High-Strain-Rate Deformation Behavior of Co0.96Cr0.76Fe0.85Ni1.01Hf0.40 Eutectic High-Entropy Alloy at Room and Cryogenic Temperatures

Abstract

1. Introduction

2. Experimental Methods

2.1. Material Preparation

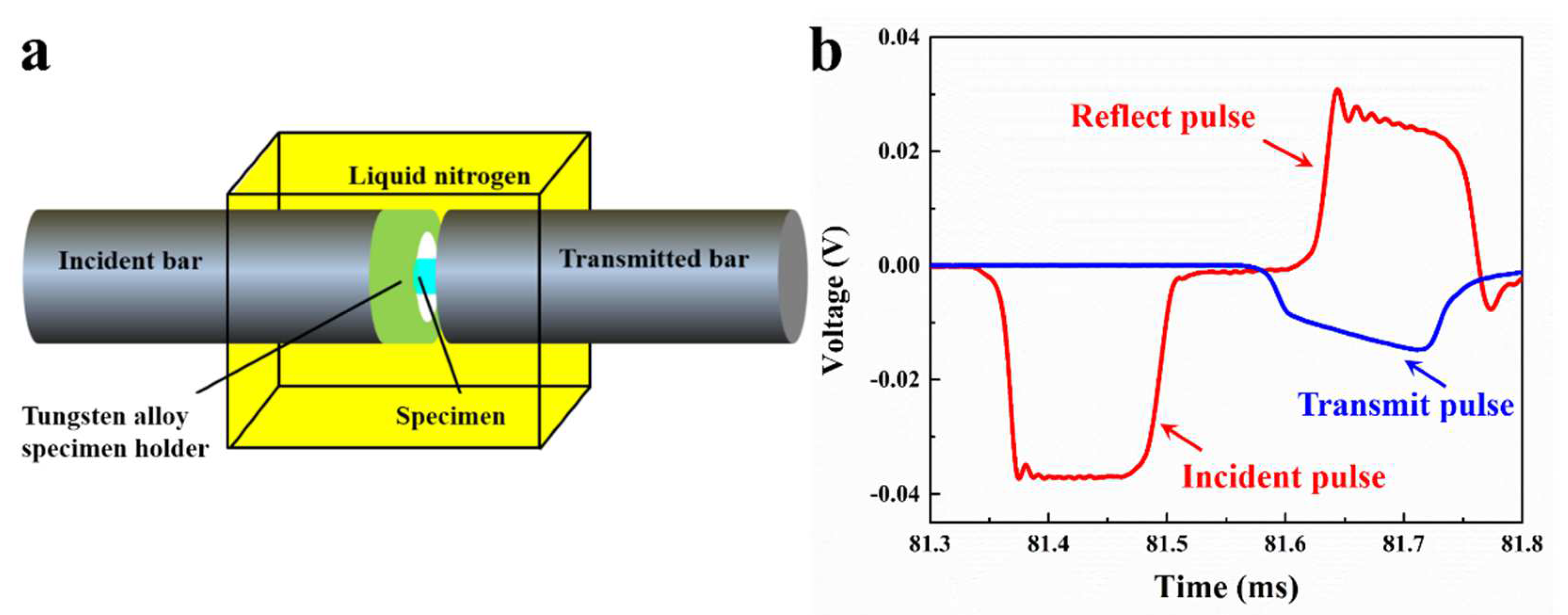

