Giant Elastocaloric Effect and Improved Cyclic Stability in a Directionally Solidified (Ni50Mn31Ti19)99B1 Alloy

Abstract

1. Introduction

2. Materials and Methods

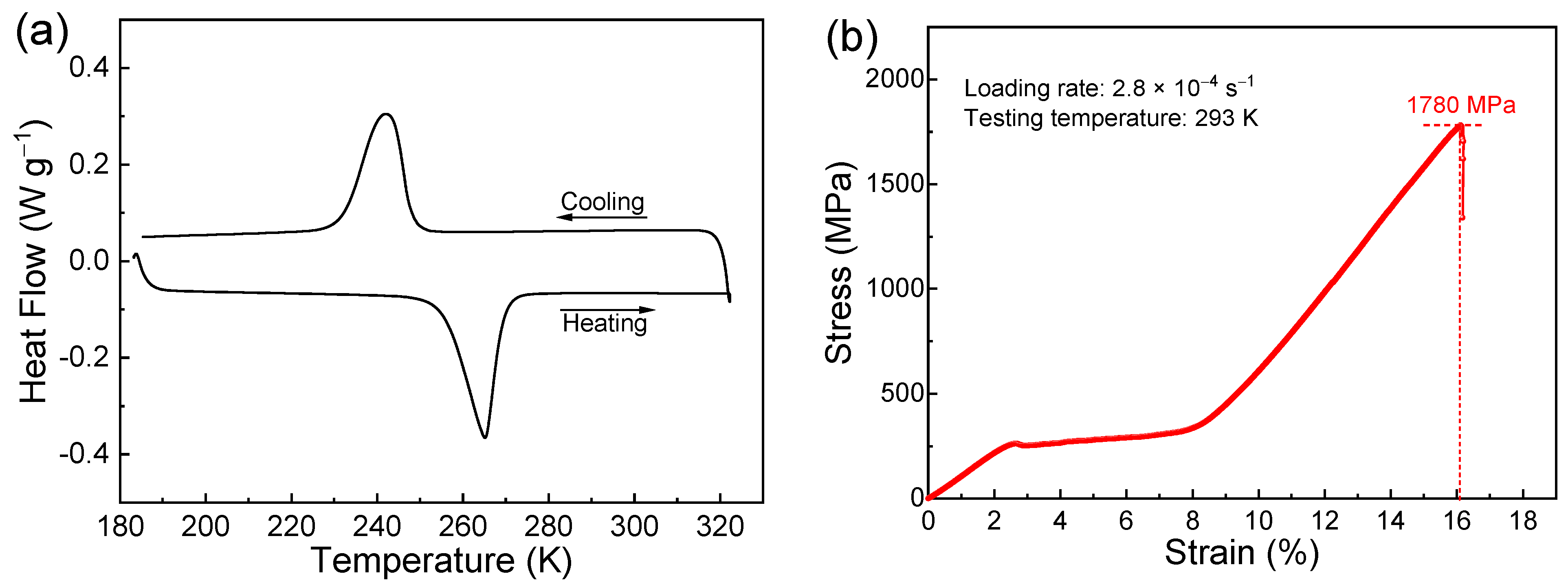

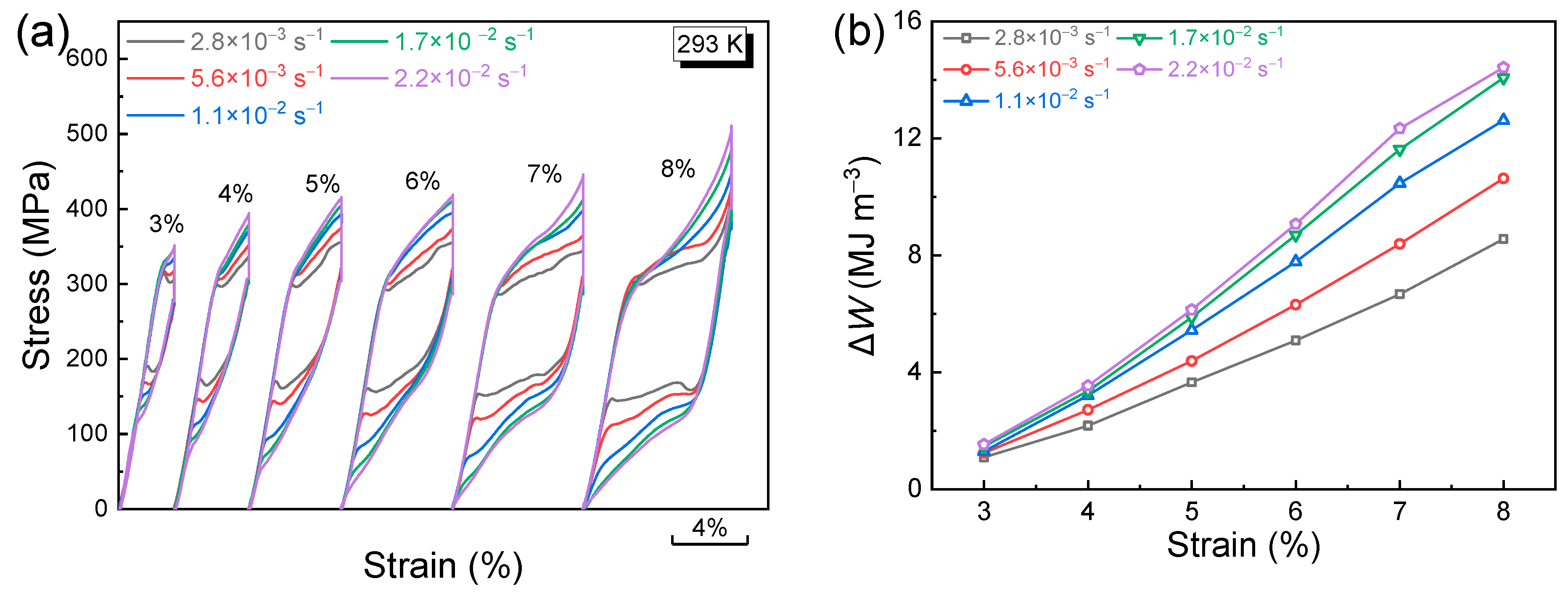

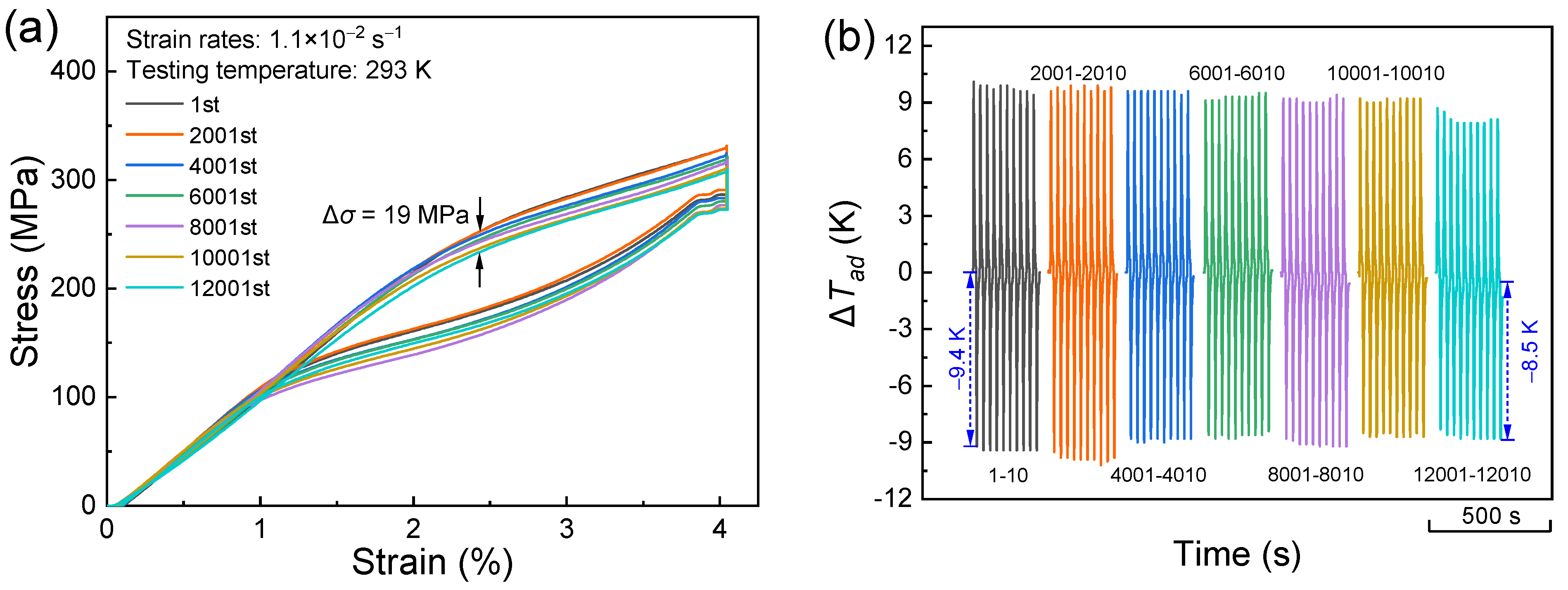

