New Eco-Cements Made with Marabou Weed Biomass Ash

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Methodology

2.2.1. Pozzolanic Activity Method

2.2.2. Rheological Properties

2.2.3. Physical Properties

2.2.4. Mechanical Properties

2.3. Instrumental Techniques

3. Results

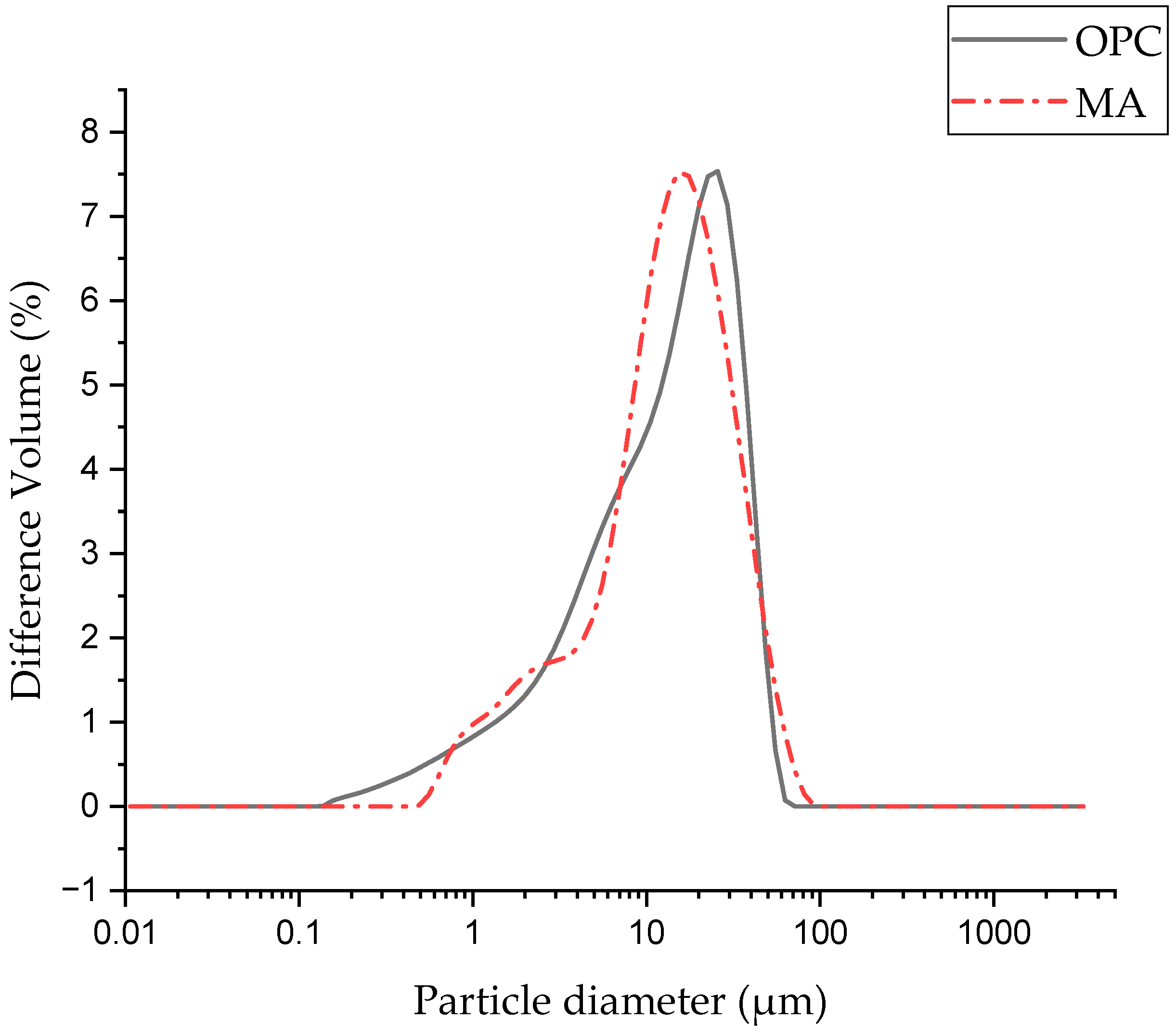

3.1. Characterization of the Starting Materials

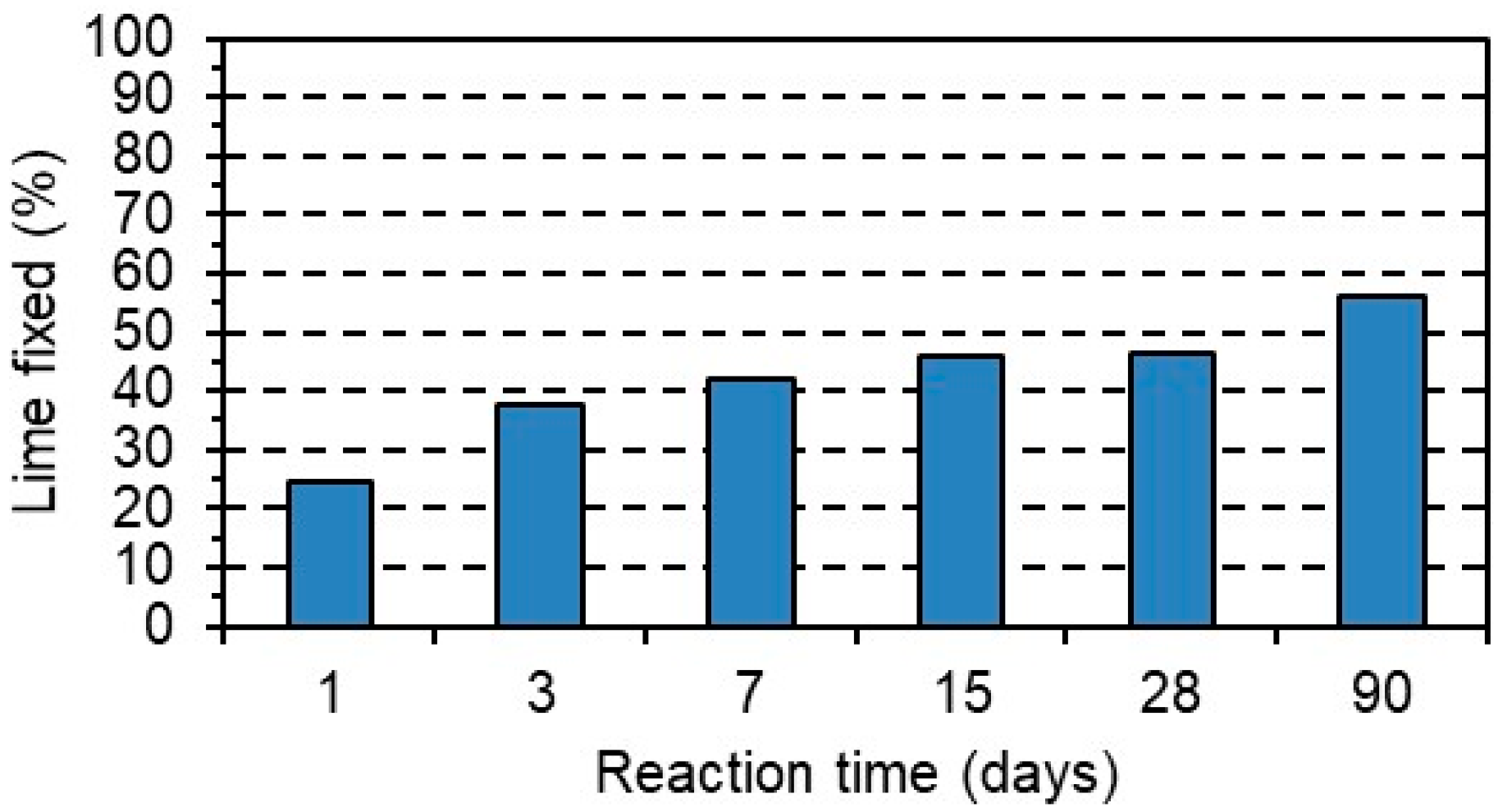

3.2. Pozzolanic Activity

3.2.1. Accelerated Chemical Method

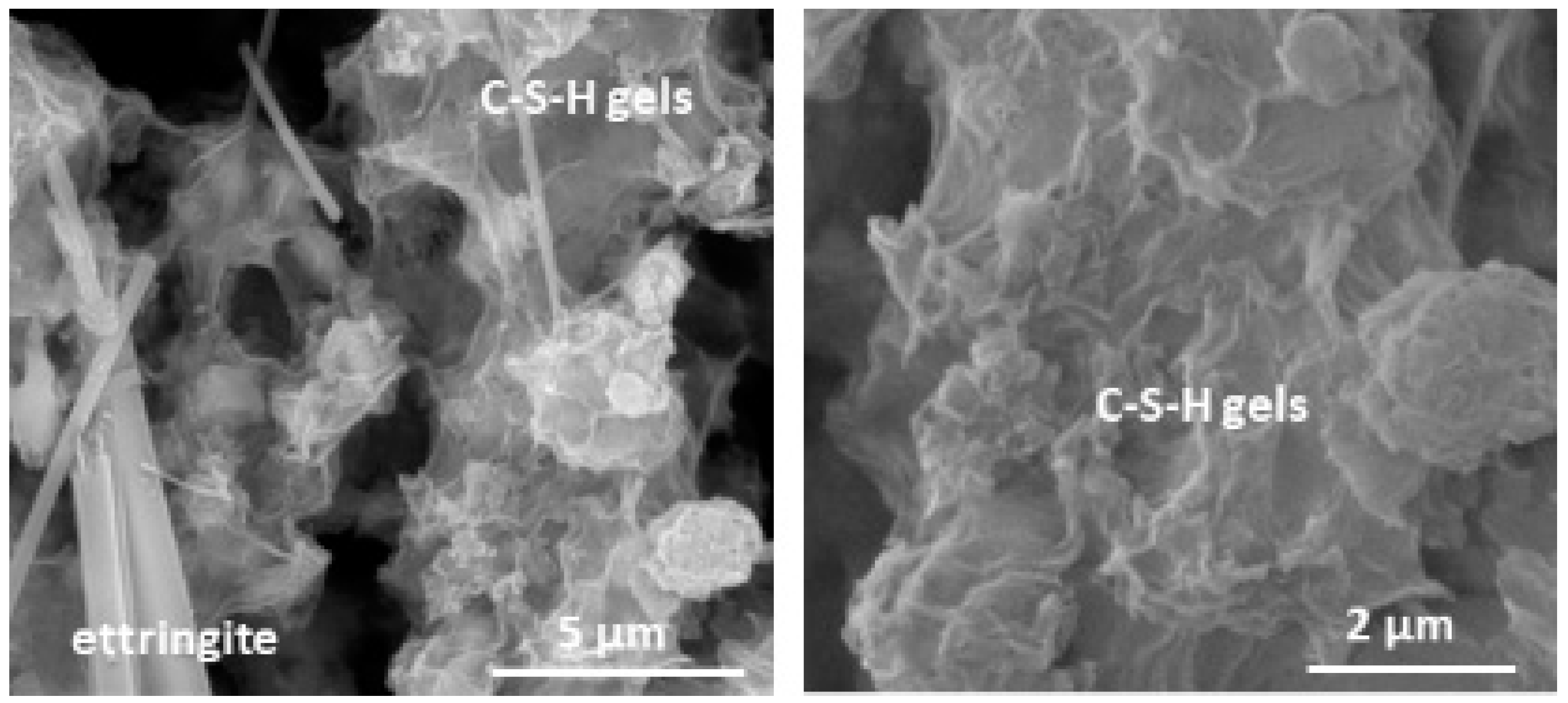

3.2.2. Mineralogical Analysis of the Pozzolanic Reaction Using the XRD–Rietveld Method and SEM–EDX

