Analysis of Acoustic Absorption Coefficients and Characterization of Epoxy Adhesive Compositions Based on the Reaction Product of Bisphenol A with Epichlorohydrin Modified with Fillers

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Samples

2.3. Test Methods

2.3.1. Scanning Electron Microscopy (SEM)

2.3.2. Tensile Strength Tests

2.3.3. Compressive Strength Tests

2.3.4. Bending Strength Tests

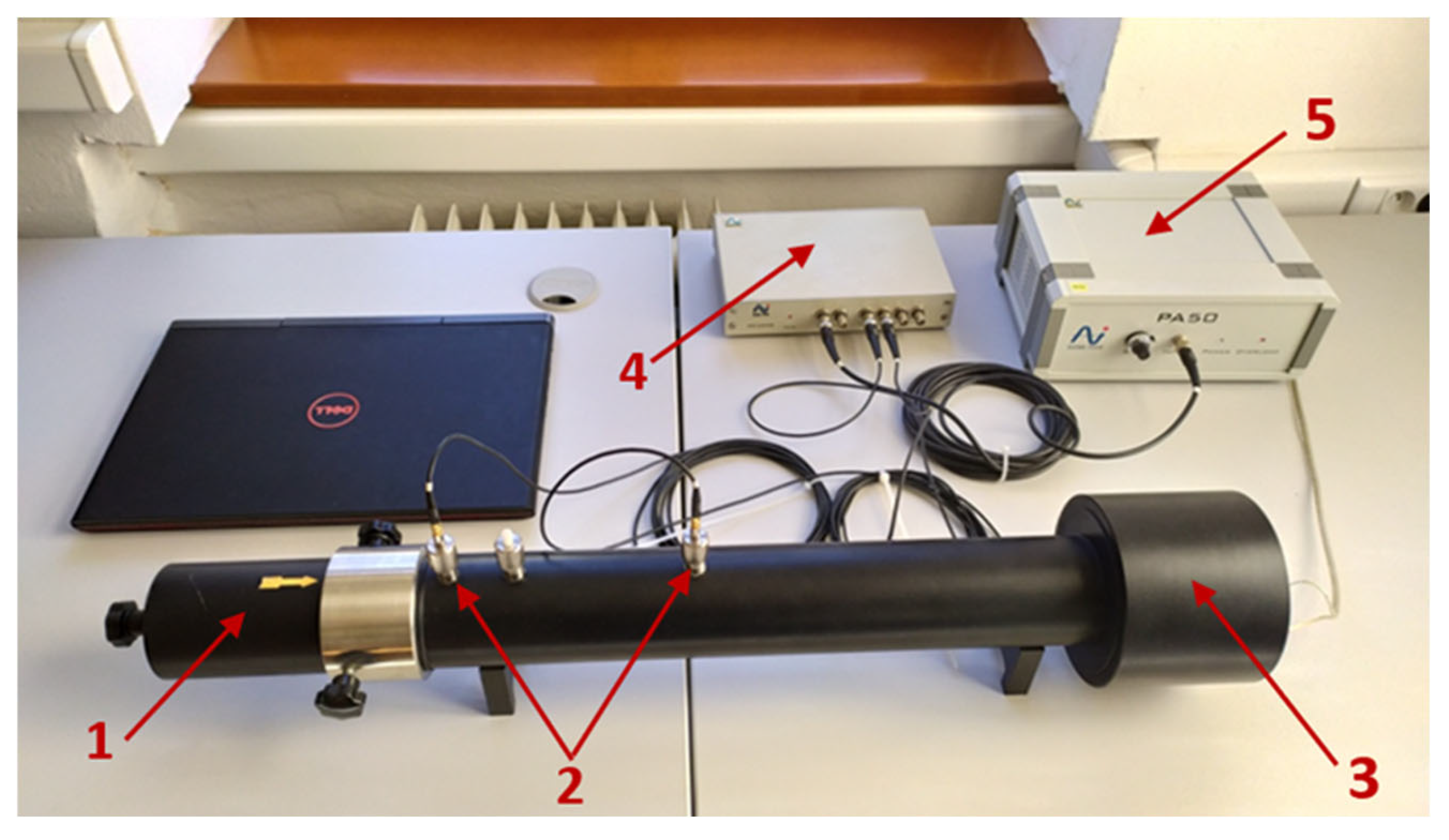

2.3.5. Sound Absorption

3. Results and Discussion

3.1. Results of SEM

3.2. Strength Test Results

3.3. Sound Absorption Test Results

4. Conclusions

- Physical modification of epoxy adhesive compositions does not always yield positive results;

- In the cases of analyzed adhesive compositions, the changes in strength parameters were generally insignificant, with significant differences observed at the assumed significance level p = 0.05 only in the following case:

- Tensile strength: A significant decrease for the composition E5/PAC/CWZ-22/100:80:20 compared to the reference composition;

- Compressive strength: A significant increase in strength for all modified compositions;

- Bending strength: A significant decrease for the compositions E5/PAC/ZR2/100:80:1 and E5/PAC/CWZ-22/100:80:20 compared to the reference composition;

- Regarding the sound absorption test, it can be observed that all tested materials show low values of the sound absorption coefficient; therefore, low sound absorption in both thicknesses was investigated (10 mm and 60 mm). Only minimal differences are noticeable between the different materials in terms of sound absorption;

- For the reduction index, better results are observed than for sound absorption for all materials. Only minimal differences between the individual materials are noticeable, but stable values are seen across the frequency band;

- Analyzing the SEM images of the tested compositions, it is evident that gas bubbles are visible on the surfaces, but the structure cannot be concluded to be porous in nature. In the case of the modified compositions, more gas bubbles are present compared to the reference composition, which may be due to the double-mixing step;