2.2. Mechanical Characterization upon Quasi-Static and Dynamic Tests

2.3. Microstructure Characterizations

3. Results and Discussions

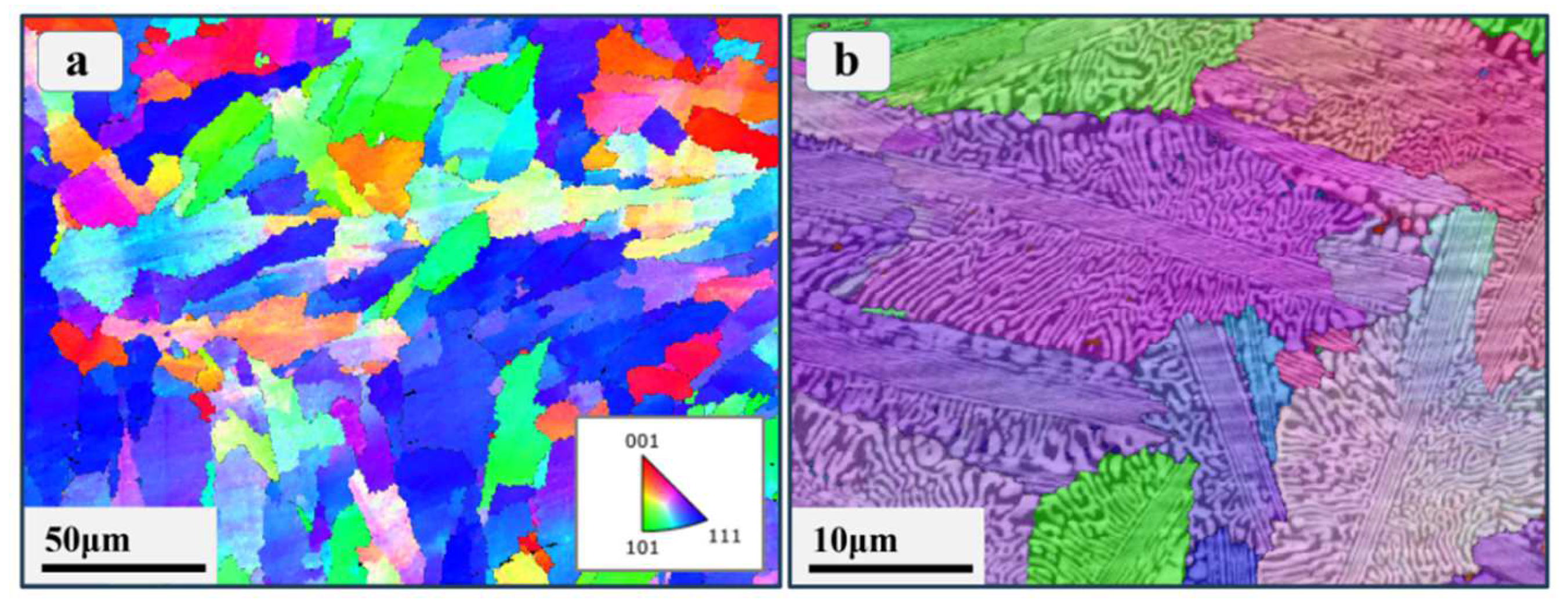

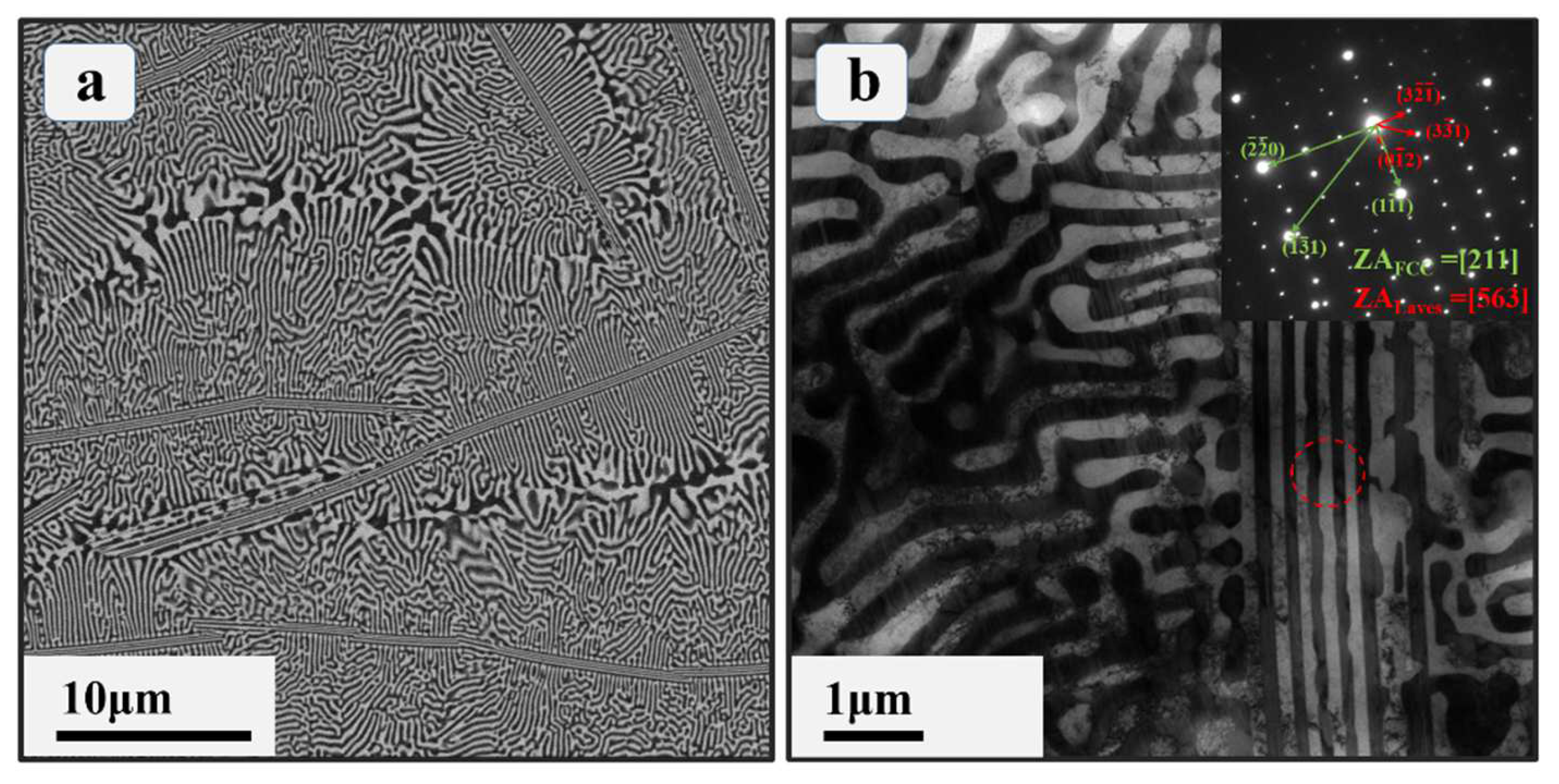

