Building a Layer-Structured Aluminum/Graphene Composite with Significant Improvement in Electrical Conductivity

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

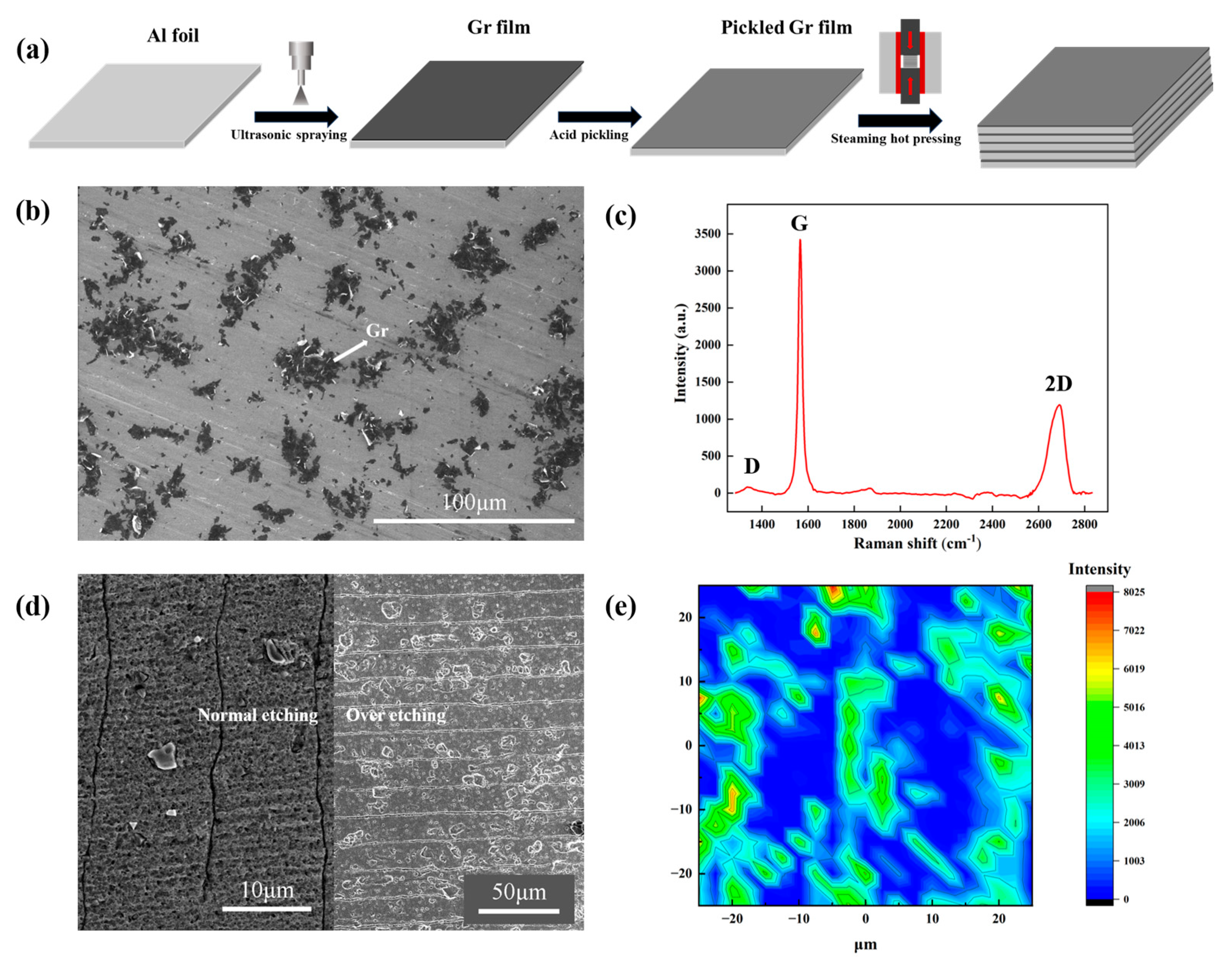

2.2. Fabrication of Al/Gr Composite Material

2.3. Characterization of Al/Gr Composite

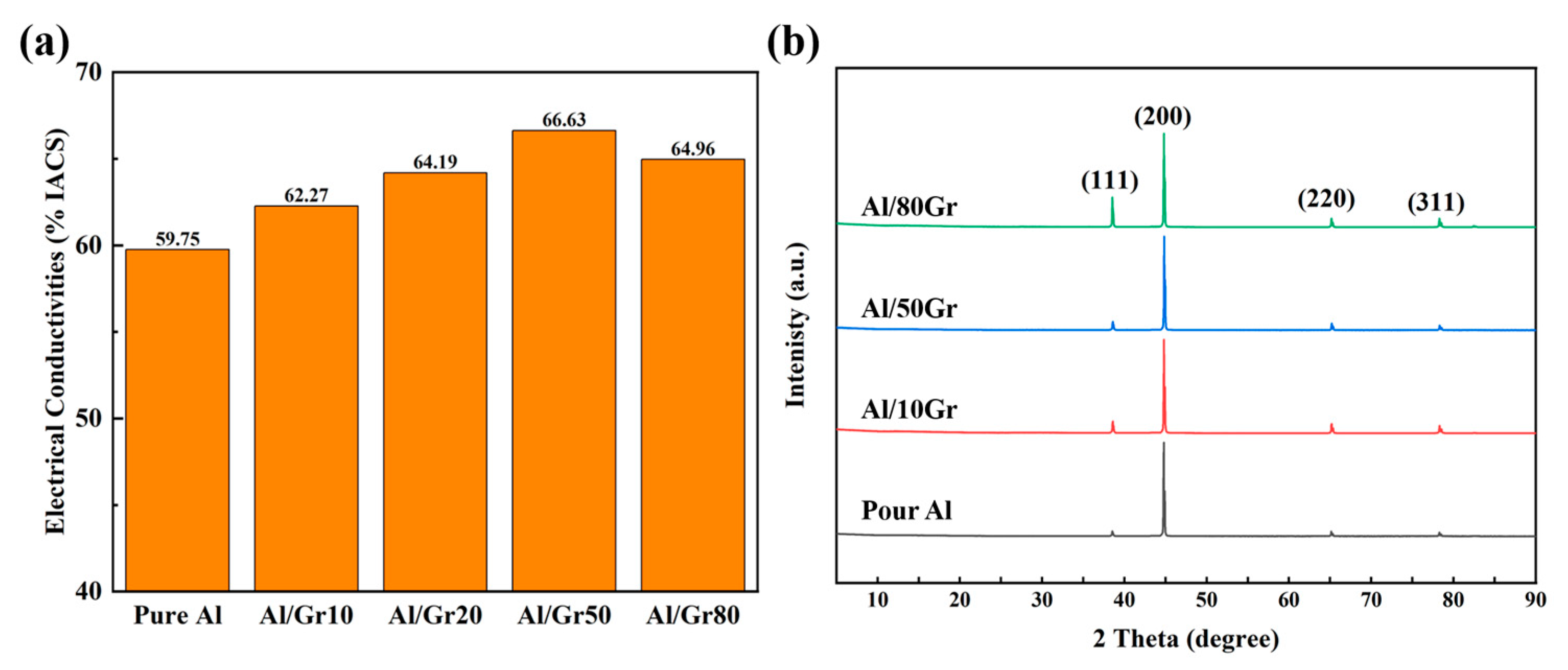

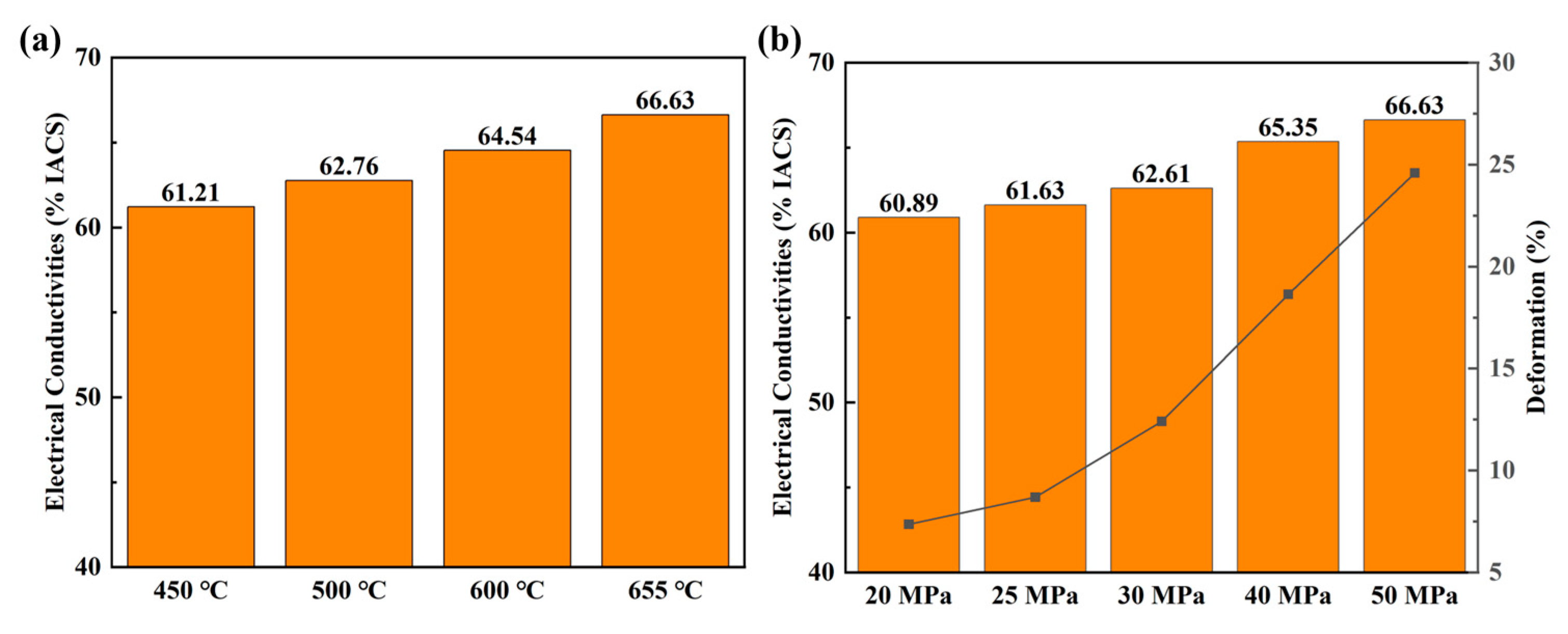

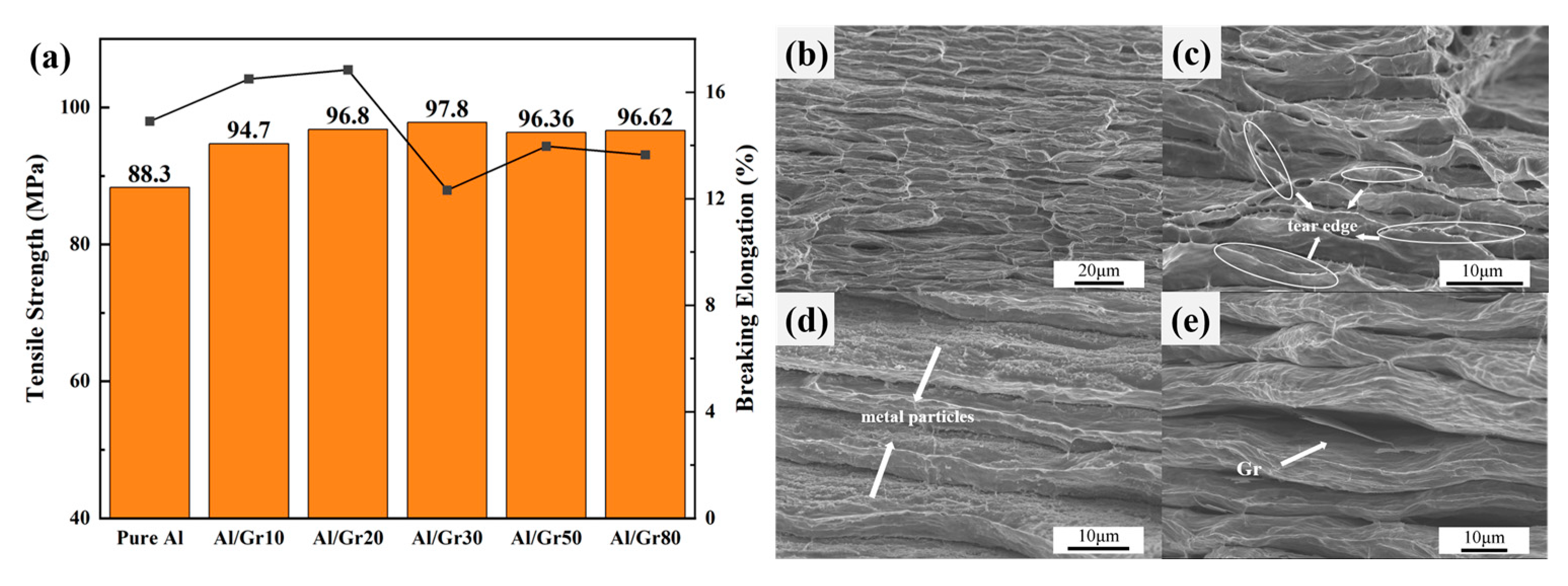

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grosselle, F.; Timelli, G.; Bonollo, F.; Molina, R. Correlation between microstructure and mechanical properties of Al-Si diecast engine blocks. Metall. Sci. Technol. 2009, 27, 2–10. [Google Scholar]