3.3. Chemical Characterization of the Anhydrous Blended Cements

3.4. Rheological Behavior of the Blended Cement Pastes

3.5. Physical and Mechanical Behavior of the Blended Cement Mortars

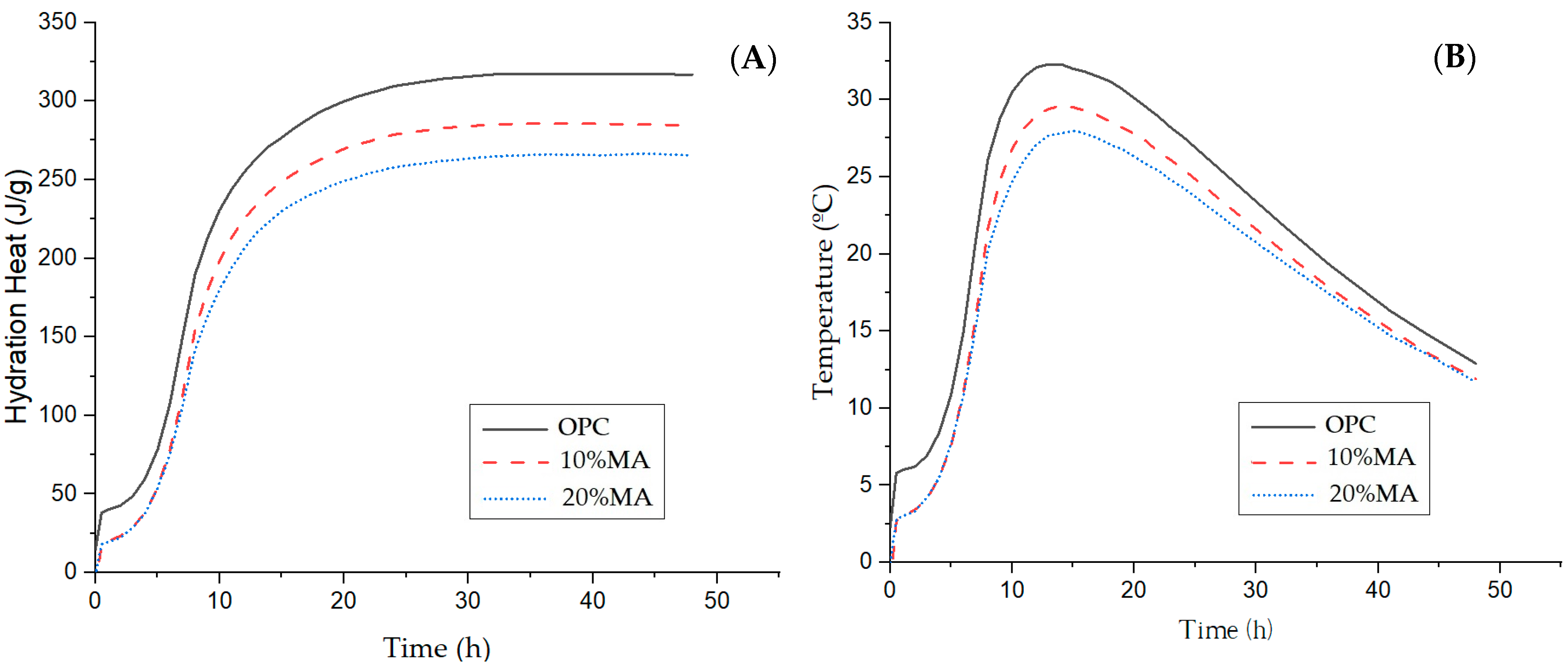

3.5.1. Calorimetric Behavior of the Mortars

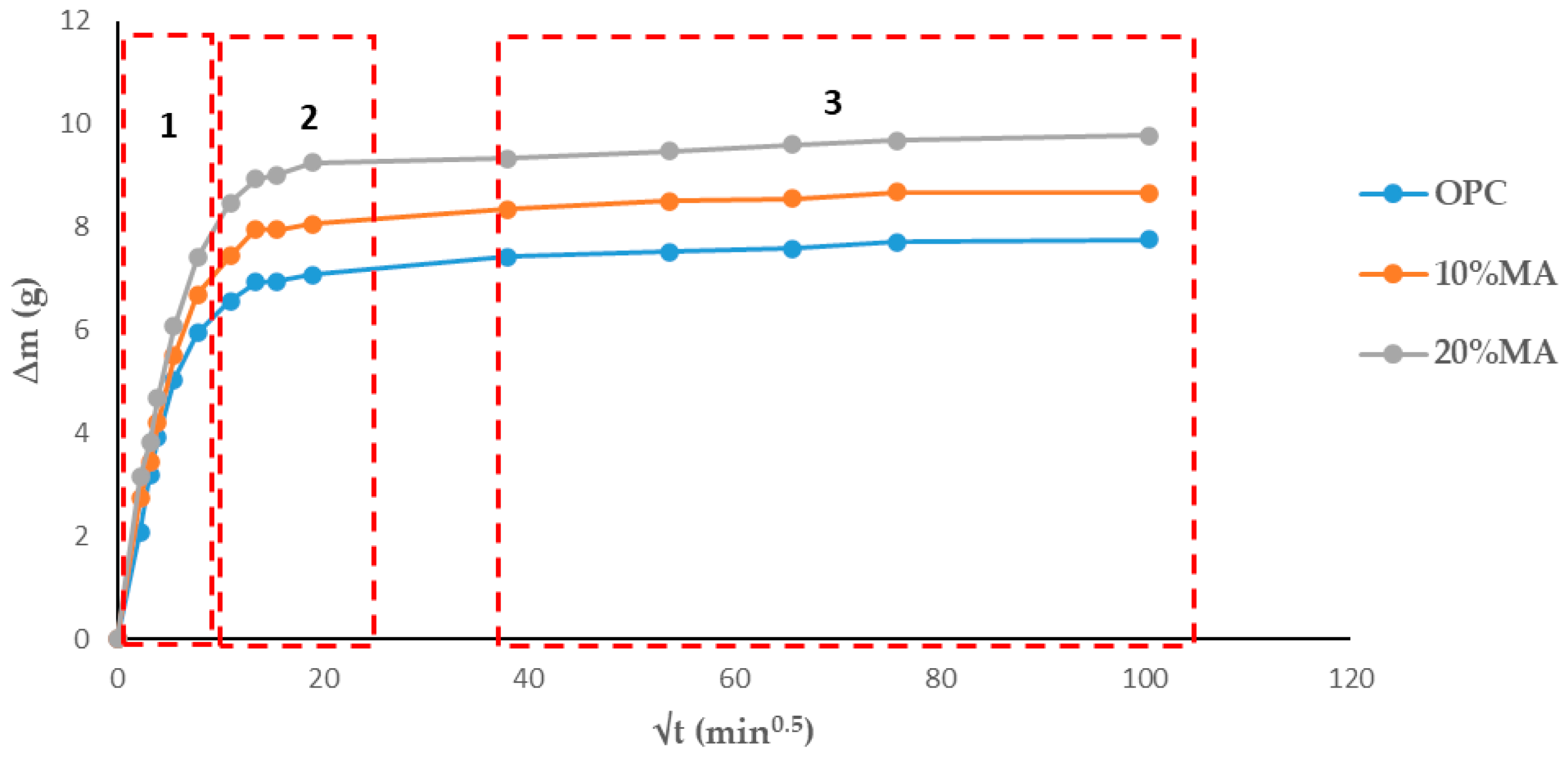

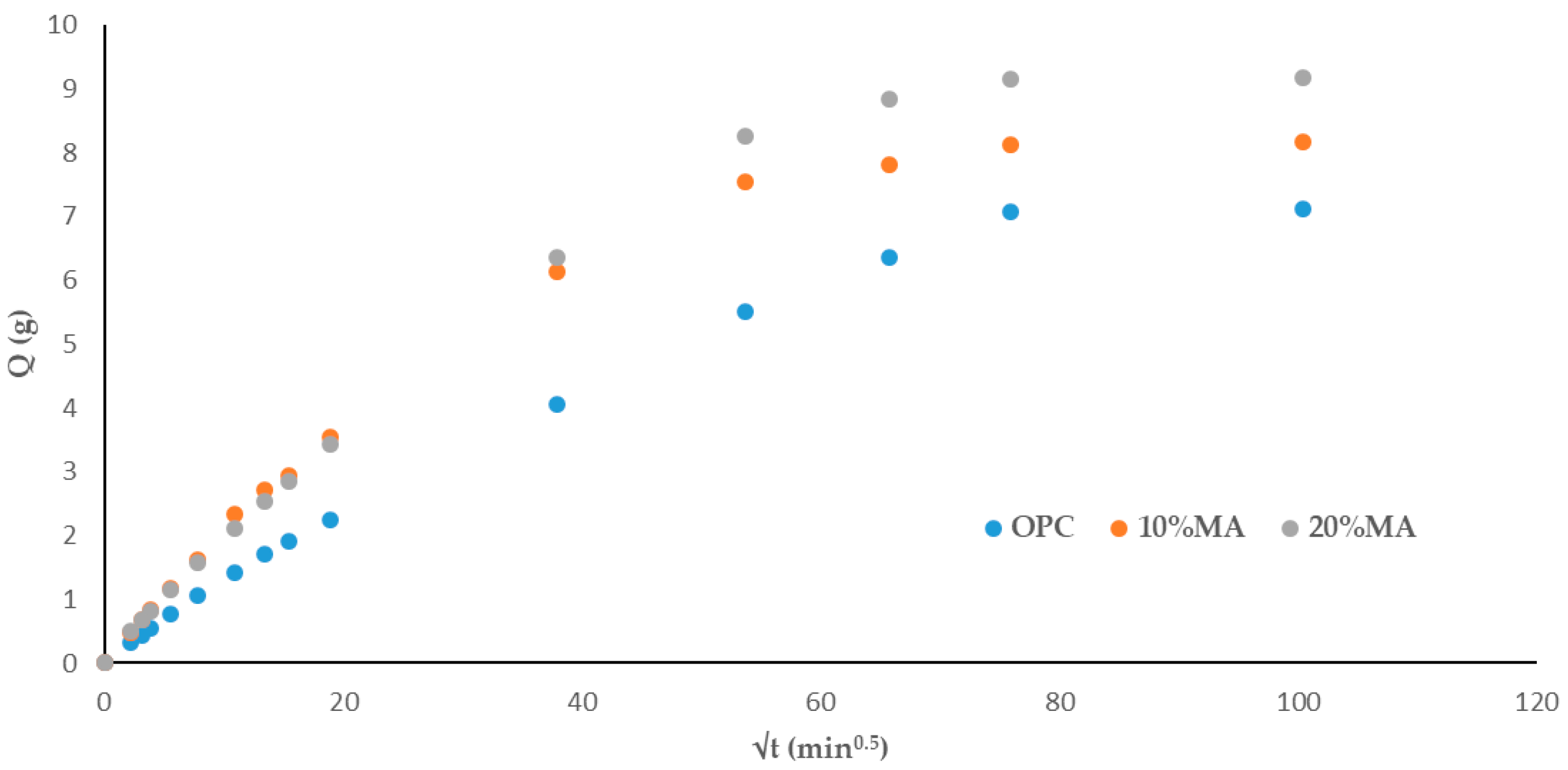

3.5.2. Total and Capillary Water Absorption

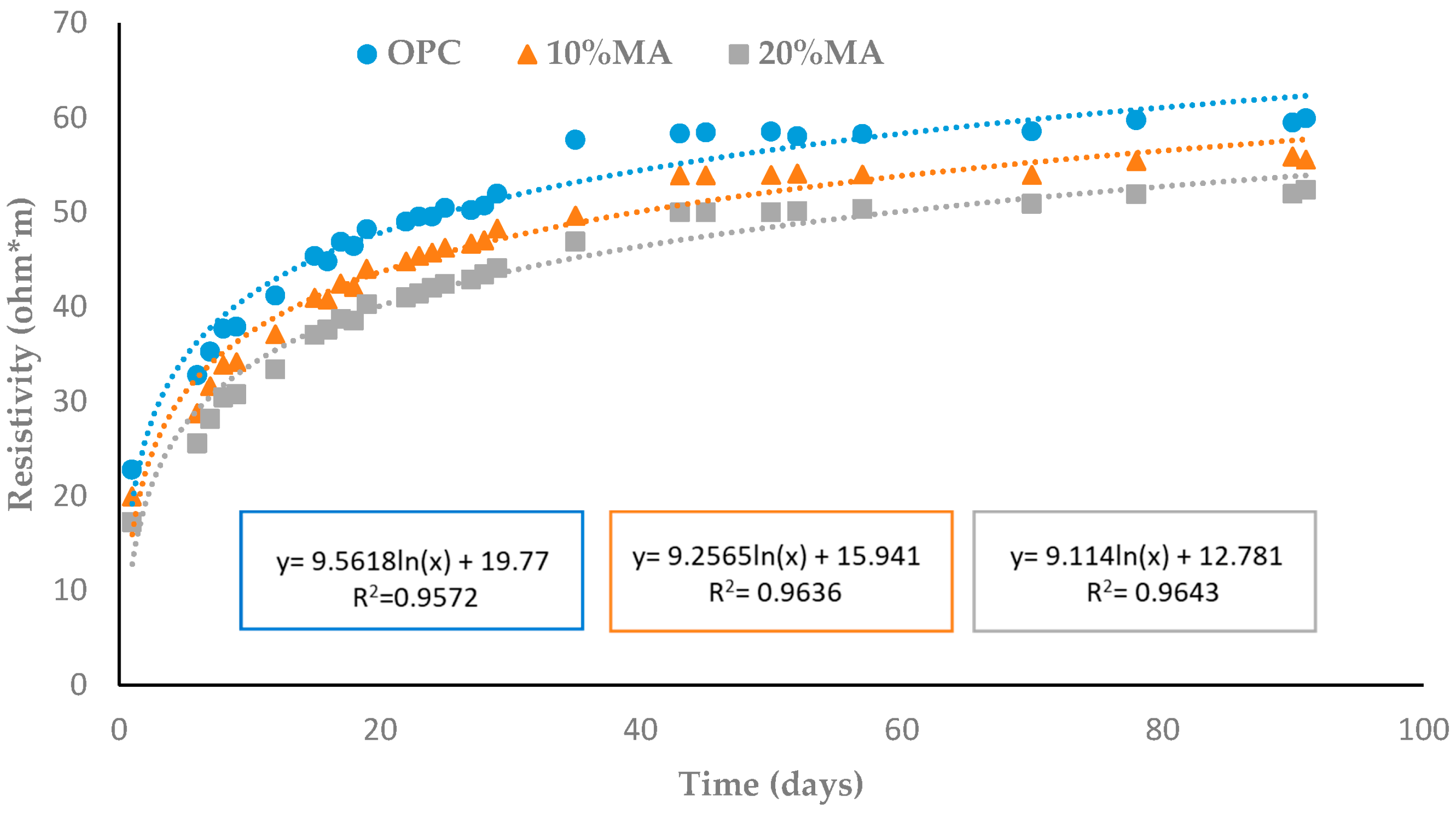

3.5.3. Electrical Resistivity

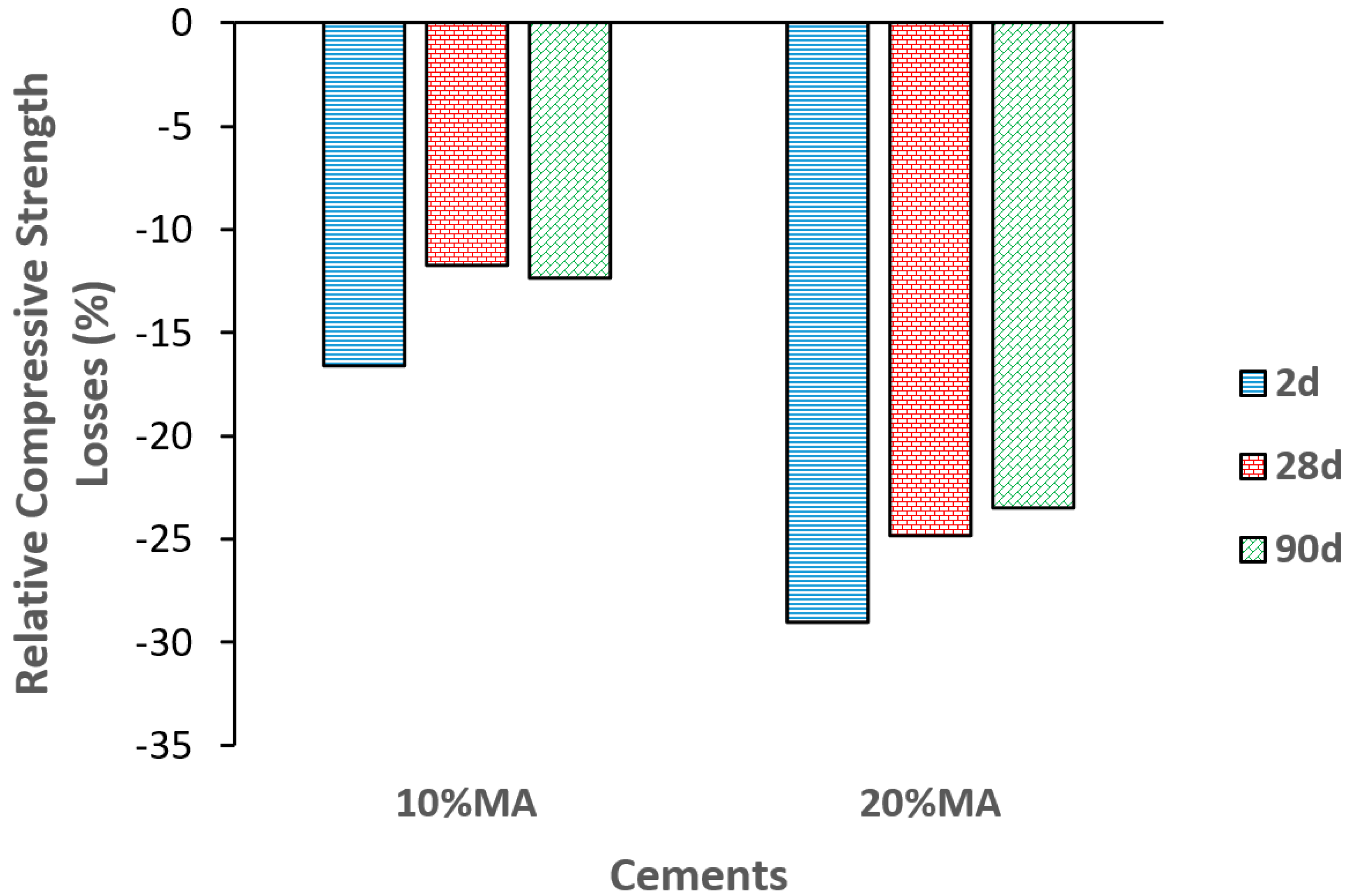

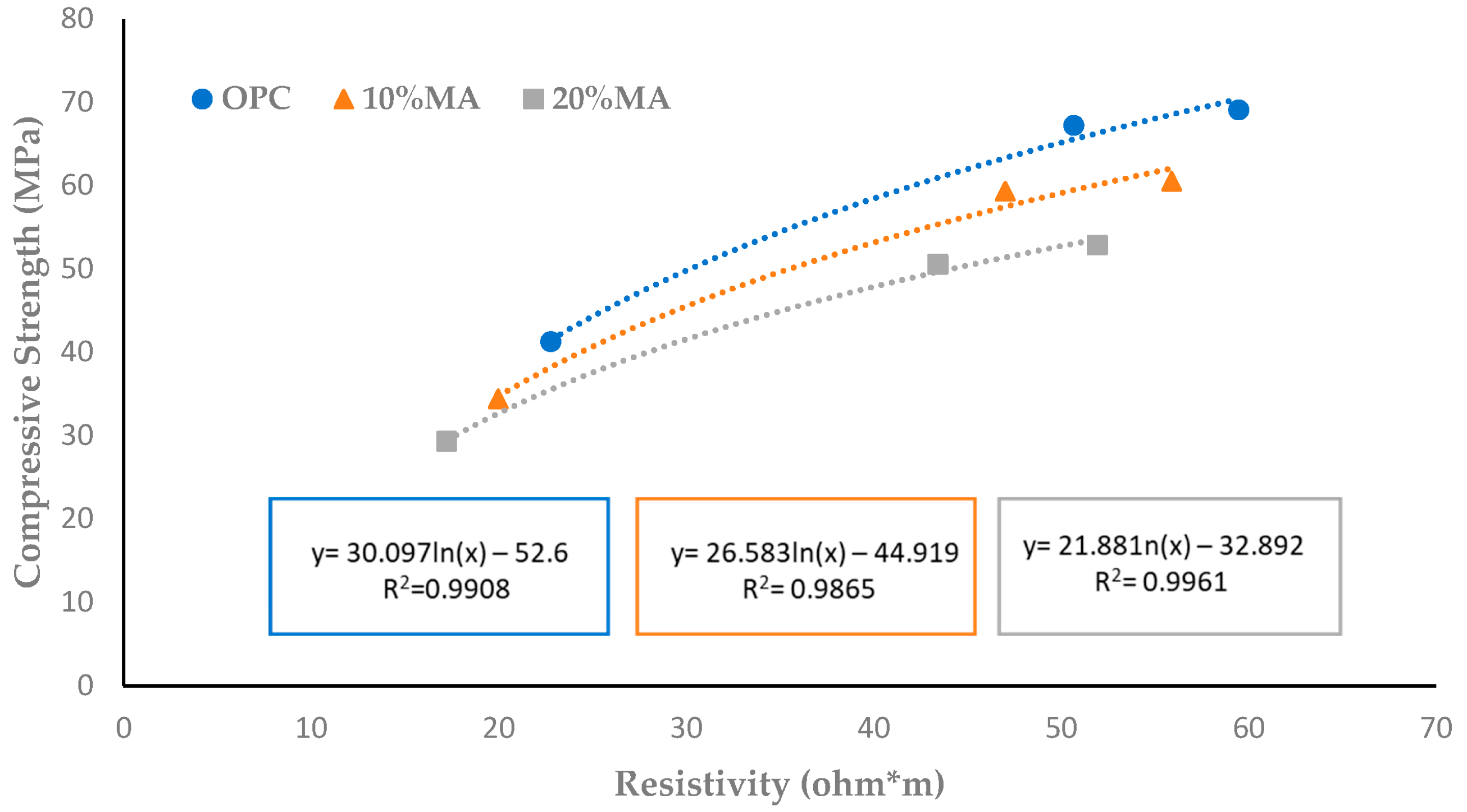

3.5.4. Compressive Strength and Microporosity

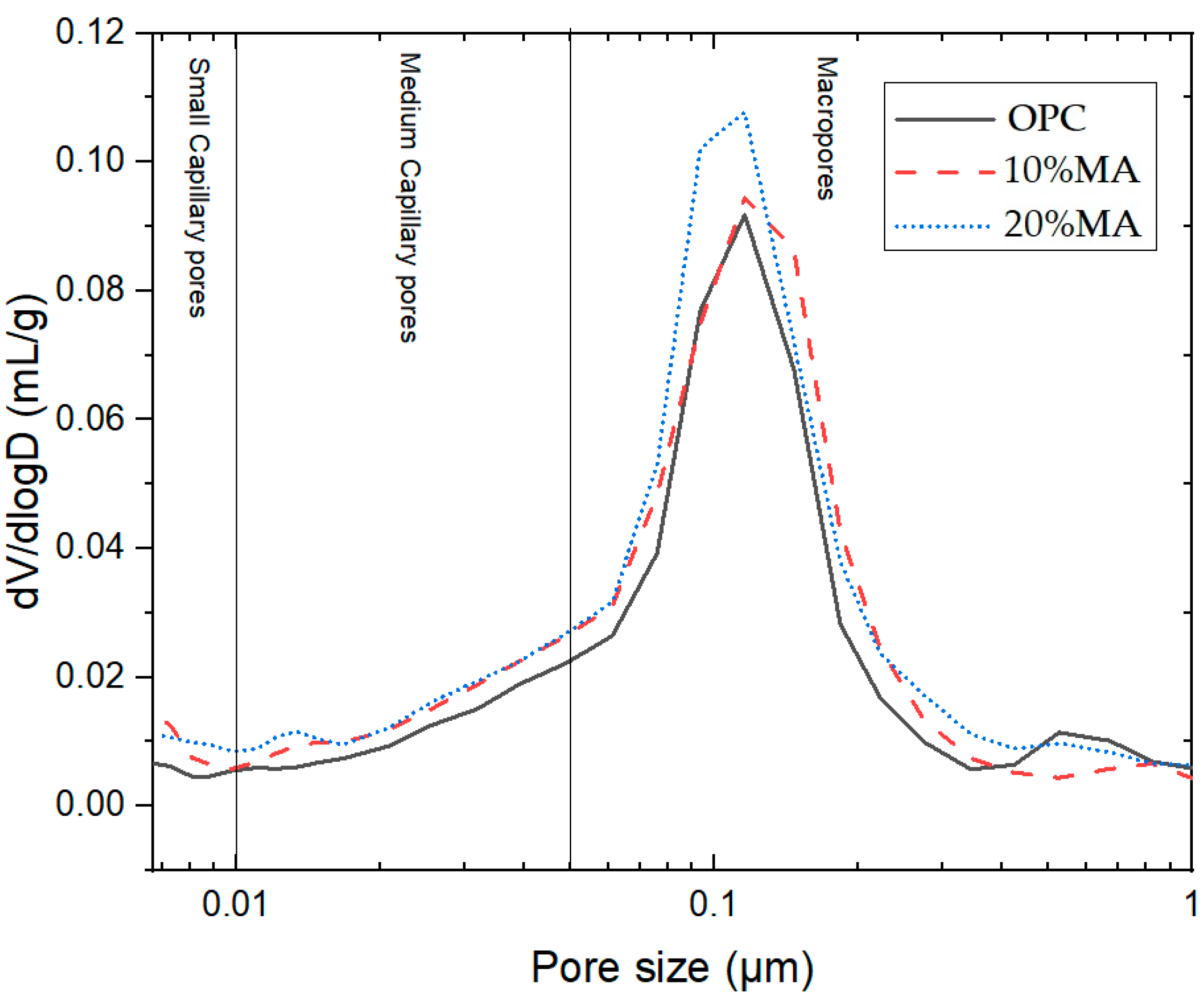

