Microstructure and Wear Behavior of Ti-xFe-SiC In Situ Composite Ceramic Coatings on TC4 Substrate from Laser Cladding

Abstract

:1. Introduction

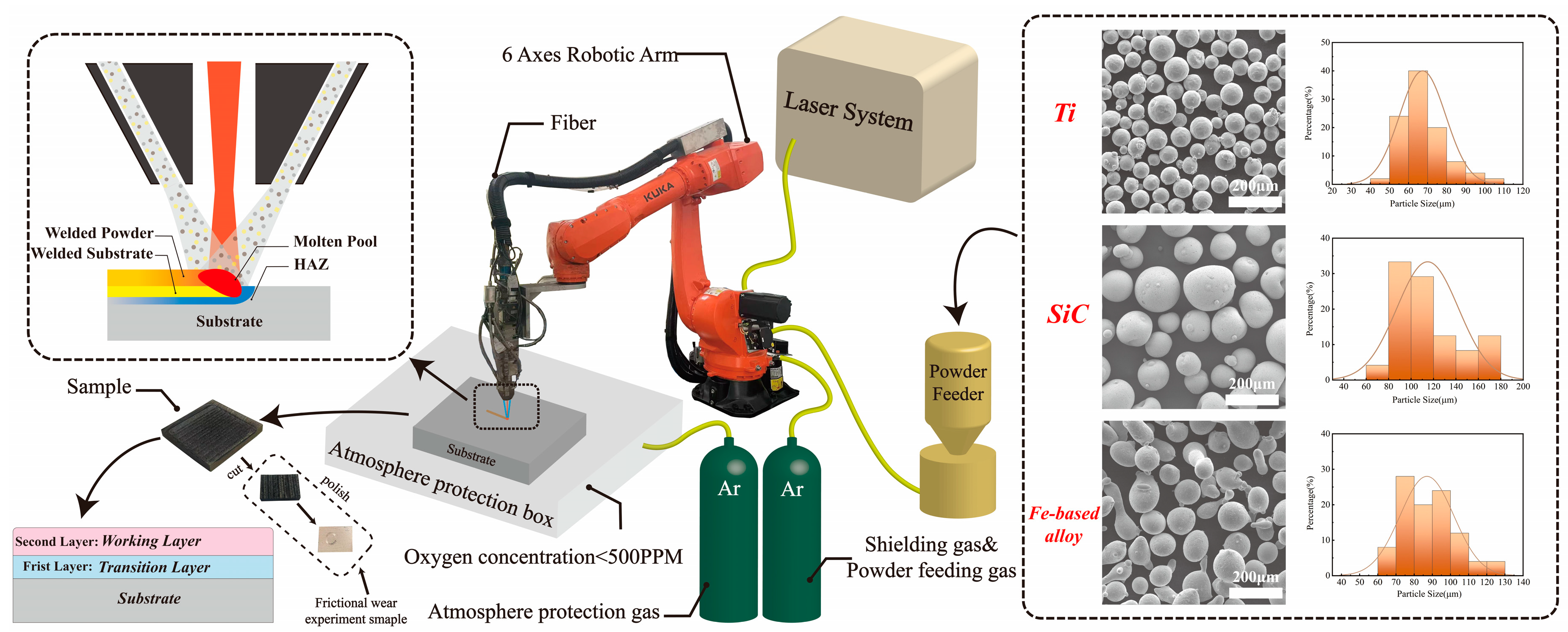

2. Experimental Section

2.1. Raw Materials

2.2. Preparation of the Coating

