Evaluation of the Tensile and Puncture Properties of Geotextiles Influenced by Soil Moisture under Freezing Conditions

Abstract

1. Introduction

2. Experimental Content

2.1. Materials

2.2. Experimental Apparatus

2.3. Specimen Preparation

3. Results and Discussion

3.1. Tensile Properties

3.1.1. Tensile Strength

3.1.2. Elongations at Failure

3.2. Puncture Properties

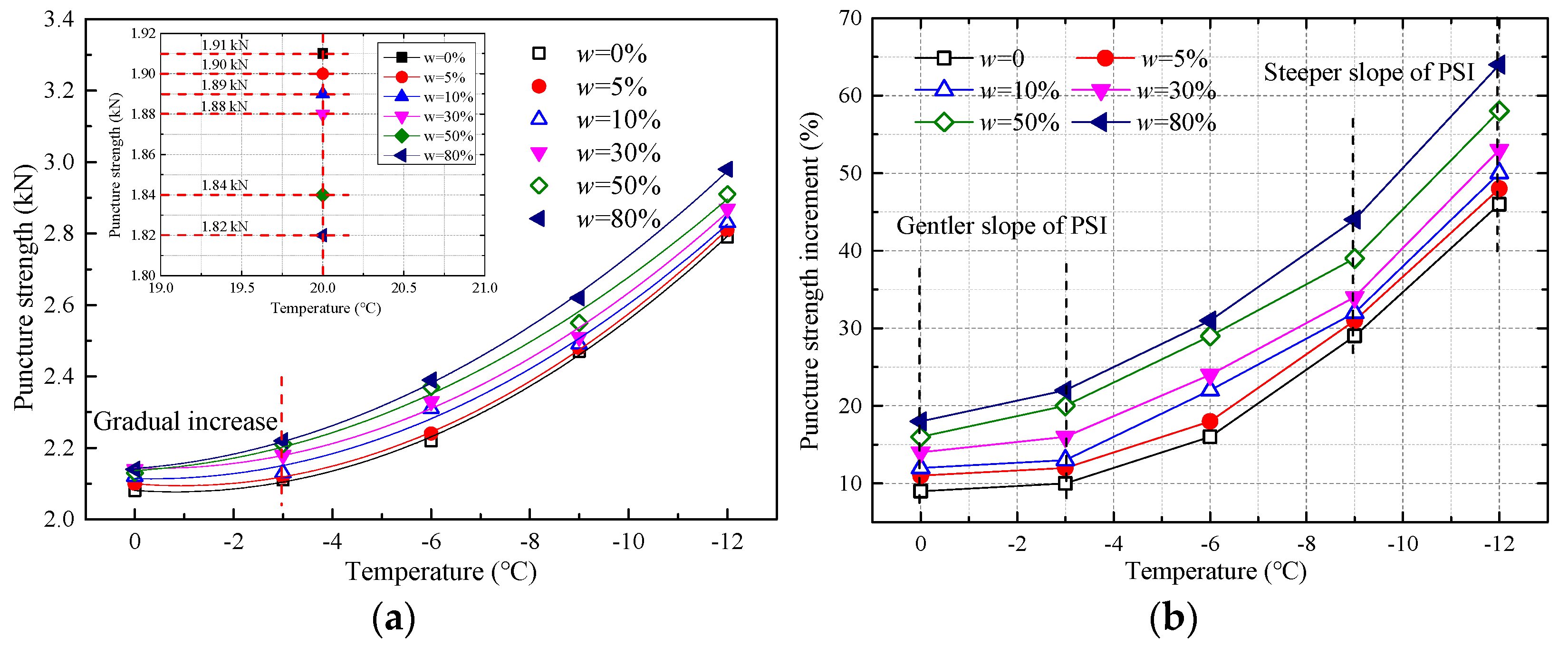

3.2.1. Puncture Strength

3.2.2. Puncture Strength Increment

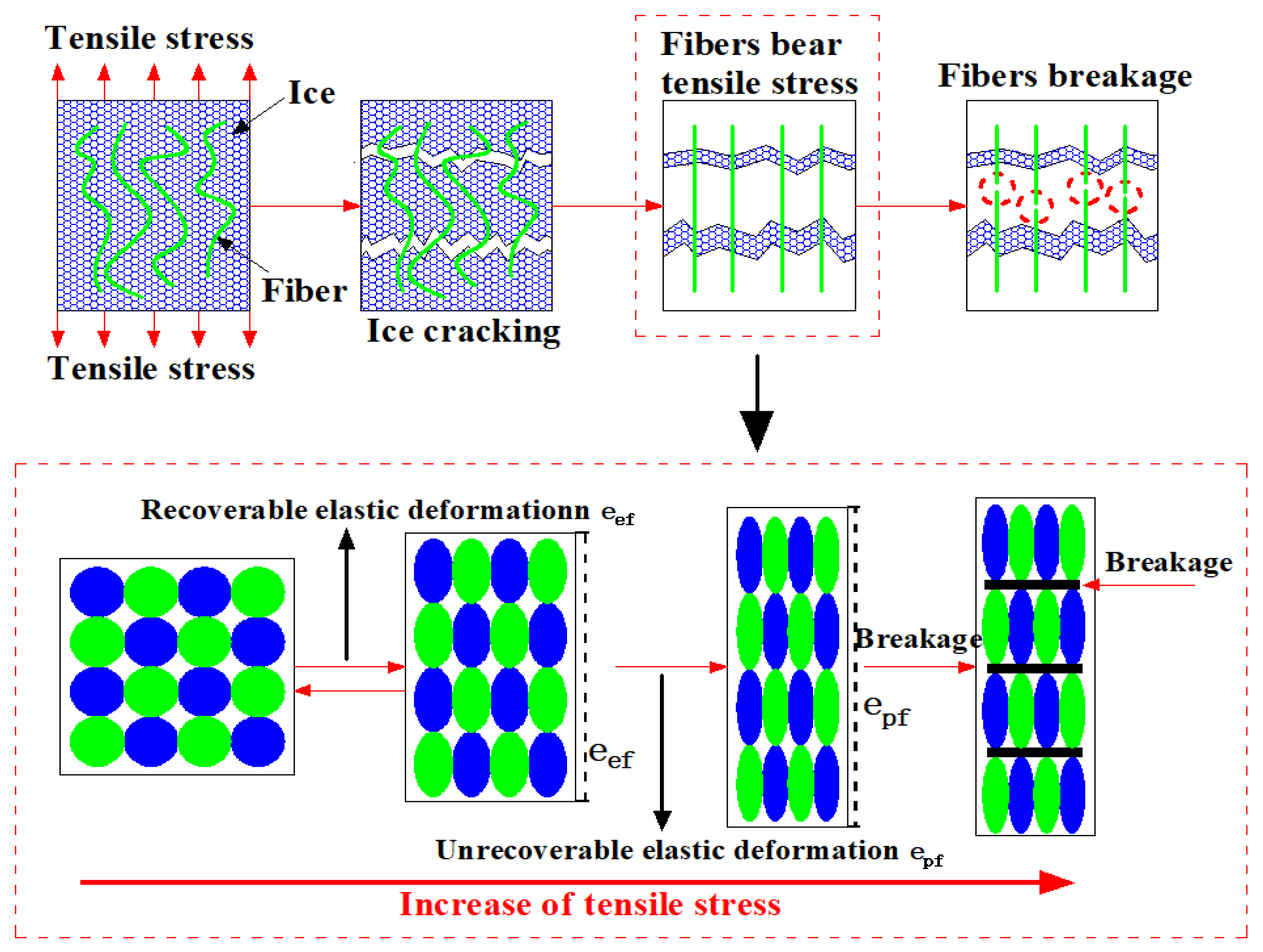

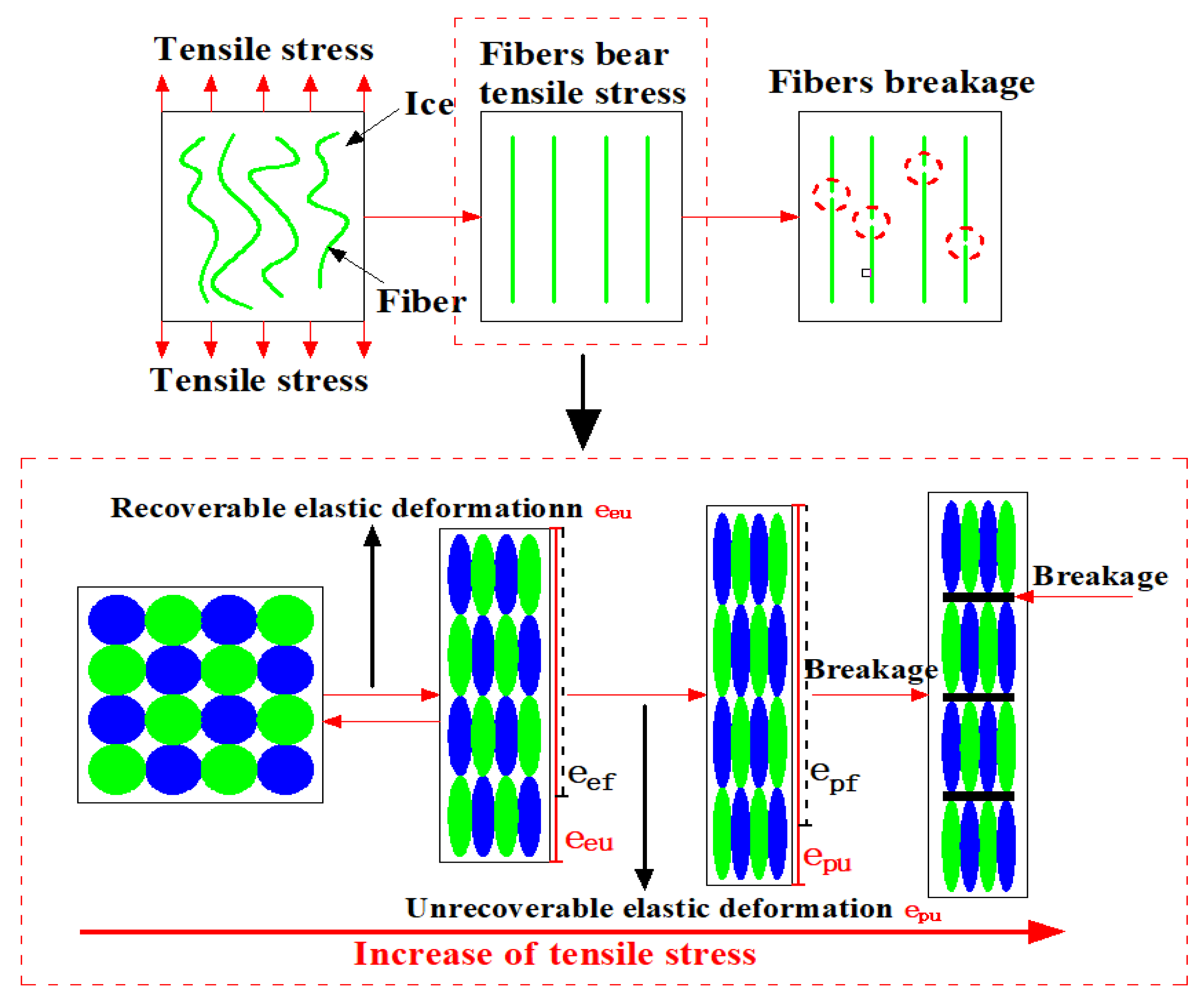

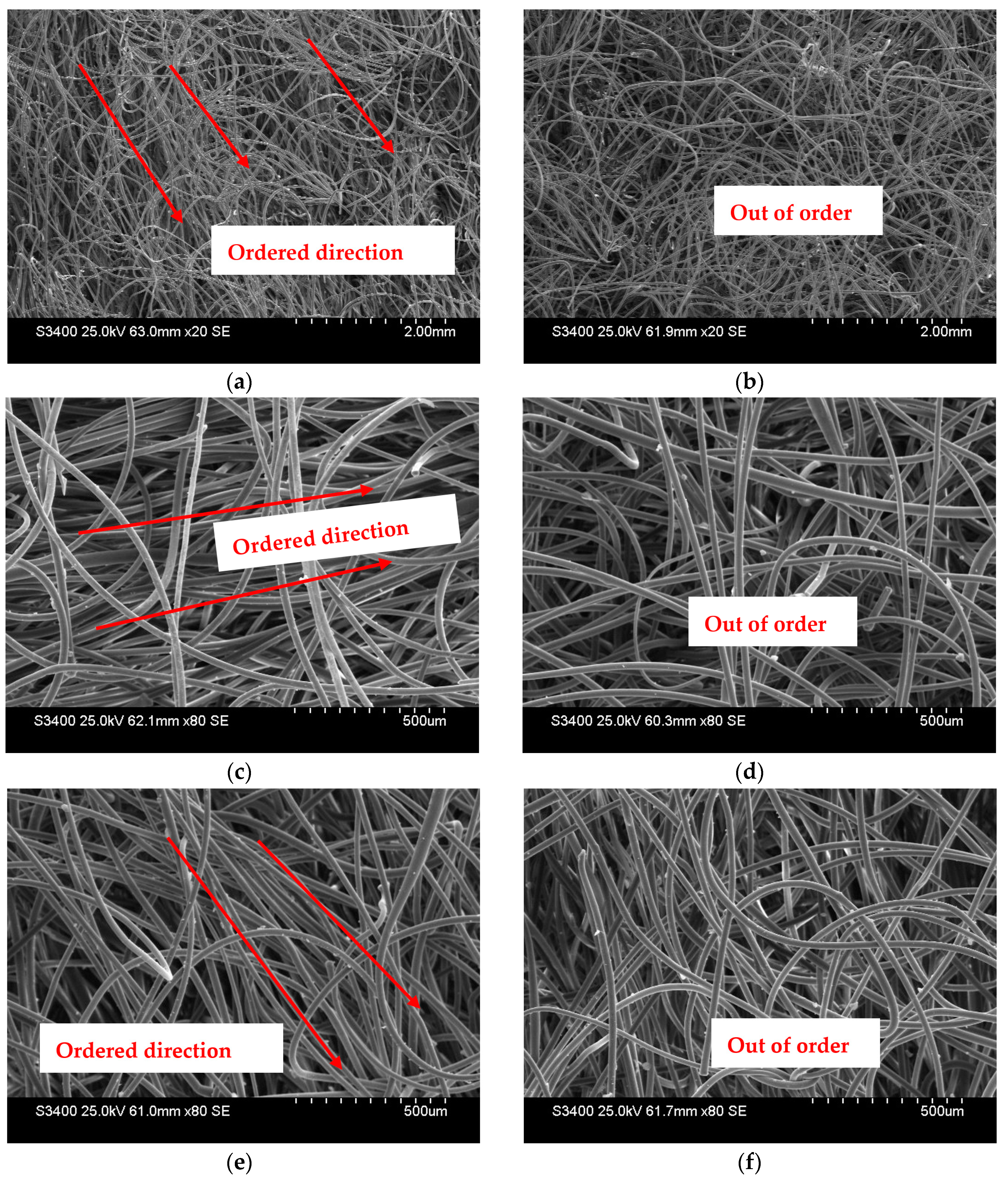

3.3. Failure Mechanism Analysis Based on Low Temperature and Moisture Content