4. Conclusions

- Chemical analysis determined by the XRF of the MA shows that the sum of SiO2 + Al2O3 + Fe2O3 (4.43%) oxides is far below the minimum value recommended by the regulations for active cement admixtures (≥70%). In addition, it presents 30% LOI due to its calcium and unburned material content, and 6.92% K2O.

- From a mineralogical point of view, MA comprises 46% calcareous minerals (calcite and dolomite) and 41% amorphous phase.

- MA exhibits medium–low pozzolanic activity in the pozzolan/lime system due to its chemical and mineral composition. SEM-EDX analyses at 28 days of reaction identified CSH gels and ettringite as mineralogical phases produced by the pozzolanic reaction.

- 10% and 20% MA blended cements meet the chemical (SO3 and Cl−) and physical (NCW, IST, and S) requirements set out in the regulations.

- The heating curves and heat of hydration of the mortars containing 10% and 20% MA decrease in inverse proportion to the ash content. The types of cement made with 20% MA qualify as low heat-of-hydration cement (≤270 J/g).

- In terms of intrinsic properties, the addition of MA results in an increase in water absorption (total and capillary), lower electrical resistivity (up to 13%), and classification of the blended mortars as durable from the point of view of penetration by aggressive agents.

- Although, when compared to the OPC mortar, the MA cement mortars experience a decrease in compressive strength at 28 d of curing roughly equivalent to the replacement rate, the binary cement made with 10% and 20% MA meet the mechanical requirements for the manufacture of commercial cement. At 2 d of hydration, the materials maintain the initial strength category (52.5), but at 28 days the 20% MA cement drops to the lower strength category (42.5). A good coefficient of correlation (≥0.98) was found between strength and resistivity.