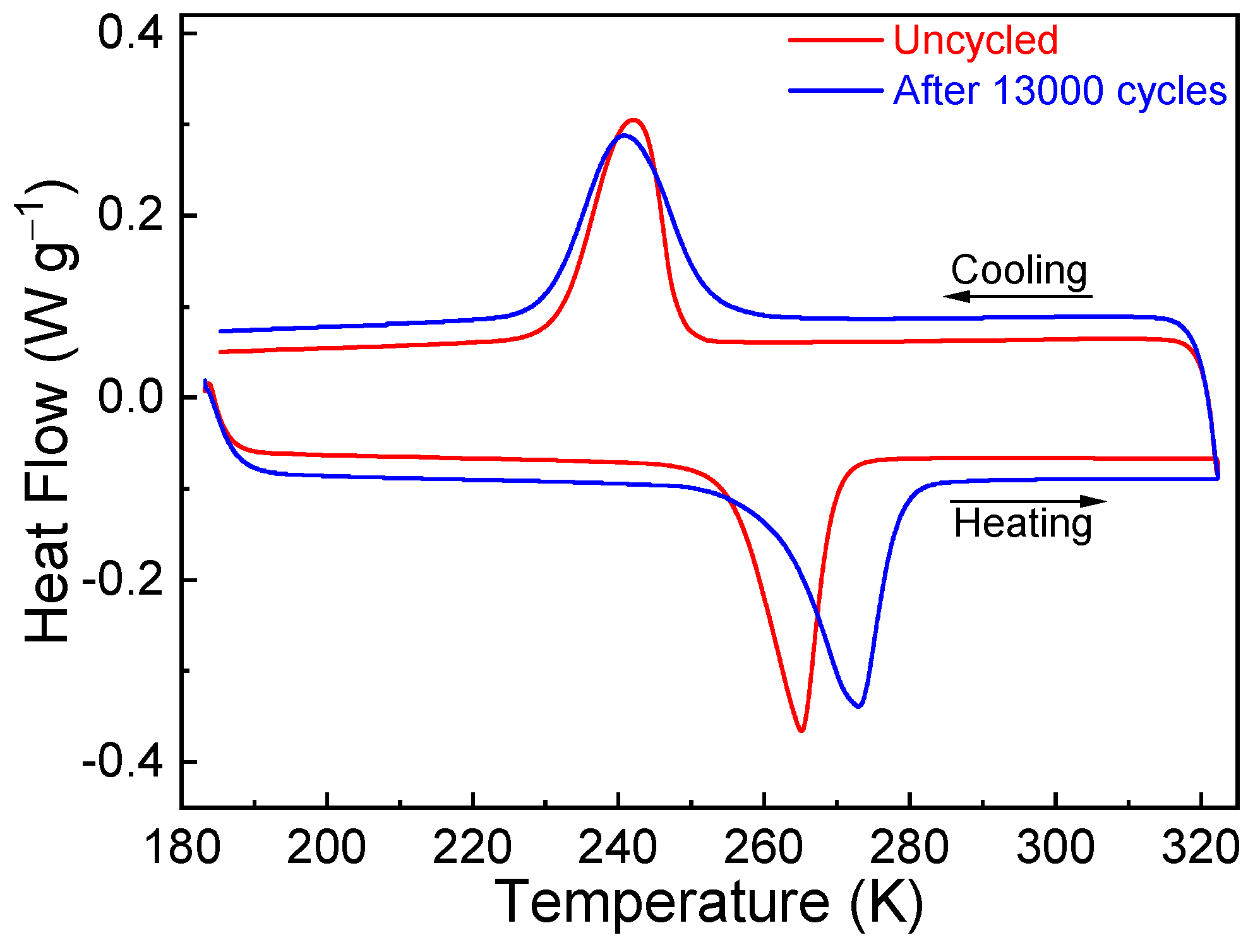

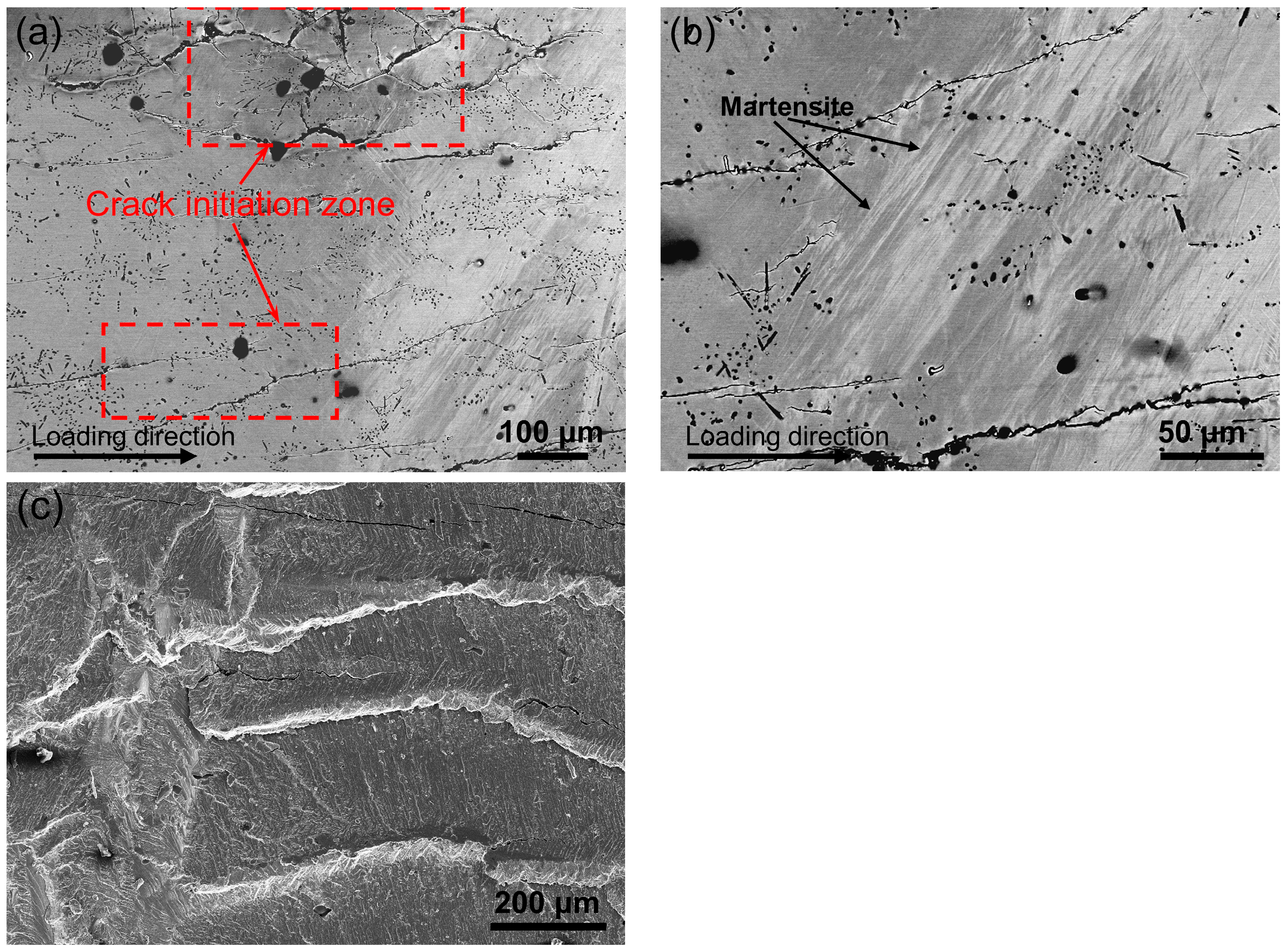

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lloveras, P.; Stern-Taulats, E.; Barrio, M.; Tamarit, J.L.; Crossley, S.; Li, W.; Pomjakushin, V.; Planes, A.; Mañosa, L.; Mathur, N.D.; et al. Giant barocaloric effects at low pressure in ferrielectric ammonium sulphate. Nat. Commun. 2015, 6, 8801. [Google Scholar] [CrossRef] [PubMed]

- Mañosa, L.; Planes, A.; Acet, M. Advanced materials for solid-state refrigeration. J. Mater. Chem. A 2013, 1, 4925–4936. [Google Scholar] [CrossRef]