4. Conclusions and Suggestions

- The parabolic and exponential function model of tensile strength and elongations at failure with the decreasing temperature of geotextiles was proposed considering different moisture content levels. In addition, the tensile strength and elongations at failure reached the maximum values of 14.67% and 34.22%, respectively, at the moisture content of 30% when the temperature decreased from 0 to −12 °C.

- The puncture strength of geotextiles presents a parabolic increase with decreasing temperature. Moreover, under the freezing temperature environment, the higher the moisture content of geotextiles, the greater the puncture strength increment is.

- Under the freezing temperature, the appearance of broken ice bodies surrounding the geotextile fibers provides a bonding force to resist tensile failure and enhances the tensile strength of the geotextiles. At low temperature, the activity of polymer molecular chains decreases and the active zone gradually shrinks, thus shortening the deformation of geotextiles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J.; Zhang, J.; Yang, X.; Zhang, A.; Yu, M. Monte Carlo simulations of deformation behaviour of unbound granular materials based on a real aggregate library. Int. J. Pavement Eng. 2023, 24, 2165650. [Google Scholar] [CrossRef]

- Wiewel, B.V.; Lamoree, M. Geotextile composition, application and ecotoxicology—A review. J. Hazard. Mater. 2016, 317, 640–655. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Cai, G.; Zhang, J.; Liu, X.; Liu, K. Evaluation of engineering properties and environmental effect of recycled waste tire-sand/soil in geotechnical engineering: A compressive review. Renew. Sustain. Energy Rev. 2020, 126, 109831. [Google Scholar] [CrossRef]

- Prambauer, M.; Wendeler, C.; Weitzenböck, J.; Burgstaller, C. Biodegradable geotextiles—An overview of existing and potential materials. Geotext. Geomembr. 2019, 47, 48–59. [Google Scholar] [CrossRef]

