Properties of Sn-Doped PBZT Ferroelectric Ceramics Sintered by Hot-Pressing Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and Technological Process

2.2. Characterization

3. Results and Discussion

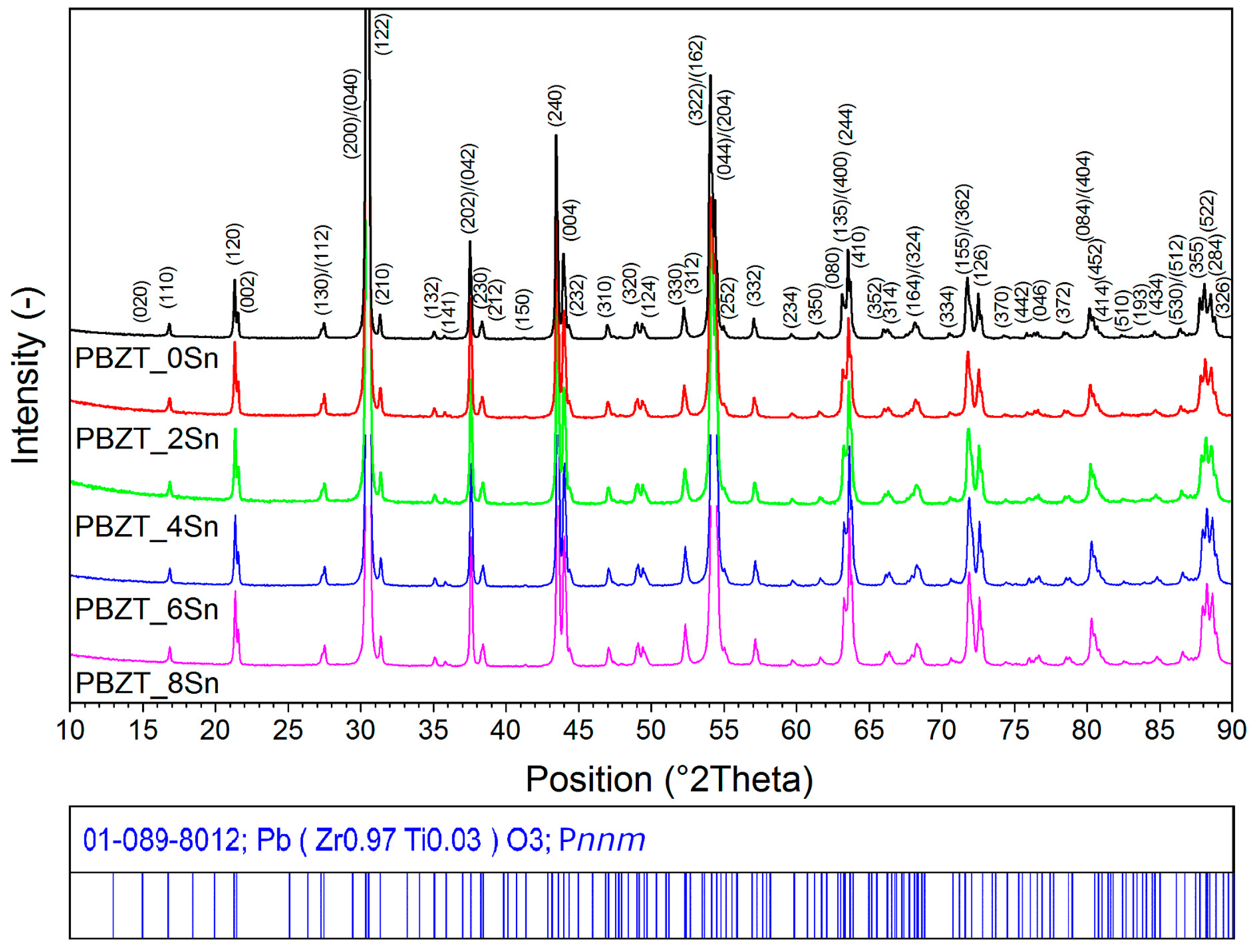

3.1. Structural Test

3.2. Microstructure

3.3. Ferroelectric Properties

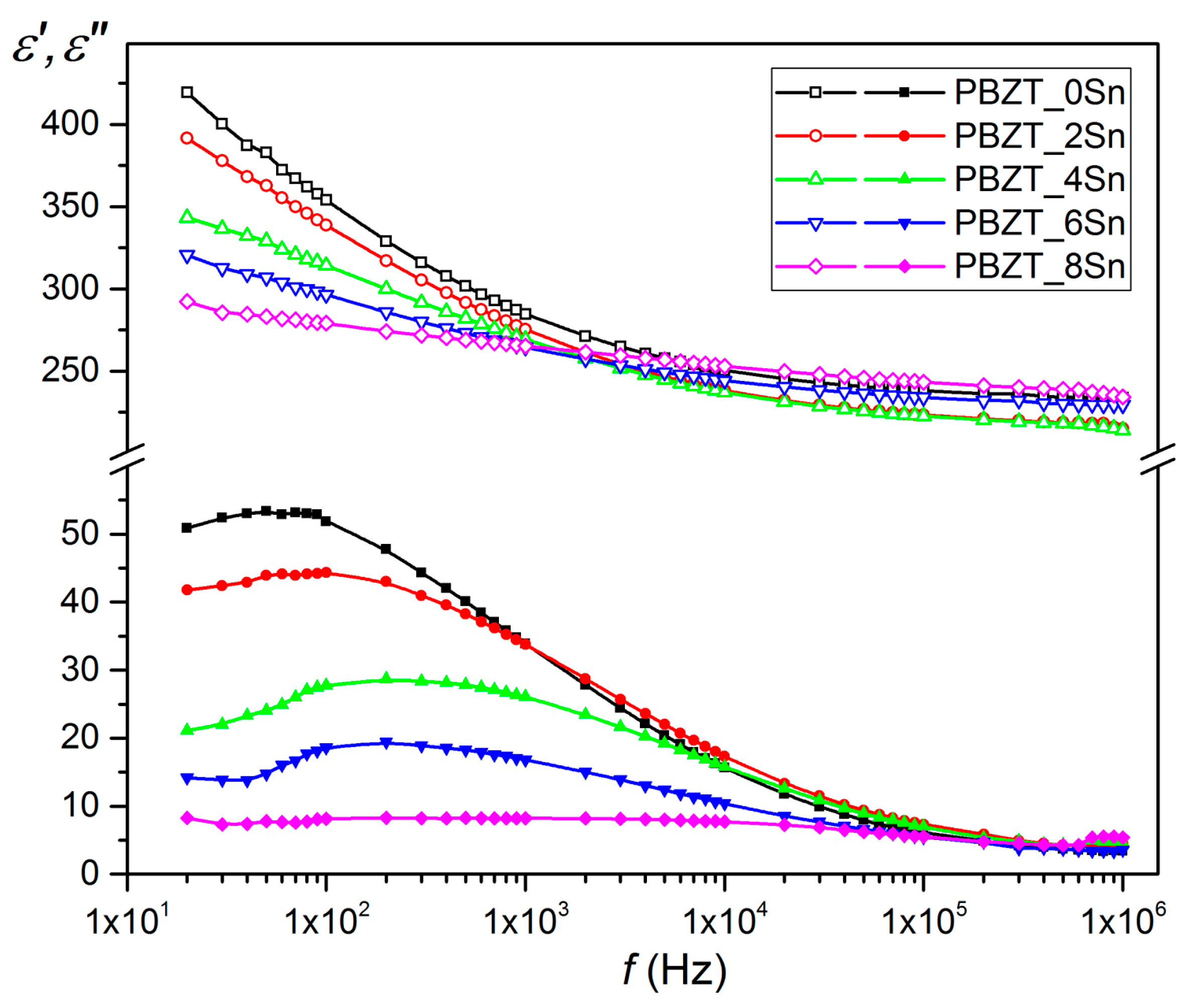

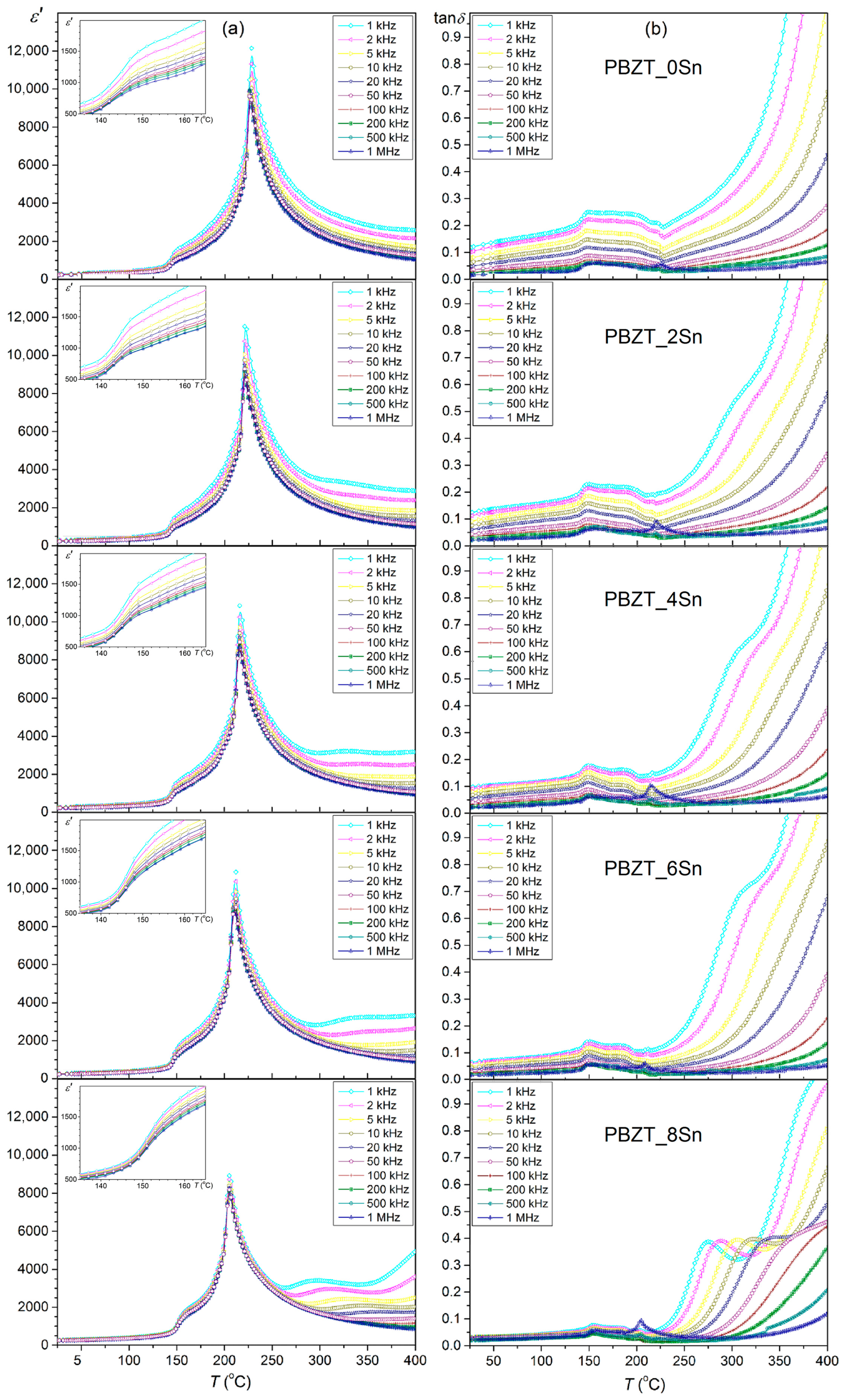

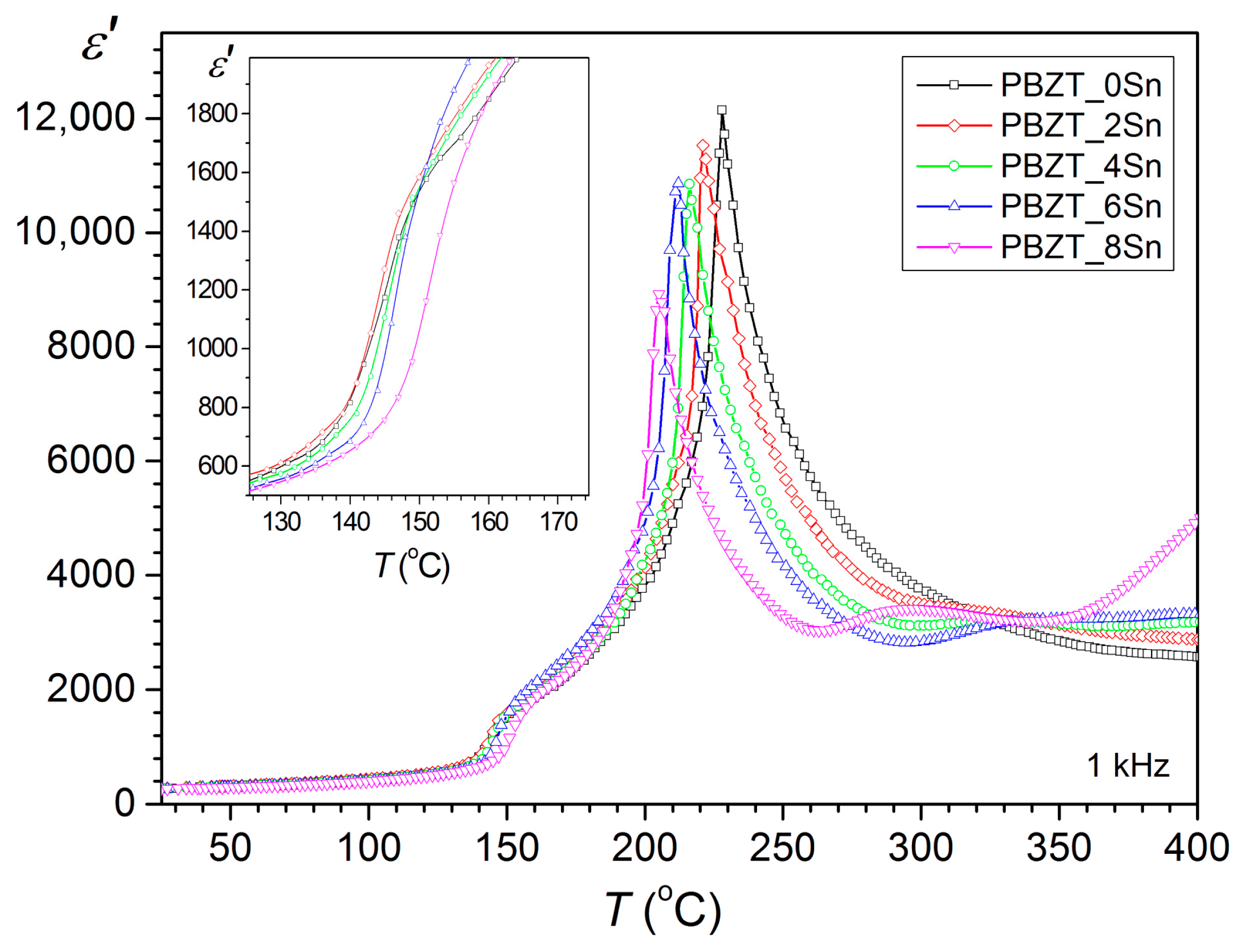

