Study on Dynamic Characteristics of Resilient Mount Under Preload

Abstract

1. Introduction

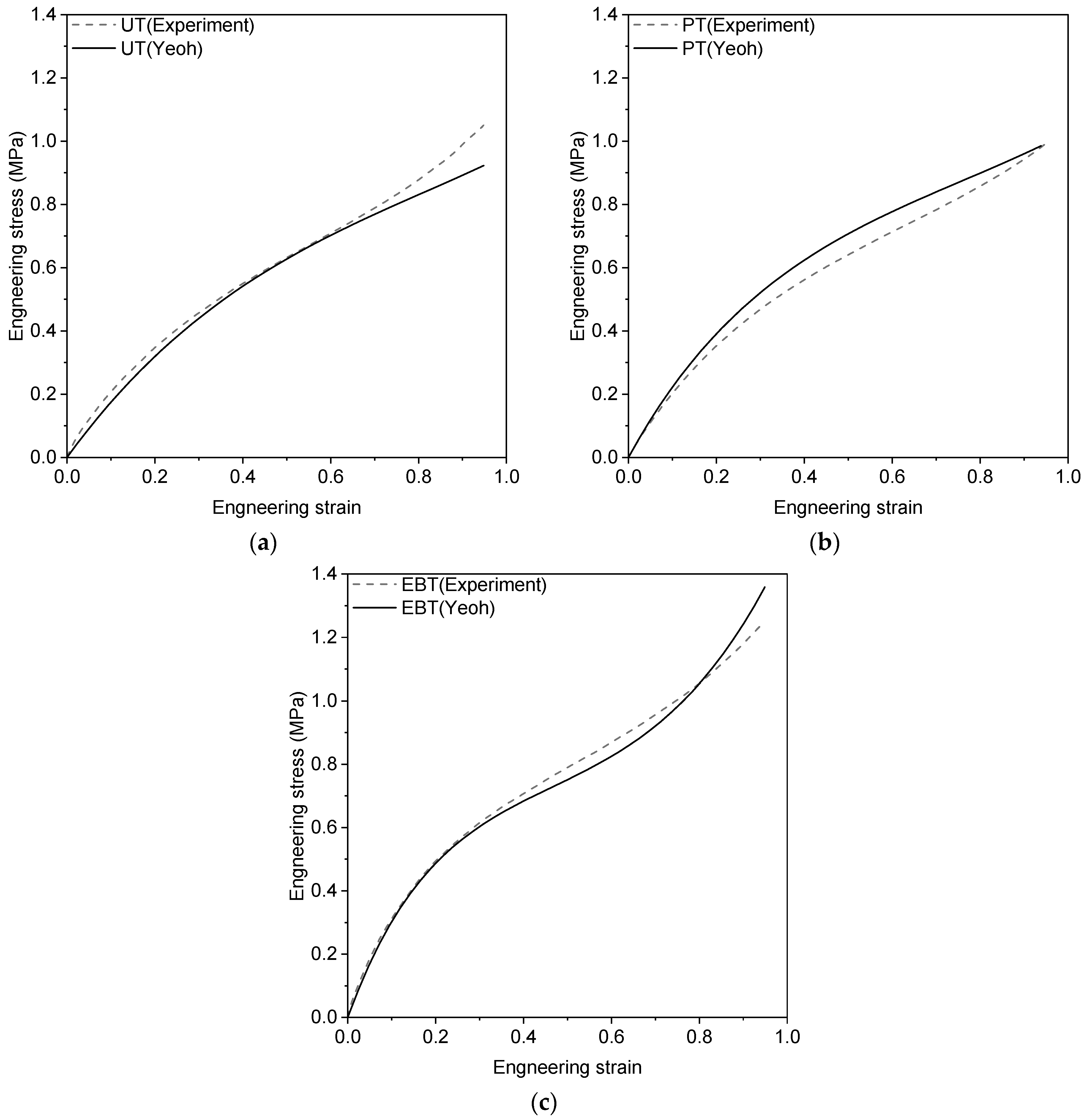

2. Parameters Identification of Hyperelastic Material

2.1. Yeoh Model

