Synthesis of Heterostructured TiO2 Nanopores/Nanotubes by Anodizing at High Voltages

Abstract

1. Introduction

2. Experimental Procedure

2.1. Anodizing Titanium with High Voltage

2.2. Surface Morphology Analysis and Electrochemical Characteristics

2.3. Biological Compatibility Evaluation

3. Results and Discussion

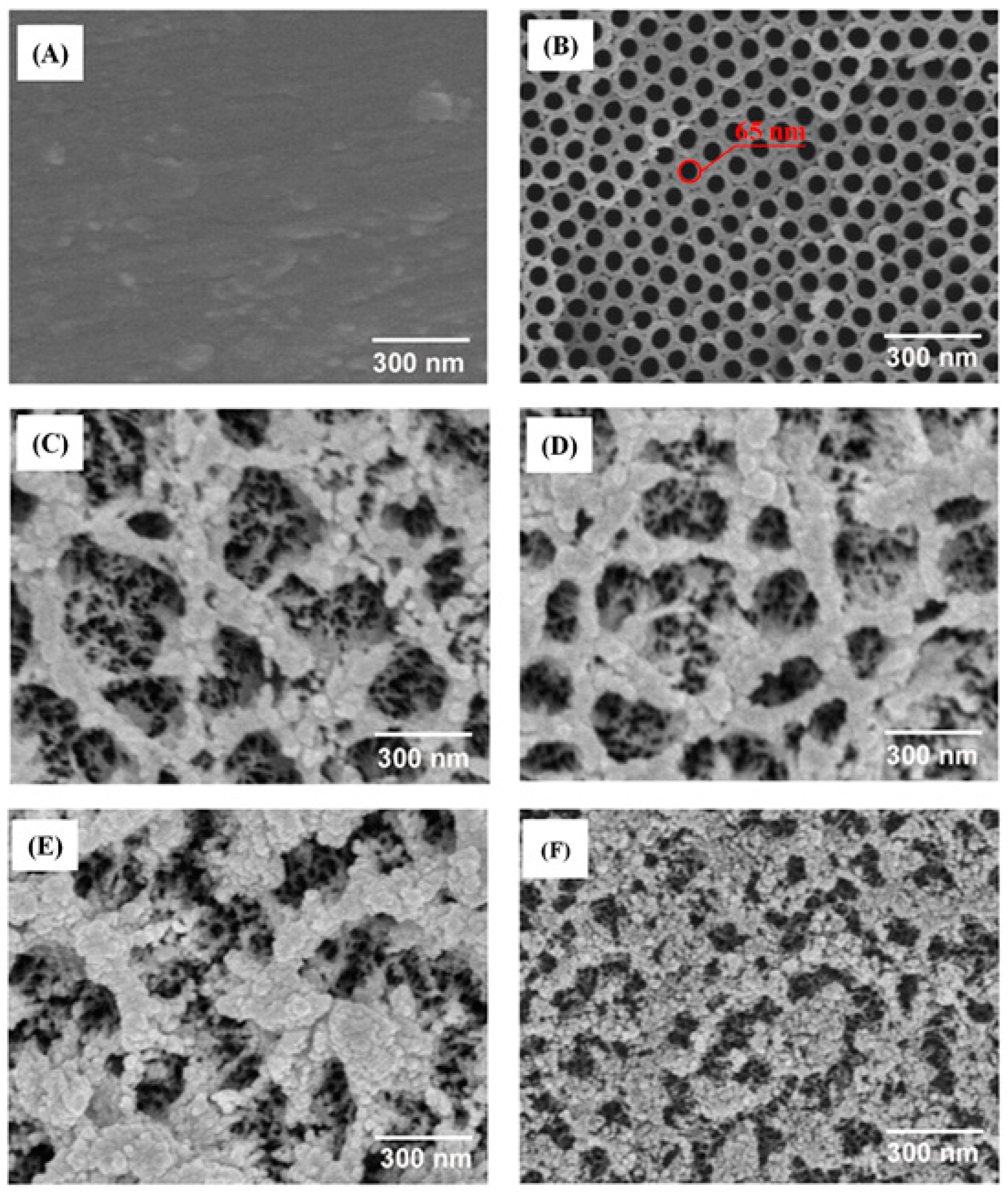

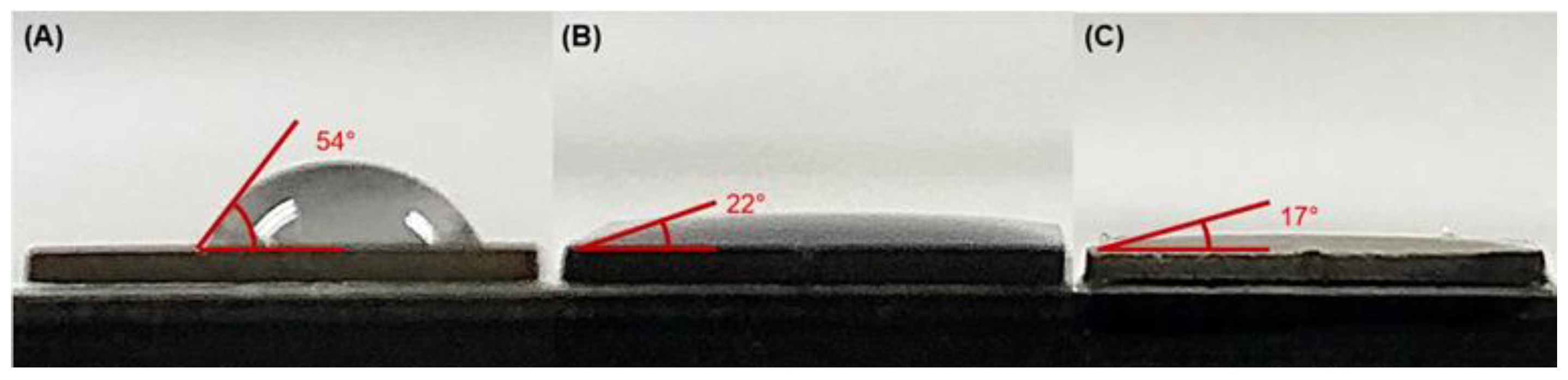

3.1. Surface Properties

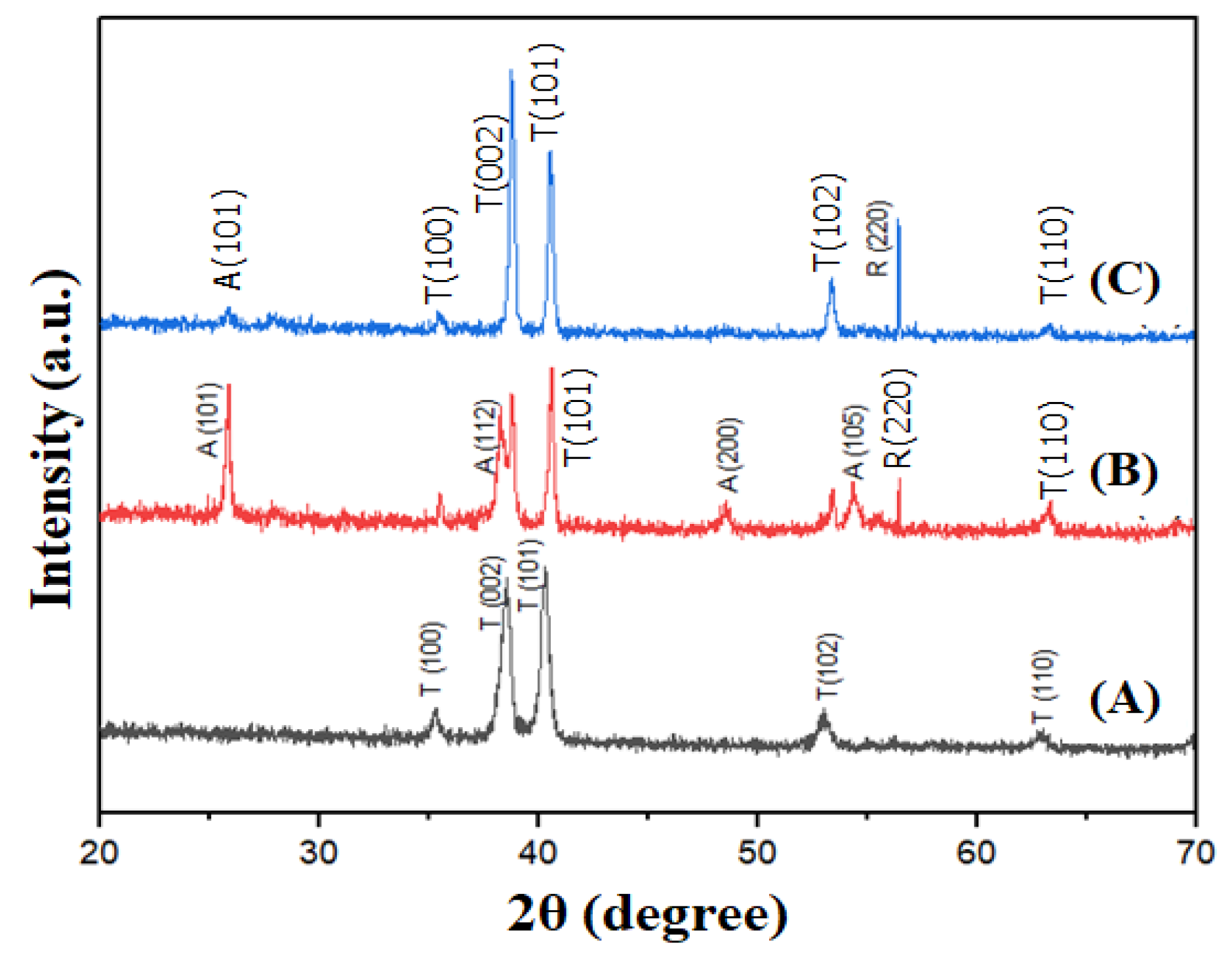

3.2. X-ray Diffraction Study

3.3. Electrochemical Properties

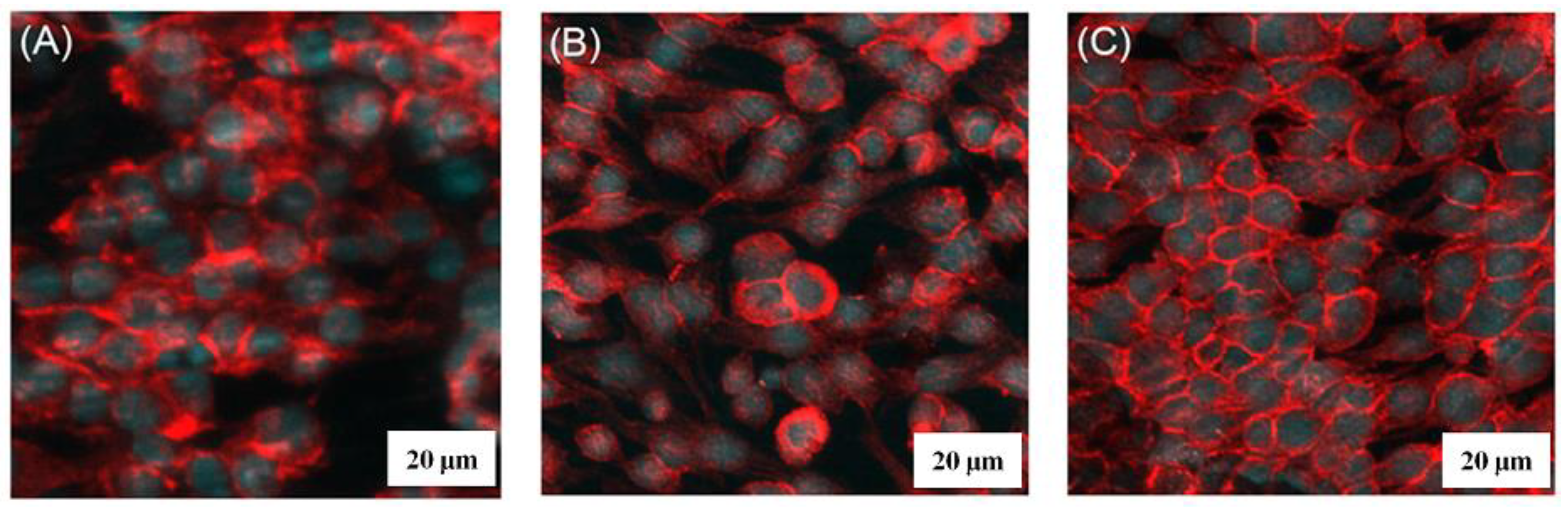

3.4. Cell Attachment Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Manivasagam, V.K.; Popat, K.C. Hydrothermally treated titanium surfaces for enhanced osteogenic differentiation of adipose derived stem cells. Mater. Sci. Eng. C 2021, 128, 112315. