Adhesive Performance of Resin Cement to Glass-Ceramic and Polymer-Based Ceramic CAD/CAM Materials after Applying Self-Etching Ceramic Primer or Different Surface Treatments

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation and Surface Treatments

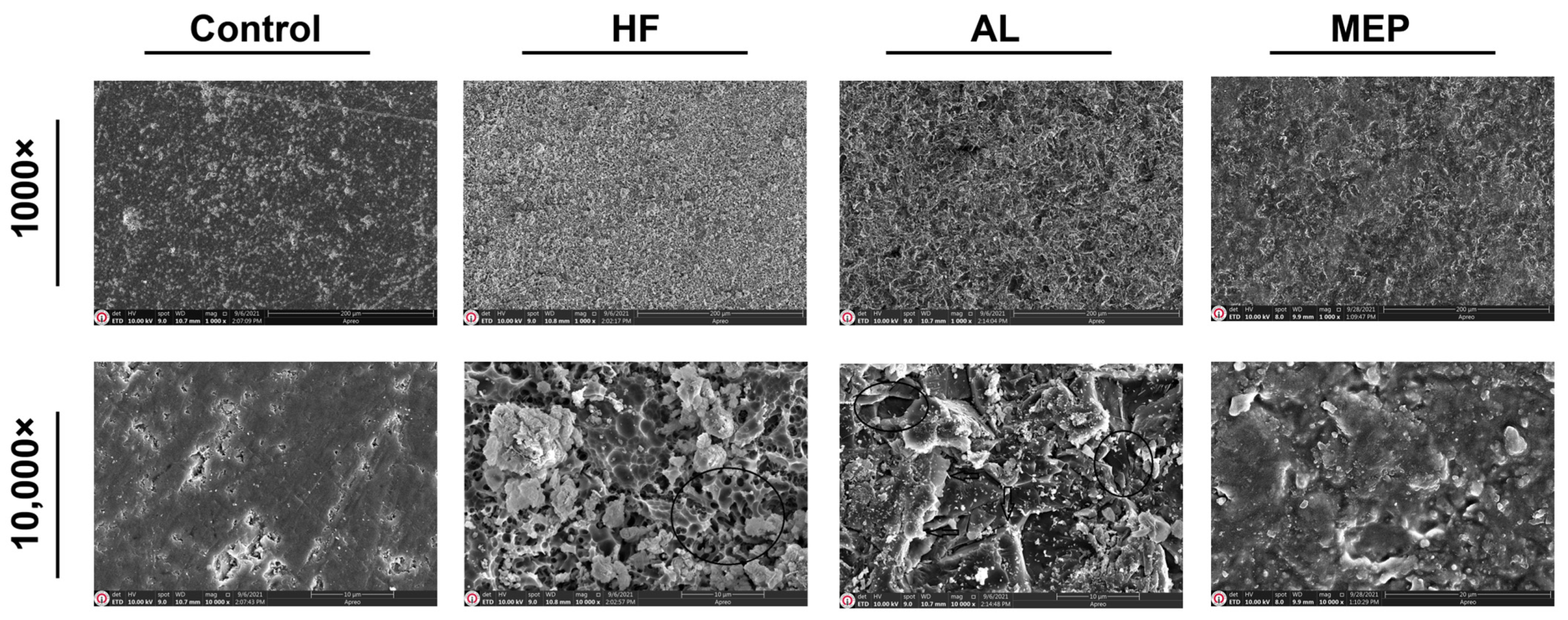

