A Model to Account for the Effects of Load Ratio and Hydrogen Pressure on the Fatigue Crack Growth Behavior of Pressure Vessel Steels

Abstract

:1. Introduction and Background

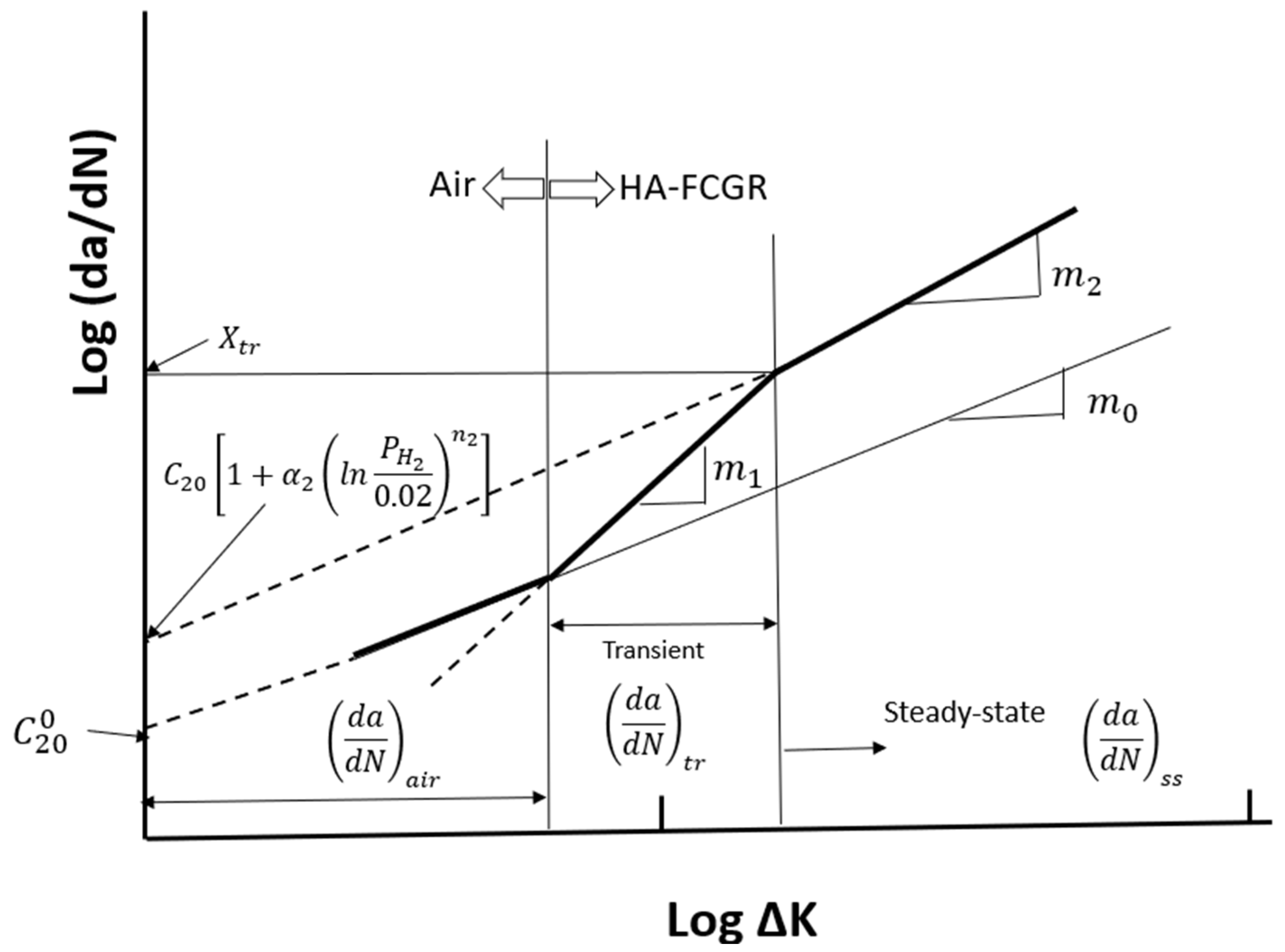

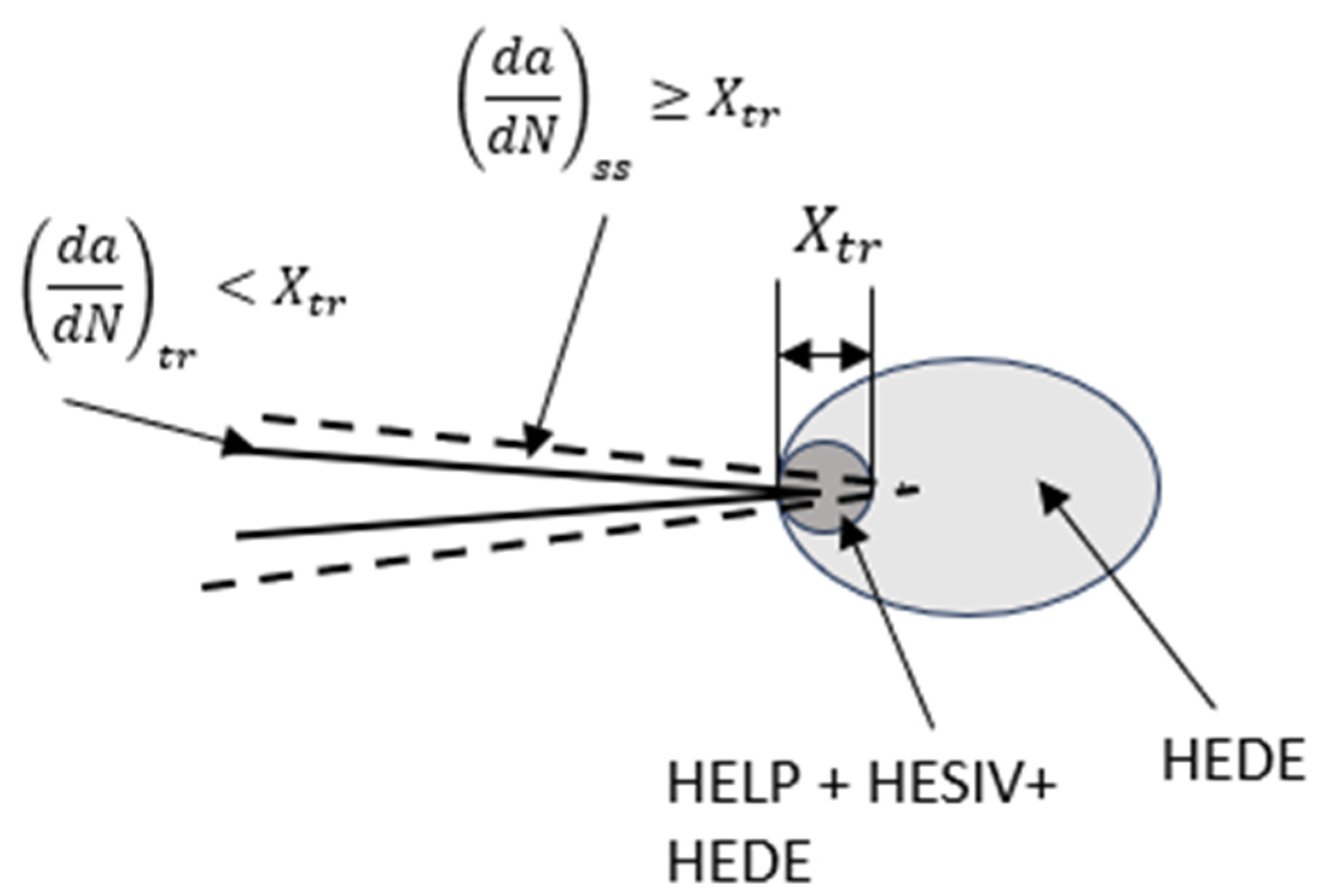

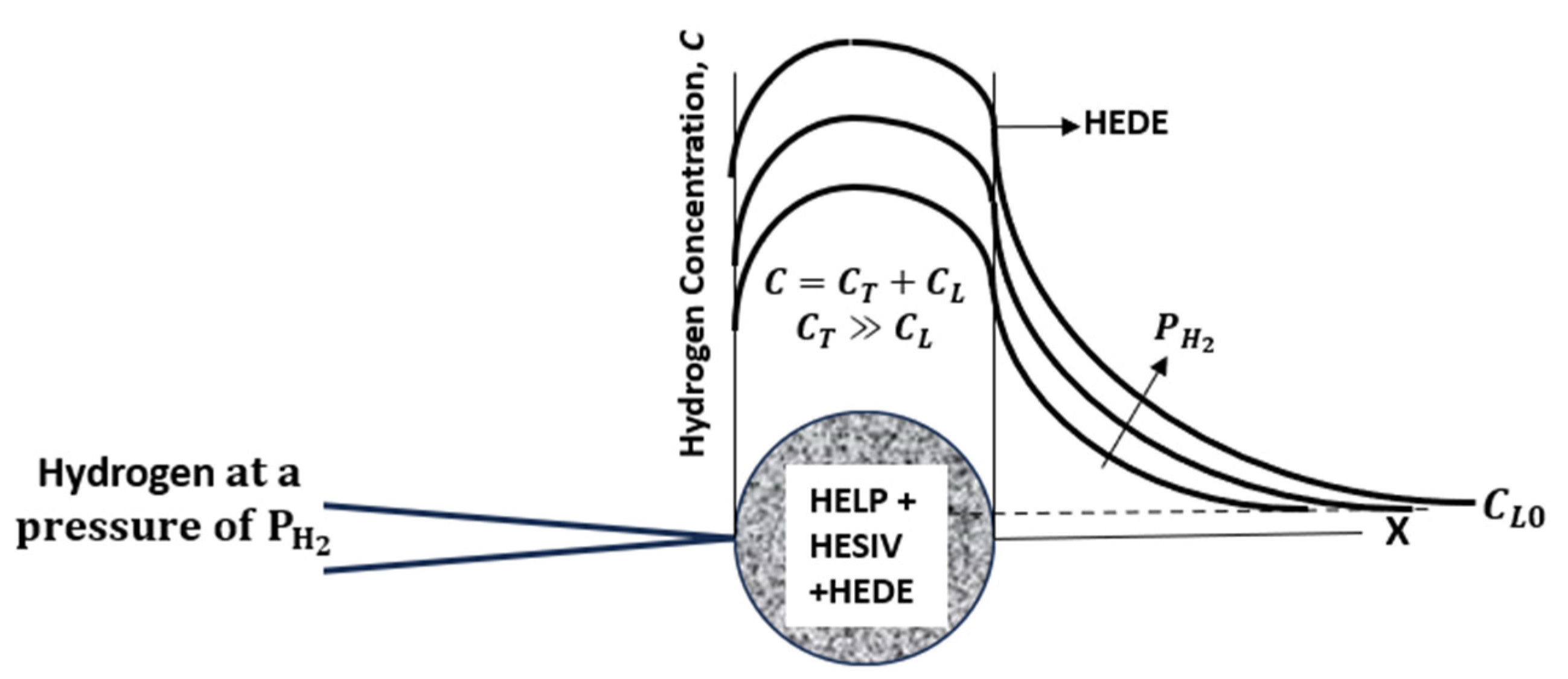

