High Emissivity MoSi2-SiC-Al2O3 Coating on Rigid Insulation Tiles with Enhanced Thermal Protection Performance

Abstract

:1. Introduction

2. Materials and Methods

3. Results

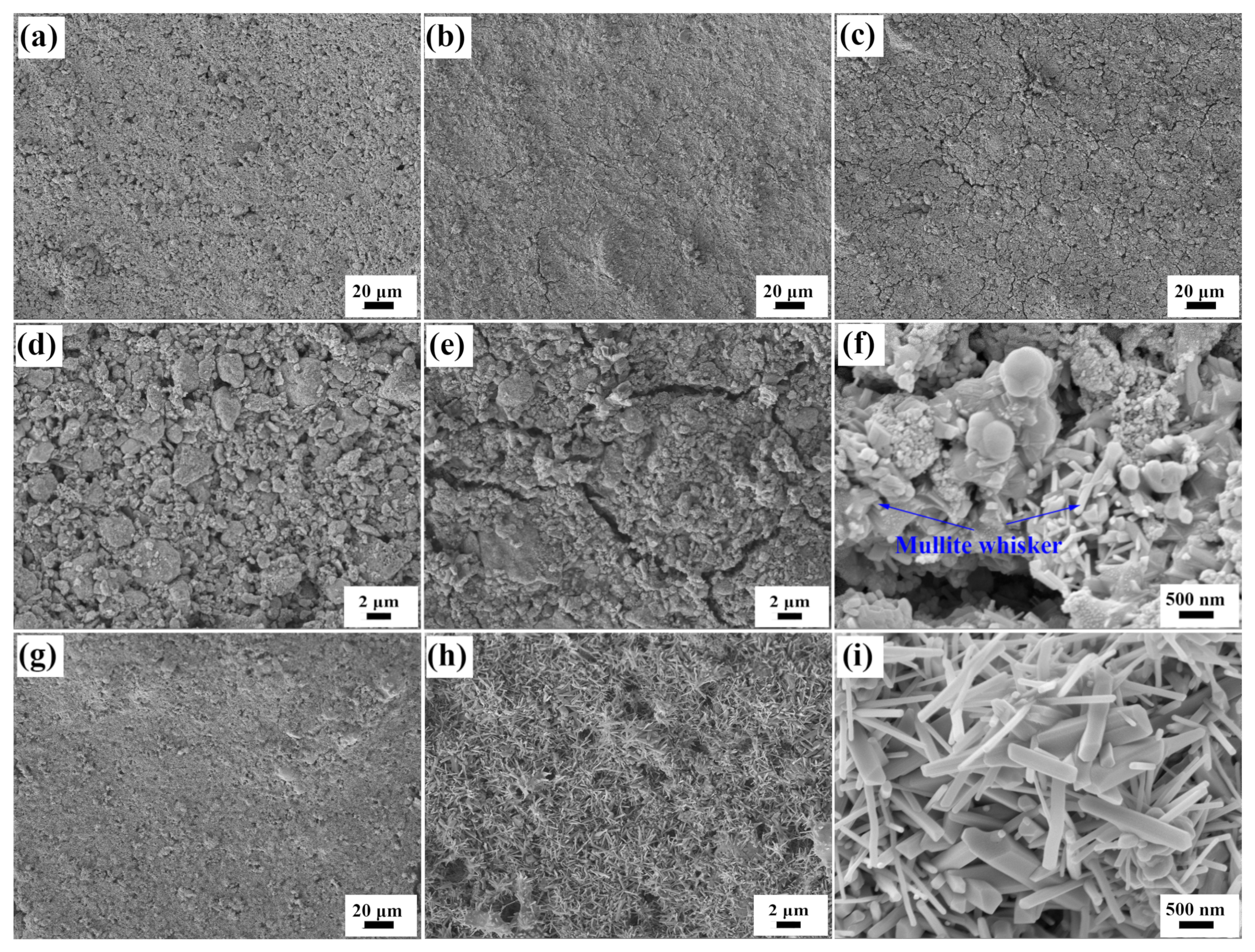

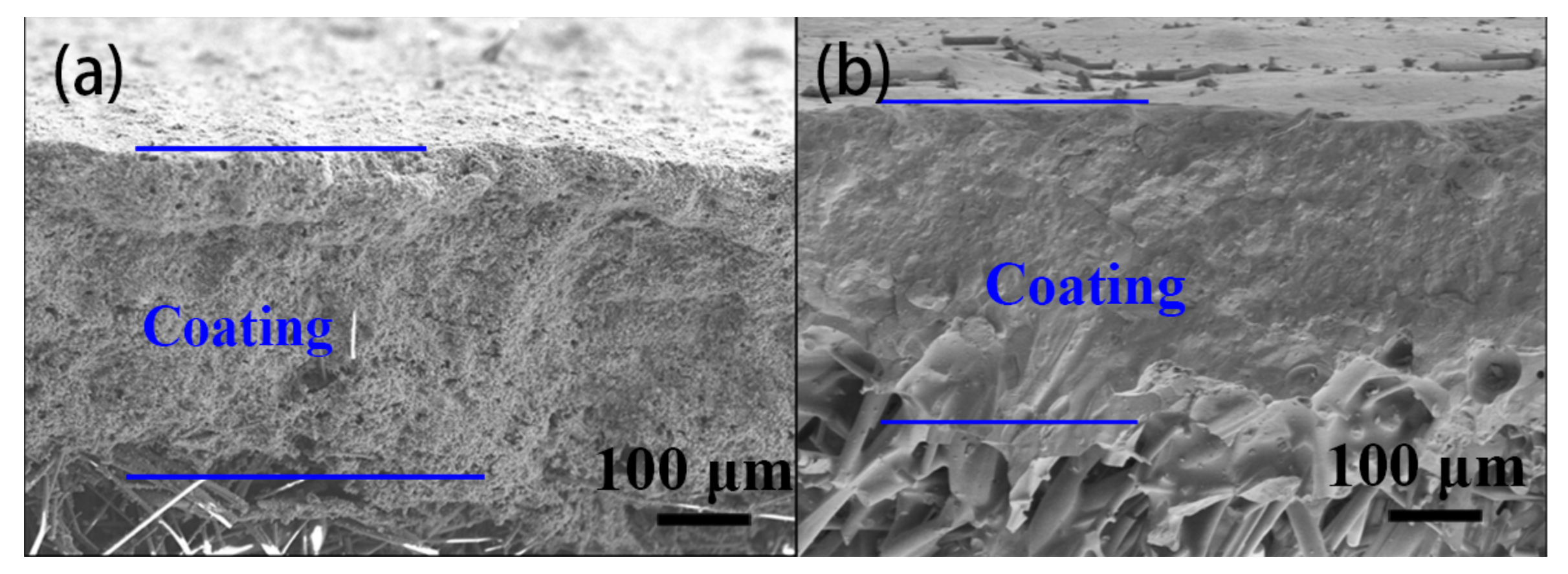

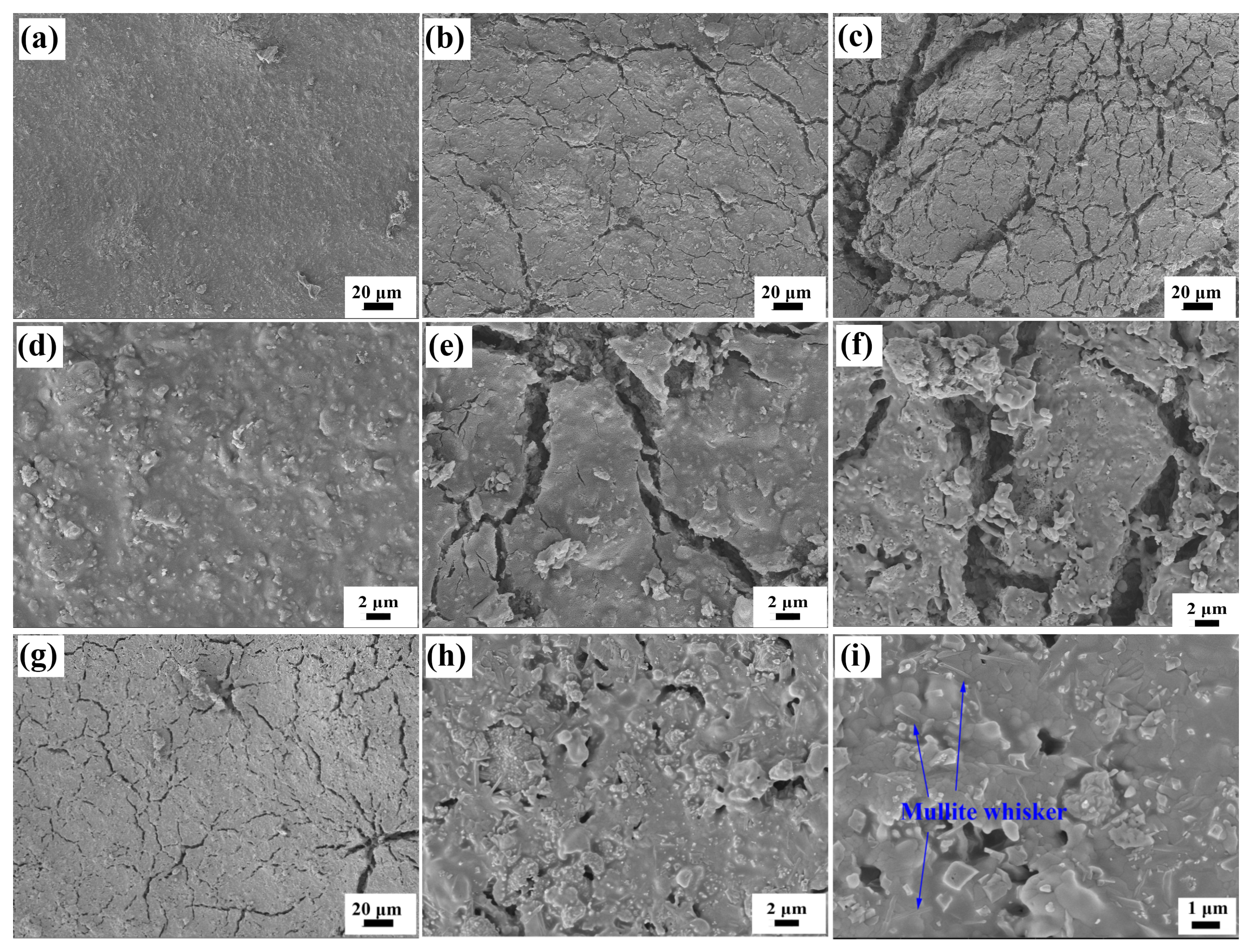

3.1. Coating Structure

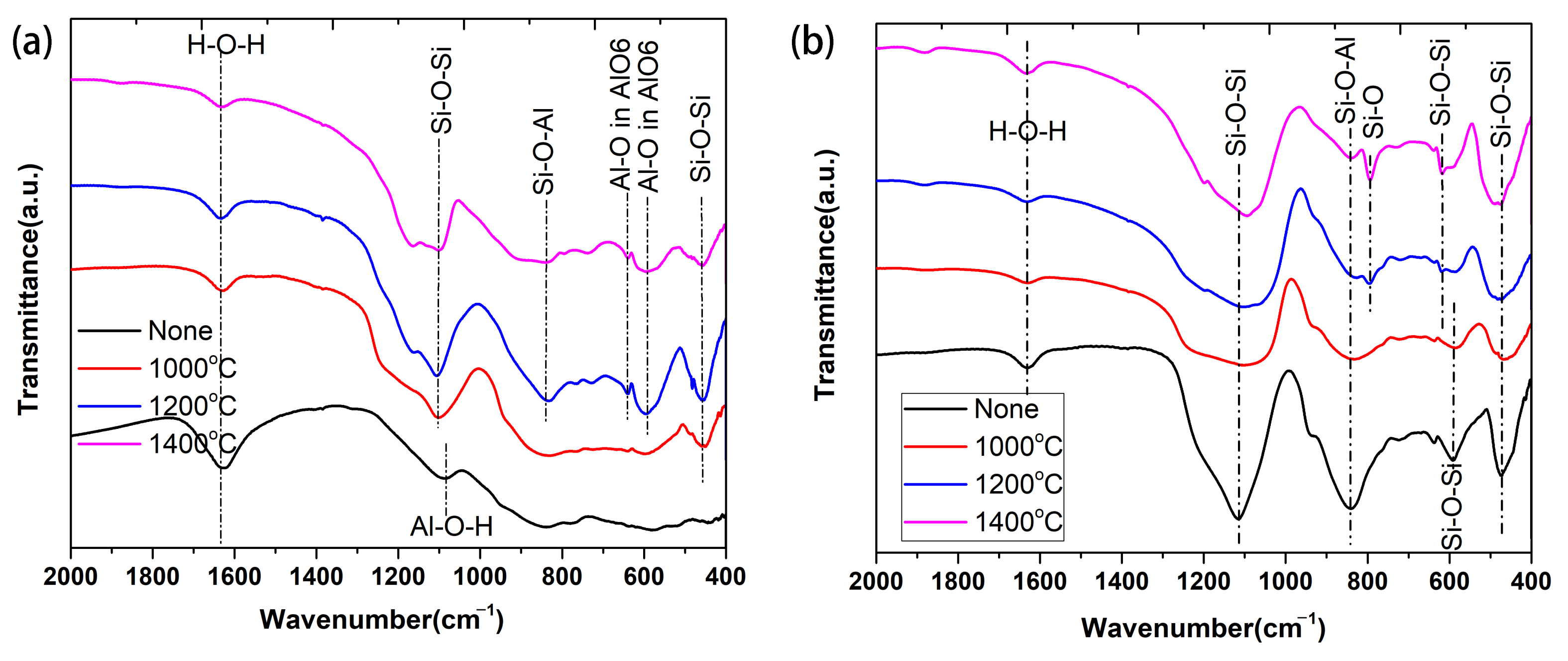

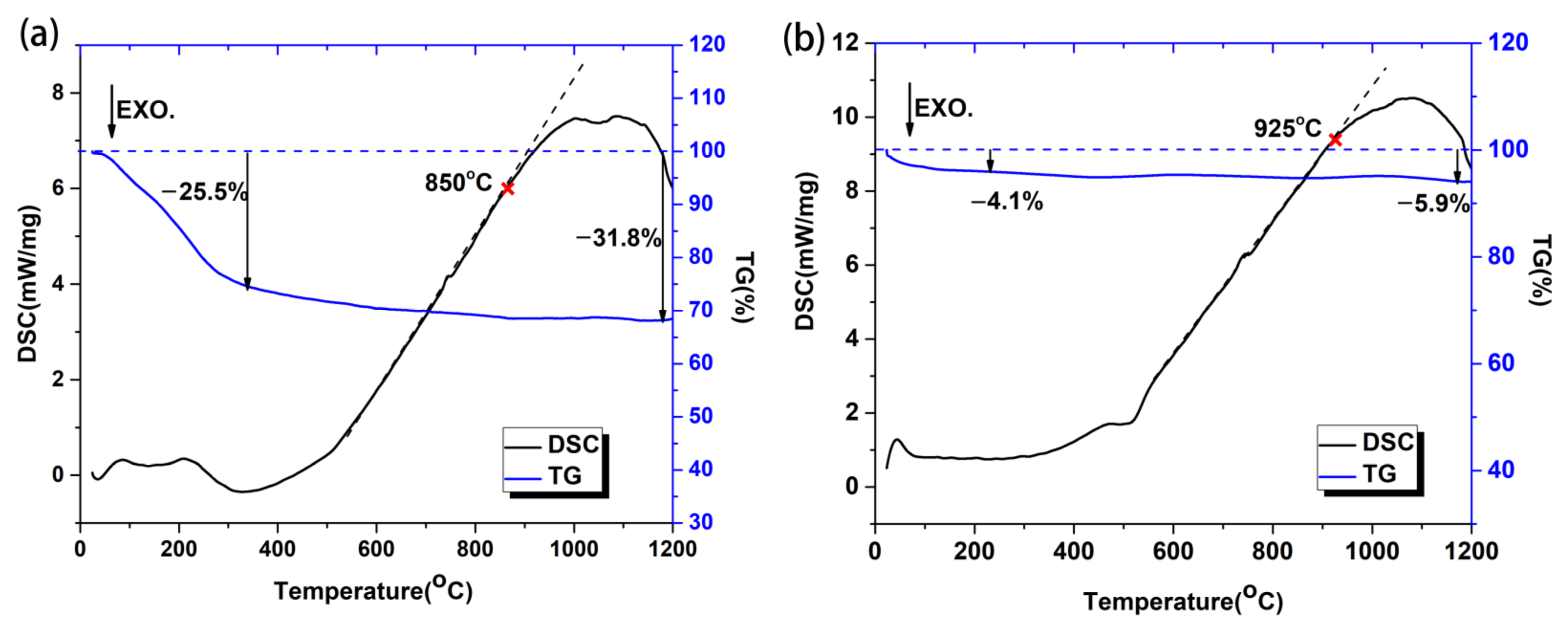