2.3. Microstructure Characterization

2.4. Frictional Wear Experiment

3. Results

3.1. Microstructure

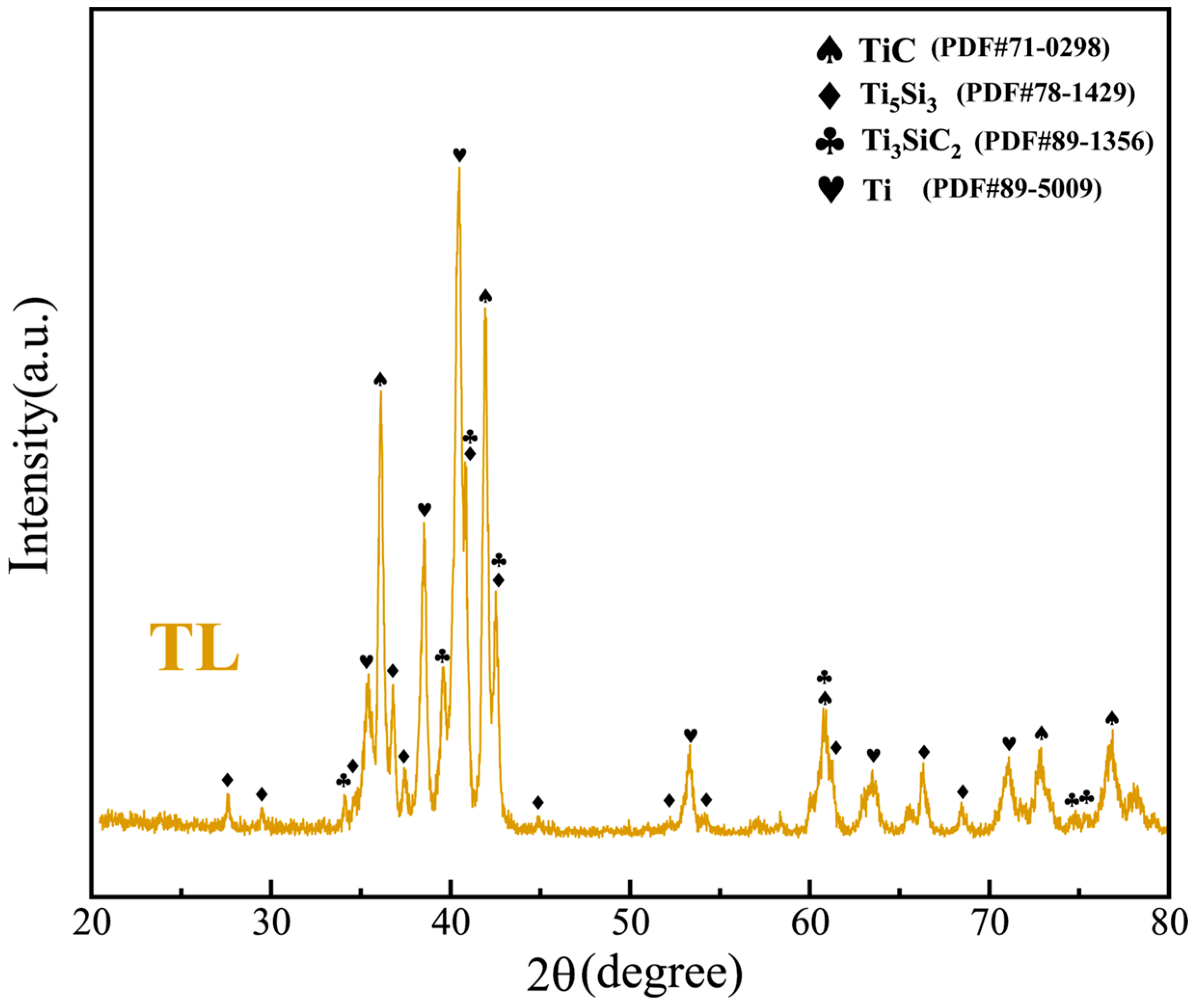

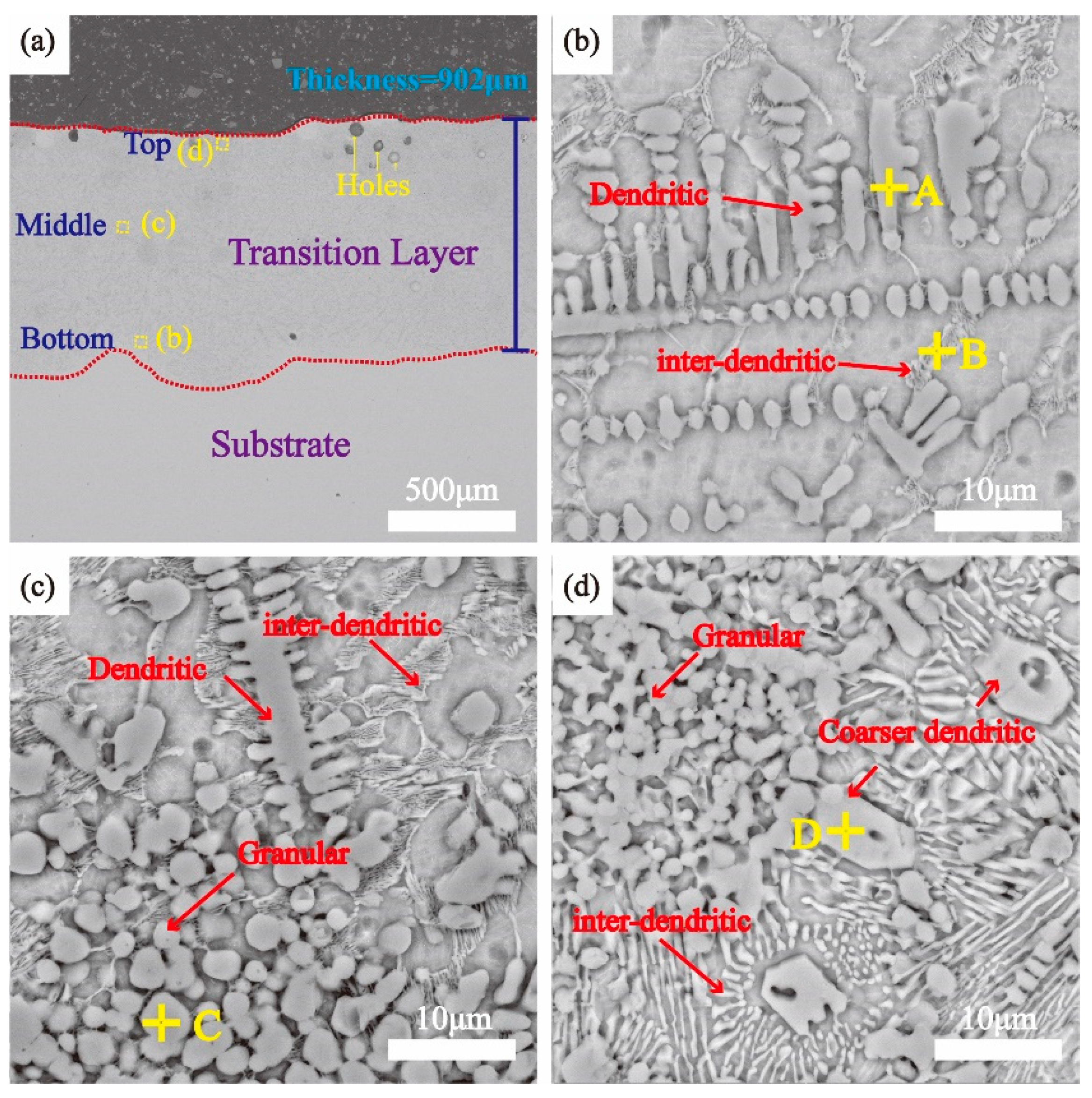

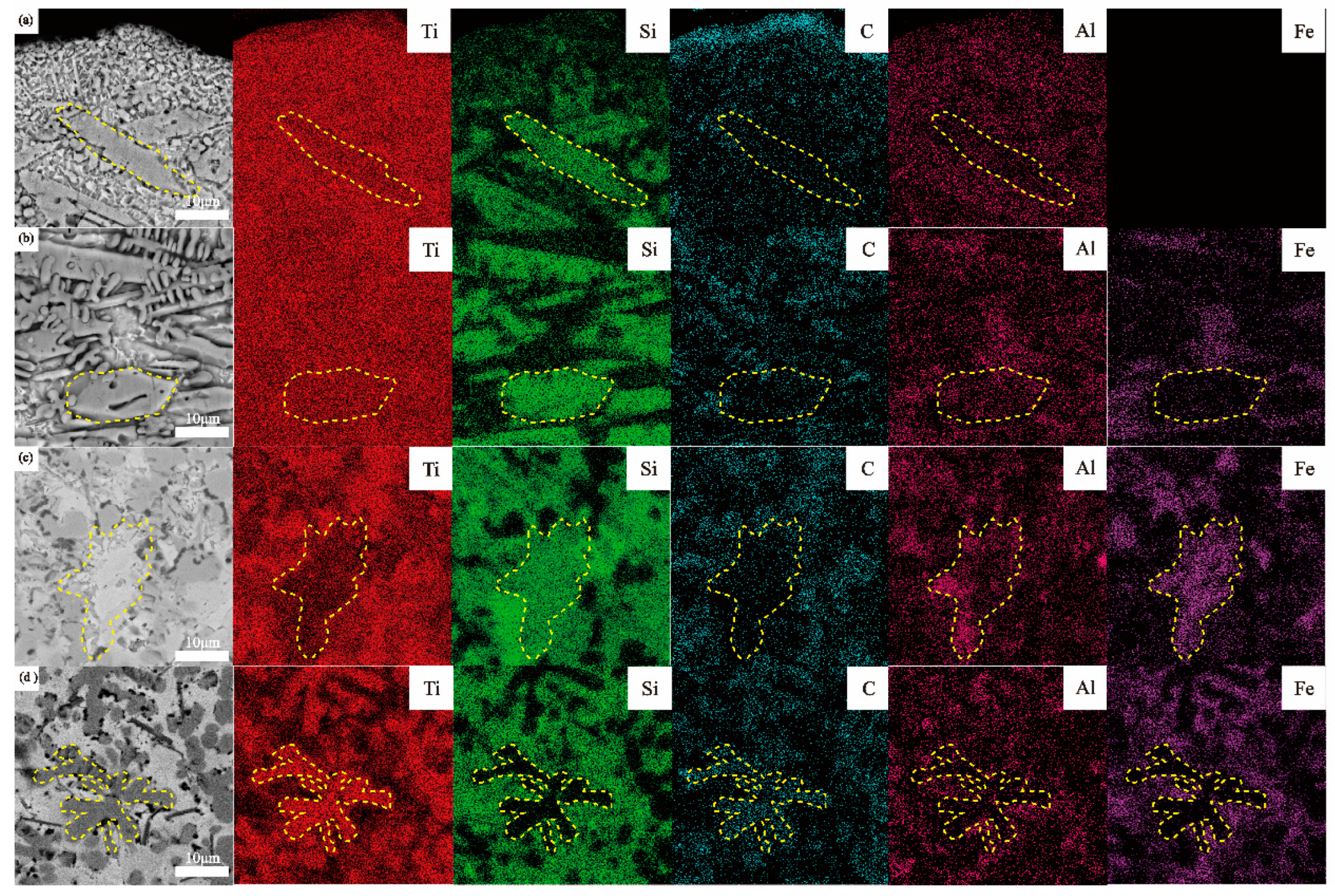

3.1.1. Microstructure