Natural Fiber-Reinforced Composite Incorporated with Anhydride-Cured Epoxidized Linseed-Oil Resin and Atmospheric Pressure Plasma-Treated Flax Fibers

Abstract

:1. Introduction

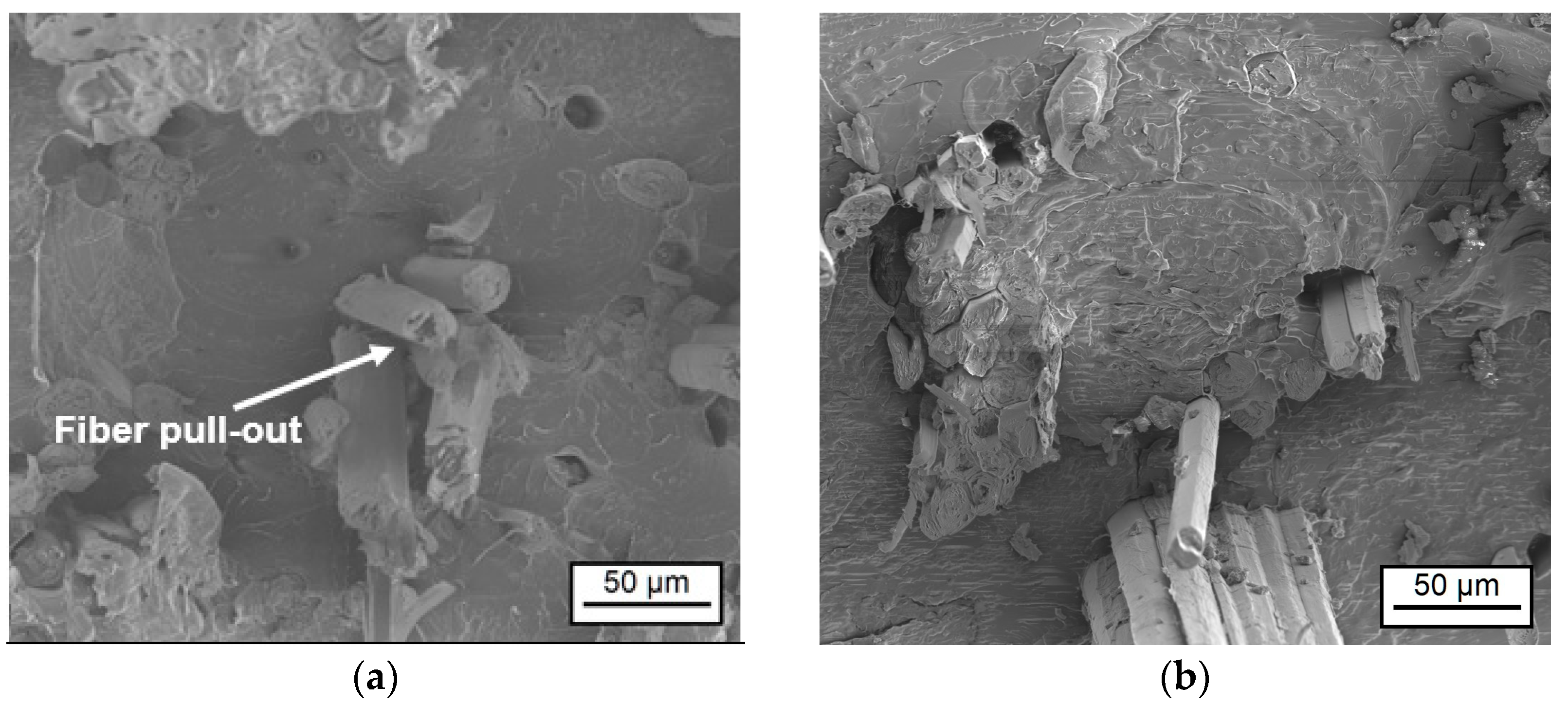

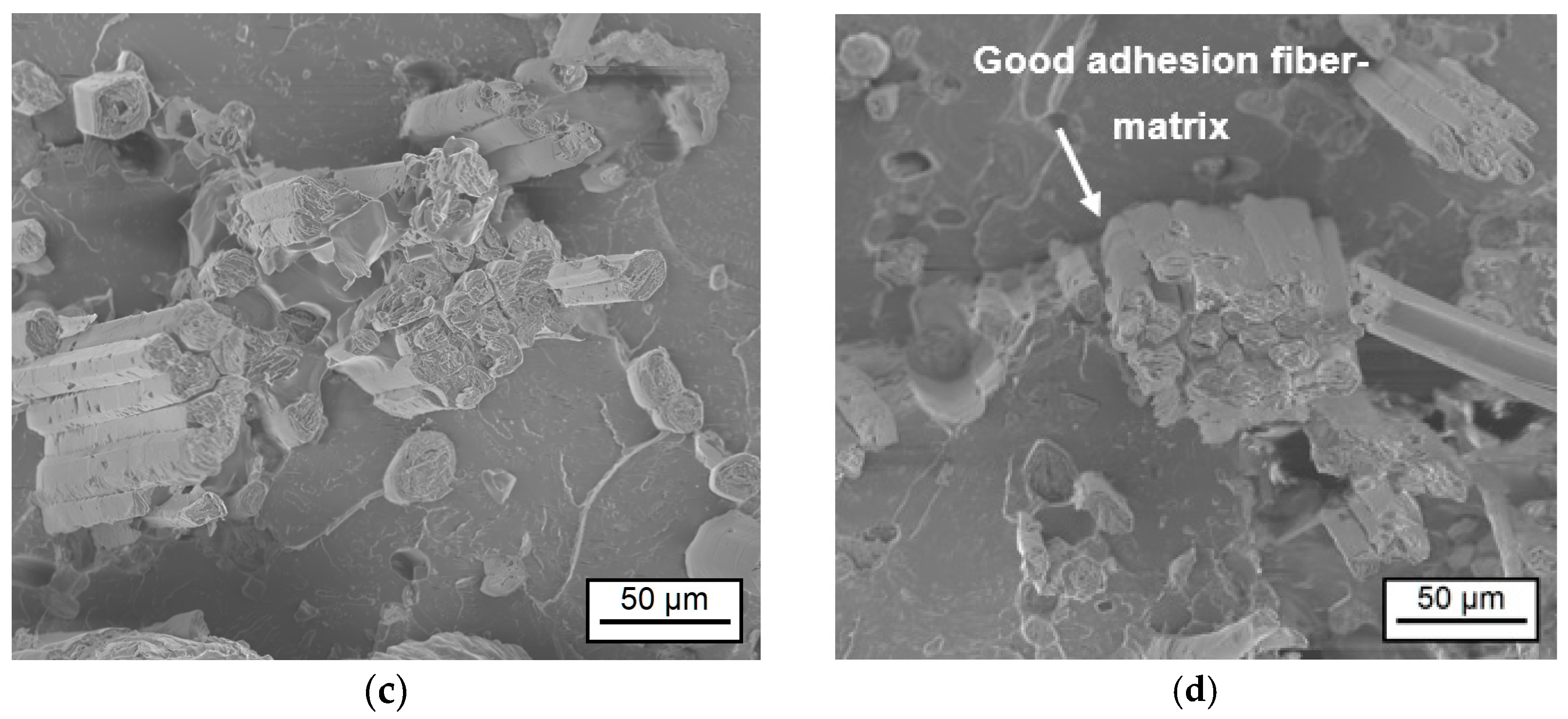

2. Materials and Methods

2.1. Materials

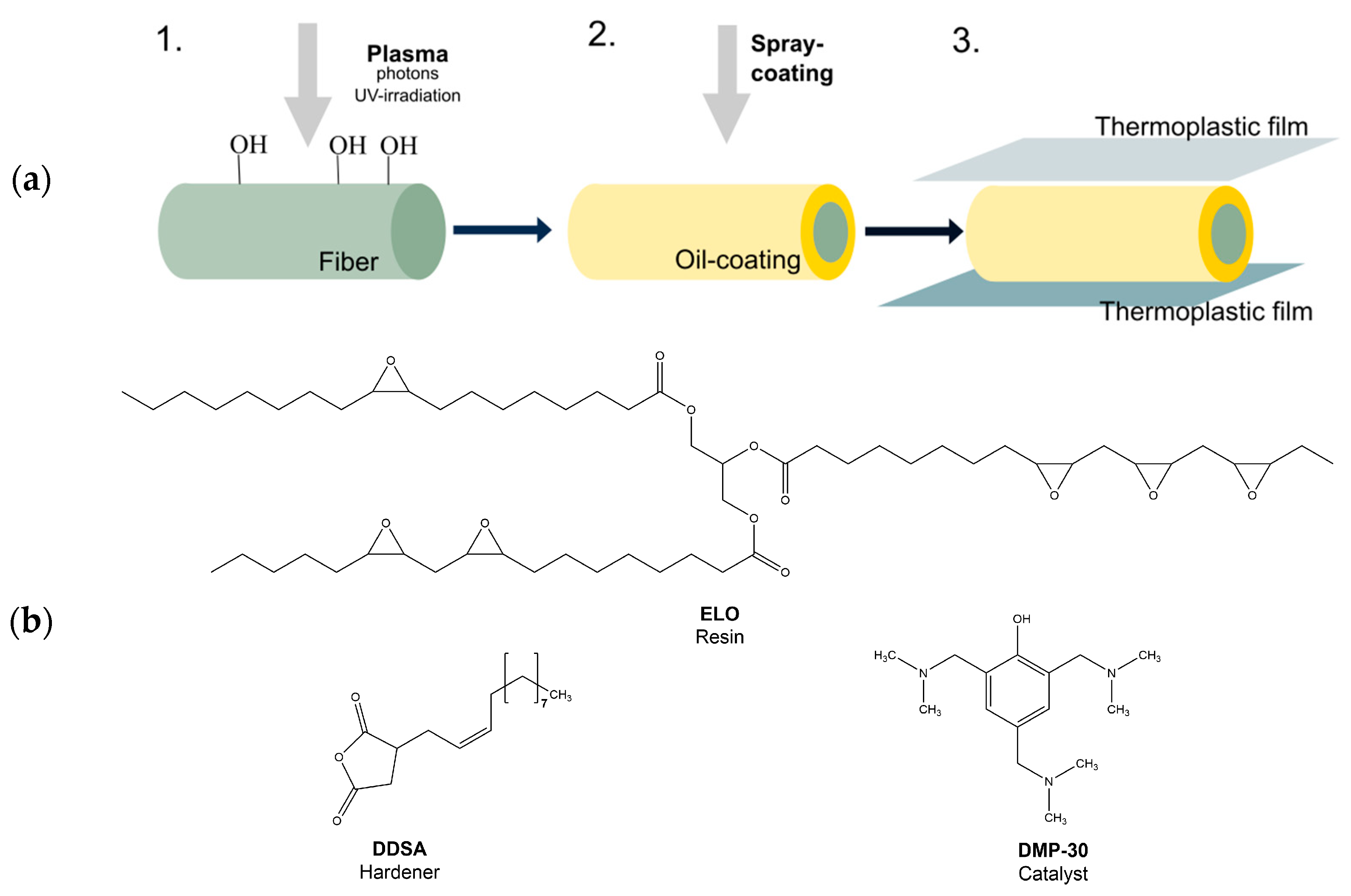

2.2. Methods

2.2.1. Plasma Pretreatment

2.2.2. Resin Preparation

2.2.3. Coating Application

2.2.4. Preparing the NFRC

2.2.5. Characterization

3. Results and Discussion

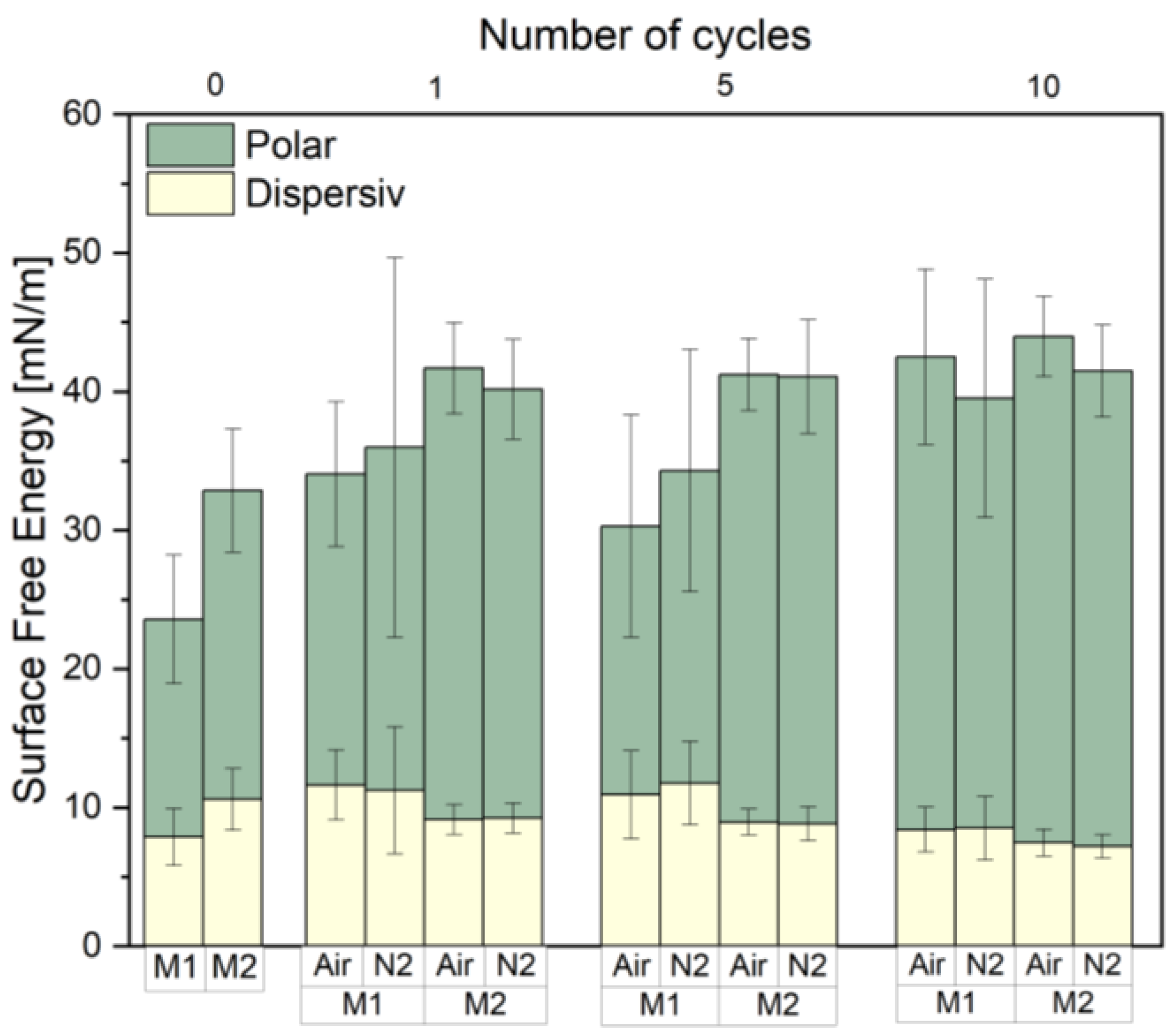

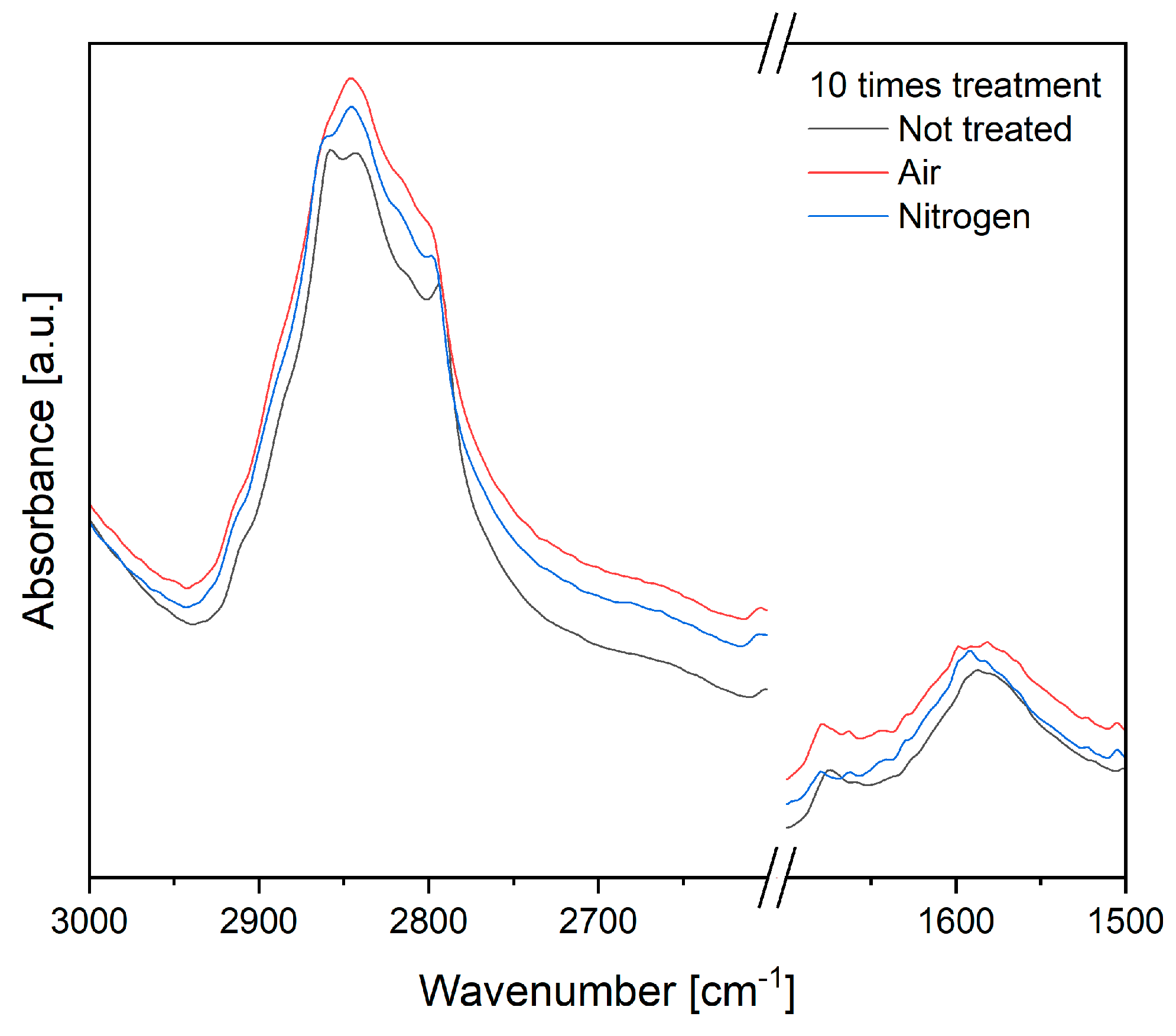