- Tušek, J.; Engelbrecht, K.; Millán-Solsona, R.; Mañosa, L.; Vives, E.; Mikkelsen, L.P.; Pryds, N. The elastocaloric effect: A way to cool efficiently. Adv. Energy Mater. 2015, 5, 1500361. [Google Scholar] [CrossRef]

- Mañosa, L.; Planes, A. Materials with giant mechanocaloric effects: Cooling by strength. Adv. Mater. 2017, 29, 1603607. [Google Scholar] [CrossRef]

- Yang, J.; Wang, H.; Li, Z.; Zou, N.; Yan, H.; Yang, B.; Zuo, L. Crystallography of stress-induced martensitic transformation and giant elastocaloric effect in a <001>A textured Ni27Cu21Mn46Sn6 shape memory alloy. Acta Mater. 2024, 263, 119546. [Google Scholar]

- Heczko, O.; Cejpek, P.; Drahokoupil, J.; Holý, V. Structure and microstructure of Ni-Mn-Ga single crystal exhibiting magnetic shape memory effect analysed by high resolution X-ray diffraction. Acta Mater. 2016, 115, 250–258. [Google Scholar] [CrossRef]

- Heczko, O.; Kopeček, J.; Straka, L.; Seiner, H. Differently mobile twin boundaries and magnetic shape memory effect in 10M martensite of Ni–Mn–Ga. Mater. Res. Bull. 2013, 48, 5105–5109. [Google Scholar] [CrossRef]

- Liu, J.; Gottschall, T.; Skokov, K.P.; Moore, J.D.; Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nat. Mater. 2012, 11, 620–626. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Frincu, B.; Gutfleisch, O. Large reversible magnetocaloric effect in Ni-Mn-In-Co. Appl. Phys. Lett. 2015, 106, 118694. [Google Scholar] [CrossRef]

- Zhang, G.Y.; Li, Z.B.; Yang, J.J.; Yang, B.; Wang, D.H.; Zhang, Y.D.; Esling, C.; Hou, L.; Li, X.; Zhao, X.; et al. Giant elastocaloric effect in a Mn-rich Ni44Mn46Sn10 directionally solidified alloy. Appl. Phys. Lett. 2020, 116, 023902. [Google Scholar] [CrossRef]

- Wang, H.; Li, D.; Zhang, G.; Li, Z.; Yang, B.; Yan, H.; Cong, D.; Esling, C.; Zhao, X.; Zuo, L. Highly sensitive elastocaloric response in a directionally solidified Ni50Mn33In15.5Cu1.5 alloy with strong <001>A preferred orientation. Intermetallics 2022, 140, 107379. [Google Scholar]

- Wei, L.; Zhang, X.; Liu, J.; Geng, L. Orientation dependent cyclic stability of the elastocaloric effect in textured Ni-Mn-Ga alloys. AIP Adv. 2018, 8, 055312. [Google Scholar] [CrossRef]

- Yang, Z.; Cong, D.Y.; Sun, X.M.; Nie, Z.H.; Wang, Y.D. Enhanced cyclability of elastocaloric effect in boron-microalloyed Ni-Mn-In magnetic shape memory alloys. Acta Mater. 2017, 127, 33–42. [Google Scholar] [CrossRef]

- Yan, H.L.; Wang, L.D.; Liu, H.X.; Huang, X.M.; Jia, N.; Li, Z.B.; Yang, B.; Zhang, Y.D.; Esling, C.; Zhao, X.; et al. Giant elastocaloric effect and exceptional mechanical properties in an all-d-metal Ni–Mn–Ti alloy: Experimental and ab-initio studies. Mater. Des. 2019, 184, 108180. [Google Scholar] [CrossRef]

- Cong, D.Y.; Xiong, W.X.; Planes, A.; Ren, Y.; Manosa, L.; Cao, P.Y.; Nie, Z.H.; Sun, X.M.; Yang, Z.; Hong, X.F.; et al. Colossal elastocaloric effect in ferroelastic Ni-Mn-Ti alloys. Phys. Rev. Lett. 2019, 122, 255703. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Sun, W.; Zhao, D.; Xu, H.; Liu, J. An 8 K elastocaloric temperature change induced by 1.3% transformation strain in Ni44Mn45−xSn11Cux alloys. Scr. Mater. 2017, 130, 278–282. [Google Scholar] [CrossRef]

- Ma, G.; Li, C.; Chen, M.; Zong, S.; Zhang, Y.; Zhao, S.; Chen, F.; Xuan, H. Elastocaloric effect and magnetic properties of Ni50Mn31.5Ti18Cu0.5 shape memory alloy. J. Supercond. Novel Magn. 2022, 35, 1669–1676. [Google Scholar] [CrossRef]

- Fornell, J.; Tuncer, N.; Schuh, C.A. Orientation dependence in superelastic Cu-Al-Mn-Ni micropillars. J. Alloys Compd. 2017, 693, 1205–1213. [Google Scholar] [CrossRef]

- Villa, F.; Villa, E.; Righi, L.; Ruggieri, P.; Bennato, N.; Battiston, S.; Passaretti, F.; Casati, R. Effect of the thermal processing on the microstructural, functional and mechanical properties of cast polycrystalline NiMnTi alloys. J. Alloys Compd. 2024, 1000, 175099. [Google Scholar] [CrossRef]

- Xiao, F.; Jin, M.J.; Liu, J.; Jin, X.J. Elastocaloric effect in Ni50Fe19Ga27Co4 single crystals. Acta Mater. 2015, 96, 292–300. [Google Scholar] [CrossRef]

- Fazeli, S.; Izadifar, M.; Dolado, J.S.; Ramazani, A.; Sadrnezhaad, S.K. Atomistic study of the effect of crystallographic orientation on the twinning and detwinning behavior of NiTi shape memory alloys. Comput. Mater. Sci. 2022, 203, 111080. [Google Scholar] [CrossRef]