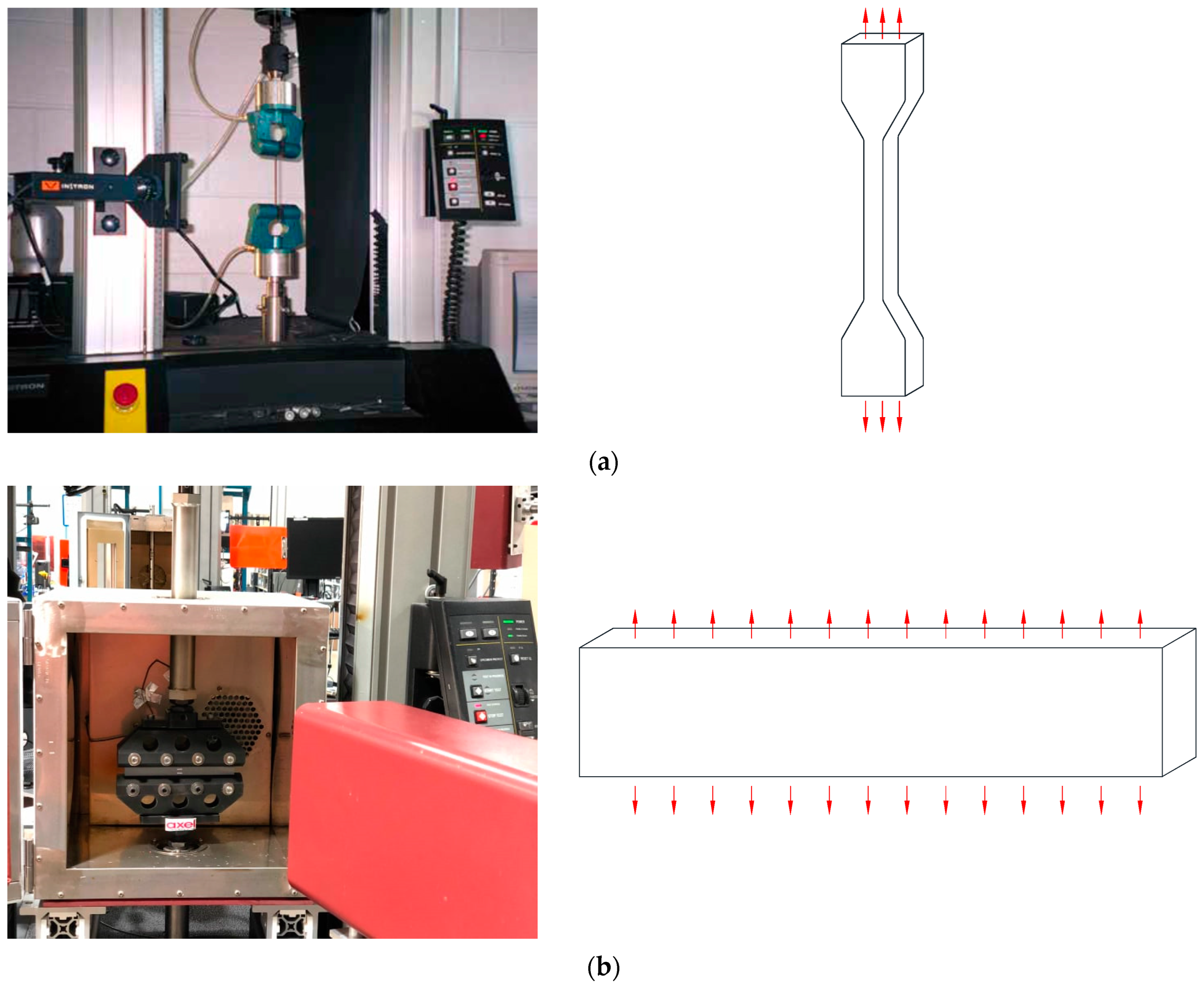

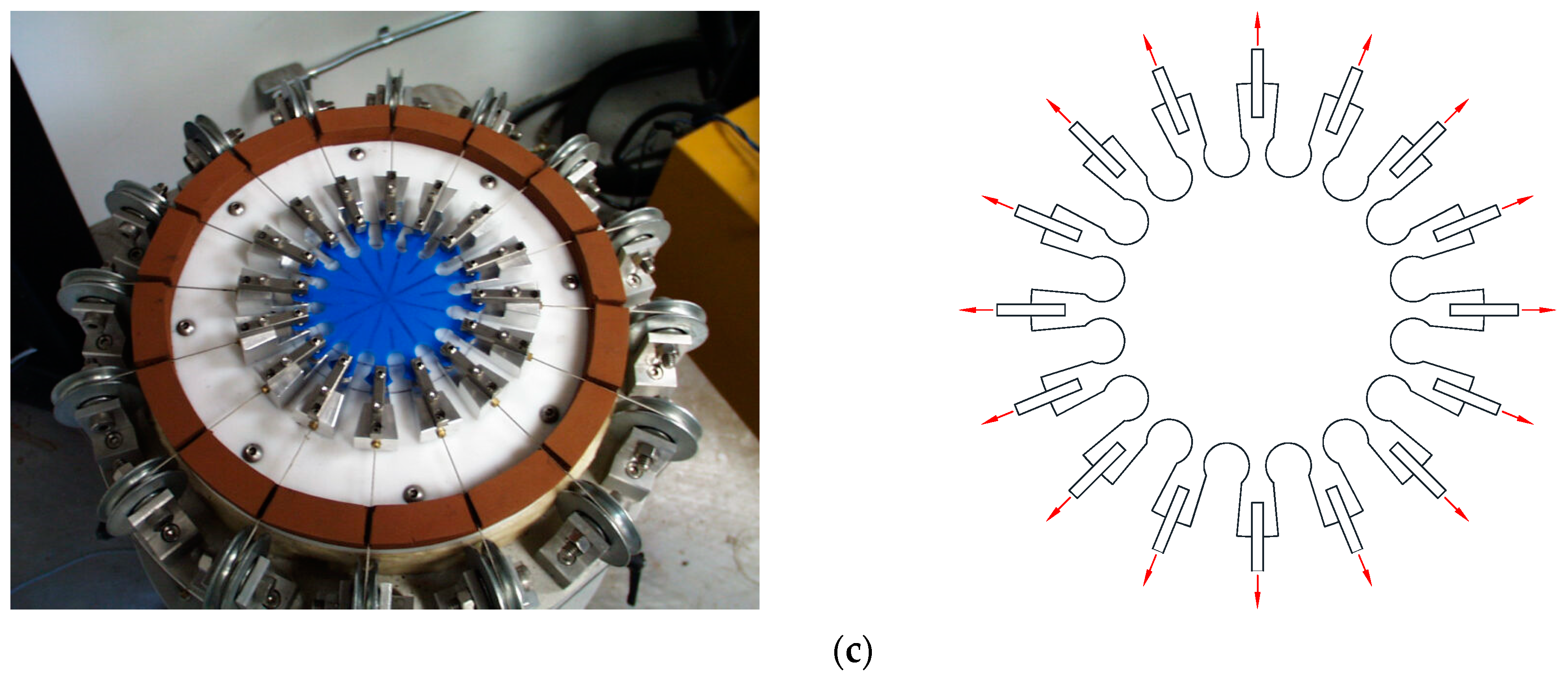

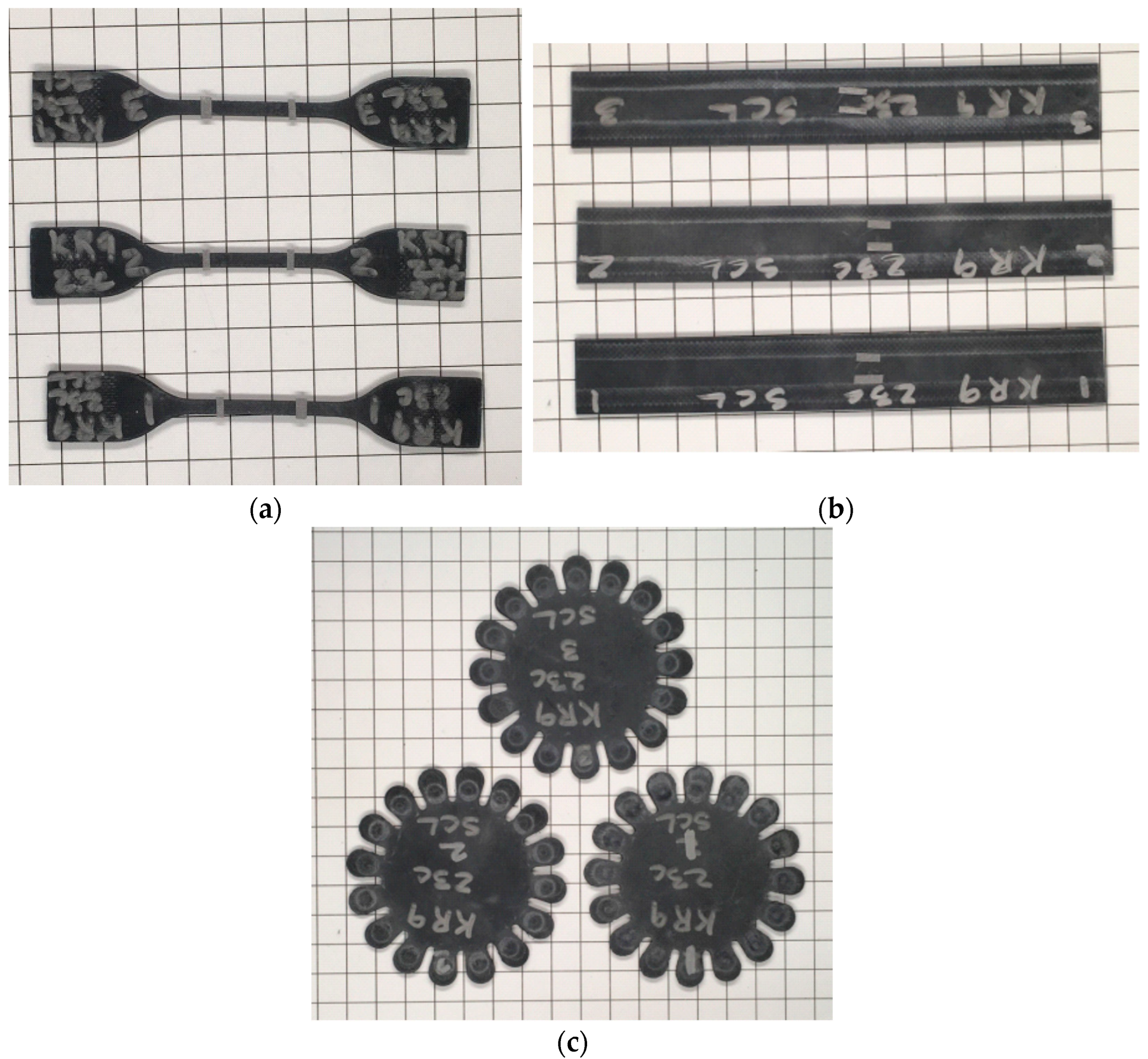

2.2. Quasi-Static Tests

2.3. Calibration of Yeoh Model Parameter

