Study on Microstructure and Texture of Fe-3%Si Ultra-Thin Ribbons Prepared by Planar Flow Casting

Abstract

1. Introduction

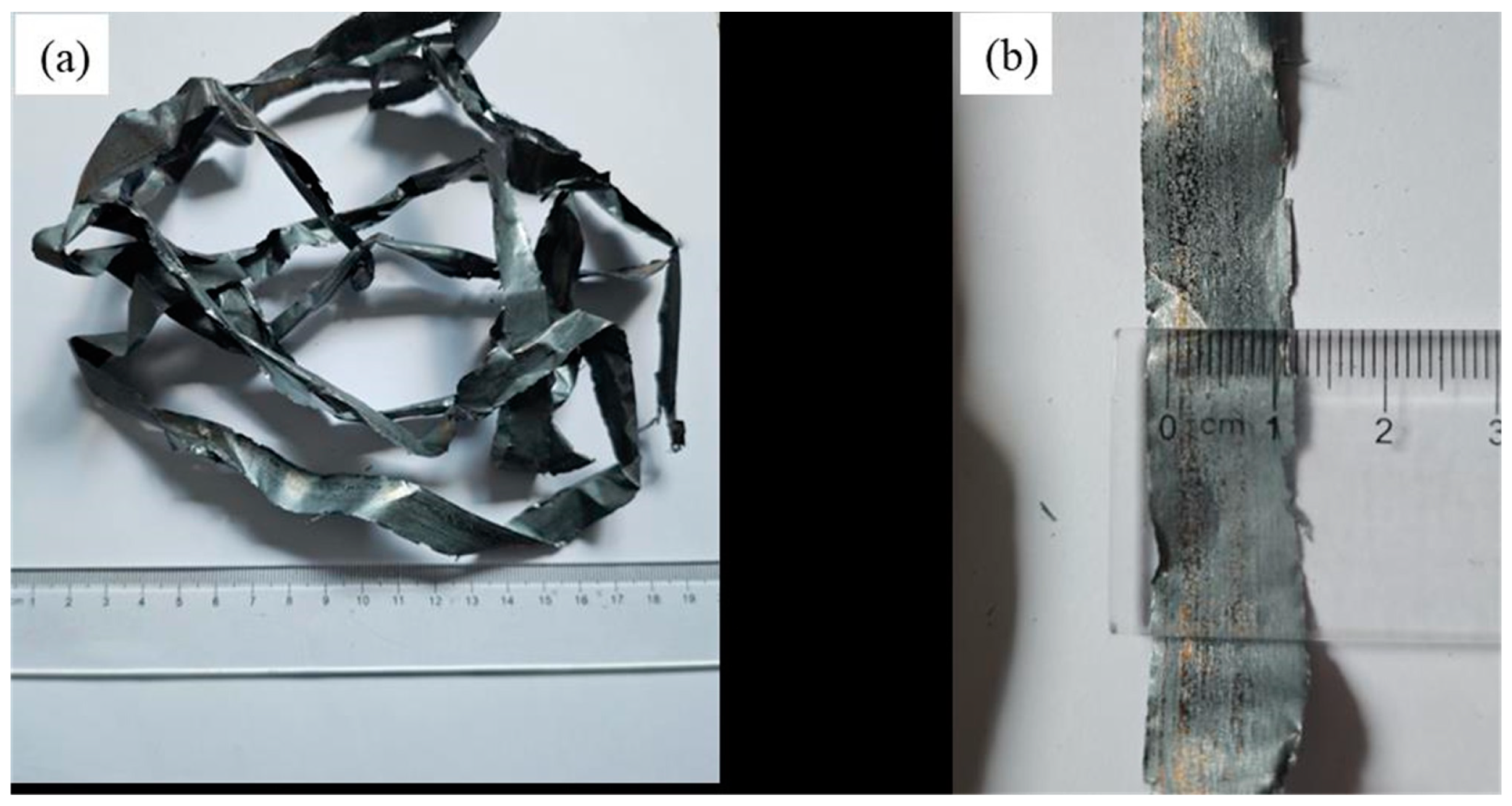

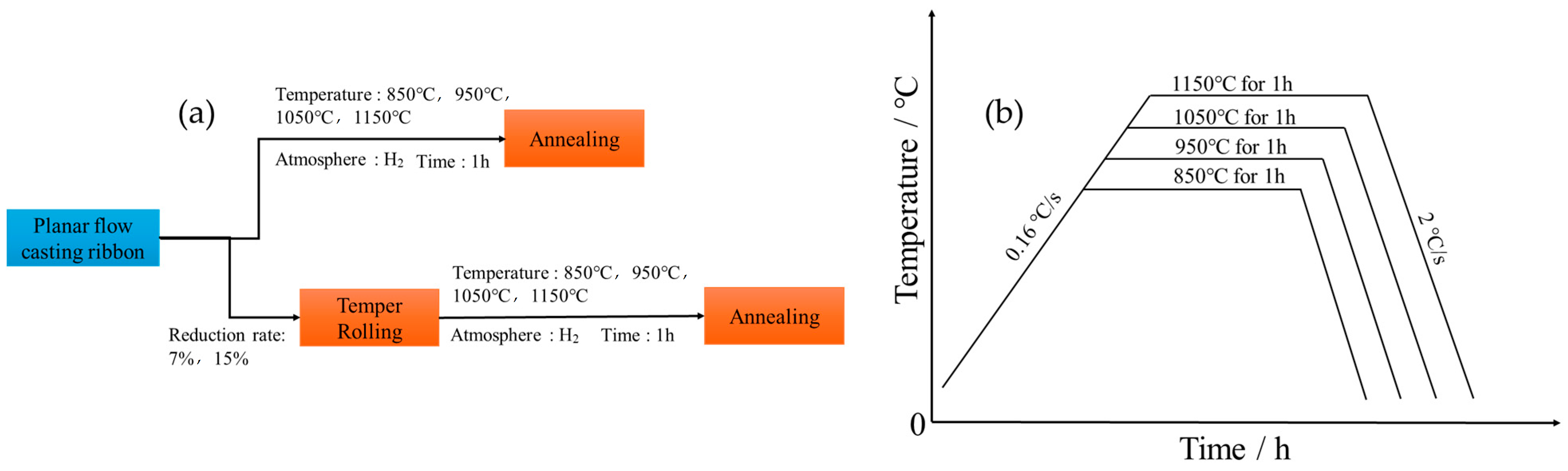

2. Materials and Methods

2.1. Experimental Materials and Characterization Methods