- Different fillers affect mechanical properties such as tensile, compressive, and bending strengths, with some enhancing strength and others improving specific properties;

- The adhesives generally exhibit low sound absorption, which can be attributed to their non-porous, solid structure;

- The reduction index R values are higher, indicating better sound reduction performance compared to sound absorption;

- The non-porous structure of the adhesives limits their sound absorption capabilities, while their homogeneous structure contributes to the stability of their mechanical properties;

- Adding different fillers into epoxy adhesive compositions significantly affects the elastic modulus. For instance, the CWZ-22 filler shows a markedly higher elastic modulus compared to other fillers, indicating its ability to increase material stiffness;

- A higher elastic modulus does not always correlate with higher tensile, compressive, or bending strength. For example, the E5/PAC/CWZ-22/100:80:20 composition, despite having the highest elastic modulus, did not always achieve the highest strength values across different tests.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lindawati, I. Sound Absorption of Arenga Pinnata Natural Fiber. World Acad. Sci. Eng. Technol. 2010, 67, 804–806. [Google Scholar]

- Haikal Mohd Fodzi, M.; Noraini, M.; Hafizuddin Hakim, S. Analysis of Epoxy Composite with Diapers Waste as Fillers: Relationship of Density, Porosity and Sound Absorption Coefficient. Int. J. Adv. Res. Eng. Technol. 2020, 11, 137–146. [Google Scholar]

- Din, I.U.; Ahmed, A.; Tarek, F.; Cantwell, W.; Khan, K.A. Ultra-Thin Composites Membrane for Deployable Structures: XCT Driven Characterization and FE Modeling of Folding Structure. Compos. Sci. Technol. 2024, 245, 110341. [Google Scholar] [CrossRef]

- Bathusha, M.S.S.; Din, I.U.; Umer, R.; Khan, K.A. In-Situ Monitoring of Crack Growth and Fracture Behavior in Composite Laminates Using Embedded Sensors of rGO Coated Fabrics and GnP Paper. Sens. Actuators Phys. 2024, 365, 114850. [Google Scholar] [CrossRef]

