Innovative Hemp Shive-Based Bio-Composites: Part I: Modification of Potato Starch Binder by Sodium Meta-Silicate and Glycerol

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

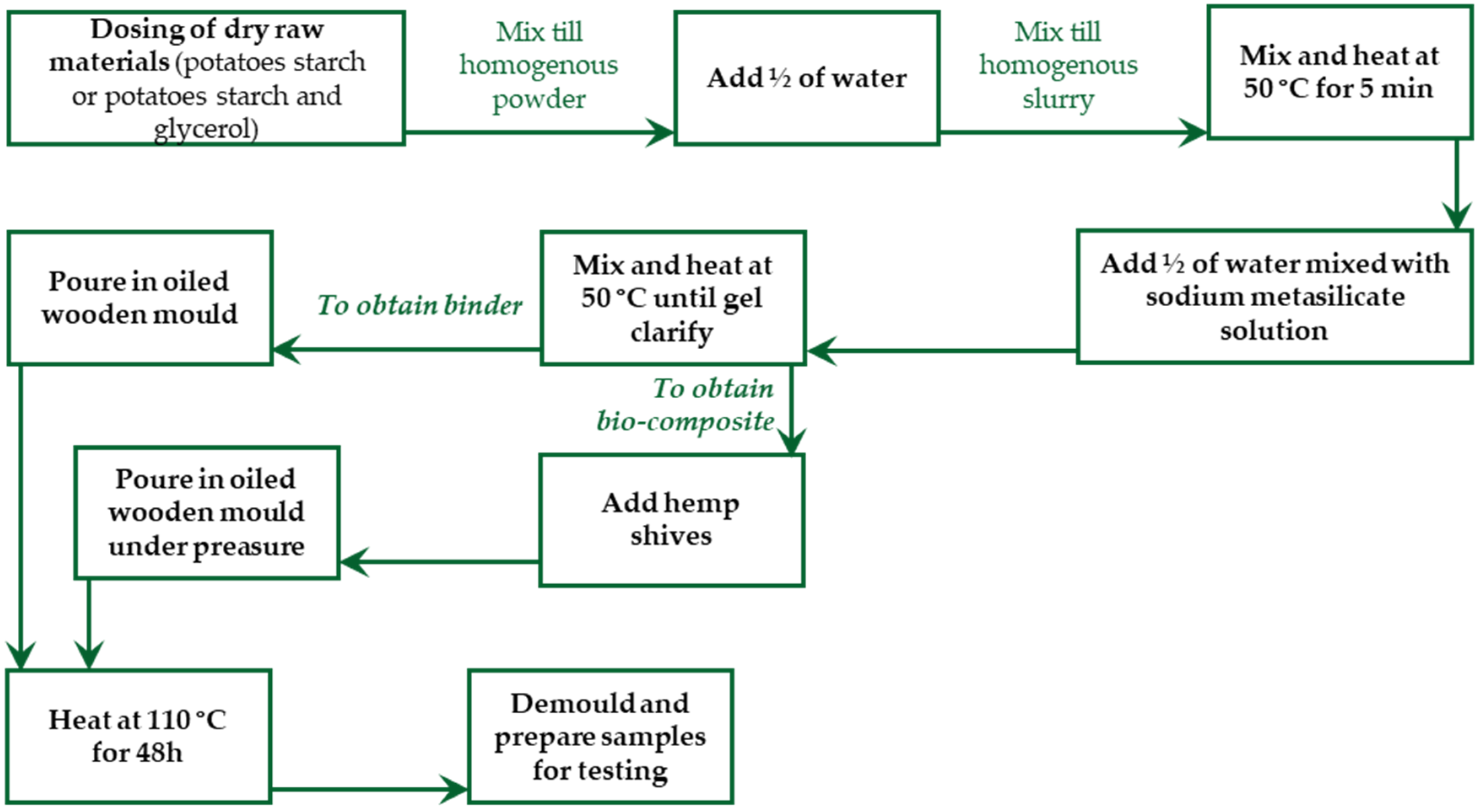

2.2. Mixture Design and Sample Preparation

2.3. Testing Methods

