim, S.K.; Hong, W.-K.; Hun Lee, B.; Lee, D.-S.; Park, S.-J.; Lee, T. Au Nanoparticle-Decorated Graphene Electrodes for GaN-Based Optoelectronic Devices. Appl. Phys. Lett. 2012, 101, 031115. [Google Scholar] [CrossRef]

- Seo, T.H.; Lee, K.J.; Park, A.H.; Hong, C.-H.; Suh, E.-K.; Chae, S.J.; Lee, Y.H.; Cuong, T.V.; Pham, V.H.; Chung, J.S.; et al. Enhanced Light Output Power of Near UV Light Emitting Diodes with Graphene/Indium Tin Oxide Nanodot Nodes for Transparent and Current Spreading Electrode. Opt. Express 2011, 19, 23111–23117. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Xu, S.; Liu, W.; Tao, H.; Su, H.; Hu, L.; Zhang, J.; Hao, Y. Enhanced Performance of GaN-Based Ultraviolet Light Emitting Diodes with ITO/Graphene/ITO Transparent Conductive Layer. Results Phys. 2023, 51, 106714. [Google Scholar] [CrossRef]

- Fan, X.; Xu, S.; Huang, Y.; Liu, W.; Tao, H.; Zhang, J.; Hao, Y. Improved Efficiency Droop of 370 nm UV LEDs with ITO/Au/ITO Structure. ECS J. Solid State Sci. Technol. 2023, 12, 096001. [Google Scholar] [CrossRef]

- Hrong, R.-H.; Zeng, Y.-Y.; Wang, W.-K.; Tsai, C.-L.; Fu, Y.-K.; Kuo, W.-H. Transparent Electrode Design for AlGaN Deep-Ultraviolet Light-Emitting Diodes. Opt. Exp. 2017, 25, 32206–32213. [Google Scholar] [CrossRef]

- Sheikhi, M.; Xu, H.; Jiang, J.; Wu, S.; Yang, X.; Yang, Z.; Liao, M.; Guo, W.; Ye, J. GaN Based UV-LEDs with Ni/Au Nanomeshes as Transparent P-type Electrodes. Phys. Status Solidi A 2019, 216, 1800684. [Google Scholar] [CrossRef]

- Xie, C.X.; Wei, W.; Zhou, Y. Large-Area Flexible Organic Solar Cells with a Robust Silver Nanowire-Polymer Composite as Transparent Top Electrode. Adv. Funct. Mater. 2023, 33, 2210675. [Google Scholar] [CrossRef]

- Zhou, J.; Li, S.; Lv, X.; Li, X.; Li, Y.; Zheng, Y.-Z.; Tao, X. Ultra-Low-Cost All-Air Processed Carbon-Based Perovskite Solar Cells from Bottom Electrode to Counter Electrode. J. Power Sources 2020, 478, 228764. [Google Scholar] [CrossRef]

- Jeong, G.-J.; Lee, J.-H.; Han, S.-H.; Jin, W.-Y.; Kang, J.-W.; Lee, S.-N. Silver Nanowires for Transparent Conductive Electrode to GaN-Based Light-Emitting Diodes. Appl. Phys. Lett. 2015, 106, 031118. [Google Scholar] [CrossRef]

- Oh, M.; Jin, W.-Y.; Jeong, H.J.; Jeong, M.S.; Kang, J.-W.; Kim, H. Silver Nanowire Transparent Conductive Electrodes for High-Efficiency III-Nitride Light-Emitting Diodes. Sci. Rep. 2015, 5, 13483. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Ma, J.; Xu, H.; Wang, C.; Liu, Y. Fabrication of Silver Nanowires and Metal Oxide Composite Transparent Electrodes and Their Application in UV Light-Emitting Diodes. J. Phys. D Appl. Phys. 2016, 49, 325103. [Google Scholar] [CrossRef]

- Song, M.; Kim, J.-K.; Yang, S.-Y.; Kang, J.-W. Transport and Magnetic Properties of ZnCo2O4/Si Heterostructures Grown by Radio Frequency Magnetron Sputtering. Thin Solid Film. 2014, 573, 14–17. [Google Scholar] [CrossRef]

- Seo, T.H.; Lee, S.; Min, K.H.; Chandramohan, S.; Park, A.H.; Lee, G.H.; Park, M.; Suh, E.-K.; Kim, M.J. The Role of Graphene Formed on Silver Nanowire Transparent Conductive Electrode in Ultra-Violet Light Emitting Diodes. Sci. Rep. 2016, 6, 29464. [Google Scholar] [CrossRef]

- Park, J.-S.; Kim, J.-H.; Kim, J.-Y.; Kim, D.-H.; Na, J.-Y.; Kim, S.-K.; Kang, D.; Seong, T.-Y. Formation of an Indium Tin Oxide Nanodot/Ag Nanowire Electrode as a Current Spreader for Near Ultraviolet AlGaN-Based Light-Emitting Diodes. Nanotechnology 2016, 28, 045205. [Google Scholar] [CrossRef]

- Park, J.-S.; Kim, J.-H.; Kim, J.-Y.; Kim, D.-H.; Kang, D.; Sung, J.-S.; Seong, T.-Y. Hybrid Indium Tin Oxide/Ag Nanowire Electrodes for Improving the Light Output Power of Near Ultraviolet AlGaN-Based Light-Emitting Diode. Curr. Appl. Phys. 2016, 16, 545–548. [Google Scholar] [CrossRef]