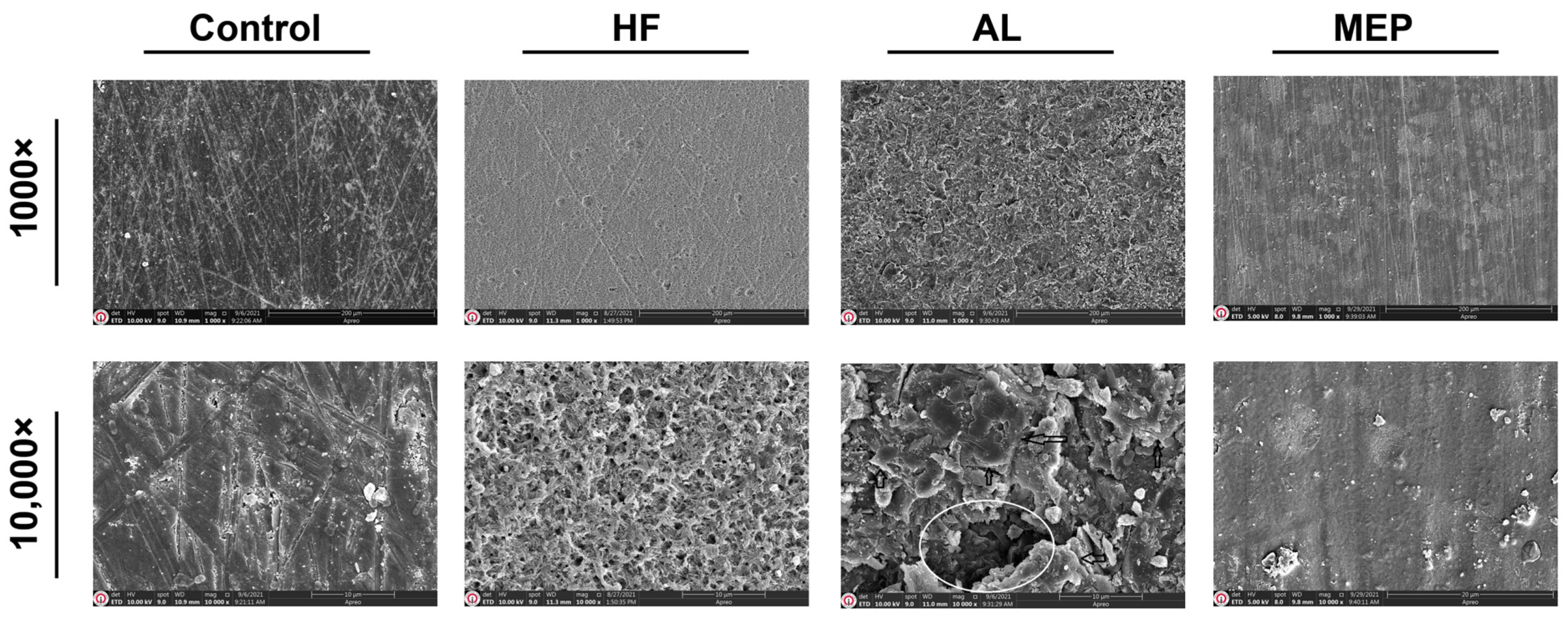

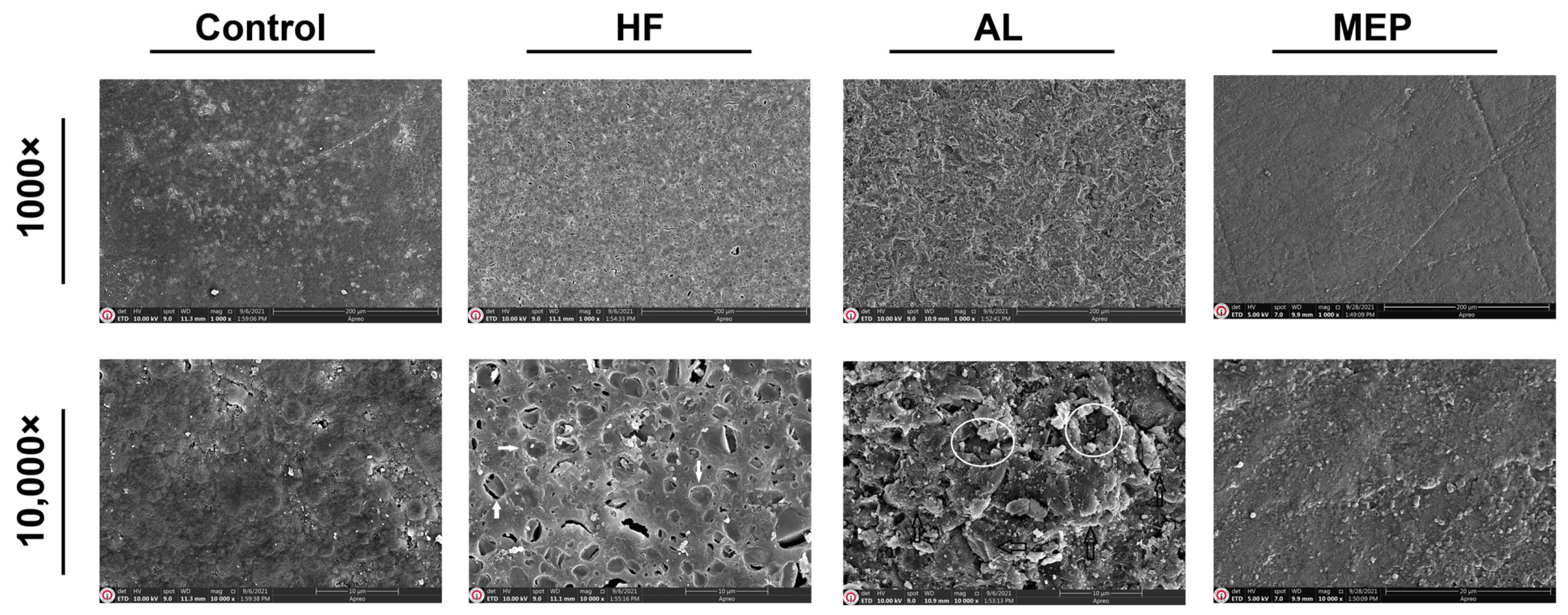

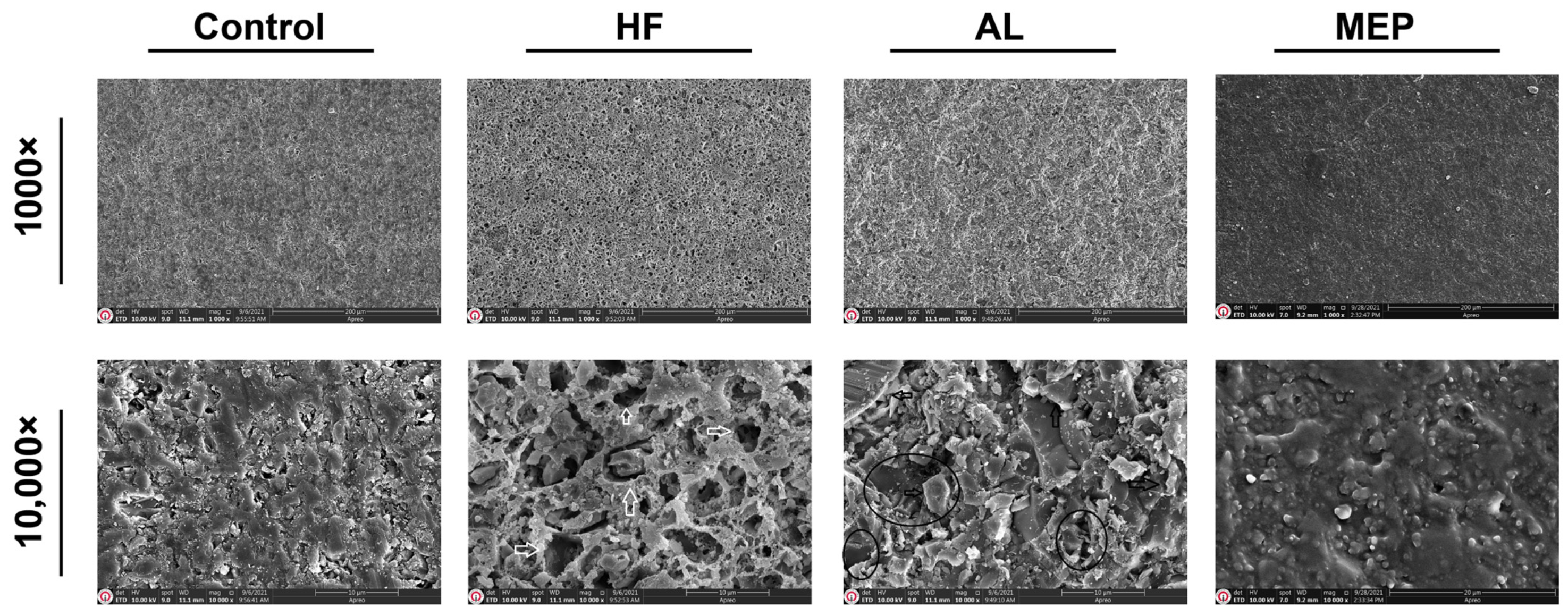

- Control: No surface treatment was administered.