3. Results

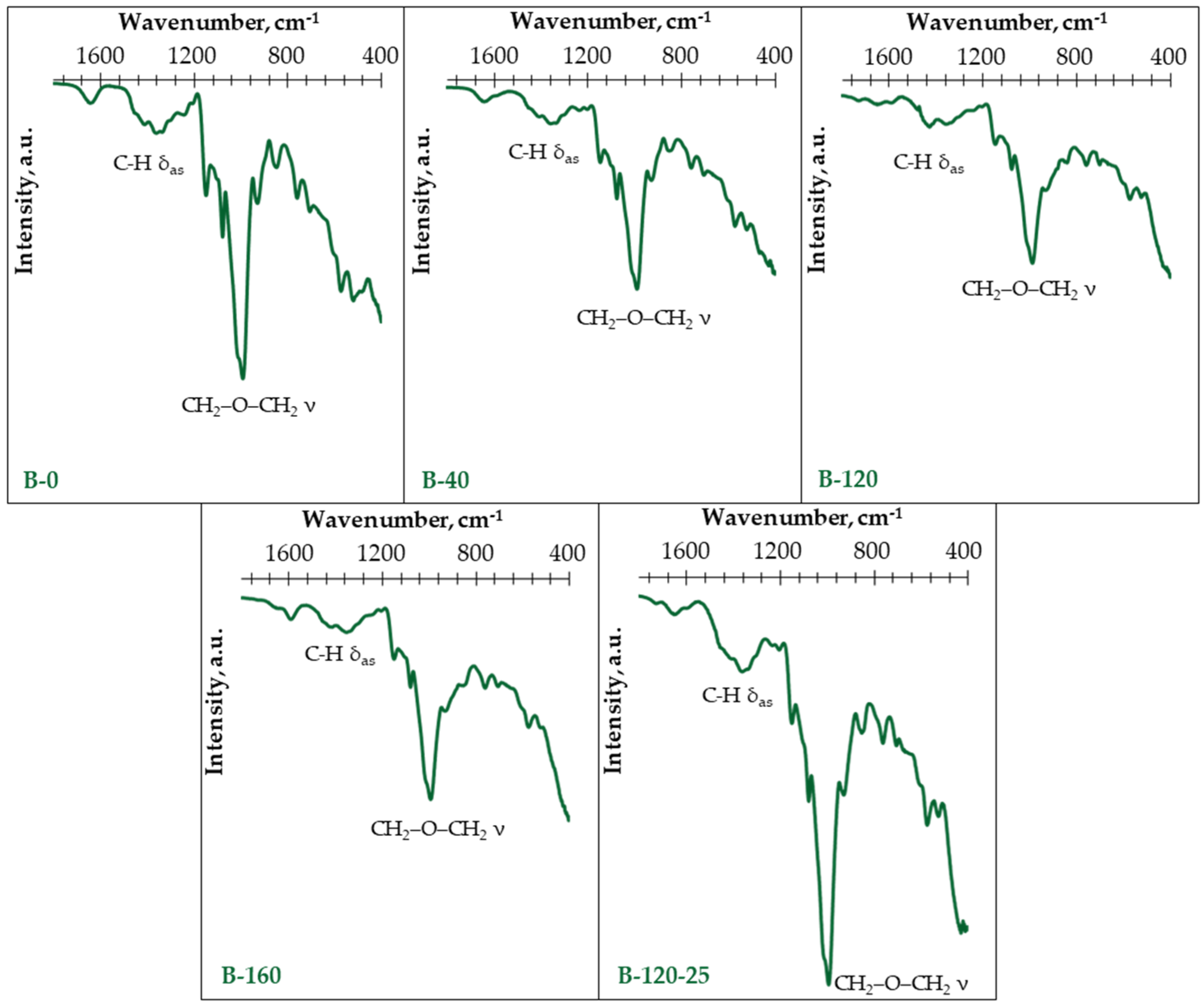

3.1. Modification of Starch Binder

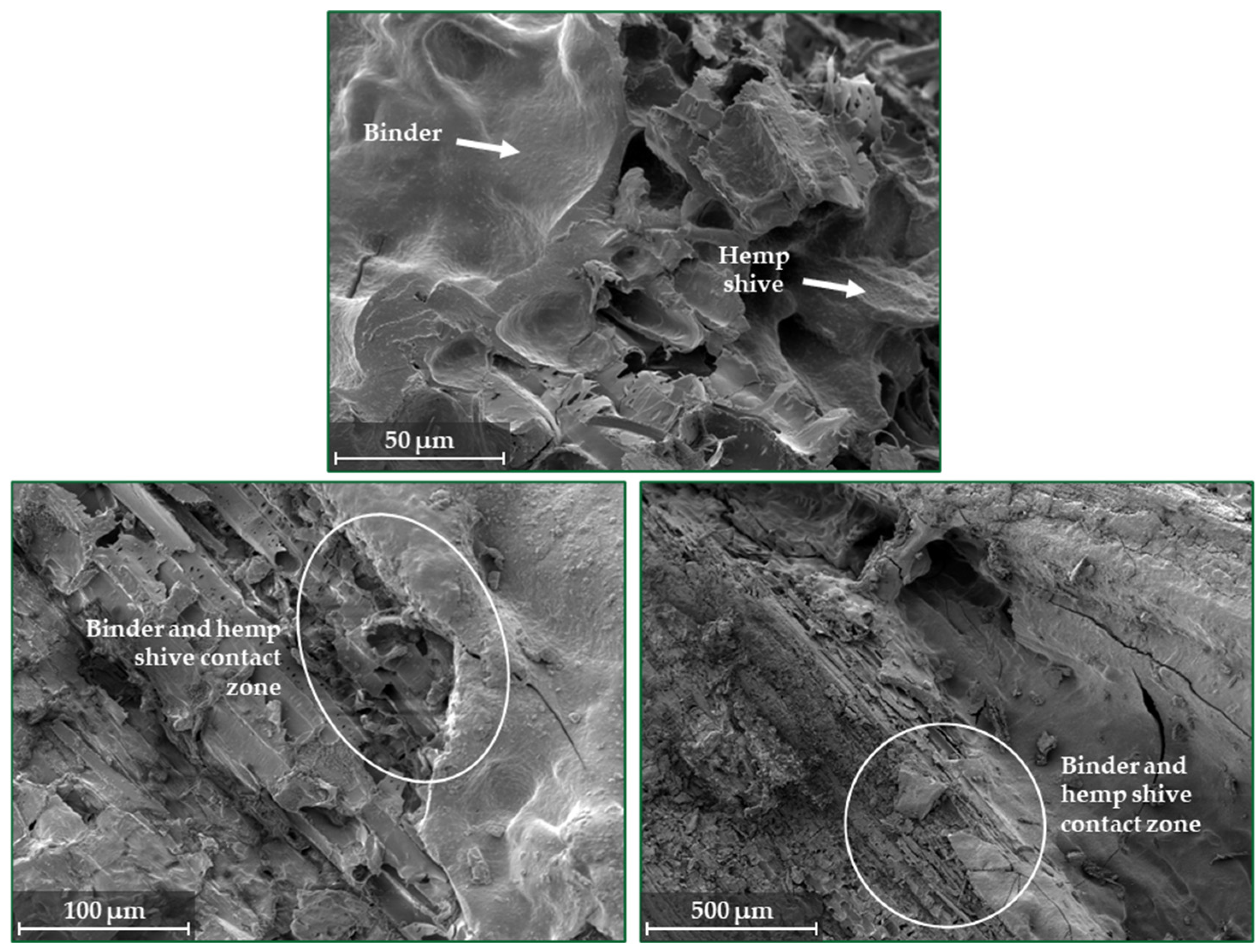

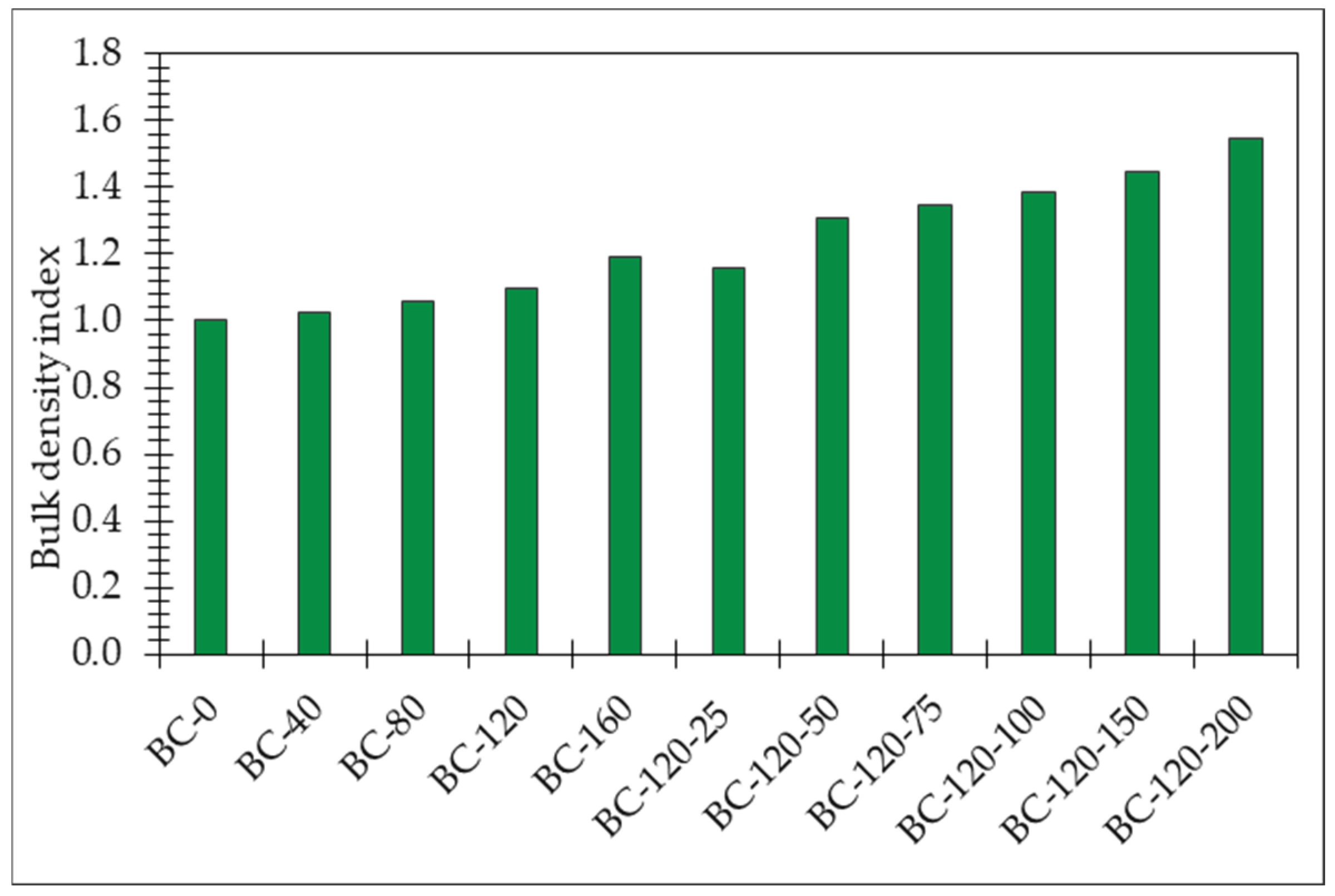

3.2. Bio-Composites Bounded by Potato-Starch-Based Binder

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- A European Green Deal | European Commission. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal/ (accessed on 21 March 2022).

- Bumanis, G.; Vitola, L.; Pundiene, I.; Sinka, M.; Bajare, D. Gypsum, Geopolymers, and Starch-Alternative Binders for Bio-Based Building Materials: A Review and Life-Cycle Assessment. Sustainability 2020, 12, 5666. [Google Scholar] [CrossRef]

- Vitola, L.; Gendelis, S.; Sinka, M.; Pundiene, I.; Bajare, D. Assessment of Plant Origin By-Products as Lightweight Aggregates for Bio-Composite Bounded by Starch Binder. Energies 2022, 15, 5330. [Google Scholar] [CrossRef]