- Miravalles, M. The Creep Behaviour of Adhesives. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2007. [Google Scholar]

- Dunn, D.J. Engineering and Structural Adhesives; Rapra Review Reports; Rapra Technology: Shrewsbury, UK, 2004; ISBN 978-1-85957-436-2. [Google Scholar]

- Association of Plastics Manufacturers Bisphenol a and Material Benefits—Fact Sheet Material Benefits. Plastics Europe 2011. Available online: https://legacy.plasticseurope.org/download_file/force/1101/181 (accessed on 2 February 2024).

- Szlezyngier, W.; Brzozowski, Z.K. Plastics: Chemistry, Manufacturing Technology, Properties, Processing, Applications. T. 2, T. 2; Fosze Educational Publishing House: Rzeszów, Poland, 2012; ISBN 978-83-7586-076-4. [Google Scholar]

- Jayamani, E.; Hamdan, S.; Rahman, M.R.; Bakri, M.K.B. Investigation of Fiber Surface Treatment on Mechanical, Acoustical and Thermal Properties of Betelnut Fiber Polyester Composites. Procedia Eng. 2014, 97, 545–554. [Google Scholar] [CrossRef]

- Mazela, W.; Czub, P.; Pielichowski, J. Modification of Low Molecular Weight Epoxy Resins with Carbazole Derivatives. Sci. Pap. Inst. Org. Plast. Technol. Wrocław Univ. Technol. Conf. 2001, 50, 446–449. [Google Scholar]

- Ramos, V.D.; da Costa, H.M.; Soares, V.L.P.; Nascimento, R.S.V. Modification of Epoxy Resin: A Comparison of Different Types of Elastomer. Polym. Test. 2005, 24, 387–394. [Google Scholar] [CrossRef]

- Ratna, D. Modification of Epoxy Resins for Improvement of Adhesion: A Critical Review. J. Adhes. Sci. Technol. 2003, 17, 1655–1668. [Google Scholar] [CrossRef]

- Chikhi, N.; Fellahi, S.; Bakar, M. Modification of Epoxy Resin Using Reactive Liquid (ATBN) Rubber. Eur. Polym. J. 2002, 38, 251–264. [Google Scholar] [CrossRef]

- Yoon, I.-N.; Lee, Y.; Kang, D.; Min, J.; Won, J.; Kim, M.; Soo Kang, Y.; Kim, S.; Kim, J.-J. Modification of Hydrogenated Bisphenol A Epoxy Adhesives Using Nanomaterials. Int. J. Adhes. Adhes. 2011, 31, 119–125. [Google Scholar] [CrossRef]

- Mizera, C.; Herak, D.; Hrabe, P.; Muller, M.; Kabutey, A. Mechanical Behavior of Ensete Ventricosum Fiber under Tension Loading. J. Nat. Fibers 2017, 14, 287–296. [Google Scholar] [CrossRef]

- Wang, X.; Peng, F.; Chang, B. Sound Absorption of Porous Metals at High Sound Pressure Levels. J. Acoust. Soc. Am. 2009, 126, EL55–EL61. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.-N.; Torng, J.-H. Experimental Study of the Absorption Characteristics of Some Porous Fibrous Materials. Appl. Acoust. 2001, 62, 447–459. [Google Scholar] [CrossRef]

- Moravec, M.; Badida, M.; Mikušová, N.; Sobotová, L.; Švajlenka, J.; Dzuro, T. Proposed Options for Noise Reduction from a Wastewater Treatment Plant: Case Study. Sustainability 2021, 13, 2409. [Google Scholar] [CrossRef]

- Gumanová, V.; Sobotová, L.; Dzuro, T.; Badida, M.; Moravec, M. Experimental Survey of the Sound Absorption Performance of Natural Fibres in Comparison with Conventional Insulating Materials. Sustainability 2022, 14, 4258. [Google Scholar] [CrossRef]