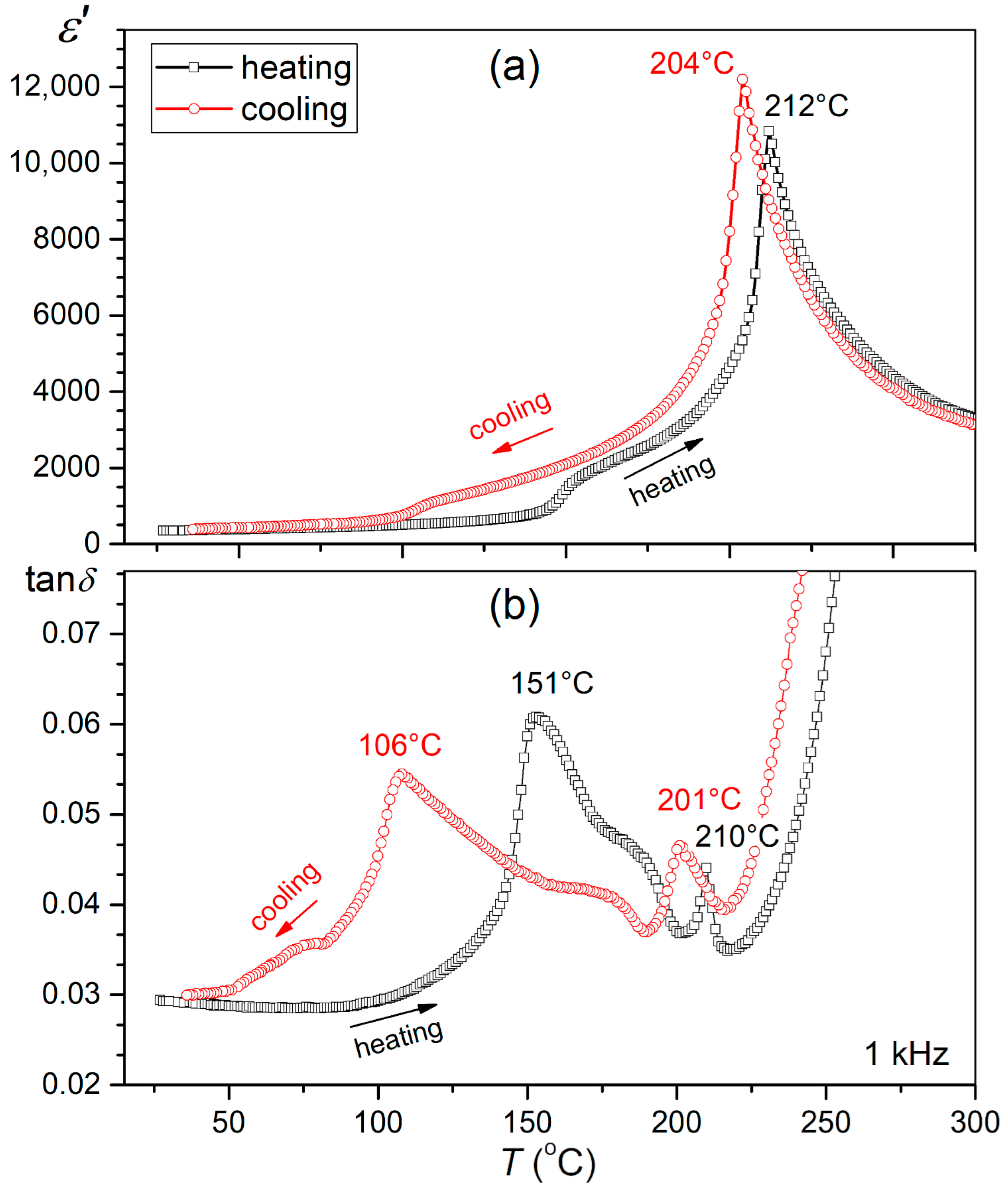

3.4. Dielectric Properties

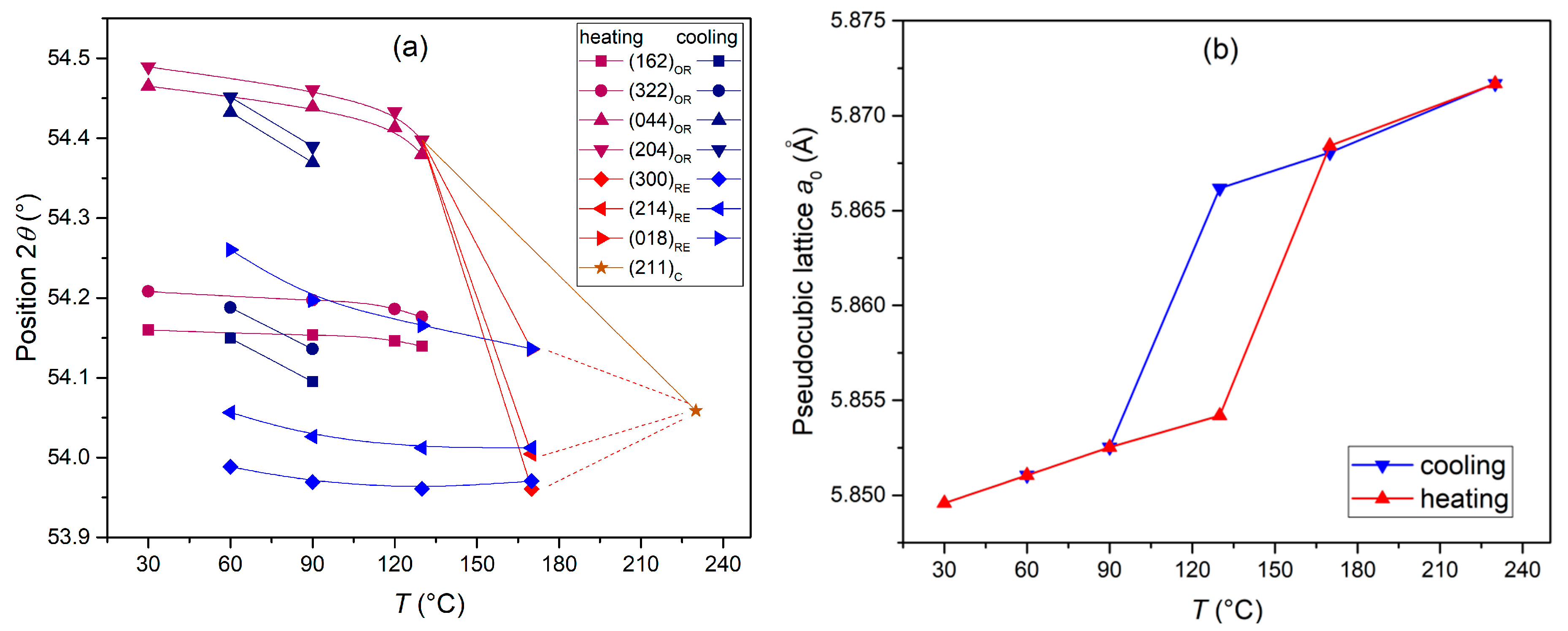

3.5. Temperature X-ray Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sorayani Bafqi, M.S.; Sadeghi, A.H.; Latifi, M.; Bagherzadeh, R. Design and fabrication of a piezoelectric out-put evaluation system for sensitivity measurements of fibrous sensors and actuators. J. Ind. Text. 2021, 50, 1643–1659. [Google Scholar] [CrossRef]

- Kahoul, F.; Hamzioui, L.; Abdessalem, N.; Boutarfaia, A. Synthesis and piezoelectric properties of Pb0.98Sm0.02[(Zry,Ti1−y)0.98](Fe3+1/2,Nb5+1/2)0.02]O3 ceramics. Mater. Sci. Appl. 2012, 3, 50–58. [Google Scholar] [CrossRef][Green Version]

- Jaffe, B.; Cook, W.; Jaffe, H. Piezoelectric Ceramics; Academic Press: Cambridge, MA, USA, 1971. [Google Scholar]

- Badapanda, T.; Sarangi, S.; Behera, B.; Anwar, S.; Sinha, T.P.; Ranjan, R.; Luz, G.E., Jr.; Longo, E.; Cavalcante, L.S. Structural refinement, optical and electrical properties of [Ba1−xSm2x/3](Zr0.05Ti0.95)O3 ceramics. J. Mater. Sci. Mater. Electron. 2014, 25, 3427–3439. [Google Scholar] [CrossRef]

- Kozielski, L.; Płońska, M. Optic and piezoelectric coupling in the sol-gel PLZT electroceramics. Mater. Sci. Forum 2013, 730–732, 129–134. [Google Scholar] [CrossRef]