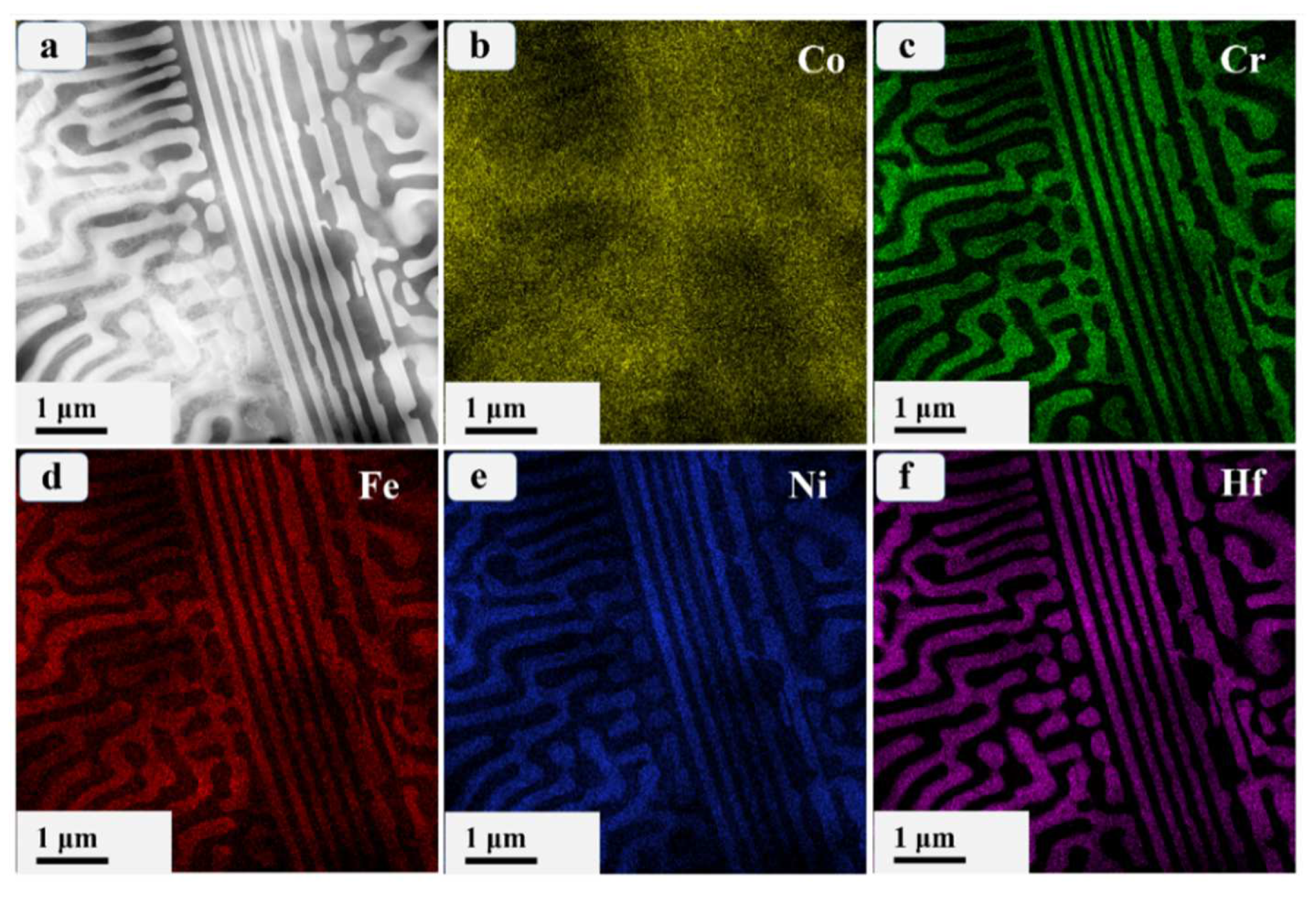

3.1. Initial Microstructural Characterization of the Prepared EHEA

3.2. Mechanical Properties

3.3. Microstructural Characterization after Dynamic Compression Tests

4. Conclusions

- (1)