- Badida, M.; Sobotova, L.; Badidova, A.; Moravec, M.; Mikulova, A. Research of Chosen Acoustics Descriptors of Developed Materials from Old Automobile Recycled Materials †. Recycling 2018, 3, 29. [Google Scholar] [CrossRef]

- Amares, S.; Sujatmika, E.; Hong, T.W.; Durairaj, R.; Hamid, H.S.H.B. A Review: Characteristics of Noise Absorption Material. J. Phys. Conf. Ser. 2017, 908, 012005. [Google Scholar] [CrossRef]

- BN-89 6376-02; Industry Standard. Epoxy Resins Epidian 1, 2, 3, 4, 5, 6. Zakłady Chemiczne Organika-Sarzyna: Nowa Sarzyna, Poland, 2013. (In Polish)

- Information Catalogue of Ciech S.A. Available online: https://Ciechgroup.Com/Produkty/Chemia-Organiczna/Zywice/Zywice-Epoksydowe/ (accessed on 20 February 2024).

- BN-73 6376-01; Industry Standard. Epoxy Resins Epidian 51 i 53. Zjednoczenie Przemysłu Organicznego: Warszawa, Poland, 2013. (In Polish)

- Miturska-Barańska, I.; Rudawska, A. Method of Manufacturing the Adhesive Composition and the Adhesive Composition. Patent Application Number A1 439374, 12 September 2022. [Google Scholar]

- Miturska, I.; Rudawska, A.; Müller, M.; Valášek, P. The Influence of Modification with Natural Fillers on the Mechanical Properties of Epoxy Adhesive Compositions after Storage Time. Materials 2020, 13, 291. [Google Scholar] [CrossRef]

- Miturska, I.; Rudawska, A.; Müller, M.; Hromasová, M. The Influence of Mixing Methods of Epoxy Composition Ingredients on Selected Mechanical Properties of Modified Epoxy Construction Materials. Materials 2021, 14, 411. [Google Scholar] [CrossRef]

- Zhou, Y.; Pervin, F.; Rangari, V.K.; Jeelani, S. Influence of Montmorillonite Clay on the Thermal and Mechanical Properties of Conventional Carbon Fiber Reinforced Composites. J. Mater. Process. Technol. 2007, 191, 347–351. [Google Scholar] [CrossRef]

- Jin, F.-L.; Park, S.-J. Interfacial Toughness Properties of Trifunctional Epoxy Resins/Calcium Carbonate Nanocomposites. Mater. Sci. Eng. A 2008, 475, 190–193. [Google Scholar] [CrossRef]

- He, H.; Li, K.; Wang, J.; Sun, G.; Li, Y.; Wang, J. Study on Thermal and Mechanical Properties of Nano-Calcium Carbonate/Epoxy Composites. Mater. Des. 2011, 32, 4521–4527. [Google Scholar] [CrossRef]

- Chen, S.; Feng, J. Epoxy Laminated Composites Reinforced with Polyethyleneimine Functionalized Carbon Fiber Fabric: Mechanical and Thermal Properties. Compos. Sci. Technol. 2014, 101, 145–151. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, Y.; Zhou, Z.; Rahman, A.; Wu, X.-F.; Wu, W.; Xu, T.; Fong, H. Fabrication and Mechanical Properties of Hybrid Multi-Scale Epoxy Composites Reinforced with Conventional Carbon Fiber Fabrics Surface-Attached with Electrospun Carbon Nanofiber Mats. Compos. Part B Eng. 2013, 44, 1–7. [Google Scholar] [CrossRef]

- PN-EN ISO 527-1; Plastics—Determination of Mechanical Properties in Static Tension. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 604; Plastics—Determination of Properties in Compression. International Organization for Standardization: Geneva, Switzerland, 2002.