- Haq, M. Application of piezo transducers in biomedical science for health monitoring and energy harvesting problems. Mater. Res. Express 2019, 6, 022002. [Google Scholar] [CrossRef]

- Ramesh, S.; Ravinder, D.; Naidu, K.C.B.; Kumar, N.S.; Srinivas, K.; Baba Basha, D.; Chandra Sekhar, B. A review on giant piezoelectric coefficient, materials and applications. Biointerface Res. Appl. Chem. 2019, 9, 4205–4216. [Google Scholar] [CrossRef]

- Bochenek, D.; Surowiak, Z.; Gavrilyachenko, S.V.; Kupriyanov, M.F. Multicomponent ceramic materials on the basis of PZT to production of the piezoelectric resonators. Arch. Acoust. 2005, 30, 87–107. [Google Scholar]

- Yousefi, F.; Esfahani, H. Role of Nb5+-Nd3+ co-dopant in morphotropic boundary of electrospun PZT nanoneedles; study on dielectric and piezoelectric sensitivity. J. Alloys Compd. 2023, 966, 171531. [Google Scholar] [CrossRef]

- Niu, X.; Jia, W.; Qian, S.; Zhu, J.; Zhang, J.; Hou, X.; Mu, J.; Geng, W.; Cho, J.; He, J.; et al. High-performance PZT-based stretchable piezoelectric nanogenerator. ACS Sustain. Chem. Eng. 2018, 7, 979–985. [Google Scholar] [CrossRef]

- Song, P.; Zhu, Z.; Yao, Z.; Hao, H.; Cao, M.; Liu, H. Piezoelectric enhancement of 0.6Pb(Zr,Ti)O3-0.4Pb(Ni1/3Nb2/3)O3 ceramics with artificial MPB engineering. J. Mater. Sci. Mater. Electron. 2024, 35, 58. [Google Scholar] [CrossRef]

- Avanish Babu, T.; Madhuri, W. Microwave synthesis technique for LTCC and colossal dielectric constant in PZT. Chem. Phys. Lett. 2022, 799, 139641. [Google Scholar] [CrossRef]

- Kim, B.S.; Ji, J.H.; Koh, J.H. Improved strain and transduction values of low-temperature sintered CuO-doped PZT-PZNN soft piezoelectric materials for energy harvester applications. Ceram. Int. 2021, 47, 6683–6690. [Google Scholar] [CrossRef]

- Fan, F.; Tang, W.; Wang, Z. Flexible nanogenerators for energy harvesting and self-powered electronics. Adv. Mater. 2016, 28, 4283–4305. [Google Scholar] [CrossRef]

- Panigrahi, S.C.; Das, P.R.; Choudhary, R.N.P. Ferroelectric studies for soft Gd modified PZT ceramics. Phase Transit. 2018, 91, 703–714. [Google Scholar] [CrossRef]

- Cuong, D.D.; Lee, B.; Choi, K.M.; Ahn, H.S.; Han, S.; Lee, J. Oxygen vacancy clustering and electron localization in oxygen-deficient SrTiO3: LDA+U study. Phys. Rev. Lett. 2007, 98, 115503. [Google Scholar] [CrossRef]

- Abdessalem, N.; Boutarfaia, A. Effect of composition on the electromechanical properties of Pb[ZrxTi(0.9–x)(Cr1/5,Zn1/5,Sb3/5)0.1]O3 ceramics. Ceram. Int. 2007, 33, 293–296. [Google Scholar] [CrossRef]

- Kumari, N.; Monga, S.; Arif, M.; Sharma, N.; Sanger, A.; Singh, A.; Vilarinho, P.M.; Gupta, V.; Sreenivas, K.; Katiyar, R.S.; et al. Multifunctional behavior of acceptor-cation substitution at higher doping concentration in PZT ceramics. Ceram. Int. 2019, 45, 12716–12726. [Google Scholar] [CrossRef]

- Niemiec, P.; Bochenek, D.; Brzezińska, D. Effect of various sintering methods on the properties of PZT-type ceramics. Ceram. Inter. 2023, 49, 35687–35698. [Google Scholar] [CrossRef]

- Gao, B.; Yao, Z.; Lai, D.; Guo, Q.; Pan, W.; Hao, H.; Cao, M.; Liu, H. Unexpectedly high piezoelectric response in Sm-doped PZT ceramics beyond the morphotropic phase boundary region. J. Alloys Compd. 2020, 836, 155474. [Google Scholar] [CrossRef]

- Khacheba, M.; Abdessalem, N.; Hamdi, A.; Khemakhem, H. Effect of acceptor and donor dopants (Na, Y) on the microstructure and dielectric characteristics of high Curie point PZT-modified ceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 361–372. [Google Scholar] [CrossRef]

- Li, J.; Sun, Q. Effects of Cr2O3 doping on the electrical properties and the temperature stabilities of PZT binary piezoelectric ceramics. Rare Met. 2008, 27, 362. [Google Scholar] [CrossRef]

- Kelley, K.P.; Morozovska, A.N.; Eliseev, E.A.; Sharma, V.; Yilmaz, D.E.; van Duin, A.C.T.; Ganesh, P.; Borisevich, A.; Jesse, S.; Maksymovych, P.; et al. Oxygen vacancy injection as a pathway to enhancing electromechanical response in ferroelectrics. Adv. Mater. 2022, 34, 2106426. [Google Scholar] [CrossRef]

- Tai, D.; Zhao, X.; Zheng, T.; Wu, J. Establishing a relationship between the piezoelectric response and oxygen vacancies in lead-free piezoelectrics. ACS Appl. Mater. Interfaces 2023, 15, 36564–36575. [Google Scholar] [CrossRef]

- Liu, C.L.; Du, Q.; Zhou, H.; Wu, J.M.; Zhang, G.; Shi, Y.S. Effect of the polystyrene particle size on performance of PZT piezoelectric ceramics via vat photopolymerization (VPP). Addit. Manuf. 2023, 78, 103857. [Google Scholar] [CrossRef]

