Confined Layer Slip Process in Nanolaminated Ag and Two Ag/Cu Nanolaminates

Abstract

1. Introduction

2. Materials and Methods

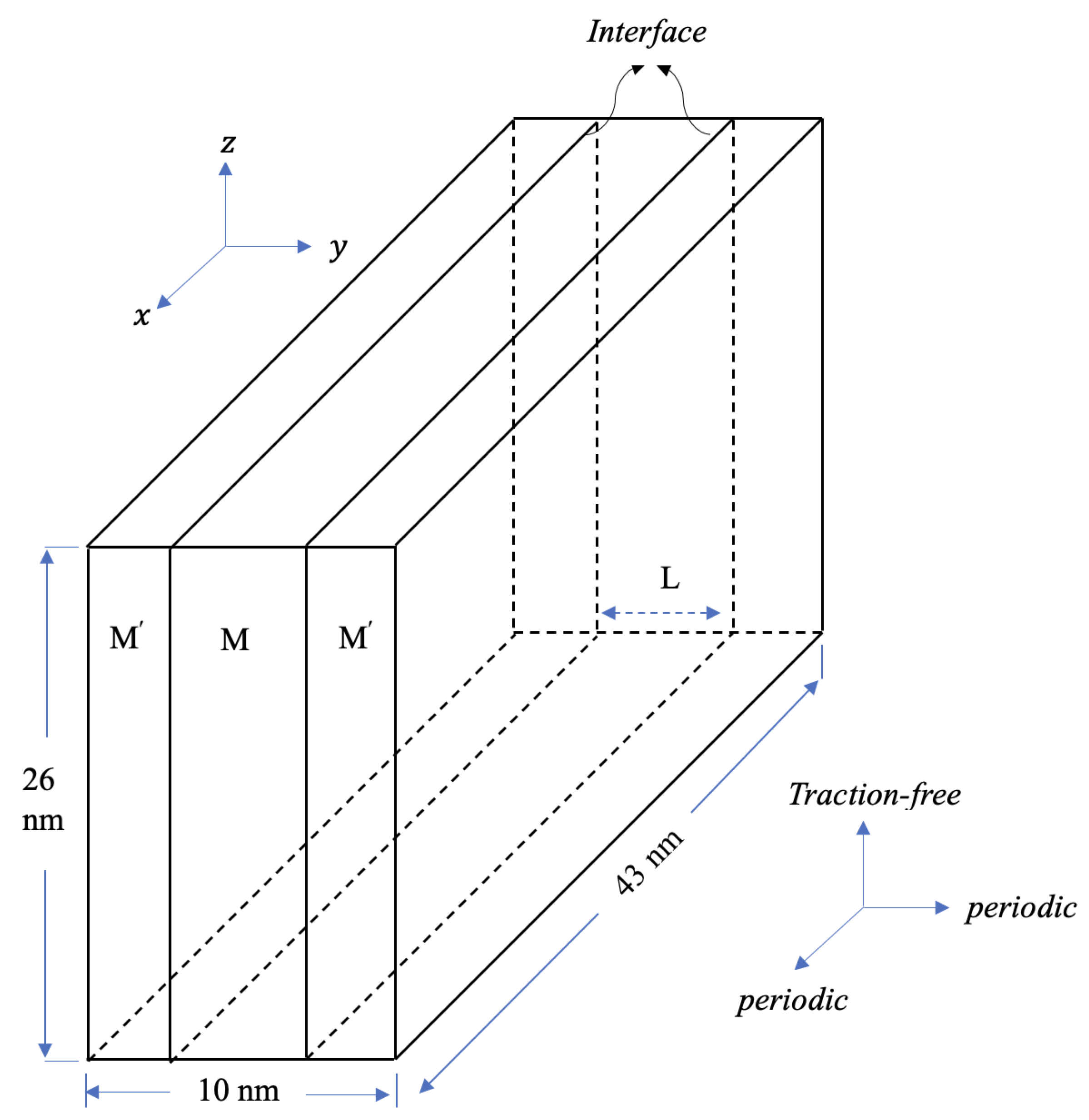

2.1. Single Crystal Model

