Stress-Strain Behavior and Strength Development of High-Amount Phosphogypsum-Based Sustainable Cementitious Materials

Abstract

1. Introduction

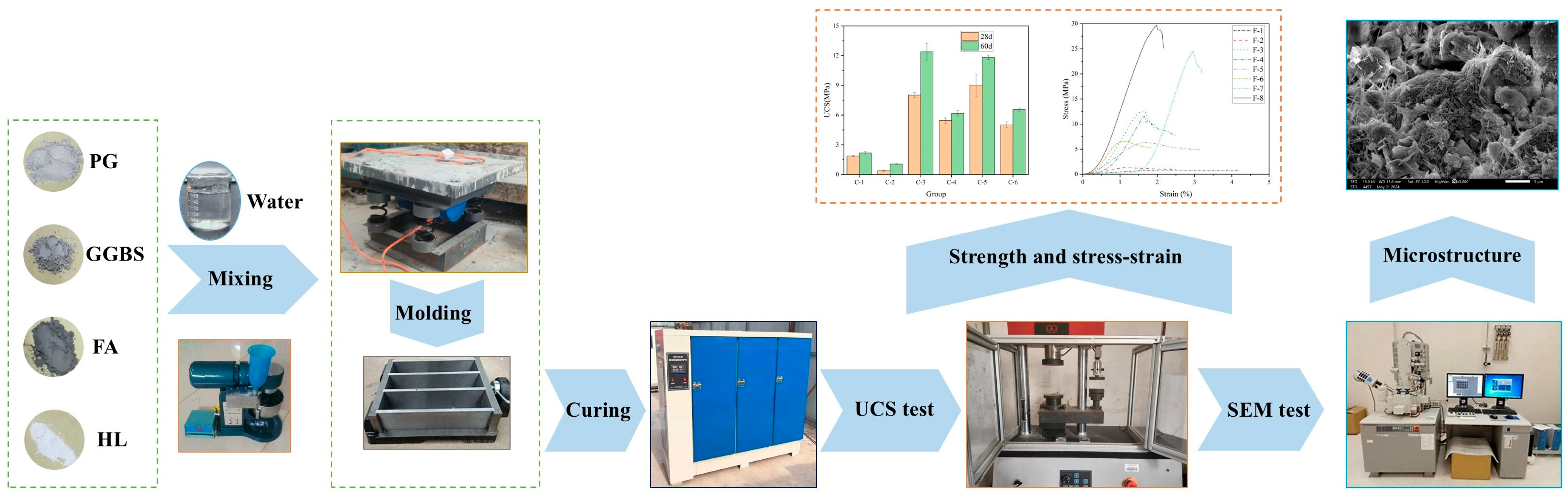

2. Experimental Program

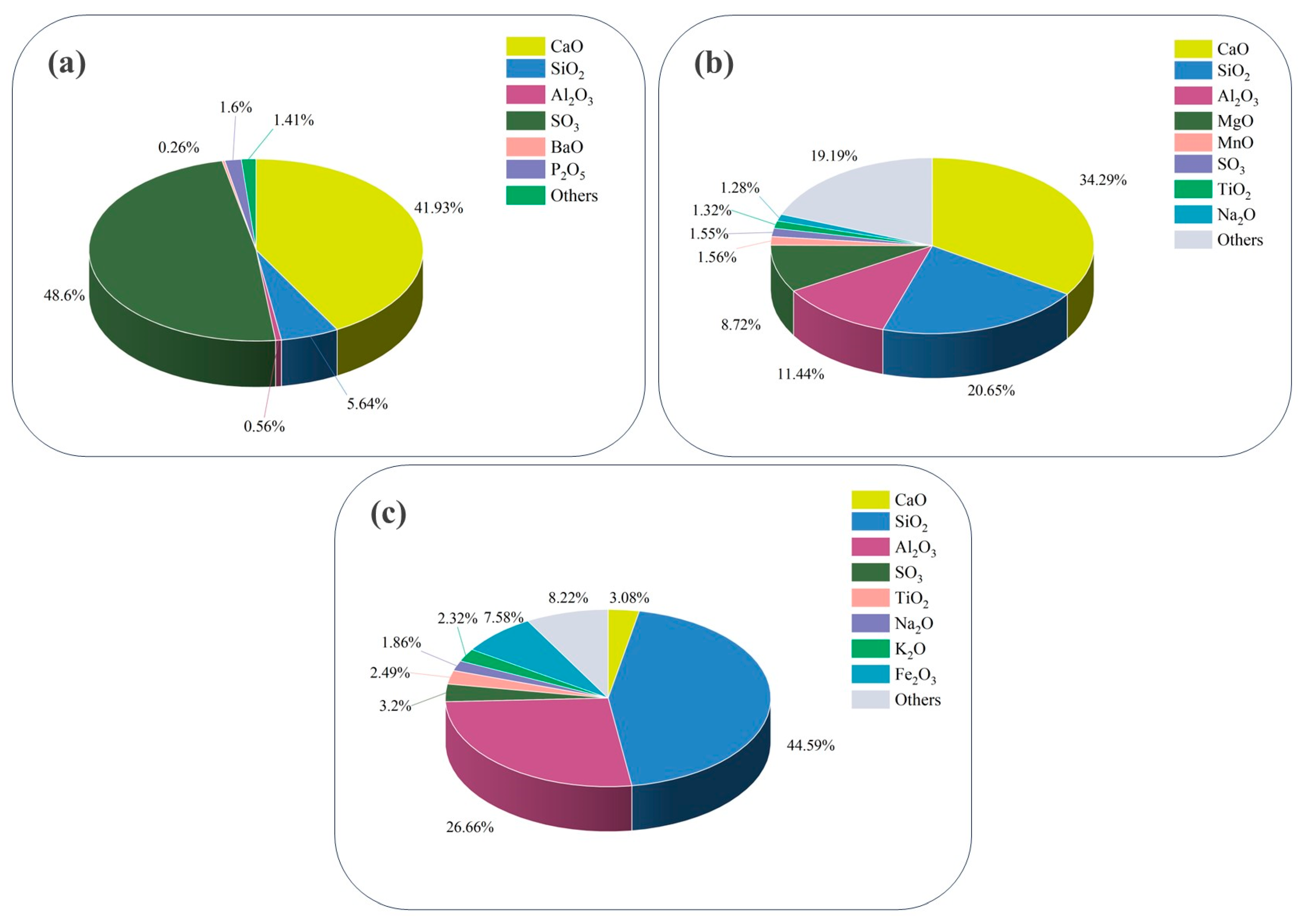

2.1. Raw Materials

2.2. Test Method

3. Result and Discussion

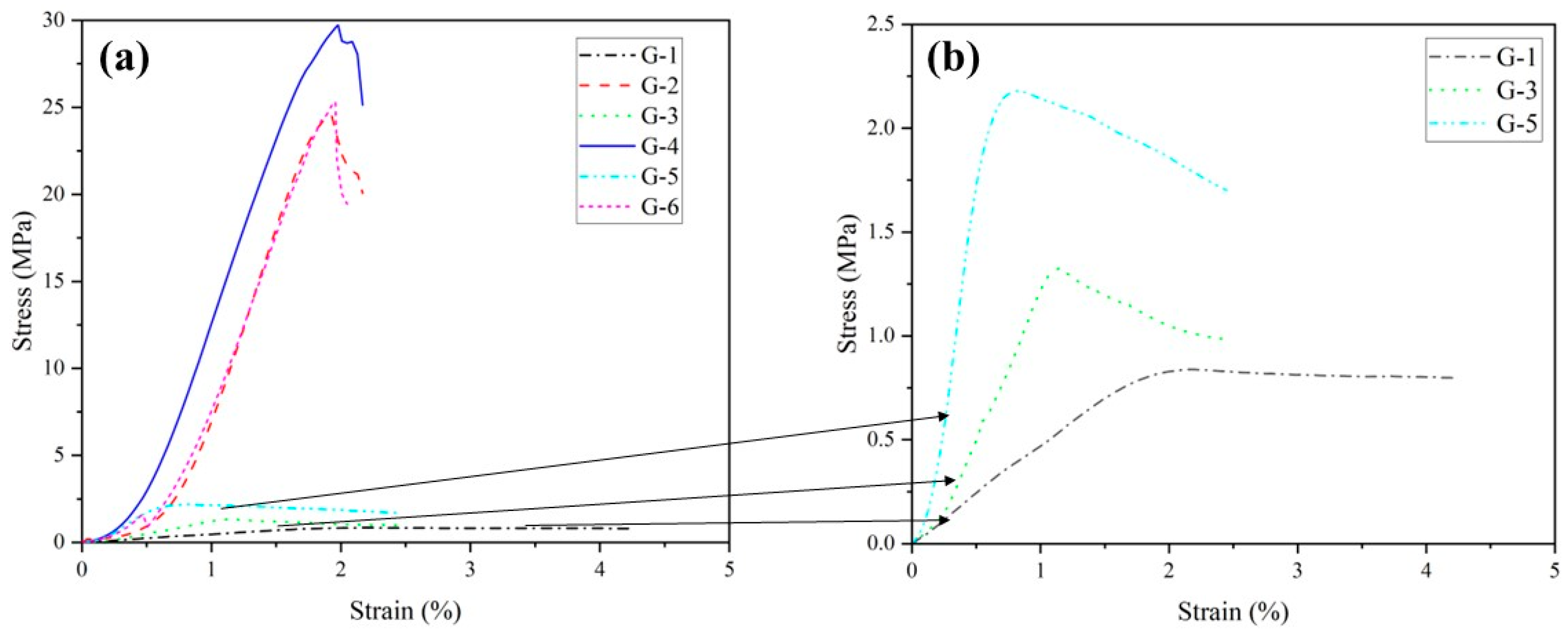

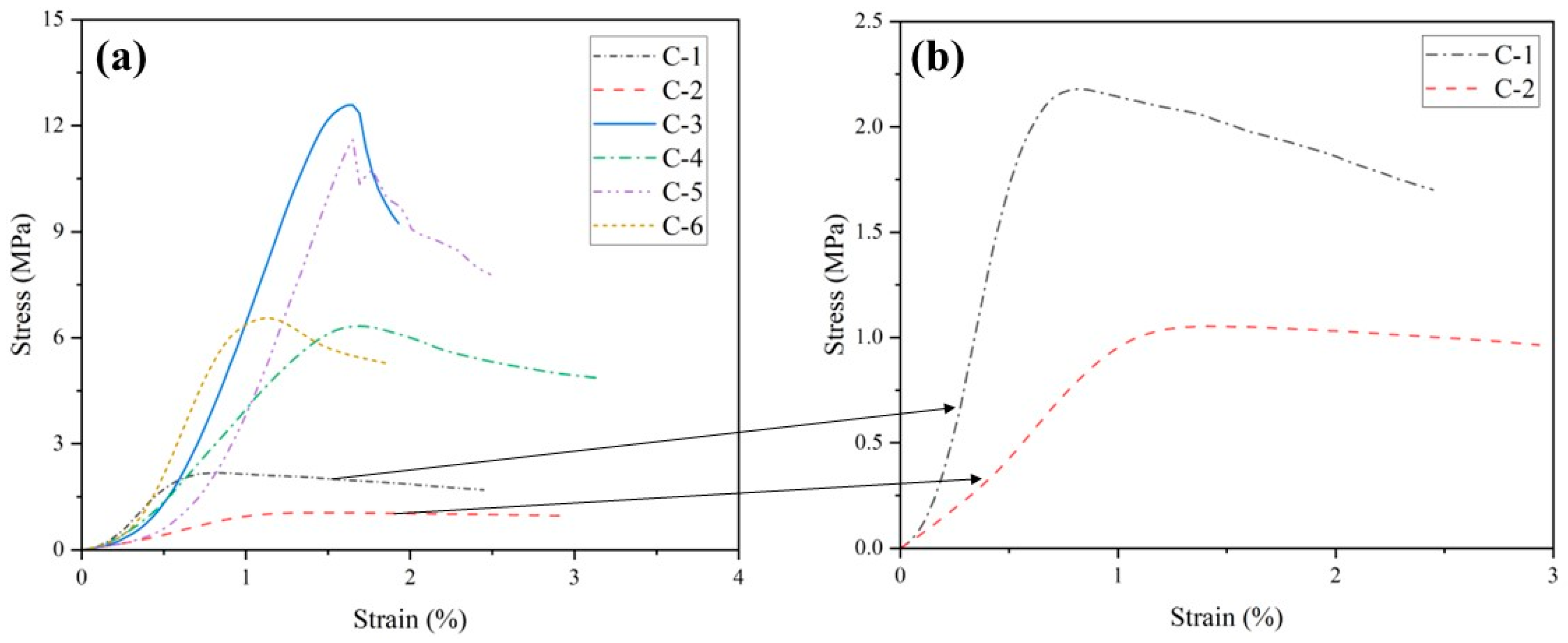

3.1. Stress and Strain

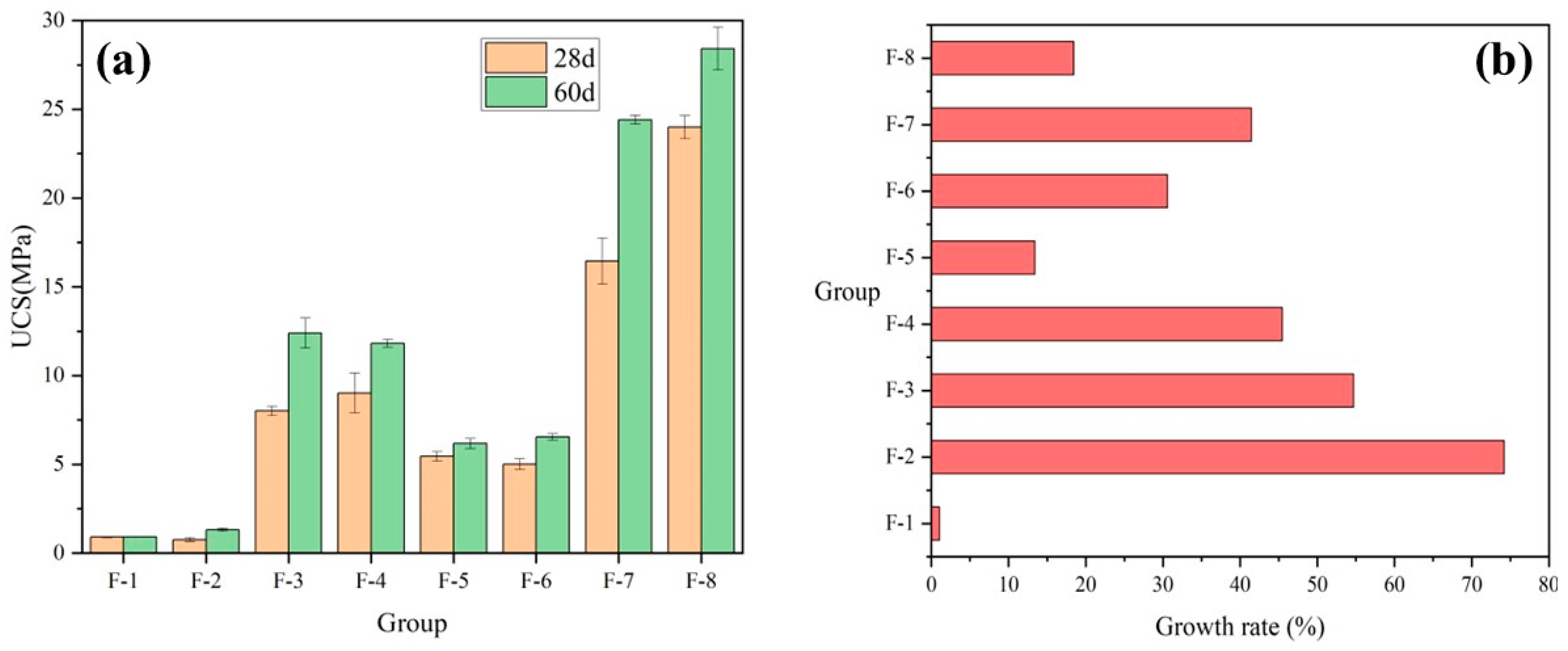

3.2. Compressive Strength

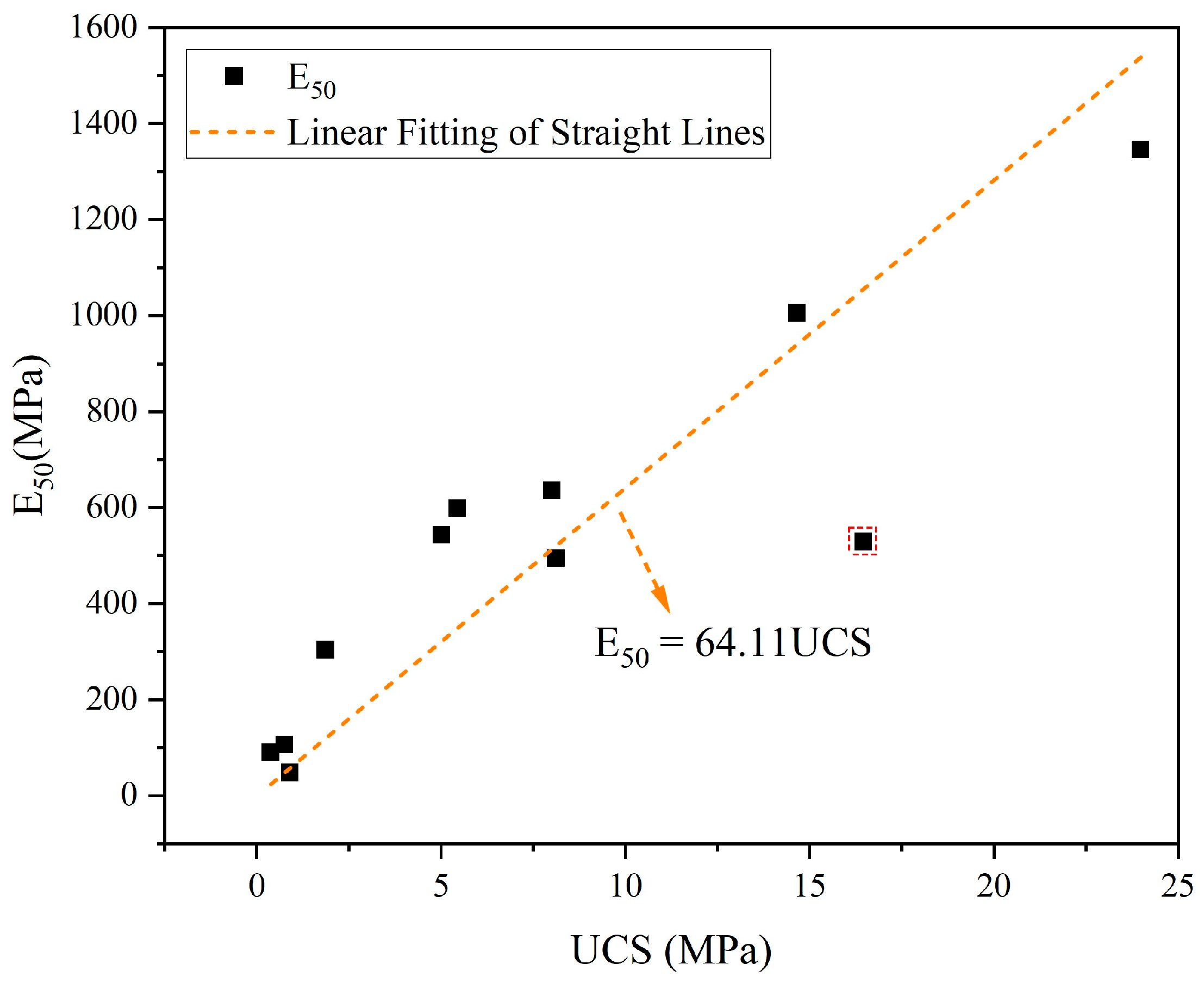

3.3. Prediction Model

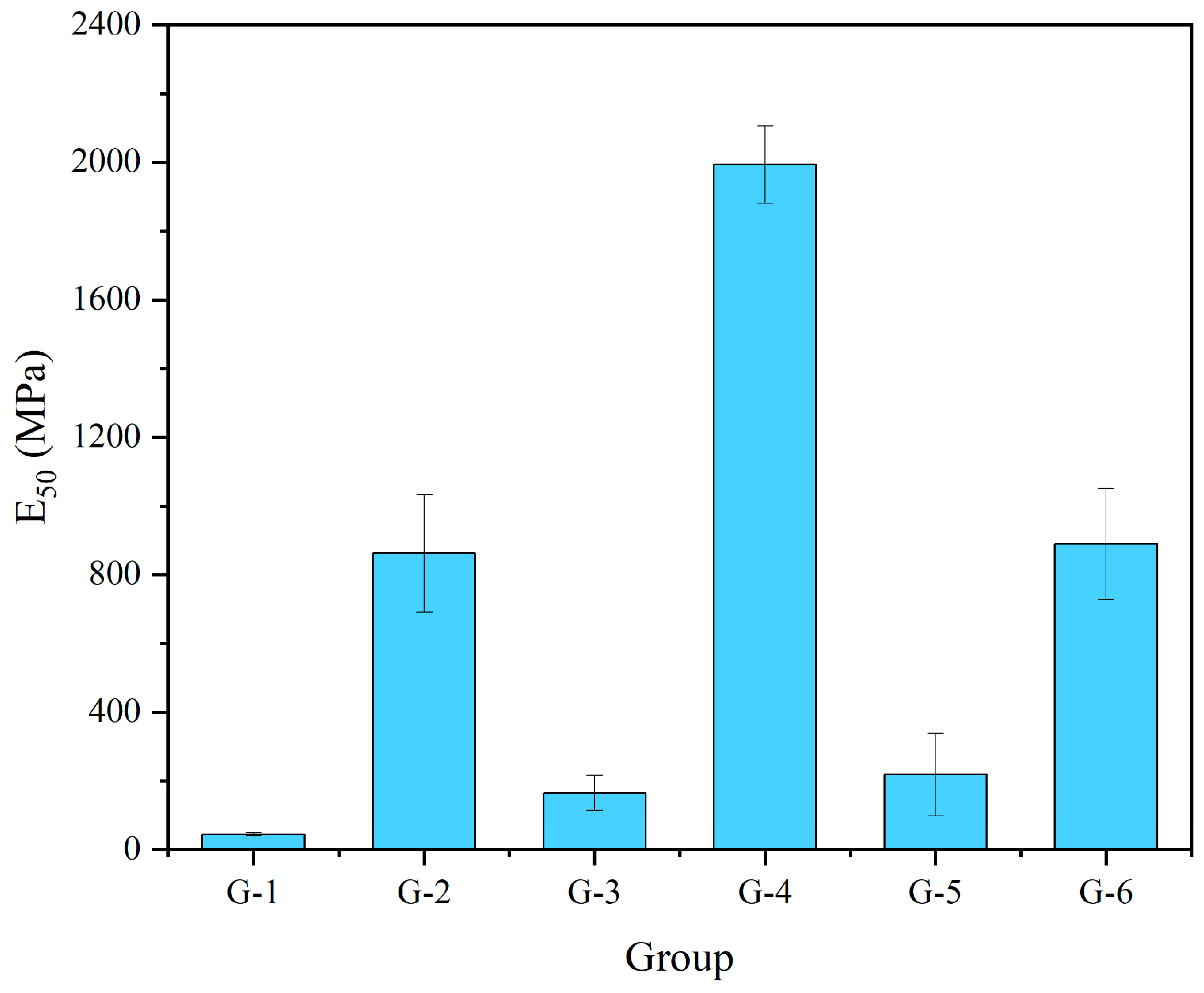

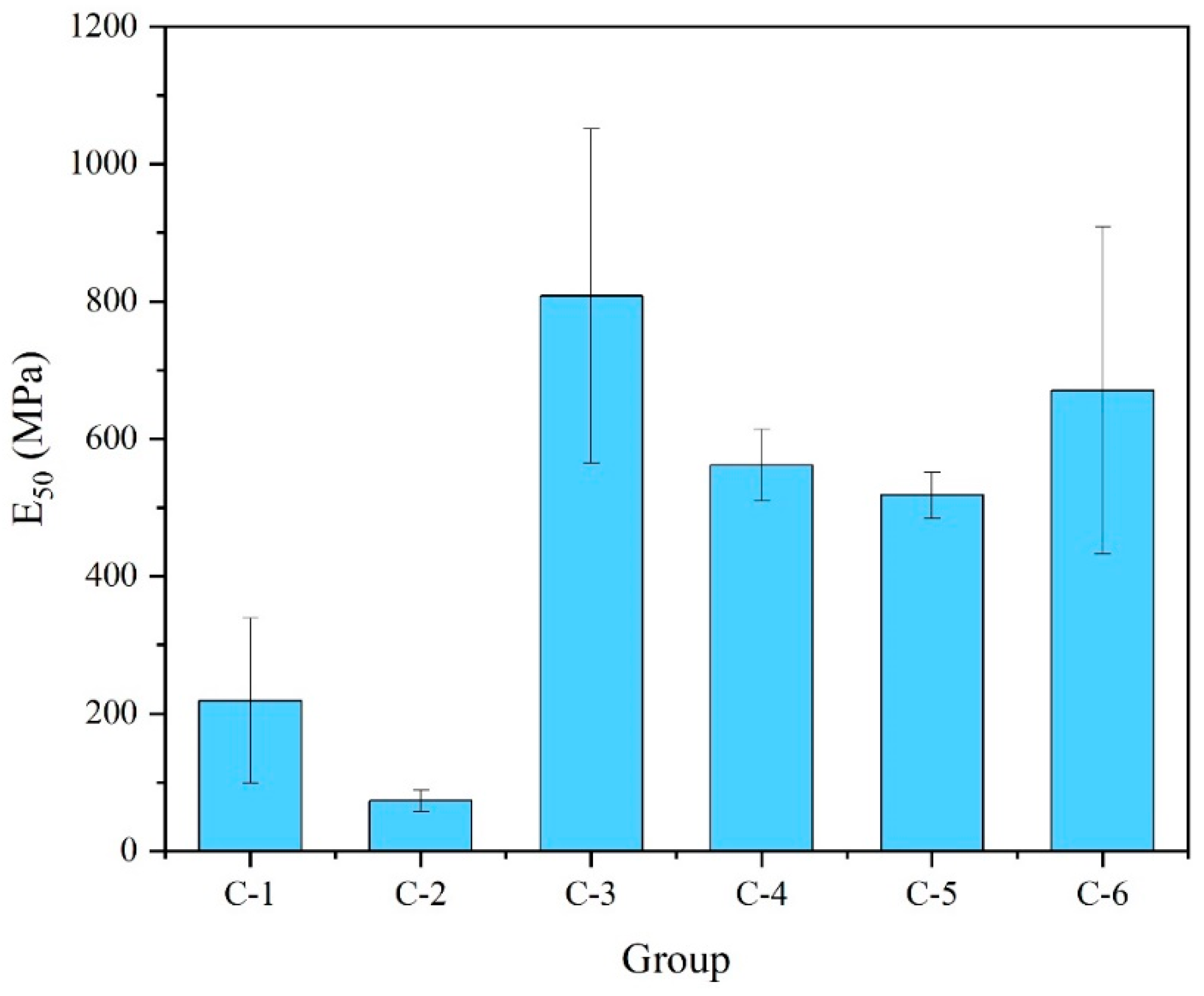

3.4. Elastic Modulus

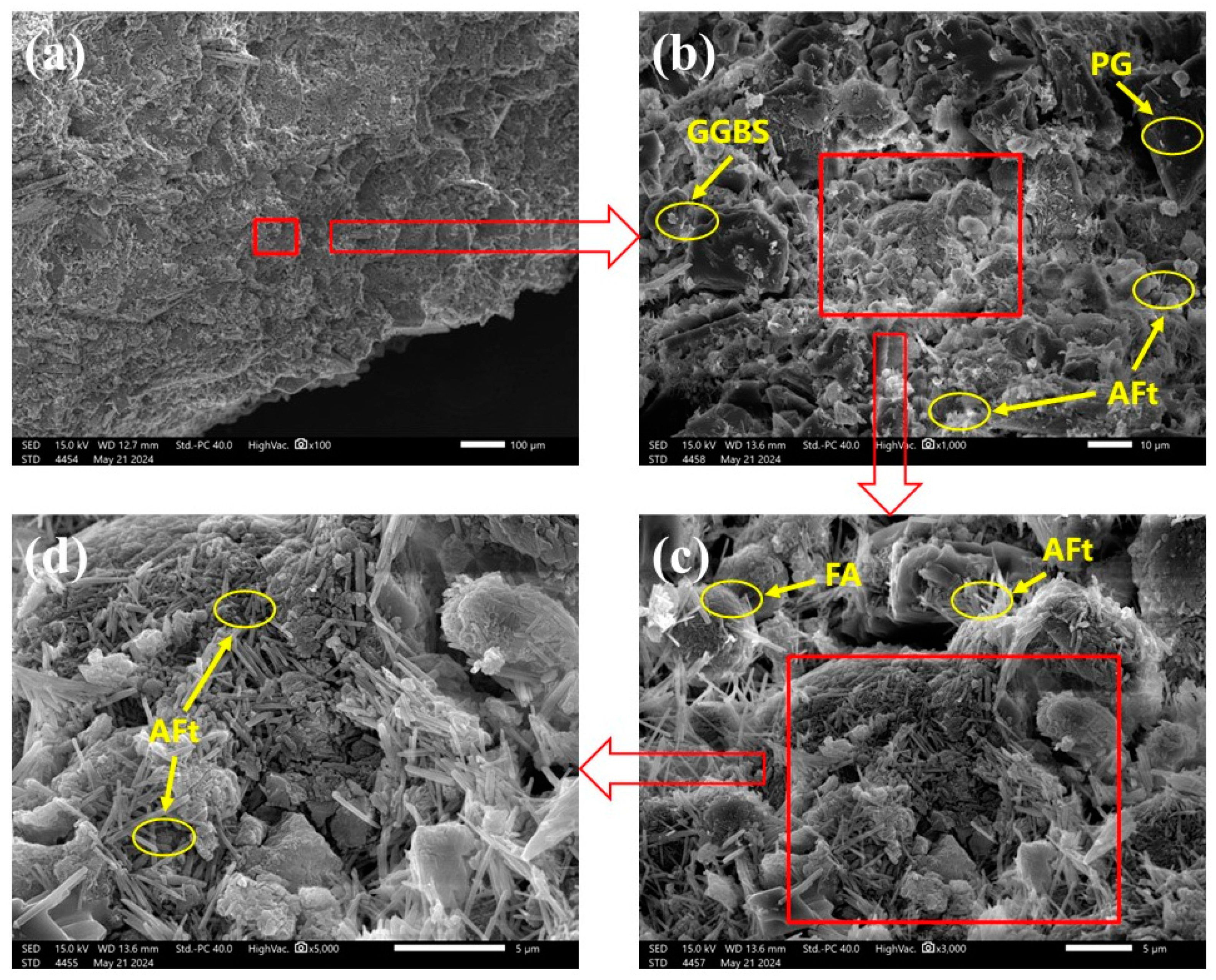

3.5. SEM

4. Conclusions