- The porosimetry tests corroborate the findings of the intrinsic tests, highlighting that the MA cement admixture produces an increase in total porosity, although a slight refinement of less than 100 nm is observed in the pore density curves.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cement Roadmap. Available online: https://iea.blob.core.windows.net/assets/e3d8a122-455c-49f1-9347-635f46529826/Cement_Roadmap_Foldout_WEB.pdf (accessed on 29 May 2024).

- Sanjuán, M.Á.; Martínez, R.; Alarcón Barrio, A.; Josa Garcia-Tornel, A. Análisis Prenormativo de Los Constituyentes Potenciales de Los Cementos Pórtland. Cem. Hormig. 2023, 1015, 27–39. [Google Scholar]

- AENOR UNE-EN 197-1; Cemento. Parte 1: Composición, Especificaciones y Criterios de Conformidad de Los Cementos Comunes. Asociación Española de Normalización: Madrid, Spain, 2018.

- Vashistha, P.; Park, S.; Pyo, S. A Review on Sustainable Fabrication of Futuristic Cementitious Binders Based on Application of Waste Concrete Powder, Steel Slags, and Coal Bottom Ash. Int. J. Concr. Struct. Mater. 2022, 16, 51. [Google Scholar] [CrossRef]

- Meziani, M.; Leklou, N.; Chelouah, N.; Amiri, O. Mechanical and Thermal Modification of Mordenite-Rich Tuff and Its Effect on Cement Pastes. Constr. Build. Mater. 2022, 318, 126008. [Google Scholar] [CrossRef]

- Pinheiro, V.D.; Alexandre, J.; Xavier, G.D.; Marvila, M.T.; Monteiro, S.N.; de Azevedo, A.R. Methods for Evaluating Pozzolanic Reactivity in Calcined Clays: A Review. Materials 2023, 16, 4778. [Google Scholar] [CrossRef]

- Pillay, D.L.; Olalusi, O.B.; Mostafa, M.M.H. A Review of the Engineering Properties of Concrete with Paper Mill Waste Ash—Towards Sustainable Rigid Pavement Construction. Silicon 2021, 13, 3191–3207. [Google Scholar] [CrossRef]

- Vegas, I.; Frías, M.; Urreta, J.; San José, J.T. Obtaining a Pozzolanic Addition from the Controlled Calcination of Paper Mill Sludge. Performance in Cement Matrices. Mater. Constr. 2006, 56, 49–60. [Google Scholar]

- Frías, M. The Effect of Metakaolin on the Reaction Products and Microporosity in Blended Cement Pastes Submitted to Long Hydration Time and High Curing Temperature. Adv. Cem. Res. 2006, 18, 1–6. [Google Scholar] [CrossRef]

- Velardo, P.; Sáez del Bosque, I.F.; Sánchez de Rojas, M.I.; De Belie, N.; Medina, C. Design and Evaluation of Physical, Mechanical and Micro-Structural Properties of Eco-Friendly Binary-Blended Mortars Using Biomass Bottom Ash or Construction and Demolition Waste Powder. Cem. Concr. Compos. 2023, 143, 105252. [Google Scholar] [CrossRef]

- Zhai, J.; Burke, I.T.; Stewart, D.I. Beneficial Management of Biomass Combustion Ashes. Renew. Sustain. Energy Rev. 2021, 151, 111555. [Google Scholar] [CrossRef]

- European Directive 2023/2413 to the Promotion of Energy from Renewable Source. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32023L2413&qid=1699364355105 (accessed on 29 May 2024).

- Adhikary, S.K.; Ashish, D.K.; Rudžionis, Ž. A Review on Sustainable Use of Agricultural Straw and Husk Biomass Ashes: Transitioning towards Low Carbon Economy. Sci. Total Environ. 2022, 838, 156407. [Google Scholar] [CrossRef]

- Silva, L.H.P.; de Paiva, F.F.G.; Tamashiro, J.R.; Kinoshita, A. Potential of Bamboo Leaf Ash as Supplementary Binder Materials—A Systematic Literature Review. J. Build. Eng. 2023, 71, 106547. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Frías, M.; Savastano, H.; Rodier, L.; Sánchez de Rojas, M.I.; Sáez del Bosque, I.F.; Medina, C. Quantitative Comparison of Binary Mix of Agro-Industrial Pozzolanic Additions for Elaborating Ternary Cements: Kinetic Parameters. Materials 2021, 14, 2944. [Google Scholar] [CrossRef] [PubMed]

- Moreno, S.; Rosales, M.; Rosales, J.; Agrela, F.; Díaz-López, J.L. Feasibility of Using New Sustainable Mineral Additions for the Manufacture of Eco-Cements. Materials 2024, 17, 777. [Google Scholar] [CrossRef] [PubMed]

- Rithuparna, R.; Jittin, V.; Bahurudeen, A. Influence of Different Processing Methods on the Recycling Potential of Agro-Waste Ashes for Sustainable Cement Production: A Review. J. Clean. Prod. 2021, 316, 128242. [Google Scholar] [CrossRef]

- Nakanishi, E.Y.; Frías, M.; Santos, S.F.; Rodrigues, M.S.; Vigil de la Villa, R.; Rodriguez, O.; Junior, H.S. Investigating the Possible Usage of Elephant Grass Ash to Manufacture the Eco-Friendly Binary Cements. J. Clean. Prod. 2016, 116, 236–243. [Google Scholar] [CrossRef]

- Yin, K.; Ahamed, A.; Lisak, G. Environmental Perspectives of Recycling Various Combustion Ashes in Cement Production—A Review. Waste Manag. 2018, 78, 401–416. [Google Scholar] [CrossRef]

- Kasaniya, M.; Thomas, M.D.A.; Moffatt, E.G. Efficiency of Natural Pozzolans, Ground Glasses and Coal Bottom Ashes in Mitigating Sulfate Attack and Alkali-Silica Reaction. Cem. Concr. Res. 2021, 149, 106551. [Google Scholar] [CrossRef]

- Frías, M.; Caneda-Martínez, L.; Sánchez de Rojas, M.I.; Tenazoa, C.; Flores, E. Scientific and Technical Studies on Eco-Efficient Binary Cements Produced with Thermally Activated Ichu Grass: Behaviour and Properties. Cem. Concr. Compos. 2020, 111, 103613. [Google Scholar] [CrossRef]

- Pedroso, D.T.; Kaltschmitt, M. Dichrostachys Cinerea as a Possible Energy Crop—Facts and Figures. Biomass Convers. Biorefin. 2012, 2, 41–51. [Google Scholar] [CrossRef]

- Hernández Sardiñas, A.; González Morales, V.M.; Freide Orozco, M.L. Aprovechamiento de Las Posibles Fuentes de Biomasa Para Entregar Más Electricidad En La Fábrica de Azúcar Antonio Sánchez. Centro. Azúcar. 2017, 44, 88–97. [Google Scholar]

- Rubio-González, A.; Iturria Quintero, P.J.; Rodríguez-Machín, L.; Palmero Marín, D. Propiedades del marabú (Dichrostachys cinerea L.) cosechado con máquinas, como combustible para la generación de electricidad (primera parte). Centro. Azúcar. 2021, 48, 93–104. [Google Scholar]

- Sagastume Gutiérrez, A.; Cabello Eras, J.J.; Vandecasteele, C.; Hens, L. Data Supporting the Assessment of Biomass Based Electricity and Reduced GHG Emissions in Cuba. Data Brief. 2018, 17, 716–723. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Valencia-Morales, E.; González-Rodríguez, R.; Hernández-Ruíz, J. Kinetics of the Pozzolanic Reaction between Lime and Sugar Cane Straw Ash by Electrical Conductivity Measurement: A Kinetic–Diffusive Model. Cem. Concr. Res. 2003, 33, 517–524. [Google Scholar] [CrossRef]

- AENOR UNE-EN 196-3; Métodos de Ensayo de Cementos. Parte 3: Determinación del Tiempo de Fraguado y de La Estabilidad de Volumen. Asociación Española de Normalización: Madrid, Spain, 2017.

- Spanish Standard UNE 83982; Determinación de La Absorción de Agua Por Capilaridad Del Hormigón Endurecido. Asociación Española de Normalización: Madrid, Spain, 2008.