2.2. Bicrystal Model

3. Results and Discussion

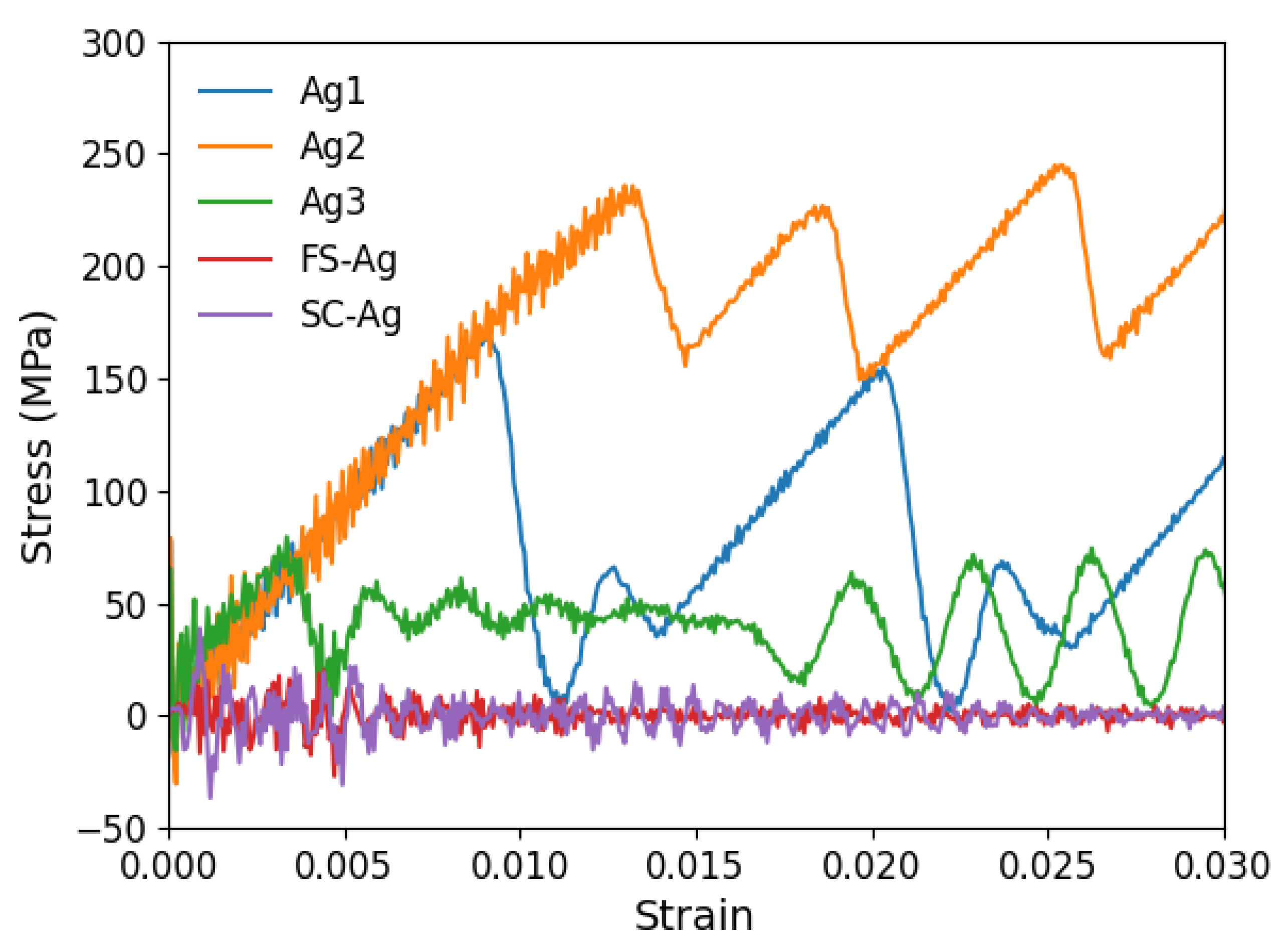

3.1. Nanolaminated Ag, SC-Ag, and FS-Ag

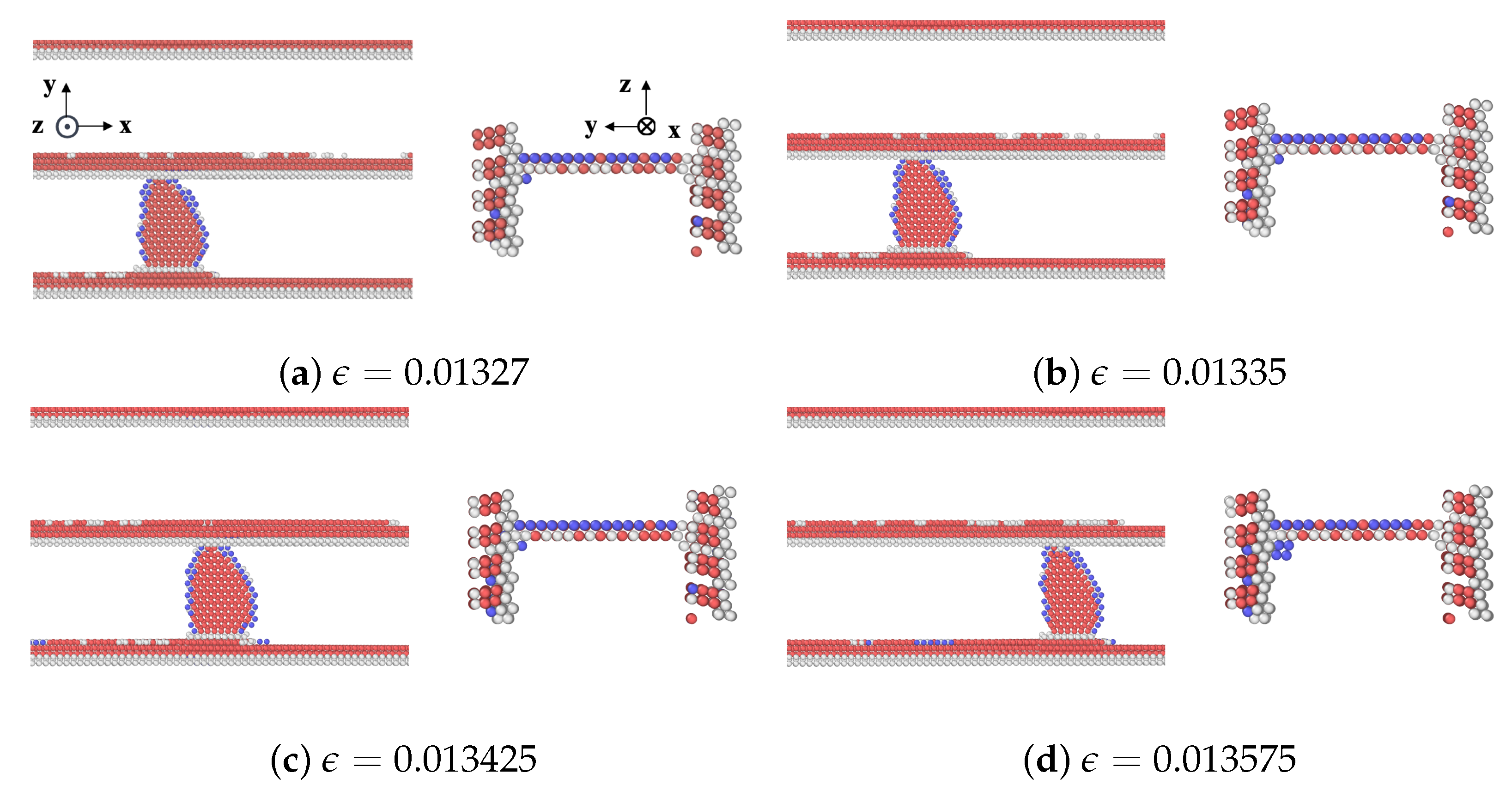

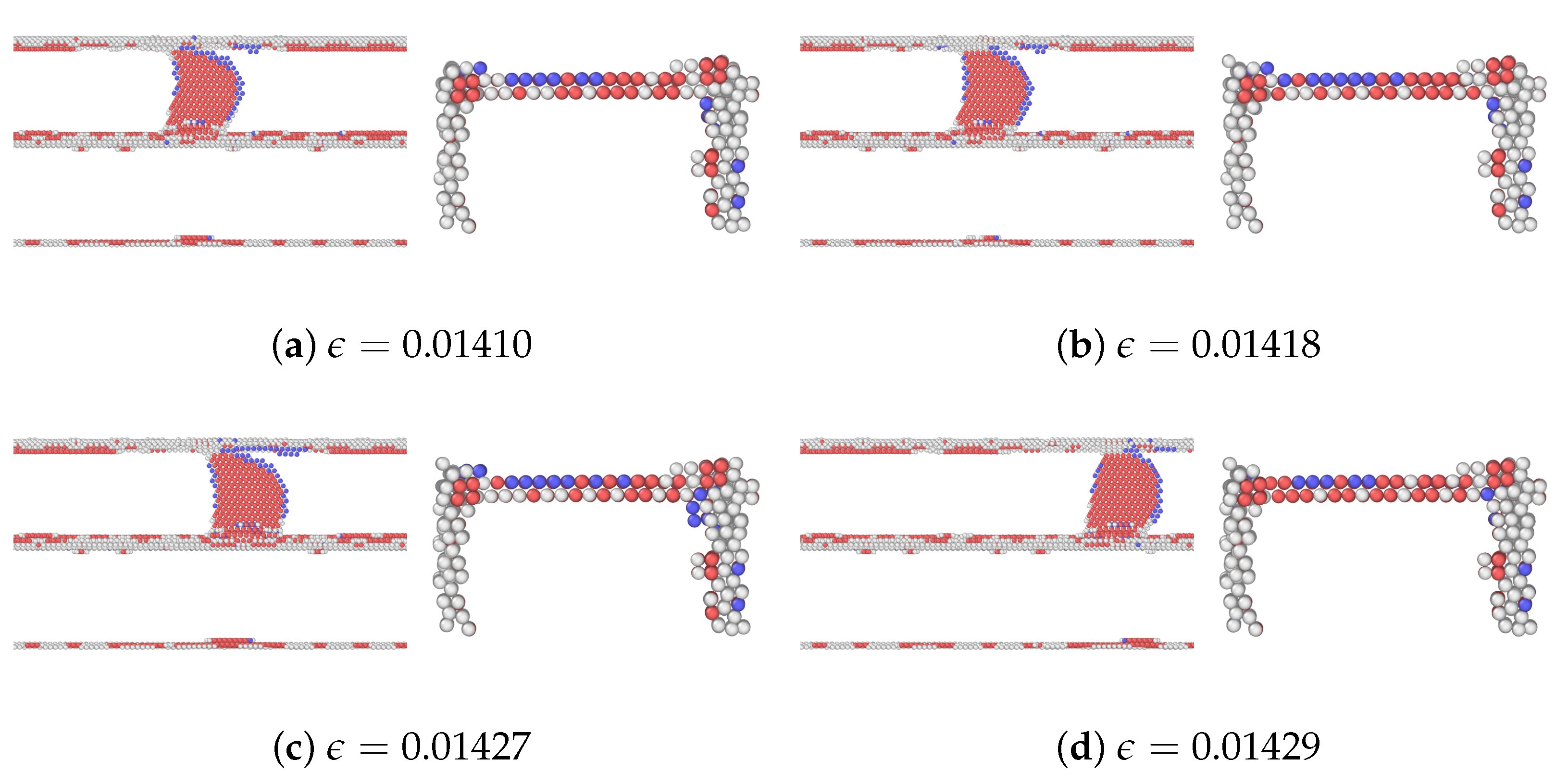