- Ramana, M.V.; Kiran, S.R.; Reddy, N.R.; Kumar, K.V.S.; Murthy, V.R.K.; Murty, B.S. Investigation and characterization of Pb(Zr0.52Ti0.48)O3 nanocrystalline ferroelectric ceramics: By conventional and microwave sintering methods. Mater. Chem. Phys. 2011, 126, 295–300. [Google Scholar] [CrossRef]

- Bochenek, D.; Skulski, R.; Wawrzała, P.; Brzezińska, D. Dielectric properties of Pb0.75Ba0.25(Zr0.65Ti0.35)1-zSnzO3 ceramics. Ferroelectrics 2011, 418, 82–87. [Google Scholar] [CrossRef]

- Sharma, P.K.; Ounaies, Z.; Varadan, V.V.; Varadan, V.K. Dielectric and piezoelectric properties of microwave sintered PZT. Smart Mater. Struct. 2001, 10, 878–883. [Google Scholar] [CrossRef]

- Marakhovsky, M.A.; Panich, A.A.; Talanov, M.V.; Marakhovskiy, V.A. Comparative study of the hard and soft PZT-based ceramics sintered by various methods. Ferroelectrics 2021, 575, 43–49. [Google Scholar] [CrossRef]

- Wu, Y.J.; Uekawa, N.; Kakegawa, K.; Sasaki, Y. Compositional fluctuation and dielectric properties of Pb(Zr0.3Ti0.7)O3 ceramics prepared by spark plasma sintering. Mater. Lett. 2002, 57, 771–775. [Google Scholar] [CrossRef]

- Mudinepalli, V.R.; Leng, F. Dielectric and ferroelectric studies on high dense Pb(Zr0.52Ti0.48)O3 nanocrystalline ceramics by high energy ball milling and spark plasma sintering. Ceramics 2019, 2, 13–24. [Google Scholar] [CrossRef]

- Tokita, M. Progress of spark plasma sintering (SPS) method, systems, ceramics applications and industrialization. Ceramics 2021, 4, 160–198. [Google Scholar] [CrossRef]

- Jia, Y.; Su, X.; Wu, Y.; Bai, G.; Wang, Z.; Yan, X.; Ai, T.; Zhao, P. Fabrication of lead zirconate titanate ceramics by reaction flash sintering of PbO-ZrO2-TiO2 mixed oxides. J. Eur. Ceram. Soc. 2019, 39, 3915–3919. [Google Scholar] [CrossRef]

- Wang, D.; Tsuji, K.; Randall, C.A.; Trolier-McKinstry, S. Model for the cold sintering of lead zirconate titanate ceramic composites. J. Am. Ceram. Soc. 2020, 103, 4894–4902. [Google Scholar] [CrossRef]

- Gupta, S.; Wang, D.; Randall, C.A.; Trolier-McKinstry, S. Comparison of different sintering aids in cold sinter-assisted densification of lead zirconate titanate. J. Am. Ceram. Soc. 2021, 104, 5479–5488. [Google Scholar] [CrossRef]

- Fernándeza, C.P.; Zabottob, F.L.; Garciab, D.; Kiminami, R.H.G.A. In situ sol-gel cosynthesis at as low hydrolysis rate and microwave sintering of PZT/Fe2CoO4 magnetoelectric composite ceramics. Ceram. Int. 2017, 43, 5925–5933. [Google Scholar] [CrossRef]

- Wang, D.; Ou-Yang, J.; Guo, W.; Yang, X.; Zhu, B. Novel fabrication of PZT thick films by an oil-bath based hydrothermal method. Ceram. Int. 2017, 43, 9573–9576. [Google Scholar] [CrossRef]

- Djellabi, R.; Frias Ordonez, M.; Conte, F.; Falletta, E.; Bianchi, C.L.; Rossetti, I. A review of advances in multifunctional XTiO3 perovskite-type oxides as piezo-photocatalysts for environmental remediation and energy production. J. Hazard. Mater. 2022, 421, 126792. [Google Scholar] [CrossRef]

- Fraile, I.; Gabilondo, M.; Burgos, N.; Azcona, M.; Castro, F. Laser sintered ceramic coatings of PZT nanoparticles deposited by inkjet printing on metallic and ceramic substrates. Ceram. Int. 2018, 44, 15603–15610. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Z.Y.; Song, X.; Zhu, B.; Hsiai, T.; Wu, P.-I.; Xiong, R.; Shi, J.; Chen, Y.; Zhou, Q.; et al. Three dimensional printing of high dielectric capacitor using projection based stereolithography method. Nano Energy 2016, 22, 414–421. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Handerek, J.; Adamczyk, M.; Ujma, Z. Dielectric and pyroelectric properties of (Pb0.75Ba0.25)(Zr0.70Ti0.30)O3 [x = 0.25÷0.35] ceramics exhibiting the relaxor ferroelectrics behavior. Ferroelectrics 1999, 233, 253–270. [Google Scholar] [CrossRef]

- Roleder, K. Properties and phase transitions in PbZr1−xTixO3 (PZT). Key Eng. Mat. 1998, 155–156, 123–158. [Google Scholar] [CrossRef]

- Roleder, K. Polar regions in the paraelectric phase in a PbZr0.992Ti0. 008O3 single crystal. Phase Transit. 1989, 15, 77–821. [Google Scholar] [CrossRef]

- Dec, J.; Kwapulinski, J. Phase boundaries in NaNbO3 single crystals. Phase Transit. 1989, 18, 1–9. [Google Scholar] [CrossRef]

- Rodriguez-Carvajal, J. Recent advances in magnetic structure determination by neutron powder diffraction. Phys. B Condens. Matter 1995, 192, 55–69. [Google Scholar] [CrossRef]

- Skulski, R.; Wawrzała, P.; Ćwikiel, K.; Bochenek, D. Dielectric and electromechanical behaviors of PMN-PT ceramic samples. J. Intel. Mat. Syst. Str. 2007, 18, 1049–1056. [Google Scholar] [CrossRef]