- Spanish Standard IME 83966; Acondicionamiento de Probetas de Hormigón Para Los Ensayos de Permeabilidad a Gases y Capilaridad. Asociación Española de Normalización: Madrid, Spain, 2008.

- Spanish Standard UNE 83988-2; Durabilidad Del Hormigón. Métodos de Ensayo. Determinación de La Resistividad Eléctrica. Parte 2: Método de Las Cuatro Puntas o de Wenner. Asociación Española de Normalización: Madrid, Spain, 2014.

- Attari, A.; McNally, C.; Richardson, M.G. A Probabilistic Assessment of the Influence of Age Factor on the Service Life of Concretes with Limestone Cement/GGBS Binders. Constr. Build. Mater. 2016, 111, 488–494. [Google Scholar] [CrossRef]

- AENOR UNE-EN 196-1; Métodos de Ensayo de Cementos. Parte 1: Determinación de Resistencias Mecánicas. Asociación Española de Normalización: Madrid, Spain, 2018.

- European Standard EN 196-9; Methods of Testing Cement—Part 9: Heat of Hydration-Semi-Adiabatic Method. European Committee for Standardization: Brussels, Belgium, 2011.

- American Standard ASTM C618-23e1; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2023.

- Wang, H.; Liu, X.; Zhang, Z. Pozzolanic Activity Evaluation Methods of Solid Waste: A Review. J. Clean. Prod. 2023, 402, 136783. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Frías, M.; Savastano, H. Quantitative Comparison of Mineral Ash from Agro-Industrial Waste for Use as Pozzolanic Additions in Cement: Kinetic Parameters. Asp. Min. Miner. Sci. 2020, 5, 626–634. [Google Scholar]

- European Standard EN 450-1; Fly Ash for Concrete—Part 1: Definition, Specification and Conformity Criteria. European Committee for Standardization: Brussels, Belgium, 2013.

- Jawed, I.; Skalny, J. Alkalies in Cement: A Review: II. Effects of Alkalies on Hydration and Performance of Portland Cement. Cem. Concr. Res. 1978, 8, 37–51. [Google Scholar] [CrossRef]

- Mkahal, Z.; Maherzi, W.; Mamindy-Pajany, Y.; Bouzar, B.; Abriak, N.-E. Development of a Low-Carbon Binder Based on Raw, Ground, and Carbonated Waste Paper Fly Ash. Sustain. Mater. Technol. 2023, 36, e00650. [Google Scholar] [CrossRef]

- Zeraoui, A.; Maherzi, W.; Benzerzour, M.; Abriak, N.E.; Aouad, G. Development of Flash-Calcined Sediment and Blast Furnace Slag Ternary Binders. Buildings 2023, 13, 333. [Google Scholar] [CrossRef]

- Caneda-Martínez, L.; Medina, C.; Sánchez de Rojas, M.I.; Frías, M. Water Transport in Binary Eco-Cements Containing Coal Mining Waste. Cem. Concr. Compos. 2019, 104, 103373. [Google Scholar] [CrossRef]

- Rosales, J.; Cabrera, M.; Beltrán, M.G.; López, M.; Agrela, F. Effects of Treatments on Biomass Bottom Ash Applied to the Manufacture of Cement Mortars. J. Clean. Prod. 2017, 154, 424–435. [Google Scholar] [CrossRef]

- Senthamarai, R.M.; Manoharan, P.D.; Gobinath, D. Concrete Made from Ceramic Industry Waste: Durability Properties. Constr. Build. Mater. 2011, 25, 2413–2419. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman Scientific & Technical Jogn Wiley & Sons, Harlow: New York, NY, USA, 1995; Volume 4. [Google Scholar]

- Naji Givi, A.; Abdul Rashid, S.; Aziz, F.N.A.; Salleh, M.A.M. The Effects of Lime Solution on the Properties of SiO2 Nanoparticles Binary Blended Concrete. Compos. Part B 2011, 42, 562–569. [Google Scholar] [CrossRef]

- Medina, J.M.; Sáez del Bosque, I.F.; Frías, M.; Sánchez de Rojas, M.I.; Medina, C. Durability of New Blended Cements Additioned with Recycled Biomass Bottom ASH from Electric Power Plants. Constr. Build. Mater. 2019, 225, 429–440. [Google Scholar] [CrossRef]

- Lu, J.; Wang, K.; Qu, M.-L. Experimental Determination on the Capillary Water Absorption Coefficient of Porous Building Materials: A Comparison between the Intermittent and Continuous Absorption Tests. J. Build. Eng. 2020, 28, 101091. [Google Scholar] [CrossRef]

- Torres-Castellanos, N.; Torres-Agredo, J.; Mejía-de-Gutierrez, R. Permeation Properties of Concrete Added with a Petrochemical Industry Waste. Ing. Investig. 2017, 37, 23–29. [Google Scholar] [CrossRef]

- Silva, Y.F.; Lange, D.A.; Delvasto, S. Effect of Incorporation of Masonry Residue on the Properties of Self-Compacting Concretes. Constr. Build. Mater. 2019, 196, 277–283. [Google Scholar] [CrossRef]

- Wygocka-Domagałło, A.; Garbalińska, H. The Effect of Pore Structure on the Water Sorption Coefficient of Cement Mortars Reinforced with 12 mm Polypropylene Fibres. Constr. Build. Mater. 2020, 248, 118606. [Google Scholar] [CrossRef]

- Castañeda, A.; Albear, J.J.H.; Corvo, F.; Marrero, R. Concrete Quality Assessment before Building Structure s Submitting to Environment al Exposure Conditions. Rev. Constr. 2017, 16, 374–387. [Google Scholar]

- Trocónis, O.; Romero, A.; Andrade, C.; Helene, P.; Díaz, I. Manual de Inspección, Evaluación y Diagnóstico de Corrosión En Estructuras de Hormigón Armado; CYTED Red. Temática XV. B. Durabilidad de la Armadura: Río de Janeiro, Brazil, 1997. [Google Scholar]

- Mera, J.C.G.; Albear, J.J.H.; Valdés, A.C. Primeras Experiencias en el Desempeño por Durabilidad de un Hormigón Antes de Usarlo en el Perfil Costero de Manabí, Ecuador. Rev. CENIC Cienc. Quím. 2017, 48, 27–40. [Google Scholar]

- Monasterio, M.; Caneda-Martínez, L.; Vegas, I.; Frías, M. Progress in the Influence of Recycled Construction and Demolition Mineral-Based Blends on the Physical–Mechanical Behaviour of Ternary Cementitious Matrices. Constr. Build. Mater. 2022, 344, 128169. [Google Scholar] [CrossRef]

- Medina, C.; Sánchez de Rojas, M.I.; Thomas, C.; Polanco, J.A.; Frías, M. Durability of Recycled Concrete Made with Recycled Ceramic Sanitary Ware Aggregate. Inter-Indicator Relationships. Constr. Build. Mater. 2016, 105, 480–486. [Google Scholar] [CrossRef]

- Hou, T.-C.; Nguyen, V.K.; Su, Y.-M.; Chen, Y.-R.; Chen, P.-J. Effects of Coarse Aggregates on the Electrical Resistivity of Portland Cement Concrete. Constr. Build. Mater. 2017, 133, 397–408. [Google Scholar] [CrossRef]

- Rajamma, R.; Senff, L.; Ribeiro, M.J.; Labrincha, J.A.; Ball, R.J.; Allen, G.C.; Ferreira, V.M. Biomass Fly Ash Effect on Fresh and Hardened State Properties of Cement Based Materials. Compos. Part B 2015, 77, 1–9. [Google Scholar] [CrossRef]

- Andrade, C. Resistivity Test Criteria for Durability Design and Quality Control of Concrete in Chloride Exposures. Concr. Aust. 2014, 40, 57–64. [Google Scholar]

- Velardo, P.; Sáez del Bosque, I.F.; Sánchez de Rojas, M.I.; De Belie, N.; Medina, C. Effect of Incorporating Biomass Bottom Ash and Construction and Demolition Waste Powder on the Physical-Mechanical Properties and Micro-Structure of Ternary-Blended Mortars. Constr. Build. Mater. 2024, 432, 136628. [Google Scholar] [CrossRef]

