Effect of the Dynamic Porous Structure Generation in Laser Irradiated Multi-Functional Coatings

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

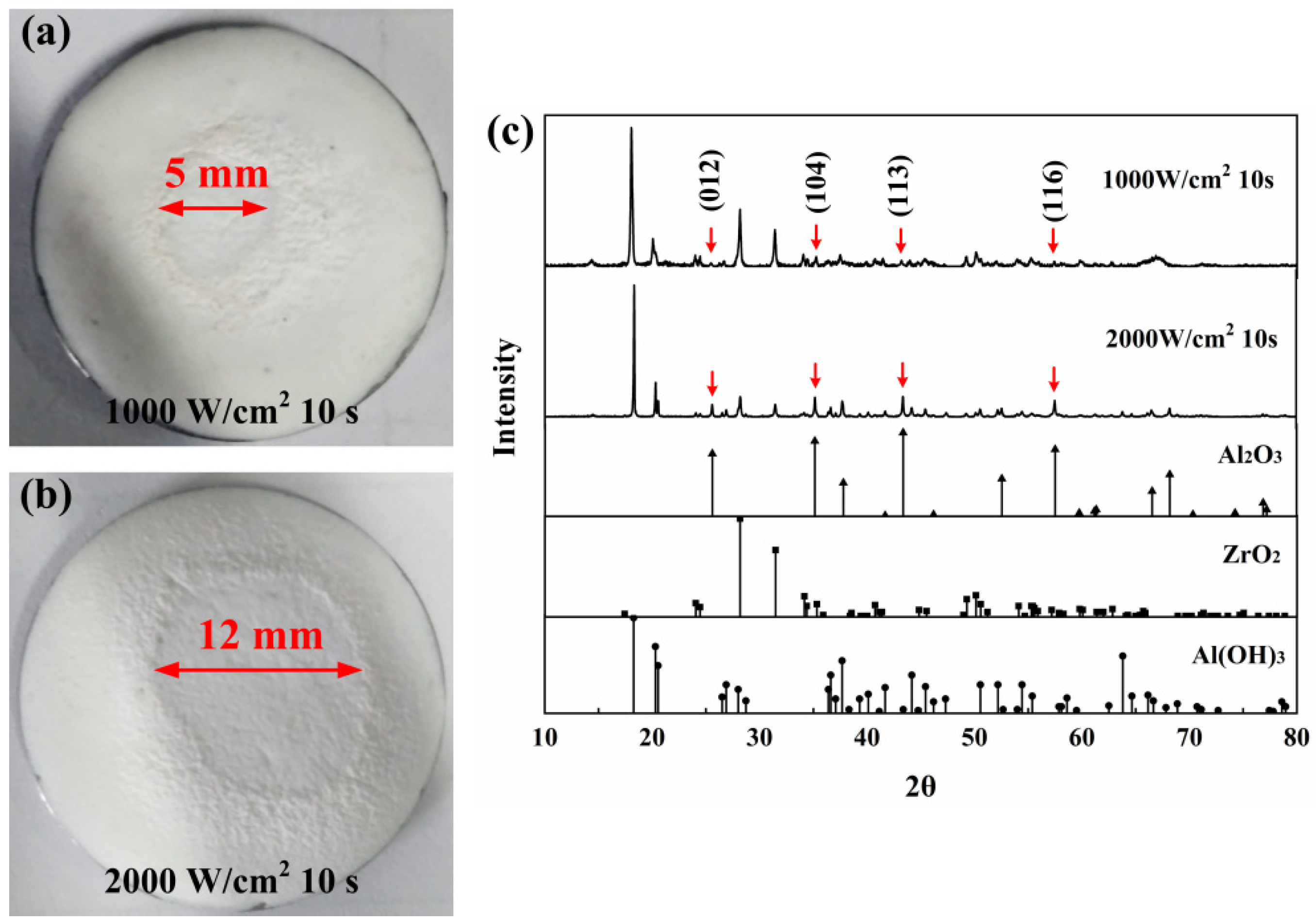