- Sahoo, B.; Joseph, J.; Sharma, A.; Paul, J. Surface modification of aluminium by graphene impregnation. Mater. Des. 2017, 116, 51–64. [Google Scholar] [CrossRef]

- Pu, B.; Zhang, X.; Chen, X.; Lin, X.; Zhao, D.; Shi, C.; Liu, E.; Sha, J.; He, C.; Zhao, N. Exceptional mechanical properties of aluminum matrix composites with heterogeneous structure induced by in-situ graphene nanosheet-Cu hybrids. Compos. Part B Eng. 2022, 234, 109731. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Kumar, A.; Omrani, E.; Kim, C.; Rohatgi, P. Synthesis, characterization, and properties of graphene reinforced metal-matrix nanocomposites. Compos. Part B Eng. 2020, 183, 107664. [Google Scholar] [CrossRef]

- Mallick, P. Advanced materials for automotive applications: An overview. In Advanced Materials in Automotive Engineering; Woodhead Publishing: Sawston, UK, 2012; pp. 5–27. [Google Scholar]

- Zhou, T.; Lei, M.; Xu, J. Recent progress in the development and properties of aluminum matrix composites reinforced with graphene: A review. Mater. Today Sustain. 2024, 25, 100674. [Google Scholar] [CrossRef]

- Rana, R.; Purohit, R.; Das, S. Reviews on the influences of alloying elements on the microstructure and mechanical properties of aluminum alloys and aluminum alloy composites. Int. J. Sci. Res. Publ. 2012, 2, 1–7. [Google Scholar]

- Mohammadi, A.; Enikeev, N.A.; Murashkin, M.Y.; Arita, M.; Edalati, K. Developing age-hardenable Al-Zr alloy by ultra-severe plastic deformation: Significance of supersaturation, segregation and precipitation on hardening and electrical conductivity. Acta Mater. 2021, 203, 116503. [Google Scholar] [CrossRef]

- Nie, Z.-R.; Jin, T.; Fu, J.; Xu, G.; Yang, J.; Zhou, J.X.; Zuo, T.Y. Research on rare earth in aluminum. In Materials Science Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2002; p. 1731. [Google Scholar]

- Wang, M.; Lv, H.; Zhang, C.; Li, M.; Gao, H.; Wang, J.; Sun, B. High strength high electrical conductivity ultrafine-grained Al–Y alloy processed via cold drawing. Mater. Sci. Eng. A 2020, 772, 138824. [Google Scholar] [CrossRef]

- Fang, S.; Wang, M.; Song, M. An approach for the aging process optimization of Al–Zn–Mg–Cu series alloys. Mater. Des. 2009, 30, 2460–2467. [Google Scholar] [CrossRef]