- Okamoto, K.; Niki, I.; Shvartser, A.; Narukawa, Y.; Mukai, T.; Scherer, A. Surface-Plasmon-Enhanced Light Emitters Based on InGaN Quantum Wells. Nat. Mater. 2004, 3, 601–605. [Google Scholar] [CrossRef]

- Kwon, M.-K.; Kim, J.-Y.; Kim, B.-H.; Park, I.-K.; Cho, C.-Y.; Byeon, C.C.; Park, S.-J. Surface-Plasmon-Enhanced Light-Emitting Diodes. Adv. Mater. 2008, 20, 1253–1257. [Google Scholar] [CrossRef]

- Oh, T.S.; Jeong, H.; Lee, Y.S.; Park, A.H.; Seo, T.H.; Kim, H.; Lee, K.J.; Jeong, M.S.; Suh, E.-K. Light Outcoupling Effect in GaN Light-Emitting Diodes via Convex Microstructures Monolithically Fabricated on Sapphire Substrate. Opt. Exp. 2011, 19, 9385–9391. [Google Scholar] [CrossRef]

- Jeong, H.; Park, D.J.; Lee, H.S.; Ko, Y.H.; Yu, J.S.; Choi, S.-B.; Lee, D.-S.; Suh, E.-K.; Jeong, M.S. Light-Extraction Enhancement of a GaN-Based LED Covered with ZnO Nanorod Arrays. Nanoscale 2014, 6, 4371–4378. [Google Scholar] [CrossRef]

- Hu, L.; Kim, H.S.; Lee, J.-Y.; Peumans, P.; Cui, Y. Scalable Coating and Properties of Transparent, Flexible, Silver Nanowire Electrodes. ACS Nano 2010, 4, 2955–2963. [Google Scholar] [CrossRef] [PubMed]

- Schubert, E.F. Light-Emitting Diodes, 2nd ed.; Cambridge University Express: Cambridge, UK, 2006; pp. 83–84. [Google Scholar]

- Kim, H.; Lee, S.-N. Theoretical Considerations on Current Spreading in GaN-Based Light Emitting Diodes Fabricated with Top-Emission Geometry. J. Electrochem. Soc. 2010, 157, H562–H564. [Google Scholar] [CrossRef]

- Kim, M.-H.; Schubert, M.F.; Dai, Q.; Kim, J.K.; Schubert, E.F.; Piprek, J.; Park, Y. Origin of Efficiency Droop in GaN-Based Light-Emitting Diodes. Appl. Phys. Lett. 2007, 91, 183507. [Google Scholar] [CrossRef]

- Piprek, J. Efficiency Droop in Nitride-Based Light-Emitting Diodes. Phys. Status Solidi A 2010, 207, 2217–2225. [Google Scholar] [CrossRef]

- Tian, P.; McKendry, J.J.D.; Gong, Z.; Guilhabert, B.; Watson, I.M.; Gu, E.; Chen, Z.; Zhang, G.; Dawson, M.D. Size-Dependent Efficiency and Efficiency Droop of Blue InGaN Micro-Light Emitting Diodes. Appl. Phys. Lett. 2012, 101, 231110. [Google Scholar] [CrossRef]

- Lee, I.-H.; Jang, L.-W.; Polyakov, A.Y. Performance enhancement of GaN-Based Light Emitting Diodes by the Interaction with Localized Surface Plasmons. Nano Energy 2015, 13, 140–173. [Google Scholar] [CrossRef]

- Yao, Y.-C.; Hwang, J.-M.; Yang, Z.-P.; Haung, J.-Y.; Lin, C.-C.; Shen, W.-C.; Chou, C.-Y.; Wang, M.-T.; Huang, C.-Y.; Chen, C.-Y.; et al. Enhanced External Quantum Efficiency in GaN-Based Vertical-Type Light-Emitting Diodes by Localized Surface Plasmons. Sci. Rep. 2016, 6, 22659. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, M.; Jeong, M.S.; Cho, J.; Kim, H. Hybrid Functional ITO/Silver Nanowire Transparent Conductive Electrodes for Enhanced Output Efficiency of Ultraviolet GaN-Based Light-Emitting Diodes. Materials 2024, 17, 5385. https://doi.org/10.3390/ma17215385

Oh M, Jeong MS, Cho J, Kim H. Hybrid Functional ITO/Silver Nanowire Transparent Conductive Electrodes for Enhanced Output Efficiency of Ultraviolet GaN-Based Light-Emitting Diodes. Materials. 2024; 17(21):5385. https://doi.org/10.3390/ma17215385

Chicago/Turabian StyleOh, Munsik, Mun Seok Jeong, Jaehee Cho, and Hyunsoo Kim. 2024. "Hybrid Functional ITO/Silver Nanowire Transparent Conductive Electrodes for Enhanced Output Efficiency of Ultraviolet GaN-Based Light-Emitting Diodes" Materials 17, no. 21: 5385. https://doi.org/10.3390/ma17215385

APA StyleOh, M., Jeong, M. S., Cho, J., & Kim, H. (2024). Hybrid Functional ITO/Silver Nanowire Transparent Conductive Electrodes for Enhanced Output Efficiency of Ultraviolet GaN-Based Light-Emitting Diodes. Materials, 17(21), 5385. https://doi.org/10.3390/ma17215385