Comparison between Mechanical Properties and Joint Performance of AA 2024-T351 Aluminum Alloy Welded by Friction Stir Welding, Metal Inert Gas and Tungsten Inert Gas Processes

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

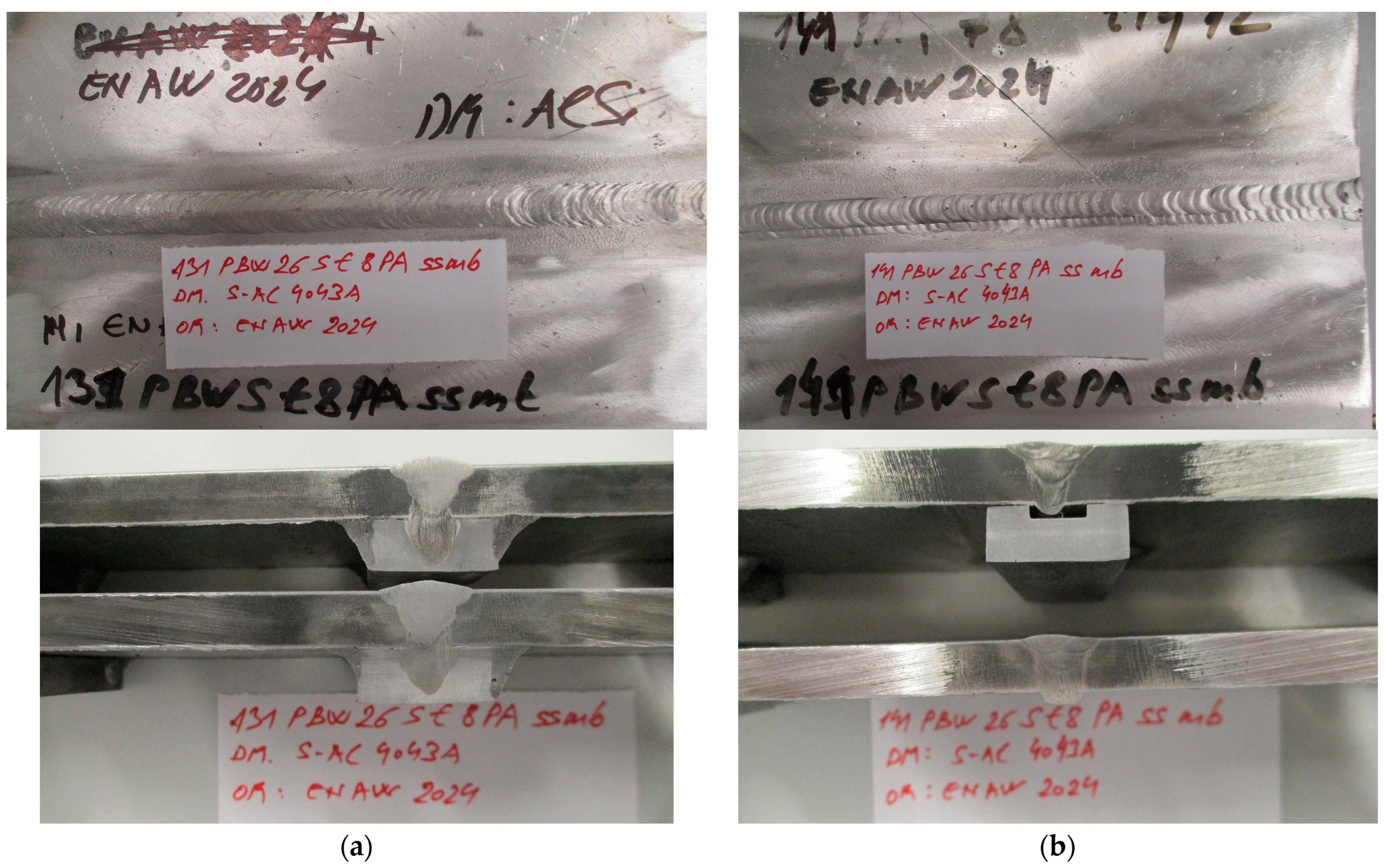

2.2. Fusion Welding of AA2024-T351

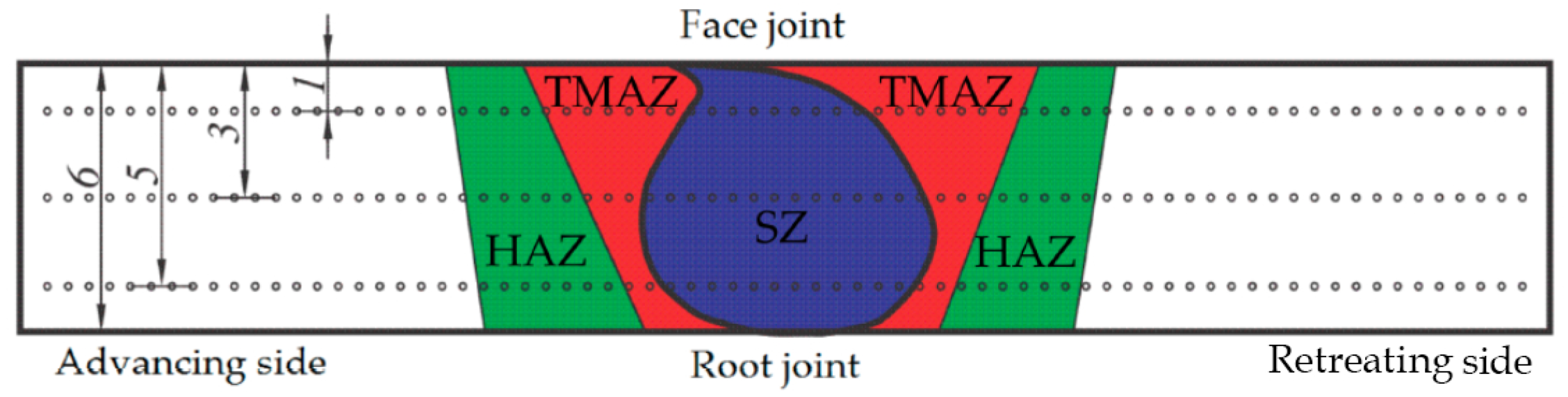

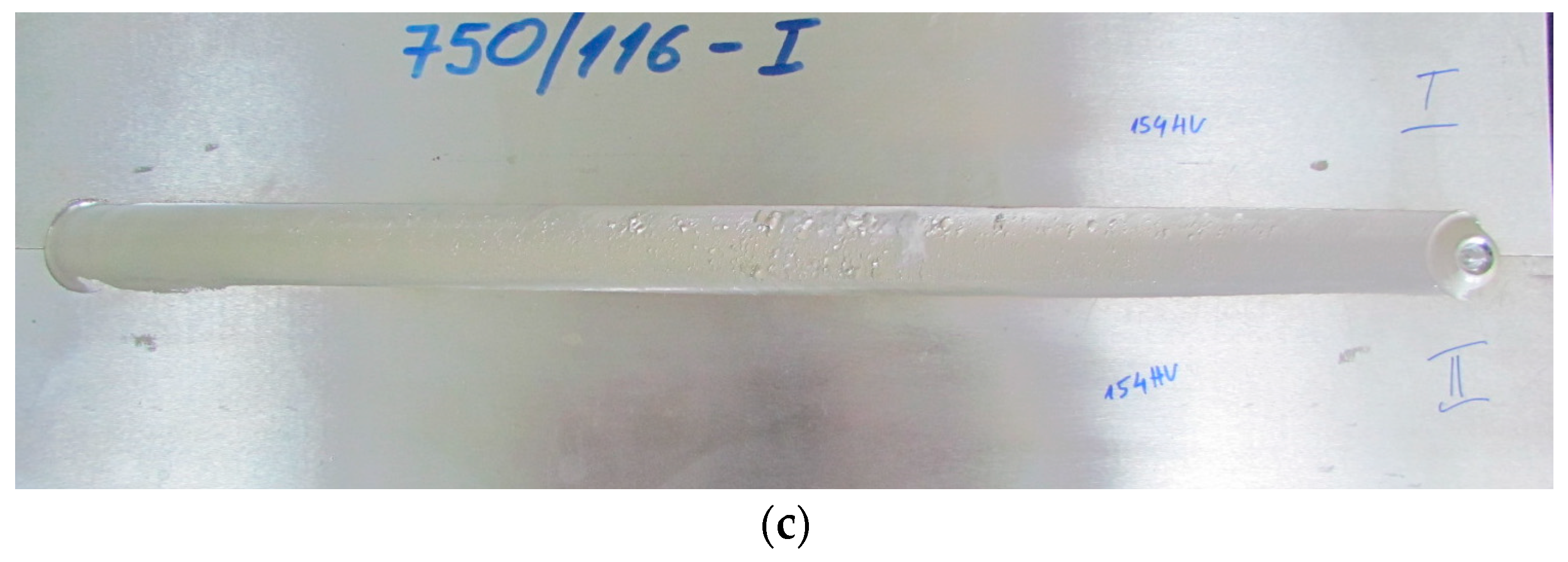

2.3. FSW of AA2024-T351

2.4. Characterization of AA2024-T351 Welds

3. Results and Discussion

3.1. Visual Inspections

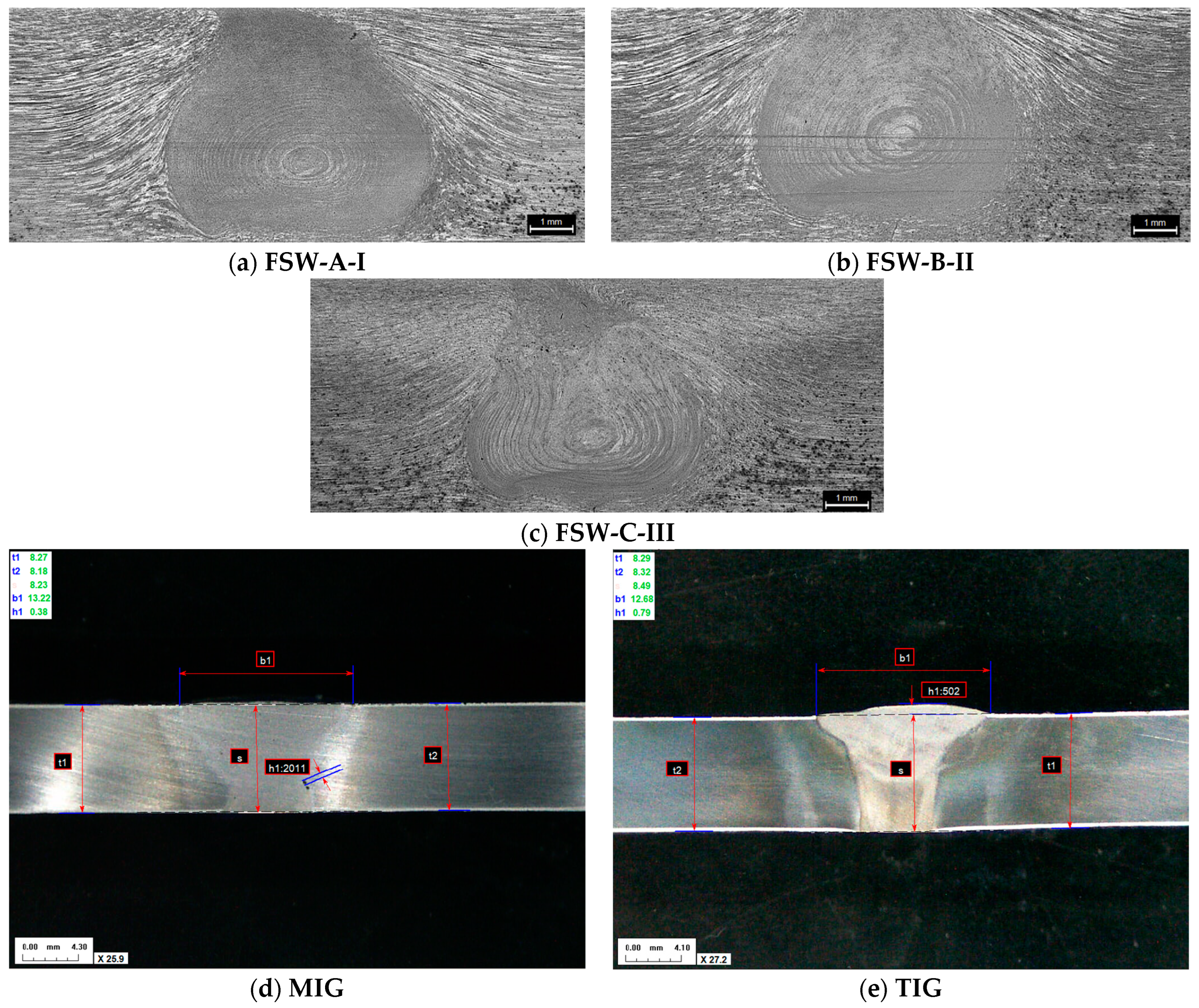

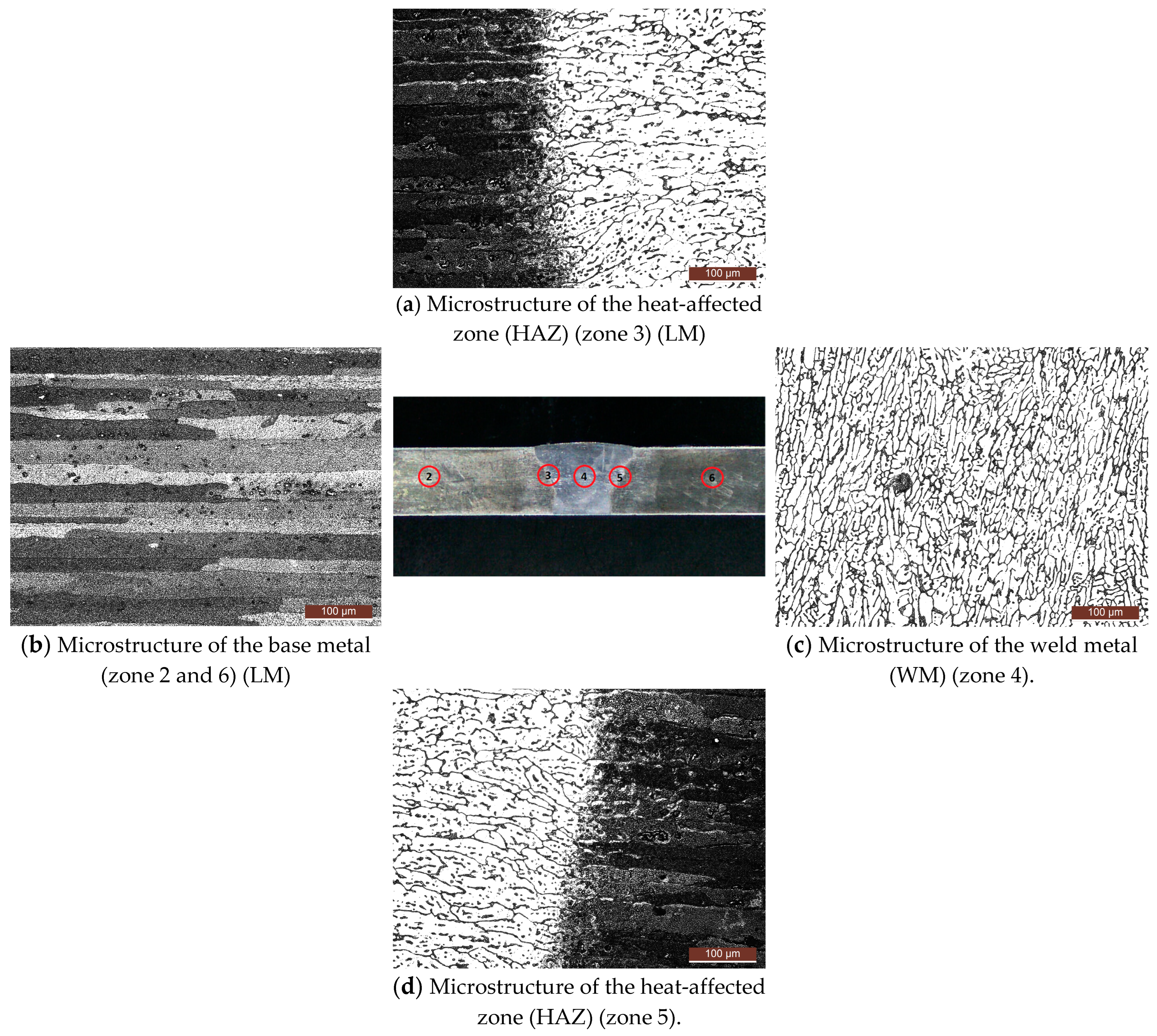

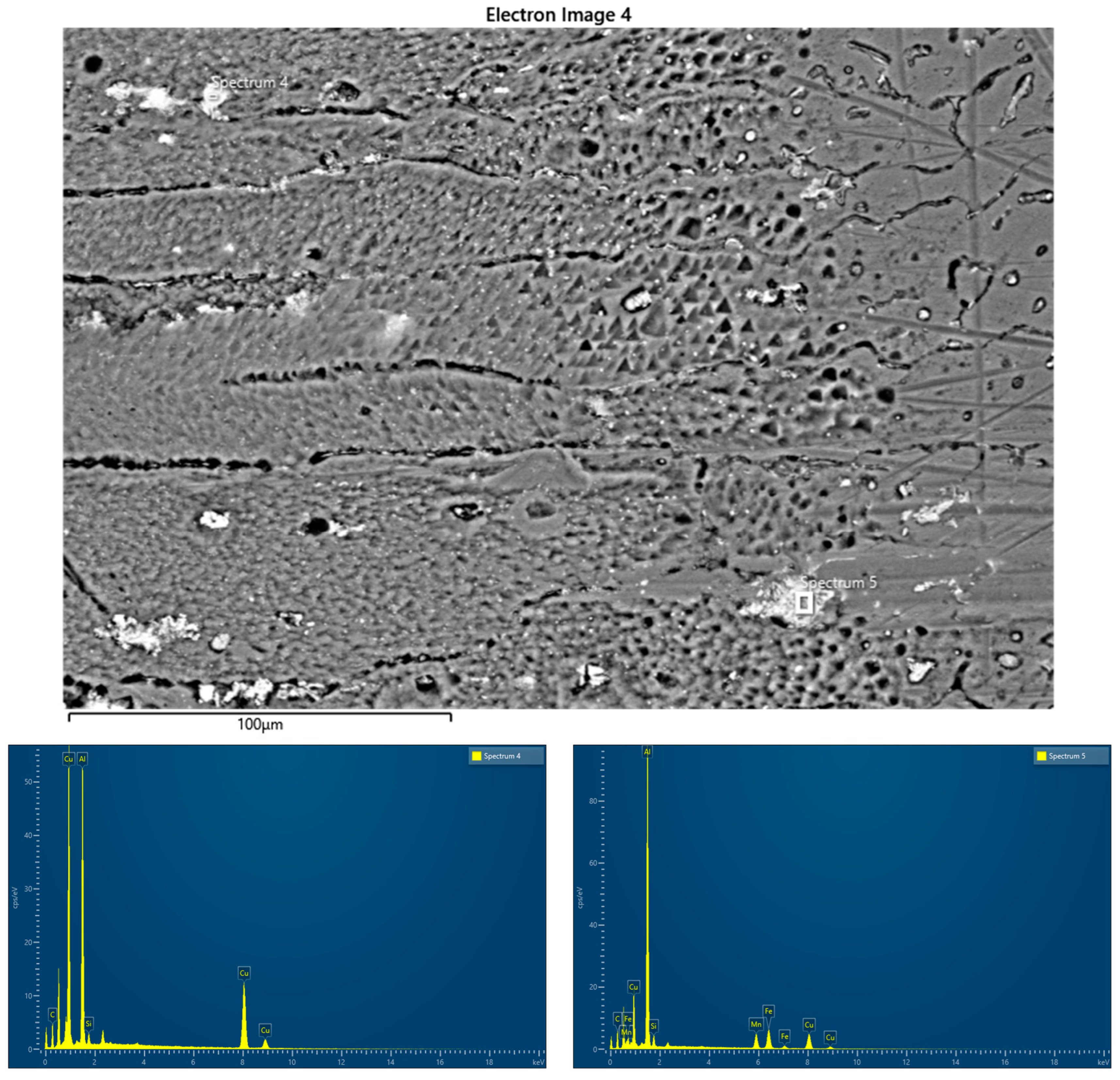

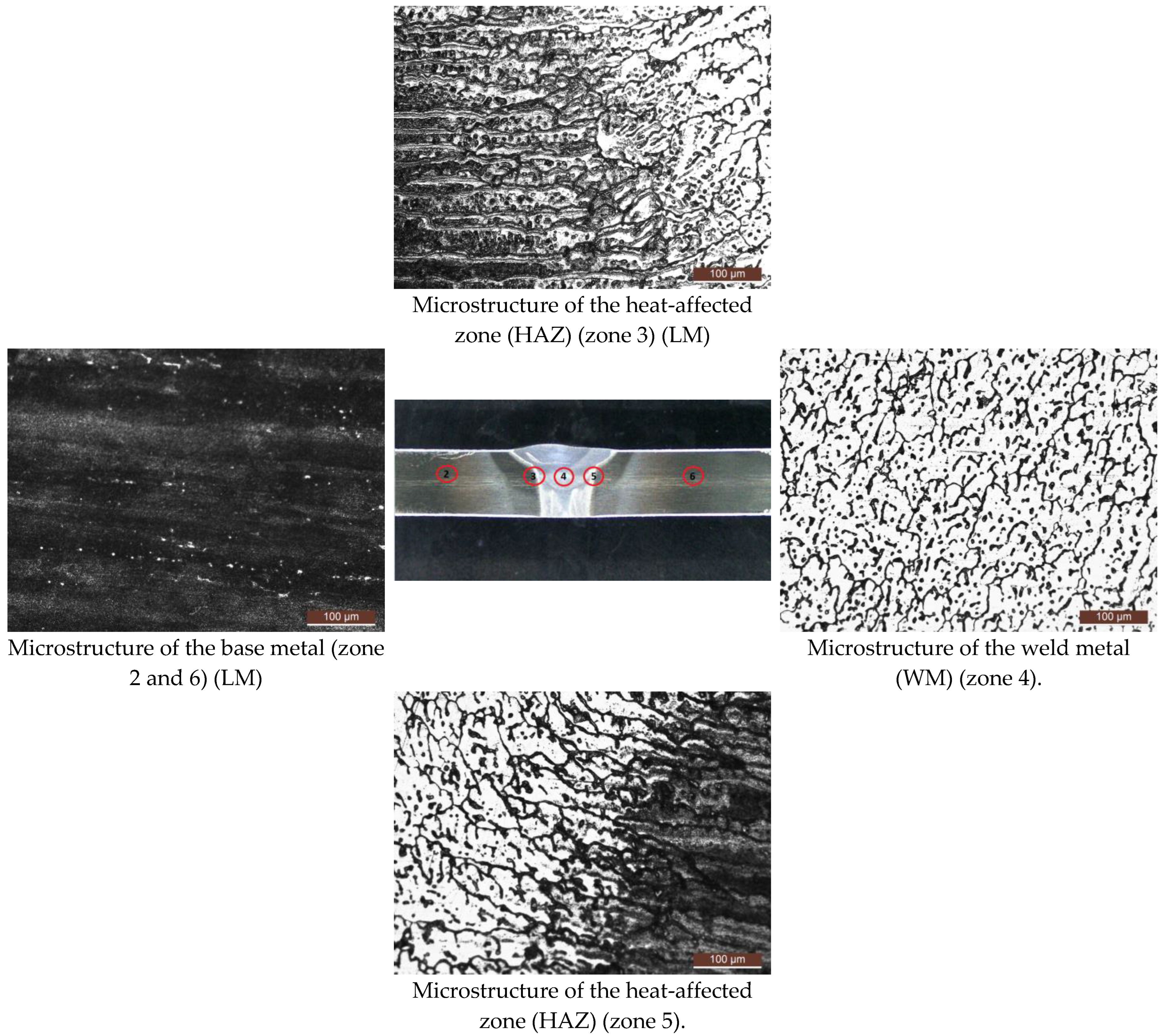

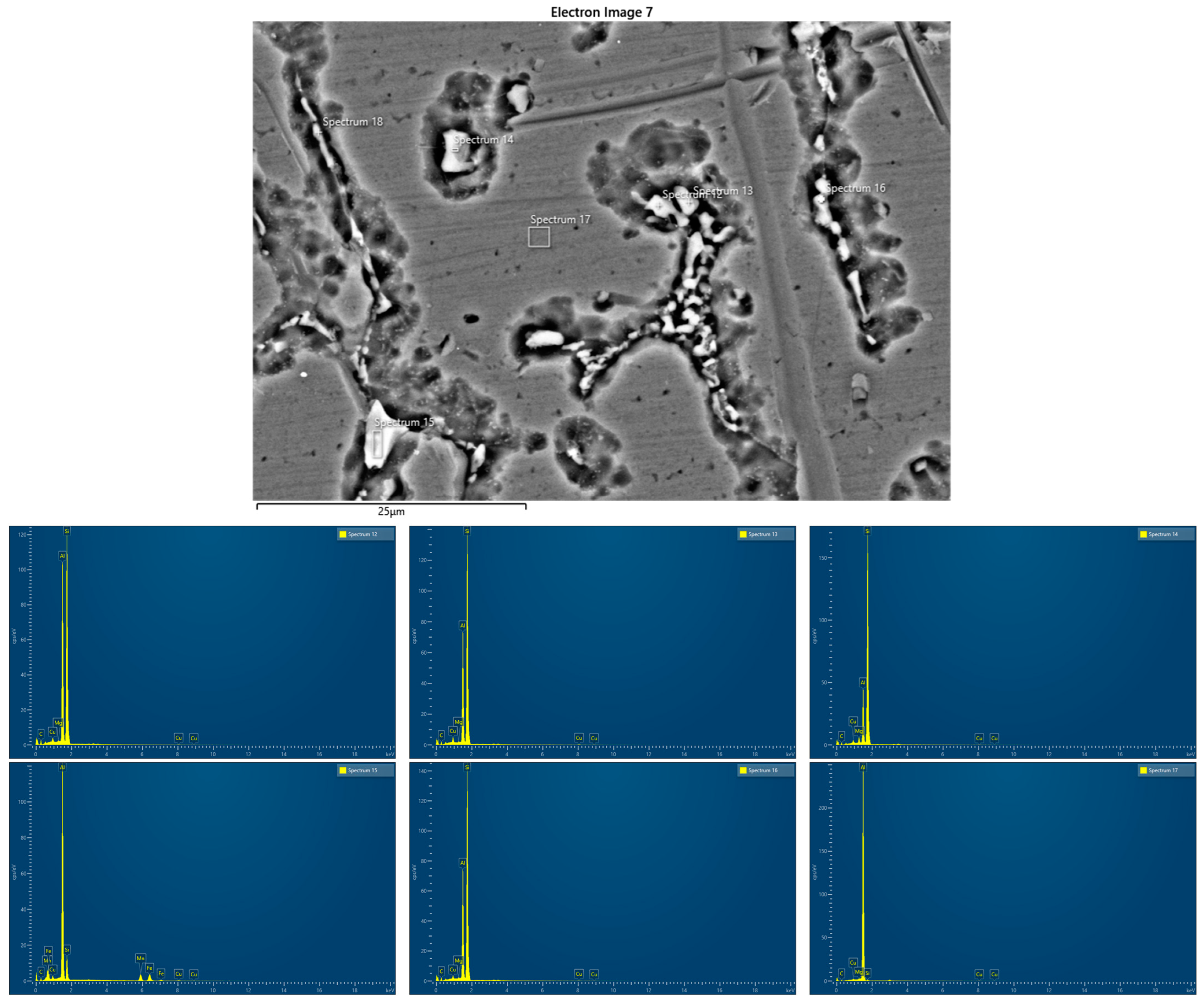

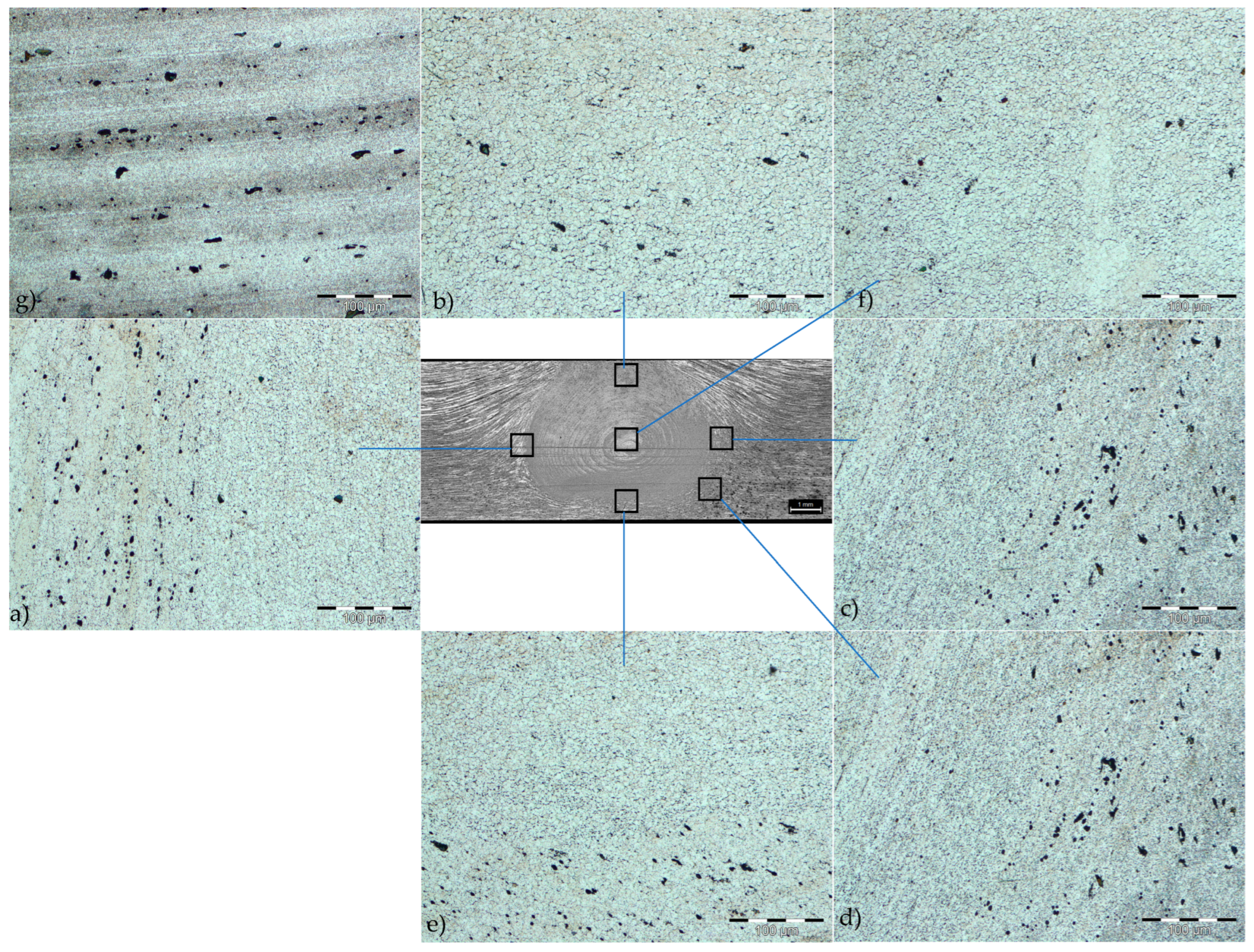

