Thermomechanical Processing for Improved Mechanical Properties of HT9 Steels

Abstract

1. Introduction

2. Experimental

2.1. Compositions and Thermodynamics Guidance

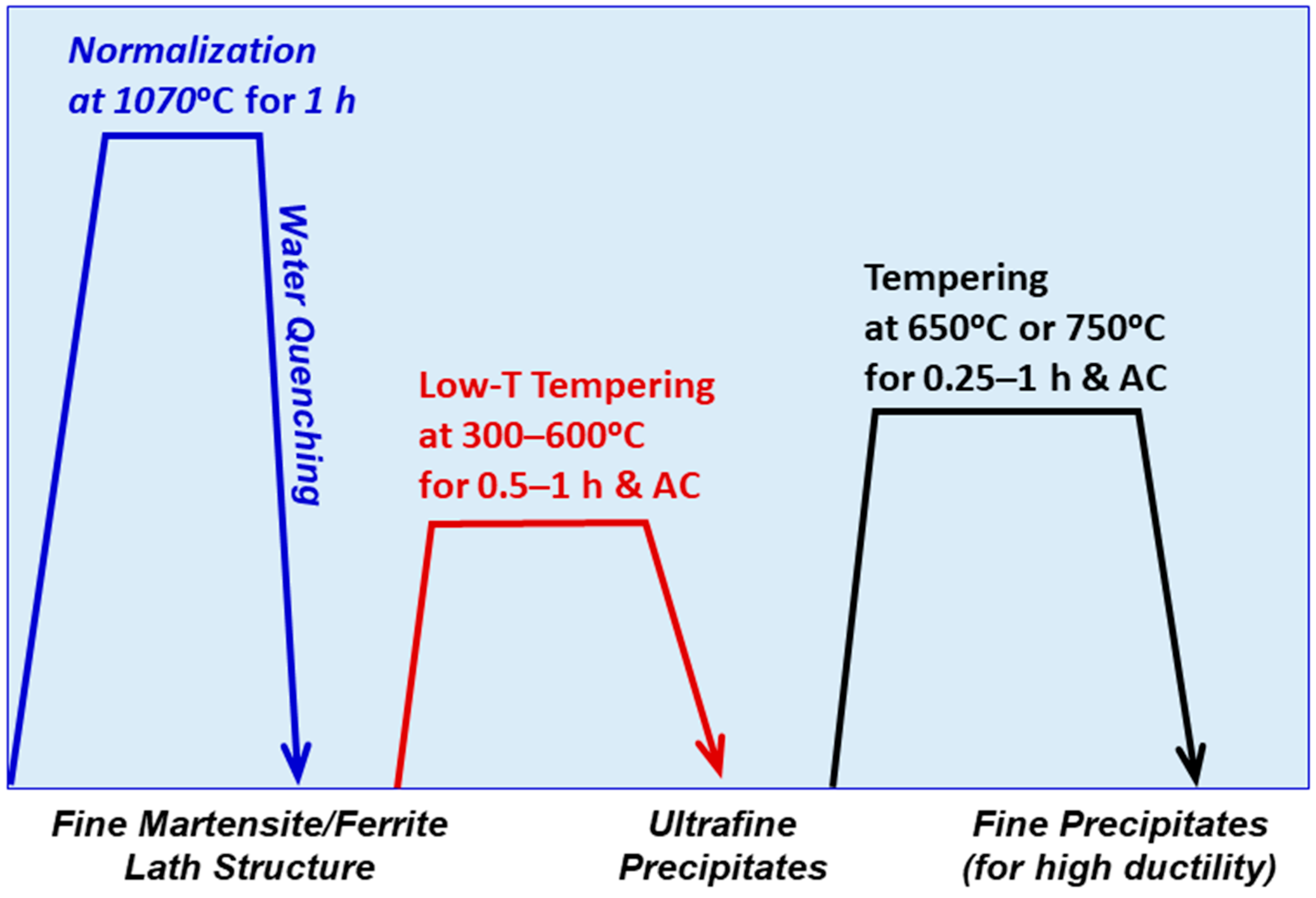

2.2. Heat Treatment Schedules

2.3. Mechanical Testing

3. Results

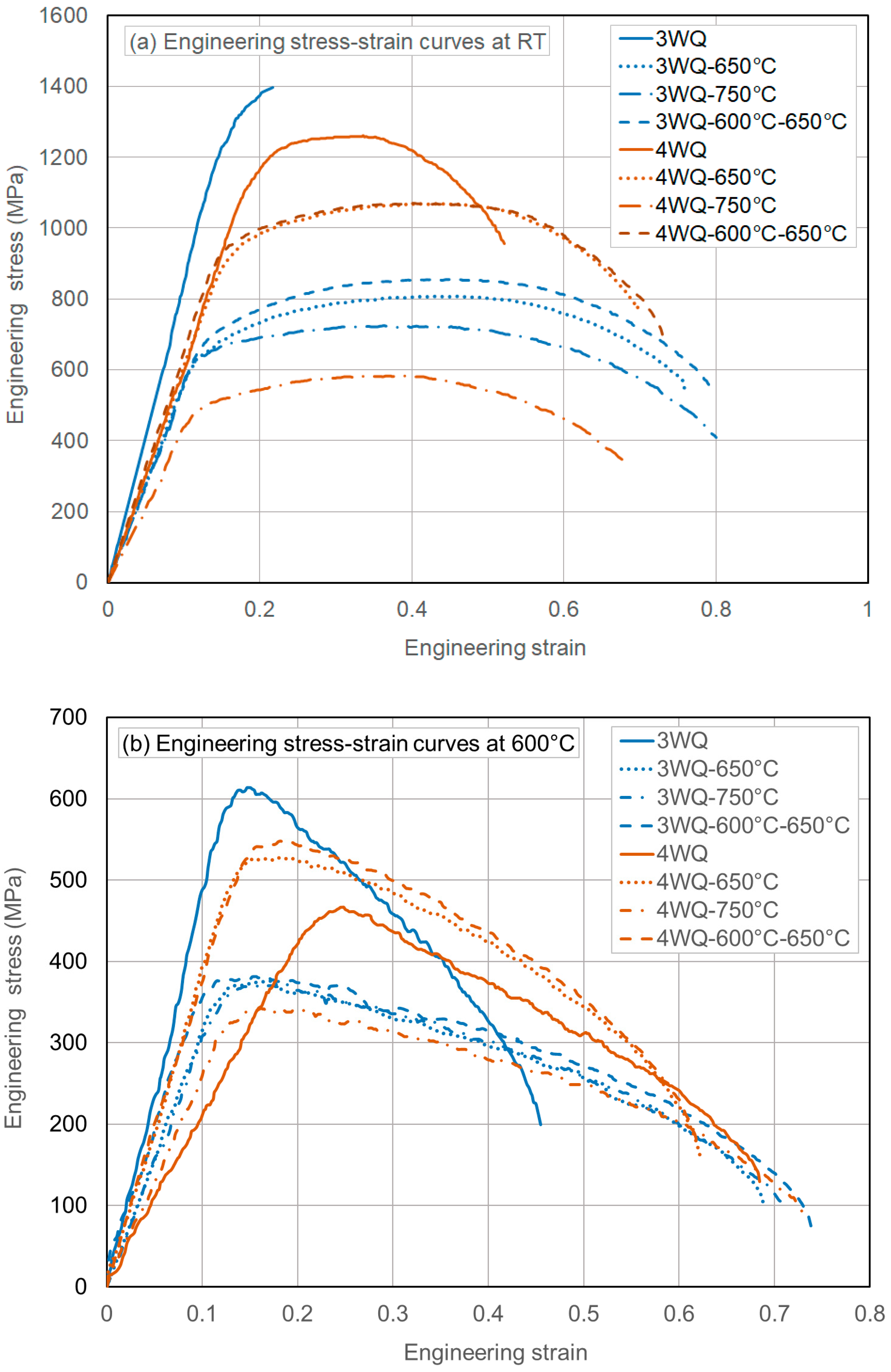

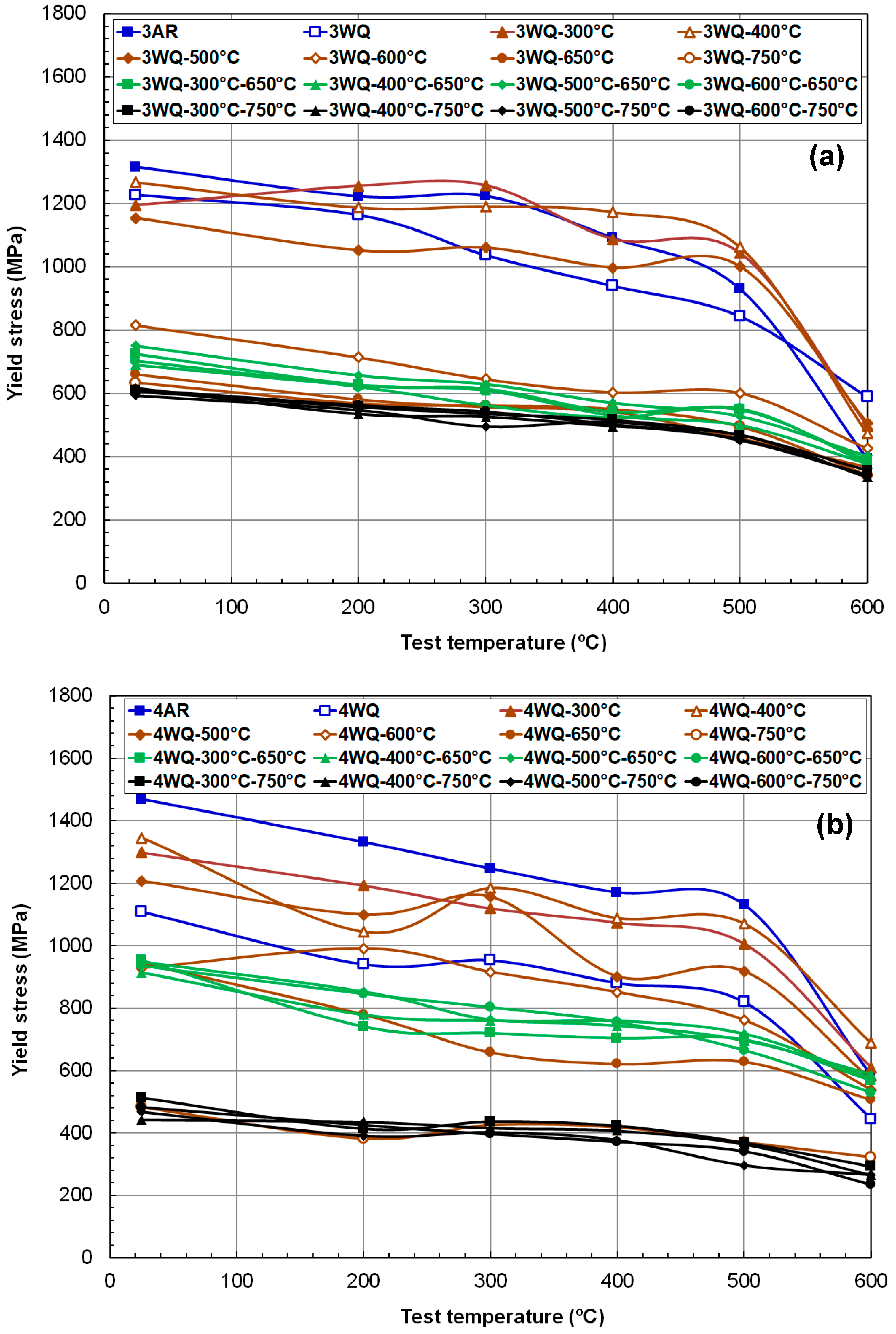

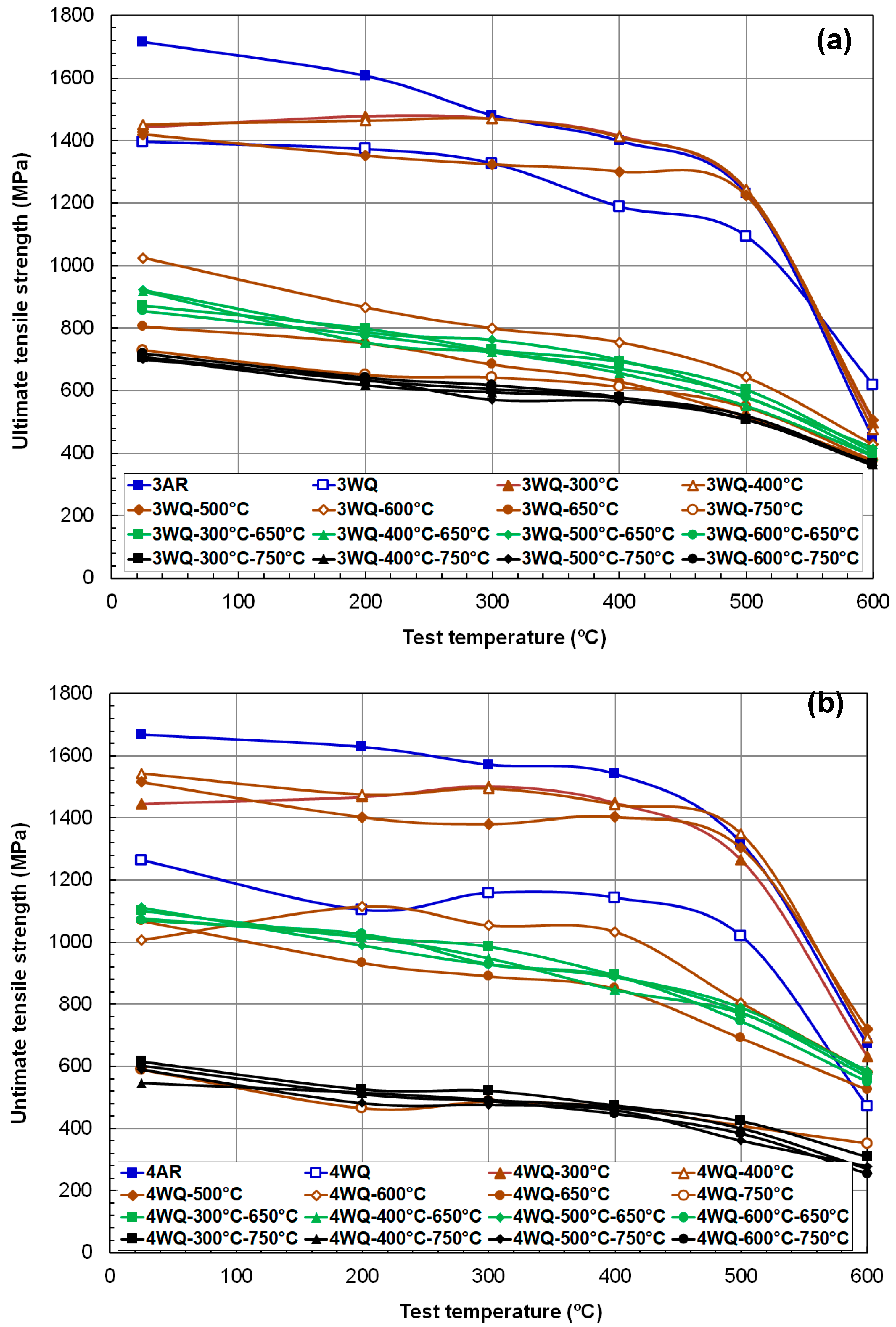

3.1. Stress-Strain Behavior and Strength of HT9 Steels in Various TMP Conditions

3.2. Ductility of HT9 Steels in Various TMP Conditions

3.3. Effect of TMP Route on the Static Fracture Toughness of HT9 Steels

4. Discussion on Microstructure and Mechanical Properties

5. Summary and Conclusions

- [1]

- The Fe–12Cr alloys exhibited a broad range of strength depending on the thermomechanical processing route, particularly influenced by the tempering conditions. Notably, both HT9 alloys achieved ultrahigh yield stresses above 1 GPa either before tempering or after single tempering below 600 °C. Yield strength (YS) and ultimate tensile strength (UTS) of HT9 steels exhibited a consistent decrease with increasing test temperature, irrespective of alloy composition or TMP routes. The final tempering temperature emerged as the predominant factor influencing the strength of the HT9 steels.

- [2]

- The relative strengths between the two HT9 alloys varied significantly across different thermomechanical processing routes, with nitrogen addition generally reducing the strength of HT9 steel under most TMT conditions. The underlying reasons for this strength reduction with nitrogen doping are currently not well understood, necessitating further comprehensive investigation.

- [3]

