Vat Photopolymerization of Sepiolite Fiber and 316L Stainless Steel-Reinforced Alumina with Functionally Graded Structures

Abstract

1. Introduction

2. Experiments and Measurement Procedures

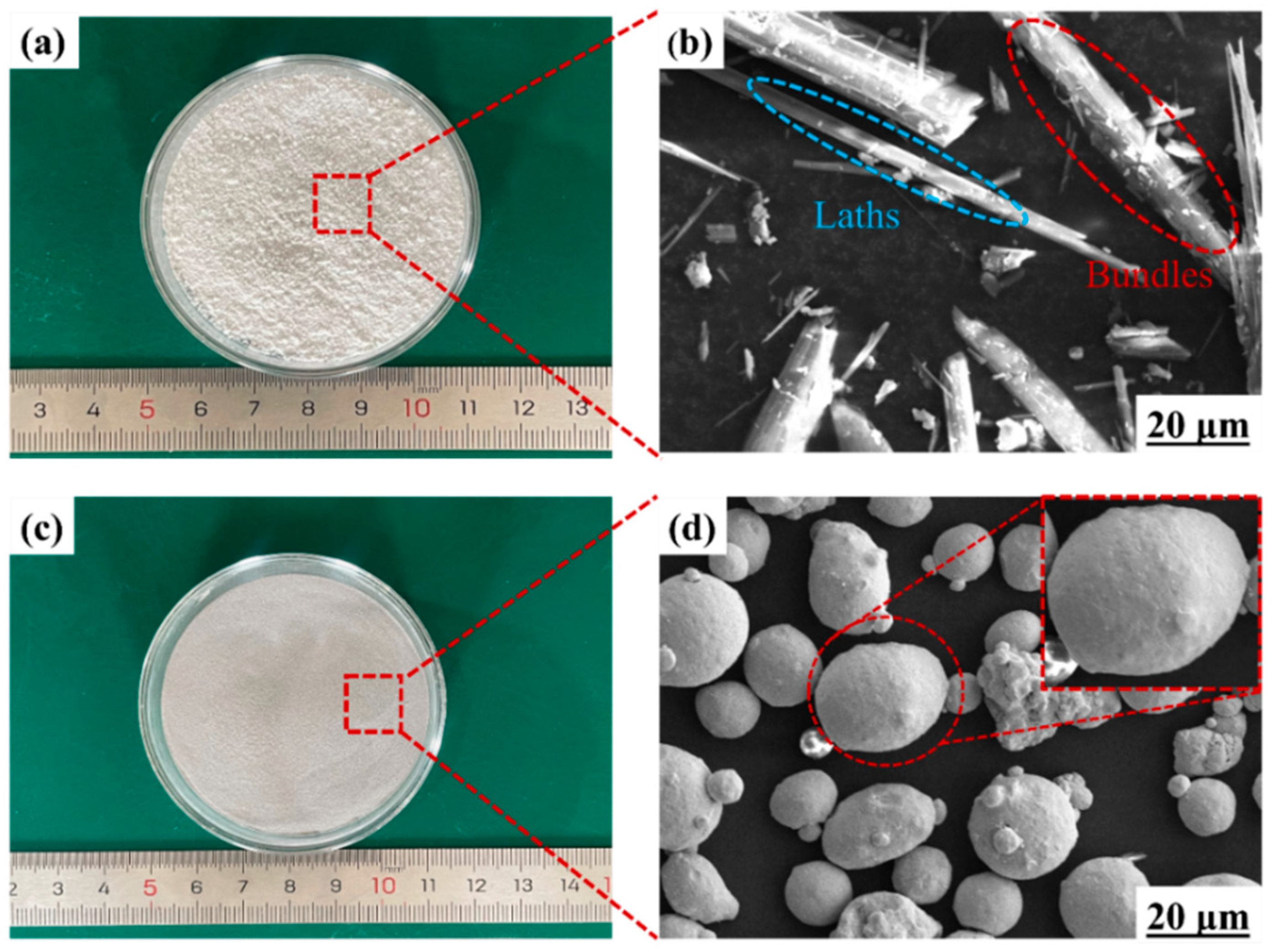

