Evaluation of Vibration Damping Enhancement in Laminated Aluminum Sheets for Automotive Application

Abstract

1. Introduction

2. Materials

2.1. Fabrication of the Laminated Aluminum Sheets (LAS)

2.2. Automotive Dash Panel with LAS

3. Experiments

3.1. Shaker Vibration Test in a Sheet Specimen

3.2. Impact Hammer Test in an Automotive Dash Panel

4. Results and Discussion

4.1. Vibration Characteristics in a Sheet Specimen

4.2. Vibration Characteristics in an Automotive Dash Panel

5. Summary

- The yield stress, the ultimate tensile stress, the uniform elongation, and the total elongation of the LAS were compared with those of the MAS as the representative material properties. However, the material properties do not show big differences between the two materials.

- For the vibration damping characteristics in a sheet specimen and an automotive dash panel, the automotive dash panel was manufactured with five sequential operations consisting of the draw, the restrike, the piercing, and the trimming process. The overall vibration was reduced in the frequency response function in terms of peak amplitude and damping ratios for the LAS in a sheet specimen and an automotive dash panel. It was confirmed that the LAS has a better noise and vibration damping effect compared to the MAS.

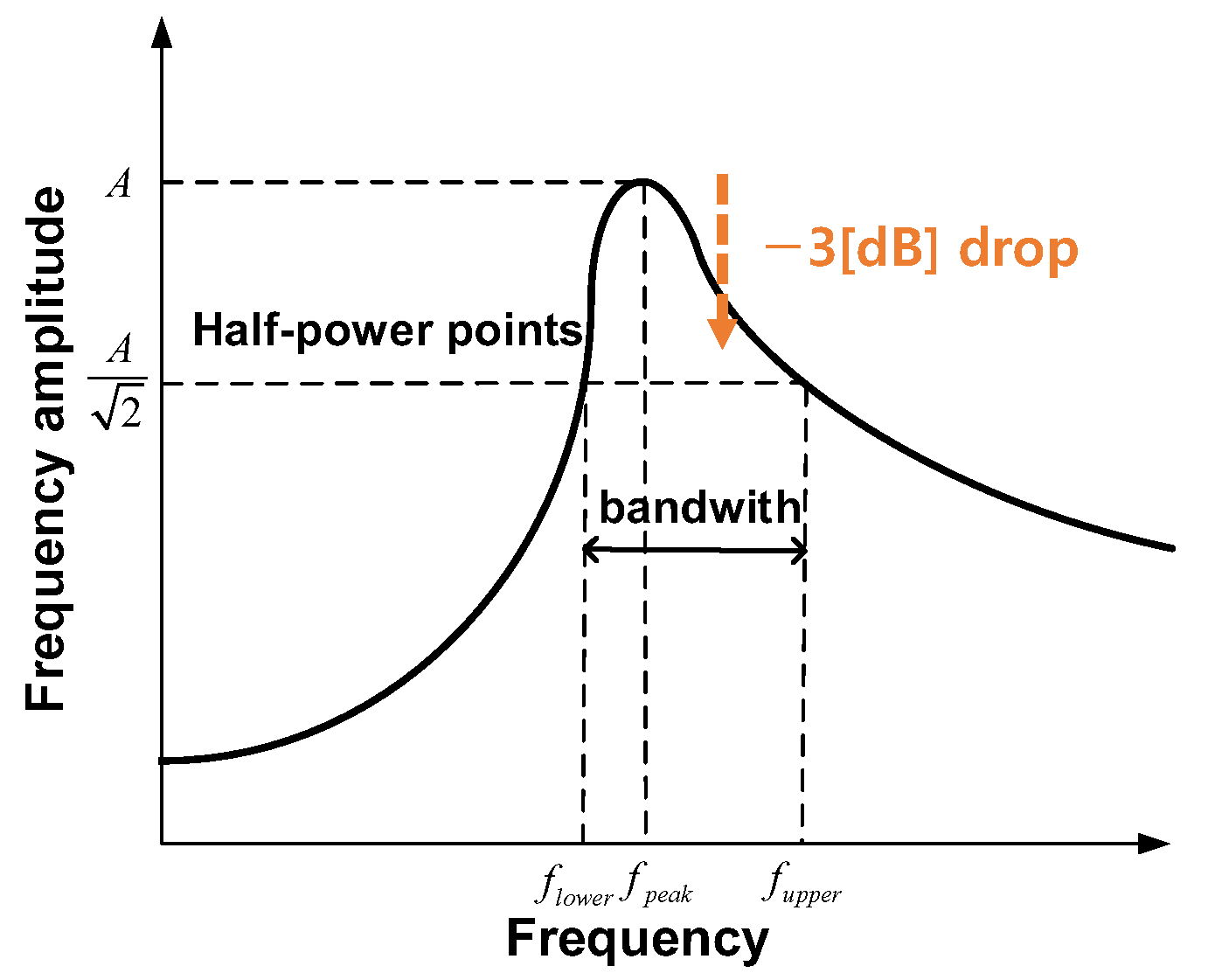

- Based on the definition of the half-power bandwidth method, the calculated damping ratio is proportional to the difference in frequency. As the thickness increases, the frequency increases in width. Hence, thicker material (the MAS) normally shows a higher damping ratio value obtained from the half-power bandwidth method. Although the thickness of the LAS is a little thinner than that of the MAS, the damping ratio is consistently small in the study. The works conclude that the vibration damping characteristics of the LAS are superior to those of the MAS in a sheet specimen and an automotive dash panel. Specifically, the percent change in the damping ratio of a sheet specimen increased from a minimum of 10.45% to a maximum of 