- (1)

- A high GGBS content (28%) can compensate for the pores inside the cementitious material and improve deformation resistance. Similarly, a high FA content (20%) can achieve the same function with sufficient alkalinity. However, excessive alkalinity negatively affects the material’s performance.

- (2)

- High GGBS content significantly improves the UCS of cementitious materials. Moreover, increasing FA content under appropriate HL conditions also enhances UCS.

- (3)

- A prediction model was constructed based on the UCS of cementitious materials. The statistical indices of the constructed model indicate a certain degree of reliability, and the model’s predicted data are generally consistent with the test data.

- (4)

- The pattern of change in E50 and UCS of cementitious materials tends to be the same, so the relationship between the two is modeled as a linear equation, represented as E50 = 64.11UCS.

- (5)

- SEM results indicate that ettringite primarily fills the pores within the studied cementitious material. As the curing age increases, the unreacted materials in the system gradually participate in the hydration reaction, continuously producing ettringite to further fill the pores of the cementitious material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, S.; Kumar, R.; Bandopadhyay, A. Innovative methodologies for the utilisation of wastes from metallurgical and allied industries. Resour. Conserv. Recycl. 2006, 48, 301–314. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lu, H.; Lan, W. Analysis of energy-efficiency opportunities for the cement industry in Shandong Province, China: A case study of 16 cement plants. Energy 2010, 35, 3461–3473. [Google Scholar] [CrossRef]

- Naqi, A.; Jang, J. Recent Progress in Green Cement Technology Utilizing Low-Carbon Emission Fuels and Raw Materials: A Review. Sustainability 2019, 11, 537. [Google Scholar] [CrossRef]

- Rashad, A.M.; Zeedan, S.R. The effect of activator concentration on the residual strength of alkali-activated fly ash pastes subjected to thermal load. Constr. Build. Mater. 2011, 25, 3098–3107. [Google Scholar] [CrossRef]

- Poudyal, L.; Adhikari, K. Environmental sustainability in cement industry: An integrated approach for green and economical cement production. Resour. Environ. Sustain. 2021, 4, 100024. [Google Scholar] [CrossRef]

- Zhi, X.; An, X.P. Low carbon technology roadmap of China cement industry. J. Sustain. Cem.-Based Mater. 2023, 12, 771–774. [Google Scholar] [CrossRef]

- Rashad, A.M. Metakaolin as cementitious material: History, scours, production and composition—A comprehensive overview. Constr. Build. Mater. 2013, 41, 303–318. [Google Scholar] [CrossRef]

- Valipour, M.; Yekkalar, M.; Shekarchi, M.; Panahi, S. Environmental assessment of green concrete containing natural zeolite on the global warming index in marine environments. J. Clean. Prod. 2014, 65, 418–423. [Google Scholar] [CrossRef]