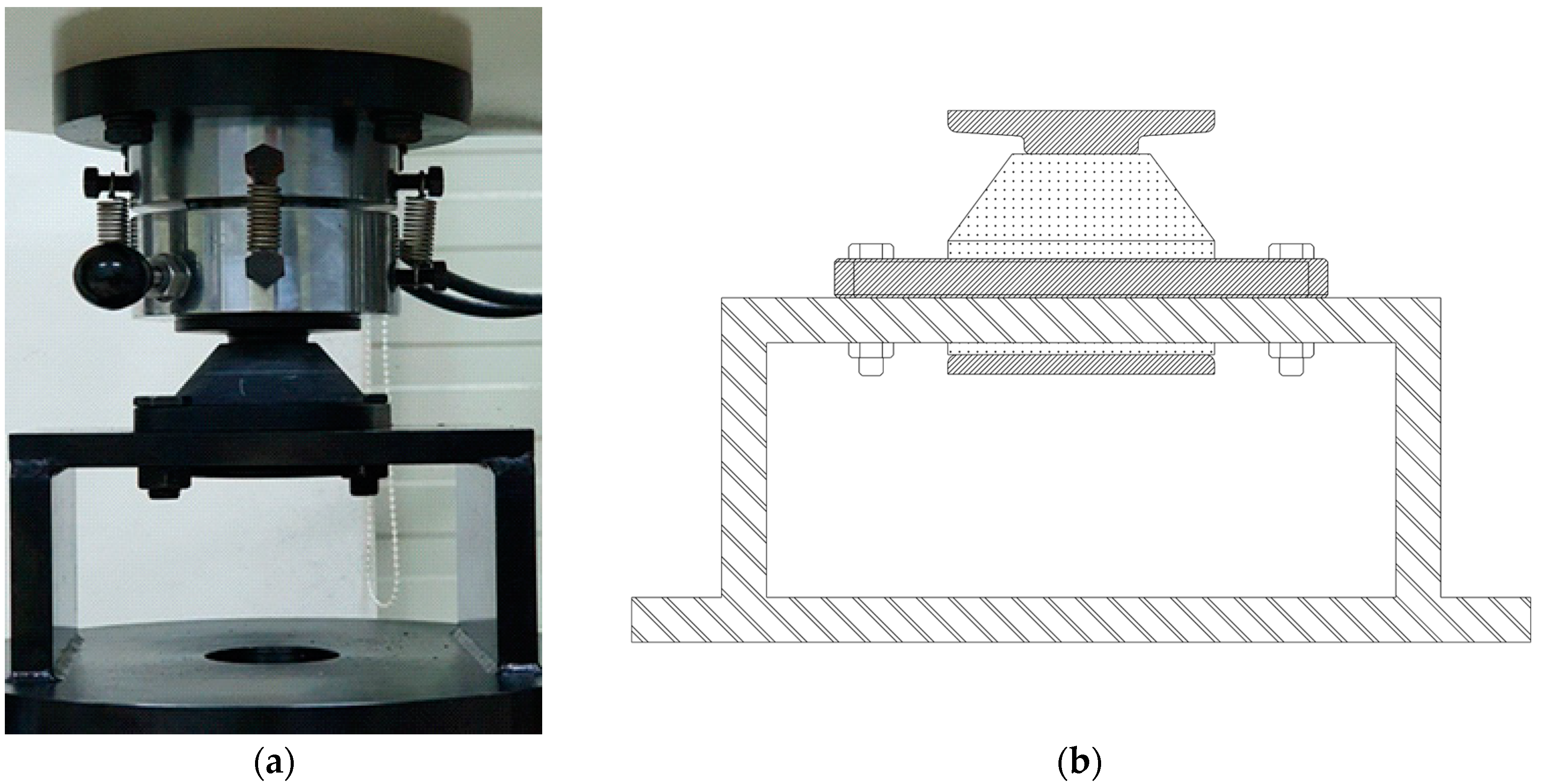

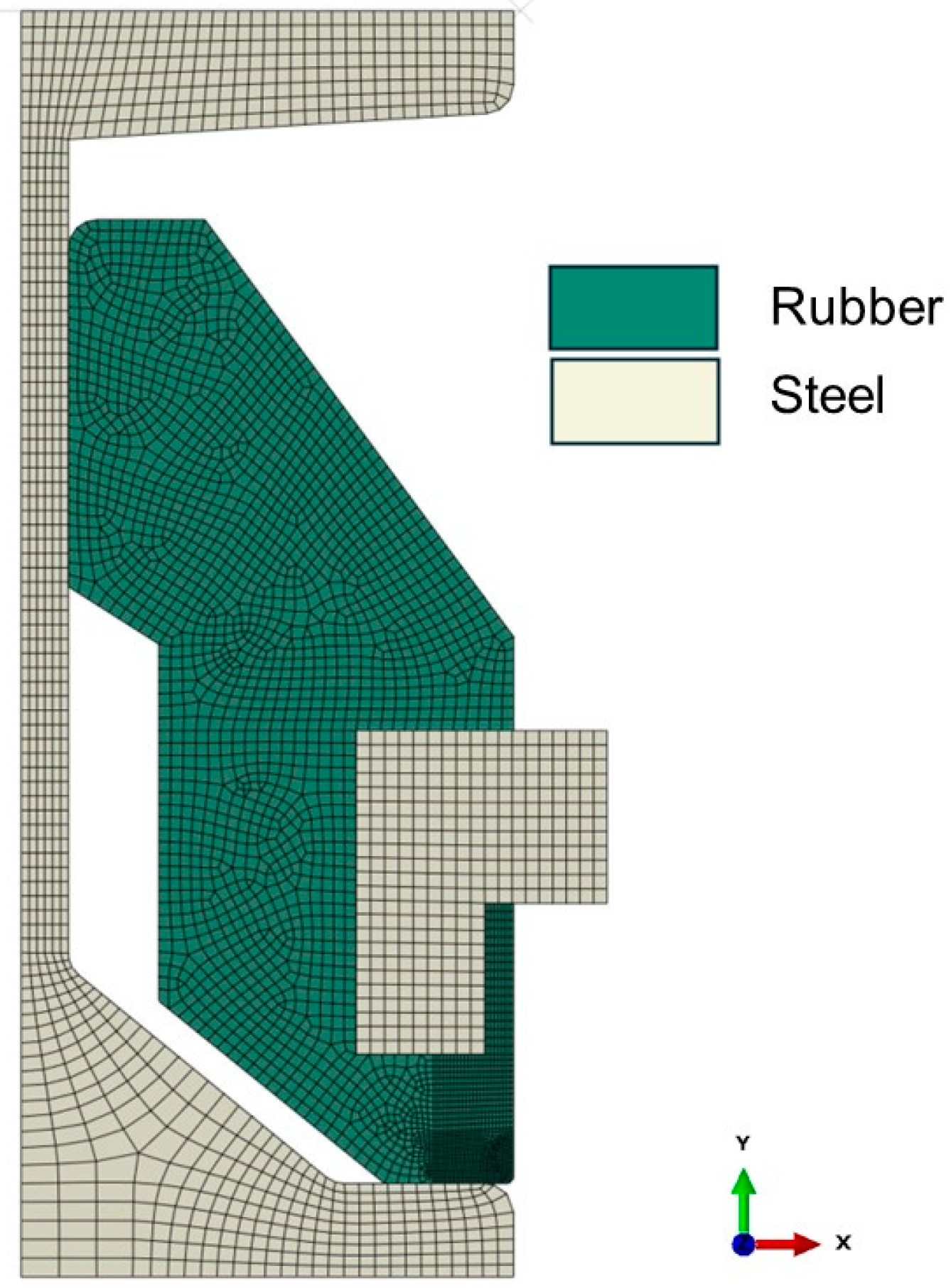

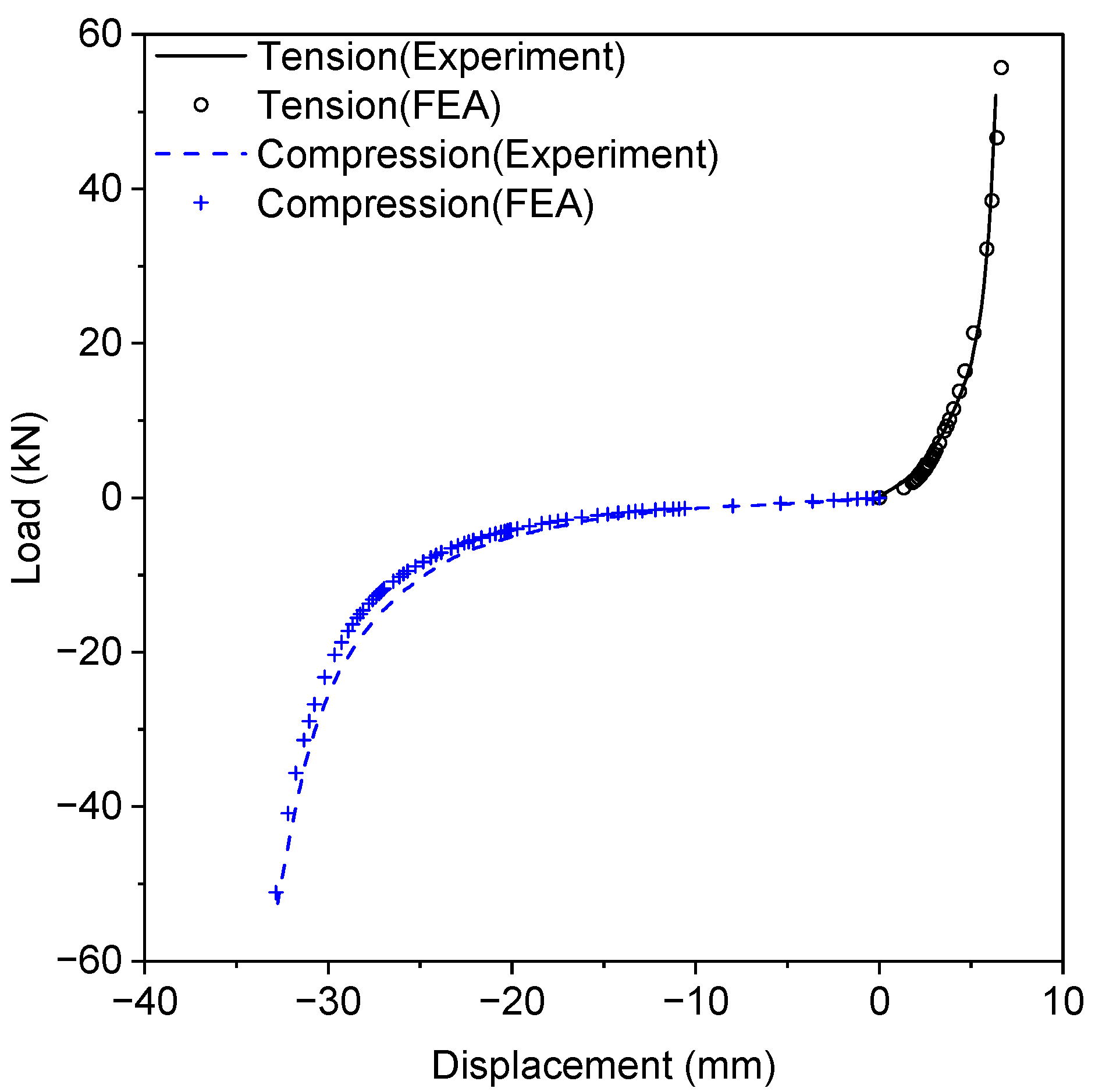

3. Validation of Static Mechanical Behavior

3.1. Description of Static Test for Resilient Mount