1329.52%. In contrast, an automotive dash panel shows the percent change in damping ratios, ranging from a minimum of 29.41% to a maximum of 1369.59%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Burger, R.; Aloe, A. Considerations of vibration fatigue for automotive components. SAE Int. J. Commer. Veh. 2017, 10, 150–158. [Google Scholar] [CrossRef]

- Panza, M.A. A review of experimental techniques for NVH analysis on a commercial vehicle. Energy Procedia 2015, 82, 1017–1023. [Google Scholar] [CrossRef]

- Sobieszczanski-Sobieski, J.; Kodiyalam, S.; Yang, R. Optimization of car body under constraints of noise, vibration, and harshness (NVH), and crash. Struct. Multidiscip. Optim. 2001, 22, 295–306. [Google Scholar] [CrossRef]

- Deulgaonkar, V.; Kallurkar, S.; Mattani, A. Review and Diagnostics of noise and vibrations in automobiles. Int. J. Mod. Eng. Res. (IJMER) 2011, 1, 242–246. [Google Scholar]

- Gloerfelt, X. Noise from automotive components. In Noise from Wall-Bounded Flows; Aerodyn: Indianapolis, IN, USA, 2009; pp. 9–13. [Google Scholar]

- Bharadwaj, S.; Gupta, A.; Narayan, S. A review of various NVH sources of combustion engines. Int. J. Mech. Eng. Autom. 2016, 3, 249–261. [Google Scholar]

- Yu, Y.; Naganathan, N.G.; Dukkipati, R.V. A literature review of automotive vehicle engine mounting systems. Mech. Mach. Theory 2001, 36, 123–142. [Google Scholar] [CrossRef]

- Priede, T. Problems and developments in automotive engine noise research. SAE Trans. 1979, 88, 783–797. [Google Scholar]

- Kuk, J.; Ryu, S.; Lim, D.; Lee, T.; Yu, S. A research on securing initial performance of vibration caused by driveline. Trans. Korean Soc. Automot. Eng. 2017, 25, 360–366. [Google Scholar] [CrossRef]

- Rabia, A.M.; Ghazaly, N.M.; Salem, M.; Abd-El-Tawwab, A.M. Experimental studies of automotive disc brake noise and vibration: A review. Int. J. Mod. Eng. Res. (IJMER) 2013, 3, 199–203. [Google Scholar]

- Yang, S.; Gibson, R. Brake vibration and noise: Reviews, comments, and proposals. Int. J. Mater. Prod. Technol. 1997, 12, 496–513. [Google Scholar]