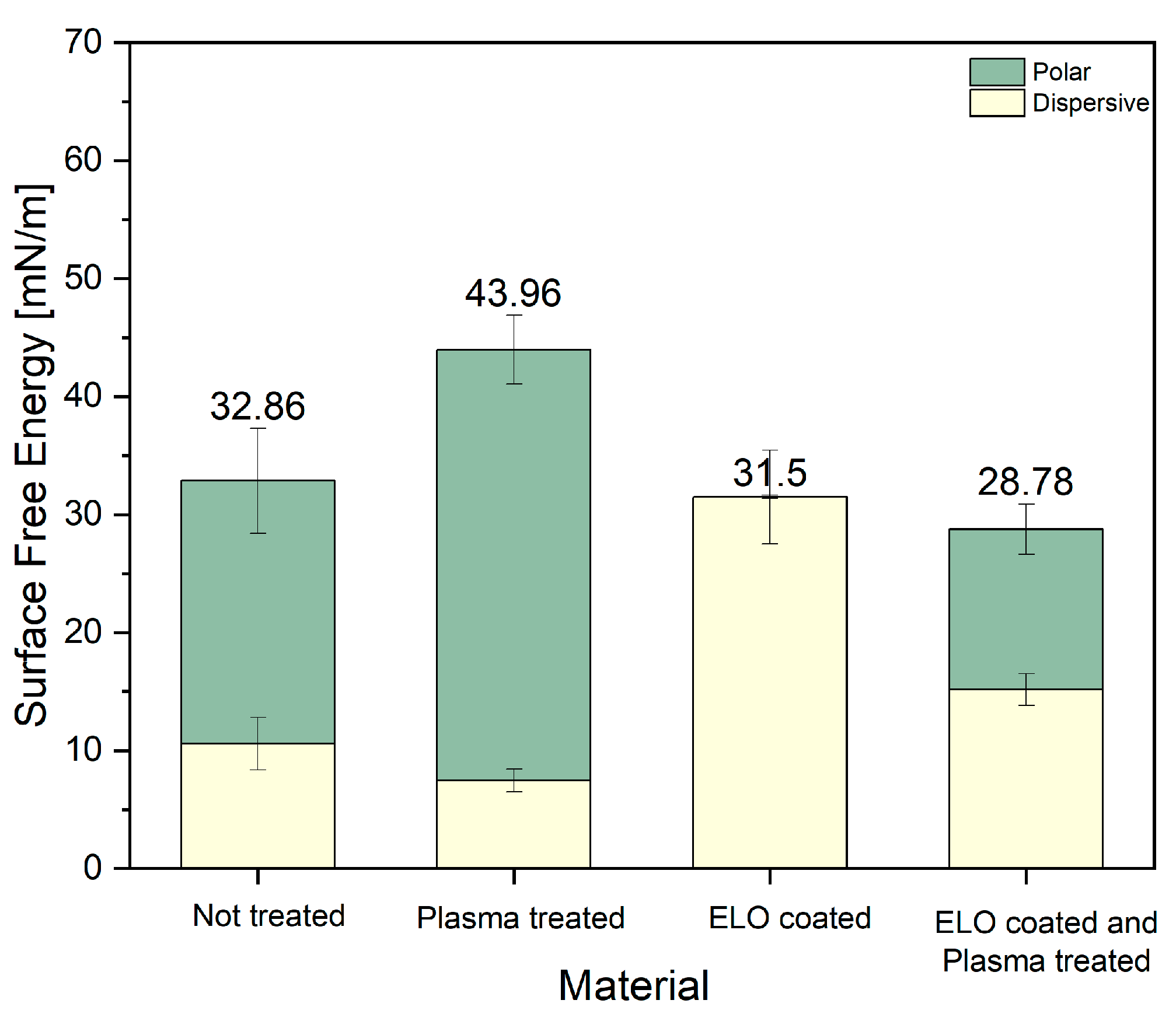

3.1. Plasma Pretreatment of the Fibers

3.2. Characterization of ELO Resin

3.3. Mechanical Characterization of the Prepared NFRC

- Different precured times (20, 30 or 40 min) for the ELO coating.

- Different proceeding speeds of the belt pressing for PLA infusion (1 m/min—referred to as I; 2.5 m/min—referred to as II).

| Material (Curing Time/Speed) | Young’s Modulus [GPa] | S.D. | Tensile Stress [MPa] | S.D. | Elongation to Break [%] | S.D. |

|---|---|---|---|---|---|---|

| Ref/I | 18.3 | 0.3 | 195.5 | 2.1 | 1.2 | 0.1 |