2. Model Development and Evaluation

2.1. Pressure Vessel Steels

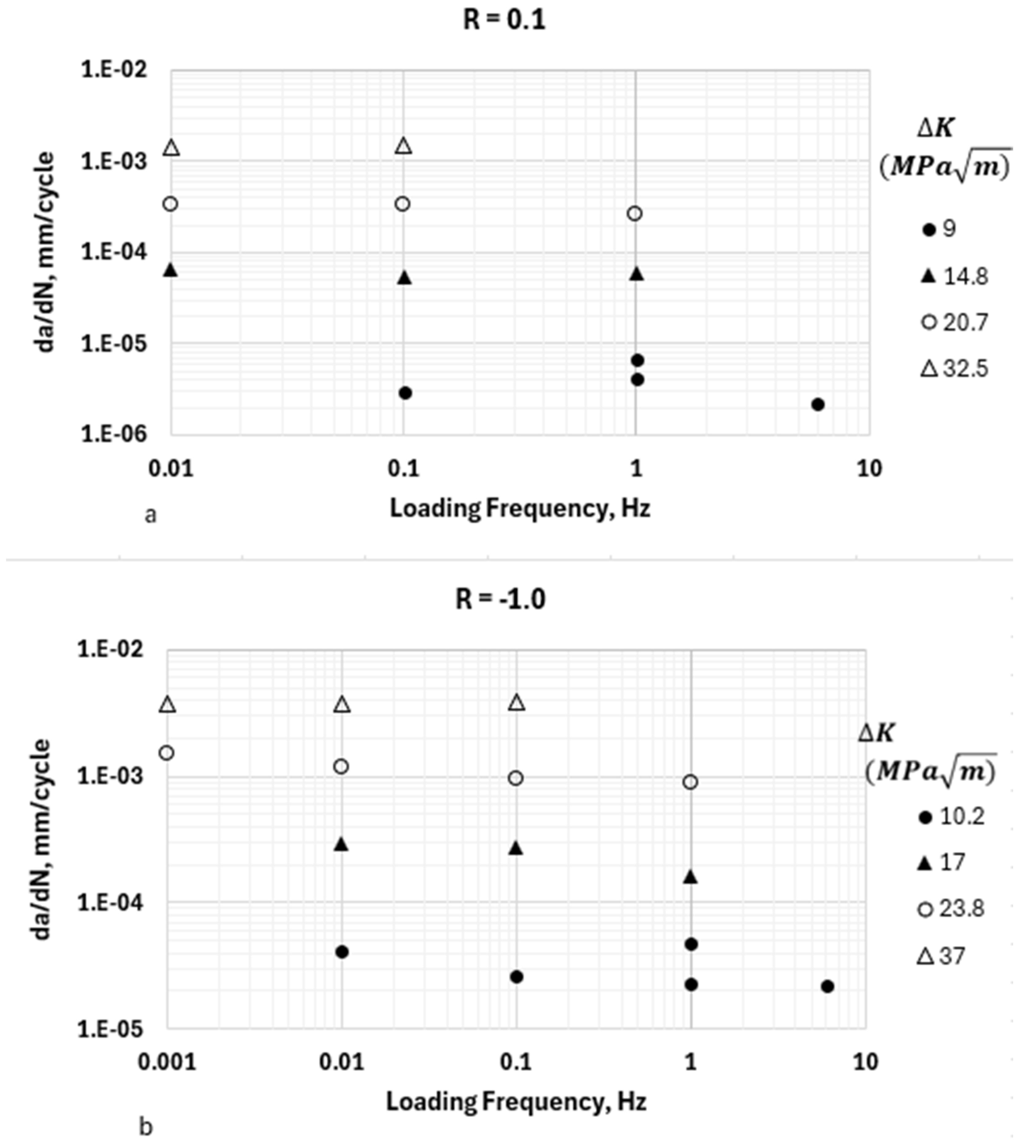

2.2. The Effects of the Loading Frequency on the HA–FCGR Behavior

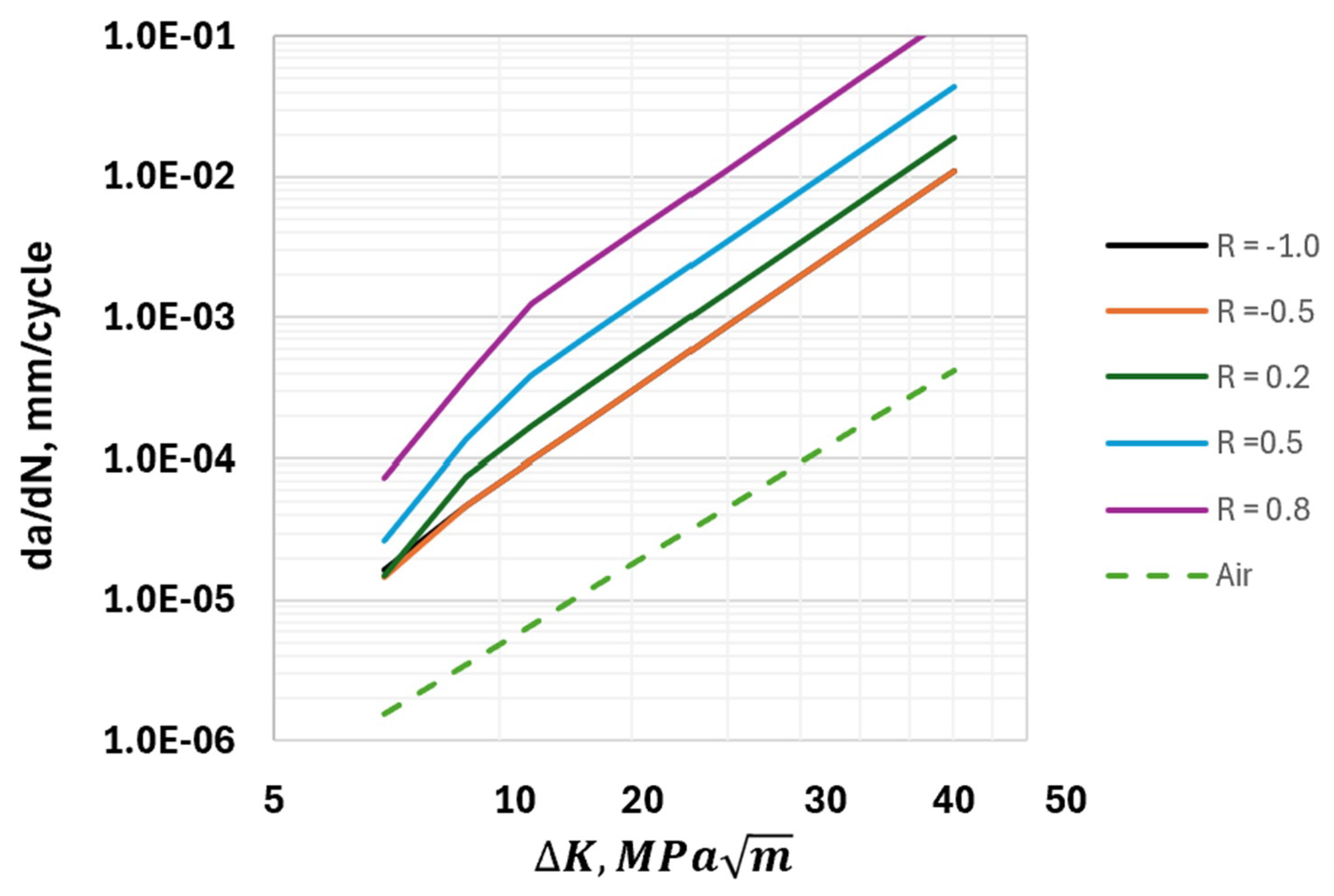

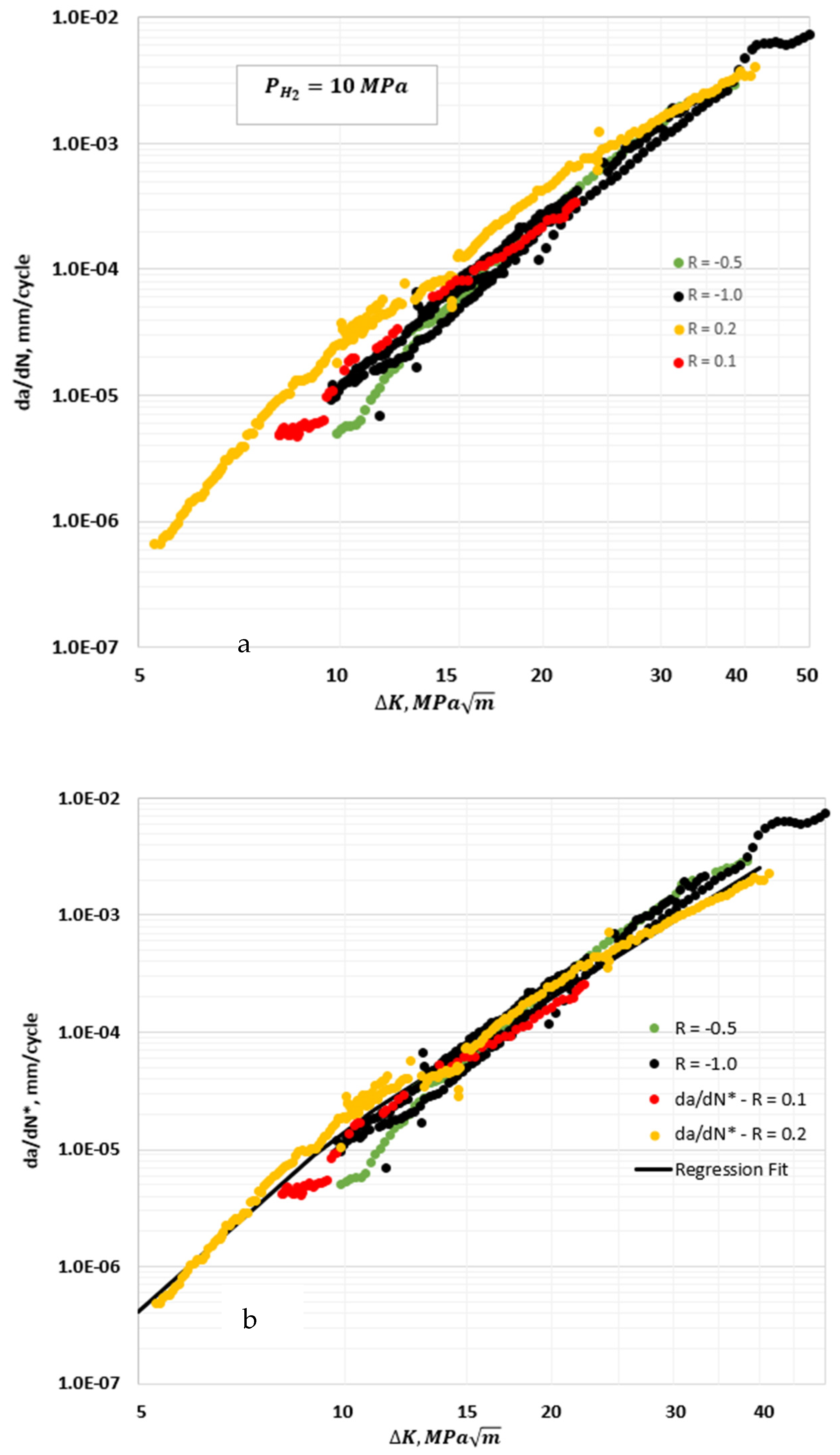

2.3. The Effects of Load Ratio R on the HA–FCGR