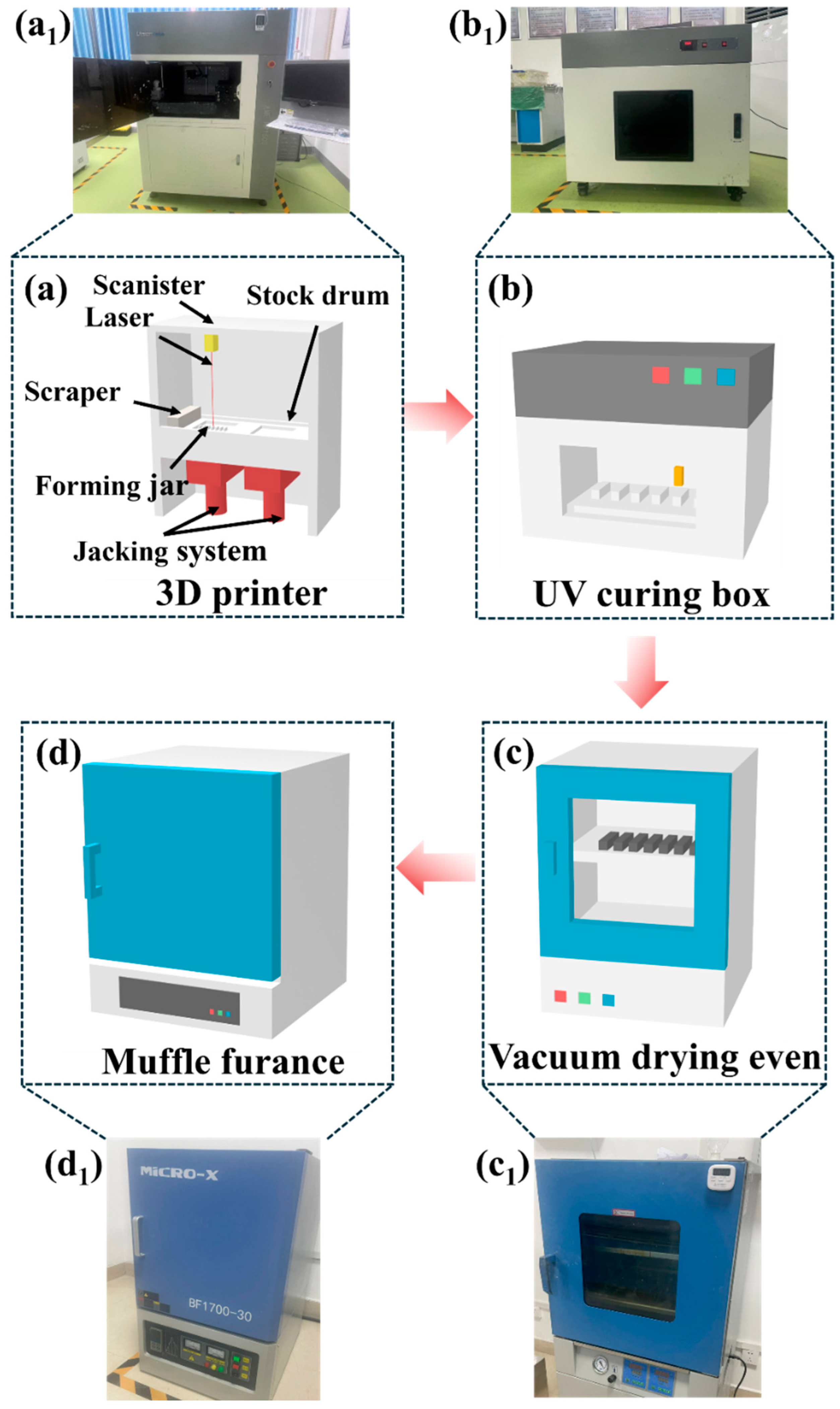

2.1. Material Preparation

2.2. Preparation of Toughened Al2O3 Ceramics with SFs and 316L SS

2.3. Characterization

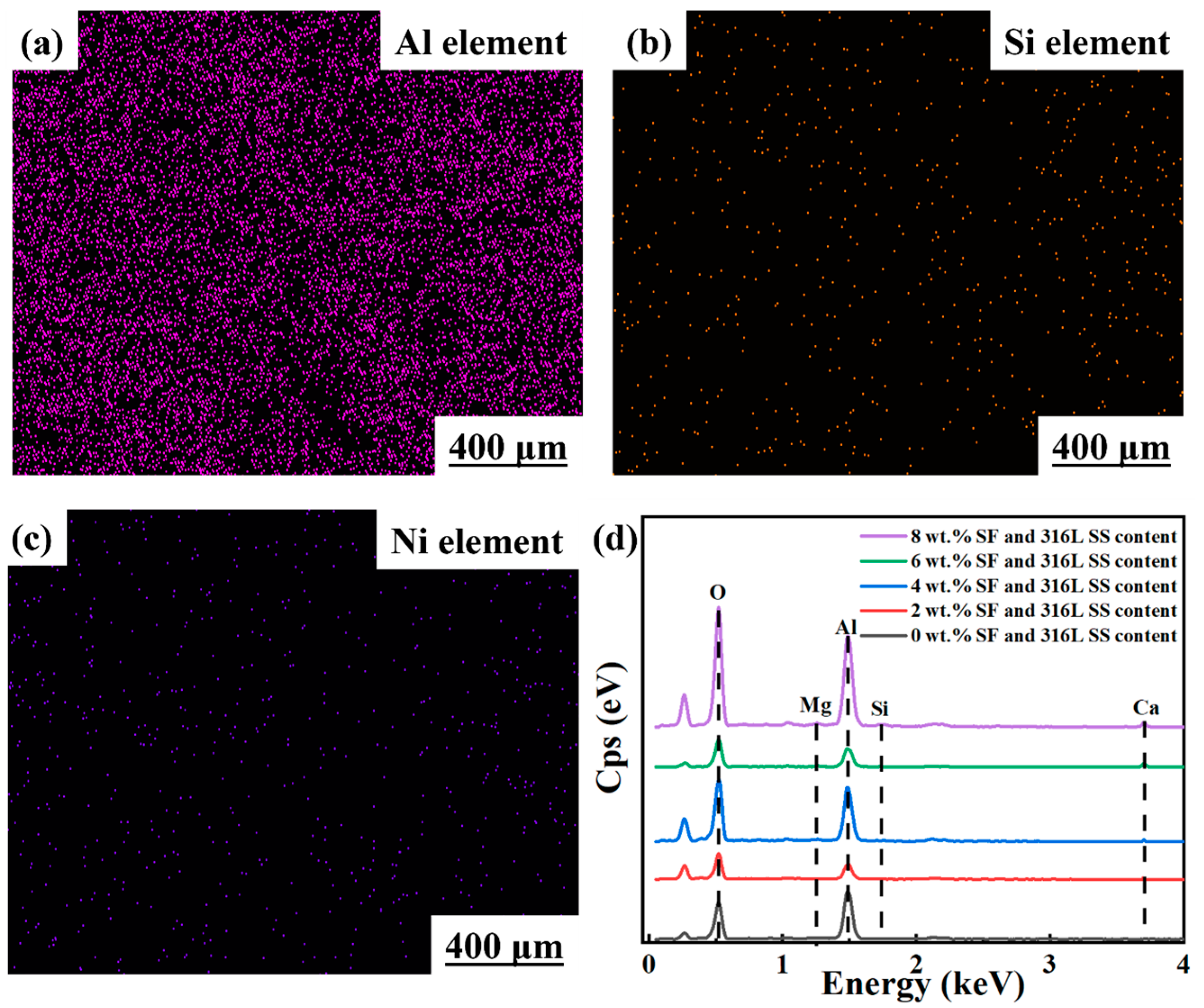