- Liu, H.-C.; Toraya, H. Ab initio structural study on Nb-doped Pb(Zr0.97Ti0.03)O3 ceramic material by synchrotron X-ray diffraction. Jpn. J. Appl. Phys. 1999, 38, 104. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Cryst. 1976, A32, 751–767. [Google Scholar] [CrossRef]

- Jaffe, B.; Roth, R.S.; Marzullo, S. Properties of piezoelectric ceramics in the solid-solution series lead titanate-lead zirconate-lead oxide: Tin oxide and lead titanate-lead hafnate. J. Res. Natl. Bur. Stand. 1955, 55, 239–254. [Google Scholar] [CrossRef]

- Kornphom, C.; Panich, C.; Bongkarn, T. Phase formation and piezoelectric properties of (Pb0.95Ba0.05)(Zr1−xTix)O3 ceramics fabricated by solid state reaction technique. Mater. Res. Innov. 2014, 18, S2-146–S2-150. [Google Scholar] [CrossRef]

- Thongtha, A.; Wattanawikkam, C.; Bongkarn, T. Phase formation and dielectric properties of (Pb0.925Ba0.075)(Zr1−xTix)O3 ceramics prepared by the solid-state reaction method. Phase Transit. 2011, 84, 952–959. [Google Scholar] [CrossRef]

- Brzezińska, D.; Bochenek, D.; Niemiec, P.; Dercz, G. Properties of PBZTS ferroelectric ceramics obtained using spark plasma sintering. Materials 2023, 16, 5756. [Google Scholar] [CrossRef]

- Brzezińska, D. Properties of Pb1–xBax(Zr1–yTiy)1–zSnzO3 (x=0.03, y=0.02, z=0÷0.08) ceramics. Arch. Metall. Mater. 2020, 65, 975–982. [Google Scholar] [CrossRef]

- Gao, L.; Wang, J.; Yang, S.; Qian, B. Electrical properties of non-stoichiometric PZT 95/5 ferroelectric ceramics. J. Mater. Sci. Mater. Electron. 2013, 24, 1664–1669. [Google Scholar] [CrossRef]

- He, W.; Li, Q.; Yan, Q.; Luo, N.; Zhang, Y.; Chu, X.; Shen, D. Temperature-dependent phase transition in orthorhombic [011]c Pb(Mg1/3Nb2/3)O3-0.35PbTiO3 single crystal. Crystals 2014, 4, 262–272. [Google Scholar] [CrossRef]

- Berlincourt, D.; Krueger, H.H.A.; Jaffe, B. Stability of phases in modified lead zirconate with variation in pressure, electric field, temperature and composition. J. Phys. Chem. Solids 1964, 25, 659–674. [Google Scholar] [CrossRef]

- Singh, A.; Chatterjee, R.; Mishra, S.K.; Krishna, P.S.R.; Chaplot, S.L. Origin of large dielectric constant in La modified BiFeO3-PbTiO3 multiferroic. J. Appl. Phys. 2013, 111, 14113. [Google Scholar] [CrossRef]

- Mondal, R.A.; Murty, B.S.; Murthy, V.R.K. Maxwell-Wagner polarization in grain boundary segregated NiCuZn ferrite. Curr. Appl. Phys. 2014, 14, 1727–1733. [Google Scholar] [CrossRef]

- Mandal, S.K.; Singh, S.; Debnath, R.; Nath, A.; Dey, P. Magnetoelectric coupling, dielectric and electrical properties of xLa0.7Sr0.3MnO3-(1−x)Pb(Zr0.58Ti0.42)O3 (x = 0.05 and 0.1) multiferroic nanocomposites. J. Alloys Compd. 2017, 720, 550–561. [Google Scholar] [CrossRef]

- Kaur, R.; Sharma, V.; Kumar, M.; Singh, M.; Singh, A. Conductivity relaxation in Pb0.9Sm0.10Zr0.405Ti0.495Fe0.10O3 solid solution. J. Alloys Compds. 2018, 735, 1472–1479. [Google Scholar] [CrossRef]

- Erbil, A.; Kim, Y.; Gerhardt, R.A. Giant permittivity in epitaxial ferroelectric heterostructures. Phys. Rev. Lett. 1996, 77, 1628–1631. [Google Scholar] [CrossRef]

- Yu, Z.; Ang, C. Maxwell–Wagner polarization in ceramic composites. J. Appl. Phys. 2002, 91, 794–797. [Google Scholar] [CrossRef]

- Zhang, T.-F.; Tang, X.-G.; Liu, Q.-X.; Lu, S.-G.; Jiang, Y.-P.; Huang, X.-X.; Zhou, Q.-F. Oxygen-vacancy-related relaxation and conduction behavior in (Pb1−xBax)(Zr0.95Ti0.05)O3 ceramics. AIP Adv. 2014, 4, 107141. [Google Scholar] [CrossRef]

- Elissalde, C.; Ravez, J. Ferroelectric ceramics: Defects and dielectric relaxations. J. Mater. Chem. 2001, 11, 1957–1967. [Google Scholar] [CrossRef]

- Zhang, T.F.; Tang, X.G.; Liu, Q.X.; Jiang, Y.P.; Huang, X.X.; Zhou, Q.F. Energy-storage properties and high-temperature dielectric relaxation behaviors of relaxor ferroelectric Pb(Mg1/3Nb2/3)O3–PbTiO3 ceramics. J. Phys. D Appl. Phys. 2016, 49, 095302. [Google Scholar] [CrossRef]

- Wang, X.F.; Lu, X.M.; Zhang, C.; Wu, X.B.; Cai, W.; Peng, S.; Bo, H.F.; Kan, Y.; Huang, F.Z.; Zhu, J.S. Oxygen-vacancy-related high-temperature dielectric relaxation in SrTiO3 ceramics. J. Appl. Phys. 2010, 107, 114101. [Google Scholar] [CrossRef]

- Ke, Q.; Lou, X.; Wang, Y.; Wang, J. Oxygen-vacancy-related relaxation and scaling behaviors of Bi0.9La0.1Fe0.98Mg0.02O3 ferroelectric thin films. J. Phys. Rev. B 2010, 82, 024102. [Google Scholar] [CrossRef]