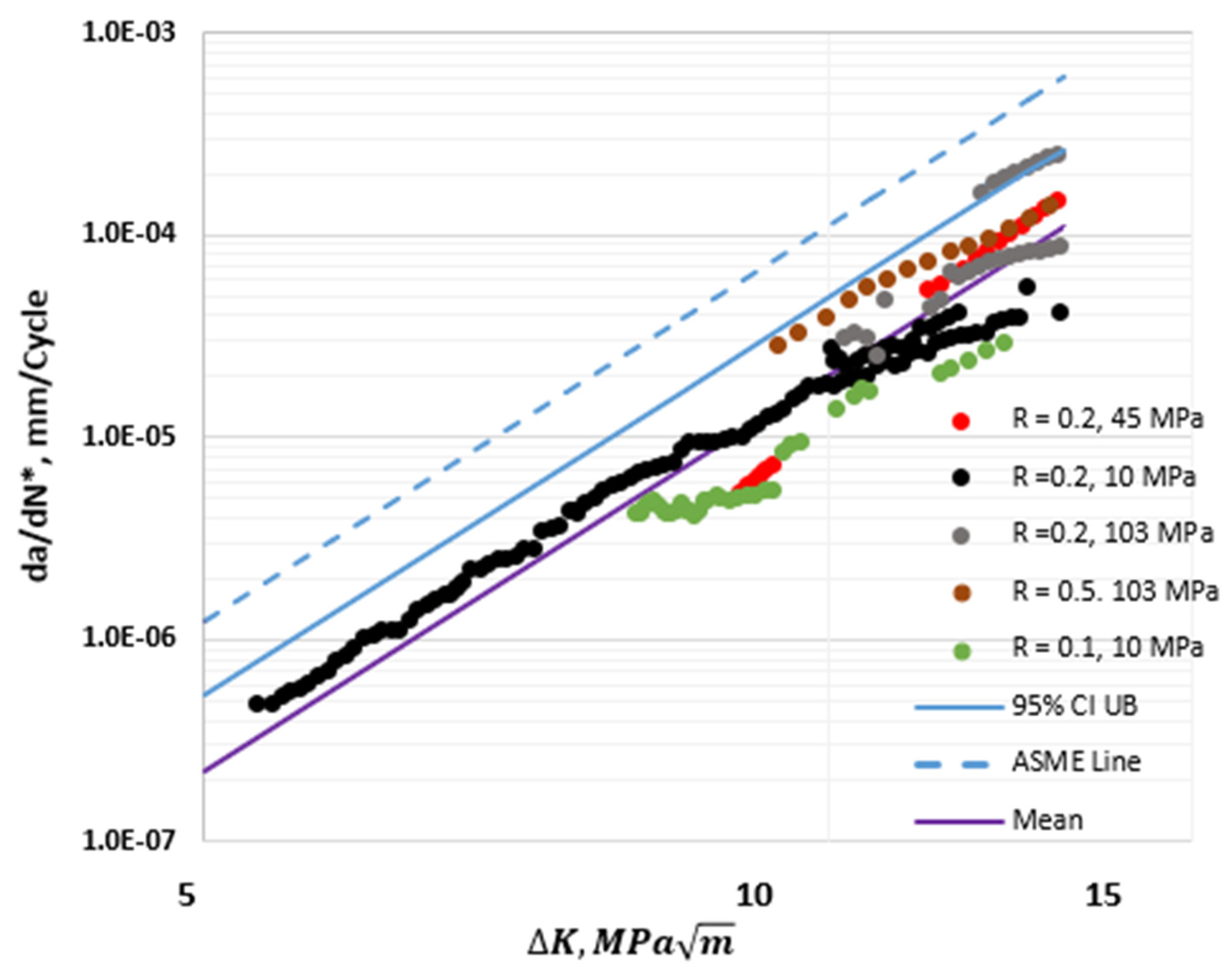

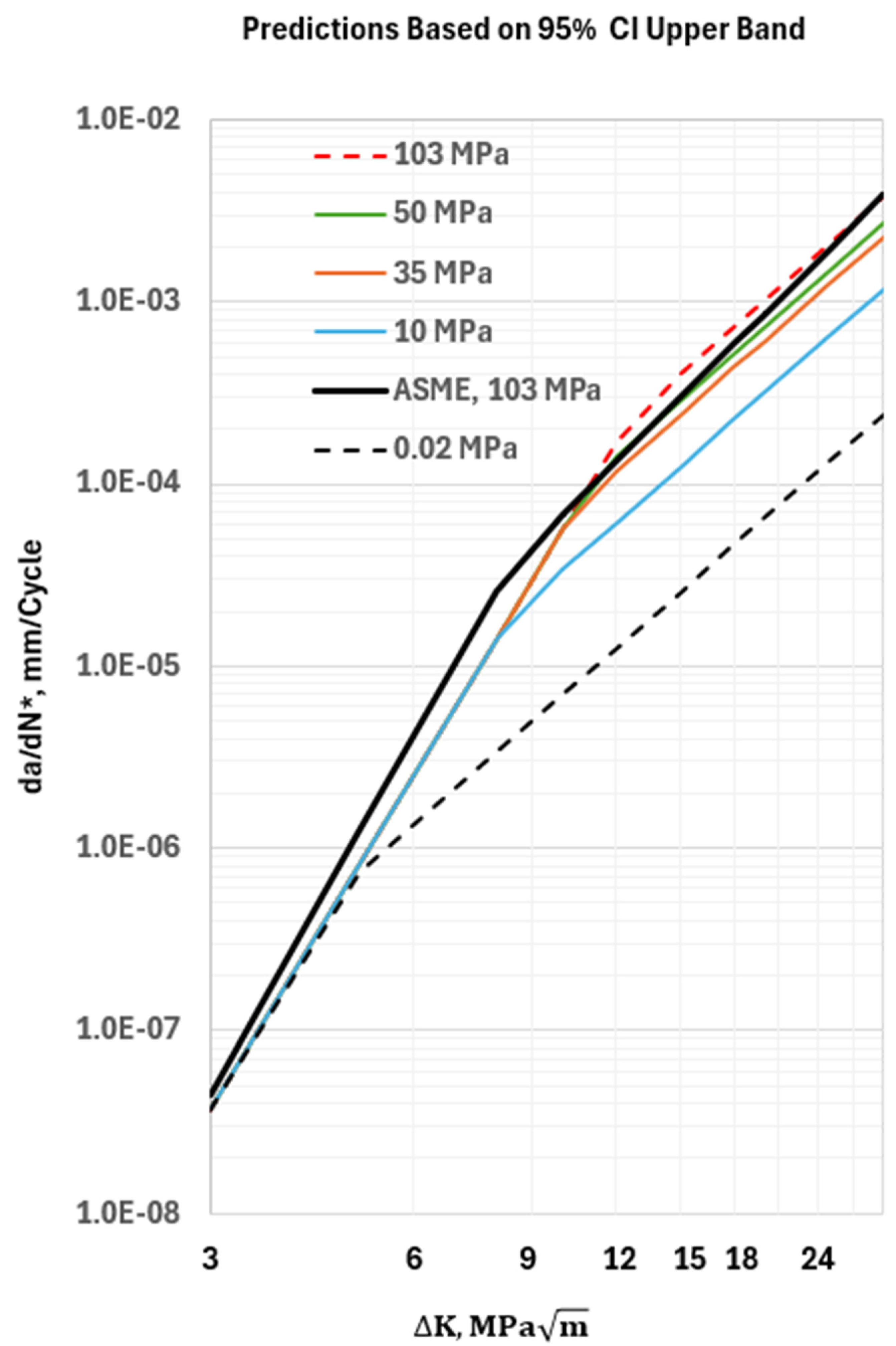

2.4. Effects of Hydrogen Pressure on the HA–FCGR Behavior

3. Discussion of the Model

4. Summary and Conclusions

- The proposed model does an excellent job of representing the HA–FCGR data on pressure vessel steels obtained over a wide range of load ratios and hydrogen pressures.

- The model assumes that the effects of hydrogen pressure and load ratio on the HA–FCGR behavior are separable and the data over a wide range, i.e., and MPa, supports this assumption.

- A load-ratio-compensated HA–FCGR da/dN* was defined, which allows for data at different load ratios to be included in obtaining the model constants related to hydrogen pressure, thereby increasing the fidelity of the model.

- The HA–FCGR behavior at negative load ratios for a hydrogen pressure of 10 MPa was considered from a previous study in formulating the model. The practice of not including the negative loads in the estimation of ΔK was supported by the HA–FCGR data at R = −1 and −0.5. The approximated HA–FCGR behavior at R = 0 using the model was shown to represent the behavior at all negative load ratios.