3.2. Ag/Cu Type I Nanolaminate

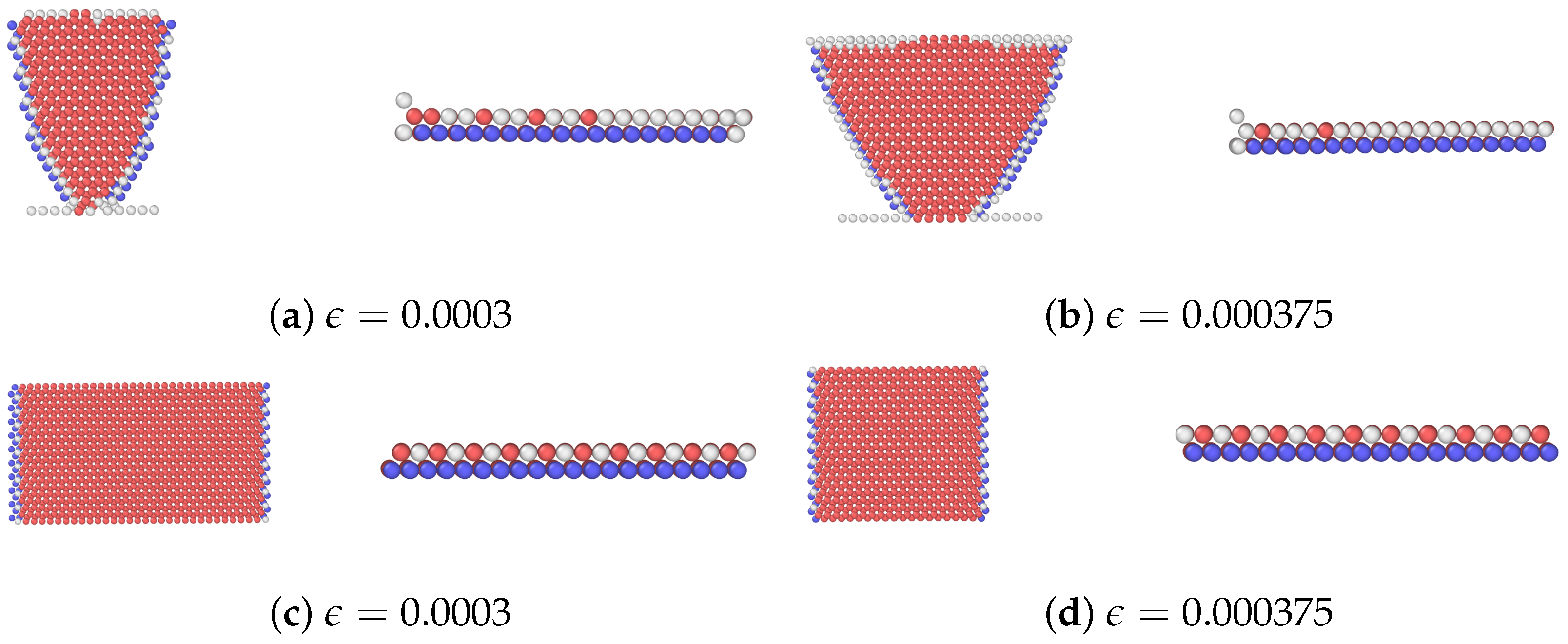

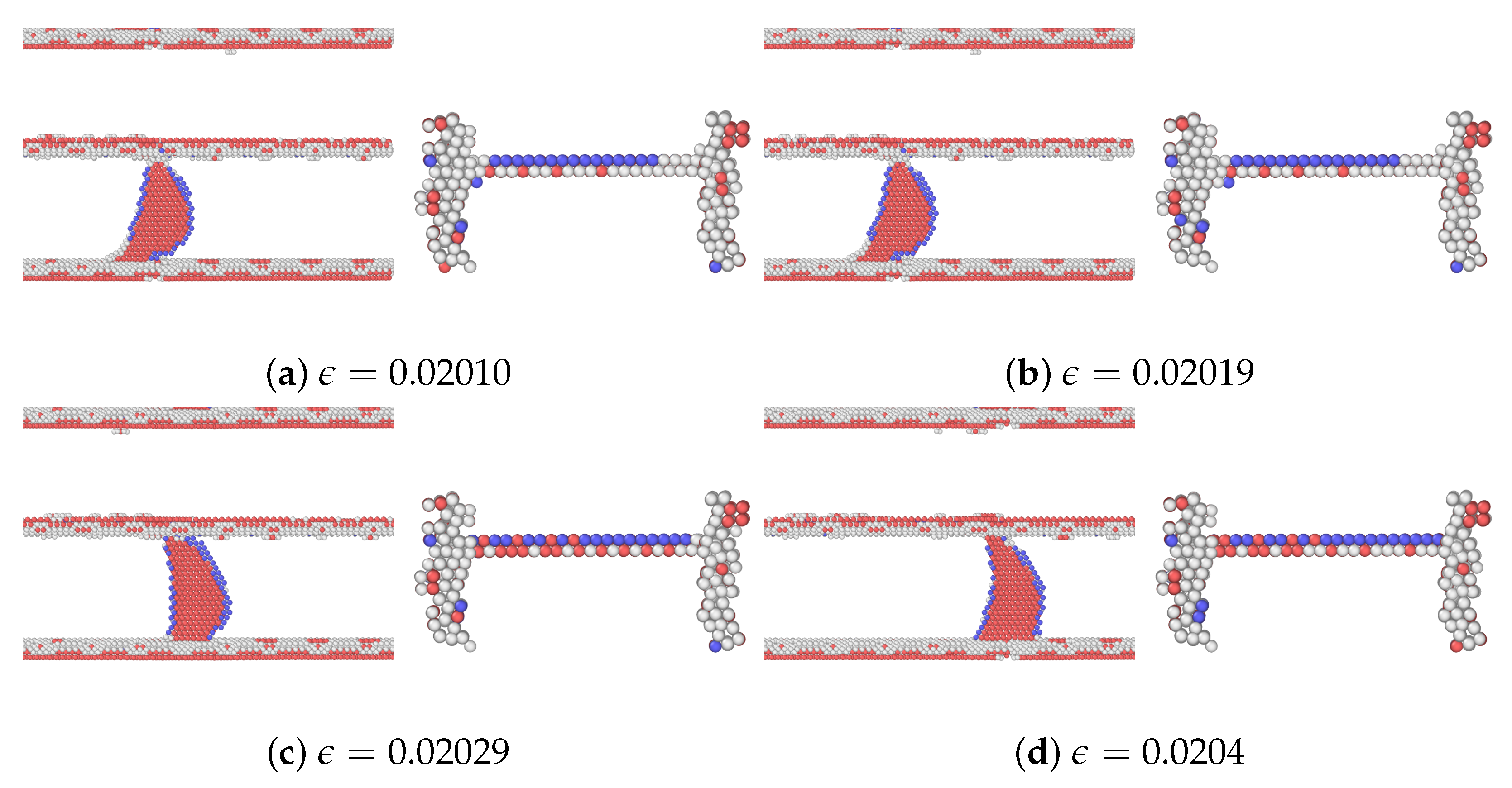

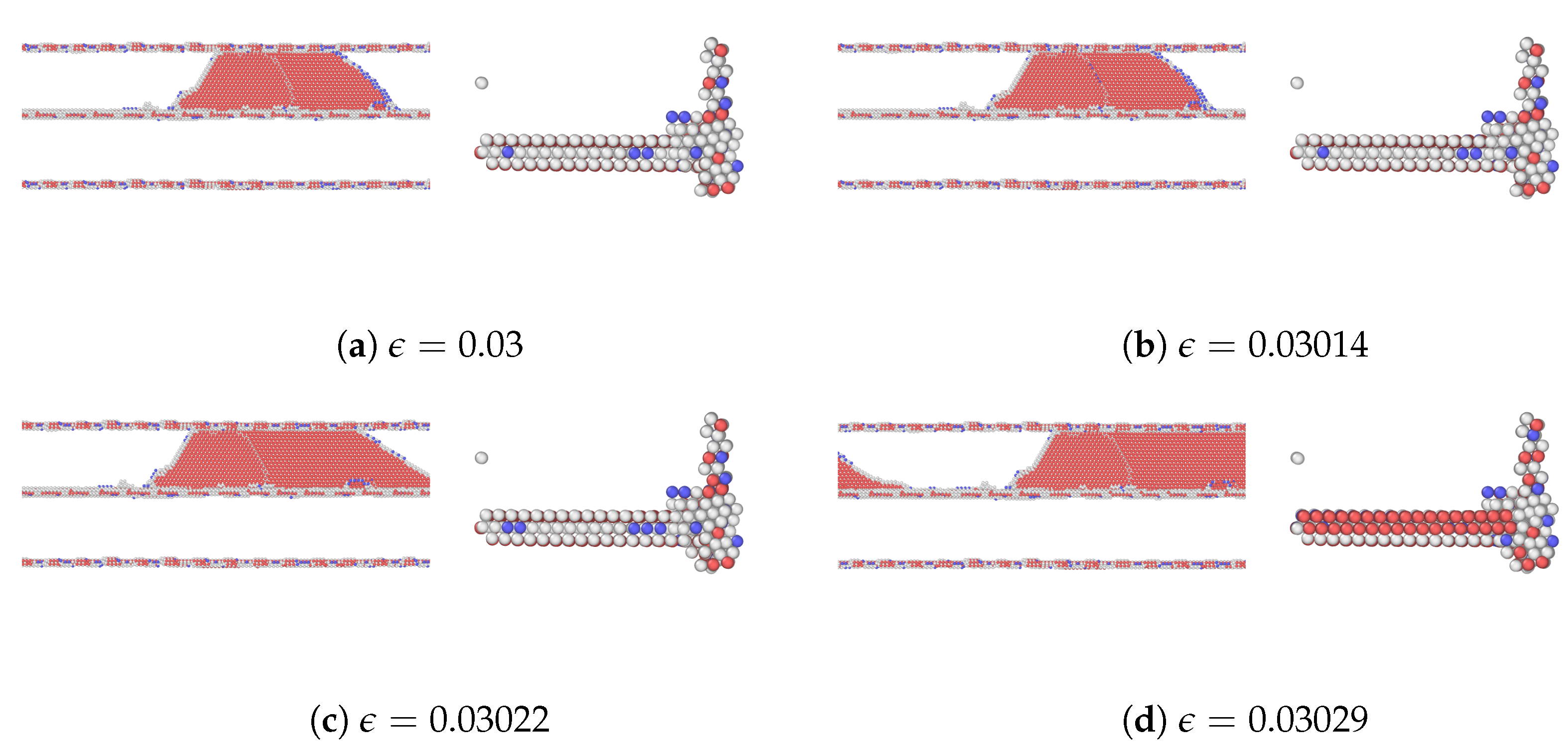

3.3. Ag/Cu Type II Nanolaminate

4. Conclusions

- The CLS of the nanolaminated Ag exhibits oscillatory behavior, characterized by the dislocation moving forward and then reversing its direction repeatedly. Dislocations advance more forward than backward, which results in an overall forward advancement as the strain increases.

- We also consider two Ag single crystals, which exhibit substantially lower initial peak stresses than all nanolaminates.