- Correia, N.d.S.; Bueno, B.D.S. Effect of bituminous impregnation on nonwoven geotextiles tensile and permeability properties. Geotext. Geomembranes 2011, 29, 92–101. [Google Scholar] [CrossRef]

- Wu, H.; Yao, C.; Li, C.; Miao, M.; Zhong, Y.; Lu, Y.; Liu, T. Review of application and innovation of geotextiles in geotechnical engineering. Materials 2020, 13, 1774. [Google Scholar] [CrossRef]

- Sudarsanan, N.; Karpurapu, R.; Amrithalingam, V. An investigation on the interface bond strength of geosynthet-ic-reinforced asphalt concrete using Leutner shear test. Constr. Build. Mater. 2018, 186, 423–437. [Google Scholar] [CrossRef]

- Liu, X.; Congress SS, C.; Cai, G.; Liu, L.; Liu, S.; Puppala, A.J.; Zhang, W. Development and validation of a method to predict the soil thermal conductivity using thermal piezocone penetration testing (T-CPTU). Can. Geotech. J. 2022, 59, 510–525. [Google Scholar] [CrossRef]

- Liu, X.; Congress SS, C.; Cai, G.; Liu, L.; Puppala, A.J. Evaluating the thermal performance of unsaturated bentonite–sand–graphite as buffer material for waste repository using an improved prediction model. Can. Geotech. J. 2022, 60, 301–320. [Google Scholar] [CrossRef]

- Saathoff, F.; Oumeraci, H.; Restall, S. Australian and German experiences on the use of geotextile containers. Geotext. Geomembranes 2007, 25, 251–263. [Google Scholar] [CrossRef]

- Moo-Young, H.K.; A Gaffney, D.; Mo, X. Testing procedures to assess the viability of dewatering with geotextile tubes. Geotext. Geomembranes 2002, 20, 289–303. [Google Scholar] [CrossRef]

- Kutay, M.E.; Aydilek, A.H. Retention performance of geotextile containers confining geomaterials. Geosynth. Ternational 2004, 11, 100–113. [Google Scholar] [CrossRef]

- Hakimelahi, N.; Bayat, M.; Ajalloeian, R.; Nadi, B. Effect of woven geotextile reinforcement on mechanical behavior of calcareous sands. Case Stud. Const. Mat. 2003, 18, e02014. [Google Scholar] [CrossRef]

- Rawal, A.; Sayeed, M.A.; Saraswat, H.; Shah, T. A comparison of wide-width tensile strength to its axi-symmetric tensile strength of hybrid needlepunched nonwoven geotextiles. Geotext. Geomembranes 2013, 36, 66–70. [Google Scholar] [CrossRef]

- Sawicki, A.; Kazimierowicz-Frankowska, K. Creep behaviour of geosynthetics. Geotext. Geomembr. 1998, 16, 365–382. [Google Scholar] [CrossRef]

- Bacas, B.M.; Cañizal, J.; Konietzky, H. Shear strength behavior of geotextile/geomembrane interfaces. J. Rock Mech. Geotech. Eng. 2015, 7, 638–645. [Google Scholar] [CrossRef]

- Pinho-Lopes, M.; De Lurdes Lopes, M. Influence of mechanical damage induced in laboratory on the soil-geosynthetic interaction in inclined-plane shear. Constr. Build. Mater. 2018, 185, 468–480. [Google Scholar] [CrossRef]

- Gautier, K.B.; Kocher, C.W.; Drean, J.-Y. Anisotropic mechanical behavior of nonwoven geotextiles stressed by uniaxial tension. Text. Res. J. 2007, 77, 20–28. [Google Scholar] [CrossRef]

- Punetha, P.; Mohanty, P.; Samanta, M. Microstructural investigation on mechanical behavior of soil-geosynthetic interface in direct shear test. Geotext. Geomembr. 2017, 45, 197–210. [Google Scholar] [CrossRef]

- Kongkitkul, W.; Tabsombut, W.; Jaturapitakkul, C.; Tatsuoka, F. Effects of temperature on the rupture strength and elastic stiffness of geogrids. Geosynth. Int. 2012, 19, 106–123. [Google Scholar] [CrossRef]

- Chantachot, T.; Kongkitkul, W.; Tatsuoka, F. Effects of temperature rise on load-strain-time behaviour of geogrids and simulations. Geosynth. Int. 2018, 25, 287–303. [Google Scholar] [CrossRef]

- Zornberg, J.G.; Byler, B.R.; Knudsen, J.W. Creep of geotextiles using time–Temperature superposition methods. J. Geotech. Geoenvironmental Eng. 2004, 130, 1158–1168. [Google Scholar] [CrossRef]

- ASTM D4595; Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method. ASTM: West Conshohocken, PA, USA, 2011.