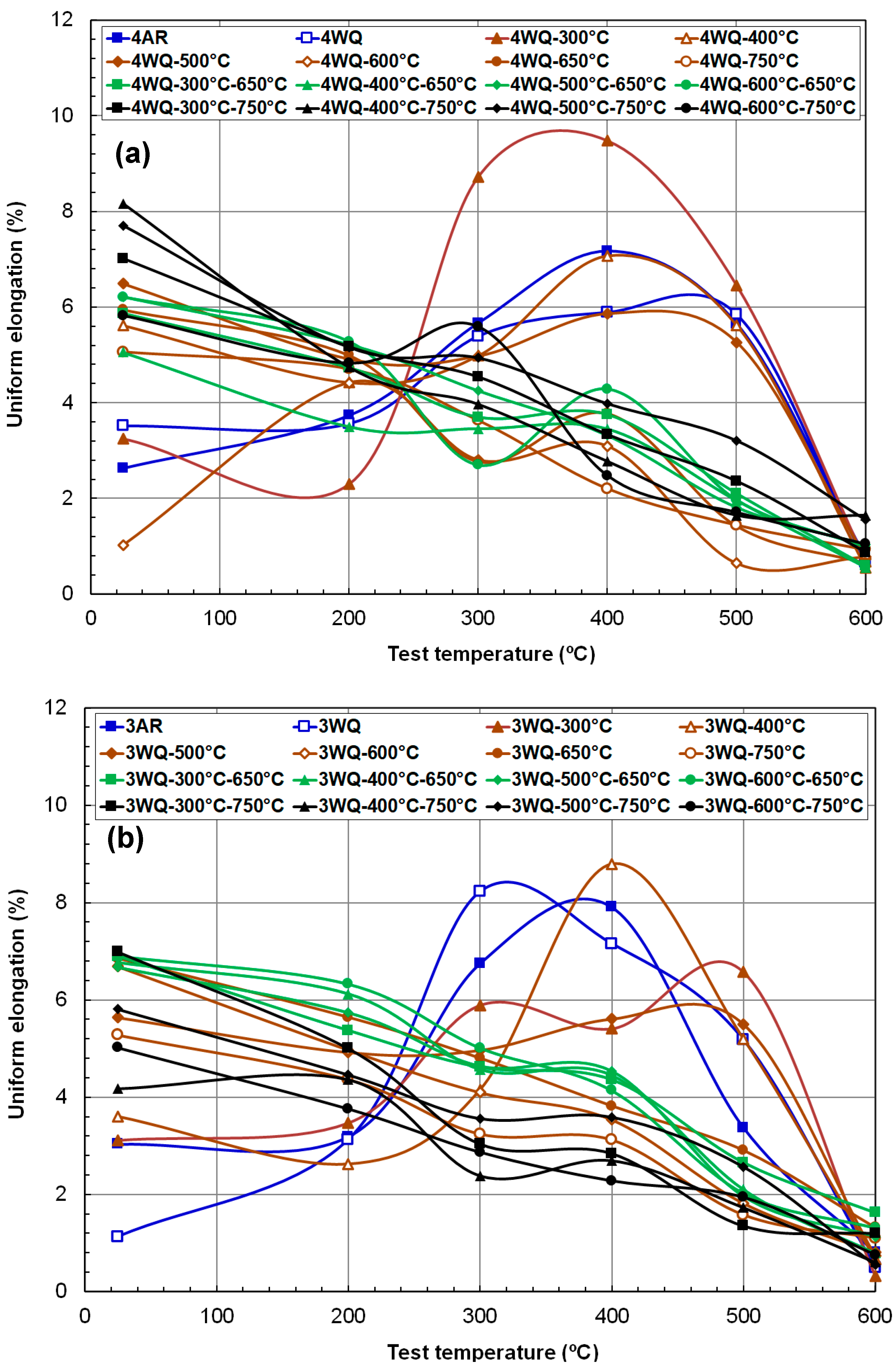

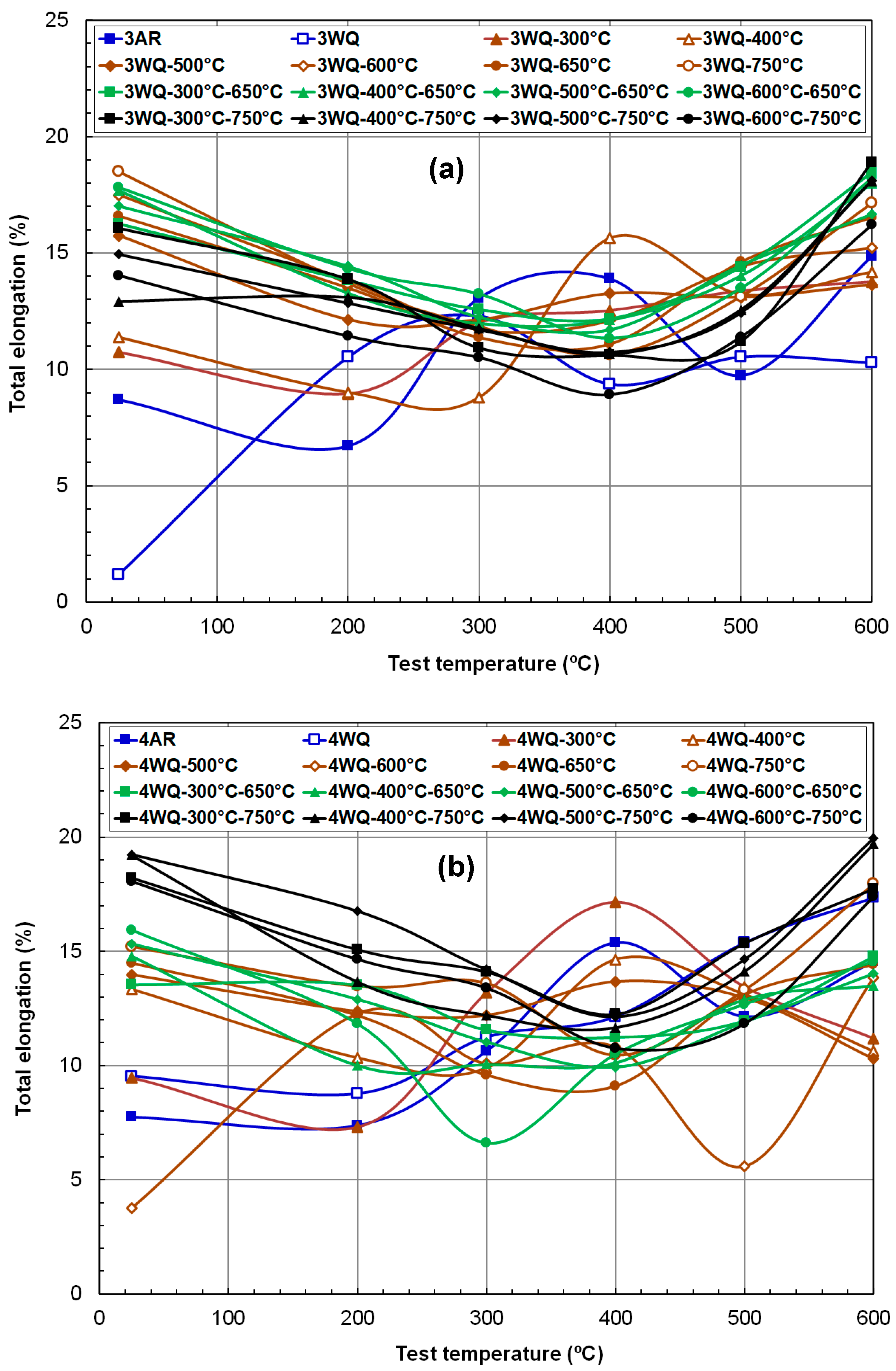

- In contrast to the straightforward temperature dependence observed in YS and UTS, ductility parameters, such as uniform elongation (UE) and total elongation (TE), displayed more complex behavior influenced by the specific processing routes and resulting material strengths. Generally, the rankings of room-temperature strength parameters were approximately reversed in terms of ductility parameters.