3.2. Macro- and Microscopic Examinations

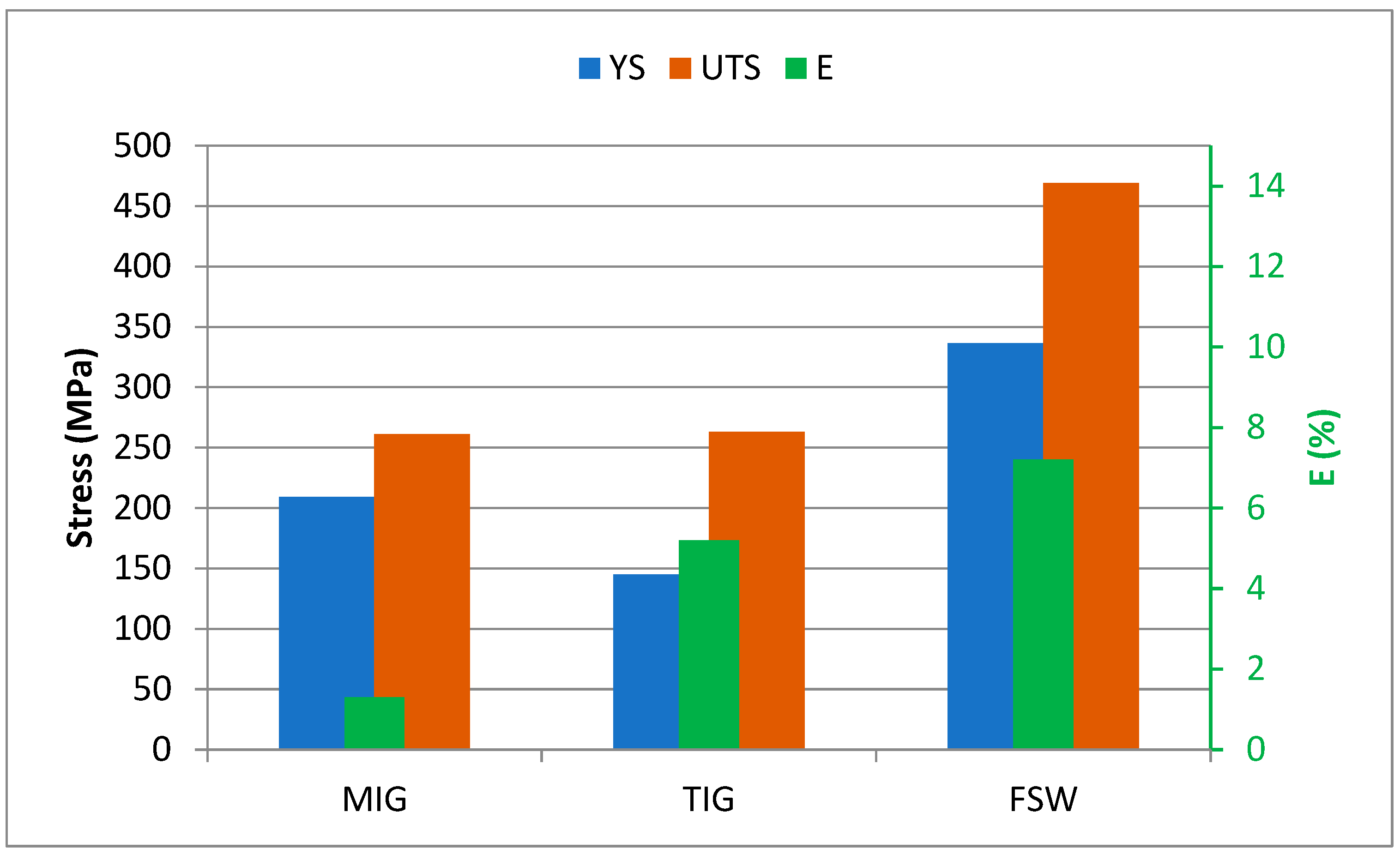

3.3. Tensile Testing

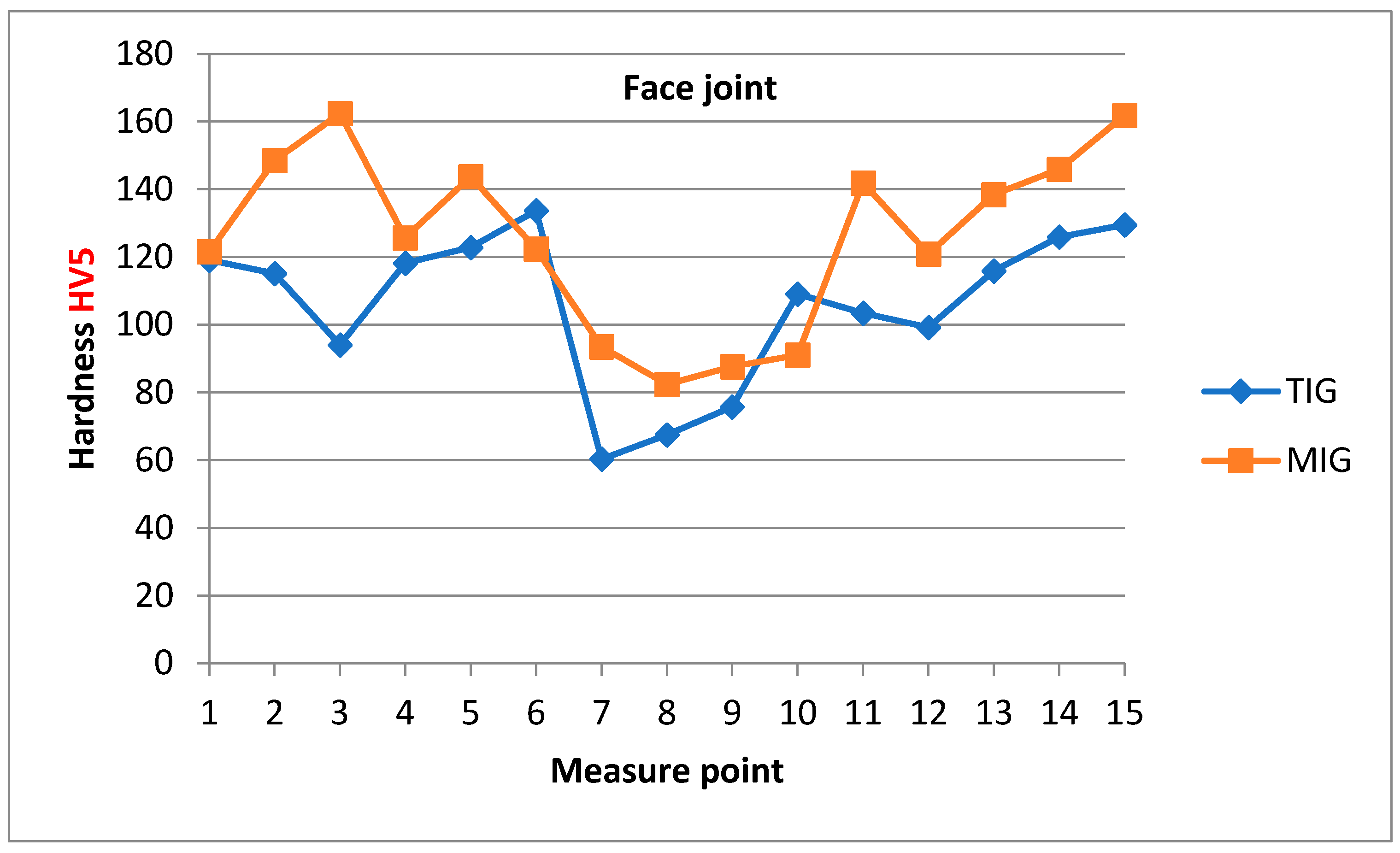

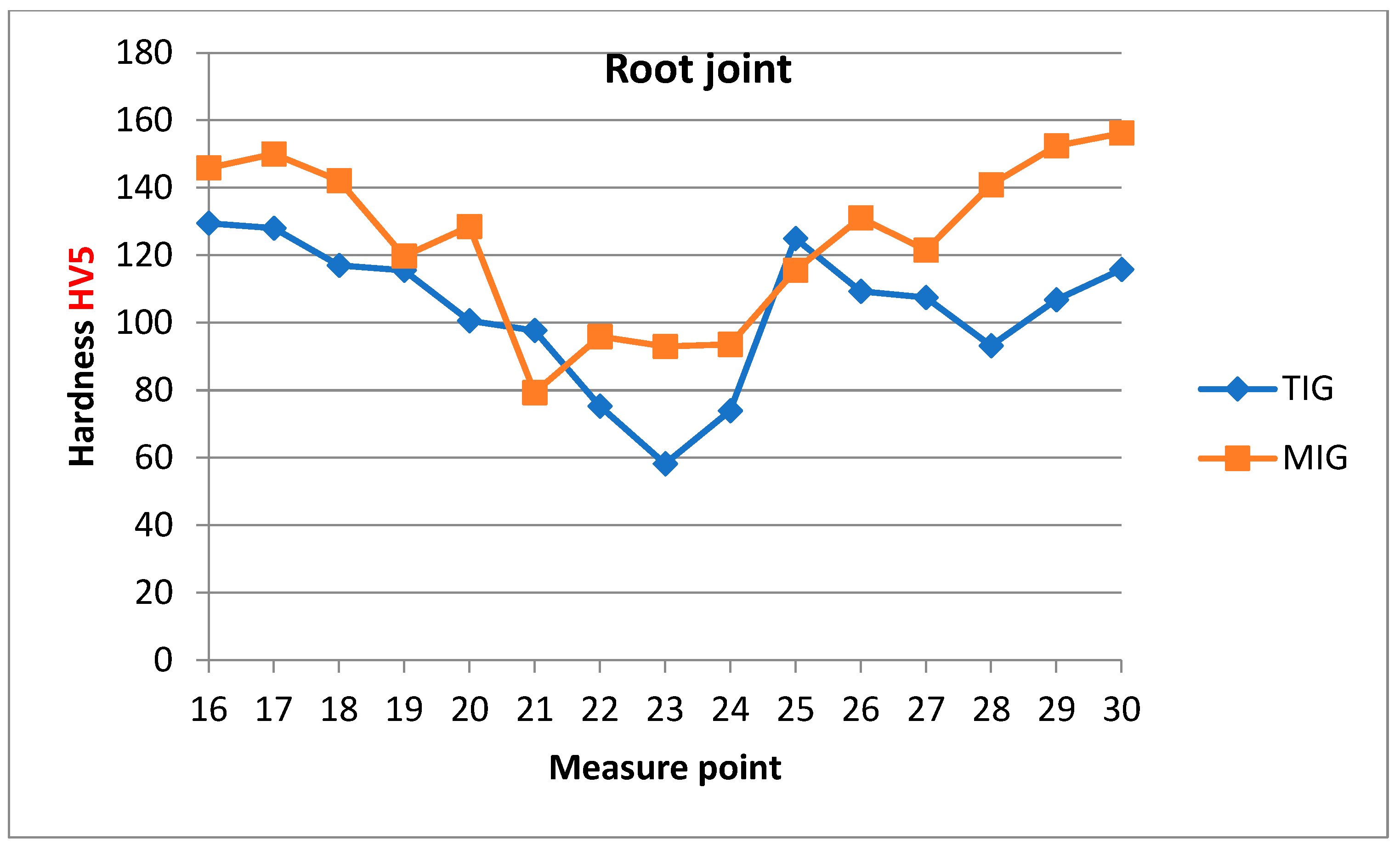

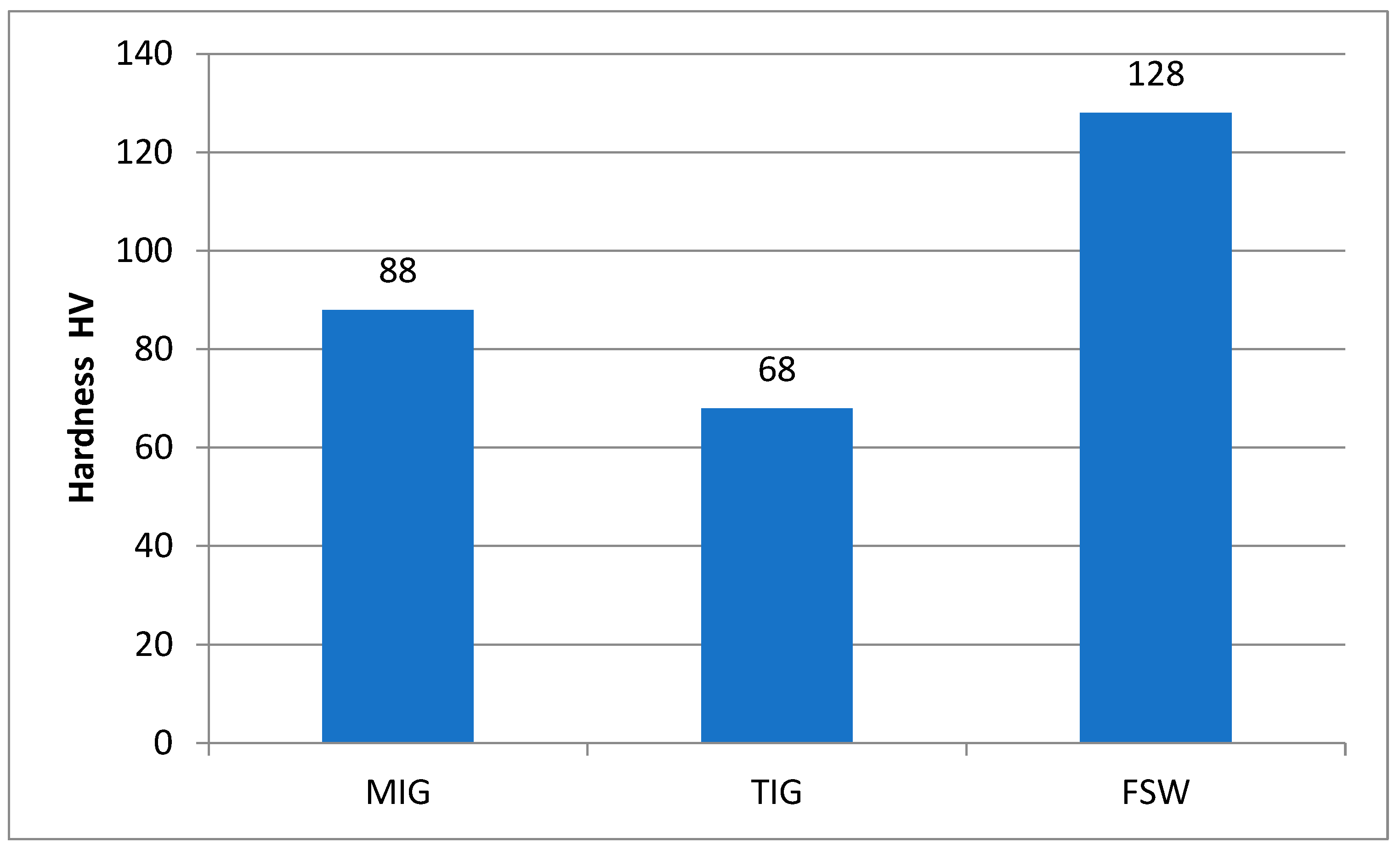

3.4. Hardness Distribution

4. Conclusions

- The average hardness value for FSW joints in the stir zone is about 10% lower relative to the BM. The highest hardness is in the stir zone due to recrystallization.

- The average hardness value of the metal weld zone for the MIG and TIG techniques using ER4043 have a lower hardness value than the heat-affected zone (HAZ) and base metal (BM) due to the differences in their main elements where the filler material ER4043 is Al-Si.