- Arrigoni, A.; Pelosato, R.; Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life Cycle Assessment of Natural Building Materials: The Role of Carbonation, Mixture Components and Transport in the Environmental Impacts of Hempcrete Blocks. J Clean Prod 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Sinka, M.; Van Den Heede, P.; De Belie, N.; Bajare, D.; Sahmenko, G.; Korjakins, A. Comparative Life Cycle Assessment of Magnesium Binders as an Alternative for Hemp Concrete. Resour. Conserv. Recycl. 2018, 133, 288–299. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation Materials for the Building Sector: A Review and Comparative Analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Lagouin, M.; Magniont, C.; Sénéchal, P.; Moonen, P.; Aubert, J.E.; Laborel-préneron, A. Influence of Types of Binder and Plant Aggregates on Hygrothermal and Mechanical Properties of Vegetal Concretes. Constr. Build. Mater. 2019, 222, 852–871. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Sapuan, S.M. Morphological Study and Performance Deterioration of Sustainable Lignocellulosic Corn Fiber Bio-Composites. J. Mater. Cycles Waste Manag. 2023, 25, 337–345. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, Physical and Chemical Characterisation of Mycelium-Based Composites with Different Types of Lignocellulosic Substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties Characterization of Chemically Modified Hemp Hurds. Materials 2014, 7, 8131. [Google Scholar] [CrossRef] [PubMed]

- Sinka, M.; Radina, L.; Sahmenko, G.; Korjakins, A.; Bajare, D. Enhancement of lime-hemp concrete properties using different. In Proceedings of the 1st International Conference on Bio-based Building Materials, Clermont-Ferrand, France, 22–24 June 2015; pp. 301–308, ISBN PRO 99: 978-2-35158-154-4. [Google Scholar]

- Cuthbertson, D.; Berardi, U.; Briens, C.; Berruti, F. Biochar from Residual Biomass as a Concrete Filler for Improved Thermal and Acoustic Properties. Biomass Bioenergy 2019, 120, 77–83. [Google Scholar] [CrossRef]

- Le, A.T.; Gacoin, A.; Li, A.; Mai, T.H.; El Wakil, N. Influence of Various Starch/Hemp Mixtures on Mechanical and Acoustical Behavior of Starch-Hemp Composite Materials. Compos. B Eng. 2015, 75, 201–211. [Google Scholar] [CrossRef]

- Hedayati, S.; Niakousari, M. Microstructure, Pasting and Textural Properties of Wheat Starch-Corn Starch Citrate Composites. Food Hydrocoll. 2018, 81, 1–5. [Google Scholar] [CrossRef]

- Pundiene, I.; Vitola, L.; Pranckeviciene, J.; Bajare, D. Hemp Shive-Based Bio-Composites Bounded by Potato Starch Binder: The Roles of Aggregate Particle Size and Aspect Ratio. J. Ecol. Eng. 2022, 23, 220–234. [Google Scholar] [CrossRef]

- Jagadeesan, S.; Govindaraju, I.; Mazumder, N. An Insight into the Ultrastructural and Physiochemical Characterization of Potato Starch: A Review. Am. J. Potato Res. 2020, 97, 464–476. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, P.; Li, Y.; Li, J.; Li, X.; Yang, J.; Ji, M.; Li, F.; Zhang, C. Recent Advances and Future Challenges of the Starch-Based Bio-Composites for Engineering Applications. Carbohydr. Polym. 2023, 307, 120627. [Google Scholar] [CrossRef]

- Amini, M.H.M.; Hashim, R.; Sulaiman, N.S.; Mohamed, M.; Sulaiman, O. Citric Acid-Modified Starch as an Environmentally Friendly Binder for Wood Composite Making. Bioresources 2020, 15, 4234–4248. [Google Scholar] [CrossRef]

- Owodunni, A.A.; Hashim, R.; Taiwo, O.F.A.; Hussin, M.H.; Kassim, M.H.M.; Bustami, Y.; Sulaiman, O.; Amini, M.H.M.; Hiziroglu, S. Flame-Retardant Properties of Particleboard Made from Coconut Fibre Using Modified Potato Starch as a Binder. J. Phys. Sci. 2020, 31, 129–143. [Google Scholar] [CrossRef]

- Arifuzzaman, M.; Al Mamun, C.; Professor, A.; Author, A. Compressive Properties of Sawdust Composites Consisting of Sodium Silicate Solution and Corn Starch as Binder. Int. J. Sci. Bus. 2020, 4, 129–136. [Google Scholar] [CrossRef]

- Basiak, E.; Lenart, A.; Debeaufort, F. How Glycerol and Water Contents Affect the Structural and Functional Properties of Starch-Based Edible Films. Polymers 2018, 10, 412. [Google Scholar] [CrossRef]

- DIN EN 1602; Thermal Insulating Products for Building Applications—Determination of the Apparent Density. European Standards. 2013. Available online: https://www.en-standard.eu/din-en-1602-thermal-insulating-products-for-building-applications-determination-of-the-apparent-density/?gclid=Cj0KCQiA5aWOBhDMARIsAIXLlkc2Qc1sUX7jjO7uIKzgRIDC9IO9Z4ZxEXKHFitcvhBJsyzXUUCxuVgaAvEkEALw_wcB (accessed on 27 December 2021).