- [4]

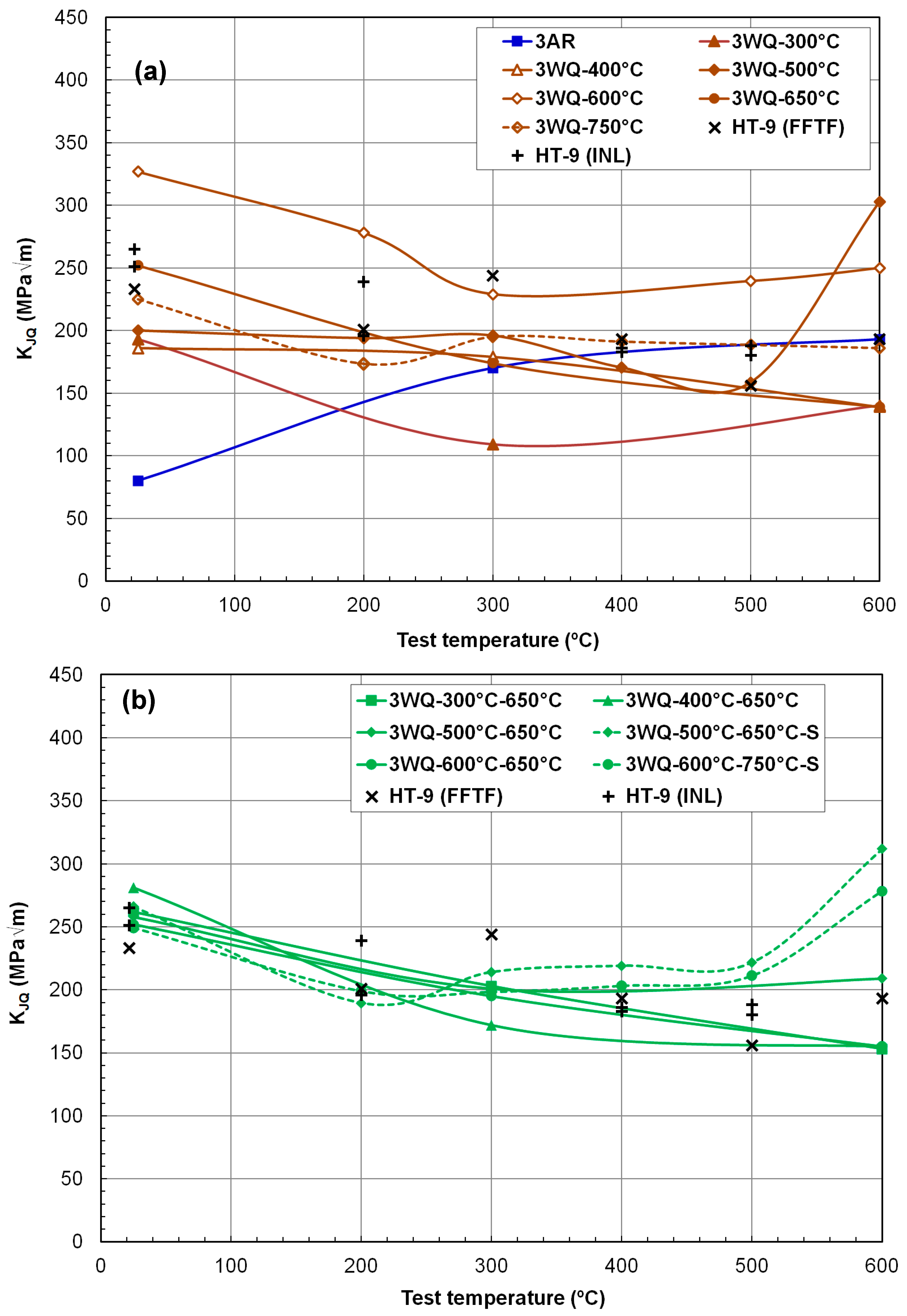

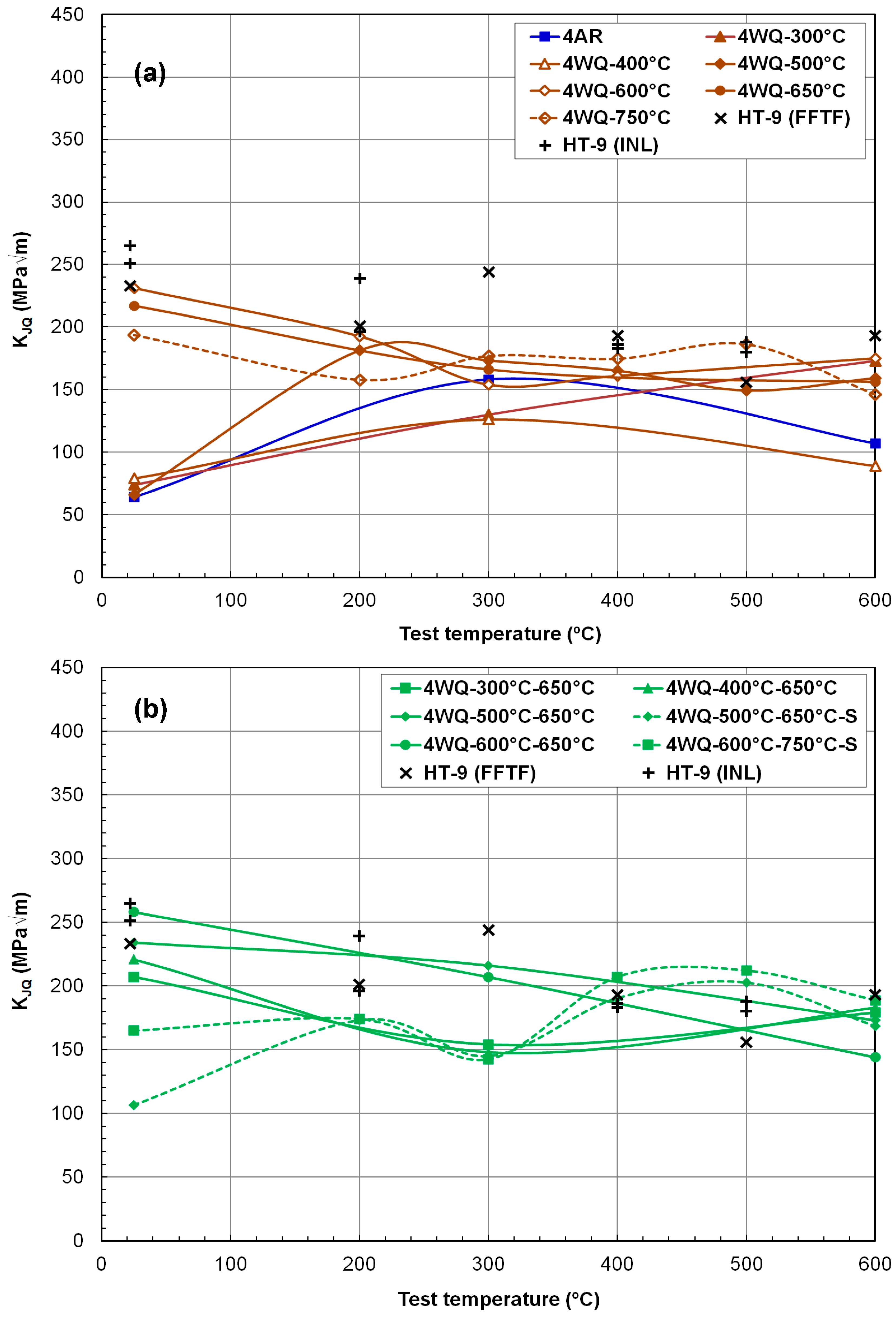

- The room-temperature fracture toughness of HT9 steels was generally high (i.e., >~200 MPa√m), except in cases with no or low-temperature tempering (e.g., AR, WQ-300 °C, WQ-400 °C). The temperature dependence of fracture toughness above room temperature was strongly correlated with the degree of tempering. Overall, the KJQ range of HT9 heat-4 tended to be slightly lower across most TMPs compared to HT9 heat-3.

- [5]

- Certain limited tempering processes on HT9 heat-3, such as WQ-500 °C, WQ-600 °C, WQ-500 °C–650 °C-S, and WQ-600 °C–750 °C-S, significantly enhanced fracture toughness (KJQ) at 600 °C, achieving values of 250–320 MPa√m. This improvement represents a substantial enhancement compared to the typical KJQ range of 150–200 MPa√m observed in fully tempered HT9 steels. However, the newly tested TMPs on heat-4 showed minimal improvement in fracture toughness, although WQ-500 °C–650 °C and WQ-600 °C–650 °C did achieve considerable additional strengthening without compromising fracture toughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Izhutov, A.l.; Krasheninnikov, Y.M.; Zhemkov, I.Y.; Varivtsev, A.V.; Naboishchikov, Y.V.; Neustroev, V.S.; Shamardin, V.K. Prolongation of the BOR-60 reactor operation. Nucl. Eng. Technol. 2015, 147, 253–259. [Google Scholar] [CrossRef]

- Maloy, S.A.; Toloczko, M.B.; Cole, J.; Byun, T.S. Core materials development for the fuel cycle R&D program. J. Nucl. Mater. 2011, 415, 302–305. [Google Scholar]

- Allen, T.R.; Busby, J.T.; Klueh, R.L.; Maloy, S.A.; Toloczko, M.B. Cladding and duct materials for advanced nuclear recycle reactors. JOM 2008, 60, 15–23. [Google Scholar] [CrossRef]

- Cheon, J.S.; Lee, C.B.; Lee, B.O.; Raison, J.P.; Mizuno, T.; Delage, F.; Carmack, J. Sodium fast reactor evaluation: Core materials. J. Nucl. Mater. 2009, 392, 324–330. [Google Scholar] [CrossRef]