| Ref/II | 18.1 | 2.7 | 182.2 | 7.4 | 1.2 | 0.1 |

| 20 min/I | 14.8 | 1.8 | 162.5 | 4 | 1.1 | 0.1 |

| 20 min/II | 18.3 | 0.2 | 171.1 | 4.6 | 1 | 0.04 |

| 30 min/I | 15.9 | 1.6 | 147.7 | 12.4 | 0.8 | 0.2 |

| 30 min/II | 17.7 | 0.4 | 147.4 | 1.2 | 0.9 | 0.01 |

| 40 min/I | 15.9 | 2.7 | 131.7 | 4.5 | 0.9 | 0.2 |

| 40 min/II | 16.5 | 0.6 | 143.8 | 1.9 | 1 | 0.04 |

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Weyhrich, C.W.; Petrova, S.P.; Edgar, K.J.; Long, T.E. Renewed Interest in Biopolymer Composites: Incorporation of Renewable, Plant-Sourced Fibers. Green Chem. 2023, 25, 106–129. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Hartung, D.; Celevics, S.; Hirsch, P.; Jahn, I.; Kneisel, L.; Kölzig, K.; Matthes, A.; Cebulla, H. Manufacturing and Analysis of Natural Fiber-Reinforced Thermoplastic Tapes Using a Novel Process Assembly. Sustainability 2023, 15, 6250. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- Sun, Z.; Duan, Y.; An, H.; Wang, X.; Liang, S.; Li, N. Research Progress and Application of Natural Fiber Composites. J. Nat. Fibers 2023, 20, 2206591. [Google Scholar] [CrossRef]

- Zwawi, M. A Review on Natural Fiber Bio-Composites, Surface Modifications and Applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef]