- EN 1609:2013; Thermal Insulating Products for Building Applications—Determination of Short Term. Available online: https://standards.iteh.ai/catalog/standards/cen/44e29fdf-6f87-49b8-b21d-0d23b3c71358/en-1609-2013?srsltid=AfmBOorATWqTnhUXJLVfTl5EMcCiHJOaaWV0DAA69eD2D7UUzeS6e3E6 (accessed on 12 August 2024).

- EN 826:2013; Thermal Insulating Products for Building Applications—Determination of Compression. Available online: https://standards.iteh.ai/catalog/standards/cen/f54055a6-cacc-4d69-b85a-b190aea8ed7f/en-826-2013 (accessed on 27 May 2021).

- BS EN 12667:2001; Thermal Performance of Building Materials and Products. Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods. Products of High and Medium Thermal Resistance. European Standards. 2011. Available online: https://www.en-standard.eu/bs-en-12667-2001-thermal-performance-of-building-materials-and-products-determination-of-thermal-resistance-by-means-of-guarded-hot-plate-and-heat-flow-meter-methods-products-of-high-and-medium-thermal-resistance/?gclid=Cj0KCQjwhr2FBhDbARIsACjwLo1pb8NrtU8p6ioZmL1LkJ1QyFoZK8Y-qush6anNv1B59IbEQqtNMCoaAt6REALw_wcB (accessed on 27 May 2021).

- Pigłowska, M.; Kurc, B.; Rymaniak, Ł.; Lijewski, P.; Fuć, P.F. Kinetics and Thermodynamics of Thermal Degradation of Different Starches and Estimation the OH Group and H2O Content on the Surface by TG/DTG-DTA. Polymers 2020, 12, 357. [Google Scholar] [CrossRef]

- Castelló, M.L.; Dweck, J.; Aranda, D.A.G. Thermal Stability and Water Content Determination of Glycerol by Thermogravimetry. J. Therm. Anal. Calorim. 2009, 97, 627–630. [Google Scholar] [CrossRef]

- Subasri, R.; Näfe, H. Phase Evolution on Heat Treatment of Sodium Silicate Water Glass. J. Non. Cryst. Solids 2008, 354, 896–900. [Google Scholar] [CrossRef]

- Ryu, Y.B.; Lee, M.S. Infrared Spectra and Thermal Properties of Sodium Silicate Solutions. J. Korean Inst. Met. Mater. 2018, 56, 72–78. [Google Scholar]

- Ellerbrock, R.; Stein, M.; Schaller, J. Comparing Amorphous Silica, Short-Range-Ordered Silicates and Silicic Acid Species by FTIR. Sci. Rep. 2022, 12, 11708. [Google Scholar] [CrossRef]

- Saifuddin, N.; Refal, H.; Kumaran, P. Rapid Purification of Glycerol By-Product from Biodiesel Production through Combined Process of Microwave Assisted Acidification and Adsorption via Chitosan Immobilized with Yeast. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 593–602. [Google Scholar] [CrossRef]

- Dankar, I.; Haddarah, A.; Omar, F.E.L.; Pujolà, M.; Sepulcre, F. Characterization of Food Additive-Potato Starch Complexes by FTIR and X-Ray Diffraction. Food Chem. 2018, 260, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, A.H.D.; Chalimah, S.; Primadona, I.; Hanantyo, M.H.G. Physical and Chemical Properties of Corn, Cassava, and Potato Starchs. IOP Conf. Ser. Earth Environ. Sci. 2018, 160, 012003. [Google Scholar] [CrossRef]

- (2) (PDF) Microwave and Ultrasound Activation Effect on Cationization of Corn and Potato Starches Microwave and Ultrasound Activation Effect on Cationization of Corn and Potato Starches. Available online: https://www.researchgate.net/publication/237090936_Microwave_and_Ultrasound_Activation_Effect_on_Cationization_of_Corn_and_Potato_Starches_MICROWAVE_AND_ULTRASOUND_ACTIVATION_EFFECT_ON_CATIONIZATION_OF_CORN_AND_POTATO_STARCHES (accessed on 8 April 2024).