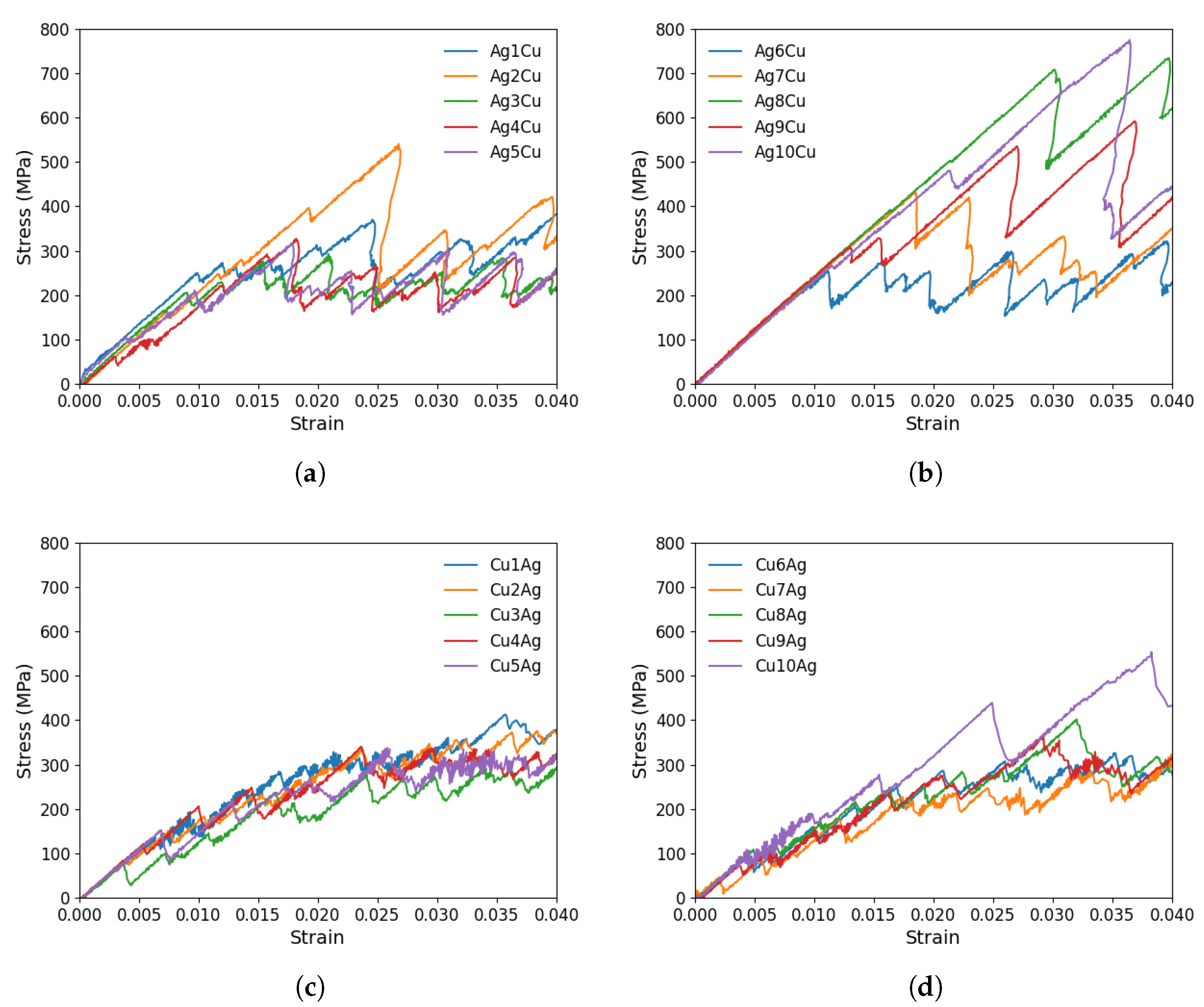

- There are irregular stress–strain responses for CLS in the Ag/Cu nanolaminates, either highly fluctuating or featuring periods of sharp stress increases followed by rapid stress declines. In the Ag/Cu nanolaminates, characterized by an incoherent interface with misfit dislocation arrays, the CLS exhibits jerky behavior in both the Ag and Cu layers. For the Ag layer, the CLS is most difficult to initiate in the Ag/Cu type II nanolaminate, followed by the nanolaminatesd Ag, and the easiest in the Ag/Cu type I nanolaminate. Interestingly, the order is the same as that in their interfacial energies. For the Cu layer, the CLS is more difficult in the type I nanolaminate than the type II one.

- Our study in this paper primarily focuses on unit CLS processes involving a single dislocation and three interfaces. Therefore, our findings cannot be directly used to understand the macroscopic behavior of nanolaminates, which are characterized by an abundance of dislocations and interfaces. Nevertheless, our results might offer insights and serve as a foundational guide for future research on nanolaminates. Additionally, these nanolaminates are sometimes used in constructions exposed to intense irradiation. Such harsh environments gradually lead to the formation and accumulation of defects within the materials, ultimately resulting in internal damage [51,52]. For example, irradiation-induced voids and helium bubbles may evolve into large clusters. Therefore, studying the CLS in these systems becomes crucial and will be in our future work.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pathak, S.; Velisavljevic, N.; Baldwin, J.K.; Jain, M.; Zheng, S.; Mara, N.A.; Beyerlein, I.J. Strong, ductile, and thermally stable bcc-Mg nanolaminates. Sci. Rep. 2017, 7, 8264. [Google Scholar] [CrossRef] [PubMed]

- Nasim, M.; Li, Y.; Wen, M.; Wen, C. A review of high-strength nanolaminates and evaluation of their properties. J. Mater. Sci. Technol. 2020, 50, 215–244. [Google Scholar] [CrossRef]

- Demkowicz, M.J.; Beyerlein, I.J. The effects of nanoscale confinement on the behavior of metal laminates. Scr. Mater. 2020, 187, 130–136. [Google Scholar] [CrossRef]

- Beyerlein, I.; Caro, A.; Demkowicz, M.; Mara, N.; Misra, A.; Uberuaga, B. Radiation damage tolerant nanomaterials. Mater. Today 2013, 16, 443–449. [Google Scholar] [CrossRef]

- Kong, X.; Gao, N.; Beyerlein, I.J.; Yao, B.; Zheng, S.; Ma, X.; Legut, D.; Germann, T.C.; Zhang, H.; Zhang, R. Interface facilitated transformation of voids directly into stacking fault tetrahedra. Acta Mater. 2020, 188, 623–634. [Google Scholar] [CrossRef]

- Wang, Y.C.; Misra, A.; Hoagland, R. Fatigue properties of nanoscale Cu/Nb multilayers. Scr. Mater. 2006, 54, 1593–1598. [Google Scholar] [CrossRef]

- Han, W.; Misra, A.; Mara, N.; Germann, T.; Baldwin, J.; Shimada, T.; Luo, S. Role of interfaces in shock-induced plasticity in Cu/Nb nanolaminates. Philos. Mag. 2011, 91, 4172–4185. [Google Scholar] [CrossRef]

- Pan, Q.; Zhou, H.; Lu, Q.; Gao, H.; Lu, L. History-independent cyclic response of nanotwinned metals. Nature 2017, 551, 214–217. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhou, H.; Lu, Q.; Gao, H.; Lu, L. Extra strengthening and work hardening in gradient nanotwinned metals. Science 2018, 362, eaau1925. [Google Scholar] [CrossRef]

- Bufford, D.; Wang, H.; Zhang, X. High strength, epitaxial nanotwinned Ag films. Acta Mater. 2011, 59, 93–101. [Google Scholar] [CrossRef]

- Wang, M.; Beyerlein, I.J.; Zhang, J.; Han, W.Z. Defect-interface interactions in irradiated Cu/Ag nanocomposites. Acta Mater. 2018, 160, 211–223. [Google Scholar] [CrossRef]

- Wang, C.; Yao, B.; Liu, Z.; Kong, X.; Legut, D.; Zhang, R.; Deng, Y. Effects of solutes on dislocation nucleation and interface sliding of bimetal semi-coherent interface. Int. J. Plast. 2020, 131, 102725. [Google Scholar] [CrossRef]

- Li, N.; Nastasi, M.; Misra, A. Defect structures and hardening mechanisms in high dose helium ion implanted Cu and Cu/Nb multilayer thin films. Int. J. Plast. 2012, 32–33, 1–16. [Google Scholar] [CrossRef]

- Jian, W.R.; Su, Y.; Xu, S.; Ji, W.; Beyerlein, I.J. Effect of interface structure on dislocation glide behavior in nanolaminates. J. Mater. Res. 2021, 36, 2802–2815. [Google Scholar] [CrossRef]