- Mohammed, M.; Rahman, R.; Mohammed, A.M.; Adam, T.; Betar, B.O.; Osman, A.F.; Dahham, O.S. Surface Treatment to Improve Water Repellence and Compatibility of Natural Fiber with Polymer Matrix: Recent Advancement. Polym. Test. 2022, 115, 107707. [Google Scholar] [CrossRef]

- Marcuello, C.; Chabbert, B.; Berzin, F.; Bercu, N.B.; Molinari, M.; Aguié-Béghin, V. Influence of Surface Chemistry of Fiber and Lignocellulosic Materials on Adhesion Properties with Polybutylene Succinate at Nanoscale. Materials 2023, 16, 2440. [Google Scholar] [CrossRef]

- Charca, S.; Jiao-Wang, L.; Santiuste, C. Influence of Reinforcement Architecture on Behavior of Flax/PLA Green Composites under Low-Velocity Impact. Materials 2024, 17, 2958. [Google Scholar] [CrossRef]

- Meon, M.S.; Othman, M.F.; Husain, H.; Remeli, M.F.; Syawal, M.S.M. Improving Tensile Properties of Kenaf Fibers Treated with Sodium Hydroxide. Procedia Eng. 2012, 41, 1587–1592. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F.; Aravinthan, T. Mechanical Properties of Chemically-Treated Hemp Fibre Reinforced Sandwich Composites. Compos. Part B Eng. 2012, 43, 159–169. [Google Scholar] [CrossRef]