3.2. Coating Composition Evolution

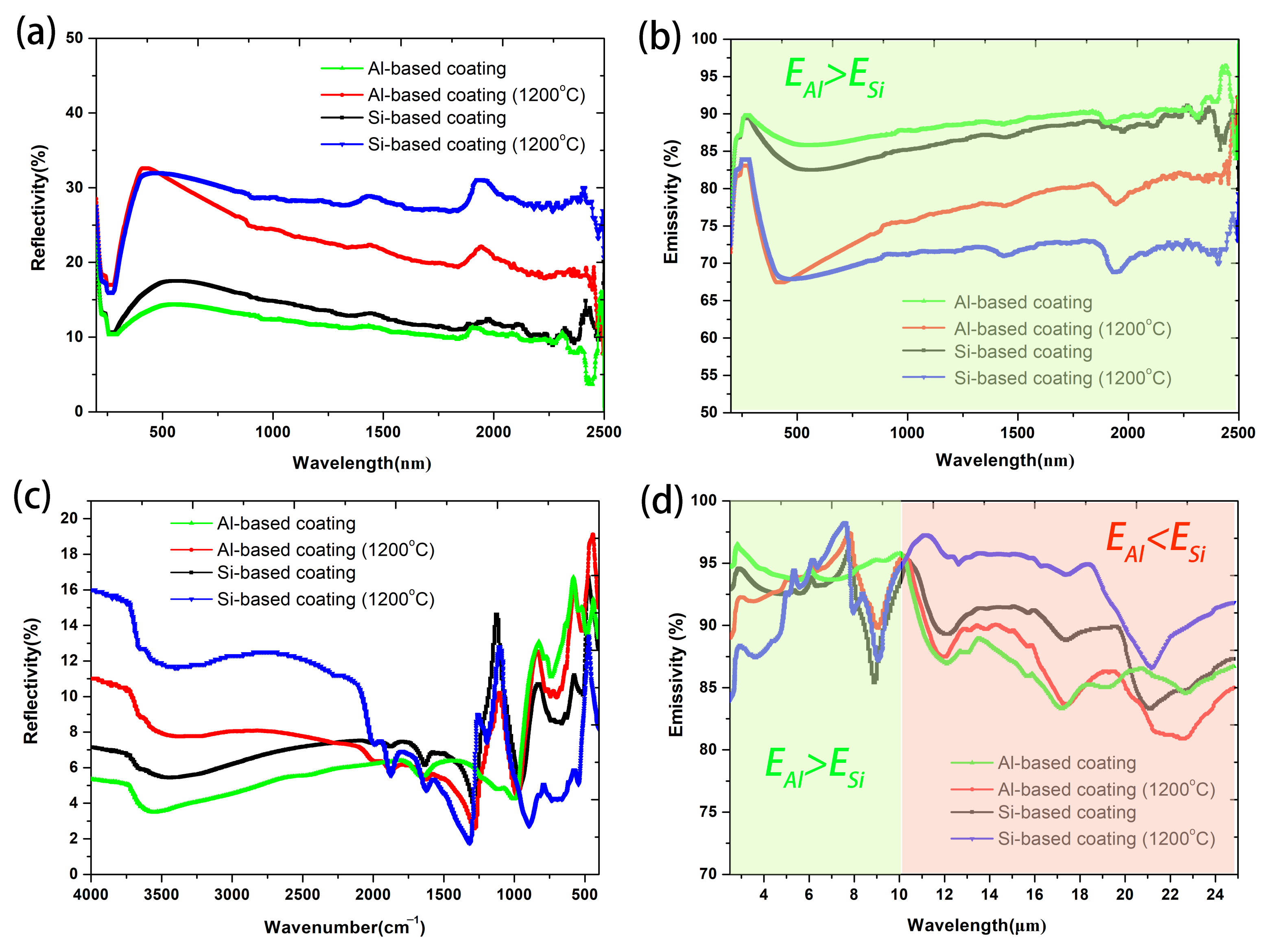

3.3. Emissivity of the Coating

3.4. Thermal Shielding and Insulation Performance

4. Conclusions

- (1)

- The as-prepared Si-based coating shows a denser structure, while the Al-based coating is porous, and the surface is rougher. After high-temperature heat treatment, the coating surface forms a network of micro-cracks, but the cracks are finer, and the network is more uniform in the Al-based coating. The more stable structure of Al-based coating with the increase in temperature increases the temperature resistance of the coating and increases the safety of service greatly.

- (2)

- When calcined at 1400 °C, an acicular mullite whisker is formed on the coating surface, but when the generation temperature is lowered by 75 °C, the whisker yield is significantly higher in the Al-based coating. The formation of mullite whisker is expected to improve the thermal shock resistance of the coating and its matching with the substrate.

- (3)

- The total emissivity of the as-prepared Al-based coating is 0.922 and 0.897 at the wavelength range of 200–2500 nm and 2.5–25 μm, respectively. The superior emissivity at low wavelength (<10 μm) is related to the higher surface roughness and reduced feature absorption. The spectral emissivity of the coatings calcined at 1200 °C decreases in the low wavelength range (<6 μm) due to oxidation of the emissive agents, and the emissivity reduction in the Al-based coating (−10.2%) is smaller than that of the Si-based coating (−18.6%). The high emissivity and low emissivity degradation at high temperatures make the Al-based coating an excellent radiative heat protection coating.