- AL: Specimen surfaces underwent sandblasting with a micro sandblaster (DENTO-PREP™ Microblaster, Rønvig Dental Products Inc., Daugaard, Denmark) positioned 10 mm away from the surface of the specimen. This was done at a pressure of 2 bars with 50 µm aluminum-oxide (Al2O3) particles (RondoFlex Preparation Powder; KaVo, Biberach/Riss, Germany). Following treatment, the specimens were soaked in distilled water for 5 min in an ultrasonic bath before being air-dried.

- HF: CAD/CAM material surfaces were subjected to 5% hydrofluoric acid (IPS Ceramic Etching Gel, Ivoclar Vivadent, Schaan, Liechtenstein) for 60 s, except for LDC specimens, which were etched for 20 s in accordance with the manufacturer’s instructions [2,21]. Then, the surfaces were washed off with distilled water and dried with an air spray.

- MEP: Monobond Etch and Prime was kindly rubbed using a microbrush for 20 s. After waiting 40 s, the specimens were washed off and dried with air spray for 10 s, following the manufacturer’s instructions.

2.2. Adhesive Cementation and Thermocycling

2.3. Microshear Bond Strength Testing

- Adhesive (A): When the failure occurs at the interface between different materials.

- Mixed (M): When the failure occurs at the interface between different materials and within the resin cement or ceramic.

- Cohesive in resin cement (CRC): When the failure occurs within the resin cement material.

- Cohesive in CAD/CAM material (CC): When the failure occurs within the CAD/CAM material.

2.4. Scanning Electron Microscopy Evaluation

2.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

- The effectiveness of the surface treatment method on bond strength is mainly material dependent.

- Mechanical roughening by sandblasting is more effective in enhancing bond strength for polymer-based ceramics than glass ceramics.

- Chemical etching with HF resulted in the highest μSBS for glass ceramics and PICN material in terms of enhancing bond strength.

- MEP is more effective for glass ceramics such as leucite or lithium disilicate-reinforced glass ceramics, but it does not enhance bond strength as much as HF.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Turunç-Oğuzman, R.; Şişmanoğlu, S. Effect of surface treatments on shear bond strength between CAD/CAM bioceramic and resin blocks and orthodontic metal brackets bonded to each other. J. Aust. Ceram. Soc. 2023, 59, 187–196. [Google Scholar] [CrossRef]

- Cengiz-Yanardag, E.; Kurtulmus Yilmaz, S.; Karakaya, I.; Ongun, S. Effect of different surface treatment methods on micro-shear bond strength of CAD-CAM restorative materials to resin cement. J. Adhes. Sci. Technol. 2019, 33, 110–123. [Google Scholar] [CrossRef]

- Calheiros-Lobo, M.J.; Carbas, R.; da Silva, L.F.M.; Pinho, T. Impact of in vitro findings on clinical protocols for the adhesion of CAD-CAM blocks: A Systematic integrative review and meta-analysis. J. Prosthet. Dent. 2022; in press. [Google Scholar] [CrossRef] [PubMed]

- Spitznagel, F.A.; Boldt, J.; Gierthmuehlen, P.C. CAD/CAM ceramic restorative materials for natural teeth. J. Dent. Res. 2018, 97, 1082–1091. [Google Scholar] [CrossRef]

- Turunç-Oğuzman, R.; Şişmanoğlu, S. Influence of surface treatments and adhesive protocols on repair bond strength of glass-matrix and resin-matrix CAD/CAM ceramics. J. Esthet. Restor. Dent. 2023, 35, 1322–1331. [Google Scholar] [CrossRef]

- Murillo-Gómez, F.; De Goes, M.F. Bonding effectiveness of tooth-colored materials to resin cement provided by self-etching silane primer after short- and long-term storage. J. Prosthet. Dent. 2019, 121, 713.e1–713.e8. [Google Scholar] [CrossRef]