3.1. Macrostructure and Phase Analysis of Irradiated Coatings

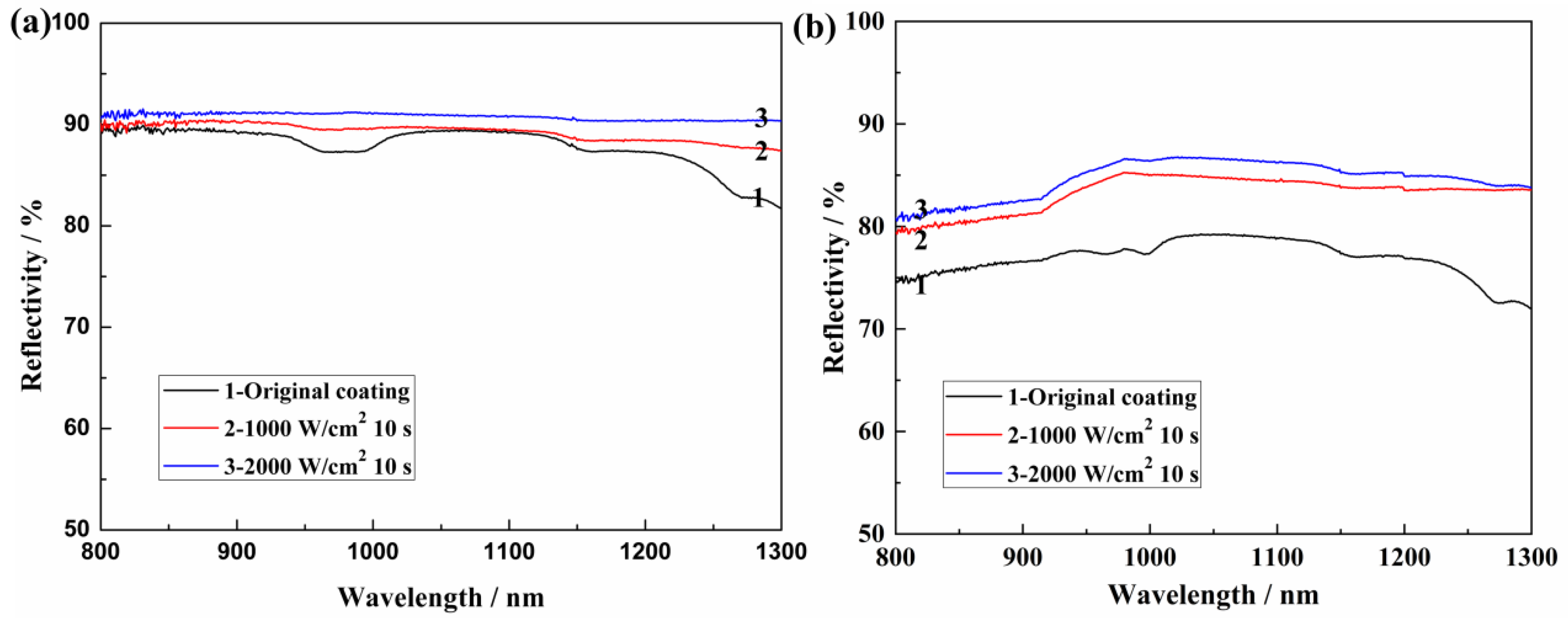

3.2. Optical Properties of As-Prepared and Irradiated Coatings

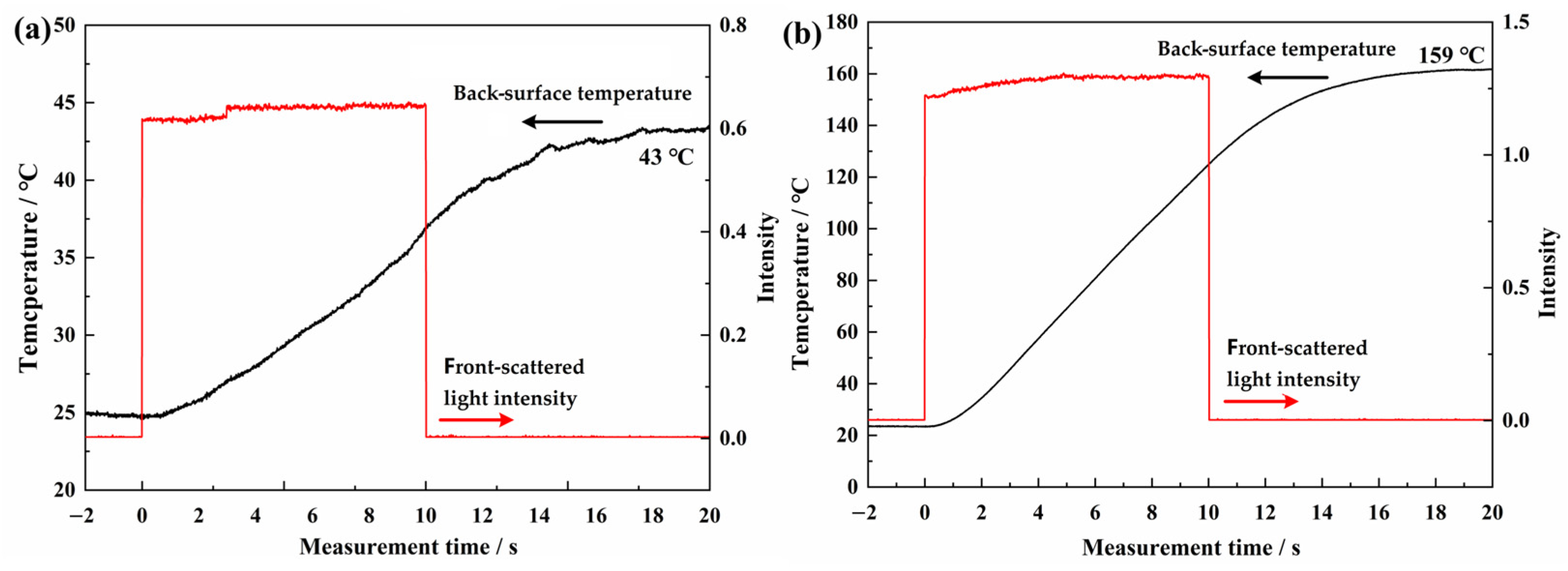