- ASTM D6241; Standard Test Method for the Static Puncture Strength of Geotextiles and Geotextile-Related Products Using a 50-mm Probe. ASTM: West Conshohocken, PA, USA, 2014.

- Hsieh, J.-C.; Li, J.-H.; Huang, C.-H.; Lou, C.-W.; Lin, J.-H. Statistical analyses for tensile properties of nonwoven geotextiles at different ambient environmental temperatures. J. Ind. Text. 2017, 47, 331–347. [Google Scholar] [CrossRef]

- Liu, T.; Yang, X.; Zhang, Y. A Review of Gassy Sediments: Mechanical Property, Disaster Simulation and In-Situ Test. Front. Earth Sci. 2022, 10, 915735. [Google Scholar] [CrossRef]

- Liu, L.; Cai, G.; Liu, S. Compression properties and micro-mechanisms of rubber-sand particle mixtures considering grain breakage. Constr. Build. Mater. 2018, 187, 1061–1072. [Google Scholar] [CrossRef]

| Moisture Content | Fitted Equations | Correlation Coefficient |

|---|---|---|

| 0% | Pt = −0.0033T2 − 0.123T + 15.339 | 0.996 |

| 5% | Pt = −0.0039T2 − 0.183T + 16.19 | 0.987 |

| 15% | Pt = −0.0087T2 − 0.062T + 16.575 | 0.977 |

| 30% | Pt = 0.0068T2 − 0.122T + 16.983 | 0.993 |

| 50% | Pt = 0.0072 − 0.112T + 17.184 | 0.996 |

| 80% | Pt = 0.0064T2 − 0.099T + 17.522 | 0.999 |

| Moisture Content | Fitted Equations | Correlation Coefficient |

|---|---|---|

| 0% | L = 27.58e0.126T | 0.964 |

| 5% | L = 29.4e0.028T | 0.992 |

| 15% | L = 32.18e0.026T | 0.972 |

| 30% | L = 34.05e0.027T | 0.951 |

| 50% | L = 36.09e0.024T | 0.954 |

| 80% | L = 37.56e0.026T | 0.965 |

| Moisture Content/% | Fitted Equation | R2 |

|---|---|---|

| 0% | Pp = 0.0057T2 − 0.0029T + 2.0809 | 0.9979 |

| 5% | Pp = 0.0059T2 − 0.0011T + 2.097 | 0.9982 |

| 10% | Pp = 0.0053T2 − 0.0041T + 2.114 | 0.9945 |

| 30% | Pp = 0.0053T2 − 0.0041T + 2.144 | 0.9558 |

| 50% | Pp = 0.0046T2 − 0.0081T + 2.137 | 0.9894 |

| 80% | Pp = 0.0049T2 − 0.0103T + 2.143 | 0.9842 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Zhang, H.; Zhu, J.; Lv, S.; Liu, L. Evaluation of the Tensile and Puncture Properties of Geotextiles Influenced by Soil Moisture under Freezing Conditions. Materials 2024, 17, 376. https://doi.org/10.3390/ma17020376

Liu L, Zhang H, Zhu J, Lv S, Liu L. Evaluation of the Tensile and Puncture Properties of Geotextiles Influenced by Soil Moisture under Freezing Conditions. Materials. 2024; 17(2):376. https://doi.org/10.3390/ma17020376

Chicago/Turabian StyleLiu, Lanjun, Haiku Zhang, Jinhuan Zhu, Shixin Lv, and Lulu Liu. 2024. "Evaluation of the Tensile and Puncture Properties of Geotextiles Influenced by Soil Moisture under Freezing Conditions" Materials 17, no. 2: 376. https://doi.org/10.3390/ma17020376

APA StyleLiu, L., Zhang, H., Zhu, J., Lv, S., & Liu, L. (2024). Evaluation of the Tensile and Puncture Properties of Geotextiles Influenced by Soil Moisture under Freezing Conditions. Materials, 17(2), 376. https://doi.org/10.3390/ma17020376