- DIN-EN ISO 178; Plastics—Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 10534-2:2023; Acoustics. Determination of Acoustic Properties in Impedance Tubes. Part 2: Two-Microphone Technique for Normal Sound Absorption Coefficient and Normal Surface Impedance. International Organization for Standardization: Geneva, Switzerland, 2023.

- Arunkumar, B.; Jeyanthi, S. Design and Analysis of Impedance Tube for Sound Absorption Measurement. ARPN J. Eng. Appl. Sci. 2017, 12, 1400–1405. [Google Scholar]

- Labašová, E.; Ďuriš, R. Measurement of the Acoustic Absorption Coefficient by Impedance Tube. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2019, 27, 94–101. [Google Scholar] [CrossRef]

- Niresh, J.; Neelakrishnan, S.; Subharani, S.; Kannaian, T.; Prabhakaran, R. Review of Acoustic Characteristics of Materials Using Impedance Tube. ARPN J. Eng. Appl. Sci. 2015, 10, 3319–3326. [Google Scholar]

- Gumanová, V.; Džuňová, L.; Sobotová, L.; Králiková, R. Impedance Tube as a Tool for Evaluating Acoustic Noise Descriptors—The Experimental Measurement of Acoustic Parameters. Acta Mech. Slovaca 2020, 24, 56–64. [Google Scholar] [CrossRef]

- Liptai, P.; Moravec, M.; Dzuro, T.; Badida, M. Design and Effectiveness Verification of Sound Reduction Measures in Production Hall. Adv. Sci. Technol. Res. J. 2017, 11, 220–224. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, X.; Zhang, C.; Xin, F. A Novel Multiscale Porous Composite Structure for Sound Absorption Enhancement. Compos. Struct. 2021, 276, 114456. [Google Scholar] [CrossRef]

- Miturska-Barańska, I.; Rudawska, A.; Doluk, E. Influence of Physical Modification of the Adhesive Composition on the Strength Properties of Aerospace Aluminum Alloy Sheet Adhesive Joints. Materials 2022, 15, 7799. [Google Scholar] [CrossRef] [PubMed]

| Properties | Epidian 5 Epoxy Resin |

|---|---|

| Epoxy number | 0.48–0.52 mol/100 g |

| pH value | approx. 7 |

| Viscosity at 25 °C | 20,000–30,000 mPa·s |

| Density at 20 °C | 1.16 g/cm3 |

| Flash point | 266 °C |

| Auto-ignition temperature | 490 °C |

| Melting point | 30–50 °C |

| Initial boiling point | not indicated—degradation |

| Properties | PAC Curing Agent |

|---|---|

| Viscosity at 25 °C | 10,000–25,000 mPa·s |

| Density at 20 °C | 1.10–1.20 g/cm3 |

| Amine number | 290–360 mg KOH/g |

| Gelling time (example for composition with Epidian 5 at 20 °C) | 180 min |

| Parameter | ZR2 NanoBent |

|---|---|

| Form | cream-colored lamellar powder |

| Water content | ≤3.0% wag. |

| 650 °C roasting loss | 25–30% wag. |

| Swelling in xylene | >20% obj. |

| Vapour absorption of white spirit 48 h | >20% wag. |

| Bulk density | <0.5 g/cm3 |

| Ion exchange capacity CEC of bentonite raw material | min. 80 mmol/100 g dry bentonite raw material |

| Properties | CaCO3 Calcium Carbonate |

|---|---|

| Form | light-grey solid in various sizes: lumps or fine powder |

| pH value | 9.2 (at 25 °C) |

| Temperature melting point | >450 °C (degradation temperature −825 °C) |

| Flammability | non-flammable |

| Limits explosiveness | non-explosive (free of any chemical structures associated with explosive properties) |

| Relative density | 2.711 g/cm3 (at 20°) |

| Solubility in water | 14 mg/dm3 (at 25 °C) |

| Viscosity | not applicable (solid with melting point > 450 °C) |

| Explosive properties | non-explosive (free of any chemical structures associated with explosive properties) |