- (4)

- A flame heating experiment shows that the cold surface temperature of the Al-based coating coated substrate is 30 °C and 215 °C lower than the bare substrate when the substrate thickness is 15 mm and 8 mm, respectively. Overall, the Al-based coating produces good temperature resistance, high emissivity, and excellent thermal insulation performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Borella, L.; Rozo, A.; Perfetti, C.; Iorio, C.S. Characterization of Composite Freeze-Dried Aerogels with Simulant Lunar Regolith for Space Applications. Materials 2023, 16, 5797. [Google Scholar] [CrossRef] [PubMed]

- De Cesare, M.; Savino, L.; Ceglia, G.; Alfano, D.; Di Carolo, F.; French, A.D.; Rapagnani, D.; Gravina, S.; Cipullo, A.; Del Vecchio, A.; et al. Applied radiation physics techniques for diagnostic evaluation of the plasma wind and thermal protection system critical parameters in aerospace re-entry. Prog. Aerosp. Sci. 2020, 112, 100550. [Google Scholar] [CrossRef]

- Uyanna, O.; Najafi, H. Thermal protection systems for space vehicles: A review on technology development, current challenges and future prospects. Acta Astronaut. 2020, 176, 341–356. [Google Scholar] [CrossRef]

- Jamshed, W.; Nisar, K.S.; Gowda, R.J.P.; Kumar, R.N.; Prasannakumara, B.C. Radiative heat transfer of second grade nanofluid flow past a porous flat surface: A single-phase mathematical model. Phys. Scr. 2021, 96, 064006. [Google Scholar] [CrossRef]

- Xue, Y.; Huang, Z.; Yang, X.; Zhao, J.; Zhang, H.; Zhang, G.; Guo, A.; Yan, L.; Hou, F.; Liu, J. High temperature-resistant flexible inorganic coating for aluminium silicate fiber cloth with low solar absorption ratio and high emissivity. Ceram. Int. 2023, 49, 13799–13806. [Google Scholar] [CrossRef]

- Niranjan, K.; Soum-Glaude, A.; Carling-Plaza, A.; Bysakh, S.; John, S.; Barshilia, H.C. Extremely high temperature stable nanometric scale multilayer spectrally selective absorber coating: Emissivity measurements at elevated temperatures and a comprehensive study on ageing mechanism. Sol. Energy Mat. Sol. C 2021, 221, 110905. [Google Scholar] [CrossRef]

- Bokov, D.; Jalil, A.T.; Chupradit, S.; Suksatan, W.; Ansari, M.J.; Shewael, I.H.; Valiev, G.H.; Kianfar, E. Nanomaterial by sol-gel method: Synthesis and application. Adv. Mater. Sci. Eng. 2021, 2021, 5102014. [Google Scholar] [CrossRef]

- Imparato, C.; Bifulco, A.; Malucelli, G.; Aronne, A. Solids containing Si-O-P bonds: Is the hydrolytic sol-gel route a suitable synthesis strategy. J. Sol-Gel Sci. Technol. 2023, 1–26. [Google Scholar] [CrossRef]

- Guo, L.; Hu, X.; Tao, X.; Du, H.; Guo, A.; Liu, J. Low-temperature oxidation resistance of the silica-coated MoSi2 powders prepared by sol-gel preoxidation method. Ceram. Int. 2020, 46, 23471–23478. [Google Scholar] [CrossRef]

- Guo, L.; Li, Y.; Hu, X.; Wu, J.; Tao, X.; Du, H.; Guo, A.; Liu, J. Microstructure evolution and bonding mechanisms of silica sol bonded coating at elevated temperatures. J. Eur. Ceram. Soc. 2020, 40, 5051–5058. [Google Scholar] [CrossRef]

- Tao, X.; Liu, J.; Xu, X.; Hong, W.; Wang, M.; Guo, A.; Hou, F. Comparative study of MoSi2-borosilicate glass coatings on fibrous ceramics prepared by in-situ reaction method and two-step method. J. Alloys Compd. 2016, 684, 488–495. [Google Scholar] [CrossRef]

- Rangdal, P.; Patil, S.B. Synthesis of Alumina Sol Binder for Pure Alumina Refractory Castable and its Comparison with Other Commercially Available Binders. J. Inst. Eng. (India) Ser. D 2023, 104, 805–809. [Google Scholar] [CrossRef]

- Singh, A.K.; Sarkar, R. Urea based sols as binder for nano-oxide bonded high alumina refractory castables. J. Alloys Compd. 2018, 758, 140–147. [Google Scholar] [CrossRef]

- Singh, A.K.; Sarkar, R. Synthesis and Characterization of Alumina Sol and Its Use as Binder in No Cement High-Alumina Refractory Castables. Int. J. Appl. Ceram. Technol. 2015, 12, E54–E60. [Google Scholar] [CrossRef]

- Nateq, M.H.; Ceccato, R. Enhanced Sol–Gel Route to Obtain a Highly Transparent and Conductive Aluminum-Doped Zinc Oxide Thin Film. Materials 2019, 12, 1744. [Google Scholar] [CrossRef] [PubMed]

- Parin, R.; Rigon, M.; Bortolin, S.; Martucci, A.; Del Col, D. Optimization of Hybrid Sol-Gel Coating for Dropwise Condensation of Pure Steam. Materials 2020, 13, 878. [Google Scholar] [CrossRef]