- Zhou, W.; Cai, B.; Li, W.-J.; Liu, Z.-X.; Yang, S. Heat-resistant Al–0.2 Sc–0.04 Zr electrical conductor. Mater. Sci. Eng. A 2012, 552, 353–358. [Google Scholar] [CrossRef]

- Gao, H.; Feng, W.; Gu, J.; Wang, J.; Sun, B. Aging and recrystallization behavior of precipitation strengthened Al-0.25 Zr-0.03 Y alloy. J. Alloys Compd. 2017, 696, 1039–1045. [Google Scholar] [CrossRef]

- Hou, J.; Li, R.; Wang, Q.; Yu, H.; Zhang, Z.; Chen, Q.; Ma, H.; Wu, X.; Li, X.; Zhang, Z. Three principles for preparing Al wire with high strength and high electrical conductivity. J. Mater. Sci. Technol. 2019, 35, 742–751. [Google Scholar] [CrossRef]

- Liu, L.; Jiang, J.-T.; Zhang, B.; Shao, W.-Z.; Zhen, L. Enhancement of strength and electrical conductivity for a dilute Al-Sc-Zr alloy via heat treatments and cold drawing. J. Mater. Sci. Technol. 2019, 35, 962–971. [Google Scholar] [CrossRef]

- Sun, L.; Tao, N.; Lu, K. A high strength and high electrical conductivity bulk CuCrZr alloy with nanotwins. Scr. Mater. 2015, 99, 73–76. [Google Scholar] [CrossRef]

- Dumitraschkewitz, P.; Gerstl, S.S.; Stephenson, L.T.; Uggowitzer, P.J.; Pogatscher, S. Clustering in age-hardenable aluminum alloys. Adv. Eng. Mater. 2018, 20, 1800255. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Lin, F.; Yang, G.; Niu, C.; Wang, Y.; Zhu, Z.; Luo, H.; Dai, C.; Mayerich, D.; Hu, Y.; Hu, J. Planar alignment of graphene sheets by a rotating magnetic field for full exploitation of graphene as a 2D material. Adv. Funct. Mater. 2018, 28, 1805255. [Google Scholar] [CrossRef]

- Ando, T. The electronic properties of graphene and carbon nanotubes. NPG Asia Mater. 2009, 1, 17–21. [Google Scholar] [CrossRef]

- Lin, Q.-Y.; Zeng, Y.-H.; Liu, D.; Jing, G.Y.; Liao, Z.-M.; Yu, D. Step-by-step fracture of two-layer stacked graphene membranes. ACS Nano 2014, 8, 10246–10251. [Google Scholar] [CrossRef]

- Neto, A.C.; Guinea, F.; Peres, N.M.; Novoselov, K.S.; Geim, A.K. The electronic properties of graphene. Rev. Mod. Phys. 2009, 81, 109. [Google Scholar] [CrossRef]

- Shin, S.; Choi, H.; Shin, J.; Bae, D. Strengthening behavior of few-layered graphene/aluminum composites. Carbon 2015, 82, 143–151. [Google Scholar] [CrossRef]

- Yu, Z.; Yang, W.; Zhou, C.; Zhang, N.; Chao, Z.; Cao, Y.; Sun, Y.; Shao, P.; Wu, G. Effect of ball milling time on graphene nanosheets reinforced Al6063 composite fabricated by pressure infiltration method. Carbon 2019, 141, 25–39. [Google Scholar] [CrossRef]

- Alipour, M.; Eslami-Farsani, R. Synthesis and characterization of graphene nanoplatelets reinforced AA7068 matrix nanocomposites produced by liquid metallurgy route. Mater. Sci. Eng. A 2017, 706, 71–82. [Google Scholar] [CrossRef]

- Hu, Z.; Chen, F.; Xu, J.; Nian, Q.; Lin, D.; Chen, C.; Zhu, X.; Chen, Y.; Zhang, M. 3D printing graphene-aluminum nanocomposites. J. Alloys Compd. 2018, 746, 269–276. [Google Scholar] [CrossRef]