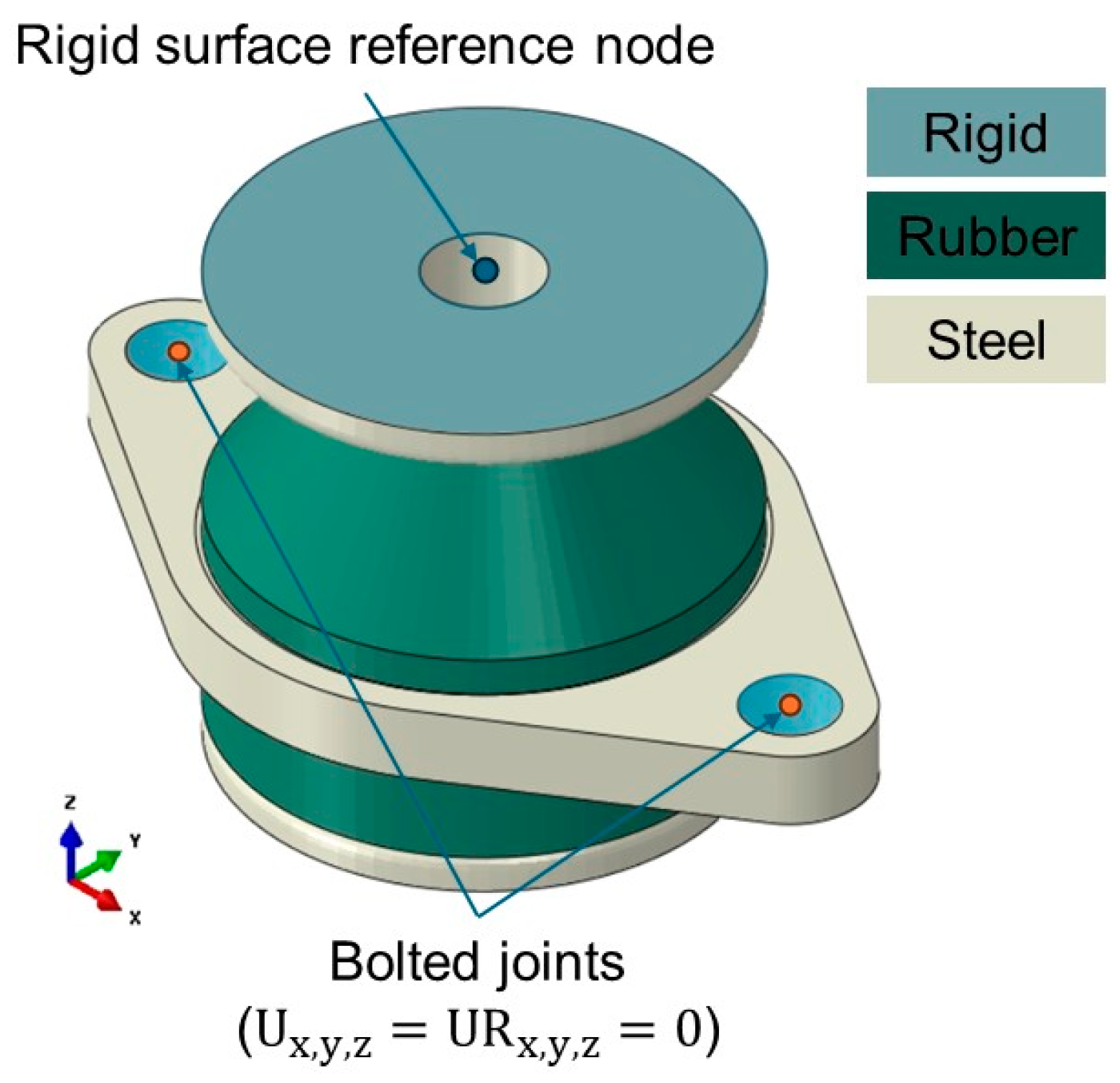

3.2. Finite Element Analysis

4. Dynamic Characterization of Resilient Mount

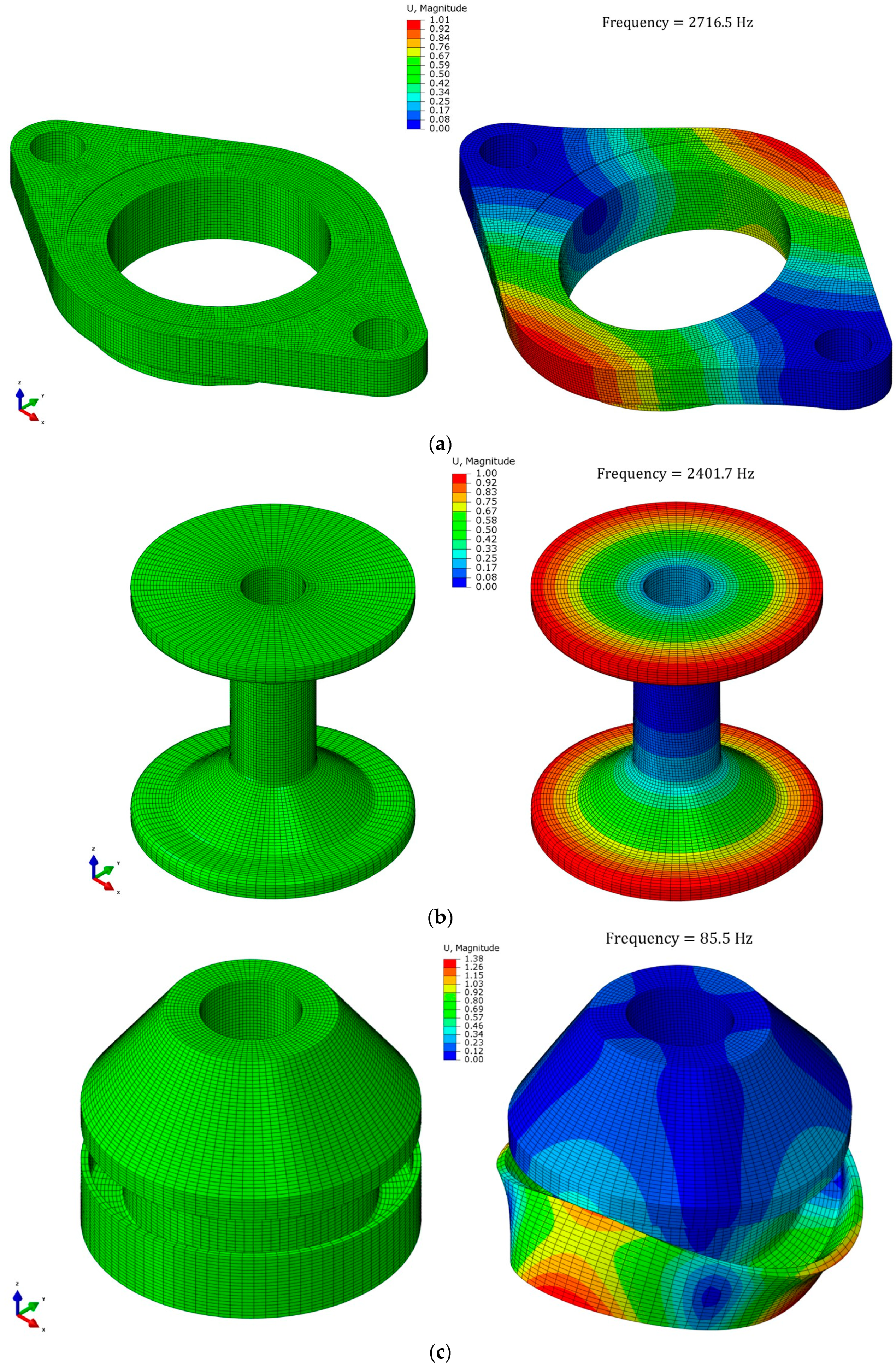

4.1. Modal Behavior of the Resilient Mount Parts