2.2. Finite Element Simulation of Crystal Plasticity

3. Results

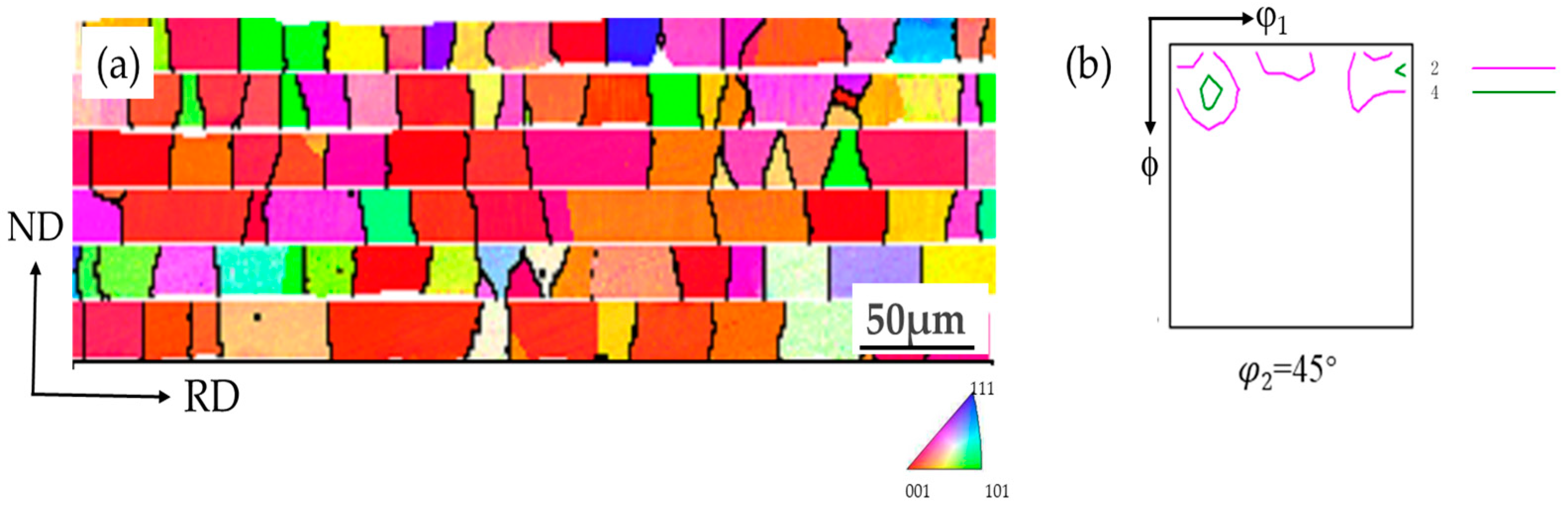

3.1. Microstructure and Texture of Planar-Flow-Casted Ribbons

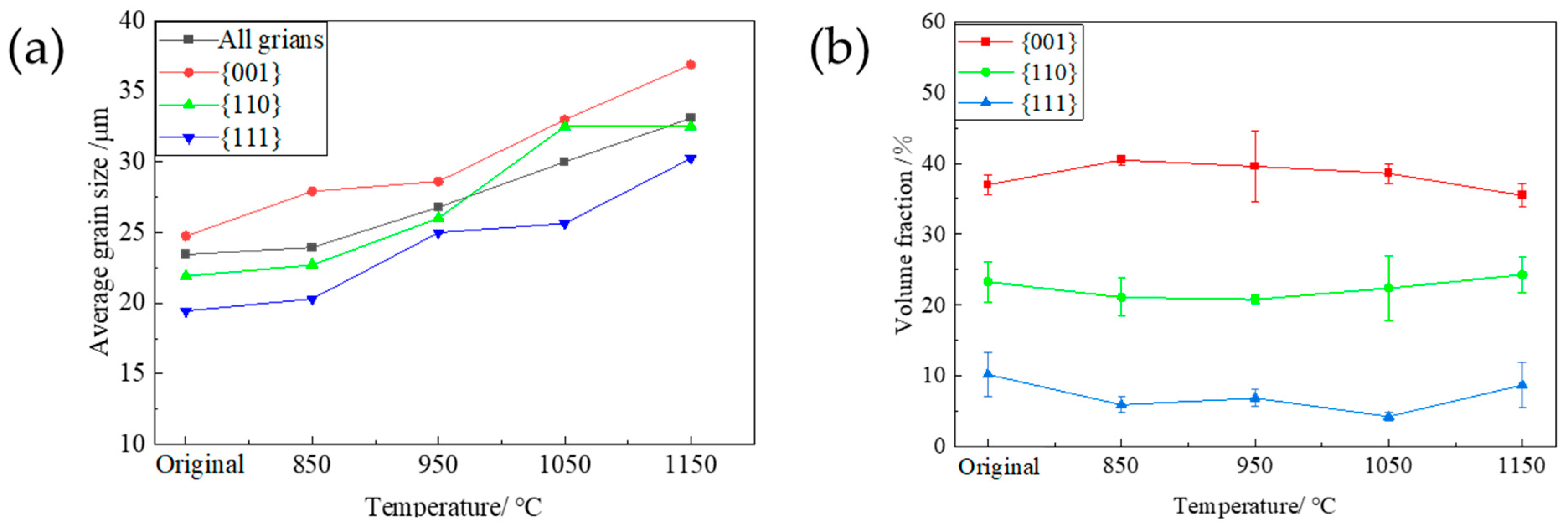

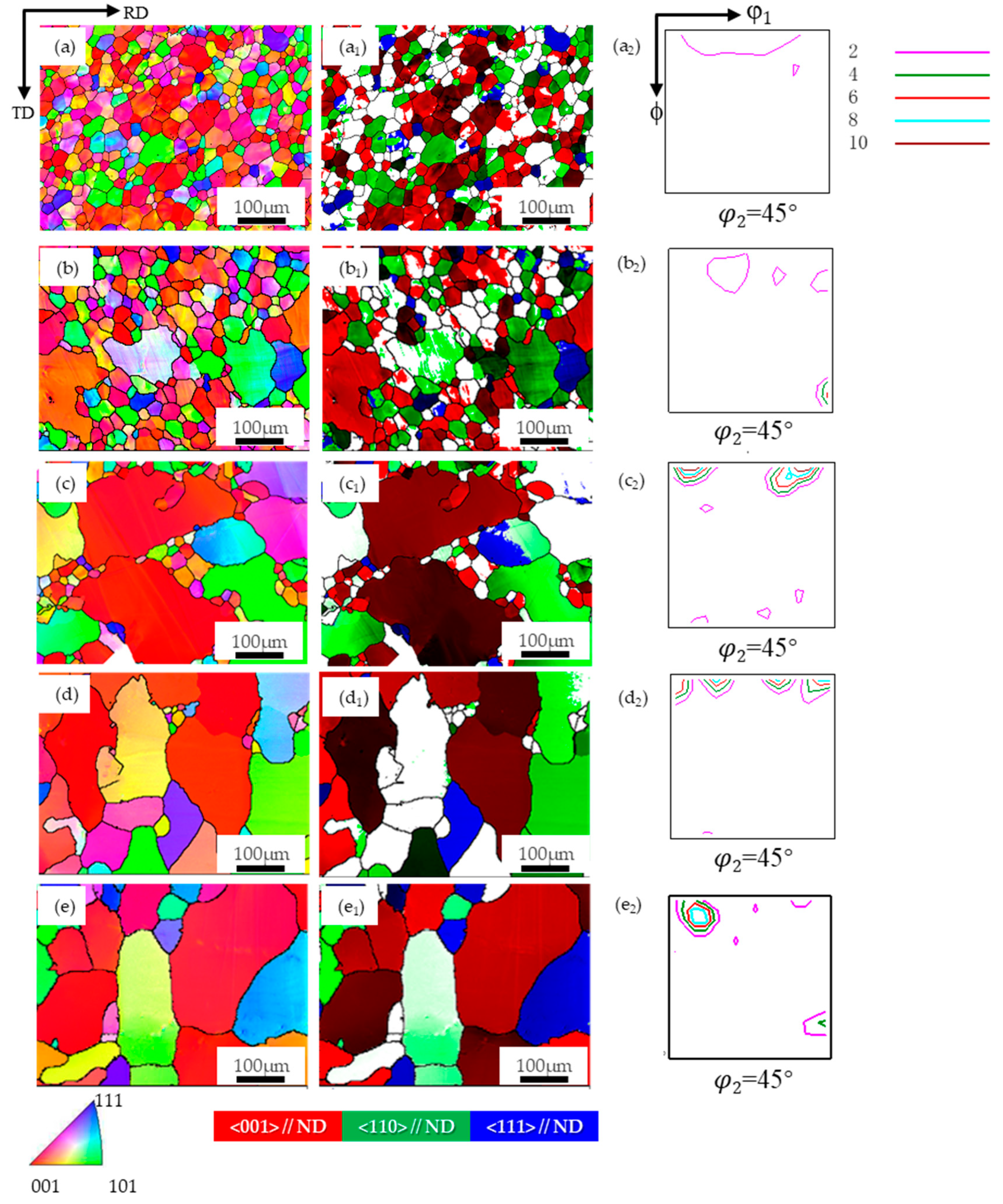