- El Boustani, M.; Lebrun, G.; Brouillette, F.; Belfkira, A. Effect of a solvent-free acetylation treatment on reinforcements permeability and tensile behaviour of flax/epoxy and flax/wood fibre/epoxy composites. Can. J. Chem. Eng. 2017, 95, 1082–1092. [Google Scholar] [CrossRef]

- Thomas, S. Non-Thermal Plasma Technology for Polymeric Materials: Applications in Composites, Nanostructured Materials and Biomedical Fields; Elsevier: Cambridge, MA, USA, 2019. [Google Scholar]

- Pin, J.M.; Sbirrazzuoli, N.; Mija, A. From Epoxidized Linseed Oil to Bioresin: An Overall Approach of Epoxy/Anhydride Cross-Linking. ChemSusChem 2015, 8, 1232–1243. [Google Scholar] [CrossRef] [PubMed]

- Todorovic, A.; Resch-Fauster, K.; Mahendran, A.R.; Oreski, G.; Kern, W. Curing of Epoxidized Linseed Oil: Investigation of the Curing Reaction with Different Hardener Types. J. Appl. Polym. Sci. 2021, 138, 50239. [Google Scholar] [CrossRef]

- Goodman, S.H.; Dodiuk-Kenig, H. Handbook of Thermoset Plastics, 3rd ed.; Elsevier: Cambridge, MA, USA, 2014. [Google Scholar]

- Sukanto, H.; Raharjo, W.W.; Ariawan, D.; Triyono, J.; Kaavesina, M. Epoxy Resins Thermosetting for Mechanical Engineering. Open Eng. 2021, 11, 797–814. [Google Scholar] [CrossRef]

- Ramaswamy, R.; Achary, P.S.; Shine, K.G. The Synthesis and Characterization of Dodecenyl Succinic Anhydride (DDSA)—A Curing Agent for Epoxy Resins. J. Appl. Polym. Sci. 1987, 33, 49–65. [Google Scholar] [CrossRef]

- Kyriazis, A.; Kilian, R.; Sinapius, M.; Rager, K.; Dietzel, A. Tensile Strength and Structure of the Interface between a Room-Curing Epoxy Resin and Thermoplastic Films for the Purpose of Sensor Integration. Polymers 2021, 13, 330. [Google Scholar] [CrossRef]

- Hodgkin, J.H.; Simon, G.P.; Varley, R.J. Thermoplastic Toughening of Epoxy Resins: A Critical Review. Polym. Adv. Technol. 1998, 9, 3–10. [Google Scholar] [CrossRef]

- Bauer, P.; Becker, Y.N.; Motsch-Eichmann, N.; Mehl, K.; Müller, I.; Hausmann, J. Hybrid Thermoset-Thermoplastic Structures: An Experimental Investigation on the Interface Strength of Continuous Fiber-Reinforced Epoxy and Short-Fiber Reinforced Polyamide 6. Compos. Part C Open Access 2020, 3, 100060. [Google Scholar] [CrossRef]

- Epoxidized Linseed Oil Supplier—Hobum Oleochemicals GmbH. Available online: https://www.hobum.de/de/produkt-kategorie/epoxidierte-ester-und-oele/ (accessed on 29 February 2024).

- Smith, J.; Doe, A.; Brown, C. Surface modification of flax nonwovens for the development of sustainable, high performance, and durable calcium aluminate cement composites. J. Sustain. Mater. Technol. 2016, 15, 123–135. [Google Scholar]

- DIN EN ISO 527; Kunststoffe—Bestimmung der Zugeigenschaften—Teil 1: Allgemeine Grundsätze (ISO 527-1:2019); Deutsche Fassung EN ISO 527-1:2019. DIN Deutsches Institut für Normung: Berlin, Germany, 2019.

- van Dam, J.P.B.; Abrahami, S.T.; Yilmaz, A.; Gonzalez-Garcia, Y.; Terryn, H.; Mol, J.M.C. Effect of surface roughness and chemistry on the adhesion and durability of a steel-epoxy adhesive interface. Int. J. Adhes. Adhes. 2020, 96, 102450. [Google Scholar] [CrossRef]

- Baldan, A. Adhesion Phenomena in Bonded Joints. Int. J. Adhes. Adhes. 2012, 38, 95–116. [Google Scholar]

- Camargo, J.S.G.D.; Menezes, A.J.D.; Cruz, N.C.D.; Rangel, E.C.; Delgado-Silva, A.D.O. Morphological and Chemical Effects of Plasma Treatment with Oxygen (O2) and Sulfur Hexafluoride (SF6) on Cellulose Surface. Mat. Res. 2018, 20 (Suppl. S2), 842–850. [Google Scholar] [CrossRef]