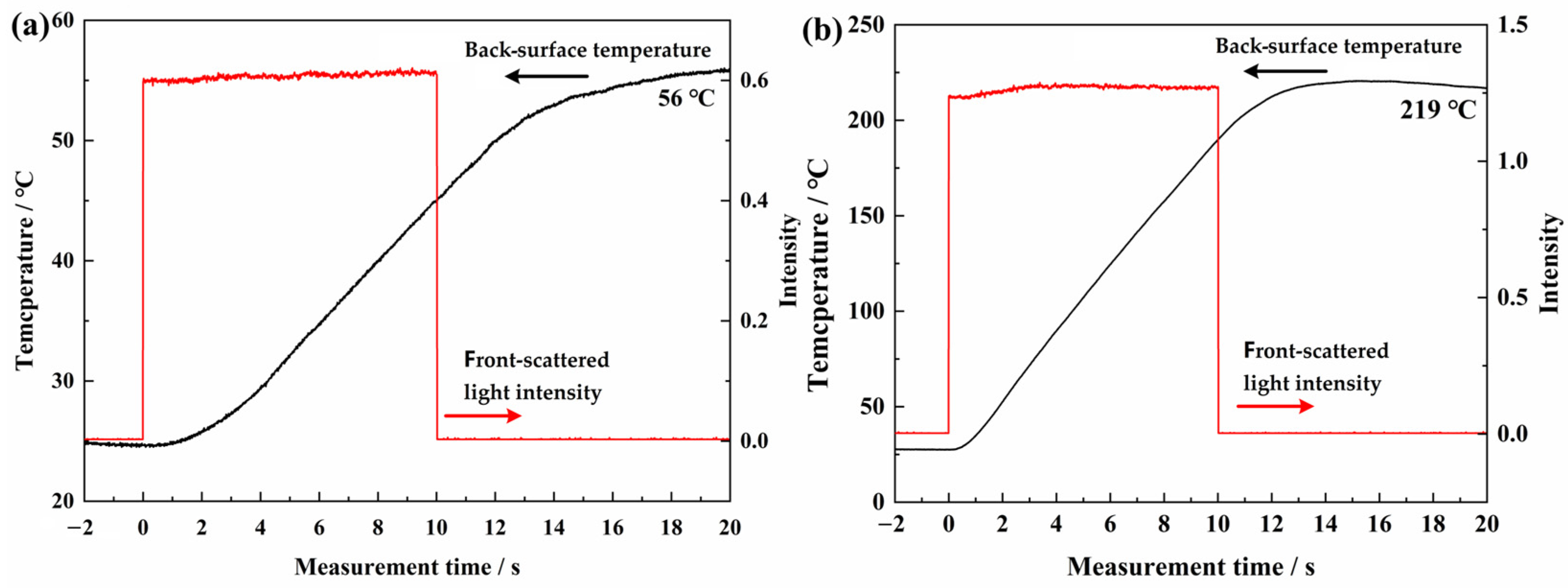

3.3. Back-Surface Temperature and Front-Scattered Light Analysis

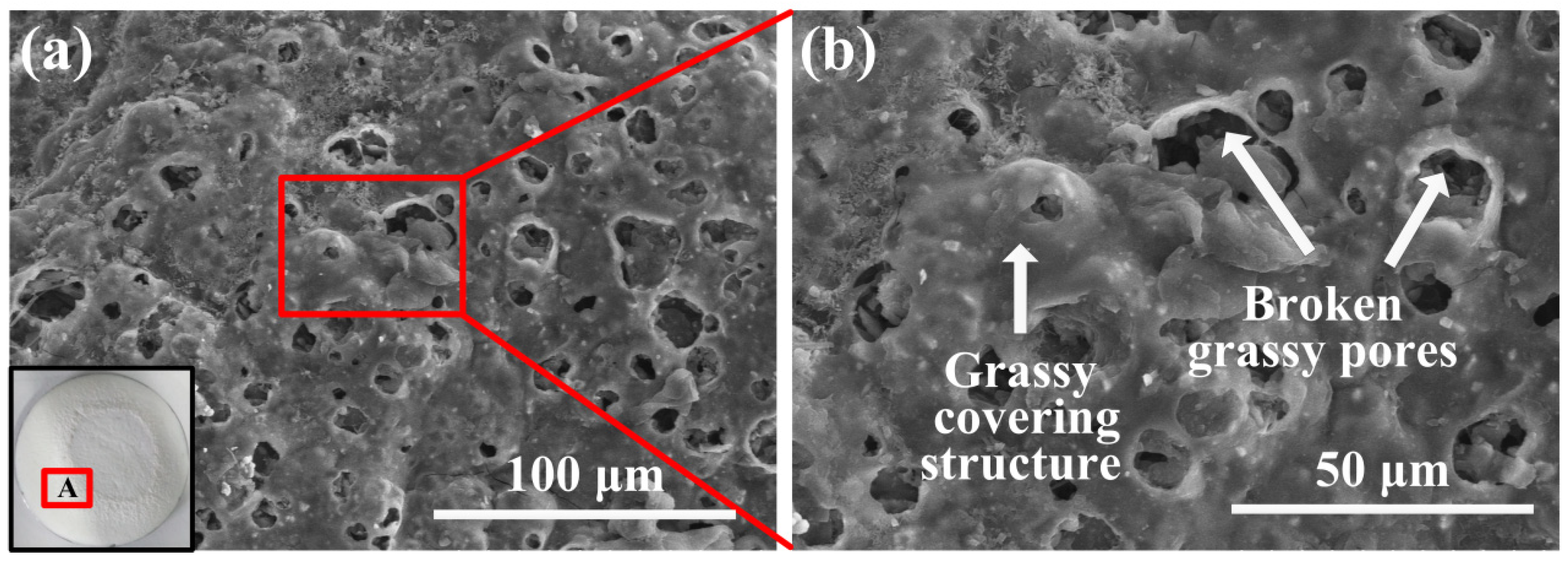

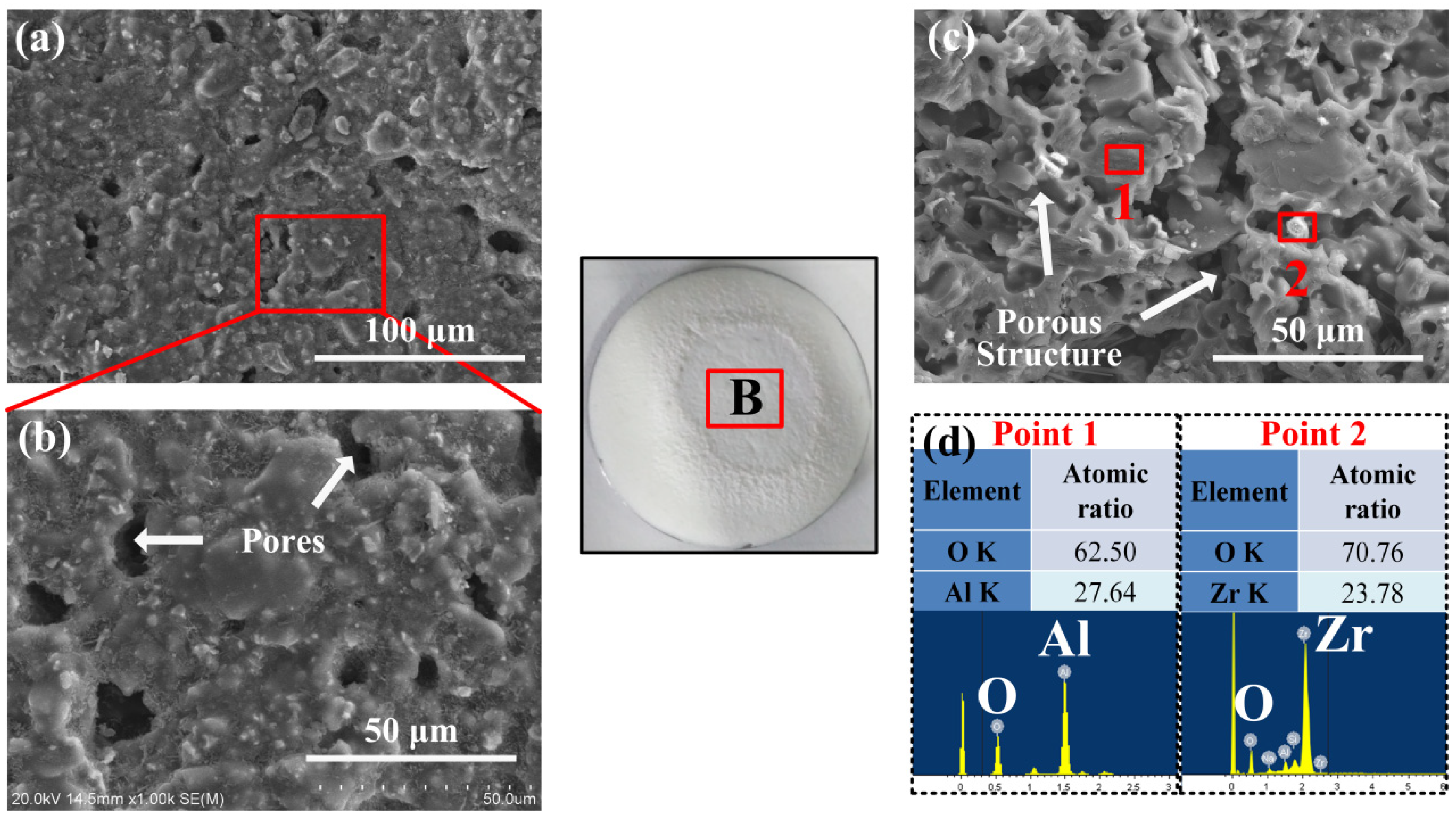

