The Effect of Heat Aging on the Microstructure and Properties of Spray-Deposited AlZnMgCu Alloy Extruded Plates

Abstract

:1. Introduction

2. Experiment

3. Results

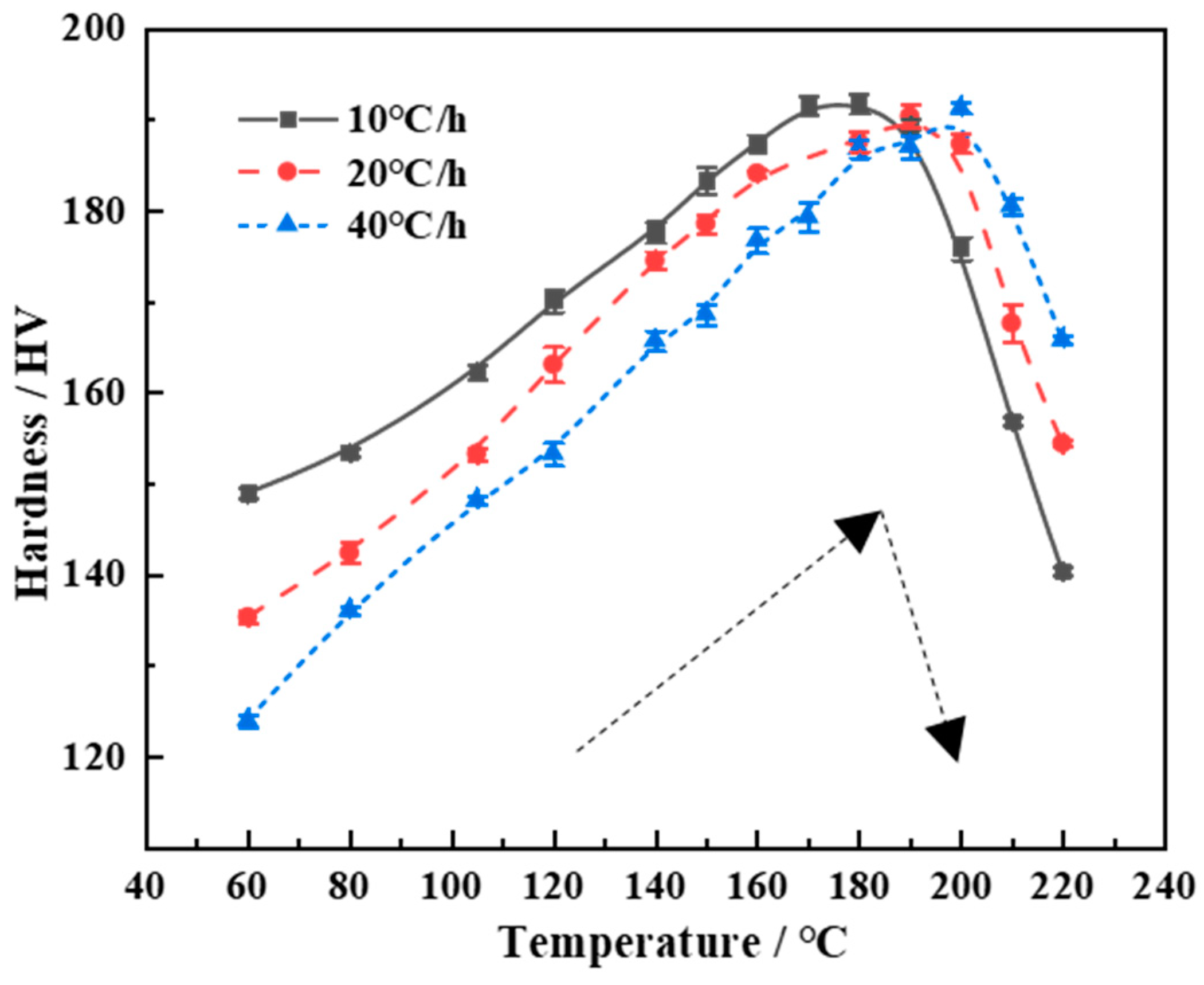

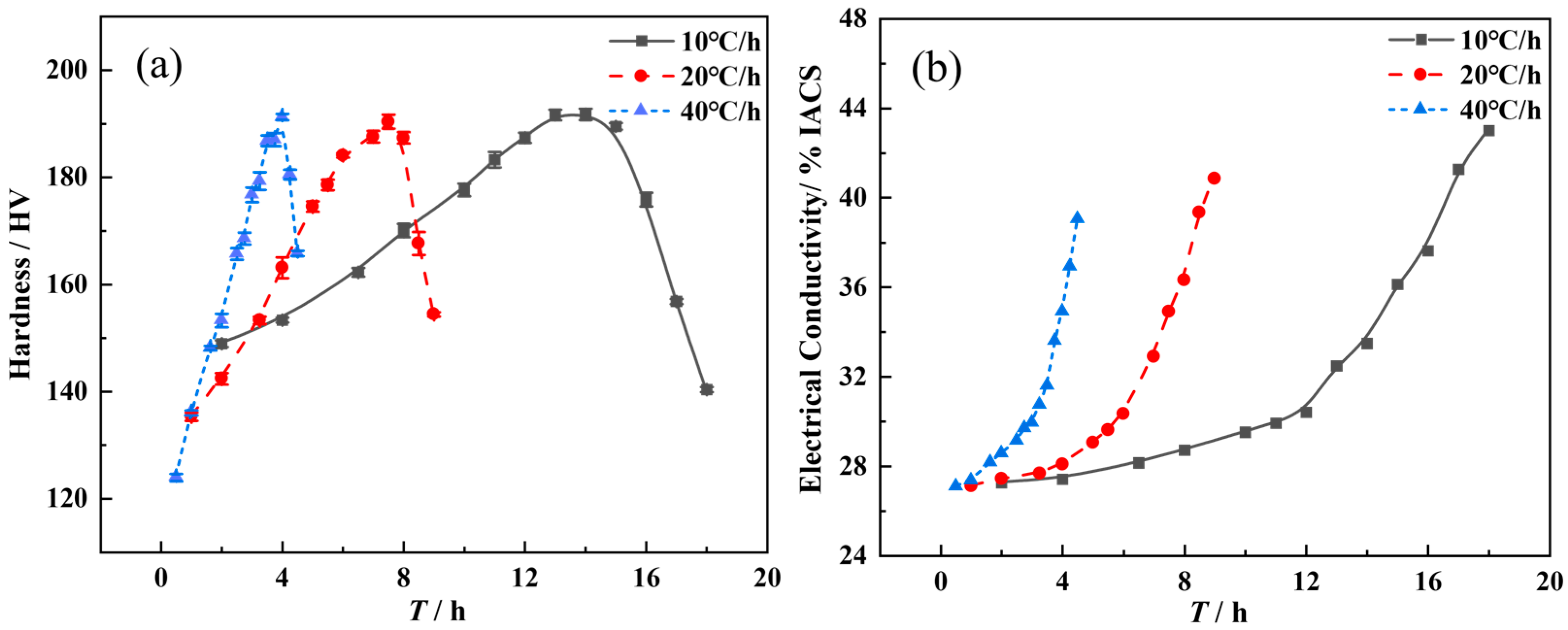

3.1. The Evolution of Hardness at Different Heating Rates

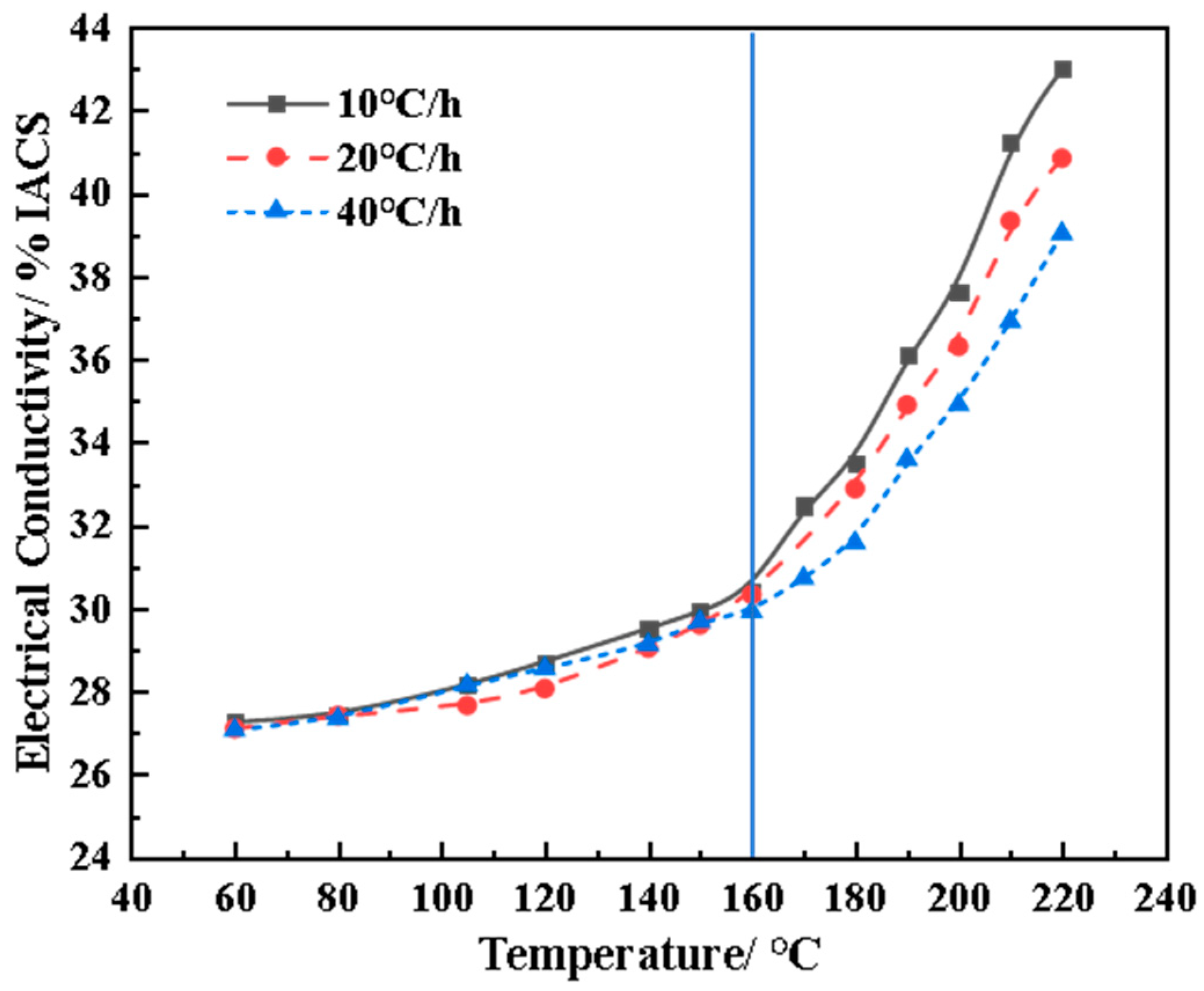

3.2. The Evolution of Electrical Conductivity at Different Heating Rates

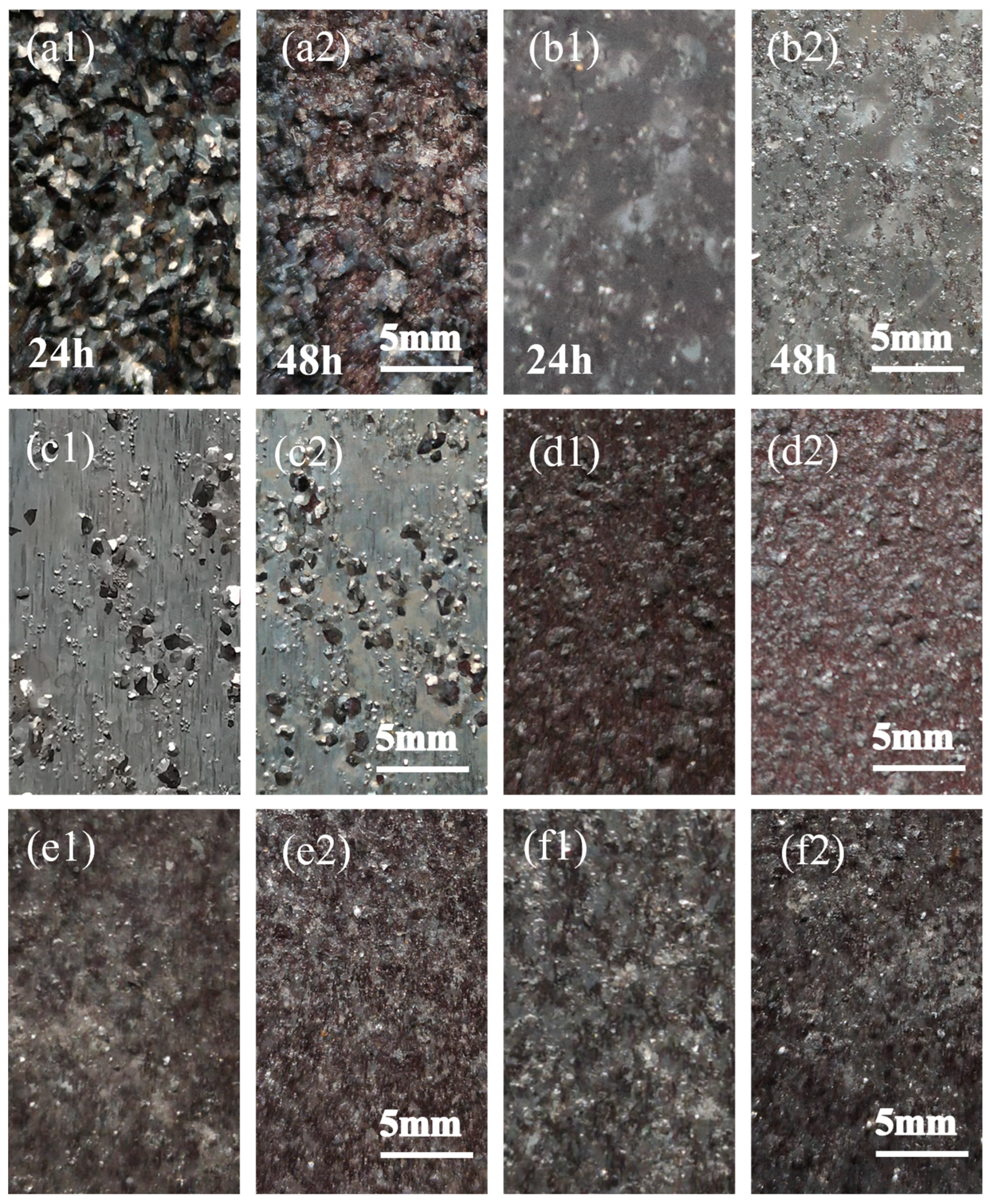

3.3. The Exfoliation Corrosion Resistance at Different Heating Rates

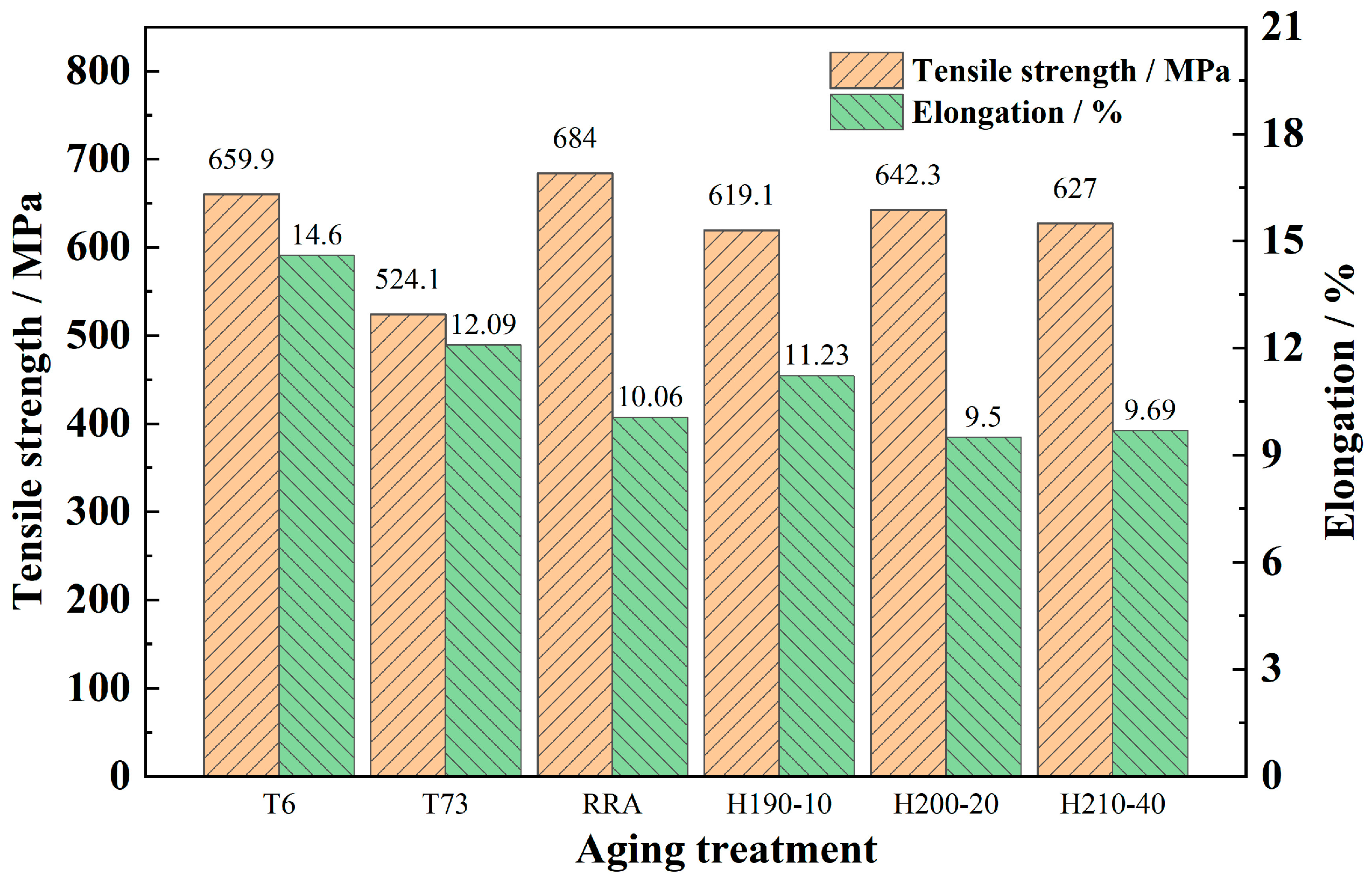

3.4. The Tensile Strength at Different Heating Rates