- Liu, C.; Tian, J.; Cheng, K.; Xu, X.; Wang, Y.; Liu, X.; Liu, Z.; Bian, R.; Zhang, X.; Xia, S.; et al. Topsoil microbial biomass carbon pool and the microbial quotient under distinct land-use types across China: A data synthesis. Soil Sci. Environ. 2023, 2, 5. [Google Scholar] [CrossRef]

- Yue, Q.; Cheng, K.; Sheng, J.; Wang, L.; Ji, C.; Zhang, Y.; Zheng, J. Greenhouse gas emissions from managed freshwater wetlands under intensified aquaculture. Soil Sci. Environ. 2023, 2, 3. [Google Scholar] [CrossRef]

- Ahmad, J.; Kontoleon, K.J.; Al-Mulali, M.Z.; Shaik, S.; El Ouni, M.H.; El-Shorbagy, M.A. Partial Substitution of Binding Material by Bentonite Clay (BC) in Concrete: A Review. Buildings 2022, 12, 634. [Google Scholar] [CrossRef]

- Wang, H.; Zentar, R.; Wang, D. Rheological Characterization of Fine-Grained Sediments under Steady and Dynamic Conditions. Int. J. Geomech. 2022, 22, 04021260. [Google Scholar] [CrossRef]

- Wang, H.; Zentar, R.; Wang, D. Predicting the compaction parameters of solidified dredged fine sediments with statistical approach. Mar.Geores.Geotechnol. 2023, 41, 195–210. [Google Scholar] [CrossRef]

- Ren, F.-R.; Chen, K.-J.; Tian, Z.; Zhang, Y. The investment and treatment efficiencies of industrial solid waste in China’s Yangtze and non-Yangtze River Economic Belts. J. Mater. Cycles Waste Manag. 2022, 24, 900–916. [Google Scholar] [CrossRef]

- Wu, C. Investigation of foundation theory of safety & security complexity. J. Saf. Sustain. 2024, 1, 14–25. [Google Scholar]

- Zhang, Y.; Qi, H.; Li, C.; Zhou, J. Enhancing safety, sustainability, and economics in mining through innovative pillar design: A state-of-the-art review. J. Saf. Sustain. 2024, 1, 53–73. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, F.Y.; Tan, D.Y.; Yang, A.W. A deep learning informed-mesoscale cohesive numerical model for investigating the mechanical behavior of shield tunnels with crack damage. Structures 2024, 66, 106902. [Google Scholar] [CrossRef]

- Zhou, B.Y.; Sun, C.X.; Yi, H.T. Solid Waste Disposal in Chinese Cities: An Evaluation of Local Performance. Sustainability 2017, 9, 2234. [Google Scholar] [CrossRef]

- Ramanayaka, S.; Tsang, D.C.W.; Hou, D.Y.; Ok, Y.S.; Vithanage, M. Green synthesis of graphitic nanobiochar for the removal of emerging contaminants in aqueous media. Sci. Total Environ. 2020, 706, 135725. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Tsang, D.C.W.; Li, J.S.; Yeung, T.L.Y.; Ding, S.M.; Poon, C.S. Green remediation of contaminated sediment by stabilization/solidification with industrial by-products and CO2 utilization. Sci. Total Environ. 2018, 631–632, 1321–1327. [Google Scholar] [CrossRef]

- Adesina, A. Performance and sustainability overview of sodium carbonate activated slag materials cured at ambient temperature. Resour. Environ. Sustain. 2021, 3, 100016. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Y.; Zhang, S.; Chang, T.; Sun, L. Preparation and classification, hydration mechanism and durability of magnesium cementitious materials. J. Min. Sci. Technol. 2023, 8, 856–867. [Google Scholar] [CrossRef]

- Yang, P.; Liu, L.; Suo, Y.; Qu, H.; Xie, G.; Zhang, C.; Deng, S.; Lv, Y. Investigating the synergistic effects of magnesia-coal slag based solid waste cementitious materials and its basic characteristics as a backfill material. Sci. Total Environ. 2023, 880, 163209. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zentar, R.; Wang, D.; Ouendi, F. New Applications of Ordinary Portland and Calcium Sulfoaluminate Composite Binder for Recycling Dredged Marine Sediments as Road Materials. Int. J. Geomech. 2022, 22, 04022068. [Google Scholar] [CrossRef]

- Zentar, R.; Wang, H.; Wang, D. Comparative study of stabilization/solidification of dredged sediments with ordinary Portland cement and calcium sulfo-aluminate cement in the framework of valorization in road construction material. Constr. Build. Mater. 2021, 279, 122447. [Google Scholar] [CrossRef]

- Zhu, M.; Xie, G.; Liu, L.; Wang, R.; Ruan, S.; Yang, P.; Fang, Z. Strengthening mechanism of granulated blast-furnace slag on the uniaxial compressive strength of modified magnesium slag-based cemented backfilling material. Process Saf. Environ. Protect. 2023, 174, 722–733. [Google Scholar] [CrossRef]

- Liu, J.; Tan, X.; He, Y.; Zheng, k.; Wang, H.; He, Y.; Xie, N.; Wang, D. Semi-flexible pavement application of red mud-based cementitious materials. J. Chang. Univ. (Nat. Sci. Ed.) 2022, 42, 21–32. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, A. A Review of the Properties and Engineering Applications of Geopolymer Cementitious Materials. J. Archit. Civ. Eng. 2020, 37, 13–38. [Google Scholar] [CrossRef]

- Calderón-Morales, B.R.S.; García-Martínez, A.; Pineda, P.; García-Tenório, R. Valorization of phosphogypsum in cement-based materials: Limits and potential in eco-efficient construction. J. Build. Eng. 2021, 44, 102506. [Google Scholar] [CrossRef]

- Cui, Y.; Bai, J.; Chang, I.S.; Wu, J. A systematic review of phosphogypsum recycling industry based on the survey data in China–applications, drivers, obstacles, and solutions. Environ. Impact Assess. Rev. 2024, 105, 107405. [Google Scholar] [CrossRef]

- Rashad, A.M. Phosphogypsum as a construction material. J. Clean. Prod. 2017, 166, 732–743. [Google Scholar] [CrossRef]

- Bilal, E.; Bellefqih, H.; Bourgier, V.; Mazouz, H.; Dumitraş, D.-G.; Bard, F.; Laborde, M.; Caspar, J.P.; Guilhot, B.; Iatan, E.-L.; et al. Phosphogypsum circular economy considerations: A critical review from more than 65 storage sites worldwide. J. Clean. Prod. 2023, 414, 137561. [Google Scholar] [CrossRef]

- Chernysh, Y.; Yakhnenko, O.; Chubur, V.; Roubík, H. Phosphogypsum Recycling: A Review of Environmental Issues, Current Trends, and Prospects. Appl. Sci. 2021, 11, 1575. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Y.; Zhu, Q.; Zhou, S.; Min, C.; Shi, Y. Slurry Preparation Effects on the Cemented Phosphogypsum Backfill through an Orthogonal Experiment. Minerals 2019, 9, 31. [Google Scholar] [CrossRef]