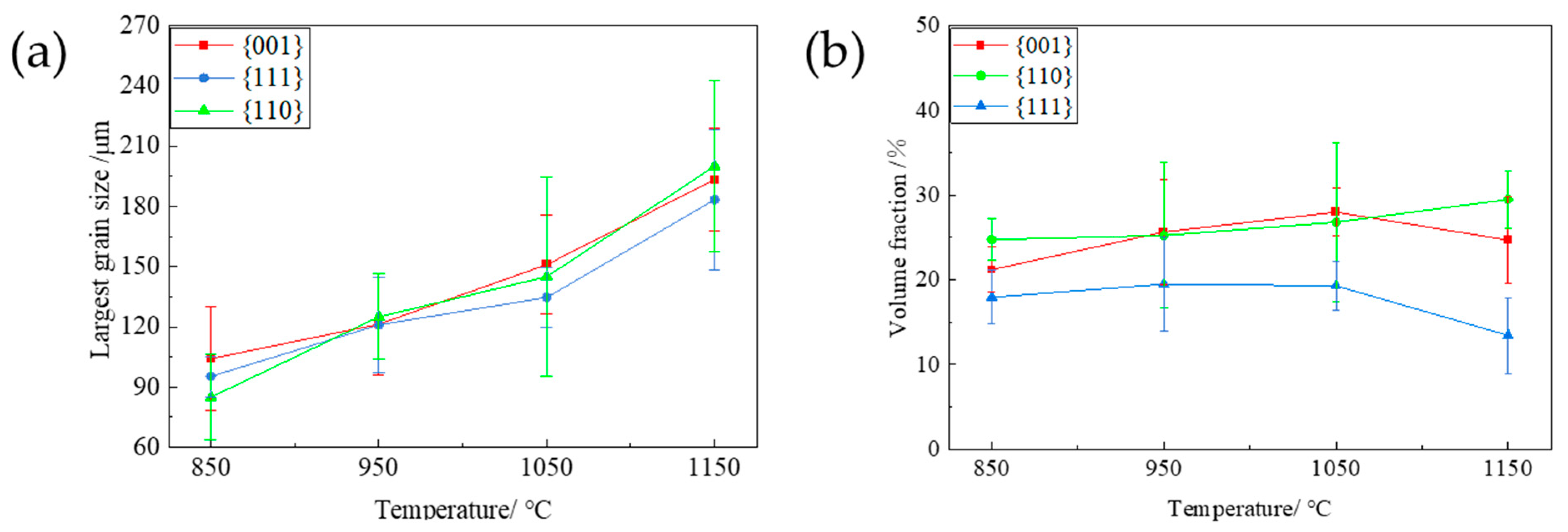

3.2. Microstructure and Texture Changes during the Direct Annealing of Planar-Flow-Casted Ribbons

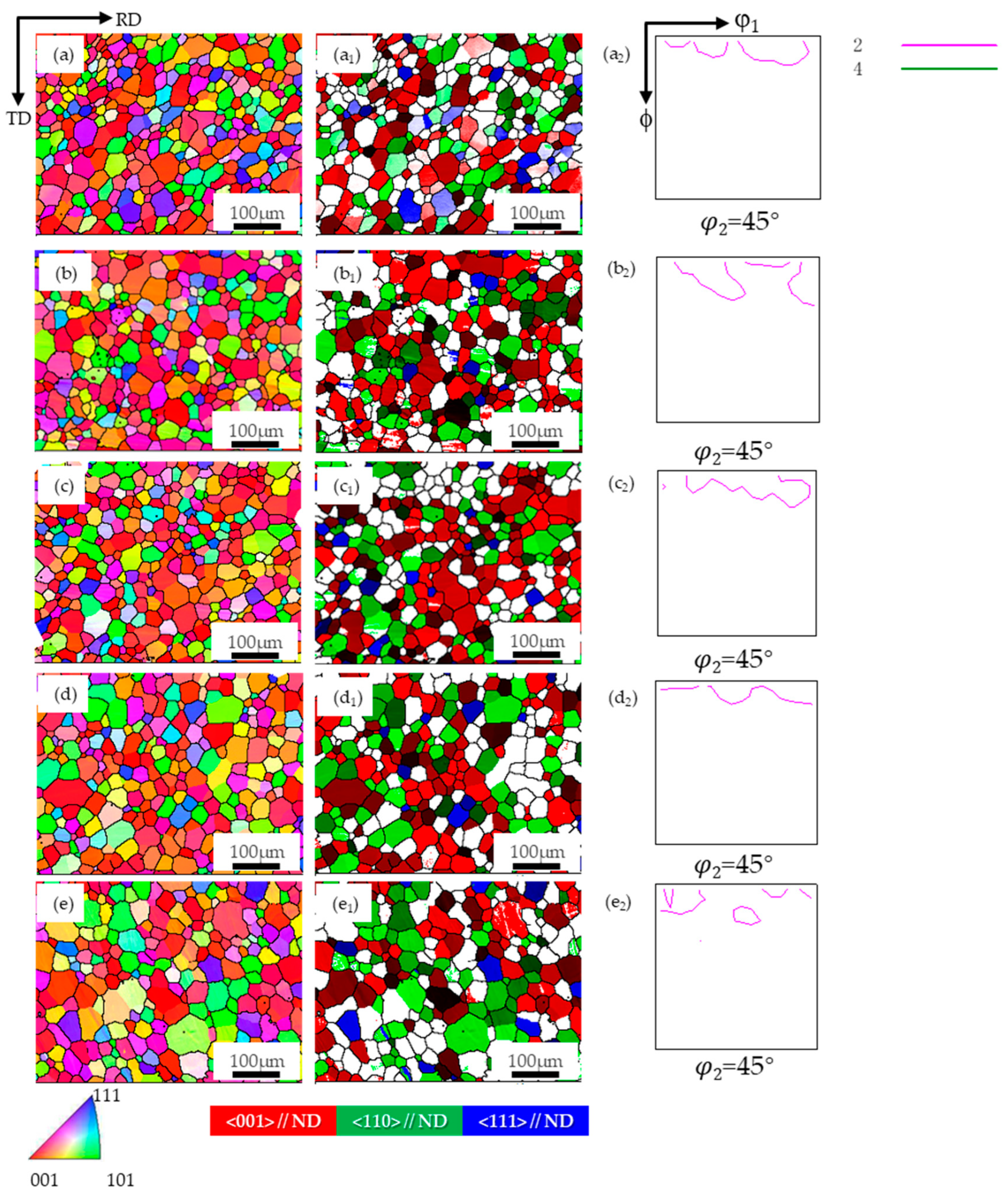

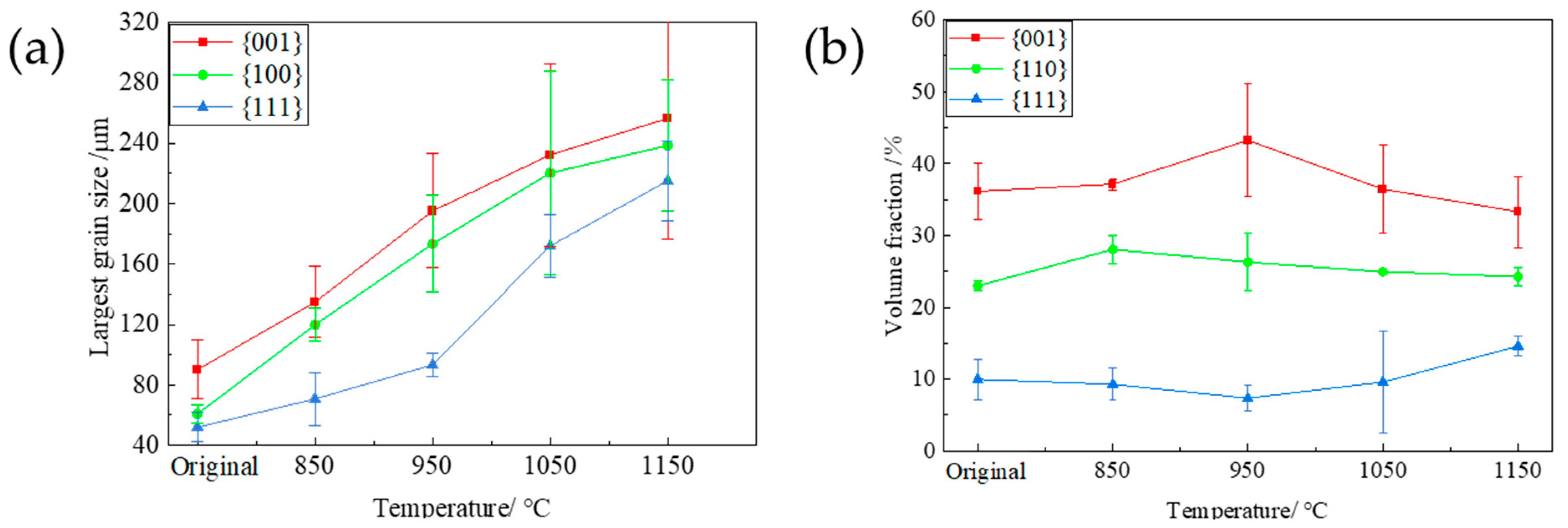

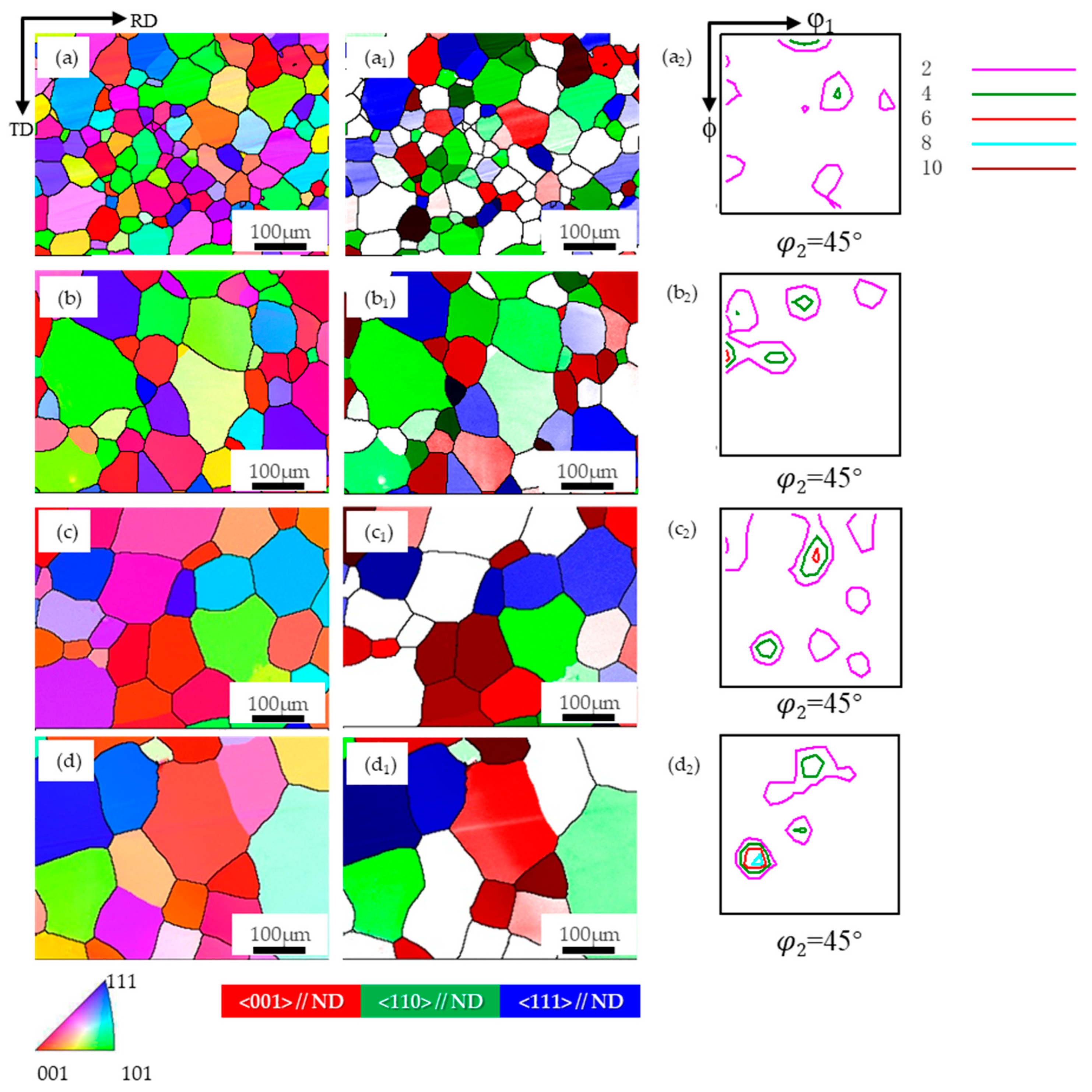