- The HA–FCGR behavior in the transient regime did not show systematic variations due to hydrogen pressure. Higher data scatter in the HA–FCGR was observed in the transition region between the transient and steady-state regions.

- The mean values and the 95% confidence interval values for the model constants were estimated for use in the structural integrity assessments. The predicted crack growth rates from the model can reduce the conservatism of the model constants recommended in the current version of the ASME Code.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Tang, T.Z.; Sripragash, L.; Narasimhachary, S.B.; Saxena, A. A Model for Estimating the Autofrettage Pressure and Residual Stresses in Walls of Type 2 Pressure Vessels. In Proceedings of the ASME 2023 Pressure Vessel and Piping Conference, PVP 2023-105506, Atlanta, GA, USA, 16–21 July 2023. [Google Scholar]

- San Marchi, C.; Ronevich, J.; Bortot, P.; Wada, Y.; Felbaum, J.; Rana, M. Technical Basis for Master Curve for Fatigue Crack Growth of Ferritic Steels in High-Pressure Hydrogen in ASME Section VIII-3 Code. In Proceedings of the ASME Pressure Vessels and Piping Conference, PVP 2019, PVP 2019-93907, San Antonio, TX, USA, 14–19 July 2019. [Google Scholar]

- Ronevich, J.; San Marchi, C.; Nibur, K.A.; Bortot, P.; Bassanini, G.; SILEO, M. Measuring fatigue crack growth behavior of ferritic steels near threshold in high-pressure hydrogen gas. In Proceedings of the ASME 2020 Pressure Vessels and Piping Conference, PVP2020-21263, Minneapolis, MN, USA, 19–24 July 2020. [Google Scholar]

- San Marchi, C.; Ronevich, J.A. Fatigue and Fracture of Pipeline Steels in High-Pressure Hydrogen. In Proceedings of the ASME 2022 Pressure Vessel and Piping Conference, PVP 2022-84757, Las Vegas, NV, USA, 17–22 July 2022. [Google Scholar]

- Amaro, R.L.; Rustagi, N.; Findley, K.O.; Drexler, E.S.; Slifka, A.J. Modeling the Fatigue Crack Growth of X-100 Pipeline Steel in Gaseous Hydrogen. Int. J. Fatigue 2014, 50, 262–271. [Google Scholar] [CrossRef]

- Slifka, A.J.; Drexler, E.S.; Nanninga, N.E.; Levy, Y.S.; McCloskey, D.; Amaro, R.L.; Stevenson, A.E. Fatigue Crack Growth of Pipeline Steels in Pressurized Hydrogen Environment. Corros. Sci. 2014, 79, 313–321. [Google Scholar] [CrossRef]

- Saxena, A.; Findley, K.O. Modelling the Effects of Hydrogen Pressure of the Fatigue Crack Growth Behavior of SA372 Pressure Vessel Steels. In Proceedings of the ASME 2022 Pressure Vessels and Piping Conference, PVP 2022-83958, Las Vegas, NV, USA, 17–22 July 2022. [Google Scholar]

- Koch, G.H. Stress corrosion cracking and hydrogen embrittlement. In ASM Handbook; Lampman, S.E., Ed.; Fatigue and Fracture; ASM International: Metals Park, OH, USA, 1996; Volume 19, pp. 483–506. [Google Scholar]

- Pao, P.S. Mechanisms of corrosion fatigue. In ASM Handbook; Lampman, S.E., Ed.; Fatigue and Fracture; ASM International: Metals Park, OH, USA, 1996; Volume 19, pp. 185–192. [Google Scholar]

- Birnbaum, H.K.; Sofronis, P. Hydrogen Enhanced Localized Plasticity—A Mechanism for Hydrogen Related Fracture. Mater. Sci. Eng. 1994, A176, 191–202. [Google Scholar] [CrossRef]

- Gangloff, R.P. Hydrogen assisted cracking in high strength alloys. In Comprehensive Structural Integrity; Milne, I., Ritchie, R.O., Karihaloo, B., Petit, J., Scott, P., Eds.; Elsevier Science: New York, NY, USA, 2003; Volume 6, pp. 31–101. [Google Scholar]

- Somerday, B.P.; Sofronis, P.; Nibur, K.A.; San Marchi, C.; Kirchheimer, R. Elucidating the variables affecting accelerated fatigue crack growth of steels in hydrogen gas with low oxygen concentrations. Acta Mater. 2013, 61, 6153–6170. [Google Scholar] [CrossRef]

- Li, X.; Ma, X.; Zhang, J.A.; Kiyama, E.A.; Wang, Y.; Song, X. Review of Hydrogen Embrittlement in Metals: Hydrogen Diffusion, Hydrogen Characterization, Hydrogen Embrittlement Mechanism and Prevention. Acta Metall. Sin. 2020, 23, 759–773. [Google Scholar] [CrossRef]

- Liu, M.; Yu, H.; Ding, Y.; Wang, G.; Olden, V.; Alvaro, A.; He, J.; Zhang, Z. A Predictive Model Unifying Hydrogen Enhanced Plasticity and Decohesion. Scr. Met. 2022, 215, 114707. [Google Scholar]