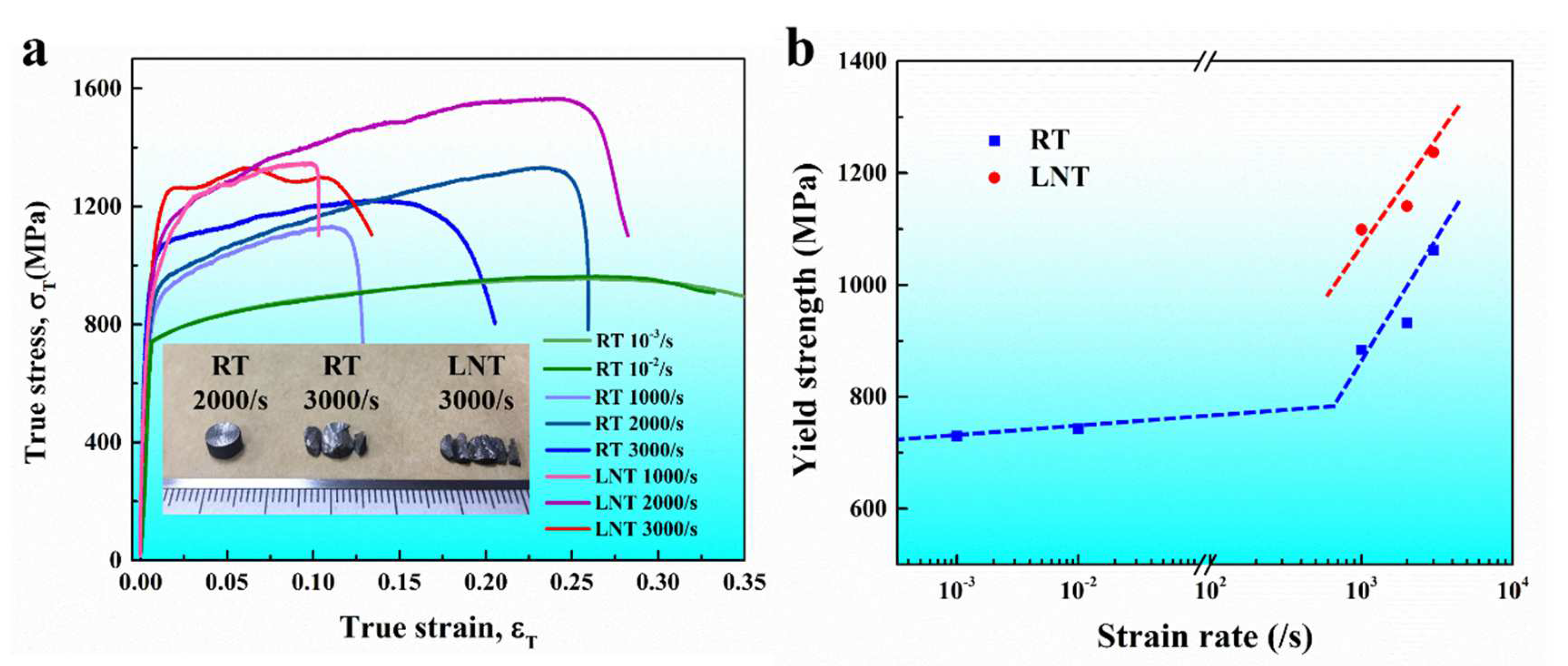

- The current Co0.96Cr0.76Fe0.85Ni1.01Hf0.40 EHEA exhibits a high yield strength of 740 MPa along with a high fracture strain of 35% under quasi-static loading. A remarkable positive strain rate effect can be observed, and its yield strength increased to 1060 MPa when the strain rate increased to 3000/s. Decreasing temperature will further enhance the yield strength significantly. The yield strength of this alloy at strain rates of 3000/s increased to 1240 MPa under the LNT condition.

- (2)