- Hsu, Y.T.; Wu, C.T.; Chen, C.H. Nanoscale-precipitate-strengthened (Ni,Cu)-rich TiNiCu shape memory alloy with stable superelasticity and elastocaloric performance. J. Alloys Compd. 2024, 997, 174937. [Google Scholar] [CrossRef]

- Meng, J.; Xie, L.; Yu, Q.; Wang, J.; Jiang, C. Toughening the grain boundaries by introducing a small amount of the second phase: Ni-Cu-Mn-Ga shape memory alloys as an example. Acta Mater. 2024, 263, 119469. [Google Scholar] [CrossRef]

- Guan, Z.; Bai, J.; Zhang, Y.; Sun, S.; Gu, J.; Liang, X.; Zhang, Y.; Esling, C.; Zhao, X.; Zuo, L. Achieved good mechanical properties and large elastocaloric effect in Ni-Mn-Ti-Cu-B alloy: Experiments and first-principles calculations. J. Alloys Compd. 2023, 930, 167477. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, S.; Wang, L.; Pan, S.; Zhang, J.; Liu, X.; Wang, C. Development of boron-microalloyed Co–V–Al–Fe shape memory alloys. Intermetallics 2023, 157, 107889. [Google Scholar] [CrossRef]

- Li, X.; Fautrelle, Y.; Gagnoud, A.; Du, D.; Wang, J.; Ren, Z.; Nguyen-Thi, H.; Mangelinck-Noel, N. Effect of a weak transverse magnetic field on solidification structure during directional solidification. Acta Mater. 2014, 64, 367–381. [Google Scholar] [CrossRef]

- Li, B.; Li, S.M.; Yang, B.; Zhong, H.; Liu, Z.P.; Li, D. Enhancing the elastocaloric effect and thermal cycling stability in dendritic-like Ni50Mn31.6Ti18.4 single crystal. J. Alloys Compd. 2023, 936, 168310. [Google Scholar] [CrossRef]

- Xu, F.; Zhu, C.; Wang, J.; Luo, F.; Zhu, X.; Xu, J.; Chen, S.; Wang, J.; Ma, G.; Chen, F.; et al. Enhanced elastocaloric effect and mechanical properties of Gd-doped Ni-Co-Mn-Ti-Gd metamagnetic shape memory alloys. J. Alloys Compd. 2023, 960, 170768. [Google Scholar] [CrossRef]

- Li, B.; Zheng, L.J.; Zhang, H. Microstructure-property relationship in Zr-alloyed Ni-rich NiTi alloys: Enhancements in high-temperature stability and superelasticity. Mater. Charact. 2024, 208, 113649. [Google Scholar] [CrossRef]

- Zhao, Y.; Hou, L.; Li, X.; Su, H.; Zhang, J. On the formation of gradient-distributed dendrites in a single crystal nickel-based superalloy directionally solidified under transverse static magnetic field. Mater. Charact. 2024, 207, 113508. [Google Scholar] [CrossRef]

- Niu, Y.; Chen, H.; Zhang, X.; Li, S.; Cong, D.; Ma, T.; Li, S.; Lin, J.; Wang, Y.D. Achieving excellent superelasticity and extraordinary elastocaloric effect in a directionally solidified Co-V-Ga alloy. Scr. Mater. 2021, 204, 114123. [Google Scholar] [CrossRef]

- Zhao, Y.; Ming, F.; Jia, N.; Chen, J.; Ren, S.; Xu, W.; Qu, X. High-strength superelastic as-cast Ni50.9Ti49.1-TiB2 in-situ composites. Mater. Sci. Eng. A 2021, 818, 141451. [Google Scholar] [CrossRef]

- Pfeuffer, L.; Lemke, J.; Shayanfar, N.; Riegg, S.; Koch, D.; Taubel, A.; Scheibel, F.; Kani, N.A.; Adabifiroozjaei, E.; Molina-Luna, L.; et al. Microstructure engineering of metamagnetic Ni-Mn-based Heusler compounds by Fe-doping: A roadmap towards excellent cyclic stability combined with large elastocaloric and magnetocaloric effects. Acta Mater. 2021, 221, 117390. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Li, S.; Niu, Y.; Yin, T.; Song, C.; Lang, R.; Cong, D.; Li, S.; Wang, Y.D. Enhanced cyclability of superelasticity and elastocaloric effect in Cu and B co-doped Co-Ni-Ga shape memory alloys. J. Alloys Compd. 2022, 918, 165633. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, M.; Cui, T.; Li, J.; Liu, Q.; Wang, H. The enhancement of the mechanical properties and the shape memory effect for the Cu-13.0Al-4.0Ni alloy by boron addition. J. Alloys Compd. 2019, 776, 326–333. [Google Scholar] [CrossRef]

- Li, X.W.; Yang, M.H.; Sun, C.H.; Ruan, Y.; Wei, B. Enhanced tensile performance of ternary Fe-Ni-Ti peri-eutectic alloy through directional solidification associated with thermal processing. Mater. Lett. 2024, 369, 136743. [Google Scholar] [CrossRef]

- Qian, S.X.; Ling, J.Z.; Hwang, Y.; Radermacher, R.; Takeuchi, I. Thermodynamics cycle analysis and numerical modeling of thermoelastic cooling systems. Int. J. Refrig. 2015, 56, 65–80. [Google Scholar] [CrossRef]

- Moya, X.; Defay, E.; Heine, V.; Mathur, N.D. Too cool to work. Nat. Phys. 2015, 11, 202–205. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, H.; Li, Z.; Yang, B.; Yan, H.; Zuo, L. Giant elastocaloric effect covering a wide temperature region in a directionally solidified Ni50Mn30Ti20 alloy. Scr. Mater. 2023, 237, 115725. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Yang, J.; Li, Z.; Yang, B.; Yan, H.; Wang, D.; Hou, L.; Li, X.; Zhang, Y.; et al. Large elastocaloric effect driven by stress-induced two-step structural transformation in a directionally solidified Ni55Mn18Ga27 alloy. Scr. Mater. 2019, 163, 116–120. [Google Scholar] [CrossRef]