3.5. The Microstructure Observations of Heat Aging at 20 °C/h

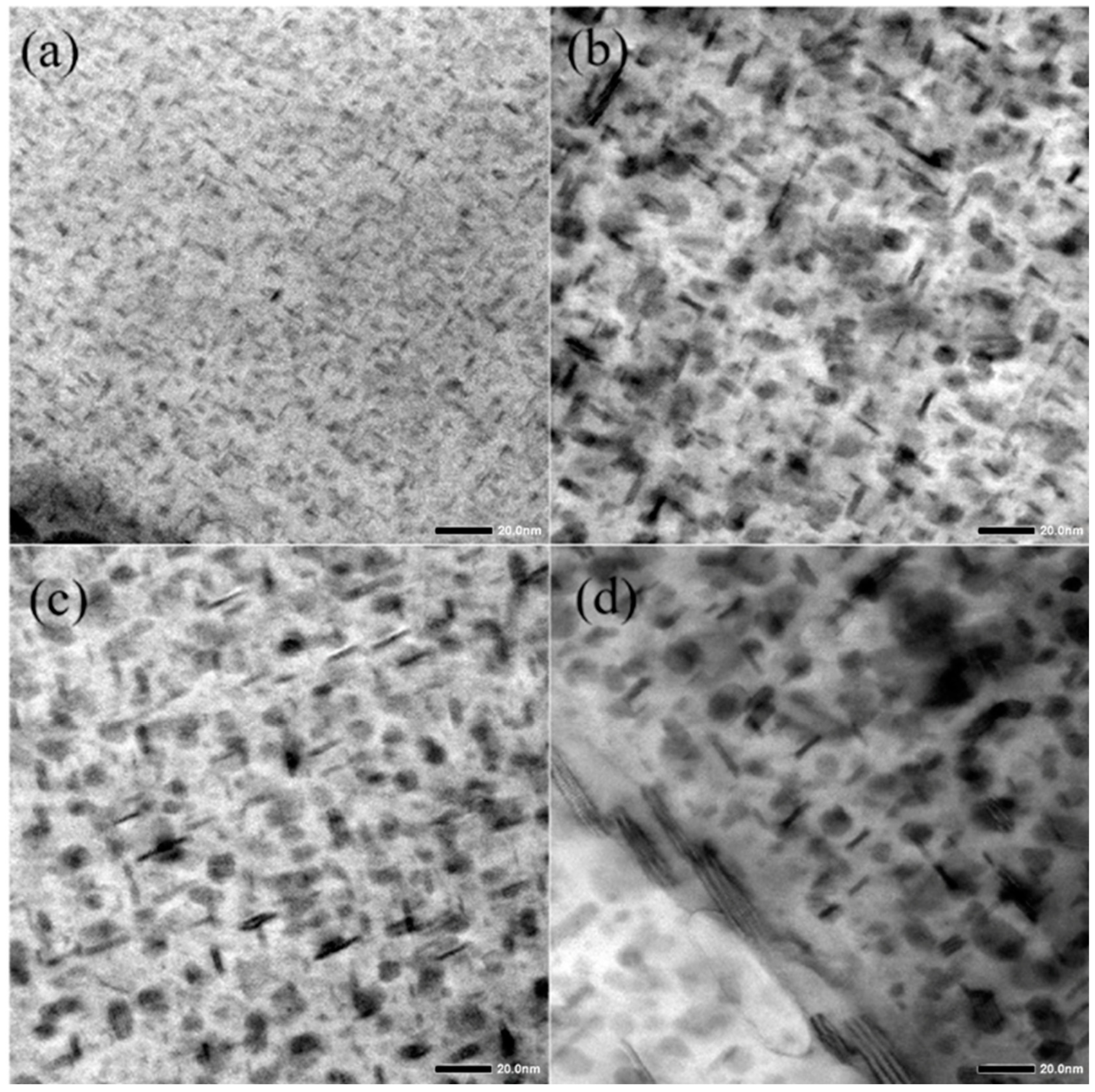

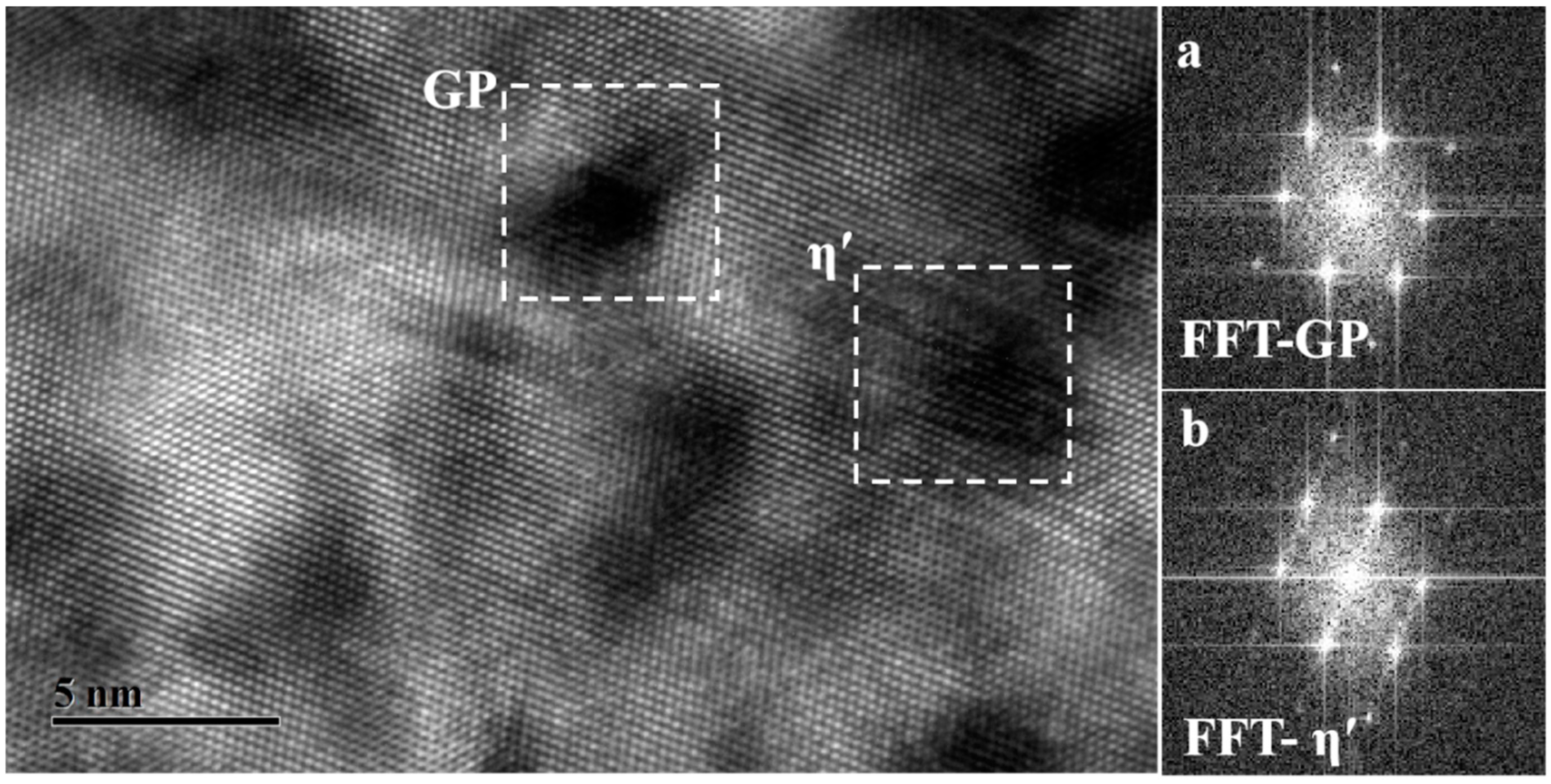

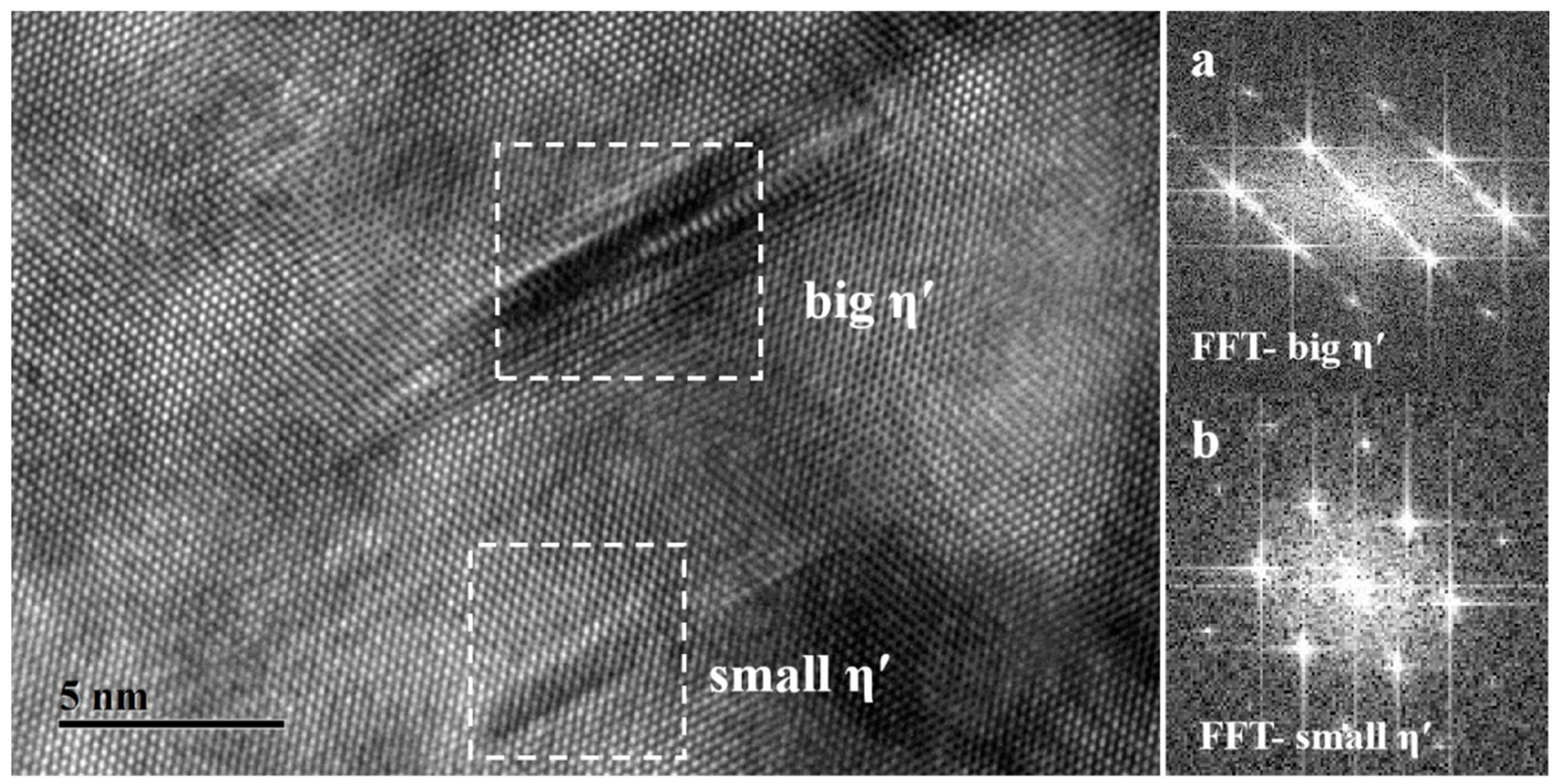

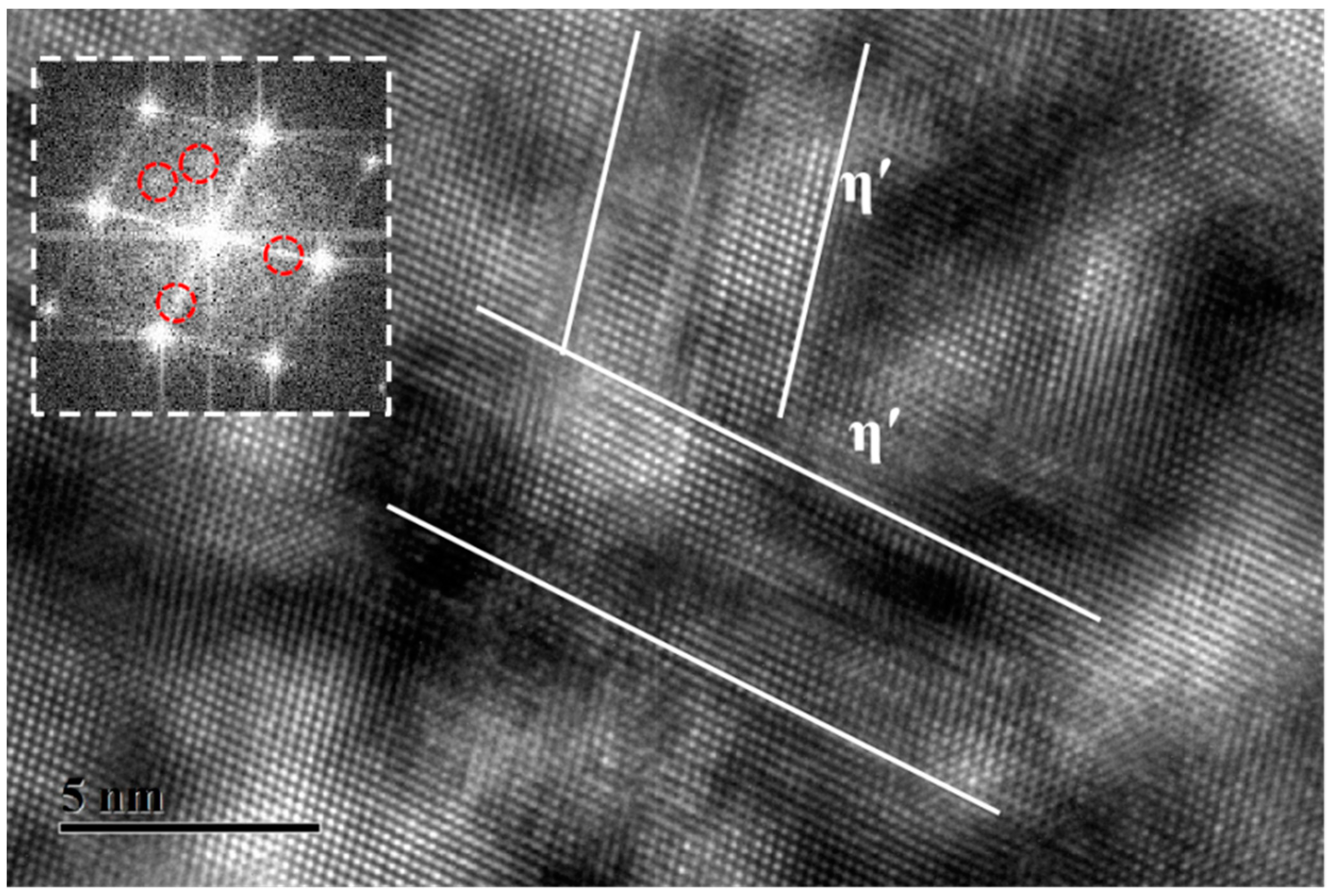

3.5.1. Intragranular Precipitates

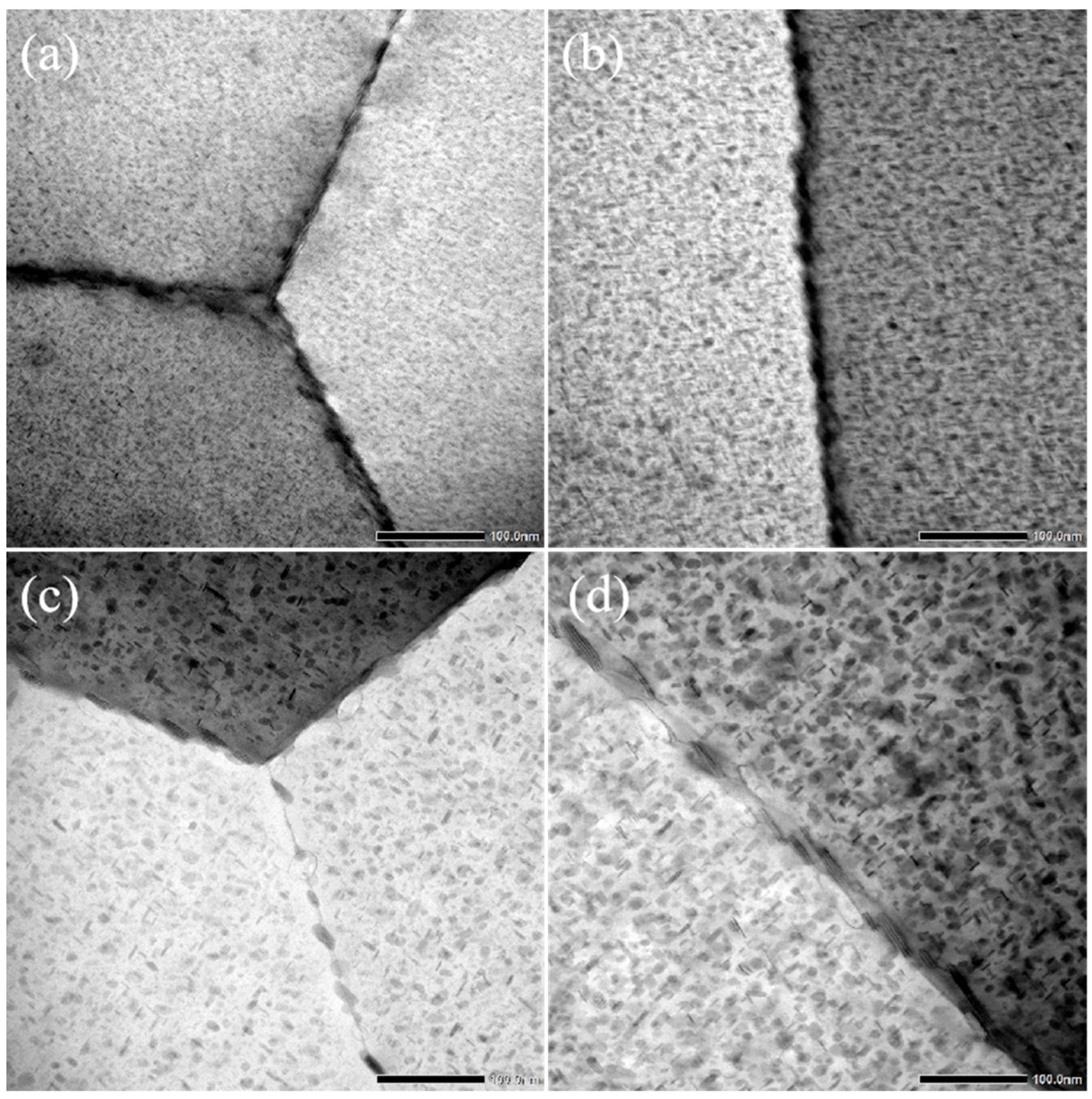

3.5.2. Grain Boundary Precipitates

4. Discussion

4.1. The Effect of the Heating Rate on the Precipitation Behavior of Alloys

4.2. The Effect of the Termination Temperature on the Precipitation Behavior

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.P.; Han, Z.K.; Xu, L.L.; Ni, H.H.; Hu, X.J.; Zhou, H.F.; Zou, Y.; Wang, J.W. Evolution of precipitate and precipitate/matrix interface in Al-Zn-Mg-Cu (-Ag) alloys. J. Mater. Sci. Technol. 