- Fernandez-Dez-Souza, R.; Betegon, C.; Martinez–Paneda, E. Analysis of Influence of Microstructural Traps on Hydrogen Assisted Fatigue. Acta Mater. 2020, 199, 201–202. [Google Scholar]

- Macarde, A.; Artamanov, M.; Matsuoka, J.; Furtado, J. Effects of hydrogen pressure and test frequency on fatigue crack growth properties of Ni-Cr-Mo candidate steel candidate for a storage cylinder of a 70 MPa H2 filling station. Eng. Fract. Mech. 2011, 78, 3196–3211. [Google Scholar]

- Saxena, A.; Nibur, K.A.; Prakash, A. Applications of Fracture Mechanics in Assessing Structural Integrity of Hydrogen Storage Systems. Eng. Fract. Mech. 2018, 187, 368–380. [Google Scholar] [CrossRef]

- E647-15; Standard Test Method for Measurement of Fatigue Crack Growth Rates. American Society for Testing and Materials, ASTM: Conshohocken, PA, USA, 2015.

- Somerday, B.P.; Campbell, J.A.; Lee, K.L.; Ronevich, J.A.; San Marchi, C. Enhancement safety of hydrogen containment components through materials testing under in-service conditions. Int. J. Hydrogen Energy 2017, 42, 7314–7321. [Google Scholar] [CrossRef]

- ASME BPVC Code Case 2938-1; Hydrogen Crack Growth Rate Constants, Threshold Stress Intensity Factor KIH, and Critical Crack Size Requirements for SA 372 and SA723 Steels Section VIII, Div 3. ASME: New York, NY, USA, 2021.

- Begley, M.R.; Begley, J.A.; Landis, C.M. Continuum mechanics modeling of hydrogen embrittlement. In Gaseous Hydrogen Embrittlement of Materials in Energy Technology, Volume 2: Mechanisms, Modeling, and Future Developments; Gangloff, R.P., Somerday, B.P., Eds.; Woodhead Publishing Ltd.: Cambridge, MA, USA, 2012; pp. 286–325. [Google Scholar]

- Sieverts, A. The Absorption of Gases in Metals. Z. Met. 1929, 21, 37–46. [Google Scholar]

| Element | C | Mn | P | S | Ni | Si | Cr | Mo | Cu | Al | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ASME SA-372 Gr J Class 70 | 0.35–0.50 | 0.75–1.05 | <0.025 | <0.025 | - | 0.15–0.35 | 0.80–1.15 | 0.15–0.25 | - | - | Bal |

| Material | 0.2% Yield Strength, MPa | Tensile Strength, MPa | % Elongation |

|---|---|---|---|

| SA-372, Grade J Class 70 Standard | 482.5 Min | 827–930 | 18 Min |

| PH2 = 103 MPa | ||||||||

| Range of R | Transient Regime | Steady-State Regime | ||||||

| C10 | CH1 | m1 | C20 | CH2 | m2 | |||

| da/dN in in/cycle, ∆K in | da/dN in mm/cycle, ∆K in | da/dN in in/cycle, ∆K in | da/dN in mm/cycle, ∆K in | |||||

| 2.54 × 10−12 | 3.5 × 10−11 | 0.43 | 6.5 | 8.34 × 10−10 | 1.5 × 10−8 | 2.0 | 3.66 | |

| 0 | 0 | |||||||

| PH2 = 10 MPa | ||||||||

| 5.83 × 10−12 | 9 × 10−11 | 0.43 | 5.23 | 1.68 × 10−10 | 3 × 10−9 | 2.0 | 3.7 | |

| 0 | 0 | |||||||

| CH1 | CH2 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R ≥ 0 | R ≤ 0 | R ≥ 0 | R ≤ 0 | |||||||

| Mean | 2.0 × 10−11 | 6.15 | 0.43 | 0 | 2.94 × 10−9 | 3.219 | 2.0 | 0 | 4.2 | 0.0018 |

| 95% CI UB | 3.94 × 10−11 | 6.15 | 0.43 | 0 | 4.21 × 10−9 | 3.219 | 2.0 | 0 | 4.2 | 0.0018 |

| 95% CI LB | 1.01 × 10−11 | 6.15 | 0.43 | 0 | 2.05 × 10−9 | 3.219 | 2.0 | 0 | 4.2 | 0.0018 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saxena, A.; Findley, K.O. A Model to Account for the Effects of Load Ratio and Hydrogen Pressure on the Fatigue Crack Growth Behavior of Pressure Vessel Steels. Materials 2024, 17, 4308. https://doi.org/10.3390/ma17174308

Saxena A, Findley KO. A Model to Account for the Effects of Load Ratio and Hydrogen Pressure on the Fatigue Crack Growth Behavior of Pressure Vessel Steels. Materials. 2024; 17(17):4308. https://doi.org/10.3390/ma17174308

Chicago/Turabian StyleSaxena, Ashok, and Kip O. Findley. 2024. "A Model to Account for the Effects of Load Ratio and Hydrogen Pressure on the Fatigue Crack Growth Behavior of Pressure Vessel Steels" Materials 17, no. 17: 4308. https://doi.org/10.3390/ma17174308

APA StyleSaxena, A., & Findley, K. O. (2024). A Model to Account for the Effects of Load Ratio and Hydrogen Pressure on the Fatigue Crack Growth Behavior of Pressure Vessel Steels. Materials, 17(17), 4308. https://doi.org/10.3390/ma17174308