- Zhao, D.; Castán, T.; Planes, A.; Li, Z.; Sun, W.; Liu, J. Enhanced caloric effect induced by magnetoelastic coupling in NiMnGaCu Heusler alloys: Experimental study and theoretical analysis. Phys. Rev. B 2017, 96, 224105. [Google Scholar] [CrossRef]

- Huang, X.M.; Zhao, Y.; Yan, H.L.; Tang, S.; Yang, Y.; Jia, N.; Yang, B.; Li, Z.; Zhang, Y.; Esling, C.; et al. A first-principle assisted framework for designing high elastocaloric Ni–Mn-based magnetic shape memory alloy. J. Mater. Sci. Technol. 2023, 134, 151–162. [Google Scholar] [CrossRef]

- Sun, W.; Liu, J.; Zhao, D.; Zhang, M. Directional solidification and elastocaloric effect in a Ni45Mn44Sn11 magnetic shape memory alloy. J. Phys. D Appl. Phys. 2017, 50, 444001. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Yang, J.; Li, D.; Yang, B.; Yan, H.; Nie, Z.; Hou, L.; Li, X.; Zhang, Y.; et al. Large elastocaloric effect in a polycrystalline Ni45.7Co4.2Mn37.3Sb12.8 alloy with low transformation strain. Scr. Mater. 2019, 162, 486–491. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, C.; Wang, H.; Li, Z.; Li, J.; Yang, B.; Yan, H.; Zuo, L. Orientation dependence of elastocaloric effect in a Cu71.3Al17.5Mn11.2 single crystal. J. Alloys Compd. 2023, 969, 172392. [Google Scholar] [CrossRef]

- Wu, Y.; Ertekin, E.; Sehitoglu, H. Elastocaloric cooling capacity of shape memory alloys—Role of deformation temperatures, mechanical cycling, stress hysteresis and inhomogeneity of transformation. Acta Mater. 2017, 135, 158–176. [Google Scholar] [CrossRef]

- Tušek, J.; Engelbrecht, K.; Mikkelsen, L.P.; Pryds, N. Elastocaloric effect of Ni-Ti wire for application in a cooling device. J. Appl. Phys. 2015, 117, 124901. [Google Scholar] [CrossRef]

- Qian, S.X.; Geng, Y.L.; Wang, Y.; Muehlbauer, J.; Ling, J.Z.; Hwang, Y.; Radermacher, R.; Takeuchi, I. Design of a hydraulically driven compressive elastocaloric cooling system. Sci. Technol. Built Environ. 2016, 22, 500–506. [Google Scholar] [CrossRef]

- Wang, J.; Yu, Q.; Xu, K.; Zhang, C.; Wu, Y.; Jiang, C. Large room-temperature elastocaloric effect of Ni57Mn18Ga21In4 alloy undergoing a magnetostructural coupling transition. Scr. Mater. 2017, 130, 148–151. [Google Scholar]

- Masdeu, F.; Pons, J.; Torrens-Serra, J.; Chumlyakov, Y.; Cesari, E. Superelastic behavior and elastocaloric effect in a Ni51.5Fe21.5Ga27.0 ferromagnetic shape memory single crystal under compression. Mater. Sci. Eng. A 2022, 833, 142362. [Google Scholar] [CrossRef]

- Li, Z.Z.; Li, Z.B.; Li, D.; Yang, J.J.; Yang, B.; Hu, Y.; Wang, D.H.; Zhang, Y.D.; Esling, C.; Zhao, X.; et al. Achieving a broad refrigeration temperature region through the combination of successive caloric effects in a multiferroic Ni50Mn35In15 alloy. Acta Mater. 2020, 192, 52–59. [Google Scholar] [CrossRef]

- Zhao, D.W.; Liu, J.; Chen, X.; Sun, W.; Li, Y.; Zhang, M.X.; Shao, Y.Y.; Zhang, H.; Yan, A. Giant caloric effect of low-hysteresis metamagnetic shape memory alloys with exceptional cyclic functionality. Acta Mater. 2017, 133, 217–223. [Google Scholar] [CrossRef]

- Yuan, B.; Zhong, S.; Qian, M.; Zhang, X.; Geng, L. Elastocaloric effect in bamboo-grained Cu71.1Al17.2Mn11.7 microwires. J. Alloys Compd. 2021, 850, 156612. [Google Scholar] [CrossRef]

- Xu, S.; Huang, H.; Xie, J.; Takekawa, S.; Xu, X.; Omori, T.; Kainuma, R. Giant elastocaloric effect covering wide temperature range in columnar-grained Cu71.5Al17.5Mn11 shape memory alloy. APL Mater. 2016, 4, 106106. [Google Scholar] [CrossRef]

- Liu, C.; Li, Z.B.; Wang, H.L.; Wang, Y.P.; Yang, B.; Yan, H.L.; Cong, D.Y.; Zhao, X.; Zuo, L. Long-term stable elastocaloric effect in a Heusler-type Co51V33Ga16 polycrystalline alloy. ACS Appl. Energy Mater. 2022, 5, 12953–12965. [Google Scholar] [CrossRef]

- Zhou, M.; Li, Y.; Zhang, C.; Li, L. Elastocaloric effect and mechanical behavior for NiTi shape memory alloys. Chin. Phys. B 2018, 27, 106501. [Google Scholar] [CrossRef]

- Liu, S.; Xuan, H.; Cao, T.; Wang, L.; Xie, Z.; Liang, X.; Li, H.; Feng, L.; Chen, F.; Han, P. Magnetocaloric and elastocaloric effects in all-d-metal Ni37Co9Fe4Mn35Ti15 magnetic shape memory alloy. Phys. Status Solidi 2019, 216, 1900563. [Google Scholar] [CrossRef]

- Sidharth, R.; Abuzaid, W.; Vollmer, M.; Niendorf, T.; Sehitoglu, H. Fatigue crack initiation in the iron-based shape memory alloy FeMnAlNiTi. Shape Mem. Superelasticity 2020, 6, 323–331. [Google Scholar] [CrossRef]