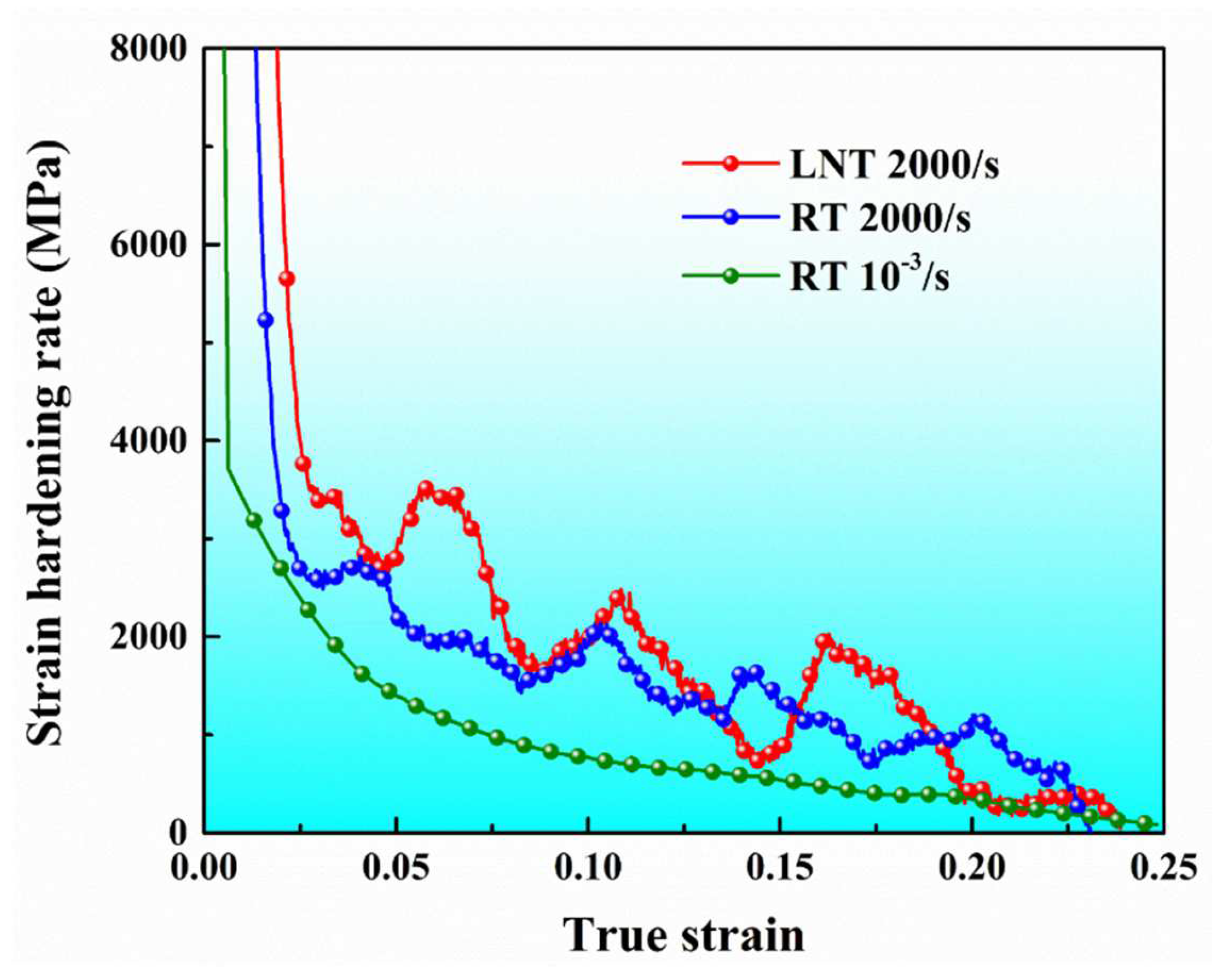

- The current EHEA exhibited a notable increased strain-hardening ability with either an increasing strain rate or a decreasing temperature. However, this alloy will undergo a ductile–brittle transition as the strain rate increases, and cryogenic temperature will expedite this transition.

- (3)

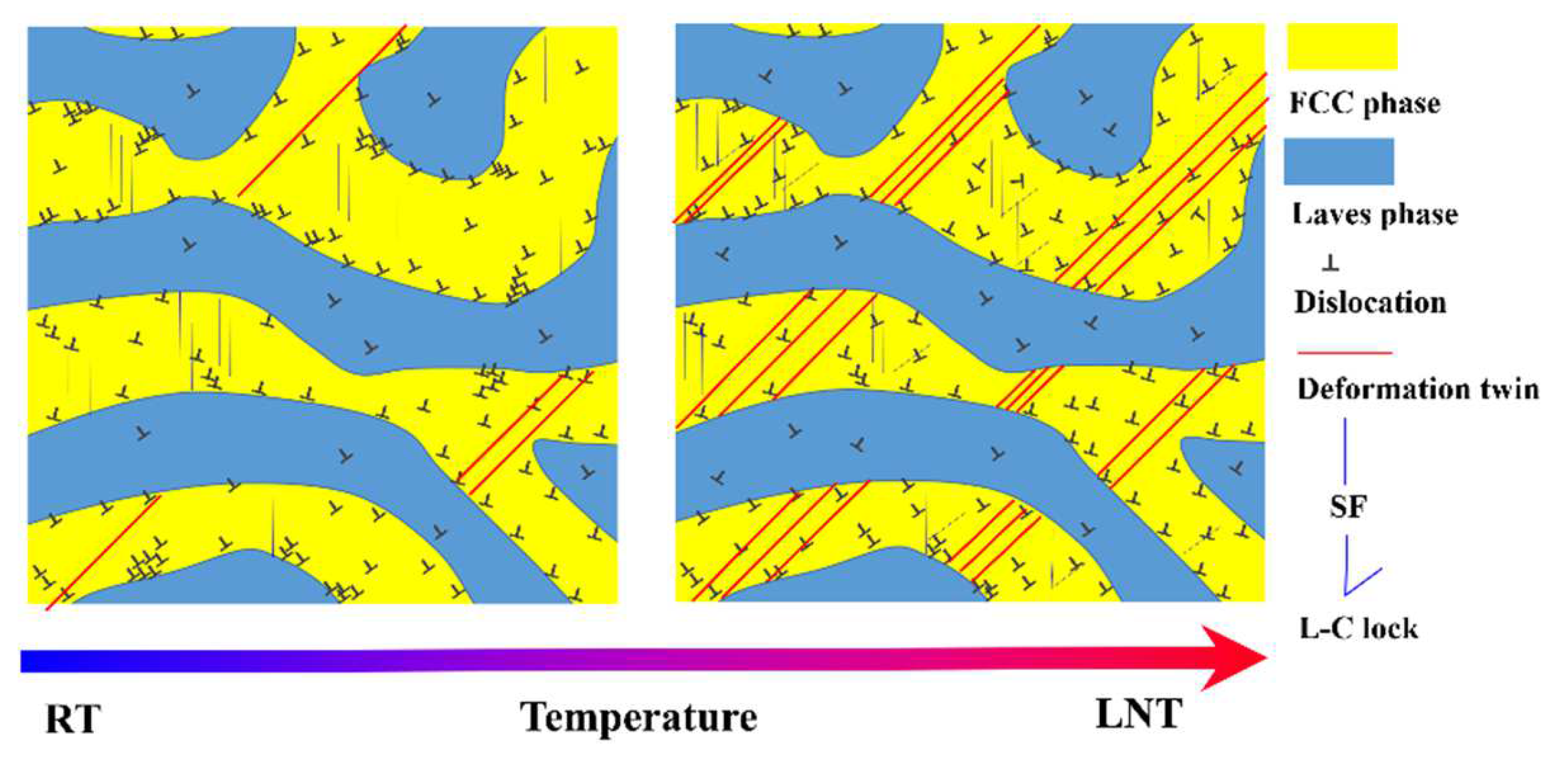

- The analysis of microstructure after deformation suggests that the dynamic plastic deformation of the current Co0.96Cr0.76Fe0.85Ni1.01Hf0.40 EHEA at RT is dominated by dislocation slip. The deformation twins, SFs and immobile dislocation locks that emerge serve as effective dislocation impediments, thereby contributing to the pronounced strain-hardening rate during dynamic deformation at LNT.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- George, E.P.; Curtin, W.A.; Tasan, C.C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 2020, 188, 435–474. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Li, W.; Xie, D.; Li, D.; Zhang, Y.; Gao, Y.; Liaw, P.K. Mechanical behavior of high-entropy alloys. Prog. Mater. Sci. 2021, 118, 100777. [Google Scholar] [CrossRef]