- Min, C.; Shi, Y.; Liu, Z. Properties of cemented phosphogypsum (PG) backfill in case of partially substitution of composite Portland cement by ground granulated blast furnace slag. Constr. Build. Mater. 2021, 305, 124786. [Google Scholar] [CrossRef]

- Zhou, S.; Li, X.; Zhou, Y.; Min, C.; Shi, Y. Effect of phosphorus on the properties of phosphogypsum-based cemented backfill. J. Hazard. Mater. 2020, 399, 122993. [Google Scholar] [CrossRef]

- Chen, M.; Liu, P.; Kong, D.; Li, Y.; Chen, Y.; Cui, G.; Wang, J.; Yu, K.; Wu, N. Performance Study and Multi-Index Synergistic Effect Analysis of Phosphogypsum-Based Composite Cementitious Material. Coatings 2022, 12, 1918. [Google Scholar] [CrossRef]

- Xu, J.Q.; Chen, P.; Zhang, C.Y.; Yang, Y.H. Influence of phosphogypsum on mechanical properties and microstructure of iron tailings cementitious material. Arch. Civ. Mech. Eng. 2023, 24, 18. [Google Scholar] [CrossRef]

- Liu, X.; Tang, P.; Chen, W. Development of an ettringite-based low carbon binder by promoting the nucleation and Ostwald ripening process. Constr. Build. Mater. 2024, 427, 136282. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, K.; Yang, Y.; Chang, J. Investigation on the preparation of low carbon cement materials from industrial solid waste phosphogypsum: Clinker preparation, cement properties, and hydration mechanism. J. Clean Prod. 2024, 452, 142203. [Google Scholar] [CrossRef]

- Min, C.; Li, X.; He, S.; Zhou, S.; Zhou, Y.; Yang, S.; Shi, Y. Effect of mixing time on the properties of phosphogypsum-based cemented backfill. Constr. Build. Mater. 2019, 210, 564–573. [Google Scholar] [CrossRef]

- Ma, F.; Chen, L.; Lin, Z.; Liu, Z.; Zhang, W.; Guo, R. Microstructure and Key Properties of Phosphogypsum-Red Mud-Slag Composite Cementitious Materials. Materials 2022, 15, 6069. [Google Scholar] [CrossRef] [PubMed]

- Dong, S.; Zhuo, Q.; Chen, L.; Wu, F.; Xie, L. Reuse of Pretreated Red Mud and Phosphogypsum as Supplementary Cementitious Material. Sustainability 2023, 15, 2856. [Google Scholar] [CrossRef]

- Huang, Y.; Lin, Z. Investigation on phosphogypsum-steel slag-granulated blast-furnace slag-limestone cement. Constr. Build. Mater. 2010, 24, 1296–1301. [Google Scholar] [CrossRef]

- Yang, X.; Jia, Y.; Yang, C.; He, X.; Jia, Y.; Xu, L. Research on formulation optimization and hydration mechanism of phosphogypsum-based filling cementitious materials. Front. Environ. Sci. 2022, 10, 1012057. [Google Scholar] [CrossRef]

- Zeng, L.-L.; Bian, X.; Zhao, L.; Wang, Y.-J.; Hong, Z.-S. Effect of phosphogypsum on physiochemical and mechanical behaviour of cement stabilized dredged soil from Fuzhou, China. Geomech. Energy Environ. 2021, 25, 100195. [Google Scholar] [CrossRef]

- Zhu, J.; Qu, Z.; Huang, Y.; Song, L.; Liu, S.; Min, H.; Li, Z. Investigating Mechanical Properties of Alkali-Activated Slag Cementitious Material for Load-Bearing Layer of Sandwich Panels. Materials 2023, 16, 6398. [Google Scholar] [CrossRef]

- Xu, Z.; Han, X.; Feng, K.; Zhang, W.; Ma, K. Improvement of Mechanical Properties and Microstructure of Cementitious Materials in a Hot-Dry Environment. Crystals 2022, 12, 981. [Google Scholar] [CrossRef]

- Jongpradist, P.; Jamsawang, P.; Kongkitkul, W. Equivalent void ratio controlling the mechanical properties of cementitious material-clay mixtures with high water content. Mar. Georesources Geotechnol. 2019, 37, 1151–1162. [Google Scholar] [CrossRef]

- Deng, Y.; Yan, C.; Zhang, J.; Yin, L.; Liu, S.; Yan, Y. Preparation and mechanical characterization of engineered cementitious composites with high-volume fly ash and waste glass powder. J. Clean. Prod. 2022, 333, 130222. [Google Scholar] [CrossRef]

- Sun, L.; Hao, Q.; Zhao, J.; Wu, D.; Yang, F. Stress strain behavior of hybrid steel-PVA fiber reinforced cementitious composites under uniaxial compression. Constr. Build. Mater. 2018, 188, 349–360. [Google Scholar] [CrossRef]

- Lu, D.; Du, X.; Ma, C.; Wang, Y. Study on static and dynamic stress–strain relationship of cement mortar material. Mater. Res. Innov. 2014, 18, S2-799–S2-805. [Google Scholar] [CrossRef]

- Kohees, M.; Rajeev, P.; Sanjayan, J.G. Stress-strain relationship of cement paste under triaxial compression. Proc. Inst. Civ. Eng.-Constr. Mater. 2022, 175, 233–241. [Google Scholar] [CrossRef]

- Zhou, J.-k.; Ge, L.-m. Effect of strain rate and water-to-cement ratio on compressive mechanical behavior of cement mortar. J. Cent. South Univ. 2015, 22, 1087–1095. [Google Scholar] [CrossRef]

- Shi, Y.; Li, Y.; Wang, H. Eco-friendly solid waste-based cementitious material containing a large amount of phosphogypsum: Performance optimization, micro-mechanisms, and environmental properties. J. Clean. Prod. 2024, 471, 143335. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Standardization Administration of the People’s Republic of China: Beijing, China, 2021; p. 24.