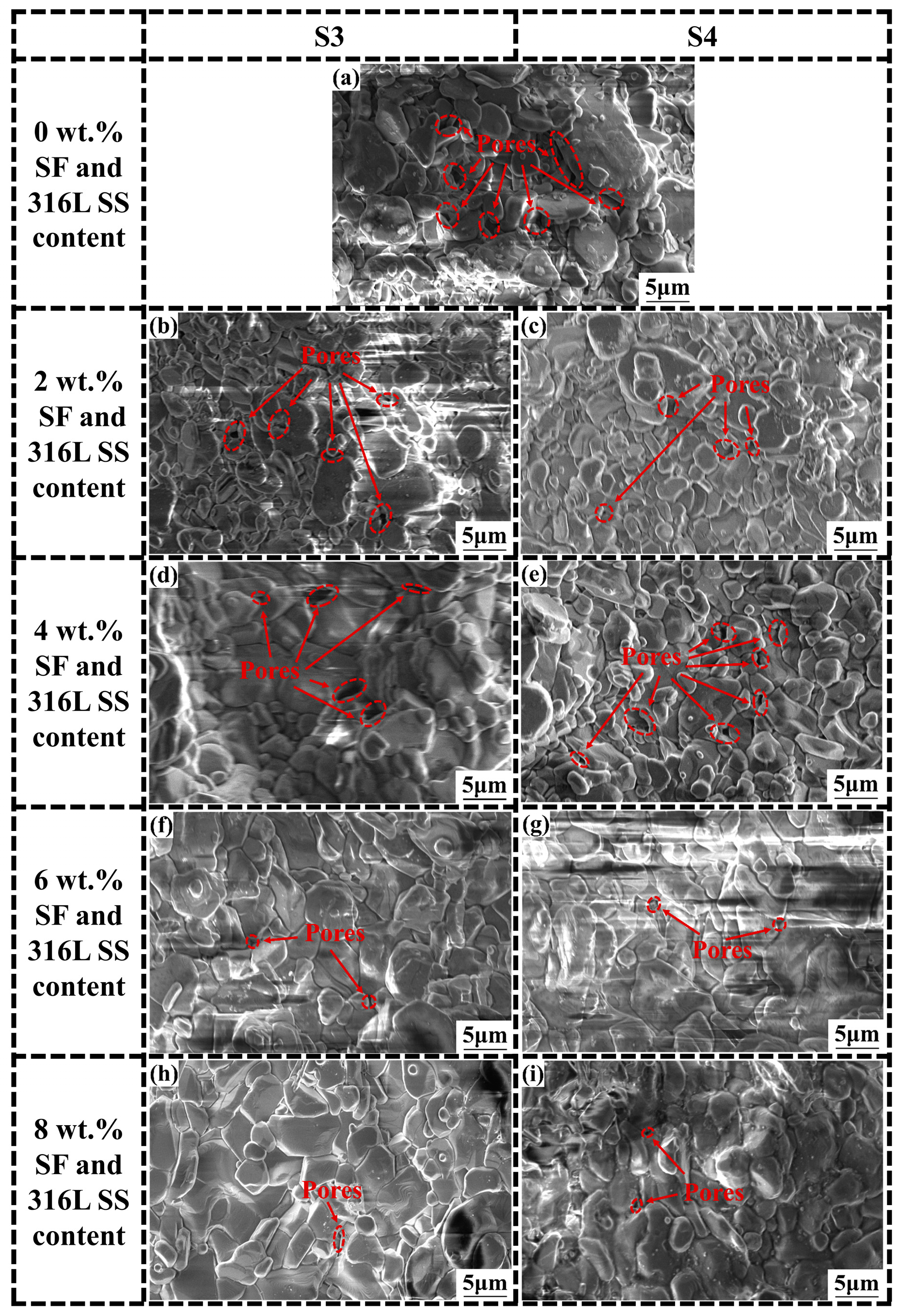

3. Results and Discussion

3.1. Debinding and Sintering of VPP-Printed Green Bodies

3.2. Effects on Physical Properties

3.3. Effects on Mechanical Properties

4. Conclusions

- A novel gradient printing process was proposed, distinguished from conventional VPP printing techniques by its method of creating green bodies with varying second-phase particle ratios across different layers.