2023, 138, 157–170. [Google Scholar] [CrossRef]

- Xiong, H.Q.; Zhou, Y.X.; Kong, C.; Yu, H.L. Effect of retrogression treatment with different heating rates on microstructure, strength and corrosion behaviors of 7050 alloy. Mater. Charact. 2022, 186, 111819. [Google Scholar] [CrossRef]

- Khan, M.A.; Wang, Y.W.; Anjum, M.J.; Yasin, G.; Malik, A.; Nazeer, F.; Khan, S.; Ahmad, T.; Zhang, H. Effect of heat treatment on the precipitate behaviour, corrosion resistance and high temperature tensile properties of 7055 aluminum alloy synthesis by novel spray deposited followed by hot extrusion. Vacuum 2020, 174, 109185. [Google Scholar] [CrossRef]

- Liu, L.L.; Pan, Q.L.; Wang, X.D.; Xiong, S.W. The effects of aging treatments on mechanical property and corrosion behavior of spray formed 7055 aluminum alloy. J. Alloys Compd. 2018, 735, 261–276. [Google Scholar] [CrossRef]

- Lin, X.M.; Cao, L.F.; Wu, X.D.; Tang, S.B.; Zou, Y. Precipitation behavior of spray-formed aluminum alloy 7055 during high temperature aging. Mater. Charact. 2022, 9, 112347. [Google Scholar] [CrossRef]

- Lu, Z.P.; Jiang, Y.Z.; Yu, L.H.; Xu, J.H.; Peng, J.D.; Xiang, K.Y. The effect of minor scandium addition on microstructure evolution and mechanical properties of spray formed Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2023, 948, 169710. [Google Scholar] [CrossRef]