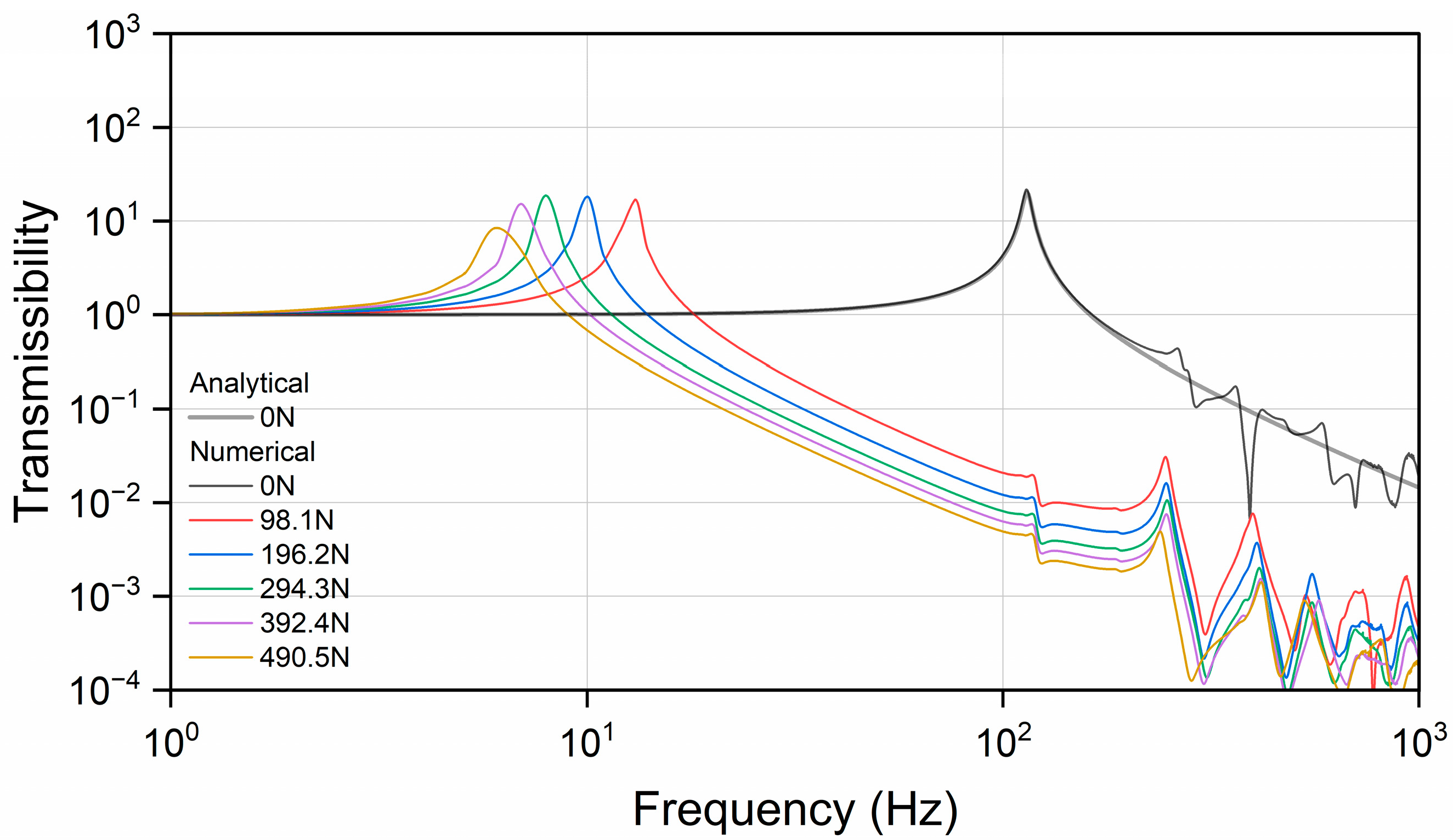

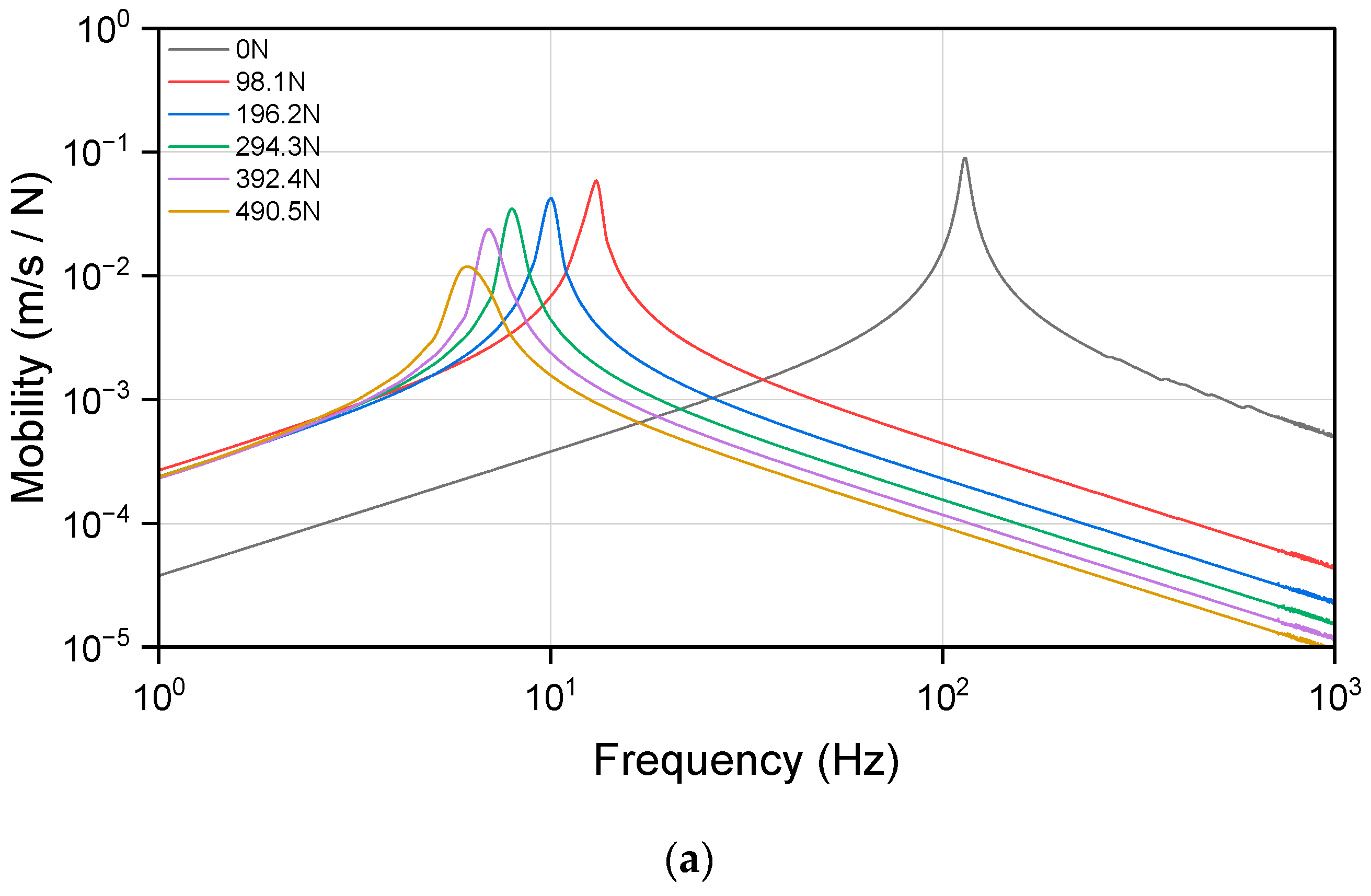

4.2. Dynamic Simulation for the Resilient Mount

5. Conclusions

- Quasi-static tests (uniaxial tension, planar tension, and equi-biaxial tension) were conducted to investigate the static behavior of the rubber material used in resilient mounts. These tests provided essential data for calibrating the Yeoh hyperelastic model.