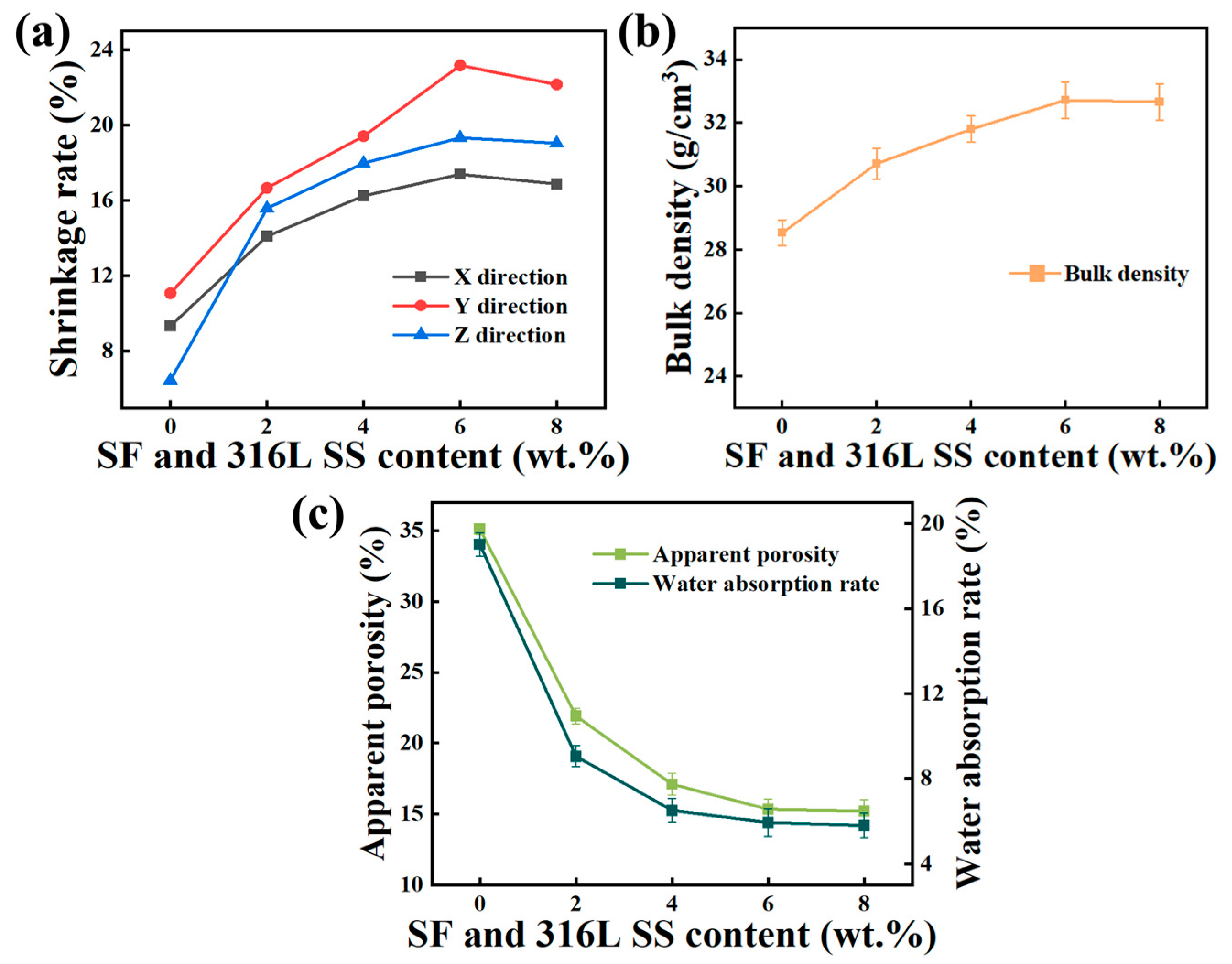

- Experimental results indicate that Al2O3 parts printed through this process exhibit optimal performance when the content of SF and 316L SS is 6 wt.%, with shrinkage rates of 17.38%, 23.156%, and 19.316% in the X, Y, and Z directions, respectively, a porosity rate of 15.34%, and a water absorption rate of 5.935%.

- A more significant conclusion is that compared to Al2O3 parts without added SF and 316L SS, their flexural strength and toughness increased by 490.32% and 420.8%, respectively.

- This study provides implications for future research into the introduction of multiple second-phase particles for gradient printing of Al2O3 ceramics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, Z.; Xu, Y.; Chen, X.; Han, C.; Jiang, W.; Yang, B.; Xu, B.; Liu, D. Preparation of AlN under Vacuum by the Alumina Carbothermal Reduction Nitridation Method. Ceram. Int. 2020, 46, 4095–4103. [Google Scholar] [CrossRef]

- Nadi, M.; Esmaeilzadeh, A.H.; Raftar, O.R.; Khajehzadeh, M.; Razfar, M.R. An Experimental Study on the Creep Feed Grinding of Laser Macro-Structured Alumina Considering Constant Material Removal Volume. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 238, 1385–1397. [Google Scholar] [CrossRef]

- Becker, L.C.; Boyer, I.; Bergfeld, W.F.; Belsito, D.V.; Hill, R.A.; Klaassen, C.D.; Liebler, D.C.; Marks, J.G.; Shank, R.C.; Slaga, T.J.; et al. Safety Assessment of Alumina and Aluminum Hydroxide as Used in Cosmetics. Int. J. Toxicol. 2016, 35, 16S–33S. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, W.; Ning, C.; Zhu, X.; Wang, Y.; Lu, B.; Li, Y.; Zhang, X. Alpha-to-Gamma Phase Transformation Self-Reinforcing of Alumina Ceramic Slit Array in Nd:YAG Laser Cutting Based on Vapor-to-Melt Ratio Controlling. Ceram. Int. 2022, 48, 16977–16989. [Google Scholar] [CrossRef]