- Abouelleil, H.; Colon, P.; Jeannin, C.; Goujat, A.; Attik, N.; Laforest, L.; Gauthier, R.; Grosgogeat, B. Impact of the microstructure of CAD/CAM blocks on the bonding strength and the bonded interface. J. Prosthodont. 2022, 31, 72–78. [Google Scholar] [CrossRef]

- Şişmanoğlu, S.; Turunç-Oğuzman, R. Microshear bond strength of contemporary self-adhesive resin cements to CAD/CAM restorative materials: Effect of surface treatment and aging. J. Adhes. Sci. Technol. 2020, 34, 2484–2498. [Google Scholar] [CrossRef]

- Hashem, R. Shear bond strength of various dental ceramics treated with two techniques of surface treatment after thermocycling. Egypt. Dent. J. 2022, 68, 875–883. [Google Scholar] [CrossRef]

- Salem, S.K.; Ziada, A.; Elbanna, K.A. Effect of two different surface treatments on micro-shear bond strength of CAD/CAM and heat pressed glass ceramics. Egypt. Dent. J. 2019, 65, 1853–1864. [Google Scholar] [CrossRef][Green Version]

- Moura, D.M.D.; Veríssimo, A.H.; Leite Vila-Nova, T.E.; Calderon, P.S.; Özcan, M.; Assunção Souza, R.O. Which surface treatment promotes higher bond strength for the repair of resin nanoceramics and polymer-infiltrated ceramics? A systematic review and meta-analysis. J. Prosthet. Dent. 2022, 128, 139–149. [Google Scholar] [CrossRef] [PubMed]

- Azevedo, V.L.B.; de Castro, E.F.; Bonvent, J.J.; de Andrade, O.S.; Nascimento, F.D.; Giannini, M.; Cavalli, V. Surface treatments on CAD/CAM glass–ceramics: Influence on roughness, topography, and bond strength. J. Esthet. Restor. Dent. 2021, 33, 739–749. [Google Scholar] [CrossRef] [PubMed]

- Al-Harthi, A.A.; Aljoudi, M.H.; Almaliki, M.N.; El-Banna, K.A. Laboratory study of micro-shear bond strength of two resin cements to leucite ceramics using different ceramic primers. J. Contemp. Dent. Pract. 2018, 19, 918–924. [Google Scholar] [CrossRef] [PubMed]

- Shalaby, F.A.; Elgohary, N.M.; El Wassefy, N.A.; El-Naga, A.A.A. Influence of different conditioning protocols on bond strength to glass ceramic. Mansoura J. Dent. 2023, 10, 34–41. [Google Scholar] [CrossRef]

- Yu, P.; Wang, X.Y. Effects of surface treatment procedures on bond strength of lithium disilicate glass ceramic. Chin. J. Dent. Res. 2021, 24, 119–124. [Google Scholar] [CrossRef] [PubMed]

- Levartovsky, S.; Bohbot, H.; Shem-Tov, K.; Brosh, T.; Pilo, R. Effect of different surface treatments of lithium disilicate on the adhesive properties of resin cements. Materials 2021, 14, 3302. [Google Scholar] [CrossRef] [PubMed]

- Alnafaiy, S.; Labban, N.; Maawadh, A.; Alshehri, H.; Albaijan, R. Repair bond strength of composite resin to aged resin and glass-matrix CAD/CAM ceramic materials using two different repair systems. Coatings 2021, 11, 1331. [Google Scholar] [CrossRef]

- Dimitriadi, M.; Zinelis, S.; Zafiropoulou, M.; Silikas, N.; Eliades, G. Self-etch silane primer: Reactivity and bonding with a lithium disilicate ceramic. Materials 2020, 13, 641. [Google Scholar] [CrossRef]

- Vila-Nova, T.E.L.; Moura, D.M.D.; de Araújo, G.M.; Pinto, R.d.A.S.; Leite, F.P.P.; Melo, R.M.; Özcan, M.; Souza, R.O.d.A.E. Effect of adhesive resin application on the durability of adhesion to CAD/CAM Glass-ceramics after either hydrofluoric acid etching or self-etch primer application. J. Adhes. Dent. 2022, 24, 279–289. [Google Scholar] [CrossRef]