- The ultimate tensile strength (UTS) of the FSW tensile specimen has been found to be 80% higher than that of the MIG and TIG tensile specimens.

- FSW welds show the highest efficiency, around 97%, compared to 54% and 55% for MIG and TIG welds, respectively.

- The place of fracture of the tensile tested specimens obtained by all welding procedures are in the weld metal for TIG and MIG welded specimens, i.e., in the stir zone for the FSW specimen.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mallick, P.K. Materials, Design and Manufacturing for Lightweight Vehicles; Woodhead Publishing: Sawston, UK, 2010. [Google Scholar]

- Li, S.S.; Yue, X.; Li, Q.Y.; Peng, H.L.; Dong, B.X.; Liu, T.S.; Yang, H.Y.; Fan, J.; Shu, S.L.; Qiu, F.; et al. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Lean, P.P.; Gil, L.; Ureña, A. Dissimilar welds between unreinforced AA6082 and AA6092/SiC/25p composite by pulsed-MIG arc welding using unreinforced filler alloys (Al–5Mg and Al–5Si). J. Mater. Process. Technol. 2003, 143–144, 846–850. [Google Scholar] [CrossRef]

- Nawres, J.N. Mechanical Properties of MIG Joints for Dissimilar Aluminum Alloys (2024-T351 and 6061-T651). Al-Khwarizmi Eng. J. 2016, 12, 121–128. [Google Scholar]

- Liamine, K.; Mohammed, E.D.; Seddik, O.; Sami, K. Dissimilar welding of aluminum alloys 2024 T3 and 7075 T6 by TIG process with double tungsten electrodes. Int. J. Adv. Manuf. Technol. 2022, 118, 937–948. [Google Scholar] [CrossRef]

- Meshram, S.D.; Paradkar, A.G.; Reddy, G.M.; Pandey, S. Friction stir welding: An alternative to fusion welding for better stress corrosion cracking resistance of maraging steel. J. Manuf. Process. 2017, 25, 94–103. [Google Scholar] [CrossRef]