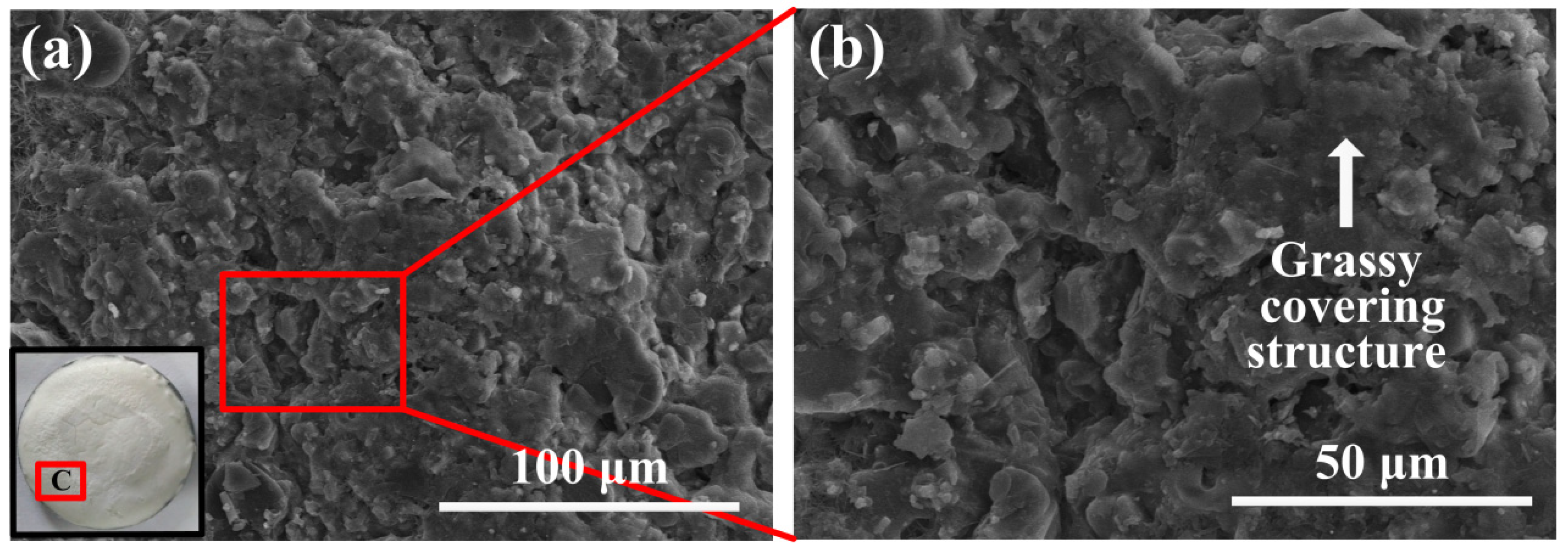

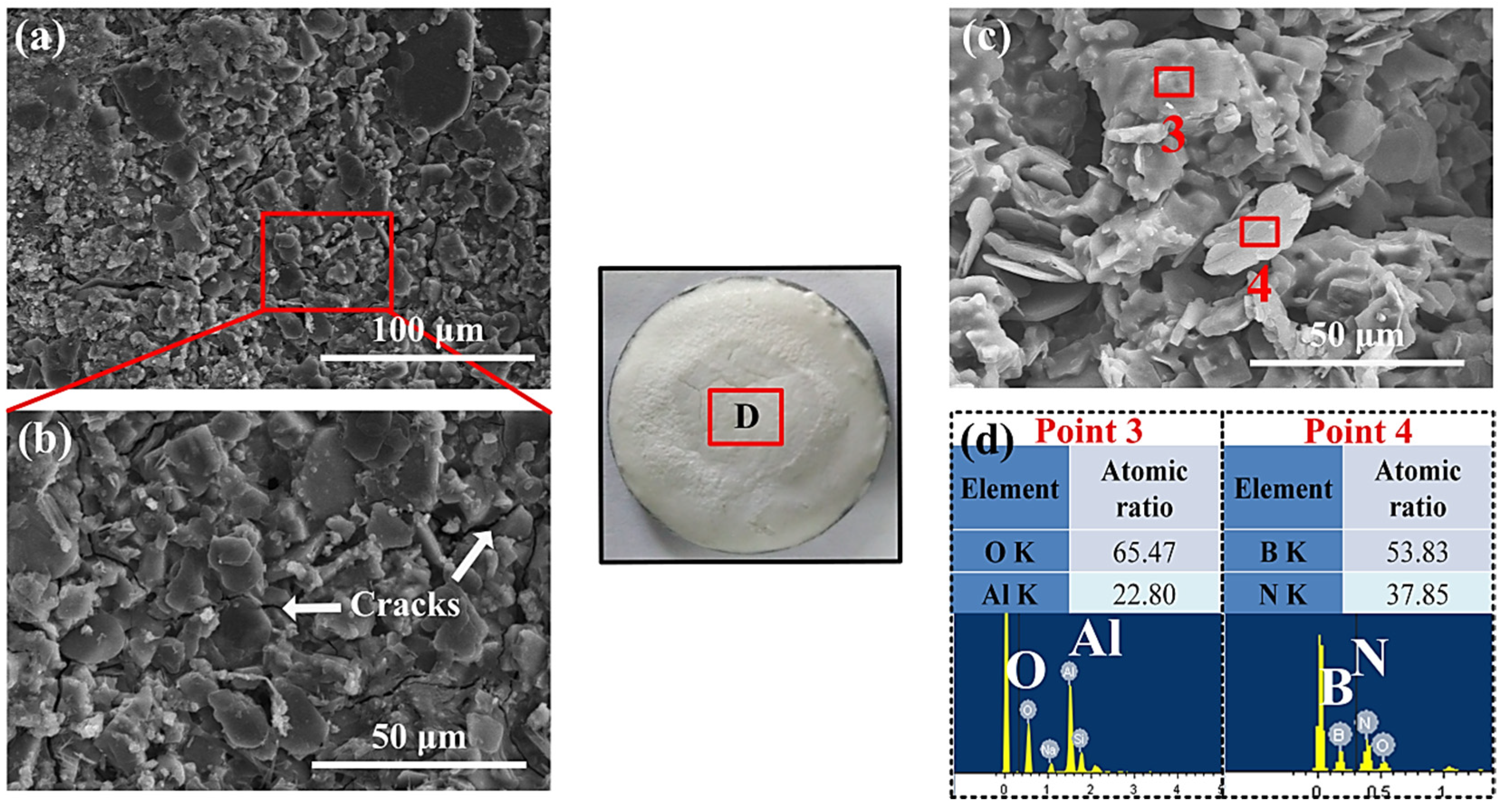

3.4. Evolution of Micro-Morphologies during Laser Irradiation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gallais, L.; Commandré, M. Laser-induced damage thresholds of bulk and coating optical materials at 1030 nm, 500 fs. Appl. Opt. 2014, 53, 186–196. [Google Scholar] [CrossRef] [PubMed]

- Ling, X.; Wang, G.; Zhao, Y.; Shao, J.; Fan, Z. Laser-induced damage of the optical films prepared by electron beam evaporation and ion beam sputtering in vacuum. Optik 2014, 125, 6474–6477. [Google Scholar] [CrossRef]