- Ueda, N.; Takagaki, T.; Nikaido, T.; Takahashi, R.; Ikeda, M.; Tagami, J. The effect of different ceramic surface treatments on the repair bond strength of resin composite to lithium disilicate ceramic. Dent. Mater. J. 2021, 40, 1073–1079. [Google Scholar] [CrossRef]

- El-Damanhoury, H.M.; Elsahn, N.A.; Sheela, S.; Gaintantzopoulou, M.D. Adhesive luting to hybrid ceramic and resin composite CAD/CAM blocks:Er:YAG laser versus chemical etching and micro-abrasion pretreatment. J. Prosthodont. Res. 2021, 65, 225–234. [Google Scholar] [CrossRef] [PubMed]

- Aswal, G.S.; Nair, C.K. Effects of various parameters of alumina air abrasion on the mechanical properties of low-fusing feldspathic porcelain laminate material. S. Afr. Dent. J. 2015, 70, 150–155. [Google Scholar]

- Strasser, T.; Preis, V.; Behr, M.; Rosentritt, M. Roughness, surface energy, and superficial damages of CAD/CAM materials after surface treatment. Clin. Oral Investig. 2018, 22, 2787–2797. [Google Scholar] [CrossRef] [PubMed]

- Şişmanoğlu, S.; Gürcan, A.T.; Yıldırım-Bilmez, Z.; Gümüştaş, B. Efficacy of different surface treatments and universal adhesives on the microtensile bond strength of bulk-fill composite repair. J. Adhes. Sci. Technol. 2020, 34, 1115–1127. [Google Scholar] [CrossRef]

- Schellenberg, R.; Özcan, M. Comparison of repair protocols for veneered zirconia as a function of surface conditioning parameters, ceramic primer types and defect sizes. J. Adhes. Sci. Technol. 2021, 35, 2110–2123. [Google Scholar] [CrossRef]

- Carrabba, M.; Vichi, A.; Louca, C.; Ferrari, M. Comparison of traditional and simplified methods for repairing CAD/CAM feldspathic ceramics. J. Adv. Prosthodont. 2017, 9, 257–264. [Google Scholar] [CrossRef]

- Alrahlah, A.; Awad, M.M.; Vohra, F.; Al-Mudahi, A.; Al jeaidi, Z.A.; Elsharawy, M. Effect of self etching ceramic primer and universal adhesive on bond strength of lithium disilicate ceramic. J. Adhes. Sci. Technol. 2017, 31, 2611–2619. [Google Scholar] [CrossRef]

- Sismanoglu, S.; Yildirim-Bilmez, Z.; Erten-Taysi, A.; Ercal, P. Influence of different surface treatments and universal adhesives on the repair of CAD-CAM composite resins: An in vitro study. J. Prosthet. Dent. 2020, 124, 238.e1–238.e9. [Google Scholar] [CrossRef]

- Mine, A.; Kabetani, T.; Kawaguchi-Uemura, A.; Higashi, M.; Tajiri, Y.; Hagino, R.; Imai, D.; Yumitate, M.; Ban, S.; Matsumoto, M.; et al. Effectiveness of current adhesive systems when bonding to CAD/CAM indirect resin materials: A review of 32 publications. Jpn. Dent. Sci. Rev. 2019, 55, 41–50. [Google Scholar] [CrossRef]

- Dapieve, K.S.; Pilecco, R.O.; Temp, R.W.; Villetti, M.A.; Pereira, G.K.R.; Valandro, L.F. Adhesion to lithium disilicate glass-ceramics after aging: Resin viscosity and ceramic surface treatment effects. J. Mech. Behav. Biomed. Mater. 2023, 142, 105819. [Google Scholar] [CrossRef]

- Chen, B.; Lu, Z.; Meng, H.; Chen, Y.; Yang, L.; Zhang, H.; Xie, H.; Chen, C. Effectiveness of pre-silanization in improving bond performance of universal adhesives or self-adhesive resin cements to silica-based ceramics: Chemical and in vitro evidences. Dent. Mater. 2019, 35, 543–553. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, P.C.K.; Almeida, C.C.M.S.; Souza, R.O.A.; Tango, R.N. The effect of a 10-MDP-based dentin adhesive as alternative for bonding to implant abutment materials. Materials 2022, 15, 5449. [Google Scholar] [CrossRef] [PubMed]