- Prabhakar, D.A.P.; Shettigar, A.K.; Herbert, M.A.; Patel, G.C.M.; Pimenov, D.Y.; Giasin, K.; Prakash, C. A comprehensive review of friction stir techniques in structural materials and alloys: Challenges and trends. J. Mater. Res. Technol. 2022, 20, 3025–3060. [Google Scholar] [CrossRef]

- Du, Z.; Chen, H.C.; Tan, M.J.; Bi, G.; Chua, C.K. Investigation of porosity reduction, microstructure and mechanical properties for joining of selective laser melting fabricated aluminium composite via friction stir welding. J. Manuf. Process. 2018, 36, 33–43. [Google Scholar] [CrossRef]

- Wang, T.; Sidhar, H.; Mishra, R.S.; Hovanski, Y.; Upadhyay, P.; Carlson, B. Evaluation of intermetallic compound layer at aluminum/steel interface joined by friction stir scribe technology. Mater. Des. 2019, 174, 107795. [Google Scholar] [CrossRef]

- Mehdi, H.; Mishra, R.S. Effect of friction stir processing on mechanical properties and heat transfer of TIG welded joint of AA6061 and AA7075. Def. Technol. 2021, 17, 715–727. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.; Yang, L.; Zhang, G. Effect of preheat & post-weld heat treatment on the microstructure and mechanical properties of 6061-T6 aluminum alloy welded sheets. Mater. Sci. Eng. A 2022, 841, 143081. [Google Scholar] [CrossRef]

- Kasman, Ş.; Yenier, Z. Analyzing dissimilar friction stir welding of AA5754/AA7075. Int. J. Adv. Manuf. Technol. 2014, 70, 145–156. [Google Scholar] [CrossRef]

- Youbao, S.; Xinqi, Y.; Lei, C.; Xiaopeng, H.; Shen, Z.; Xu, Y. Defect features and mechanical properties of friction stir lap welded dissimilar AA2024–AA7075 aluminum alloy sheets. Mater. Des. 2014, 55, 9–18. [Google Scholar] [CrossRef]

- Mastanaiah, P.; Sharma, A.R.; Madhusudhan, G. Dissimilar friction stir welds in AA2219-AA5083 aluminium alloys: Effect of process parameters on material inter-mixing, defect formation, and mechanical properties. Trans. Indian Inst. Met. 2016, 69, 1397–1415. [Google Scholar] [CrossRef]

- Hasan, M.M.; Ishak, M.; Rejab, R. Influence of machine variables and tool profile on the tensile strength of dissimilar AA7075-AA6061 friction stir welds. Int. J. Adv. Manuf. Technol. 2017, 90, 2605–2615. [Google Scholar] [CrossRef]