- Kim, D.; Nam, S.; Roh, A.; Yoo, S.; Quevedo-Lopez, M.; Choi, H. Effect of interfacial features on the mechanical and electrical properties of rGO/Al composites. J. Mater. Sci. 2017, 52, 12001–12012. [Google Scholar] [CrossRef]

- Chyada, F.A.; Jabur, A.R.; Alwan, H.A. Effect addition of graphene on electrical conductivity and tensile strength for Recycled electric power transmission wires. Energy Procedia 2017, 119, 121–130. [Google Scholar] [CrossRef]

- Cao, M.; Xiong, D.B.; Yang, L.; Li, S.; Xie, Y.; Guo, Q.; Li, Z.; Adams, H.; Gu, J.; Fan, T. Ultrahigh electrical conductivity of graphene embedded in metals. Adv. Funct. Mater. 2019, 29, 1806792. [Google Scholar] [CrossRef]

- Cao, M.; Luo, Y.; Xie, Y.; Tan, Z.; Fan, G.; Guo, Q.; Su, Y.; Li, Z.; Xiong, D.B. The influence of interface structure on the electrical conductivity of graphene embedded in aluminum matrix. Adv. Mater. Interfaces 2019, 6, 1900468. [Google Scholar] [CrossRef]

- Erdogan, P.; Yuksel, B.; Birol, Y. Effect of chemical etching on the morphology of anodic aluminum oxides in the two-step anodization process. Appl. Surf. Sci. 2012, 258, 4544–4550. [Google Scholar] [CrossRef]

- Shen, H.-Z.; Wang, Y.; Chen, S.-M.; Shen, P. Wettability and reactivity between molten aluminum and randomly aligned carbon nanotubes. J. Mater. Sci. 2021, 56, 7799–7810. [Google Scholar] [CrossRef]

- Xu, W.; Chenchong, W.; Zhichao, Z.; Ping, L.; Yanhua, S.; Guofu, Z. Interfacial microstructure and growth mechanism of Al4C3 in Grf/Al composites fabricated by liquid pressure method. Micron 2014, 65, 10–14. [Google Scholar] [CrossRef] [PubMed]

- Travessa, D.N.; da Rocha, G.V.; Cardoso, K.R.; Lieblich, M. Carbon nanotube-reinforced aluminum matrix composites produced by high-energy ball milling. J. Mater. Eng. Perform. 2017, 26, 2998–3006. [Google Scholar] [CrossRef]

- Subedi, K.N.; Nepal, K.; Ugwumadu, C.; Kappagantula, K.; Drabold, D.A. Electronic transport in copper–graphene composites. Appl. Phys. Lett. 2023, 122, 031903. [Google Scholar] [CrossRef]

- Wang, J.; Guo, L.-n.; Lin, W.-m.; Chen, J.; Liu, C.-l.; Zhang, S.; Zhen, T.-t. Effect of the graphene content on the microstructures and properties of graphene/aluminum composites. New Carbon Mater. 2019, 34, 275–285. [Google Scholar] [CrossRef]

- Bhadauria, A.; Singh, L.K.; Laha, T. Effect of physio-chemically functionalized graphene nanoplatelet reinforcement on tensile properties of aluminum nanocomposite synthesized via spark plasma sintering. J. Alloys Compd. 2018, 748, 783–793. [Google Scholar] [CrossRef]

- Zhou, W.; Mikulova, P.; Fan, Y.; Kikuchi, K.; Nomura, N.; Kawasaki, A. Interfacial reaction induced efficient load transfer in few-layer graphene reinforced Al matrix composites for high-performance conductor. Compos. Part B Eng. 2019, 167, 93–99. [Google Scholar] [CrossRef]

- Qian, D.; Dickey, E.C.; Andrews, R.; Rantell, T. Load transfer and deformation mechanisms in carbon nanotube-polystyrene composites. Appl. Phys. Lett. 2000, 76, 2868–2870. [Google Scholar] [CrossRef]

- Guo, Y.; Yi, D.; Liu, H.; Wang, B.; Jiang, B.; Wang, H. Mechanical properties and conductivity of graphene/Al-8030 composites with directional distribution of graphene. J. Mater. Sci. 2020, 55, 3314–3328. [Google Scholar] [CrossRef]