- Zhao, H.; Peterson, P.F. Multiple reheat helium Brayton cycles for sodium cooled fast reactors. Nucl. Eng. Des. 2008, 238, 1535–1546. [Google Scholar] [CrossRef]

- Henry, J.; Maloy, S.A. Irradiation-resistant ferritic and martensitic steels as core materials for Generation IV nuclear reactors. In Structural Materials for Generation IV Nuclear Reactors; Yvon, P., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 329–355. [Google Scholar]

- Garner, F.A.; Toloczko, M.B.; Sencer, B.H. Compositional and temperature dependence of void swelling in model Fe–Cr base alloys irradiated in the EBR-II fast reactor. J. Nucl. Mater. 2000, 276, 123–142. [Google Scholar] [CrossRef]

- Sencer, B.H.; Kennedy, J.R.; Cole, J.I.; Maloy, S.A.; Garner, F.A. Microstructural analysis of an HT9 fuel assembly duct irradiated in FFTF to 155 dpa at 443 C. J. Nucl. Mater. 2009, 393, 235–241. [Google Scholar] [CrossRef]

- Klueh, R.L. Elevated temperature ferritic and martensitic steels and their application to future nuclear reactors. Inter. Mater. Rev. 2005, 50, 287–310. [Google Scholar] [CrossRef]

- Toloczko, M.B.; Garner, F.A. Irradiation creep and void swelling of two LMR heats of HT9 at∼ 400 C and 165 dpa. J. Nucl. Mater. 1996, 233–237, 289–292. [Google Scholar] [CrossRef]

- Toloczko, M.B.; Garner, F.A.; Eiholzer, C.R. Irradiation creep and swelling of the US fusion heats of HT9 and 9Cr-1Mo to 208 dpa at ~400 C. J. Nucl. Mater. 1994, 212–215, 604–607. [Google Scholar] [CrossRef]

- Maloy, S.A.; Toloczko, M.B.; McClellan, K.J.; Romero, T.; Kohno, Y.; Garner, F.A.; Kurtz, R.J.; Kimura, A. The effects of fast reactor irradiation conditions on the tensile properties of two ferritic/martensitic steels. J. Nucl. Mater. 2006, 356, 62–69. [Google Scholar] [CrossRef]