- Zhu, D.; Yu, X.; Sai, Q.; Wang, S.; Barton, D.; Fieldhouse, J.; Kosarieh, S. Noise and vibration performance of automotive disk brakes with laser-machined M-shaped grooves. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 237, 978–990. [Google Scholar] [CrossRef]

- O’Boy, D.J.; Dowling, A.P. Tyre/road interaction noise—Numerical noise prediction of a patterned tyre on a rough road surface. J. Sound Vib. 2009, 323, 270–291. [Google Scholar] [CrossRef]

- Azizi, Y. Generation mechanisms of tire/road noise, In Automotive Tire Noise and Vibrations: Analysis, Measurement and Simulation; Wang, X., Ed.; Butterworth-Heinemann: Oxford, UK, 2020; pp. 91–114. [Google Scholar]

- Goetchius, G.M. Body structure noise and vibration refinement. In Vehicle Noise and Vibration Refinement; Wang, X., Ed.; Woodhead Publishing: Cambridge, UK, 2010; pp. 351–386. [Google Scholar]

- Burdzik, R.; Konieczny, Ł.; Adamczyk, B. Automatic Control Systems and Control of Vibrations in Vehicles Car. In Telematics—Support for Transport. TST 2014. Communications in Computer and Information Science; Mikulski, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; Volume 471, pp. 120–129. [Google Scholar]

- Rao, M.D. Recent applications of viscoelastic damping for noise control in automobiles and commercial airplanes. J. Sound Vib. 2003, 262, 457–474. [Google Scholar] [CrossRef]

- Jones, D.I.G. Handbook of Viscoelastic Vibration Damping; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Zhou, X.; Yu, D.; Shao, X.; Zhang, S.; Wang, S. Research and applications of viscoelastic vibration damping materials: A review. Compos. Struct. 2016, 136, 460–480. [Google Scholar] [CrossRef]

- Flügge, W. Viscoelastic models. In Viscoelasticity; Springer: Berlin/Heidelberg, Germany, 1975; pp. 4–33. [Google Scholar]

- Maxwell, J.C., IV. On the dynamical theory of gases. Philos. Trans. R. Soc. Lond. 1867, 157, 49–88. [Google Scholar]

- Murase, M.; Mukaihara, F.; Izawa, M.; Naruse, Y.; Ichida, T. Development of Vibration Damping Steel Sheets for Automobile Oil Pans; SAE Technical Paper; SAE: Warrendale, PA, USA, 1993; ISSN 0148-7191. [Google Scholar]

- Hiroshi, E.; Mizuo, E.; Yoshimasa, Z. The development of vibration damping steel sheet for automotive use. SAE Trans. 1989, 98, 670–677. [Google Scholar]

- Sakai, K.; Fujiwara, H.; Sato, M. Damping Composite Sheet for Noise Control; SAE Technical Paper; SAE: Warrendale, PA, USA, 1982; ISSN 0148-7191. [Google Scholar]

- Oberle, H.; Commaret, C.; Magnaud, R.; Minier, C.; Pradere, G. Optimizing resistance spot welding parameters for vibration damping steel sheets. Weld. J. 1998, 77, 8-s–13-s. [Google Scholar]

- Kim, J.-K.; Yu, T.-X. Forming and failure behaviour of coated, laminated and sandwiched sheet metals: A review. J. Mater. Process. Technol. 1997, 63, 33–42. [Google Scholar] [CrossRef]

- Chen, Y.; Hsu, T.; Chen, S. Vibration damping characteristics of laminated steel sheet. Metall. Trans. A 1991, 22, 653–656. [Google Scholar] [CrossRef]

- Sarlin, E.; Liu, Y.; Vipploa, M.; Zogg, M.; Ermanni, P.; Vourinen, J.; Lepisto, T. Vibration damping properties of steel/rubber/composite hybrid structures. Compos. Struct. 2012, 94, 3327–3335. [Google Scholar] [CrossRef]