- Valente, F.; Mavriqi, L.; Traini, T. Effects of 10-mdp based primer on shear bond strength between zirconia and new experimental resin cement. Materials 2020, 13, 235. [Google Scholar] [CrossRef] [PubMed]

- Anwar, M.; El Tannir, A.; Elbasty, R. Effect of a novel ceramic surface treatment on the retention of lithium disilicate crowns bonded with two different luting approaches an in vitro study. Egypt. Dent. J. 2021, 67, 2239–2251. [Google Scholar] [CrossRef]

- Oliveira, L.; de Castro, E.; Azevedo, V.; de Andrade, O.; Faraoni, J.; Palma-Dibb, R.; Dias, C.; Giannini, M. Effect of ceramic conditioners on surface morphology, roughness, contact angle, adhesion, microstructure, and composition of CAD/CAM ceramics. Oper. Dent. 2023, 48, 277–293. [Google Scholar] [CrossRef] [PubMed]

- El-Damanhoury, H.M.; Gaintantzopoulou, M.D. Self-etching ceramic primer versus hydrofluoric acid etching: Etching efficacy and bonding performance. J. Prosthodont. Res. 2018, 62, 75–83. [Google Scholar] [CrossRef] [PubMed]

- Tunca, M.; Unalan Degirmenci, B. Influence of surface treatments on the bond strength of metal brackets to cad/cam materials and discoloration after various refinishing procedures: Scanning electron microscopy and atomic force microscopy study. J. Orofac. Orthop. 2023, 84, 231–243. [Google Scholar] [CrossRef]

- Andermatt, L.; Özcan, M. Micro-shear bond strength of resin composite cement to coronal enamel/dentin, cervical enamel, cementoenamel junction and root cementum with different adhesive systems. J. Adhes. Sci. Technol. 2021, 35, 2079–2093. [Google Scholar] [CrossRef]

- Edelhoff, D.; Özcan, M. To what extent does the longevity of fixed dental prostheses depend on the function of the cement? Working group 4 materials: Cementation. Clin. Oral Implants Res. 2007, 18, 193–204. [Google Scholar] [CrossRef]

| Material | Lot. No. | Type | Composition | Manufacturer |

|---|---|---|---|---|

| LEU | Y45442 | Leucite-based glass-ceramic | SiO2 (60–65 %wt), Al2O3 (16–20 %wt), K2O (10–14 %wt), Na2O (3.5–6.5 %wt), other oxides (0.5–7 %wt), pigments (0.2–1 %wt). | IPS Empress CAD; Ivoclar Vivadent AG, Schaan, Liechtenstein |

| LDC | Z00921 | Lithium disilicate glass-ceramic | SiO2 (57–80%), Li2O (11–19%), K2O (0–13 %wt), P2O5 (0–11%), ZrO2 (0–8%), ZnO (0–8%), Al2O3 (0–5%) MgO (0–5%), coloring oxides (0–8% by weight). | IPS e.max CAD; Ivoclar Vivadent AG, Schaan, Liechtenstein |

| RNC | N619802 | Resin nanoceramic | Bis-GMA, UDMA, Bis-EMA, TEGDMA. Filler: ZrO2 (4–11 nm) and SiO2 (20 nm), aggregated zirconia/silica cluster filler, 80% by weight. | Lava Ultimate; 3M ESPE, St. Paul, MN, USA |

| PICN | 51540 | Polymer-infiltrated ceramic network | UDMA, TEGDMA. Filler: Feldspar ceramic enriched with aluminum oxide, 86% by weight. | Vita Enamic; VITA Zahnfabrik H. Rauter, Bad Sackingen, Germany |

| MEP | Z01RL2 | Self-etching glass-ceramic primer | Butanol, tetrabutylammonium dihydrogen trifluoride, methacrylated phosphoric acid ester, trimethoxypropyl methacrylate monomer, ethanol, colorant, water. | Monobond Etch and Prime; Ivoclar Vivadent AG, Schaan, Liechtenstein |

| Clearfil ceramic primer plus | 4F0078 | Universal prosthetic primer | 3-MPS, ethanol, 10-MDP. | Kuraray Noritake, Tokyo, Japan |

| Panavia V5 | 4R0197 | Dual-cure resin cement | Bis-GMA, TEGDMA, hydrophobic aromatic dimethacrylate, hydrophilic aliphaticdimethacrylate, initiators, accelerators, silanated barium glass filler, silanated fluoroaluminosilicate glass filler, colloidal silica, silanated aluminum oxide filler, dl-camphorquinone, pigments. | Kuraray Noritake, Tokyo, Japan |