3.3. Effect of Temper Rolling and Annealing on the Microstructure and Texture of Planar-Flow-Casted Ribbons

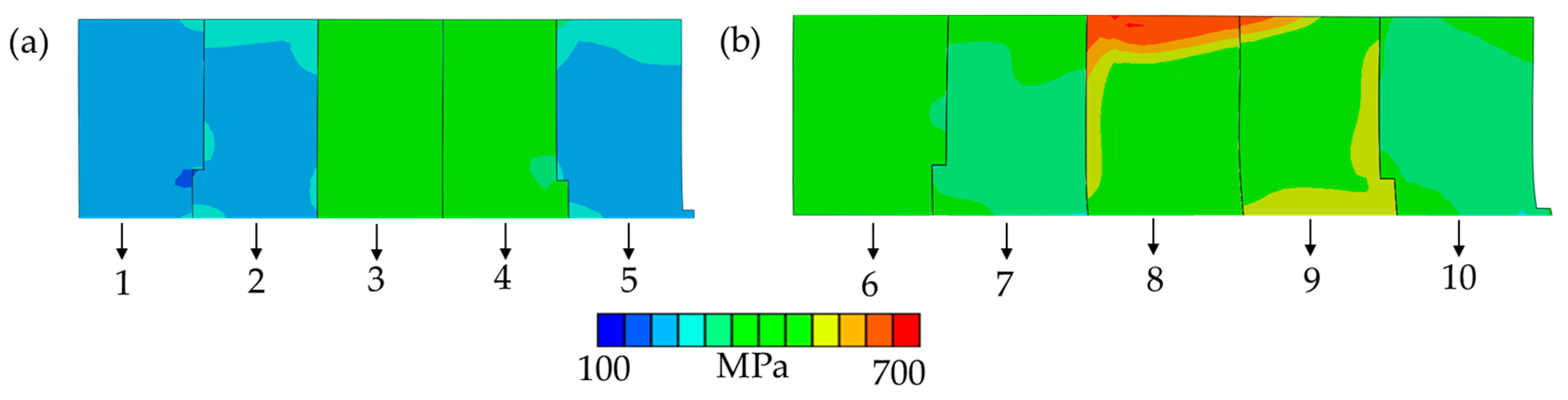

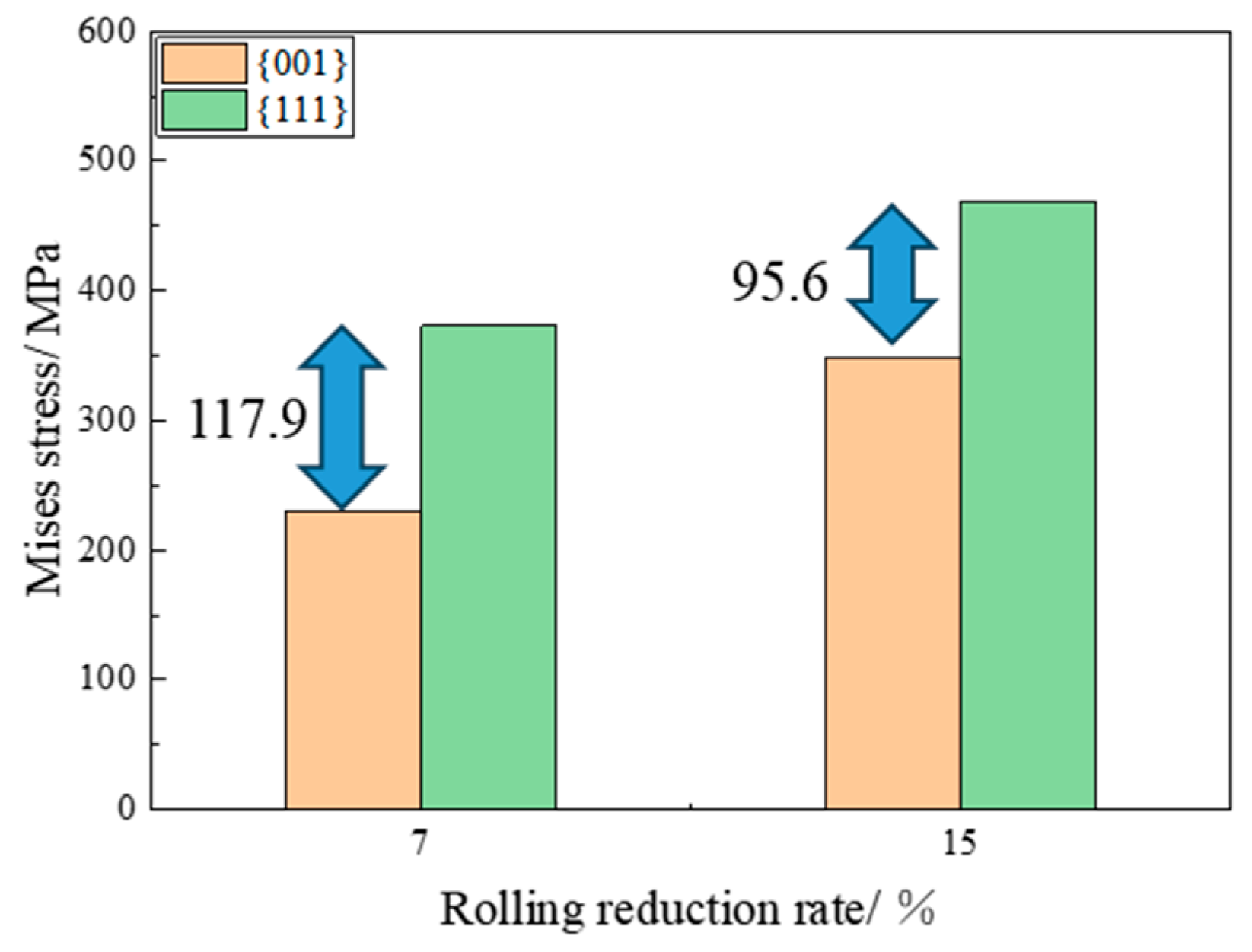

3.4. Differential Analysis of Grain Deformation Stored Energy with Different Characteristic Orientations

4. Conclusions

- (1)

- The Fe-3% Si ultra-thin non-oriented silicon steel ribbons prepared by planar flow casting (PFC) exhibit a significant columnar crystal structure, with {001}-oriented grains constituting over 30%. After annealing, the average grain size exhibits a slight increment with the rising annealing temperature. The grains of different orientations grow evenly, the proportion of grains of each orientation is basically unchanged, and the {001} favorable texture is well preserved.