- Han, S.; Yu, W.R. Effect of interfacial properties on the damping performance of steel–polymer sandwich cantilever beam composites. J. Vib. Control. 2023, 29, 400–410. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Yu, R.P.; Ren, J.W.; Zhang, Q.C.; Zhao, Z.Y.; Chang, Y.N.; Bin, H.; Lu, T.J. Enhanced vibration and damping characteristics of novel corrugated sandwich panels with polyurea-metal laminate face sheets. Compos. Struct. 2020, 251, 112591. [Google Scholar] [CrossRef]

- Liu, J.; Liu, W.; Xue, W. Forming limit diagram prediction of AA5052/polyethylene/AA5052 sandwich sheets. Mater. Des. 2013, 46, 112–120. [Google Scholar] [CrossRef]

- Kim, K.J.; Rhee, M.H.; Choi, B.-I.; Kim, C.-W.; Sung, C.-W.; Han, C.-P.; Kang, K.-W.; Won, S.-T. Development of application technique of aluminum sandwich sheets for automotive hood. Int. J. Precis. Eng. Manuf. 2009, 10, 71–75. [Google Scholar] [CrossRef]

- Kim, K.J.; Kim, C.-W.; Choi, B.-I.; Sung, C.W.; Kim, H.Y.; Won, S.-T.; Ryu, H.-Y. Formability of aluminum 5182-polypropylene sandwich sheet for automotive application. J. Solid Mech. Mater. Eng. 2008, 2, 574–581. [Google Scholar] [CrossRef]

- Shin, K.S.; Kim, K.J.; Choi, S.-W.; Rhee, M.H. Mechanical properties of aluminum/polypropylene/aluminum sandwich sheets. Met. Mater. 1999, 5, 613–618. [Google Scholar] [CrossRef]

- Park, H.; Kim, S.-J.; Lee, J.; Kim, D. Material characterization of high strength sound-deadening sheets and its application on a square cup drawing simulation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 651, 012037. [Google Scholar] [CrossRef]

- Park, H.; Kim, S.-J.; Lee, J.; Kim, J.H.; Kim, D. Characterization of the mechanical properties of a high-Strength laminated vibration damping steel sheet and their application to formability prediction. Met. Mater. Int. 2019, 25, 1326–1340. [Google Scholar] [CrossRef]

- ASTM D1002; Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal). ASTM: West Conshohocken, PA, USA, 2010.

- Irvine, T. The half power bandwidth method for damping calculation. In Vibrationdata; Tom Irvine: Madison, AL, USA, 2005; pp. 1–8. [Google Scholar]

- Papagiannopoulos, G.A.; Hatzigeorgiou, G.D. On the use of the half-power bandwidth method to estimate damping in building structures. Soil Dyn. Earthq. Eng. 2011, 31, 1075–1079. [Google Scholar] [CrossRef]

- Yerrawar, R.; Arakerimath, R. Experimental investigations of damping characteristic for MR strut by half-power bandwidth method. J. Meas. Eng. 2018, 6, 163–172. [Google Scholar] [CrossRef]

- Thomson, W. Theory of Vibration with Application, 4th ed.; Chapman and Hal: London, UK, 1993. [Google Scholar]

- Hujare, P.P.; Sahasrabudhe, A.D. Experimental Investigation of Damping Performance of Viscoelastic Material Using Constrained Layer Damping Treatment. Procedia Mater. Sci. 2014, 5, 726–733. [Google Scholar] [CrossRef]

- Macioce, P. Viscoelastic damping 101. Sound Vib. Mag. 2003, 4, 4–5. [Google Scholar]

- Wang, X. Vehicle Noise and Vibration Refinement; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

| Materials | Direction | Yield Stress (MPa) | Ultimate Tensile Stress (MPa) | Uniform Elongation (%) | Total Elongation (%) |

|---|---|---|---|---|---|

| MAS | RD | 95.8 | 204.2 | 16.5 | 19.7 |

| DD | 94.9 | 198.2 | 20.2 | 27.1 | |

| TD | 96.5 | 195.7 | 21.3 | 25.3 | |

| LAS | RD | 94.8 | 202.6 | 18.9 | 20.3 |

| DD | 93.9 | 195.9 | 25.3 | 27.3 | |

| TD | 93.9 | 194.3 | 22.1 | 25.3 |

| Major Peaks | Frequency (Hz) | Peak Amplitude (dB) | Damping Ratio | δ (%) | |||