- Laplanche, G.; Bonneville, J.; Varvenne, C.; Curtin, W.A.; George, E.P. Thermal activation parameters of plastic flow reveal deformation mechanisms in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2018, 143, 257–264. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Horst, O.M.; Eggeler, G.; George, E.P. Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2016, 118, 152–163. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Reinhart, C.; Hunfeld, J.; Eggeler, G.; George, E.P. Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 2017, 128, 292–303. [Google Scholar] [CrossRef]

- Miao, J.; Slone, C.E.; Smith, T.M.; Niu, C.; Bei, H.; Ghazisaeidi, M.; Pharr, G.M.; Mills, M.J. The evolution of the deformation substructure in a Ni-Co-Cr equiatomic solid solution alloy. Acta Mater. 2017, 132, 35–48. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Wang, S.; Wu, M.; Shu, D.; Zhu, G.; Wang, D.; Sun, B. Mechanical instability and tensile properties of TiZrHfNbTa high entropy alloy at cryogenic temperatures. Acta Mater. 2020, 201, 517–527. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, Y.; Guo, S.; Jiang, L.; Kang, H.; Wang, T.; Wen, B.; Wang, Z.; Jie, J.; Cao, Z.; et al. A Promising New Class of High-Temperature Alloys: Eutectic High-Entropy Alloys. Sci. Rep. 2014, 4, 6200. [Google Scholar] [CrossRef] [PubMed]

- Baker, I.; Wu, M.; Wang, Z. Eutectic/eutectoid multi-principle component alloys: A review. Mater. Charact. 2019, 147, 545–557. [Google Scholar] [CrossRef]

- Xie, T.; Xiong, Z.; Xu, Z.; Cheng, X. Varying the eutectic composition of Co–Cr–Fe–Ni-Hf high-entropy system using a modified simple mixture method. Mater. Sci. Eng. A 2020, 786, 139420. [Google Scholar] [CrossRef]

- Xie, T.; Xiong, Z.; Xu, Z.; Liu, Z.; Cheng, X. Another eutectic point of Co–Cr–Fe–Ni-M (Hf, Ta, Nb) high-entropy system determined using a simple mixture method correlated with mixing enthalpy. Mater. Sci. Eng. A 2021, 802, 140634. [Google Scholar] [CrossRef]

- Lozinko, A.; Gholizadeh, R.; Zhang, Y.; Klement, U.; Tsuji, N.; Mishin, O.V.; Guo, S. Evolution of microstructure and mechanical properties during annealing of heavily rolled AlCoCrFeNi2.1 eutectic high-entropy alloy. Mater. Sci. Eng. A 2022, 833, 142558. [Google Scholar] [CrossRef]

- Shi, P.; Zhong, Y.; Li, Y.; Ren, W.; Zheng, T.; Shen, Z.; Yang, B.; Peng, J.; Hu, P.; Zhang, Y.; et al. Multistage work hardening assisted by multi-type twinning in ultrafine-grained heterostructural eutectic high-entropy alloys. Mater. Today 2020, 41, 62–71. [Google Scholar] [CrossRef]

- Shi, P.; Ren, W.; Zheng, T.; Ren, Z.; Hou, X.; Peng, J.; Hu, P.; Gao, Y.; Zhong, Y.; Liaw, P.K. Enhanced strength-ductility synergy in ultrafine-grained eutectic high-entropy alloys by inheriting microstructural lamellae. Nat. Commun. 2019, 10, 489. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; He, F.; Li, J.; Kim, H.S.; Wang, Z.; Wang, J. Phase-selective recrystallization makes eutectic high-entropy alloys ultra-ductile. Nat. Commun. 2022, 13, 4697. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharjee, T.; Wani, I.S.; Sheikh, S.; Clark, I.T.; Okawa, T.; Guo, S.; Bhattacharjee, P.P.; Tsuji, N. Simultaneous Strength-Ductility Enhancement of a Nano-Lamellar AlCoCrFeNi2.1 Eutectic High Entropy Alloy by Cryo-Rolling and Annealing. Sci. Rep. 2018, 8, 3276. [Google Scholar] [CrossRef]

- Gwalani, B.; Gangireddy, S.; Zheng, Y.; Soni, V.; Mishra, R.S.; Banerjee, R. Influence of ordered L12 precipitation on strain-rate dependent mechanical behavior in a eutectic high entropy alloy. Sci. Rep. 2019, 9, 6371. [Google Scholar] [CrossRef]

- Muskeri, S.; Hasannaeimi, V.; Salloom, R.; Sadeghilaridjani, M.; Mukherjee, S. Small-scale mechanical behavior of a eutectic high entropy alloy. Sci. Rep. 2020, 10, 2669. [Google Scholar] [CrossRef] [PubMed]

- Shi, P.; Li, R.; Li, Y.; Wen, Y.; Zhong, Y.; Ren, W.; Shen, Z.; Zheng, T.; Peng, J.; Liang, X.; et al. Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys. Science 2021, 373, 912–918. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Lu, Y.; Wang, T.; Zhang, C.; Cao, Z.; Li, T.; Liaw, P.K. A novel bulk eutectic high-entropy alloy with outstanding as-cast specific yield strengths at elevated temperatures. Scr. Mater. 2021, 204, 114132. [Google Scholar] [CrossRef]