- Frías, M.; de Rojas, M.I.S.; Rodríguez, C. The Influence of SiMn Slag on Chemical Resistance of Blended Cement Pastes. Constr. Build. Mater. 2009, 23, 1472–1475. [Google Scholar] [CrossRef]

| OPC | MA | |

|---|---|---|

| SiO2 | 20.06 | 2.63 |

| Al2O3 | 4.96 | 1.02 |

| Fe2O3 | 3.28 | 0.78 |

| CaO | 62.19 | 45.42 |

| MgO | 2.12 | 6.36 |

| SO3 | 3.14 | 4.14 |

| Na2O | 0.37 | 0.48 |

| K2O | 0.66 | 6.92 |

| TiO2 | 0.25 | 0.09 |

| P2O5 | 0.29 | 1.13 |

| Cl | 0.07 | 0.77 |

| ZnO | 0.17 | - |

| SrO | 0.16 | - |

| Cr2O3 | 0.04 | - |

| LOI | 2.11 | 30.00 |

| Raw Material | D10 (µm) | D50 (µm) | D90 (µm) |

|---|---|---|---|

| OPC | 2.11 | 14.10 | 34.40 |

| MA | 2.40 | 13.60 | 34.70 |

| Mineral (%) | OPC | MA |

|---|---|---|

| Quartz | n.d. | 13 |

| Calcite | 4 | 34 |

| Dolomite | n.d. | 12 |

| K-feldspar | n.d. | n.d. |

| C3S | 52 | n.d. |

| C2S | 20 | n.d. |

| C4AF | 6 | n.d. |

| C3A | 9 | n.d. |

| Amorphous matter | 9 | 41 |

| RB | 17.2 | 19.6 |

| X2 | 7.3 | 9.4 |

| Parameters | Rate K (h−1) | Free Energy of Activation AG#, kJ/mol | Ccorr | Coefficient of Multiple Determination (R2) | |

|---|---|---|---|---|---|

| MA | 108.9 ± 0.1 | (2.57 ± 0.07)·10−3 | 113.61 | 0.88 ± 0.007 | 0.9852 |

| % | Quartz | Calcite | Dolomite | Amorphous Phase | RB | X2 |

|---|---|---|---|---|---|---|

| Starting MA | 13 | 34 | 12 | 41 | 19.6 | 9.4 |

| 28 d MA | 16 | 47 | traces | 37 | 18.6 | 7.4 |

| Oxides (%) | CSH Gels | Ettringite |

|---|---|---|

| MgO | 12.74 ± 2.35 | n.d. |

| Al2O3 | 6.65 ± 2.19 | 16.57 ± 2.25 |

| SiO2 | 20.91 ± 2.86 | 6.26 ± 2.87 |

| SO3 | 4.25 ± 1.63 | 22.71 ± 4.72 |

| P2O5 | 3.34 ± 1.25 | n.d. |

| K2O | 0.88 ± 0.32 | n.d. |

| CaO | 48.80 ± 4.26 | 54.43 ± 4.53 |

| Fe2O3 | 2.44 ± 0.71 | n.d. |

| Oxides (%) | OPC | 10% MA | 20% MA | EN 197-1 |

|---|---|---|---|---|

| SiO2 | 20.06 | 18.32 | 16.57 | - |

| Al2O3 | 4.96 | 4.57 | 4.17 | - |

| Fe2O3 | 3.28 | 3.03 | 2.78 | - |

| CaO | 62.19 | 60.51 | 58.84 | - |

| MgO | 2.12 | 2.54 | 2.97 | - |

| SO3 | 3.14 | 3.24 | 3.34 | ≤3.5–4.0 |

| Na2O | 0.37 | 0.38 | 0.39 | - |

| K2O | 0.66 | 1.29 | 1.91 | - |

| TiO2 | 0.25 | 0.23 | 0.22 | - |

| P2O5 | 0.29 | 0.37 | 0.46 | - |

| Cl | 0.06 | 0.05 | 0.05 | ≤0.1 |

| ZnO | 0.17 | 0.15 | 0.14 | |

| SrO | 0.16 | 0.14 | 0.13 | |

| Cr2O3 | 0.04 | 0.04 | 0.03 | |

| LOI | 2.11 | 4.90 | 7.69 |

| OPC | 10% MA | 20% MA | EN Standard | |

|---|---|---|---|---|

| NCW (±1 g) | 150 | 151 | 154 | - |

| IST (±10 min) | 138 | 129 | 126 | ≥60 |

| S (mm) | 0.15 | 0.10 | 0.10 | ≤10 |

| Sample | Time (h) | Heat of Hydration (J/g) |

|---|---|---|

| OPC | 41 | 317.4 |

| 10% MA | 41 | 285.54 |

| 20% MA | 41 | 265.54 |

| Cement | Total Water Absorption (wt%) | Absorption Rate (g/min0.5) | R2 |

|---|---|---|---|

| OPC | 4.26 | 0.78 | 0.96 |

| 10% MA | 4.83 | 0.86 | 0.97 |

| 20% MA | 5.63 | 0.94 | 0.97 |

| Material | Rate 1 | Rate 2 | Rate 3 |

|---|---|---|---|

| Intervals | 2.24–7.75 min0.5 | 10.95–18.97 min0.5 | 37.95–14,400 min0.5 |

| OPC | 0.682 | 0.058 | 0.006 |

| 10% MA | 0.729 | 0.067 | 0.005 |

| 20% MA | 0.788 | 0.092 | 0.007 |

| Material | K (kg/m2min0.5) | (cm3/cm3) | m (min/cm2) |

|---|---|---|---|

| OPC | 0.736 | 0.788 | 87.210 |

| 10% MA | 1.112 | 1.190 | 87.316 |

| 20% MA | 1.173 | 1.252 | 87.698 |

| OPC | 10% MA | 20% MA | |

|---|---|---|---|

| q | 0.231 | 0.246 | 0.265 |

| 19.716 | 17.566 | 15.179 | |

| R2 | 0.964 | 0.969 | 0.971 |

| Mortar | 2 d | 28 d | 90 d | EN 197-1 |

|---|---|---|---|---|

| OPC | 41.23 ± 0.01 | 67.17 ± 0.18 | 69.03 ± 1.07 | ≥20–30 (2 d) ≥52.5 (28 d) |

| 10% MA | 34.73 ± 0.24 | 59.29 ± 0.16 | 60.50 ± 0.08 | |

| 20% MA | 29.27 ± 0.46 | 50.50 ± 0.61 | 52.81 ± 0.05 |

| Total Porosity (vol. %) | ||

|---|---|---|

| 2 d | 90 d | |

| OPC | 13.96 | 11.70 |

| 10% MA | 16.83 | 13.01 |

| 20% MA | 17.14 | 14.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frías, M.; Moreno de los Reyes, A.M.; Villar-Cociña, E.; García, R.; Vigil de la Villa, R.; Vasić, M.V. New Eco-Cements Made with Marabou Weed Biomass Ash. Materials 2024, 17, 5012. https://doi.org/10.3390/ma17205012

Frías M, Moreno de los Reyes AM, Villar-Cociña E, García R, Vigil de la Villa R, Vasić MV. New Eco-Cements Made with Marabou Weed Biomass Ash. Materials. 2024; 17(20):5012. https://doi.org/10.3390/ma17205012

Chicago/Turabian StyleFrías, Moisés, Ana María Moreno de los Reyes, Ernesto Villar-Cociña, Rosario García, Raquel Vigil de la Villa, and Milica Vidak Vasić. 2024. "New Eco-Cements Made with Marabou Weed Biomass Ash" Materials 17, no. 20: 5012. https://doi.org/10.3390/ma17205012

APA StyleFrías, M., Moreno de los Reyes, A. M., Villar-Cociña, E., García, R., Vigil de la Villa, R., & Vasić, M. V. (2024). New Eco-Cements Made with Marabou Weed Biomass Ash. Materials, 17(20), 5012. https://doi.org/10.3390/ma17205012