|---|---|---|---|---|---|---|---|

| MAS | LAS | MAS | LAS | MAS | LAS | ||

| 1st | 185.00 | 167.50 | 55.04 | 52.78 | 0.0405 | 0.0448 | 10.45 |

| 2nd | 985.00 | 897.50 | 64.51 | 48.80 | 0.0076 | 0.0348 | 357.29 |

| 3rd | 2565.00 | 2362.50 | 58.66 | 43.05 | 0.0058 | 0.0836 | 1329.52 |

| Major Peaks | Frequency (Hz) | Peak Amplitude (dB) | Damping Ratio | δ (%) | |||

|---|---|---|---|---|---|---|---|

| MAS | LAS | MAS | LAS | MAS | LAS | ||

| P1 | |||||||

| 1st | 12.70 | 11.33 | 43.47 | 34.08 | 0.0346 | 0.0448 | 29.41 |

| 2nd | 56.20 | 50.54 | 29.54 | 25.07 | 0.0122 | 0.0222 | 81.97 |

| 3rd | 77.93 | 71.09 | 35.33 | 16.76 | 0.0053 | 0.0227 | 326.27 |

| 4th | 106.89 | 95.36 | 44.26 | 23.52 | 0.0023 | 0.0197 | 762.98 |

| P2 | |||||||

| 1st | 13.43 | 11.43 | 47.69 | 40.4 | 0.0164 | 0.0278 | 69.51 |

| 2nd | 56.2 | 50.63 | 46.91 | 40.96 | 0.0109 | 0.0207 | 89.91 |

| 3rd | 78.08 | 72.22 | 38.43 | 19.61 | 0.0050 | 0.0223 | 345.7 |

| 4th | 106.93 | 91.36 | 35.45 | 19.03 | 0.0025 | 0.0369 | 1369.59 |

| P3 | |||||||

| 1st | 12.7 | 11.38 | 45.72 | 40.47 | 0.0212 | 0.03 | 41.51 |

| 2nd | 56.3 | 50.73 | 42.35 | 35.9 | 0.0108 | 0.025 | 131.48 |

| 3rd | 78.03 | 70.85 | 49.54 | 31.61 | 0.0050 | 0.0362 | 623.05 |

| 4th | 114.99 | 106.06 | 42.83 | 24.79 | 0.0030 | 0.0239 | 704.77 |

| P4 | |||||||

| 1st | 13.48 | 11.38 | 44.28 | 38.68 | 0.0163 | 0.0279 | 71.17 |

| 2nd | 56.2 | 50.63 | 42.48 | 38.54 | 0.0104 | 0.0203 | 95.19 |

| 3rd | 78.08 | 71.39 | 42.68 | 24.58 | 0.0050 | 0.0215 | 329.71 |

| 4th | 114.99 | 107.81 | 42.42 | 18.99 | 0.0030 | 0.0177 | 495.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, J.-H.; Park, H.; Kim, S.-J.; Kim, D. Evaluation of Vibration Damping Enhancement in Laminated Aluminum Sheets for Automotive Application. Materials 2024, 17, 4421. https://doi.org/10.3390/ma17174421

Hong J-H, Park H, Kim S-J, Kim D. Evaluation of Vibration Damping Enhancement in Laminated Aluminum Sheets for Automotive Application. Materials. 2024; 17(17):4421. https://doi.org/10.3390/ma17174421

Chicago/Turabian StyleHong, Jong-Hwa, Hyeonil Park, Se-Jong Kim, and Daeyong Kim. 2024. "Evaluation of Vibration Damping Enhancement in Laminated Aluminum Sheets for Automotive Application" Materials 17, no. 17: 4421. https://doi.org/10.3390/ma17174421

APA StyleHong, J.-H., Park, H., Kim, S.-J., & Kim, D. (2024). Evaluation of Vibration Damping Enhancement in Laminated Aluminum Sheets for Automotive Application. Materials, 17(17), 4421. https://doi.org/10.3390/ma17174421