- Wang, X.; Zhai, W.; Wang, J.Y.; Wei, B. Strength and ductility enhancement of high-entropy FeCoNi2Al0.9 alloy by ultrasonically refining eutectic structures. Scr. Mater. 2023, 225, 115154. [Google Scholar] [CrossRef]

- Foley, D.L.; Huang, S.H.; Anber, E.; Shanahan, L.; Shen, Y.; Lang, A.C.; Barr, C.M.; Spearot, D.; Lamberson, L.; Taheri, M.L. Simultaneous twinning and microband formation under dynamic compression in a high entropy alloy with a complex energetic landscape. Acta Mater. 2020, 200, 1–11. [Google Scholar] [CrossRef]

- Jiang, K.; Li, J.G.; Gan, B.; Ye, T.; Chen, L.Y.; Suo, T. Dynamically compressive behaviors and plastic mechanisms of a CrCoNi medium entropy alloy at various temperatures. AcMSn 2022, 38, 421550. [Google Scholar] [CrossRef]

- Jiang, K.; Li, J.; Suo, T. Extensive phase transformation in an equiatomic CrCoNi medium entropy alloy under extreme uniaxial tension. Int. J. Plast. 2024, 176, 103968. [Google Scholar] [CrossRef]

- Jiang, K.; Zhang, Q.; Li, J.; Li, X.; Zhao, F.; Hou, B.; Suo, T. Abnormal hardening and amorphization in an FCC high entropy alloy under extreme uniaxial tension. Int. J. Plast. 2022, 159, 103463. [Google Scholar] [CrossRef]

- Jiang, K.; Li, J.; Meng, Y.; Hou, B.; Suo, T. Dynamic tensile behavior of Al0.1CoCrFeNi high entropy alloy: Experiments, microstructure and modeling over a wide range of strain rates and temperatures. Mater. Sci. Eng. A 2022, 860, 144275. [Google Scholar] [CrossRef]

- Jiang, K.; Ren, T.; Shan, G.; Ye, T.; Chen, L.; Wang, C.; Zhao, F.; Li, J.; Suo, T. Dynamic mechanical responses of the Al0·1CoCrFeNi high entropy alloy at cryogenic temperature. Mater. Sci. Eng. A 2020, 797, 140125. [Google Scholar] [CrossRef]

- Park, J.M.; Moon, J.; Bae, J.W.; Jang, M.J.; Park, J.; Lee, S.; Kim, H.S. Strain rate effects of dynamic compressive deformation on mechanical properties and microstructure of CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2018, 719, 155–163. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Diao, H.; Liaw, P.K.; Meyers, M.A. High-velocity deformation of Al0.3CoCrFeNi high-entropy alloy: Remarkable resistance to shear failure. Sci. Rep. 2017, 7, 42742. [Google Scholar] [CrossRef]

- Jiang, K.; Gan, B.; Li, J.; Dou, Q.; Suo, T. Towards strength-ductility synergy in a CrCoNi solid solution alloy via nanotwins. Mater. Sci. Eng. A 2021, 816, 141298. [Google Scholar] [CrossRef]

- Jiang, K.; Li, J.; Kan, X.; Zhao, F.; Hou, B.; Wei, Q.; Suo, T. Adiabatic shear localization induced by dynamic recrystallization in an FCC high entropy alloy. Int. J. Plast. 2023, 162, 103550. [Google Scholar] [CrossRef]

- Meyers, M.A. Dynamic Behavior of Materials; John Wiley & Sons: Hoboken, NJ, USA, 1994. [Google Scholar]

- Ye, T.; Zhao, F.; Chen, L.; Jiang, K.; Deng, Q.; Chen, Y.; Wang, Q.; Suo, T. Effect of strain rate and low temperature on mechanical behaviour and microstructure evolution in twinning-induced plasticity steel. Mater. Sci. Eng. A 2021, 823, 141734. [Google Scholar] [CrossRef]

- Hu, M.; Song, K.; Song, W. Dynamic mechanical properties and microstructure evolution of AlCoCrFeNi2.1 eutectic high-entropy alloy at different temperatures. J. Alloys Compd. 2022, 892, 162097. [Google Scholar] [CrossRef]

- Jin, X.; Zhou, Y.; Zhang, L.; Du, X.; Li, B. A novel Fe20Co20Ni41Al19 eutectic high entropy alloy with excellent tensile properties. Mater. Lett. 2018, 216, 144–146. [Google Scholar] [CrossRef]

- Huo, W.; Zhou, H.; Fang, F.; Xie, Z.; Jiang, J. Microstructure and mechanical properties of CoCrFeNiZrx eutectic high-entropy alloys. Mater. Des. 2017, 134, 226–233. [Google Scholar] [CrossRef]

- Tan, Y.; Li, J.; Wang, J.; Kou, H. Seaweed eutectic-dendritic solidification pattern in a CoCrFeNiMnPd eutectic high-entropy alloy. Intermetallics 2017, 85, 74–79. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Wani, I.S.; Bhattacharjee, T.; Sheikh, S.; Bhattacharjee, P.P.; Guo, S.; Tsuji, N. Tailoring nanostructures and mechanical properties of AlCoCrFeNi2.1 eutectic high entropy alloy using thermo-mechanical processing. Mater. Sci. Eng. A 2016, 675, 99–109. [Google Scholar] [CrossRef]