- Huang, K.; Ma, Q.; Ma, D.; Bosco, M. Effect of Basalt Fiber on Static and Dynamic Mechanical Properties of Metakaolin-Based Cement Clay. Adv. Civ. Eng. 2020, 2020, 1359163. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, A.; Jaksa, M. Enhancing mechanical behavior of micaceous soil with jute fibers and lime additives. J. Rock Mech. Geotech. Eng. 2021, 13, 1093–1100. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Miraftab, M.; Mohamed, M.; McMahon, P. Unconfined Compression Strength of Reinforced Clays with Carpet Waste Fibers. J. Geotech. Geoenviron. Eng. 2013, 139, 483–493. [Google Scholar] [CrossRef]

- Wang, D.; Wang, H.; Di, S. Mechanical properties and microstructure of magnesia–fly ash pastes. Road Mater. Pavement Des. 2018, 20, 1243–1254. [Google Scholar] [CrossRef]

- Zhang, F.; Li, Y.; Zhang, J.; Gui, X.; Zhu, X.; Zhao, C. Effects of slag-based cementitious material on the mechanical behavior and heavy metal immobilization of mine tailings based cemented paste backfill. Heliyon 2022, 8, e10695. [Google Scholar] [CrossRef]

- Ma, W.; Brown, P.W. Hydrothermal reactions of fly ash with Ca(OH)2 and CaSO4·2H2O. Cem. Concr. Res. 1997, 27, 1237–1248. [Google Scholar] [CrossRef]

- Mashifana, T.; Okonta, F.N.; Ntuli, F. Geotechnical Properties and Application of Lime Modified Phosphogypsum Waste. Mater. Sci. 2018, 24, 312–318. [Google Scholar] [CrossRef]

- Zhang, S.; Li, V.C.; Ye, G. Micromechanics-guided development of a slag/fly ash-based strain-hardening geopolymer composite. Cem. Concr. Compos. 2020, 109, 103510. [Google Scholar] [CrossRef]

- Seo, J.H.; Park, S.M.; Yang, B.J.; Jang, J.G. Calcined Oyster Shell Powder as an Expansive Additive in Cement Mortar. Materials 2019, 12, 1322. [Google Scholar] [CrossRef] [PubMed]

- Sevim, O.; Sengul, C.G.; Kartal, S.; Toklu, K.; Caglar, Y. Effect of Supplementary Cementitious Materials with Similar Specific Surface Area on Cementitious Composite Systems. J. Test. Eval. 2023, 51, 2971–2985. [Google Scholar] [CrossRef]

- Lin, T.; Wang, C.; Yousfani, S.; Wang, W.; Qian, X.; Xun, Z. Study on extraction technology of bamboo fiber by response surface. Acta Mater Compos. Sin 2018, 35, 876–884. [Google Scholar]

- Xu, X.H.; He, M.Z. Experimental Design and Application of Design-Expert and SPSS; Science Press: Beijing, China, 2010. (In Chinese) [Google Scholar]

- He, Z.-H.; Zhan, P.-M.; Du, S.-G.; Liu, B.-J.; Yuan, W.-B. Creep behavior of concrete containing glass powder. Compos. Part B-Eng. 2019, 166, 13–20. [Google Scholar] [CrossRef]

- Wang, P.; Xie, M.; Liu, L. Study on Early Shrinkage and Mechanical Properties of Concrete with Various Cementitious Materials. Buildings 2022, 12, 1543. [Google Scholar] [CrossRef]

- Van Roode, M.; Douglas, E.; Hemmings, R.T. X-ray diffraction measurement of glass content in fly ashes and slags. Cem. Concr. Res. 1987, 17, 183–197. [Google Scholar] [CrossRef]

- Diamond, S.; Kilgour, C.L. A Procedure for the Interpretation of Fly Ash Particle Size Data. Mater. Res. Soc. Symp. Proc. 1985, 65, 105–114. [Google Scholar] [CrossRef]

| No. | GGBS (%) | FA (%) | HL (%) | PG (%) | Total (%) |

|---|---|---|---|---|---|

| G-1 | 5 | 5 | 1.25 | 88.75 | 100 |

| G-2 | 28 | 5 | 1.25 | 65.75 | 100 |

| G-3 | 5 | 20 | 1.25 | 73.75 | 100 |

| G-4 | 28 | 20 | 1.25 | 50.75 | 100 |

| G-5 | 5 | 12.5 | 0.5 | 82.00 | 100 |

| G-6 | 28 | 12.5 | 0.5 | 59.00 | 100 |

| No. | GGBS (%) | FA (%) | HL (%) | PG (%) | Total (%) |

|---|---|---|---|---|---|

| F-1 | 5 | 5 | 1.25 | 88.75 | 100 |

| F-2 | 5 | 20 | 1.25 | 73.75 | 100 |

| F-3 | 16.5 | 5 | 0.5 | 78 | 100 |

| F-4 | 16.5 | 20 | 0.5 | 63 | 100 |

| F-5 | 16.5 | 5 | 2 | 76.5 | 100 |

| F-6 | 16.5 | 20 | 2 | 61.5 | 100 |

| F-7 | 28 | 5 | 1.25 | 65.75 | 100 |

| F-8 | 28 | 20 | 1.25 | 50.75 | 100 |

| No. | GGBS (%) | FA (%) | HL (%) | PG (%) | Total (%) |

|---|---|---|---|---|---|

| C-1 | 5 | 12.5 | 0.5 | 82 | 100 |

| C-2 | 5 | 12.5 | 2 | 80.5 | 100 |

| C-3 | 16.5 | 5 | 0.5 | 78 | 100 |

| C-4 | 16.5 | 5 | 2 | 76.5 | 100 |

| C-5 | 16.5 | 20 | 0.5 | 63 | 100 |

| C-6 | 16.5 | 20 | 2 | 61.5 | 100 |

| Variables | Coded | Levels | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| GGBS/wt.% | A | 5 | 16.5 | 28 |

| FA/wt.% | B | 5 | 12.5 | 20 |

| HL/wt.% | C | 0.5 | 1.25 | 2 |

| Curing Time | Mean | F-Value | p-Value | R2 |

|---|---|---|---|---|

| 60 d | 11.01 | 28.17 | 0.0009 | 0.9807 |

| GGBS (%) | FA (%) | HL (%) | PG (%) | Predicted UCS (MPa) | Experimental UCS (MPa) |

|---|---|---|---|---|---|

| 28.00 | 12.50 | 2.00 | 57.50 | 17.50 | 16.33 |

| 16.50 | 12.50 | 1.25 | 69.75 | 9.89 | 10.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Li, Y.; Wang, H.; Ma, Y.; Lu, X. Stress-Strain Behavior and Strength Development of High-Amount Phosphogypsum-Based Sustainable Cementitious Materials. Materials 2024, 17, 4927. https://doi.org/10.3390/ma17194927

Shi Y, Li Y, Wang H, Ma Y, Lu X. Stress-Strain Behavior and Strength Development of High-Amount Phosphogypsum-Based Sustainable Cementitious Materials. Materials. 2024; 17(19):4927. https://doi.org/10.3390/ma17194927

Chicago/Turabian StyleShi, Ying, Yue Li, Hongwei Wang, Yixuan Ma, and Xinyue Lu. 2024. "Stress-Strain Behavior and Strength Development of High-Amount Phosphogypsum-Based Sustainable Cementitious Materials" Materials 17, no. 19: 4927. https://doi.org/10.3390/ma17194927

APA StyleShi, Y., Li, Y., Wang, H., Ma, Y., & Lu, X. (2024). Stress-Strain Behavior and Strength Development of High-Amount Phosphogypsum-Based Sustainable Cementitious Materials. Materials, 17(19), 4927. https://doi.org/10.3390/ma17194927