- Zhou, W.; Fan, Y.; Feng, X.; Kikuchi, K.; Nomura, N.; Kawasaki, A. Creation of individual few-layer graphene incorporated in an aluminum matrix. Compos. Part A Appl. Sci. Manuf. 2018, 112, 168–177. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, G.; Qu, T.; Fang, G.; Bai, S.; Yan, Y.; Zhang, G.; Zhou, Z.; Shen, J.; Yao, D. Simultaneously enhancing mechanical properties and electrical conductivity of aluminum by using graphene as the reinforcement. Mater. Lett. 2020, 265, 127440. [Google Scholar] [CrossRef]

- Zhou, W.; Zhou, Z.; Kubota, K.; Ono, H.; Nomura, N.; Kawasaki, A. Design of high-performance Al4C3/Al matrix composites for electric conductor. Mater. Sci. Eng. A 2020, 798, 140331. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, S.; Xia, J.; Su, Q.; Ma, B.; Wu, J.; Zhou, J.; Wang, X.; Hu, L. Microstructural evolution, mechanical and physical properties of graphene reinforced aluminum composites fabricated via powder metallurgy. Mater. Sci. Eng. A 2021, 802, 140669. [Google Scholar] [CrossRef]

- Shao, P.; Chen, G.; Ju, B.; Yang, W.; Zhang, Q.; Wang, Z.; Tan, X.; Pei, Y.; Zhong, S.; Hussain, M. Effect of hot extrusion temperature on graphene nanoplatelets reinforced Al6061 composite fabricated by pressure infiltration method. Carbon 2020, 162, 455–464. [Google Scholar] [CrossRef]