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Corrected model | 2812.831 a | 15 | 187.522 | 45.664 | 0.000 |

| Intercept | 22,313.814 | 1 | 22,313.814 | 5433.696 | 0.000 |

| CAD/CAM material | 76.393 | 3 | 25.464 | 6.201 | 0.001 |

| Treatment | 2304.170 | 3 | 768.057 | 187.032 | 0.000 |

| CAD/CAM material × treatment | 432.269 | 9 | 48.030 | 11.696 | 0.000 |

| Error | 591.345 | 144 | 4.107 | ||

| Total | 25,717.990 | 160 | |||

| Corrected total | 3404.176 | 159 |

| CAD/CAM Materials | ||||

|---|---|---|---|---|

| LEU | LDC | RNC | PICN | |

| Control | 4.2 ± (1.2) A, b | 5.8 ± (1.5) A, c | 6.4 ± (1.3) A, c | 5.7 ± (2.0) A, c |

| AL | 12.8 ± (1.3) B, a | 12.8 ± (1.6) B, b | 16.7 ± (3.3) A, a | 16.1 ± (2.5) A, a |

| HF | 15.6 ± (1.2) A, a | 16.2 ± (2.2) A, a | 12.0 ± (1.4) B, b | 16.2 ± (1.9) A, a |

| MEP | 13.4 ± (1.4) A, a | 14.9 ± (1.2) A, ab | 8.3 ± (2.9) B, c | 12.2 ± (2.2) A, b |

| Failure Mode | |||||

|---|---|---|---|---|---|

| CAD/CAM Material | Surface Treatment | A | M | CRC | CC |

| LEU | Control | 10 | 0 | 0 | 0 |

| AL | 8 | 1 | 1 | 0 | |

| HF | 3 | 3 | 3 | 1 | |

| MEP | 4 | 3 | 3 | 0 | |

| LDC | Control | 10 | 0 | 0 | 0 |

| AL | 9 | 1 | 0 | 0 | |

| HF | 3 | 5 | 2 | 0 | |

| MEP | 5 | 4 | 1 | 0 | |

| RNC | Control | 10 | 0 | 0 | 0 |

| AL | 4 | 2 | 3 | 1 | |

| HF | 6 | 1 | 3 | 0 | |

| MEP | 6 | 2 | 2 | 0 | |

| PICN | Control | 10 | 0 | 0 | 0 |

| AL | 4 | 4 | 2 | 0 | |

| HF | 4 | 2 | 2 | 2 | |

| MEP | 5 | 2 | 3 | 0 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turunç Oğuzman, R.; Şişmanoğlu, S. Adhesive Performance of Resin Cement to Glass-Ceramic and Polymer-Based Ceramic CAD/CAM Materials after Applying Self-Etching Ceramic Primer or Different Surface Treatments. Materials 2024, 17, 2. https://doi.org/10.3390/ma17010002

Turunç Oğuzman R, Şişmanoğlu S. Adhesive Performance of Resin Cement to Glass-Ceramic and Polymer-Based Ceramic CAD/CAM Materials after Applying Self-Etching Ceramic Primer or Different Surface Treatments. Materials. 2024; 17(1):2. https://doi.org/10.3390/ma17010002

Chicago/Turabian StyleTurunç Oğuzman, Rana, and Soner Şişmanoğlu. 2024. "Adhesive Performance of Resin Cement to Glass-Ceramic and Polymer-Based Ceramic CAD/CAM Materials after Applying Self-Etching Ceramic Primer or Different Surface Treatments" Materials 17, no. 1: 2. https://doi.org/10.3390/ma17010002

APA StyleTurunç Oğuzman, R., & Şişmanoğlu, S. (2024). Adhesive Performance of Resin Cement to Glass-Ceramic and Polymer-Based Ceramic CAD/CAM Materials after Applying Self-Etching Ceramic Primer or Different Surface Treatments. Materials, 17(1), 2. https://doi.org/10.3390/ma17010002