- Baltazar-y-Jimenez, A.; Bistritz, M.; Schulz, E.; Bismarck, A. Atmospheric air pressure plasma treatment of lignocellulosic fibers: Impact on mechanical properties and adhesion to cellulose acetate butyrate. Compos. Sci. Technol. 2008, 68, 215–227. [Google Scholar] [CrossRef]

- Smolková, B.; Adam, F.; Uzhytchak, M.; Lunova, M.; Kubinová, S.; Dejneka, A.; Lunov, O. Critical Analysis of Non-Thermal Plasma-Driven Modulation of Immune Cells from Clinical Perspective. Int. J. Mol. Sci. 2020, 21, 6226. [Google Scholar] [CrossRef]

- Žigon, J.; Kariž, M.; Pavlič, M. Surface Finishing of 3D-Printed Polymers with Selected Coatings. Polymers 2020, 12, 2797. [Google Scholar] [CrossRef]

- Oksmana, K.; Skrifvars, M.; Selin, J.-F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications? Compos. Sci. Technol. 2007, 67, 462–470, ISSN 0266-3538. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Appl. Sci. Manuf. 2016, 83, 98–112, ISSN 1359-835X. [Google Scholar] [CrossRef]

- Liu, Z.; Kraus, G.; Clark, J. Photo-cured Materials. In Vegetable Oils in Green Materials from Plant Oils; Liu, Z., Kraus, G., Eds.; The Royal Society of Chemistry: Cambridge, UK, 2015; pp. 1–24. [Google Scholar]

- Böcherer, D.; Li, Y.; Kluck, S.; Nekoonam, N.; Zhu, P.; Rapp, B.E.; Kotz-Helmer, F.; Helmer, D. COLOR3D—Multicolored 3D printing of wood composites by submicron structuring. Addit. Manuf. 2023, 75, 103723. [Google Scholar] [CrossRef]

- Jaques, N.G.; Pereira Barros, J.J.; Dayane Dos Santos Silva, I.; Popp, M.; Kolbe, J.; Ramos Wellen, R.M. New Approaches of Curing and Degradation on Epoxy/Eggshell Composites. Compos. Part. B Eng. 2020, 196, 108125. [Google Scholar] [CrossRef]

- Han, Y.; Wang, Z.; Zhao, S.; Wang, J. AC Impedance Function of Electrochemical Working Station as Novel Curing Degree Monitor Method: A Model Curing System of Epoxy/Anhydride/DMP-30. Measurement 2019, 145, 600–610. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on Durability of Sustainable Biobased Composites: A Review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef]

| Tg [°C] | ΔHr [J/g] | Tr [°C] and Reaction Interval | ΔHd [J/g] | Td (DSC) [°C] and Decomposition Interval | Td (TGA) [°C] | Weight Loss [%] |

|---|---|---|---|---|---|---|

| 96.1 | 162 | 155.5 (108–250) | 91.8 | 361.6 (315–412) | 358.3 | 98.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savicheva, S.; Rapp, B.E.; Teuscher, N. Natural Fiber-Reinforced Composite Incorporated with Anhydride-Cured Epoxidized Linseed-Oil Resin and Atmospheric Pressure Plasma-Treated Flax Fibers. Materials 2024, 17, 4244. https://doi.org/10.3390/ma17174244

Savicheva S, Rapp BE, Teuscher N. Natural Fiber-Reinforced Composite Incorporated with Anhydride-Cured Epoxidized Linseed-Oil Resin and Atmospheric Pressure Plasma-Treated Flax Fibers. Materials. 2024; 17(17):4244. https://doi.org/10.3390/ma17174244

Chicago/Turabian StyleSavicheva, Sofya, Bastian E. Rapp, and Nico Teuscher. 2024. "Natural Fiber-Reinforced Composite Incorporated with Anhydride-Cured Epoxidized Linseed-Oil Resin and Atmospheric Pressure Plasma-Treated Flax Fibers" Materials 17, no. 17: 4244. https://doi.org/10.3390/ma17174244

APA StyleSavicheva, S., Rapp, B. E., & Teuscher, N. (2024). Natural Fiber-Reinforced Composite Incorporated with Anhydride-Cured Epoxidized Linseed-Oil Resin and Atmospheric Pressure Plasma-Treated Flax Fibers. Materials, 17(17), 4244. https://doi.org/10.3390/ma17174244