- Nishio, Y.; Ozawa, M. Preparation and Properties of Porous Lanthanum Doped Alumina Ceramic Composites with Self-Organization. J. Ceram. Soc. Jpn. 2009, 117, 499–502. [Google Scholar] [CrossRef][Green Version]

- Xue, L.A.; Wu, X.; Chen, I.-W. Superplastic Alumina Ceramics with Grain Growth Inhibitors. J. Am. Ceram. Soc. 1991, 74, 842–845. [Google Scholar] [CrossRef]

- Mazumder, S.; Sarkar, N.; Park, J.G.; Han, I.S.; Kim, I.J. Carbon Nanotubes-Porous Ceramic Composite by in Situ CCVD Growth of CNTs. Mater. Chem. Phys. 2016, 171, 247–251. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive Manufacturing of Functionally Graded Materials: A Review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Miyamoto, Y. The Applications of Functionally Graded Materials in Japan. Mater. Technol. 1996, 11, 230–236. [Google Scholar] [CrossRef]

- Dai, H.-L.; Rao, Y.-N.; Dai, T. A Review of Recent Researches on FGM Cylindrical Structures under Coupled Physical Interactions, 2000–2015. Compos. Struct. 2016, 152, 199–225. [Google Scholar] [CrossRef]

- Shi, H.; Zhou, P.; Li, J.; Liu, C.; Wang, L. Functional Gradient Metallic Biomaterials: Techniques, Current Scenery, and Future Prospects in the Biomedical Field. Front. Bioeng. Biotechnol. 2021, 8, 616845. [Google Scholar] [CrossRef] [PubMed]

- Gariba, A.M.M.; Islak, S.; Hraam, H.R.H.; Akkaş, M. Microstructural and Mechanical Properties of Ti-B4C/CNF Functionally Graded Materials. Metallogr. Microstruct. Anal. 2022, 11, 736–745. [Google Scholar] [CrossRef]

- Zhu, D.; Chen, J. Thermal Stress Analysis on Chemical Vapor Deposition Tungsten Coating as Plasma Facing Material for EAST. J. Nucl. Mater. 2014, 455, 185–188. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T. Laser Metal Deposition of Functionally Graded Ti6Al4V/TiC. Mater. Des. 2015, 84, 402–410. [Google Scholar] [CrossRef]

- Zhang, R.; Jiang, F.; Xue, L.; Yu, J. Review of Additive Manufacturing Techniques for Large-Scale Metal Functionally Graded Materials. Crystals 2022, 12, 858. [Google Scholar] [CrossRef]

- Xu, H.; Chen, S.; Hu, R.; Hu, M.; Xu, Y.; Yoon, Y.; Chen, Y. Continuous Vat Photopolymerization for Optical Lens Fabrication. Small 2023, 19, 2300517. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Liu, W.; Wu, J.; Wei, Q.; Ye, C. 316L-Toughened Porous Al2O3-Based Ceramic Functionally Graded Materials Using Binder Jetting. Ceram. Int. 2023, 49, 39760–39770. [Google Scholar] [CrossRef]

- Hadian, A.; Duckek, J.; Parrilli, A.; Liersch, A.; Clemens, F. Additive Manufacturing of Fiber-Reinforced Zirconia-Toughened Alumina Ceramic Matrix Composites by Material Extrusion-Based Technology. Adv. Eng. Mater. 2024, 2302158. [Google Scholar] [CrossRef]

- Wu, H.; Liu, W.; He, R.; Wu, Z.; Jiang, Q.; Song, X.; Chen, Y.; Cheng, L.; Wu, S. Fabrication of Dense Zirconia-Toughened Alumina Ceramics through a Stereolithography-Based Additive Manufacturing. Ceram. Int. 2017, 43, 968–972. [Google Scholar] [CrossRef]

- Kulka, M.; Mikolajczak, D.; Makuch, N.; Dziarski, P.; Miklaszewski, A. Wear Resistance Improvement of Austenitic 316L Steel by Laser Alloying with Boron. Surf. Coat. Technol. 2016, 291, 292–313. [Google Scholar] [CrossRef]