- Xu, Y.; Lu, B.; Sun, W.; Yan, A.; Liu, J. Large and reversible elastocaloric effect in dual-phase Ni54Fe19Ga27 superelastic alloys. Appl. Phys. Lett. 2015, 106, 201903. [Google Scholar] [CrossRef]

- Imran, M.; Zhang, X.; Qian, M.; Geng, L. Enhanced working stability of elastocaloric effects in polycrystalline Ni-Fe-Ga dual phase alloy. Intermetallics 2021, 136, 107255. [Google Scholar] [CrossRef]

- Yuan, B.; Qian, M.; Zhang, X.; Imran, M.; Geng, L. Enhanced cyclic stability of elastocaloric effect in oligocrystalline Cu–Al–Mn microwires via cold-drawing. Int. J. Refrig 2020, 114, 54–61. [Google Scholar] [CrossRef]

- Liu, K.; Yuan, Y.; Ma, S.; Feng, G.; Wan, D.; Wang, S.; Chen, C.; Luo, X.; Zhong, Z. Large elastocaloric effect around room temperature in directionally solidified Co49Fe3V33Ga15 superelastic alloy. J. Alloys Compd. 2021, 884, 161094. [Google Scholar] [CrossRef]

- Liu, C.; Li, D.; Li, Z.; Yang, B.; Yan, H.; Li, J.; Li, Z.; Zhao, X.; Zuo, L. Large elastocaloric effect in a Heusler-type Co50V35Ga14Ni1 polycrystalline alloy. Appl. Phys. Lett. 2021, 118, 103904. [Google Scholar] [CrossRef]

- Yang, Z.; Cong, D.; Yuan, Y.; Li, R.; Zheng, H.; Sun, X.; Nie, Z.; Ren, Y.; Wang, Y. Large room-temperature elastocaloric effect in a bulk polycrystalline Ni-Ti-Cu-Co alloy with low isothermal stress hysteresis. Appl. Mater. Today 2020, 21, 100844. [Google Scholar] [CrossRef]

- Bechtold, C.; Chluba, C.; Lima de Miranda, R.; Quandt, E. High cyclic stability of the elastocaloric effect in sputtered TiNiCu shape memory films. Appl. Phys. Lett. 2012, 101, 091903. [Google Scholar] [CrossRef]

- Wei, L.; Zhang, X.; Gan, W.; Ding, C.; Geng, L. Hot extrusion approach to enhance the cyclic stability of elastocaloric effect in polycrystalline Ni-Mn-Ga alloys. Scr. Mater. 2019, 168, 28–32. [Google Scholar] [CrossRef]

- Eftifeeva, A.; Panchenko, E.; Yanushonite, E.; Kurlevskaya, I.; Timofeeva, E.; Tokhmetova, A.; Surikov, N.; Tagiltsev, A.; Chumlyakov, Y. Superelasticity and elastocaloric cooling capacity in stress-induced martensite aged [001]А-oriented Ni54Fe19Ga27 single crystals. Mater. Sci. Eng. A 2022, 855, 143855. [Google Scholar] [CrossRef]

- Liang, X.; Xiao, F.; Jin, X.; Fukuda, T.; Kakeshita, T. Suppression of martensitic transformation in Co2Cr(Ga,Si) Heusler alloys by thermal cycling. Metall. Mater. Trans. A 2017, 48, 2105–2108. [Google Scholar] [CrossRef]

- Sidharth, R.; Celebi, T.B.; Sehitoglu, H. Origins of functional fatigue and reversible transformation of precipitates in NiTi shape memory alloy. Acta Mater. 2024, 274, 119990. [Google Scholar] [CrossRef]

- Dadda, J.; Maier, H.J.; Niklasch, D.; Karaman, I.; Karaca, H.E.; Chumlyakov, Y.I. Pseudoelasticity and cyclic stability in Co49Ni21Ga30 shape-memory alloy single crystals at ambient temperature. Metall. Mater. Trans. A 2008, 39, 2026–2039. [Google Scholar] [CrossRef]

- Fu, H.; Xu, S.; Zhao, H.; Dong, H.; Xie, J. Cyclic stress-strain response of directionally solidified polycrystalline Cu-Al-Ni shape memory alloys. J. Alloys Compd. 2017, 714, 154–159. [Google Scholar] [CrossRef]

- Briant, C.L.; Messmer, R.P. Electronic effects of sulphur in nickel. Philos. Mag. B 1980, 42, 569–576. [Google Scholar] [CrossRef]

- Messmer, R.P.; Briant, C.L. The role of chemical bonding in grain boundary embrittlement. Acta Metall. 1982, 30, 457–467. [Google Scholar] [CrossRef]

- Schulson, E.M.; Weihs, T.P.; Baker, I.; Frost, H.J.; Horton, J.A. Grain boundary accommodation of slip in Ni3Al containing boron. Acta Metall. 1986, 34, 1395–1399. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.T.; Heatherly, L.; George, E.P. Effect of boron on the fracture behavior and grain boundary chemistry of Ni3Fe. Scr. Mater. 2011, 64, 303–306. [Google Scholar] [CrossRef]