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, H.; Komasa, S.; Morimoto, Y.; Sekino, T.; Kawazoe, T.; Okazaki, J. UV/ozone irradiation manipulates immune response for antibacterial activity and bone regeneration on titanium. Mater. Sci. Eng. C 2021, 129, 112377. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Desai, T.A. TiO2-Based Nanotopographical Cues Attenuate the Restenotic Phenotype in Primary Human Vascular Endothelial and Smooth Muscle Cells. ACS Biomater. Sci. Eng. 2020, 6, 923–932. [Google Scholar] [CrossRef] [PubMed]

- Ocampo, R.A.; Echeverry-Rendon, M.; Robledo, S.; Echeverría, F.E. Effect of TiO2 nanotubes size, heat treatment, and UV irradiation on osteoblast behavior. Mater. Chem. Phys. 2022, 275, 125137. [Google Scholar] [CrossRef]

- Motola, M.; Capek, J.; Zazpe, R.; Bacova, J.; Hromadko, L.; Bruckova, L.; Ng, S.; Handl, J.; Spotz, Z.; Knotek, P.; et al. Thin TiO2 Coatings by ALD Enhance the Cell Growth on TiO2 Nanotubular and Flat Substrates. ACS Appl. Bio Mater. 2020, 3, 6447–6456. [Google Scholar] [CrossRef] [PubMed]

- Demetrescu, I.; Pirvu, C.; Mitran, V. Effect of nano-topographical features of Ti/TiO2 electrode surface on cell response and electrochemical stability in artificial saliva. Bioelectrochemistry 2010, 79, 122–129. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.D.; Yook, S.W.; Kim, H.E.; Koh, Y.H. Fabrication of titanium scaffolds with porosity and pore size gradients by sequential freeze casting. Mater. Lett. 2009, 63, 1545–1547. [Google Scholar] [CrossRef]

- Pham, V.H.; Jang, T.S.; Jung, H.D.; Kim, H.E.; Koh, Y.H. Creation of nanoporous tantalum (Ta)-incorporated titanium (Ti) surface onto Ti implants by sputtering of Ta in Ar under extremely high negative substrate biases. J. Mater. Chem. 2012, 22, 24798–24804. [Google Scholar] [CrossRef]

- Xiao, J.; Zhou, H.; Zhao, L.; Sun, Y.; Guan, S.; Liu, B.; Kong, L. The effect of hierarchical micro/nanosurface titanium implant on osseointegration in ovariectomized sheep. Osteoporos. Int. 2011, 22, 1907–1913. [Google Scholar] [CrossRef]