- Meng, X.N.; Zhang, D.T.; Zhang, W.W.; Qiu, C.; Liang, G.X.; Chen, J.J. Microstructure and mechanical properties of a rapidly-solidified and extruded Al-13.2Zn-2.5Mg − 1.2Cu-0.2Zr alloy and its aging hardening response at 120 °C. Mater. Sci. Eng. A 2021, 826, 141969. [Google Scholar] [CrossRef]

- Xiong, H.Q.; Zhou, Y.X.; Yang, P.; Kong, C.; Yu, H.L. Effects of cryorolling, room temperature rolling and aging treatment on mechanical and corrosion properties of 7050 aluminum alloy. Mater. Sci. Eng. A 2022, 853, 143764. [Google Scholar] [CrossRef]

- Wu, C.H.; Feng, D.; Ren, J.J.; Zang, Q.H.; Li, J.C.; Liu, S.D.; Zhang, X.M. Effect of non-isothermal retrogression and re-aging on through-thickness homogeneity of microstructure and properties of Al-8Zn-2Mg-2Cu alloy thick plate. J. Cent. S. Univ. 2022, 29, 960–972. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, X.M.; Chen, H.M.; Jin, Y.X.; Wang, G.Y. Effect of Non-Isothermal Retrogression and Re-aging on Microstructure and Properties of Al-8Zn-2Mg-2Cu Alloy Thick Plate. Acta Metall. Sin. 2018, 54, 100–109. [Google Scholar] [CrossRef]

- Wang, Y.C.; Cao, L.F.; Wu, X.D.; Tong, X.; Liao, B.; Huang, G.J.; Wang, Z.G. Effect of retrogression treatments on microstructure, hardness and corrosion behaviors of aluminum alloy 7085. J. Alloys Compd. 2020, 814, 152264. [Google Scholar] [CrossRef]

- Azarniya, A.; Taheri, A.K.; Taheri, K.K. Recent advances in aging of 7xxx series aluminum alloys: A physical metallurgy perspective. J. Alloys Compd. 2019, 781, 945–983. [Google Scholar] [CrossRef]

- Staley, J.T. Method and Process of Non-Isothermal for Aluminum Alloys. U.S. Patent 0237113Al, 28 August 2007. [Google Scholar]

- Jiang, J.T.; Tang, Q.J.; Yang, L.; Zhang, K.; Yuan, S.J.; Zhen, L. Non-isothermal aging of an Al–8Zn–2Mg–2Cu alloy for enhanced properties. J. Mater. Process. Technol. 2016, 227, 110–116. [Google Scholar] [CrossRef]