- Jian, W.R.; Xu, S.; Su, Y.; Beyerlein, I.J. Role of layer thickness and dislocation distribution in confined layer slip in nanolaminated Nb. Int. J. Plast. 2022, 152, 103239. [Google Scholar] [CrossRef]

- Jeremiah, S.S.; Miyakawa, K.; Morita, T.; Yamaoka, Y.; Ryo, A. Potent antiviral effect of silver nanoparticles on SARS-CoV-2. Biochem. Biophys. Res. Commun. 2020, 533, 195–200. [Google Scholar] [CrossRef]

- Takeda, Y.; Jamsransuren, D.; Nagao, T.; Fukui, Y.; Matsuda, S.; Ogawa, H. Application of copper iodide nanoparticle-doped film and fabric to inactivate SARS-CoV-2 via the virucidal activity of cuprous ions (Cu+). Appl. Environ. Microbiol. 2021, 87, e01824-21. [Google Scholar] [CrossRef]

- Lyubimova, J.; Freudenberger, J.; Mickel, C.; Thersleff, T.; Kauffmann, A.; Schultz, L. Microstructural inhomogeneities in Cu–Ag–Zr alloys due to heavy plastic deformation. Mater. Sci. Eng. A 2010, 527, 606–613. [Google Scholar] [CrossRef]

- Zhang, L.; Meng, L. Evolution of microstructure and electrical resistivity of Cu–12wt.% Ag filamentary microcomposite with drawing deformation. Scr. Mater. 2005, 52, 1187–1191. [Google Scholar] [CrossRef]

- Castro-Dettmer, Z.; Simmons, M.; Persad, C. Obtainable microstructures in electrical conductors made of a copper-silver alloy. IEEE Trans. Magn. 2003, 39, 323–326. [Google Scholar] [CrossRef]

- Misják, F.; Barna, P.; Tóth, A.; Ujvári, T.; Bertóti, I.; Radnóczi, G. Structure and mechanical properties of Cu–Ag nanocomposite films. Thin Solid Film. 2008, 516, 3931–3934. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, J.; Beyerlein, I.; Germann, T. Dislocation nucleation mechanisms from fcc/bcc incoherent interfaces. Scr. Mater. 2011, 65, 1022–1025. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, J.; Beyerlein, I.; Misra, A.; Germann, T. Atomic-scale study of nucleation of dislocations from fcc–bcc interfaces. Acta Mater. 2012, 60, 2855–2865. [Google Scholar] [CrossRef]

- Pang, W.; Xin, K.; Liu, A.; Chen, R.; Yu, S. The effect of interface orientation on deformation behavior of Cu/Al multilayer during tensile process. Mater. Today Commun. 2023, 34, 105133. [Google Scholar] [CrossRef]

- Embury, J.; Hirth, J. On dislocation storage and the mechanical response of fine scale microstructures. Acta Metall. Mater. 1994, 42, 2051–2056. [Google Scholar] [CrossRef]

- Nix, W.D. Mechanical properties of thin films. Metall. Trans. A 1989, 20, 2217–2245. [Google Scholar] [CrossRef]

- Li, N.; Wang, J.; Misra, A.; Huang, J.Y. Direct observations of confined layer slip in Cu/Nb multilayers. Microsc. Microanal. 2012, 18, 1155–1162. [Google Scholar] [CrossRef]

- Kardani, A.; Montazeri, A. Temperature-based plastic deformation mechanism of Cu/Ag nanocomposites: A molecular dynamics study. Comput. Mater. Sci. 2018, 144, 223–231. [Google Scholar] [CrossRef]

- Liang, Y.; Luo, A.; Yang, L.; Zhao, J.; Wang, L.; Wan, Q. Effect of interface structure and layer thickness on the mechanical properties and deformation behavior of Cu/Ag nanolaminates. Phys. B Condens. Matter 2023, 661, 414933. [Google Scholar] [CrossRef]

- Ji, W.; Jian, W.R.; Su, Y.; Xu, S.; Beyerlein, I.J. Role of stacking fault energy in confined layer slip in nanolaminated Cu. J. Mater. Sci. 2023, in press. [CrossRef]

- Ghalandari, L.; Moshksar, M. High-strength and high-conductive Cu/Ag multilayer produced by ARB. J. Alloys Compd. 2010, 506, 172–178. [Google Scholar] [CrossRef]

- Wei, Y.; Qiao, L.; Han, K.; Yang, L. Transient dislocation emission from the nanosized interface of Cu–Ag composite under the coupled thermal-mechanical shock: Molecular dynamics simulations study. Phys. B Condens. Matter 2022, 644, 414245. [Google Scholar] [CrossRef]

- Dong, H.; Chen, Y.; Guo, Y.; Shan, G.; Yang, G.; Huang, L.; Liu, F.; Li, Q. A nanostructured Ag/Cu multilayered composite exhibiting high hardness and high electrical conductivity prepared by a novel multicomponent accumulative roll bonding. Mater. Charact. 2023, 196, 112613. [Google Scholar] [CrossRef]

- Wang, M.; Beyerlein, I.J.; Zhang, J.; Han, W.Z. Bi-metal interface-mediated defects distribution in neon ion bombarded Cu/Ag nanocomposites. Scr. Mater. 2019, 171, 1–5. [Google Scholar] [CrossRef]

- Zheng, S.; Shao, S.; Zhang, J.; Wang, Y.; Demkowicz, M.J.; Beyerlein, I.J.; Mara, N.A. Adhesion of voids to bimetal interfaces with non-uniform energies. Sci. Rep. 2015, 5, 15428. [Google Scholar] [CrossRef] [PubMed]

- Kong, X.; Beyerlein, I.J.; Liu, Z.; Yao, B.; Legut, D.; Germann, T.C.; Zhang, R. Stronger and more failure-resistant with three-dimensional serrated bimetal interfaces. Acta Mater. 2019, 166, 231–245. [Google Scholar] [CrossRef]