- Kim, M.H.; Park, K.; Choi, K.H.; Kim, S.H.; Kim, S.E.; Jeong, C.M.; Huh, J.B. Cell adhesion and in vivo osseointegration of sandblasted/acid etched/anodized dental implants. Int. J. Mol. Sci. 2015, 16, 10324–10336. [Google Scholar] [CrossRef]

- Wang, G.; Wan, Y.; Ren, B.; Liu, Z. Bioactivity of micropatterned TiO2 nanotubes fabricated by micro-milling and anodic oxidation. Mater. Sci. Eng. C 2019, 95, 114–121. [Google Scholar] [CrossRef]

- Wan, Y.; Wang, T.; Wang, Z.; Jin, Y.; Liu, Z. Construction and characterization of micro/nano-topography on titanium alloy formed by micro-milling and anodic oxidation. Int. J. Adv. Manuf. Technol. 2018, 98, 29–35. [Google Scholar] [CrossRef]

- Fan, X.; Feng, B.; Liu, Z.; Tan, J.; Zhi, W.; Lu, X.; Wang, J.; Weng, J. Fabrication of TiO2 nanotubes on porous titanium scaffold and biocompatibility evaluation in vitro and in vivo. J. Biomed. Mater. Res. Part A 2012, 100A, 3422–3427. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Kim, H.E.; Shin, K.H.; Koh, Y.H. Improving the strength and biocompatibility of porous titanium scaffolds by creating elongated pores coated with a bioactive, nanoporous TiO2 layer. Mater. Lett. 2010, 64, 2526–2529. [Google Scholar] [CrossRef]

- Jeremiasz, K.; Jaroslaw, J. Effect of the High Voltage Anodic Oxidation on the Titanium Corrosion Resistance. Solid State Phenom. 2015, 227, 479–482. [Google Scholar] [CrossRef]

- Asumpinwong, W.; Kanokwan, S.; Viritpon, S. Different constant voltages of anodization on the corrosion behavior of Ti-6Al-4V alloy. Chiang Mai J. Sci. 2015, 42, 239–248. [Google Scholar]

- Il, S.P.; Tae, G.W.; Min, H.L.; Seung, G.A. Effects of anodizing voltage on the anodized and hydrothermally treated titanium surface. Met. Mater. Int. 2006, 12, 505–511. [Google Scholar] [CrossRef]

- Chayanis, V.; Tachakorn, K.; Pimduen, R.; Pisaisit, C. Color Formation on Titanium Surface Treated by Anodization and the Surface Characteristics: A Review. CM Dent. J. 2023, 44, 13–21. [Google Scholar] [CrossRef]

- Lucas, A.G.; Andrea, G.S.; Emilio, J.P.; Wido, H.S.; Silvia, M.C.; Josefina, B. Chemical and mechanical properties of anodized cp-titanium in NH4H2PO4/NH4F media for biomedical applications. Surf. Coat. Technol. 2012, 206, 4791–4798. [Google Scholar] [CrossRef]

- Giuseppe, N.; Marco, P.; Tiziana, V.; Andrea, D.S. Colouring titanium alloys by anodic oxidation. Metalurgija 2018, 57, 111. [Google Scholar]

- Bradford, J.P.; Hernandez-Moreno, G.; Pillai, R.R.; Hernandez-Nichols, A.L.; Thomas, V. Low-Temperature Plasmas Improving Chemical and Cellular Properties of Poly (Ether Ether Ketone) Biomaterial for Biomineralization. Materials 2024, 17, 171. [Google Scholar] [CrossRef]

- Tian, G.; Dong, L.; Wei, C.; Huang, J.; He, H.; Shao, J. Investigation on microstructure and optical properties of titanium dioxide coatings annealed at various temperature. Opt. Mater. 2006, 28, 1058–1063. [Google Scholar] [CrossRef]

- Mohan, L.; Dennis, C.; Padmapriya, N.; Anandan, C.; Rajendran, N. Effect of Electrolyte Temperature and Anodization Time on Formation of TiO2 Nanotubes for Biomedical Applications. Mater. Today Commun. 2020, 23, 101103. [Google Scholar] [CrossRef]