- Jiang, J.T.; Xiao, W.Q.; Yang, L.; Shao, W.Z.; Yuan, S.J.; Zhen, L. Aging behavior and stress corrosion cracking resistance of a non-isothermally aged Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 2014, 605, 167–175. [Google Scholar] [CrossRef]

- Jiang, D.M.; Liu, Y.; Liang, S.; Xie, W.L. The effects of non-isothermal aging on the strength and corrosion behavior of AlZnMgCu alloy. J. Alloys Compd. 2016, 681, 57–65. [Google Scholar] [CrossRef]

- Peng, X.Y.; Li, Y.; Liang, X.P.; Guo, Q.; Xu, G.F.; Peng, Y.Y.; Yin, Z.M. Precipitate behavior and mechanical properties of enhanced solution treated Al-Zn-Mg-Cu alloy during non-isothermal aging. J. Alloys Compd. 2018, 735, 964–974. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, X.M.; Deng, Y.L.; Liu, S.D.; Wu, Z.Z.; Guo, Y.W. Effect of pre-aging temperature and retrogression heating rate on microstructure and properties of 7055 aluminum alloy. Chin. J. Nonferrous Met. 2014, 24, 1141–1150. [Google Scholar]

- Feng, D.; Li, X.D.; Zhang, X.M.; Liu, S.D.; Wang, J.T.; Liu, Y. The novel heat treatments of aluminium alloy characterized by multistage and non-isothermal routes: A review. J. Cent. S. Univ. 2023, 30, 2833–2866. [Google Scholar] [CrossRef]

- Li, L.; Wei, L.J.; Xu, Y.J.; Mao, L.; Wu, S.S. Study on the optimizing mechanisms of superior comprehensive properties of a hot spray deposited Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. A 2019, 742, 102–108. [Google Scholar] [CrossRef]

- Zhao, H.; Ye, L.Y.; Cheng, Q.S.; Kang, Y.; Zhang, W.J. Enhanced mechanical properties and corrosion resistance of 7055 aluminum alloy through variable-rate non-isothermal aging. J. Alloys Compd. 2023, 943, 169198. [Google Scholar] [CrossRef]

- Liu, X.Y.; Zhang, D.Y.; Wang, C.C.; Wang, X.; Zhao, Z.J.; Wu, M.; Huang, J.C. Effect of grain boundary precipitation on corrosion of heating-aging treated Al-4.47Zn-2.13Mg-1.20Cu alloy. J. Mater. Res. Technol. 2020, 9, 5815–5826. [Google Scholar] [CrossRef]

- Zhao, H.; Ye, L.Y.; Cheng, Q.S.; Kang, Y.; Zhang, W.J. Effect of variable rate non-isothermal aging on microstructure and properties of Al-Zn-Mg-Cu alloy. Mater. Charact. 2023, 197, 112715. [Google Scholar] [CrossRef]

- GB/T228.1-2010; Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature. China National Standardization Administration: Beijing, China, 2010.

- GB/T 22639-2022; Test Method of Exfoliation Corrosion for Wrought Aluminium and Aluminium Alloys. China National Standardization Administration: Beijing, China, 2022.

- AMS 4206B; Aluminum Alloy, Plate (7055-T7751) 8.0Zn-2.3Cu-2.0Mg-0.16Zr Solution Heat Treated, Stress Relieved, and Overaged. Society of Automotive Engineers: Wasrendale, PA, USA, 2011.

- Marlaud, T.; Deschamps, A.; Bley, F.; Lefebvre, W.; Baroux, B. Evolution of precipitate microstructures during the retrogression and re-aging heat treatment of an Al–Zn–Mg–Cu alloy. Acta Mater. 2010, 58, 4814–4826. [Google Scholar] [CrossRef]

| Treatments | UTS (MPa) | YS (MPa) | Elongation (%) | Exfoliation Corrosion Degree | Time Consumption |

|---|---|---|---|---|---|

| SA | 659.9 | 596 | 13.1 | ED | 16 h |

| DA | 524.1 | 470 | 16.5 | EA | 30 h |

| RRA | 684.0 | 643 | 13.3 | EA | 40 h |

| H190-10 | 619.1 | 600 | 10.5 | EB | 15 h |

| H200-20 | 642.3 | 616 | 11.3 | EB | 8 h |

| H210-40 | 627.0 | 602 | 11.1 | EC | 4.3 h |

| Treatment | MPt Average Size/nm | GBP Spacing/nm | PFZ Width/nm | Hardness /HV | Electrical Conductivity/% IACS |

|---|---|---|---|---|---|

| H-160-20 | 3.9 | - | - | 184.1 | 30.3 |

| H-190-20 | 7.2 | 10.8 | - | 190.4 | 34.9 |

| H-200-20 | 8.5 | 13.7 | 25 | 187.4 | 36.3 |

| H-210-20 | 10.9 | 22.6 | 27.2 | 167.7 | 39.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Feng, D.; He, Z.; Zhu, Y.; Tao, Z.; Xu, Y.; Wang, H.; Wang, J.; Liu, Y. The Effect of Heat Aging on the Microstructure and Properties of Spray-Deposited AlZnMgCu Alloy Extruded Plates. Materials 2024, 17, 3706. https://doi.org/10.3390/ma17153706

Chen C, Feng D, He Z, Zhu Y, Tao Z, Xu Y, Wang H, Wang J, Liu Y. The Effect of Heat Aging on the Microstructure and Properties of Spray-Deposited AlZnMgCu Alloy Extruded Plates. Materials. 2024; 17(15):3706. https://doi.org/10.3390/ma17153706

Chicago/Turabian StyleChen, Chen, Di Feng, Zhiping He, Yichao Zhu, Zhiyuan Tao, Yinhui Xu, Haoran Wang, Jingtao Wang, and Ying Liu. 2024. "The Effect of Heat Aging on the Microstructure and Properties of Spray-Deposited AlZnMgCu Alloy Extruded Plates" Materials 17, no. 15: 3706. https://doi.org/10.3390/ma17153706

APA StyleChen, C., Feng, D., He, Z., Zhu, Y., Tao, Z., Xu, Y., Wang, H., Wang, J., & Liu, Y. (2024). The Effect of Heat Aging on the Microstructure and Properties of Spray-Deposited AlZnMgCu Alloy Extruded Plates. Materials, 17(15), 3706. https://doi.org/10.3390/ma17153706