- Peng, L.; Jiang, W.; Yang, L.; Chen, Z.; Li, G.; Guan, F.; Fan, Z. Effect of silica sol on performance and surface precision of alumina ceramic shell prepared by binder jetting. Ceram. Int. 2022, 48, 24372–24382. [Google Scholar] [CrossRef]

- Yona, A.M.C.; Žigon, J.; Kamlo, A.N.; Pavlič, M.; Dahle, S.; Petrič, M. Preparation, Surface Characterization, and Water Resistance of Silicate and Sol-Silicate Inorganic–Organic Hybrid Dispersion Coatings for Wood. Materials 2021, 14, 3559. [Google Scholar] [CrossRef]

- Xue, Y.; Tao, X.; Zhang, H.; Guo, A.; Yan, L.; Wu, J.; Hou, F.; Dong, S.; Liu, J. High emissivity scale structure MoSi2-silicon glass coating on aluminum silicate fiber cloths with excellent flexibility and oxidation resistance below 1000 °C. Ceram. Int. 2023, 49, 8516–8523. [Google Scholar] [CrossRef]

- Wu, J.Y.; Xu, X.J.; Xiong, Y.L.; Guan, X.Y.; Jiao, M.Y.; Yao, X.H.; Hu, X.X.; Xu, S.Y.; Tao, X.; Du, H.Y. Preparation and structure control of a scalelike MoSi2-borosilicate glass coating with improved contact damage and thermal shock resistance. Ceram. Int. 2020, 46, 7178–7186. [Google Scholar] [CrossRef]

- Knittel, S.; Mathieu, S.; Vilasi, M. The oxidation behaviour of uniaxial hot pressed MoSi2 in air from 400 to 1400 degrees C. Intermetallics 2011, 19, 1207–1215. [Google Scholar] [CrossRef]

- Van Trinh, P.; Lee, J.; Minh, P.N.; Phuong, D.D.; Hong, S.H. Effect of oxidation of SiC particles on mechanical properties and wear behavior of SiCp/Al6061 composites. J. Alloys Compd. 2018, 769, 282–292. [Google Scholar] [CrossRef]

- Milani, S.S.; Kakroudi, M.G.; Vafa, N.P.; Mokhayer, M.M.; Gharamaleki, S.H. Properties of alumina sol prepared via inorganic route. Ceram. Int. 2020, 46, 9492–9497. [Google Scholar] [CrossRef]

- Qiao, Z.; Liu, Q.; Zhang, S.; Wu, Y. The mineralogical characteristics between opaline silica in bentonite and α-cristobalite. Solid State Sci. 2019, 96, 105948. [Google Scholar] [CrossRef]

- Roy, J.; Bandyopadhyay, N.; Das, S.; Maitra, S. Studies on the Formation of Mullite from Diphasic Al2O3-SiO2 Gel by Fourier Transform Infrared Spectroscopy. Iran. J. Chem. Chem. Eng. 2011, 30, 65–71. [Google Scholar]

- Teoh, G.L.; Liew, K.Y.; Mahmood, W.A.K. Synthesis and characterization of sol–gel alumina nanofibers. J. Sol-Gel Sci. Technol. 2007, 44, 177–186. [Google Scholar] [CrossRef]

- Ebrahimpour, O.; Dubois, C.; Chaouki, J. Fabrication of mullite-bonded porous SiC ceramics via a sol–gel assisted in situ reaction bonding. J. Eur. Ceram. Soc. 2014, 34, 237–247. [Google Scholar] [CrossRef]

- Al-Oweini, R.; El-Rassy, H. Synthesis and characterization by FTIR spectroscopy of silica aerogels prepared using several Si(OR)4 and R″Si(OR′)3 precursors. J. Mol. Struct. 2009, 919, 140–145. [Google Scholar] [CrossRef]

- Nariyal, R.K.; Kothari, P.; Bisht, B. FTIR Measurements of SiO2 Glass Prepared by Sol-Gel Technique. Chem. Sci. Trans. 2014, 3, 1064–1066. [Google Scholar]

- Zhang, C.; Zhang, Z.; Tan, Y.; Zhong, M. The effect of citric acid on the kaolin activation and mullite formation. Ceram. Int. 2017, 43, 1466–1471. [Google Scholar] [CrossRef]

- Tan, H.; Ding, Y.; Yang, J. Mullite fibres preparation by aqueous sol–gel process and activation energy of mullitization. J. Alloys Compd. 2010, 492, 396–401. [Google Scholar] [CrossRef]