- Byun, T.S.; Lewis, W.D.; Toloczko, M.B.; Maloy, S.A. Impact properties of irradiated HT9 from the fuel duct of FFTF. J. Nucl. Mater. 2012, 421, 104–111. [Google Scholar] [CrossRef]

- Byun, T.S.; Toloczko, M.B.; Saleh, T.A.; Maloy, S.A. Irradiation dose and temperature dependence of fracture toughness in high dose HT9 steel from the fuel duct of FFTF. J. Nucl. Mater. 2013, 432, 1–8. [Google Scholar] [CrossRef]

- Anderoglu, O.; Byun, T.S.; Toloczko, M.; Maloy, S.A. Mechanical performance of ferritic martensitic steels for high dose applications in advanced nuclear reactors. Metall. Mater. Trans. A 2013, 44, 70–83. [Google Scholar] [CrossRef]

- Byun, T.S.; Baek, J.H.; Anderoglu, O.; Maloy, S.A.; Toloczko, M.B. Thermal annealing recovery of fracture toughness in HT9 steel after irradiation to high doses. J. Nucl. Mater. 2014, 449, 263–272. [Google Scholar] [CrossRef]

- Baek, J.H.; Byun, T.S.; Maloy, S.A.; Toloczko, M.B. Investigation of temperature dependence of fracture toughness in high-dose HT9 steel using small-specimen reuse technique. J. Nucl. Mater. 2014, 444, 206–213. [Google Scholar] [CrossRef]

- Byun, T.S.; Maloy, S.A.; Yoon, J.H. Small Specimen Reuse Technique to Evaluate Fracture Toughness of High Dose HT9 Steel. In ASTM International (STP-1576); ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Byun, T.S.; Hoelzer, D.T.; Kim, J.H.; Maloy, S.A. A comparative assessment of the fracture toughness behavior of ferritic-martensitic steels and nanostructured ferritic alloys. J. Nucl. Mater. 2017, 484, 157–167. [Google Scholar] [CrossRef]

- Klueh, R.L.; Harris, D.R. High-Chromium Ferritic and Martensitic Steels for Nuclear Applications; ASTM: West Conshohocken, PA, USA, 2001; ISBN 0-803102090-7. [Google Scholar]

- Klueh, R.L. Heat treatment behavior and tensile properties of Cr− W steels. Metall. Mater. Trans. A 1989, 20, 463–470. [Google Scholar] [CrossRef]

- Tan, L.; Byun, T.S.; Katoh, Y.; Snead, L.L. Stability of MX-type strengthening nanoprecipitates in ferritic steels under thermal aging, stress and ion irradiation. Acta Mater. 2014, 71, 11–19. [Google Scholar] [CrossRef]

- Xie, Y.; Cheng, X.; Wei, J.; Luo, R. Characterization of carbide precipitation during tempering for Quenched Dievar Steel. Materials 2022, 15, 6448. [Google Scholar] [CrossRef]

- Brailsford, A.D.; Bullough, R.; Hayns, M.R. Point defect sink strengths and void-swelling. J. Nucl. Mater. 1976, 60, 246–256. [Google Scholar] [CrossRef]

- Heald, P.T.; Miller, K.M. Point defect sink strengths in irradiated materials. J. Nucl. Mater. 1976, 66, 107–111. [Google Scholar] [CrossRef]

- Little, E.A.; Stow, D.A. Void-swelling in irons and ferritic steels: II. An experimental survey of materials irradiated in a fast reactor. J. Nucl. Mater. 1979, 87, 25–39. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Maziasz, P.J.; Stoller, R.E. Dose dependence of the microstructural evolution in neutron-irradiated austenitic stainless steel. J. Nucl. Mater. 1993, 206, 266–286. [Google Scholar] [CrossRef]

- Mansur, L.K. Theory and experimental background on dimensional changes in irradiated alloys. J. Nucl. Mater. 1994, 216, 97–123. [Google Scholar] [CrossRef]

- Mazumder, B.; Bannister, M.E.; Meyer, F.W.; Miller, M.K.; Parish, C.M.; Edmondson, P.D. Helium trapping in carbide precipitates in a tempered F82H ferritic–martensitic steel. Nucl. Mater. Energy 2015, 1, 8–12. [Google Scholar] [CrossRef]

- Byun, T.S.; Kim, J.H.; Yoon, J.H.; Hoelzer, D.T. High temperature fracture characteristics of a nanostructured ferritic alloy (NFA). J. Nucl. Mater. 2010, 407, 78–82. [Google Scholar] [CrossRef]

- Byun, T.S.; Yoon, J.H.; Hoelzer, D.T.; Lee, Y.B.; Kang, S.H.; Maloy, S.A.J. Process development for 9Cr nanostructured ferritic alloy (NFA) with high fracture toughness. J. Nucl. Mater. 2014, 449, 290–299. [Google Scholar] [CrossRef]

- Kim, J.H.; Byun, T.S.; Kim, S.W.; Lee, B.H. Effects of processing condition on the microstructural and tensile properties of 14Cr-based oxide dispersion strengthened alloys. J. Nucl. Mater. 2014, 449, 300–307. [Google Scholar] [CrossRef]

- Byun, T.S.; Yoon, J.H.; Wee, S.H.; Hoelzer, D.T.; Maloy, S.A. Fracture behavior of 9Cr nanostructured ferritic alloy with improved fracture toughness. J. Nucl. Mater. 2014, 449, 39–48. [Google Scholar] [CrossRef]

- Byun, T.S.; Collins, D.A.; Choi, J.P.; Lach, T.G.; Mattlin, K.; Overman, N.R.; Barkley, E.L.; Maloy, S.A. Mechanical properties of HT9 steels after various thermomechanical treatments. In Nuclear Technology R&D Milestone Report: M3NT-18PN020302071 (PNNL-27752); Pacific Northwest National Laboratory: Richland, WA, USA, 2018. [Google Scholar]

- Byun, T.S.; Choi, J.P.; Mattlin, K.; Collins, D.A.; Maloy, S.A. High-Temperature Mechanical Behavior of HT9 Steels after Modified Processing Routes. In Nuclear Technology R&D Milestone Report: M3FT-17PN020302071 (PNNL-26677); Pacific Northwest National Laboratory: Richland, WA, USA, 2017. [Google Scholar]

- ASTM E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2013.