- Guo, A.; Tang, R.; Guo, S.; Hu, Y.; Sheng, X.; Zhang, Y.; Zhang, M.; Qu, P.; Wang, S. Acoustic Field-Assisted Powder Bed Fusion of Tungsten Carbide-Reinforced 316L Stainless Steel Composites. J. Mater. Res. Technol. 2023, 26, 5488–5502. [Google Scholar] [CrossRef]

- Wu, H.; Guo, A.; Kong, D.; Li, X.; Wu, J.; Hu, Y.; Qu, P.; Wang, S.; Wu, Y.; Liu, C. Vat Photopolymerization of Sepiolite Fiber-Toughened Alumina: Effects of Sepiolite Fiber Content on Microstructures and Physical, Rheological, and Mechanical Properties. Mater. Today Commun. 2023, 37, 107329. [Google Scholar] [CrossRef]

- GB/T6569-2006; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Test Method for Flexural Strength of Monolithic Ceramics at Room Temperature. National Ceramic Industry Standardization Technical Committee: Beijing, China, 2006.

- Sun, J.; Chen, X.; Wade-Zhu, J.; Binner, J.; Bai, J. A Comprehensive Study of Dense Zirconia Components Fabricated by Additive Manufacturing. Addit. Manuf. 2021, 43, 101994. [Google Scholar] [CrossRef]

- Mazloumi, M.; Khalifehzadeh, R.; Sadrnezhaad, S.K.; Arami, H. Alumina Nanopowder Production from Synthetic Bayer Liquor. J. Am. Ceram. Soc. 2006, 89, 3654–3657. [Google Scholar] [CrossRef]

- Holeňák, R.; Spusta, T.; Potoček, M.; Salamon, D.; Šikola, T.; Bábor, P. 3D Localization of Spinel (MgAl2O4) and Sodium Contamination in Alumina by TOF-SIMS. Mater. Charact. 2019, 148, 252–258. [Google Scholar] [CrossRef]

- Xu, L.; Chen, M.; Huang, W.-J.; Wang, N.; Dong, J.-H.; Yin, X.-L. Effects of CaO Content on Sintering and Lightweight of Al2O3–MgO–CaO Refractories. Mater. Res. Innov. 2015, 19, S5–S212. [Google Scholar] [CrossRef]

- Qian, C.; Hu, K.; Shen, Z.; Wang, Q.; Li, P.; Lu, Z. Effect of Sintering Aids on Mechanical Properties and Microstructure of Alumina Ceramic via Stereolithography. Ceram. Int. 2023, 49, 17506–17523. [Google Scholar] [CrossRef]

- Yuan, L.; Liu, Z.; Liu, Z.; He, X.; Ma, B.; Zhu, Q.; Yu, J. Fabrication and Characterization of Porous MgAl2O4 Ceramics via a Novel Aqueous Gel-Casting Process. Materials 2017, 10, 1376. [Google Scholar] [CrossRef] [PubMed]

- Asmi, D.; Low, I.M.; Kennedy, S.; Day, R.A. Characteristics of a Layered and Graded Alumina/Calcium-Hexaluminate Composite. Mater. Lett. 1999, 40, 96–102. [Google Scholar] [CrossRef]

- Lieberthal, M.; Kaplan, W.D. Processing and Properties of Al2O3 Nanocomposites Reinforced with Sub-Micron Ni and NiAl2O4. Mater. Sci. Eng. A 2001, 302, 83–91. [Google Scholar] [CrossRef]

- Kishitake, K.; Era, H.; Otsubo, F.; Sonoda, T. Ceramic Coating on Ceramic with Metallic Bond Coating. J. Therm. Spray Technol. 1997, 6, 368–372. [Google Scholar] [CrossRef]

- Liu, C.T.; Ma, J.; Sun, X.F. Oxidation Behavior of a Single-Crystal Ni-Base Superalloy between 900 and 1000 °C in Air. J. Alloys Compd. 2010, 491, 522–526. [Google Scholar] [CrossRef]

- Marder, R.; Moshe, R.; Kaplan, W.D. The Wear Resistance of Ni Alumina and NiAl2O4 Alumina Nanocomposites. J. Eur. Ceram. Soc. 2023, 43, 1108–1116. [Google Scholar] [CrossRef]

- Wakai, F. Modeling and Simulation of Elementary Processes in Ideal Sintering. J. Am. Ceram. Soc. 2006, 89, 1471–1484. [Google Scholar] [CrossRef]