- The Yeoh hyperelastic model was calibrated using the experimental data. The calibrated model was then validated through comparison with tension and compression tests performed on an actual resilient mount, showing good agreement between numerical simulations and experimental results.

- Modal analyses of the individual components (center plate, flange, and rubber element) provided insights into their frequency characteristics, with the rubber element showing significantly lower natural frequencies compared to the steel components.

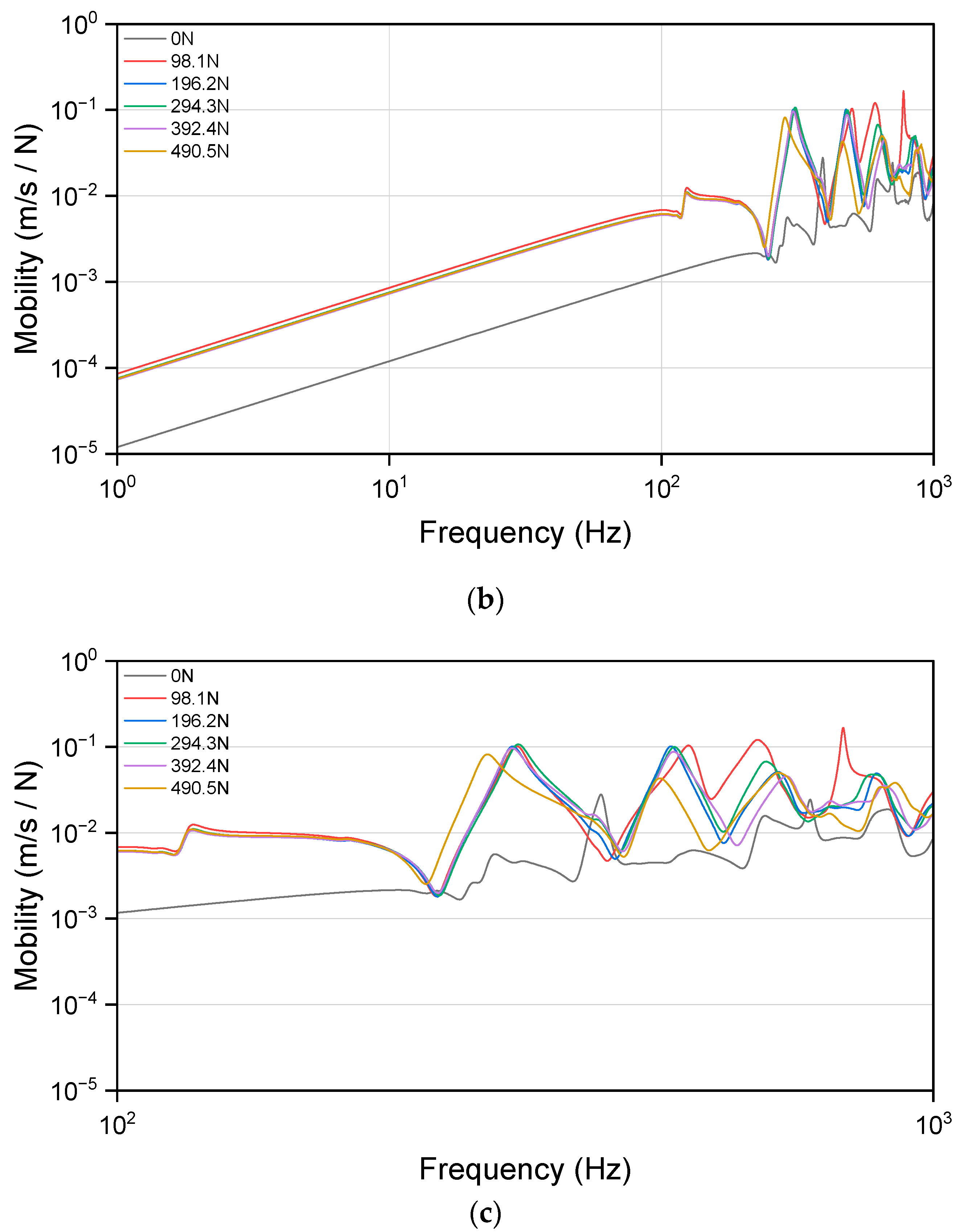

- Frequency response analysis was conducted under various preloading conditions to investigate the dynamic behavior of the resilient mount. The results demonstrated that the transmissibility curves shifted to lower frequencies with increasing preload, highlighting the significant influence of the static state of stress on the dynamic properties of rubber-isolating elements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kari, L. Dynamic Transfer Stiffness Measurements of Vibration Isolators in the Audible Frequency Range. Noise Control Eng. J. 2001, 49, 88. [Google Scholar] [CrossRef]

- Amin, A.F.; Wiraguna, S.I.; Bhuiyan, A.R.; Okui, Y. Hyperelasticity Model for Finite Element Analysis of Natural and High Damping Rubbers in Compression and Shear. J. Eng. Mech. 2006, 132, 54–64. [Google Scholar] [CrossRef]

- Sasso, M.; Palmieri, G.; Chiappini, G.; Amodio, D. Characterization of Hyperelastic Rubber-like Materials by Biaxial and Uniaxial Stretching Tests Based on Optical Methods. Polym. Test. 2008, 27, 995–1004. [Google Scholar] [CrossRef]

- Lee, Y.H.; Kim, J.S.; Kim, K.J.; Ahn, T.; Choi, B.I.; Lee, H.J.; Woo, C.S.; Kim, K.S. Prediction of Dynamic Stiffness on Rubber Components Considering Preloads. Mater. Werkst. 2013, 44, 372–379. [Google Scholar] [CrossRef]

- Ritto, T.G.; Nunes, L.C.S. Bayesian Model Selection of Hyperelastic Models for Simple and Pure Shear at Large Deformations. Comput. Struct. 2015, 156, 101–109. [Google Scholar] [CrossRef]

- Akyüz, S.; Darı, M.E.; Esiyok, Y.E.; Ermeydan, M.A. Effects of NR/SBR Ratio on Mechanical Properties and Artificial Mechanical Performance of Anti-Vibration Bushings. Iran. Polym. J. (Engl. Ed.) 2021, 30, 1317–1328. [Google Scholar] [CrossRef]

- Kamaruddin, S.; Chai, A.B.; Lim, C.L.; Ho, J.-H. Characterisation of Static and Dynamic Responses of Natural Rubber Bio-Composites. J. Phys. Conf. Ser. 2017, 908, 012028. [Google Scholar] [CrossRef]

- Luo, R.K.; Wang, W.; Xu, Q.; Li, X. An Energy Dissipation Approach on Complete Loading-Unloading and Dynamic Impact Predictions with Experimental Verification for Rubber Anti-Vibration Component. Polym. Test. 2017, 63, 314–322. [Google Scholar] [CrossRef]