- Ali, G.; Kim, H.J.; Kim, J.J.; Cho, S.O. Formation of self-organized Zircaloy-4 oxide nanotubes in organic viscous electrolyte via anodization. Nanoscale Res. Lett. 2014, 9, 553. [Google Scholar] [CrossRef]

- Guan, D.; Wang, Y. Synthesis and growth mechanism of multilayer TiO2 nanotube arrays. Nanoscale 2012, 4, 2968–2977. [Google Scholar] [CrossRef]

- Shokuhfar, T.; Sinha-Ray, S.; Sukotjo, C.; Yarin, A.L. Intercalation of anti-inflammatory drug molecules within TiO2 nanotubes. RSC Adv. 2013, 3, 17380. [Google Scholar] [CrossRef]

- Lee, K.; Mazare, A.; Schmuki, P. One-Dimensional Titanium Dioxide Nanomaterials: Nanotubes. Chem. Rev. 2014, 114, 9385–9454. [Google Scholar] [CrossRef]

- Xue, Q.G.; Annabella, S. Reactivity of Anatase TiO2 Nanoparticles: The Role of the Minority (001) Surface. J. Phys. Chem. B 2005, 109, 19560–19562. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Goldberg, M.; Doeven, E.H.; Littlefair, G. Titanium in Biomedical Applications-Properties and Fabrication: A Review. J. Biomater. Tissue Eng. 2015, 5, 593–619. [Google Scholar] [CrossRef]

- Jiang, P.; Zhang, Y.; Hu, R.; Shi, B.; Zhang, L.; Huang, Q.; Yang, Y.; Tang, P.; Lin, C. Advanced surface engineering of titanium materials for biomedical applications: From static modification to dynamic responsive regulation. Bioact. Mater. 2023, 27, 15–57. [Google Scholar] [CrossRef]

- Mutalik, C.; Hsiao, Y.-C.; Chang, Y.-H.; Krisnawati, D.I.; Alimansur, M.; Jazidie, A.; Nuh, M.; Chang, C.-C.; Wang, D.-Y.; Kuo, T.-R. High UV-Vis-NIR Light-Induced Antibacterial Activity by Heterostructured TiO2-FeS2 Nanocomposites. Int. J. Nanomed. 2020, 15, 8911–8920. [Google Scholar] [CrossRef] [PubMed]

| Samples | Ecorr (V) | icorr (10−7 A/cm2) | Rcorr (kΩcm2) | Corrosion Rate (mg/m2h) | CP Efficient H (%) |

|---|---|---|---|---|---|

| Bare Ti | −0.717 | 1.280 | 332 | 5.73 | 0% |

| TiO2 50 V | −0.442 | 0.157 | 1059 | 0.70 | 87.78% |

| TiO2 150 V | −0.515 | 0.305 | 945 | 1.36 | 76.26% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tuan, T.Q.; Toan, L.V.; Pham, V.-H. Synthesis of Heterostructured TiO2 Nanopores/Nanotubes by Anodizing at High Voltages. Materials 2024, 17, 3347. https://doi.org/10.3390/ma17133347

Tuan TQ, Toan LV, Pham V-H. Synthesis of Heterostructured TiO2 Nanopores/Nanotubes by Anodizing at High Voltages. Materials. 2024; 17(13):3347. https://doi.org/10.3390/ma17133347

Chicago/Turabian StyleTuan, Ta Quoc, Le Van Toan, and Vuong-Hung Pham. 2024. "Synthesis of Heterostructured TiO2 Nanopores/Nanotubes by Anodizing at High Voltages" Materials 17, no. 13: 3347. https://doi.org/10.3390/ma17133347

APA StyleTuan, T. Q., Toan, L. V., & Pham, V.-H. (2024). Synthesis of Heterostructured TiO2 Nanopores/Nanotubes by Anodizing at High Voltages. Materials, 17(13), 3347. https://doi.org/10.3390/ma17133347