- Sá-Lima, H.; Caridade, S.G.; Mano, J.F.; Reis, R.L. Stimuli-Responsive Chitosan-Starch Injectable Hydrogels Combined with Encapsulated Adipose-Derived Stromal Cells for Articular Cartilage Regeneration. Soft Matter 2010, 6, 5184–5195. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Y.; Zhang, X.; Zuo, Y. Study on the Effect of Organic Additives and Inorganic Fillers on Properties of Sodium Silicate Wood Adhesive Modified by Polyvinyl Alcohol. Bioresources 2015, 10, 1528–1542. [Google Scholar] [CrossRef]

- Staroszczyk, H.; Janas, P. Microwave-Assisted Synthesis of Zinc Derivatives of Potato Starch. Carbohydr. Polym. 2010, 80, 962–969. [Google Scholar] [CrossRef]

- Kremensas, A.; Kairyte, A.; Vaitkus, S.; Vejelis, S.; Balčiunas, G. Mechanical Performance of Biodegradable Thermoplastic Polymer-Based Biocomposite Boards from Hemp Shivs and Corn Starch for the Building Industry. Materials 2019, 12, 845. [Google Scholar] [CrossRef] [PubMed]

- Baishya, P.; Maji, T.K. A Comparative Study on the Properties of Graphene Oxide and Activated Carbon Based Sustainable Wood Starch Composites. Int. J. Biol. Macromol. 2018, 115, 970–977. [Google Scholar] [CrossRef] [PubMed]