- Íñiguez-Macedo, S.; Lostado-Lorza, R.; Escribano-García, R.; Martínez-Calvo, M. Finite Element Model Updating Combined with Multi-Response Optimization for Hyper-Elastic Materials Characterization. Materials 2019, 12, 1019. [Google Scholar] [CrossRef]

- Hazra, S.; Janardhan Reddy, K. Study of Dynamics Stiffness and Shape Factor of Rubber Mounts to Address High-Frequency Resonance Issue in Electric Powertrain Mounting System. SAE Int. J. Adv. Curr. Pract. Mobil. 2020, 3, 773–779. [Google Scholar] [CrossRef]

- Wu, J.X.; Shi, W.; Qian, X.; Wang, F.; Shangguan, W.B. A Method for Calculating High Frequency Dynamic Characteristics of Rubber Isolators under Different Preloads. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Moon, S.-J.; Choi, S.-M.; Nguyen, V.-Q.; Oh, J.-S.; Choi, S.-B.; Chung, J.-H.; Kwon, J.-I.; Jung, W.-J. An Inertia-Type Hybrid Mount Combining a Rubber Mount and a Piezostack Actuator for Naval Shipboard Equipment. Int. J. Nav. Archit. Ocean. Eng. 2013, 5, 62–80. [Google Scholar] [CrossRef]

- Moon, S.-J.; Ji, Y.-J.; Yoon, J.-S.; Choi, S.-B.; Lee, H.-Y.; Kim, J.-H.; Jung, W.-J. A Study on Development of an Active Hybrid Mount for Naval Ships. J. Soc. Nav. Archit. Korea 2008, 45, 288–295. [Google Scholar] [CrossRef][Green Version]

- Moon, S.-J.; Kim, H.-S.; Park, J.-W.; Park, J.-H.; Oh, K.-S.; Jeong, J.-A. Experimental Evaluation of the Performance of Large-Capacity Mounts for Naval Shipboard Equipments. J. Soc. Nav. Archit. Korea 2015, 52, 275–281. [Google Scholar] [CrossRef]

- Gong, D.; Duan, Y.; Wang, K.; Zhou, J. Modelling Rubber Dynamic Stiffness for Numerical Predictions of the Effects of Temperature and Speed on the Vibration of a Railway Vehicle Car Body. J. Sound Vib. 2019, 449, 121–139. [Google Scholar] [CrossRef]

- Fragasso, J.; Moro, L.; Lye, L.M.; Quinton, B.W.T. Characterization of Resilient Mounts for Marine Diesel Engines: Prediction of Static Response via Nonlinear Analysis and Response Surface Methodology. Ocean. Eng. 2019, 171, 14–24. [Google Scholar] [CrossRef]

- Fragasso, J.; Moro, L. Structure-Borne Noise of Marine Diesel Engines: Dynamic Characterization of Resilient Mounts. Ocean Eng. 2022, 261, 112116. [Google Scholar] [CrossRef]

- Bonisoli, E.; Rosso, C.; Venturini, S.; Rovarino, D.; Velardocchia, M. Improvements on Design and Validation of Automotive Steel Wheels. Mech. Mach. Sci. 2019, 73, 1639–1649. [Google Scholar] [CrossRef]

- Emminger, C.; Çakmak, U.D.; Preuer, R.; Graz, I.; Major, Z. Hyperelastic Material Parameter Determination and Numerical Study of TPU and PDMS Dampers. Materials 2021, 14, 7639. [Google Scholar] [CrossRef]

- Mooney, M. A Theory of Large Elastic Deformation. J. Appl. Phys. 1940, 11, 582–592. [Google Scholar] [CrossRef]

- Yeoh, O.H. Characterization of Elastic Properties of Carbon-Black-Filled Rubber Vulcanizates. Rubber Chem. Technol. 1990, 63, 792–805. [Google Scholar] [CrossRef]

- Yeoh, O.H. Some Forms of the Strain Energy Function for Rubber. Rubber Chem. Technol. 1993, 66, 754–771. [Google Scholar] [CrossRef]

- Shahzad, M.; Kamran, A.; Siddiqui, M.Z.; Farhan, M. Mechanical Characterization and FE Modelling of a Hyperelastic Material. Mater. Res. 2015, 18, 918–924. [Google Scholar] [CrossRef]

- Melly, S.K.; Liu, L.; Liu, Y.; Leng, J. A Review on Material Models for Isotropic Hyperelasticity. Int. J. Mech. Syst. Dyn. 2021, 1, 71–88. [Google Scholar] [CrossRef]

- ASTM D412-16; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM International: West Conshohocken, PA, USA, 2016.

- MIL-M-17508F; Military Specification: Mounts, Resilient: Types 6E100, 6E150, 7E450, 6E900, 6E2000, 5E3500, 6E100BB, 6E150BB, 7E450BB, and 6e900BB. Department of Navy: Monterey, CA, USA, 1990.

- Anas, K.; David, S.; Babu, R.R.; Selvakumar, M.; Chattopadhyay, S. Energy Dissipation Characteristics of Crosslinks in Natural Rubber: An Assessment Using Low and High-Frequency Analyzer. J. Polym. Eng. 2018, 38, 723–729. [Google Scholar] [CrossRef]

- Bai, Q.; Bai, Y. Pipeline Spans and VIV Fatigue. In Subsea Pipeline Design, Analysis, and Installation; Elsevier Inc.: Amsterdam, The Netherlands, 2014; pp. 337–363. [Google Scholar] [CrossRef]

- Park, S.J.; Kim, K. Study on the Static and Dynamic Characteristics of Elastic Mount. In Proceedings of the 2024 Joint Academic Conference of the Korean Association of Ocean Science and Technology Societies, Jeju-si, Republic of Korea, 23–25 May 2024. [Google Scholar]

| Label | Strain Energy Density (J/m3) | Error (%) | |

|---|---|---|---|

| Compression | Experiment | FEA | 5.26 |

| 237.25 | 224.76 | ||

| Tension | Experiment | FEA | 1.94 |

| 71.32 | 72.74 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.-J.; Park, B.; Lee, J.-Y.; Shin, Y.-H.; Jeong, C.-L.; Kim, S.-J.; Kim, K. Study on Dynamic Characteristics of Resilient Mount Under Preload. Materials 2024, 17, 5096. https://doi.org/10.3390/ma17205096

Park S-J, Park B, Lee J-Y, Shin Y-H, Jeong C-L, Kim S-J, Kim K. Study on Dynamic Characteristics of Resilient Mount Under Preload. Materials. 2024; 17(20):5096. https://doi.org/10.3390/ma17205096

Chicago/Turabian StylePark, Sung-Ju, Byoungjae Park, Joo-Yeob Lee, Yun-Ho Shin, Chae-Lim Jeong, Sung-Jae Kim, and Kookhyun Kim. 2024. "Study on Dynamic Characteristics of Resilient Mount Under Preload" Materials 17, no. 20: 5096. https://doi.org/10.3390/ma17205096

APA StylePark, S.-J., Park, B., Lee, J.-Y., Shin, Y.-H., Jeong, C.-L., Kim, S.-J., & Kim, K. (2024). Study on Dynamic Characteristics of Resilient Mount Under Preload. Materials, 17(20), 5096. https://doi.org/10.3390/ma17205096