- Natoli, J.Y.; Gallais, L.; Akhouayri, H.; Amra, C. Laser-induced damage of materials in bulk, thin-film, and liquid forms. Appl. Opt. 2002, 41, 3156–3166. [Google Scholar] [CrossRef] [PubMed]

- Riede, W.; Schroeder, H.; Bataviciute, G.; Wernham, D.; Tighe, A.; Pettazzi, F.; Alves, J. Laser-Induced Contamination on Space Optics. Proc. SPIE 2011, 8190, 81901E. [Google Scholar]

- Ma, C.; Ma, Z.; Gao, L.; Liu, Y.; Wang, J.; Song, M.; Wang, F.; Ishida, H. Laser ablation behavior of nano-copper particle-filled phenolic matrix nanocomposite coatings. Ceram Int. 2018, 155, 62–68. [Google Scholar] [CrossRef]

- Tong, Y.; Bai, S.; Zhang, H.; Ye, Y. Laser ablation behavior and mechanism of C/SiC composite. Ceram Int. 2013, 39, 6813–6820. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, L.; Jiang, F.; Liu, J.; Cheng, L.; Li, H.; Wang, Y. Laser ablation behaviors of SiC–ZrC coated carbon/carbon composites. Surf. Coat. Technol. 2011, 205, 4299–4303. [Google Scholar] [CrossRef]

- Mulser, P.; Bauer, D. High Power Laser-Matter Interaction; Springer: New York, NY, USA, 2013. [Google Scholar]

- Zhu, J.; Ma, Z.; Gao, Y.; Gao, L.; Pervak, V.; Wang, L.; Wei, C.; Wang, F. Ablation Behavior of Plasma-Sprayed La1−xSrxTiO3+δ Coating Irradiated by High-Intensity Continuous Laser. ACS Appl. Mater. Interfaces 2017, 9, 35444–35452. [Google Scholar] [CrossRef]

- Xu, W.; Gao, L.H.; Ma, C.; Ma, Z.; Wu, T.T.; Rogachev, A.A.; Wang, F.C. Design and preparation of composite coatings with increased reflectivity under high -energy continuous wave laser ablation. Ceram. Int. 2020, 46, 23457–23462. [Google Scholar] [CrossRef]

- Chen, J.; An, Q.L.; Ming, W.W.; Chen, M. Investigations on continuous-wave laser and pulsed laser induced controllable ablation of SiCf/SiC composites. J. Eur. Ceram. Soc. 2021, 41, 5835–5849. [Google Scholar] [CrossRef]

- Gao, L.; Ma, Z.; Wang, F.; Li, W. Reflectivity and Laser Irradiation of Plasma Sprayed Al Coating. In Proceedings of the Third International Symposium on Laser Interaction with Matter, Jiangsu, China, 8 May 2015; SPIE: Cergy-Pontoise, France, 2015; Volume 9543, pp. 1016–1019. [Google Scholar]

- Wang, A.; Zhu, J.; Ma, C.; Xu, W.; Ma, Z.; Gao, L.; Chen, G.; Ishida, H. Organic-inorganic composites for novel optical transformation induced by high-energy laser ablation. Ceram. Int. 2022, 48, 507–513. [Google Scholar] [CrossRef]

- Chen, G.; Zhu, S.; Jiang, Z.; Gao, L.; Ma, Z.; Liu, L. Laser ablation protection of polymer matrix composites by adhesive inorganic coatings. J. Mater. Sci. 2017, 52, 12734–12741. [Google Scholar] [CrossRef]

- Yu, Q.C.; Wan, H. Ablation capability of flake graphite reinforced barium-phenolic resin composite under long pulse laser irradiation. J. Inorg. Mater. 2012, 27, 157–161. [Google Scholar] [CrossRef]

- Zou, Y.; Zhao, L.L.; You, L.J.; Chen, X.Y.; Song, L.X. Preparation and numerical simulation investigation of high reflectance anti-laser-ablation coating. J. Inorg. Mater. 2016, 31, 869–875. [Google Scholar]

- Ma, C.; Ma, Z.; Gao, L.; Liu, Y.; Wu, T.; Wang, F.; Ishida, H. Ablation behavior of boron-modified phenolic resin irradiated by high-energy continuous-wave laser and its evolution of carbon structure. Mater. Des. 2019, 180, 107954. [Google Scholar] [CrossRef]

- Li, W.; Gao, L.; Ma, Z.; Wang, F. Ablation behavior of graphite/SiO2 composite irradiated by high-intensity continuous laser. J. Eur. Ceram. Soc. 2017, 37, 1331–1338. [Google Scholar] [CrossRef]