- (2)

- Uneven grain growth was observed when the planar-flow-casted (PFC) ribbons underwent annealing following temper rolling with 7% reduction. The growth capability of {001}-oriented grains surpassed that of {111}-oriented grains. The disparity in this growth capability initially increased and then decreased with rising annealing temperatures, and this difference peaked at 950 °C, leading to the highest proportion of {001} grains and the lowest proportion of {111}-oriented grains at this temperature. Following temper rolling with a 15% reduction rate and subsequent annealing, grains of each orientation exhibited significant growth at all temperatures. That is, the {001}-oriented grains did not have a pronounced growth advantage better than others, and the {001} texture is weakened while the {111} texture is strengthened. Overall, for the synergistic optimization of microstructure and texture, rolling at a 7% reduction rate followed by annealing at 950 °C in a hydrogen atmosphere is most advantageous.

- (3)

- Based on crystal plasticity finite element (CPFE) simulations, it was found that the deformation stored energy of {001}- and Goss-oriented grains is lower than that of {111}-oriented grains at various reduction rates. At 7% reduction, the deformation stored energy accumulation of {001} grains is much less than that of {111} grains after rolling, and this marked stored energy difference contributes to the strong growth advantage of {001} grains during annealing based on SIBM mechanism.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mao, W.M.; Yang, P. Material Principle of Electrical Steel; Higher Education Press: Beijing, China, 2013; pp. 89–90. [Google Scholar]

- Zhang, N.; Yang, P.; Mao, W.M. Effect of columnar grains on recrystallization texture evolution of Fe-3% Si electrical steel. Acta Metall. Sin. 2012, 48, 307–314. [Google Scholar] [CrossRef]

- Guthrie, R.I.L.; Isac, M.M. Continuous Casting Practices for Steel: Past, Present and Future. Metals 2022, 12, 862. [Google Scholar] [CrossRef]

- Mann, J.B.; Mohanty, D.P.; Kustas, A.B.; Stiven Puentes Rodriguez, B.; Naziru Issahaq, M.; Udupa, A.; Sugihara, T.; Trumble, K.P.; M’Saoubi, R.; Chandrasekar, S. Large-scale metal strip for power storage and energy conversion applications by machining-based deformation processing. CIRP Ann. 2023, 72, 45–48. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Lei, C.; Mao, X.; Liu, D.; Fan, X.; Luo, Z.; Luo, F. Core loss reduction for Fe-6.5wt%Si soft magnetic composites doped with Co element. J. Magn. Magn. Mater. 2020, 502, 166553. [Google Scholar] [CrossRef]

- Gutiérrez Castañeda, E.J.; Hernández Miranda, M.G.; Salinas Rodríguez, A.; Aguilar Carrillo, J.; Reyes Domínguez, I. An EBSD investigation on the columnar grain growth in non-oriented electrical steels assisted by strain induced boundary migration. Mater. Lett. 2019, 252, 42–46. [Google Scholar] [CrossRef]

- Kestens, L.; Jonas, J.J. Modeling texture change during the static recrystallization of interstitial free steels. Metall. Mater. Trans. A 1996, 27, 155–164. [Google Scholar] [CrossRef]

- Bennett, T.A.; Kalu, P.N.; Rollett, A.D. Strain-Induced Selective Growth in 1.5% Temper-Rolled Fe∼1%Si. Microsc. Microanal. 2011, 17, 362–367. [Google Scholar] [CrossRef]

- Ou, K.H.; Koo, Y.M.; Lee, D.N. Evolution of Textures and Microstructures in Low-Reduction Rolled and Annealed Low-Carbon Steels. Mater. Sci. Forum 2012, 715–716, 173–178. [Google Scholar]

- Kestens, L.; Jonas, J.J.; Van Houtte, P.; Aernoudt, E. Orientation selective recrystallization of nonoriented electrical steels. Metall. Mater. Trans. A 1996, 27, 2347–2358. [Google Scholar] [CrossRef]

- Murakami, K.; Tarasiuk, J.; Réglé, H.; Bacroix, B. Study of the Texture Formation during Strain Induced Boundary Migration in Electrical Steel Sheets. Mater. Sci. Forum 2009, 467–470, 893–898. [Google Scholar] [CrossRef]

- Ouyang, G.; Macziewski, C.R.; Jensen, B.; Ma, T.; Choudhary, R.; Dennis, K.; Zhou, L.; Paudyal, D.; Anderson, I.; Kramer, M.J.; et al. Effects of Solidification Cooling Rates on Microstructures and Physical Properties of Fe-6.5%Si Alloys. Acta Mater. 2021, 205, 116575. [Google Scholar] [CrossRef]

- Chen, S.-D.; Liu, X.-H.; Liu, L.-Z.; Song, M. Crystal plasticity finite element simulation of slip and deformation in ultra-thin copper strip rolling. Acta Metall. Sin. 2016, 52, 120–128. [Google Scholar] [CrossRef]