| Oxidizing properties | has no oxidizing properties (based on the chemical structure, the substance does not contain excess oxygen or any structural group tending to react exothermically with the combustible material) |

| Degradation temperature | 825 °C |

| Bulk weight | (0.7–1.4) 106 g/m3 (at 20 °C) |

| Electrostatic properties | the substance does not generate electrostatic charges |

| Properties | CWZ-22 Activated Carbon |

|---|---|

| Form | solid, dusty black color |

| pH value | about 6 (50 g/L H2O as a suspension, 20 °C) |

| Melting point | no data, sublimation about 3700 °C |

| Explosive limits | lack of data |

| Relative density | approximately 2 g/cm3 |

| Solubility in water | in water: insoluble, in organic solvents: no data |

| Bulk weight | about 400 · 103 g/m3 |

| Epoxy Resin | Curing Agent | Filler | Identification |

|---|---|---|---|

| Epidian 5 (100 g) | PAC (80 g) | - | E5/PAC/100:80 |

| ZR2 NanoBent (1 g) | E5/PAC/ZR2/100:80:1 | ||

| CaCO3 calcium carbonate (5 g) | E5/PAC/CaCO3/100:80:5 | ||

| CWZ-22 activated carbon (20 g) | E5/PAC/CWZ-22/100:80:20 |

| Type of Testing | Shape and Dimensions of Samples, Dimensions in Millimetres |

|---|---|

| Tensile strength test The dump-bell type 1B sample [33] |  |

| Compression strength test Cylindrical sample [34] |  |

| Bending strength test The beam sample, in accordance with ISO 178:2003 standard [35] |  |

| Sound Absorption, in accordance with ISO 10534-2 standard [36] |  |

| Scanning electron microscopy (SEM) | Gold sputtering of 100 × 10 × 4 mm beam samples using Quorum Q150R ES-Spreading Deposition Rate sputtering machine (Quorum, Laughton, UK) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miturska-Barańska, I.; Rudawska, A.; Sobotova, L.; Badida, M.; Olewnik-Kruszkowska, E.; Müller, M.; Hromasová, M. Analysis of Acoustic Absorption Coefficients and Characterization of Epoxy Adhesive Compositions Based on the Reaction Product of Bisphenol A with Epichlorohydrin Modified with Fillers. Materials 2024, 17, 4452. https://doi.org/10.3390/ma17184452

Miturska-Barańska I, Rudawska A, Sobotova L, Badida M, Olewnik-Kruszkowska E, Müller M, Hromasová M. Analysis of Acoustic Absorption Coefficients and Characterization of Epoxy Adhesive Compositions Based on the Reaction Product of Bisphenol A with Epichlorohydrin Modified with Fillers. Materials. 2024; 17(18):4452. https://doi.org/10.3390/ma17184452

Chicago/Turabian StyleMiturska-Barańska, Izabela, Anna Rudawska, Lydia Sobotova, Miroslav Badida, Ewa Olewnik-Kruszkowska, Miroslav Müller, and Monika Hromasová. 2024. "Analysis of Acoustic Absorption Coefficients and Characterization of Epoxy Adhesive Compositions Based on the Reaction Product of Bisphenol A with Epichlorohydrin Modified with Fillers" Materials 17, no. 18: 4452. https://doi.org/10.3390/ma17184452

APA StyleMiturska-Barańska, I., Rudawska, A., Sobotova, L., Badida, M., Olewnik-Kruszkowska, E., Müller, M., & Hromasová, M. (2024). Analysis of Acoustic Absorption Coefficients and Characterization of Epoxy Adhesive Compositions Based on the Reaction Product of Bisphenol A with Epichlorohydrin Modified with Fillers. Materials, 17(18), 4452. https://doi.org/10.3390/ma17184452