- Béjaud, R.; Durinck, J.; Brochard, S. Twin-interface interactions in nanostructured Cu/Ag: Molecular dynamics study. Acta Mater. 2018, 144, 314–324. [Google Scholar] [CrossRef]

- Liang, Y.; Li, J.; Luo, J.-r.; Yang, X.; Xiang, S.; Wang, L.; Zhao, J.; Wan, Q. Interaction between deformation twins and interfaces in Cu/Ag alloys. Comput. Mater. Sci. 2022, 205, 111219. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; in’t Veld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS-a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Daw, M.S.; Baskes, M.I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 1984, 29, 6443. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, R.; Beyerlein, I.; Chen, X.; Yang, H.; Germann, T. Cooperative dissociations of misfit dislocations at bimetal interfaces. APL Mater. 2016, 4, 111101. [Google Scholar] [CrossRef]

- Williams, P.; Mishin, Y.; Hamilton, J. An embedded-atom potential for the Cu–Ag system. Model. Simul. Mater. Sci. Eng. 2006, 14, 817. [Google Scholar] [CrossRef]

- Xu, S.; Su, Y.; Beyerlein, I.J. Modeling dislocations with arbitrary character angle in face-centered cubic transition metals using the phase-field dislocation dynamics method with full anisotropic elasticity. Mech. Mater. 2019, 139, 103200. [Google Scholar] [CrossRef]

- Xu, J.; Xu, S.; Beyerlein, I.J. Atomistic simulations of dipole tilt wall stability in thin films. Thin Solid Film. 2019, 689, 137457. [Google Scholar] [CrossRef]

- Tran, R.; Xu, Z.; Radhakrishnan, B.; Winston, D.; Sun, W.; Persson, K.A.; Ong, S.P. Surface energies of elemental crystals. Sci. Data 2016, 3, 160080. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Su, Y. Dislocation nucleation from symmetric tilt grain boundaries in body-centered cubic vanadium. Phys. Lett. A 2018, 382, 1185–1189. [Google Scholar] [CrossRef]

- Xu, S.; Su, Y.; Jian, W.R.; Beyerlein, I.J. Local slip resistances in equal-molar MoNbTi multi-principal element alloy. Acta Mater. 2021, 202, 68–79. [Google Scholar] [CrossRef]

- Jian, W.R.; Zhang, M.; Xu, S.; Beyerlein, I.J. Atomistic simulations of dynamics of an edge dislocation and its interaction with a void in copper: A comparative study. Model. Simul. Mater. Sci. Eng. 2020, 28, 045004. [Google Scholar] [CrossRef]

- Wang, J.; Anderoglu, O.; Hirth, J.; Misra, A.; Zhang, X. Dislocation structures of Σ3 {112} twin boundaries in face centered cubic metals. Appl. Phys. Lett. 2009, 95, 021908. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Busby, J.T. Structural materials for fission & fusion energy. Mater. Today 2009, 12, 12–19. [Google Scholar]

- Was, G.S. Fundamentals of Radiation Materials Science: Metals and Alloys; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

| Nanolaminates (M/M′) | x | y | z | x′ | y′ | z′ |

|---|---|---|---|---|---|---|

| Ag/Ag | [10] | [11] | [111] | [10] | [112] | [1] |

| Ag/Cu type I | [10] | [112] | [1] | [10] | [11] | [111] |

| Cu/Ag type I | [10] | [11] | [111] | [10] | [112] | [1] |

| Ag/Cu type II | [10] | [11] | [111] | [10] | [11] | [111] |

| Cu/Ag type II | [10] | [11] | [111] | [10] | [11] | [111] |

| Ag/Ag | Ag/Cu Type I | Ag/Cu Type II |

|---|---|---|

| 407.16 | 580.79 | 474.74 |

| Glide Plane | Ag/Cu Type I | Ag/Cu Type II |

|---|---|---|

| Ag1Cu | 332.69 | 370.11 |

| Ag2Cu | 121.39 | 540.56 |

| Ag3Cu | 59.84 | 205.24 |

| Ag4Cu | 23.14 | 327.14 |

| Ag5Cu | 77 | 315.86 |

| Ag6Cu | 97.29 | 254 |

| Ag7Cu | 181.17 | 431.69 |

| Ag8Cu | 121.05 | 707.97 |

| Ag9Cu | 120.26 | 309.63 |

| Ag10Cu | 316.64 | 480.72 |

| Mean value | 145.05 | 346.31 |

| Cu1Ag | 153.03 | 282.50 |

| Cu2Ag | 123.81 | 152.96 |

| Cu3Ag | 26.23 | 76.28 |

| Cu4Ag | 449.43 | 121.82 |

| Cu5Ag | 116.50 | 152.60 |

| Cu6Ag | 147.83 | 93.70 |

| Cu7Ag | 234 | 47.05 |

| Cu8Ag | 135.53 | 121.30 |

| Cu9Ag | 61 | 75.66 |

| Cu10Ag | 54.80 | 277.41 |

| Mean value | 150.21 | 140.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fani, M.; Jian, W.-R.; Su, Y.; Xu, S. Confined Layer Slip Process in Nanolaminated Ag and Two Ag/Cu Nanolaminates. Materials 2024, 17, 501. https://doi.org/10.3390/ma17020501

Fani M, Jian W-R, Su Y, Xu S. Confined Layer Slip Process in Nanolaminated Ag and Two Ag/Cu Nanolaminates. Materials. 2024; 17(2):501. https://doi.org/10.3390/ma17020501

Chicago/Turabian StyleFani, Mahshad, Wu-Rong Jian, Yanqing Su, and Shuozhi Xu. 2024. "Confined Layer Slip Process in Nanolaminated Ag and Two Ag/Cu Nanolaminates" Materials 17, no. 2: 501. https://doi.org/10.3390/ma17020501

APA StyleFani, M., Jian, W.-R., Su, Y., & Xu, S. (2024). Confined Layer Slip Process in Nanolaminated Ag and Two Ag/Cu Nanolaminates. Materials, 17(2), 501. https://doi.org/10.3390/ma17020501