- Seronde, F.; Echegut, P.; Coutures, J.P.; Gervais, F. Emissivity of oxides: A microscopic approach to glass coatings. Mater. Sci. Eng. B 1991, 8, 315–327. [Google Scholar] [CrossRef]

- Shao, G.; Lu, Y.; Wu, X.; Wu, J.; Cui, S.; Jiao, J.; Shen, X. Preparation and thermal shock resistance of high emissivity molybdenum disilicide-aluminoborosilicate glass hybrid coating on fiber reinforced aerogel composite. Appl. Surf. Sci. 2017, 416, 805–814. [Google Scholar] [CrossRef]

- He, X.D.; Li, Y.B.; Wang, L.D.; Sun, Y.; Zhang, S. High emissivity coatings for high temperature application: Progress and prospect. Thin Solid. Films 2009, 517, 5120–5129. [Google Scholar] [CrossRef]

- Linda Bih, N.; Aboubakar Mahamat, A.; Bidossèssi Hounkpè, J.; Azikiwe Onwualu, P.; Boakye, E.E. The Effect of Polymer Waste Addition on the Compressive Strength and Water Absorption of Geopolymer Ceramics. Appl. Sci. 2021, 11, 3540. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Wang, S.; Zou, Y.; Chen, G.; Wen, L.; Zhang, G.; Zhao, L.; Ouyang, J.; Jia, D.; et al. High-temperature oxidation resistance and high emissivity of a novel NbSi2/SiO2-Nb2O5/MoSi2-Yb2O3 multilayer coating on Nb substrate for thermal protection. Corros. Sci. 2023, 224, 111519. [Google Scholar] [CrossRef]

- Kumar, S.; Choudhary, R.B. Structural, optical, and thermal investigation of SnO2 nanoparticles incorporated PANI nanofibers as an emissive layer material. J. Mol. Struct. 2023, 1293, 136199. [Google Scholar] [CrossRef]

- Sans, M.; Schick, V.; Parent, G.; Farges, O. Experimental characterization of the coupled conductive and radiative heat transfer in ceramic foams with a flash method at high temperature. Int. J. Heat Mass. Transf. 2020, 148, 119077. [Google Scholar] [CrossRef]

- Osaze, O.; Khanna, S. Experimental Thermal Conductivity Measurement of Hollow-Structured Polypropylene Material by DTC-25 and Hot Box Test. Buildings 2023, 13, 3094. [Google Scholar] [CrossRef]

- Woo, H.K.; Zhou, K.; Kim, S.K.; Manjarrez, A.; Hoque, M.J.; Seong, T.Y.; Cai, L. Visibly Transparent and Infrared Reflective Coatings for Personal Thermal Management and Thermal Camouflage. Adv. Funct. Mater. 2022, 32, 2201432. [Google Scholar] [CrossRef]

| Items | pH | Solid Load (%) | Viscosity (mPas) | Density (g/cm3) | Particle Size (nm) |

|---|---|---|---|---|---|

| Silica sol | 5.2 | 30 | <7 | 1.21 | 10–20 |

| Alumina sol | 4.3 | 20 | <7 | 1.31 | 20–30 |

| Emissivity | 200–2500 nm | 2.5–25 μm | ||

|---|---|---|---|---|

| Fully Dried | 1200 °C/1 h | Fully Dried | 1200 °C/1 h | |

| Al-based coating | 0.922 | 0.828 | 0.897 | 0.897 |

| Si-based coating | 0.892 | 0.726 | 0.906 | 0.939 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Wan, Y.; Li, J.; Liu, J.; Wang, M.; Tao, X. High Emissivity MoSi2-SiC-Al2O3 Coating on Rigid Insulation Tiles with Enhanced Thermal Protection Performance. Materials 2024, 17, 220. https://doi.org/10.3390/ma17010220

Yang X, Wan Y, Li J, Liu J, Wang M, Tao X. High Emissivity MoSi2-SiC-Al2O3 Coating on Rigid Insulation Tiles with Enhanced Thermal Protection Performance. Materials. 2024; 17(1):220. https://doi.org/10.3390/ma17010220

Chicago/Turabian StyleYang, Xukun, Yange Wan, Jiancun Li, Jiachen Liu, Mingchao Wang, and Xin Tao. 2024. "High Emissivity MoSi2-SiC-Al2O3 Coating on Rigid Insulation Tiles with Enhanced Thermal Protection Performance" Materials 17, no. 1: 220. https://doi.org/10.3390/ma17010220

APA StyleYang, X., Wan, Y., Li, J., Liu, J., Wang, M., & Tao, X. (2024). High Emissivity MoSi2-SiC-Al2O3 Coating on Rigid Insulation Tiles with Enhanced Thermal Protection Performance. Materials, 17(1), 220. https://doi.org/10.3390/ma17010220