- Yang, M.M.; Wang, T.; Wu, M. Ablation behavior of SiC whisker and ZrB2 particle-filled ZrO2 sol-gel composite coating under high-intensity continuous laser irradiation. Ceram. Int. 2021, 47, 26327–26334. [Google Scholar] [CrossRef]

- Camino, G.; Maffezzoli, A.; Braglia, M.; Lazzaro, M.D.; Zammarano, M. Effect of hydroxides and hydroxycarbonate structure on fire retardant effectiveness and mechanical properties in ethylene-vinyl acetate copolymer. Polym. Degrad. Stab. 2001, 74, 457–464. [Google Scholar] [CrossRef]

- Dean, J.A. Lange’s Handbook of Chemistry; Mcgraw-Hill: New York, NY, USA, 1999; Chapter 9. [Google Scholar]

- Hass, G.; Cox, J.T. Highly efficient reflection-type polarizers for 10.6-μm CO2 laser radiation using aluminum oxide coated aluminum mirrors. Appl. Opt. 1978, 17, 1657–1658. [Google Scholar]

- Sun, J.; Li, X.; Zhang, W.; Yi, K.; Shao, J. High-reflectivity mirrors by Al2O3, LaF3, and AlF3, for 193 nm application. Opt. Laser Technol. 2014, 56, 65–70. [Google Scholar] [CrossRef]

- Gaggiano, R.; Moriamé, P.; Biesemans, M.; Graeve, I.D.; Terryn, H. Influence of SiO2/Na2O ratio and temperature on the mechanism of interaction of soluble sodium silicates with porous anodic alumina. Surf. Coat. Technol. 2011, 206, 1269–1276. [Google Scholar] [CrossRef]

- Huang, W.; Cheng, H.; Zhang, C.; Zhou, Y.; Cao, X. Thermal ablation of stabilized zirconia/metal coated polyimide matrix composites via plasma spray process. Plasma Chem. Plasma Process 2015, 35, 587–603. [Google Scholar] [CrossRef]

- Balagna, C.; Perero, S.; Ferraris, S.; Miola, M.; Fucale, G.; Manfredotti, C.; Battiato, A.; Santella, D.; Verne, E.; Vittone, E.; et al. Antibacterial coating on polymer for space application. Mater. Chem. Phys. 2012, 135, 714–722. [Google Scholar] [CrossRef]

- Aleksandrov, V.I.; Vasilev, A.B.; Kalgin, I.A.; Kislovskii, L.D.; Tatarintsev, V.M. Optical properties of zirconium dioxide in the infrared range. Opt. I Spektrosk. 1976, 40, 1087–1089. [Google Scholar]

- Zhou, W.Y.; Qi, S.H.; Li, H.D.; Shao, S.Y. Study on insulating thermal conductive BN/HDPE composites. Thermochim. Acta 2007, 452, 36–42. [Google Scholar] [CrossRef]

- Xue, X.; Peng, Y.; Huang, J.; Li, L.; Ni, Y.; Ma, Z.; Gao, L.; Chen, W.; Chen, G.; Ma, C. Design and preparation of resin matrix composite coating with good ablation resistance performance under high-energy laser irradiation. Ceram. Int. 2023, 49, 18962–18968. [Google Scholar] [CrossRef]

| Sample | Sodium Silicate/wt.% | ATH/wt.% | ZrO2/wt.% | BN/wt.% |

|---|---|---|---|---|

| AS-Z | 50 | 40 | 10 | 0 |

| AS-B | 50 | 40 | 0 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Zhu, Y.; He, Z.; Gao, L.; Ma, Z. Effect of the Dynamic Porous Structure Generation in Laser Irradiated Multi-Functional Coatings. Materials 2024, 17, 4493. https://doi.org/10.3390/ma17184493

Li W, Zhu Y, He Z, Gao L, Ma Z. Effect of the Dynamic Porous Structure Generation in Laser Irradiated Multi-Functional Coatings. Materials. 2024; 17(18):4493. https://doi.org/10.3390/ma17184493

Chicago/Turabian StyleLi, Wenzhi, Yichao Zhu, Zhiping He, Lihong Gao, and Zhuang Ma. 2024. "Effect of the Dynamic Porous Structure Generation in Laser Irradiated Multi-Functional Coatings" Materials 17, no. 18: 4493. https://doi.org/10.3390/ma17184493

APA StyleLi, W., Zhu, Y., He, Z., Gao, L., & Ma, Z. (2024). Effect of the Dynamic Porous Structure Generation in Laser Irradiated Multi-Functional Coatings. Materials, 17(18), 4493. https://doi.org/10.3390/ma17184493