- Kumar, N.; Ying, Q.; Nie, X.; Mishra, R.S.; Tang, Z.; Liaw, P.K.; Brennan, R.E.; Doherty, K.J.; Cho, K.C. High strain-rate compressive deformation behavior of the Al0.1CrFeCoNi high entropy alloy. Mater. Des. 2015, 86, 598–602. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, M.; Jiang, K.; Wang, H.; Qu, P.; Wang, H.; Zhu, L. Constitutive Behavior of Titanium Alloy With Dual-Phase Microstructures: Experiments and Modeling. J. Appl. Mech. 2023, 90, 071009. [Google Scholar] [CrossRef]

- Zhong, X.; Zhang, Q.; Ma, M.; Xie, J.; Wu, M.; Ren, S.; Yan, Y. Dynamic compressive properties and microstructural evolution of Al1.19Co2CrFeNi1.81 eutectic high entropy alloy at room and cryogenic temperatures. Mater. Des. 2022, 219, 110724. [Google Scholar] [CrossRef]

- Xu, X.D.; Liu, P.; Tang, Z.; Hirata, A.; Song, S.X.; Nieh, T.G.; Liaw, P.K.; Liu, C.T.; Chen, M.W. Transmission electron microscopy characterization of dislocation structure in a face-centered cubic high-entropy alloy Al0.1CoCrFeNi. Acta Mater. 2018, 144, 107–115. [Google Scholar] [CrossRef]

- Li, G.; Liu, M.; Lyu, S.; Nakatani, M.; Zheng, R.; Ma, C.; Li, Q.; Ameyama, K. Simultaneously enhanced strength and strain hardening capacity in FeMnCoCr high-entropy alloy via harmonic structure design. Scr. Mater. 2021, 191, 196–201. [Google Scholar] [CrossRef]

- Deng, Y.; Tasan, C.C.; Pradeep, K.G.; Springer, H.; Kostka, A.; Raabe, D. Design of a twinning-induced plasticity high entropy alloy. Acta Mater. 2015, 94, 124–133. [Google Scholar] [CrossRef]

- Meyers, M.A.; Vohringer, O.; Lubarda, V.A. The onset of twinning in metals: A constitutive description. Acta Mater. 2001, 49, 4025–4039. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Huang, S.; Li, W.; Lu, S.; Tian, F.; Shen, J.; Holmström, E.; Vitos, L. Temperature dependent stacking fault energy of FeCrCoNiMn high entropy alloy. Scr. Mater. 2015, 108, 44–47. [Google Scholar] [CrossRef]

- Yan, Z.; Lin, Y. On the widths of stacking faults formed by dissociation of different types of full dislocations in a nanostructured Al alloy. Mater. Sci. Eng. A 2020, 770, 138532. [Google Scholar] [CrossRef]

- Wu, X.L.; Zhu, Y.T.; Wei, Y.G.; Wei, Q. Strong strain hardening in nanocrystalline nickel. Phys. Rev. Lett. 2009, 103, 205504. [Google Scholar] [CrossRef] [PubMed]

- Yamakov, V.; Wolf, D.; Phillpot, S.R.; Mukherjee, A.K.; Gleiter, H. Dislocation processes in the deformation of nanocrystalline aluminium by molecular-dynamics simulation. Nat. Mater. 2002, 1, 45–48. [Google Scholar] [CrossRef] [PubMed]

- Dupuy, L.; Fivel, M.C. A study of dislocation junctions in FCC metals by an orientation dependent line tension model. Acta Mater. 2002, 50, 4873–4885. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, J.; Jiang, K.; Li, P.; Li, Y.; Zhang, Y.; Suo, T. Gradient structure induced simultaneous enhancement of strength and ductility in AZ31 Mg alloy with twin-twin interactions. J. Magnes. Alloys 2023, 11, 2872–2882. [Google Scholar] [CrossRef]

- Wang, P.; Cao, Y.; Zhou, D.; Li, M.; Jiang, K.; Zhou, H.; Qu, P.; Wang, H. Molecular dynamic simulations of the martensitic transformation for the dual-phase structure and dislocation activities in Ti80 alloys. Mech. Mater. 2023, 185, 104753. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, K.; Xiong, Z.; Chen, X. High-Strain-Rate Deformation Behavior of Co0.96Cr0.76Fe0.85Ni1.01Hf0.40 Eutectic High-Entropy Alloy at Room and Cryogenic Temperatures. Materials 2024, 17, 2995. https://doi.org/10.3390/ma17122995

Jiang K, Xiong Z, Chen X. High-Strain-Rate Deformation Behavior of Co0.96Cr0.76Fe0.85Ni1.01Hf0.40 Eutectic High-Entropy Alloy at Room and Cryogenic Temperatures. Materials. 2024; 17(12):2995. https://doi.org/10.3390/ma17122995

Chicago/Turabian StyleJiang, Kun, Zhiping Xiong, and Xi Chen. 2024. "High-Strain-Rate Deformation Behavior of Co0.96Cr0.76Fe0.85Ni1.01Hf0.40 Eutectic High-Entropy Alloy at Room and Cryogenic Temperatures" Materials 17, no. 12: 2995. https://doi.org/10.3390/ma17122995

APA StyleJiang, K., Xiong, Z., & Chen, X. (2024). High-Strain-Rate Deformation Behavior of Co0.96Cr0.76Fe0.85Ni1.01Hf0.40 Eutectic High-Entropy Alloy at Room and Cryogenic Temperatures. Materials, 17(12), 2995. https://doi.org/10.3390/ma17122995