- Fasquelle, D.; Carru, J.C. Electrical characterizations of PZT ceramics in large frequency and temperature ranges. J. Eur. Ceram. Soc. 2008, 28, 2071–2074. [Google Scholar] [CrossRef]

- Belboukhari, A.; Mezzane, D.; Gagou, Y.; Elmarssi, M.; Luk’yanchuk, I.; Zegzouti, A.; Saint-Grégoire, P. Dielectric properties of new ferroelectric lead potassium niobate Pb0.9K0.2Nb2O6. Moroc. J. Condens. Matter 2010, 12, 103–107. [Google Scholar] [CrossRef]

- Sawaguchi, E. Ferroelectricity versus antiferroelectricity in the solid solutions of PbZrO3 and PbTiO3. J. Phys. Soc. Jpn. 1953, 8, 615–629. [Google Scholar] [CrossRef]

| PBZT_0Sn | PBZT_2Sn | PBZT_4Sn | PBZT_6Sn | PBZT_8Sn | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| theor. | exper. | theor. | exper. | theor. | exper. | theor. | exper. | theor. | exper. | |

| TiO2 | 0.47 | 0.20 | 0.46 | 0.38 | 0.45 | 0.32 | 0.44 | 0.45 | 0.43 | 0.33 |

| ZrO2 | 35.16 | 30.04 | 34.4 | 28.74 | 33.64 | 28.86 | 32.89 | 27.90 | 32.13 | 26.79 |

| SnO2 | 0 | 0 | 0.88 | 0.88 | 1.75 | 1.36 | 2.62 | 2.30 | 3.49 | 3.38 |

| BaO | 1.34 | 1.48 | 1.34 | 1.18 | 1.33 | 1.12 | 1.33 | 0.84 | 1.33 | 1.15 |

| PbO | 63.03 | 68.27 | 62.92 | 68.82 | 62.83 | 68.34 | 62.72 | 68.50 | 62.62 | 68.35 |

| Parameter | PBZT_0Sn | PBZT_2Sn | PBZT_4Sn | PBZT_6Sn | PBZT_8Sn |

|---|---|---|---|---|---|

| ρ (g/cm3) | 7.34 | 7.38 | 7.42 | 7.60 | 7.53 |

| d (μm) | 1.42 | 1.40 | 1.87 | 1.70 | 1.86 |

| εr a,b | 274 | 275 | 269 | 265 | 269 |

| tanδ a,b | 0.119 | 0.123 | 0.097 | 0.064 | 0.031 |

| Tm (°C) b | 228 | 221 | 216 | 212 | 205 |

| εm at Tm b | 12,141 | 11,526 | 10,850 | 10,861 | 8923 |

| tanδ at Tm b | 0.194 | 0.194 | 0.151 | 0.114 | 0.056 |

| Pr (μC/cm2) a | 0.53 | 0.40 | 0.50 | 0.31 | 0.30 |

| Ec (kV/mm) a | 1.14 | 0.77 | 0.89 | 0.71 | 0.69 |

| Pmax (μC/cm2) a | 1.81 | 1.85 | 2.08 | 1.52 | 1.63 |

| Cycle | Heating | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Phase | Orthorhombic (OR) | Rhombohedral (RE) | Cubic (C) | Rp | Rwp | RB | |||

| T (°C) | a (Å) | b (Å) | c (Å) | a (Å) | c (Å) | a (Å) | |||

| 30 | 5.8653(1) | 11.7453(2) | 8.2177(1) | - | - | - | 11.4 | 9.45 | 5.21 |

| 60 | 5.8659(1) | 11.7450(2) | 8.2232(1) | - | - | - | 11.0 | 8.72 | 3.40 |

| 90 | 5.8665(1) | 11.7451(2) | 8.2286(1) | - | - | - | 11.1 | 8.86 | 3.57 |

| 130 | 5.8668(1) | 11.7445(2) | 8.2358(1) | - | - | - | 13.8 | 11.5 | 4.91 |

| 170 | - | - | - | 5.8816(2) | 14.3585(5) | - | 16.2 | 14.2 | 3.17 |

| 230 | - | - | - | - | - | 4.1519(1) | 12.5 | 8.92 | 2.18 |

| Cooling | |||||||||

| 170 | - | - | - | 5.8805(1) | 14.3585(1) | - | 15.4 | 13.6 | 2.93 |

| 130 | - | - | - | 5.8815(2) | 14.3503(5) | - | 16.8 | 15.0 | 3.27 |

| 90 | 5.8659(1) | 11.7450(2) | 8.2232(1) | 5.8779(1) | 14.3359(3) | - | 15.5 | 13.5 | 3.19 |

| 60 | 5.8667(1) | 11.7452(2) | 8.2242(2) | 5.8786(2) | 14.3245(6) | - | 11.6 | 9.44 | 2.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brzezińska, D.; Bochenek, D.; Zubko, M.; Niemiec, P.; Matuła, I. Properties of Sn-Doped PBZT Ferroelectric Ceramics Sintered by Hot-Pressing Method. Materials 2024, 17, 5072. https://doi.org/10.3390/ma17205072

Brzezińska D, Bochenek D, Zubko M, Niemiec P, Matuła I. Properties of Sn-Doped PBZT Ferroelectric Ceramics Sintered by Hot-Pressing Method. Materials. 2024; 17(20):5072. https://doi.org/10.3390/ma17205072

Chicago/Turabian StyleBrzezińska, Dagmara, Dariusz Bochenek, Maciej Zubko, Przemysław Niemiec, and Izabela Matuła. 2024. "Properties of Sn-Doped PBZT Ferroelectric Ceramics Sintered by Hot-Pressing Method" Materials 17, no. 20: 5072. https://doi.org/10.3390/ma17205072

APA StyleBrzezińska, D., Bochenek, D., Zubko, M., Niemiec, P., & Matuła, I. (2024). Properties of Sn-Doped PBZT Ferroelectric Ceramics Sintered by Hot-Pressing Method. Materials, 17(20), 5072. https://doi.org/10.3390/ma17205072