| Composition | Raw Materials for Binder, Mass Parts | |||

|---|---|---|---|---|

| Potato Starch | Sodium Metasilicate Solution | Glycerol | Water | |

| B-0 | 150 | 0 | 0.0 | 760 |

| B-40 | 150 | 40 | 0.0 | 760 |

| B-120 | 150 | 120 | 0.0 | 760 |

| B-160 | 150 | 160 | 0.0 | 760 |

| B-120-25 | 150 | 120 | 25 | 760 |

| Composition | Raw Materials for Binder, Mass Parts | Hemp Shives | |||

|---|---|---|---|---|---|

| Potato Starch | Sodium Metasilicate Solution | Glycerol | Water | ||

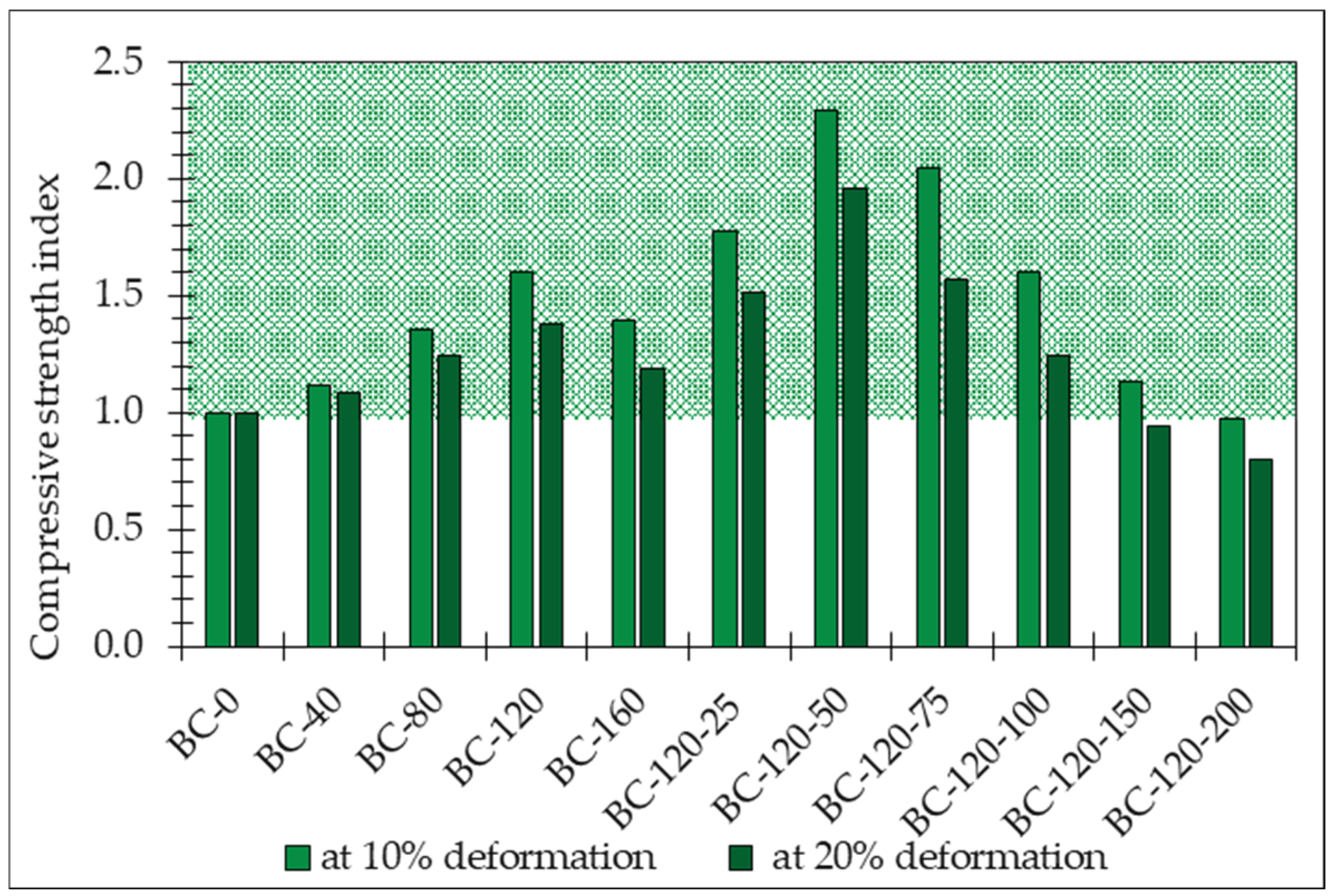

| BC-0 | 150 | 0 | 0 | 760 | 500 |

| BC-40 | 150 | 40 | 0 | 760 | 500 |

| BC-80 | 150 | 80 | 0 | 760 | 500 |

| BC-120 | 150 | 120 | 0 | 760 | 500 |

| BC-160 | 150 | 160 | 0 | 760 | 500 |

| BC-120-25 | 150 | 120 | 25 | 760 | 500 |

| BC-120-50 | 150 | 120 | 50 | 760 | 500 |

| BC-120-75 | 150 | 120 | 75 | 760 | 500 |

| BC-120-100 | 150 | 120 | 100 | 760 | 500 |

| BC-120-150 | 150 | 120 | 150 | 760 | 500 |

| BC-120-200 | 150 | 120 | 200 | 760 | 500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vitola, L.; Pundiene, I.; Pranckeviciene, J.; Bajare, D. Innovative Hemp Shive-Based Bio-Composites: Part I: Modification of Potato Starch Binder by Sodium Meta-Silicate and Glycerol. Materials 2024, 17, 4911. https://doi.org/10.3390/ma17194911

Vitola L, Pundiene I, Pranckeviciene J, Bajare D. Innovative Hemp Shive-Based Bio-Composites: Part I: Modification of Potato Starch Binder by Sodium Meta-Silicate and Glycerol. Materials. 2024; 17(19):4911. https://doi.org/10.3390/ma17194911

Chicago/Turabian StyleVitola, Laura, Ina Pundiene, Jolanta Pranckeviciene, and Diana Bajare. 2024. "Innovative Hemp Shive-Based Bio-Composites: Part I: Modification of Potato Starch Binder by Sodium Meta-Silicate and Glycerol" Materials 17, no. 19: 4911. https://doi.org/10.3390/ma17194911

APA StyleVitola, L., Pundiene, I., Pranckeviciene, J., & Bajare, D. (2024). Innovative Hemp Shive-Based Bio-Composites: Part I: Modification of Potato Starch Binder by Sodium Meta-Silicate and Glycerol. Materials, 17(19), 4911. https://doi.org/10.3390/ma17194911