- Himanshu, L.; Paranjayee, M. Cold forming of Al-5251 and Al-6082 tailored welded blanks manufactured by laser and electron beam welding. J. Manuf. Process. 2021, 68 Pt A, 1615–1636. [Google Scholar] [CrossRef]

- Heinz, A.; Haszler, A.; Keidel, C.; Moldenhauer, S.; Benedictus, R.; Miller, W. Recent development in aluminium alloys for aerospace applications. Mater. Sci. Eng. A 2000, 280, 102–107. [Google Scholar] [CrossRef]

- Milčić, M.; Milčić, D.; Vuherer, T.; Radović, L.; Radisavljević, I.; Đurić, A. Influence of Welding Speed on Fracture Toughness of Friction Stir Welded AA2024-T351 Joints. Materials 2021, 14, 1561. [Google Scholar] [CrossRef]

- Milčić, M.; Vuherer, T.; Radisavljević, I.; Milčić, D.; Kramberger, J. The influence of process parameters on the mechanical properties of friction stir welded joints of 2024 T351 aluminum alloys. Mater. Technol. 2019, 53, 771–776. [Google Scholar] [CrossRef]

- ISO 18273; Welding Consumables—Wire Electrodes, Wires and Rods for Welding of Aluminium and Aluminium Alloys—Classification. ISO: Geneva, Switzerland, 2015.

- ASTM E8M; Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2024.

- Milčić, D.; Milčić, M.; Klobčar, D.; Đurić, A.; Zdravković, N. Structure and mechanical properties of MIG welded butt-joints of aluminum alloy 2024 T351. In Proceedings of the 16th International Conference on Accomplishments in Mechanical and Industrial Engineering DEMI 2023, Banja Luka, Bosnia and Herzegovina, 1–2 June 2023; pp. 144–150. [Google Scholar]

- Salleh, M.N.M.; Ishak, M.; Shah, L.H.; Idris, S.R.A. The effect of ER4043 and ER5356 filler metal on welded Al 7075 by metal inert gas welding. In WIT Transactions on the Built Environment; WIT Press: Cambridge, MA, USA, 2016; Volume 166. [Google Scholar] [CrossRef]

- Şik, A.; Önder, M. Comparison between mechanical properties and joint performance of AA 2024-O aluminium alloy welded by friction stir welding and TIG processes. Kov. Mater.-Met. Mater. 2012, 50, 131–137. [Google Scholar] [CrossRef]

- Habba, M.I.A.; Alsaleh, N.A.; Badran, T.E.; El-Sayed Seleman, M.M.; Ataya, S.; El-Nikhaily, A.E.; Abdul-Latif, A.; Ahmed, M.M.Z. Comparative Study of FSW, MIG, and TIG Welding of AA5083-H111 Based on the Evaluation of Welded Joints and Economic Aspect. Materials 2023, 16, 5124. [Google Scholar] [CrossRef] [PubMed]

| Alloying Element | Mn | Fe | Mg | Si | Cu | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| wt.% | 0.65 | 0.17 | 1.56 | 0.046 | 4.7 | 0.11 | 0.032 | Balance |

| Yield Strength YS (MPa) | Ultimate Tensile Strength UTS (MPa) | Elongation at Break E (%) | Hardness HV |

|---|---|---|---|

| 370 | 481 | 17.9 | 137 |

| Element | Mn | Fe | Mg | Si | Cu | Zn | Ti | Be | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | <0.15 | <0.6 | <0.2 | 4.5–5.5 | <0.3 | <0.1 | <0.15 | <0.0003 | Balance |

| Welding Process | Run | Current I (A) | Voltage U (V) | Welding Speed v (cm/min) | Heat Input H = I·U·η/v (J/mm) |

|---|---|---|---|---|---|

| MIG | 1 | 155 | 21.7 | 41.88 | 385 |

| 2 | 180 | 23.2 | 52.92 | 379 | |

| 3 | 170 | 22.7 | 49.98 | 371 | |

| TIG | 1 | 230 | 12.9 | 11.55 | 1233 |

| 2 | 240 | 11.7 | 17.93 | 751.3 | |

| 3 | 200 | 12.6 | 12.09 | 998 | |

| 4 | 200 | 13.3 | 20.47 | 624 |

| Sample | Rotation Rate n rpm | Welding Speed v mm/min | Ratio n/v rev/mm |

|---|---|---|---|

| A-I | 750 | 73 | 10.27 |

| B-II | 116 | 6.47 | |

| C-III | 150 | 5 |

| Spectrum Label | Spectrum 4 | Spectrum 5 |

|---|---|---|

| Al | 42.78 | 55.23 |

| Si | 2.15 | 3.23 |

| Mn | 8.64 | |

| Fe | 12.68 | |

| Cu | 55.07 | 20.21 |

| Total | 100.00 | 100.00 |

| Spectrum Label | Spectrum 12 | Spectrum 13 | Spectrum 14 | Spectrum 15 | Spectrum 16 | Spectrum 17 |

|---|---|---|---|---|---|---|

| Mg | 0.18 | 0.21 | 1.49 | 0.23 | 0.20 | |

| Al | 35.65 | 26.70 | 16.09 | 59.44 | 26.66 | 98.10 |

| Si | 62.48 | 70.24 | 80.71 | 9.98 | 71.38 | 0.98 |

| Mn | 12.94 | |||||

| Fe | 15.07 | |||||

| Cu | 1.68 | 2.85 | 1.72 | 2.56 | 1.72 | 0.71 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| Welding Process | Yield Strength YS (MPa) | Ultimate Tensile Strength UTS (MPa) | Elongation at Break A (%) | Joint Efficiency % |

|---|---|---|---|---|

| MIG | 209 | 261 | 1.3 | 54 |

| TIG | 145 | 263 | 5.2 | 55 |

| FSW | 336.6 | 469.09 | 7.2 | 97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Milčić, M.; Klobčar, D.; Milčić, D.; Zdravković, N.; Đurić, A.; Vuherer, T. Comparison between Mechanical Properties and Joint Performance of AA 2024-T351 Aluminum Alloy Welded by Friction Stir Welding, Metal Inert Gas and Tungsten Inert Gas Processes. Materials 2024, 17, 3336. https://doi.org/10.3390/ma17133336

Milčić M, Klobčar D, Milčić D, Zdravković N, Đurić A, Vuherer T. Comparison between Mechanical Properties and Joint Performance of AA 2024-T351 Aluminum Alloy Welded by Friction Stir Welding, Metal Inert Gas and Tungsten Inert Gas Processes. Materials. 2024; 17(13):3336. https://doi.org/10.3390/ma17133336

Chicago/Turabian StyleMilčić, Miodrag, Damjan Klobčar, Dragan Milčić, Nataša Zdravković, Aleksija Đurić, and Tomaž Vuherer. 2024. "Comparison between Mechanical Properties and Joint Performance of AA 2024-T351 Aluminum Alloy Welded by Friction Stir Welding, Metal Inert Gas and Tungsten Inert Gas Processes" Materials 17, no. 13: 3336. https://doi.org/10.3390/ma17133336

APA StyleMilčić, M., Klobčar, D., Milčić, D., Zdravković, N., Đurić, A., & Vuherer, T. (2024). Comparison between Mechanical Properties and Joint Performance of AA 2024-T351 Aluminum Alloy Welded by Friction Stir Welding, Metal Inert Gas and Tungsten Inert Gas Processes. Materials, 17(13), 3336. https://doi.org/10.3390/ma17133336