- ASTM E1820; Standard Test Method for Measurement of Fracture Toughness. ASTM: West Conshohocken, PA, USA, 2008.

- Sachdev, A.K. Dynamic strain aging of various steels. Metall. Trans. A 1982, 13, 1793–1797. [Google Scholar] [CrossRef]

- Li, C.C.; Leslie, W.C. Effects of dynamic strain aging on the subsequent mechanical properties of carbon steels. Metall. Trans. A 1978, 9, 1765–1775. [Google Scholar] [CrossRef]

- Robinson, J.M.; Shaw, M.P. Microstructural and mechanical influences on dynamic strain aging phenomena. Inter. Mater. Rev. 1994, 39, 113–122. [Google Scholar] [CrossRef]

- Mariappan, K.; Shankar, V.; Sandhya, R.; Reddy, G.P.; Mathew, M.D. Dynamic strain aging behavior of modified 9Cr–1Mo and reduced activation ferritic martensitic steels under low cycle fatigue. J. Nucl. Mater. 2013, 435, 207–213. [Google Scholar] [CrossRef]

- Aydogan, E.; Gigax, J.G.; Parker, S.S.; Eftink, B.P.; Chancey, M.; Poplawsky, J.; Maloy, S.A. Nitrogen effects on radiation response in 12Cr ferritic/martensitic alloys. Scr. Mater. 2020, 189, 145–150. [Google Scholar] [CrossRef]

- Rietema, C.J.; Chancey, M.R.; Ullrich, S.K.; Finfrock, C.B.; Marshall, D.V.; Eftink, B.P.; Wang, Y.Q.; Bourne, G.R.; Maloy, S.A.; Clarke, A.J.; et al. The influence of nitrogen and nitrides on the structure and properties of proton irradiated ferritic/martensitic steel. J. Nucl. Mater. 2022, 561, 153528. [Google Scholar] [CrossRef]

| Material/Element | Fe | Cr | Mn | Mo | Ni | W | V | Si | C | N |

|---|---|---|---|---|---|---|---|---|---|---|

| HT9 Steel Heat-3 | Bal. | 11.07 | 0.55 | 1.0 | 0.51 | 0.47 | 0.3 | 0.25 | 0.2 | 0.001 |

| HT9 Steel Heat-4 | Bal. | 11.42 | 0.56 | 1.0 | 0.52 | 0.48 | 0.3 | 0.26 | 0.2 | 0.044 |

| # | TMP Route | Normalization + Quenching | Tempering-1 | Tempering-2 |

|---|---|---|---|---|

| 1 | #AR (As Rolled) | 1100 °C/30 min & Hot Rolling | None | None |

| 2 | #WQ (Water Quench) | 1070 °C/1 h & WQ | None | None |

| 3 | #WQ-300 °C | 1070 °C/1 h & WQ | 300 °C/1 h & AC | None |

| 4 | #WQ-400 °C | 1070 °C/1 h & WQ | 400 °C/1 h & AC | None |

| 5 | #WQ-500 °C | 1070 °C/1 h & WQ | 500 °C/1 h & AC | None |

| 6 | #WQ-600 °C | 1070 °C/1 h & WQ | 600 °C/1 h & AC | None |

| 7 | #WQ-650 °C | 1070 °C/1 h & WQ | 650 °C/1 h & AC | None |

| 8 | #WQ-750 °C | 1070 °C/1 h & WQ | 750 °C/1 h & AC | None |

| 9 | #WQ-300 °C–650 °C | 1070 °C/1 h & WQ | 300 °C/1 h & AC | 650 °C/0.5 h & AC |

| 10 | #WQ-400 °C–650 °C | 1070 °C/1 h & WQ | 400 °C/1 h & AC | 650 °C/0.5 h & AC |

| 11 | #WQ-500 °C–650 °C | 1070 °C/1 h & WQ | 500 °C/1 h & AC | 650 °C/0.5 h & AC |

| 12 | #WQ-600 °C–650 °C | 1070 °C/1 h & WQ | 600 °C/1 h & AC | 650 °C/0.5 h & AC |

| 13 | #WQ-300 °C–750 °C | 1070 °C/1 h & WQ | 300 °C/1 h & AC | 750 °C/0.5 h & AC |

| 14 | #WQ-400 °C–750 °C | 1070 °C/1 h & WQ | 400 °C/1 h & AC | 750 °C/0.5 h & AC |

| 15 | #WQ-500 °C–750 °C | 1070 °C/1 h & WQ | 500 °C/1 h & AC | 750 °C/0.5 h & AC |

| 16 | #WQ-500 °C–650 °C-S | 1070 °C/1 h & WQ | 500 °C/1 h & AC | 750 °C/0.25 h & AC |

| 17 | #WQ-600 °C–750 °C | 1070 °C/1 h & WQ | 600 °C/1 h & AC | 750 °C/0.5 h & AC |

| 18 | #WQ-600 °C–750 °C-S | 1070 °C/1 h & WQ | 600 °C/1 h & AC | 750 °C/0.25 h & AC |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Byun, T.S.; Collins, D.A.; Lach, T.G.; Choi, J.P.; Maloy, S.A. Thermomechanical Processing for Improved Mechanical Properties of HT9 Steels. Materials 2024, 17, 3803. https://doi.org/10.3390/ma17153803

Byun TS, Collins DA, Lach TG, Choi JP, Maloy SA. Thermomechanical Processing for Improved Mechanical Properties of HT9 Steels. Materials. 2024; 17(15):3803. https://doi.org/10.3390/ma17153803

Chicago/Turabian StyleByun, Thak Sang, David A. Collins, Timothy G. Lach, Jung Pyung Choi, and Stuart A. Maloy. 2024. "Thermomechanical Processing for Improved Mechanical Properties of HT9 Steels" Materials 17, no. 15: 3803. https://doi.org/10.3390/ma17153803

APA StyleByun, T. S., Collins, D. A., Lach, T. G., Choi, J. P., & Maloy, S. A. (2024). Thermomechanical Processing for Improved Mechanical Properties of HT9 Steels. Materials, 17(15), 3803. https://doi.org/10.3390/ma17153803