- Bordia, R.K.; Kang, S.-J.L.; Olevsky, E.A. Current Understanding and Future Research Directions at the Onset of the next Century of Sintering Science and Technology. J. Am. Ceram. Soc. 2017, 100, 2314–2352. [Google Scholar] [CrossRef]

- Zou, C.; Ou, Y.; Zhou, W.; Li, Z.; Zheng, P.; Guo, X. Microstructure and Properties of Hot Pressing Sintered SiC/Y3Al5O12 Composite Ceramics for Dry Gas Seals. Materials 2024, 17, 1182. [Google Scholar] [CrossRef] [PubMed]

- Xu, J. Achieving Uniform Nanoparticle Dispersion in Metal Matrix Nanocomposites. Ph.D. Thesis, UCLA, Los Angeles, CA, USA, 2015. [Google Scholar]

- Glasser, F.P. Advances in the Performance of Cement-Based Systems. In Advanced Ceramics III; Sōmiya, S., Ed.; Springer: Dordrecht, The Netherlands, 1990; pp. 139–162. ISBN 978-94-009-0763-8. [Google Scholar]

- Azhar, A.Z.A.; Mohamad, H.; Ratnam, M.M.; Ahmad, Z.A. The Effects of MgO Addition on Microstructure, Mechanical Properties and Wear Performance of Zirconia-Toughened Alumina Cutting Inserts. J. Alloys Compd. 2010, 497, 316–320. [Google Scholar] [CrossRef]

- Xu, L.; Wang, E.; Hou, X.; Chen, J.; He, Z.; Liang, T. Effect of Incorporation of Nitrogen on Calcium Hexaaluminate. J. Eur. Ceram. Soc. 2020, 40, 6155–6161. [Google Scholar] [CrossRef]

- Li, B.; Zheng, Y.; Wang, W.; Wu, H.; Li, Y.; Lv, J. Strengthening Mechanism of Cr Doping in Mo2FeB2-Based Cermets and Effects on Biphase Interface. Int. J. Refract. Met. Hard Mater. 2024, 118, 106485. [Google Scholar] [CrossRef]

| Grain Size | Element | Al2O3 | Fe2O3 | CaO | Na2O | TiO2 | MgO | K2O | SiO2 |

|---|---|---|---|---|---|---|---|---|---|

| 100 nm | Wt.% | ≥99.9 | 0.01 | 0.02 | 0.02 | 0.01 | <0.01 | 0.01 | <0.01 |

| 500 nm | Wt.% | 99.9 | 0.0257 | — | 0.0153 | 0.0102 | — | 0.0086 | 0.0201 |

| Element | Fe | Cr | Ni | Mo | Mn | Si | N | O | P | S | C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | Balance | 17 | 2.5 | 12 | 0.69 | 0.17 | 0.03 | 0.0226 | 0.005 | 0.0045 | 0.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Wu, H.; Guo, A.; Kong, D.; Zhao, Z.; Wang, L.; Yin, L.; Xia, G.; Su, X.; Hu, Y. Vat Photopolymerization of Sepiolite Fiber and 316L Stainless Steel-Reinforced Alumina with Functionally Graded Structures. Materials 2024, 17, 2973. https://doi.org/10.3390/ma17122973

Liu C, Wu H, Guo A, Kong D, Zhao Z, Wang L, Yin L, Xia G, Su X, Hu Y. Vat Photopolymerization of Sepiolite Fiber and 316L Stainless Steel-Reinforced Alumina with Functionally Graded Structures. Materials. 2024; 17(12):2973. https://doi.org/10.3390/ma17122973

Chicago/Turabian StyleLiu, Chang, Hailong Wu, Anfu Guo, Dekun Kong, Zhengyu Zhao, Lu Wang, Lvfa Yin, Guojun Xia, Xiaofei Su, and Yingbin Hu. 2024. "Vat Photopolymerization of Sepiolite Fiber and 316L Stainless Steel-Reinforced Alumina with Functionally Graded Structures" Materials 17, no. 12: 2973. https://doi.org/10.3390/ma17122973

APA StyleLiu, C., Wu, H., Guo, A., Kong, D., Zhao, Z., Wang, L., Yin, L., Xia, G., Su, X., & Hu, Y. (2024). Vat Photopolymerization of Sepiolite Fiber and 316L Stainless Steel-Reinforced Alumina with Functionally Graded Structures. Materials, 17(12), 2973. https://doi.org/10.3390/ma17122973