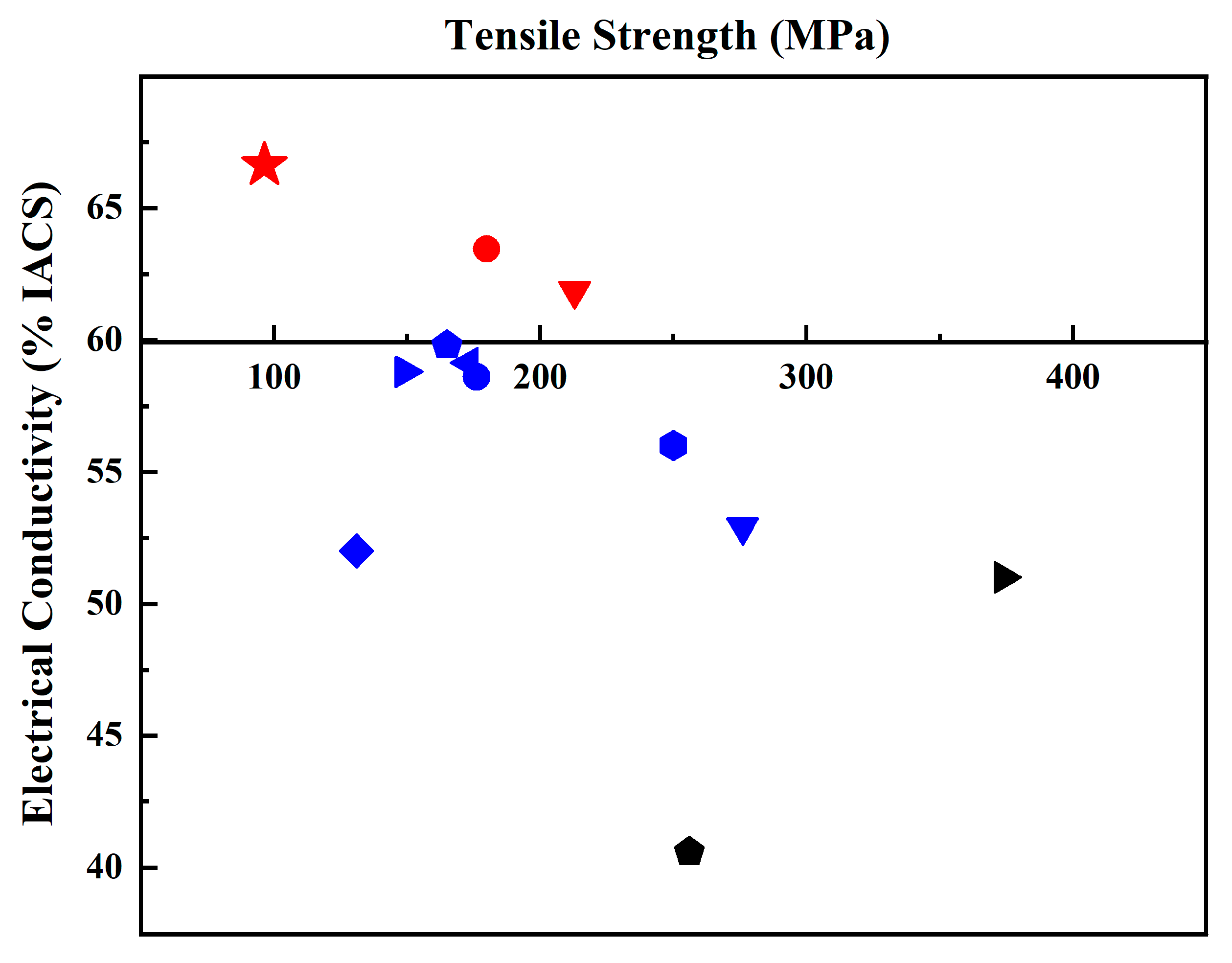

| Icon | Composites | Preparation Method |

Tensile Strength MPa |

Electrical Conductivity %IACS | Ref. |

|---|---|---|---|---|---|

| ★ | Gr/Al | Ultrasonic spraying Gr + VHP | 96.39 | 66.63 | This work |

| ● | Gr/Al | Casting + cold rolling + aging treatment | 180 | 63.45 | [28] |

| ▼ | Gr/Al8030 | Powder modification + semi-solid extrusion | 213 | 61.86 | [40] |

| ⬟ | FLG/Al | Solution mechanical stirring + SPS + hot extrusion | 165 | 59.8 | [38] |

| ◄ | FLG/Al | Colloidal mixing + SPS | 173 | 59.13 | [41] |

| ► | Gr/1060Al | FSP + hot extrusion | 149 | 58.8 | [42] |

| ● | GO/Al | Ultrasonic mixing in colloids + SPS | 176 | 58.6 | [43] |

| ⬢ | GNPs/Al | Mechanical stirring in ethanol + high temperature sintering | 250 | 56 | [44] |

| ◆ | Gr/Al | Mechanical ball milling + hot extrusion | 131 | 52 | [36] |

| ▼ | GNS/Al6063 | Mechanical ball milling + hot extrusion | 276 | 52.9 | [24] |

| ► | rGO/Al | Solution process mixing + thermal reduction | 374 | 51 | [27] |

| ⬟ | GNS/Al6061 | Mechanical ball milling + hot extrusion | 256 | 40.6 | [45] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Li, W.; Ma, J.; Liu, B.; Wang, W.; Liu, Z. Building a Layer-Structured Aluminum/Graphene Composite with Significant Improvement in Electrical Conductivity. Materials 2024, 17, 2979. https://doi.org/10.3390/ma17122979

Wang Z, Li W, Ma J, Liu B, Wang W, Liu Z. Building a Layer-Structured Aluminum/Graphene Composite with Significant Improvement in Electrical Conductivity. Materials. 2024; 17(12):2979. https://doi.org/10.3390/ma17122979

Chicago/Turabian StyleWang, Zishun, Wenhui Li, Junliang Ma, Baishan Liu, Wei Wang, and Zhaoping Liu. 2024. "Building a Layer-Structured Aluminum/Graphene Composite with Significant Improvement in Electrical Conductivity" Materials 17, no. 12: 2979. https://doi.org/10.3390/ma17122979

APA StyleWang, Z., Li, W., Ma, J., Liu, B., Wang, W., & Liu, Z. (2024). Building a Layer-Structured Aluminum/Graphene Composite with Significant Improvement in Electrical Conductivity. Materials, 17(12), 2979. https://doi.org/10.3390/ma17122979