- Chen, S.-D.; Lu, R.-H.; Sun, J.; Li, J.; Zhang, K. Effect of cold rolling reduction on crystal slipping around grain boundary of rolled single layer grain ultra-thin strip. Mater. Sci. Technol. 2018, 26, 88–96. [Google Scholar] [CrossRef]

- Chen, S.-D.; Liu, X.-H.; Liu, L.-Z.; Sun, X.-K. Crystal plasticity finite element simulation of slip system evolution in pure copper foil rolling. Learn. J. Dongbei Univ. 2016, 37, 647–652. [Google Scholar]

- Chen, S.-D.; Lu, R.-H.; Sun, J.; Li, J.; Zhang, K. Simulation of effect of grain size effect on rolling deformation mechanism of copper ultra-thin strip. Trans. Nonferrous Met. Soc. China 2018, 28, 2233–2241. [Google Scholar]

- Chen, S.-D.; Lu, R.-H.; Chen, Z.-P.; Sun, J.; Li, J. Crystal plasticity modelling of slip activation and strain localization in a copper single layer crystal under foil rolling. Mater. Guide 2021, 35, 04170–04176. [Google Scholar]

- Chu, S.J.; Sheng, K.Y.; Sha, Y.H.; Chen, X. Orientation dependence of strain stored energy and its effect on recrystallization texture in non-oriented silicon steel. Mater. Eng. 2019, 47, 147–153. [Google Scholar]

- Liu, R.X.; Qi, P.; Sun, F.; Zhang, J.; Wu, G.; Wang, S.; Zhu, Z.; Wang, M.; Mao, X. High Magnetic Performance Ultra-Thin Fe-6.5Si Ribbons Fabricated by Planner Flow Casting and Annealing. J. Magn. Magn. Mater. 2024, 589, 171538. [Google Scholar] [CrossRef]

- Cheng, Y.Y.; Bao, S.; Liu, C.; Hu, J.; Xu, D.; Chang, J.; Guo, R.; Fan, X. Effect of Wheel Speed on the Microstructure and Magnetic Properties of Fe-3.0Wt%Si Non-Oriented Silicon Steel Ultra-Thin Ribbons Prepared by Planar Flow Casting. J. Mater. Res. Technol. 2024, 30, 210–2146. [Google Scholar] [CrossRef]

- Zhang, N.; Xu, J.-J.; Tu, Y.; Zhou, X.-Z.; Zhang, B.; Meng, L. Microstructure and texture evolution during temper rolling and annealing of Fe-3% Si steel sheets prepared by planar flow casting. Electrical Steel 2024, 6, 1–5. [Google Scholar]

- Tu, Y.; Meng, L.; Zhang, N.; Xu, J.-J. Evolutions of Cube ({001}<100>) and {115}<161> Orientations in Cold-Rolled Ultra-Thin Non-Oriented Silicon Steel. Materials 2023, 16, 6735. [Google Scholar] [CrossRef] [PubMed]

- Gautam, J.; Petrov, R.H.; Leunis, E.; Kestens, L.A. Strain Induced Inward Grain Growth during Recrystallisation in Steel Sheets with BCC Crystal Structure. Mater. Sci. Forum 2012, 715–716, 303–308. [Google Scholar]

- Xu, H.-J.; Xu, Y.-B.; He, Y.L.; Yue, S.; Li, J.-P. Tracing the Recrystallization of Warm Temper-Rolled Fe-6.5 Wt% Si Non-Oriented Electrical Steel Using Aquasiin Situ Ebsd Technique. J. Mater. Sci. 2020, 55, 17183–17203. [Google Scholar] [CrossRef]

- Gao, S.; Liao, H.; Yan, X.; Xie, Q.; Chang, C.; Lu, B.; Zhang, X.; Fenineche, N.; Liu, M. Magnetic and mechanical properties of additive manufactured Fe-3wt.%Si materia. J. Magn. Magn. Mater. 2023, 580, 170907. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, S.; Qi, J.; Je, F.; Lin, J. Microstructure and properties of cost-effective Fe–6.5 wt % Si ribbons fabricated by melt-spinning. Scr. Mater. 2019, 163, 107–110. [Google Scholar] [CrossRef]

- Murakami, K.; Kubota, T.; Grégori, F.; Bacroix, B. The Effect of Dislocations in Grains on Texture Formation in Strain Induced Boundary Migration. Mater. Sci. Forum 2007, 558–559, 271–276. [Google Scholar]

- Bouaziz, O.; Allain, S.; Scott, C. Effect of grain and twin boundaries on the hardening mechanisms of twinning-induced plasticity steels. Scr. Mater. 2008, 58, 484–487. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Zhang, N.; Tu, Y.; Meng, L.; Zhou, X.; Niu, C. Study on Microstructure and Texture of Fe-3%Si Ultra-Thin Ribbons Prepared by Planar Flow Casting. Materials 2024, 17, 4893. https://doi.org/10.3390/ma17194893

Xu J, Zhang N, Tu Y, Meng L, Zhou X, Niu C. Study on Microstructure and Texture of Fe-3%Si Ultra-Thin Ribbons Prepared by Planar Flow Casting. Materials. 2024; 17(19):4893. https://doi.org/10.3390/ma17194893

Chicago/Turabian StyleXu, Jiangjie, Ning Zhang, Yang Tu, Li Meng, Xiaozhou Zhou, and Chengzhou Niu. 2024. "Study on Microstructure and Texture of Fe-3%Si Ultra-Thin Ribbons Prepared by Planar Flow Casting" Materials 17, no. 19: 4893. https://doi.org/10.3390/ma17194893

APA StyleXu, J., Zhang, N., Tu, Y., Meng, L., Zhou, X., & Niu, C. (2024). Study on Microstructure and Texture of Fe-3%Si Ultra-Thin Ribbons Prepared by Planar Flow Casting. Materials, 17(19), 4893. https://doi.org/10.3390/ma17194893