- Liu, C.T.; George, E.P. Environmental embrittlement in boron-free and boron-doped FeAl (40 at. % Al) alloys. Scr. Metall. Mater. 1990, 24, 1285–1290. [Google Scholar] [CrossRef]

| Alloy | Sample Status | Ttest (K) | |ΔTad| (K) | σmax (MPa) | Strain Rate (s−1) | Ref. |

|---|---|---|---|---|---|---|

| (Ni50Mn31Ti19)99B1 | Polycrystal (textured) | 303 | 27.2 | 412 | 3.0 × 10−1 | This work |

| Ni50Mn31.75Ti18.25 | Polycrystal (textured) | 293 | 20.4 | 913 | 2.0 | [14] |

| Ni50Mn35Ti15 | Polycrystal (untextured) | 293 | 4.5 | 450 | 2.8 × 10−2 | [19] |

| Ni50Mn31.6Ti18.4 | Single crystal | 293 | 29.0 | 830 | 2.0 | [27] |

| Ni37Co9Fe4Mn35Ti15 | Polycrystal (untextured) | 293 | 6.3 | 400 | 1.4 × 10−1 | [57] |

| (Ni50Mn31.5Ti18.5)99.8B0.2 | Polycrystal (untextured) | 308 | 31.5 | 700 | 5.33 | [15] |

| Ni55Mn18Ga27 | Polycrystal (textured) | 300 | 10.7 | 350 | 2.0 × 10−1 | [40] |

| Ni50Mn18.5Ga25Cu6.5 | Polycrystal (textured) | 315 | 8.1 | 100 | 4.2 × 10−2 | [41] |

| Ni50(Mn28.5Cu4.5)(In14Ga3) | Polycrystal (textured) | 293 | 19.0 | 710 | 2.0 | [42] |

| Ni44Mn46Sn10 | Polycrystal (textured) | 320 | 18.0 | 390 | 3.0 × 10−1 | [10] |

| Ni45Mn44Sn11 | Polycrystal (textured) | 298 | 10.0 | 310 | 3.0 × 10−2 | [43] |

| Ni47.5Co4.2Mn37.3Sb12.8 | Polycrystal (textured) | 303 | 8.7 | 400 | 5.0 × 10−2 | [44] |

| Cu71.3Al17.5Mn11.2 | Single crystal | 293 | 11.9 | 120 | 1.4 | [45] |

| Cu59.1Zn27Al13.8Zr0.1 | Single crystal | 343 | 14.2 | 200 | 2.0 × 10−1 | [46] |

| Ni48.9Ti51.1 | Wire | 322 | 21.0 | 900 | 2.0 × 10−1 | [47] |

| Ni50.8Ti49.2 | Polycrystal (textured) | 323 | 17.9 | 913 | 2.0 × 10−1 | [46] |

| Alloy | Sample Status | Number of Cycles | Degradation Rate of ΔTad (K per Cycle) | Ref. |

|---|---|---|---|---|

| (Ni50Mn31Ti19)99B1 | Polycrystal (textured) | 12,000 | 7.5 × 10−5 | This work |

| Ni50Mn30Ti20 | Polycrystal (textured) | 2000 | 5.0 × 10−4 | [39] |

| Ni37Co9Fe4Mn35Ti15 | Polycrystal (untextured) | 1000 | 2.0 × 10−4 | [57] |

| Ni50.4Mn27.3Ga22.3 | Polycrystal (textured) | 250 | 1.2 × 10−3 | [66] |

| Ni50.4Mn27.3Ga22.3 | Polycrystal (textured) | 100 | 2.0 × 10−3 | [12] |

| Ni50Fe19Ga27Co4 | Single crystal | 3000 | 9.3 × 10−4 | [20] |

| Ni54Fe19Ga27 | Single crystal | 100 | 1.0 × 10−3 | [67] |

| Ni54Fe19Ga27 | Polycrystal (untextured) | 100 | 9.0 × 10−3 | [59] |

| Ni53.2Fe19.4Ga27.4 | Polycrystal (untextured) | 480 | 2.3 × 10−3 | [60] |

| Cu71.3Al17.5Mn11.2 | Single crystal | 50 | 4.0 × 10−3 | [45] |

| Cu71Al18Mn11 | Polycrystal (textured) | 275 | 1.5 × 10−3 | [61] |

| Cu71.1Al17.2Mn11.7 | Polycrystal (textured) | 200 | 1.0 × 10−3 | [53] |

| Cu59.1Zn27Al13.8 | Polycrystal (untextured) | 10,000 | 1.4 × 10−4 | [46] |

| Co49Fe3V33Ga15 | Polycrystal (textured) | 200 | 1.5 × 10−3 | [62] |

| Co50V35Ga14Ni1 | Polycrystal (untextured) | 4000 | 8.5 × 10−4 | [63] |

| (Ni42.5Ti50Cu7.5)99Co1 | Polycrystal (textured) | 200 | 2.2 × 10−2 | [64] |

| Ti54.9Ni32.5Cu12.6 | Polycrystal (untextured) | 1502 | 2.0 × 10−4 | [65] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wang, Y.; Zhang, G.; Li, Z.; Yang, J.; Li, J.; Yang, B.; Yan, H.; Zuo, L. Giant Elastocaloric Effect and Improved Cyclic Stability in a Directionally Solidified (Ni50Mn31Ti19)99B1 Alloy. Materials 2024, 17, 4756. https://doi.org/10.3390/ma17194756

Wang H, Wang Y, Zhang G, Li Z, Yang J, Li J, Yang B, Yan H, Zuo L. Giant Elastocaloric Effect and Improved Cyclic Stability in a Directionally Solidified (Ni50Mn31Ti19)99B1 Alloy. Materials. 2024; 17(19):4756. https://doi.org/10.3390/ma17194756

Chicago/Turabian StyleWang, Honglin, Yueping Wang, Guoyao Zhang, Zongbin Li, Jiajing Yang, Jinwei Li, Bo Yang, Haile Yan, and Liang Zuo. 2024. "Giant Elastocaloric Effect and Improved Cyclic Stability in a Directionally Solidified (Ni50Mn31Ti19)99B1 Alloy" Materials 17, no. 19: 4756. https://doi.org/10.3390/ma17194756

APA StyleWang, H., Wang, Y., Zhang, G., Li, Z., Yang, J., Li, J., Yang, B., Yan, H., & Zuo, L. (2024). Giant Elastocaloric Effect and Improved Cyclic Stability in a Directionally Solidified (Ni50Mn31Ti19)99B1 Alloy. Materials, 17(19), 4756. https://doi.org/10.3390/ma17194756