of the Transition Layer

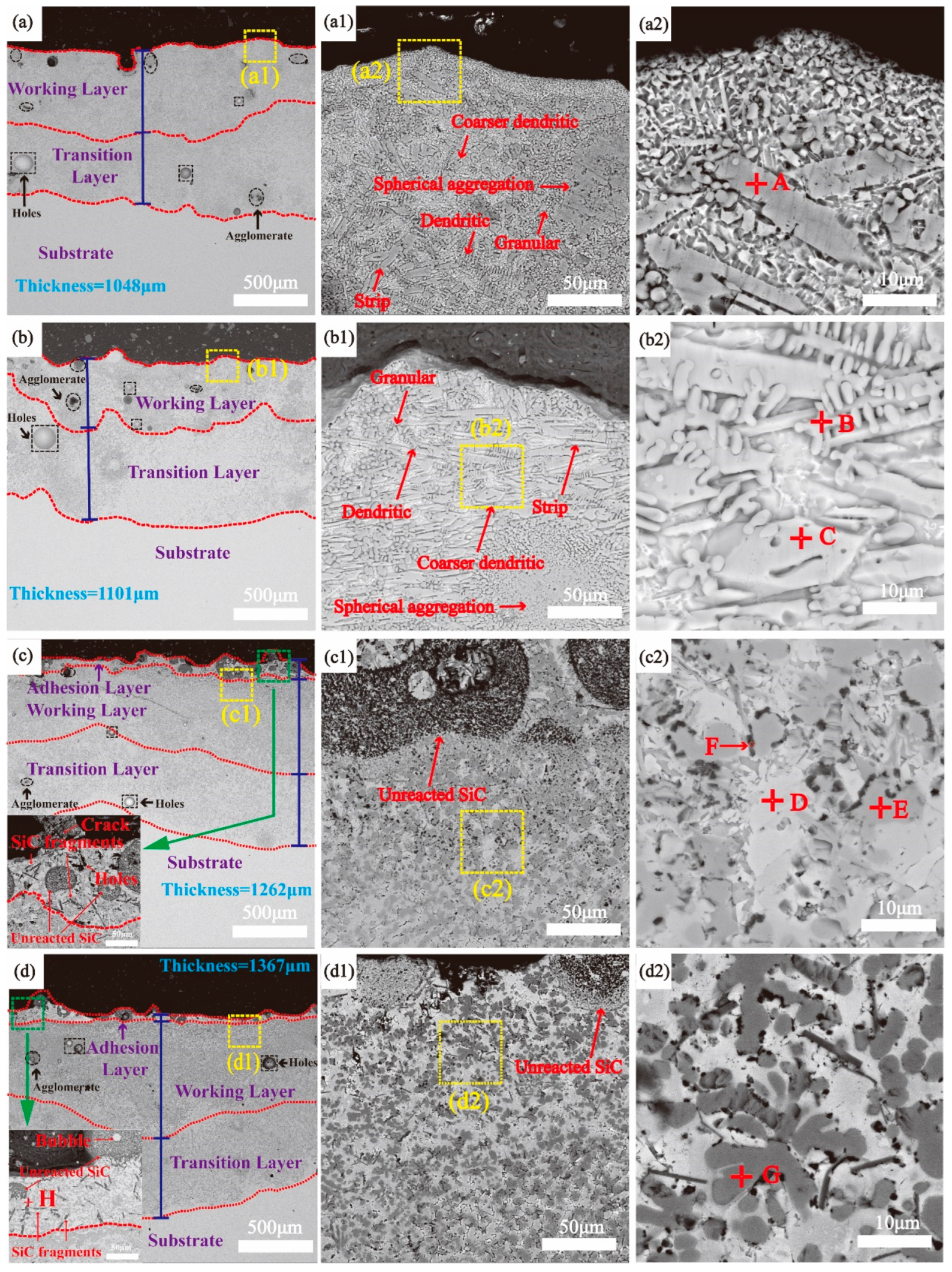

3.1.2. Microstructure of the Working Layer

3.2. Properties

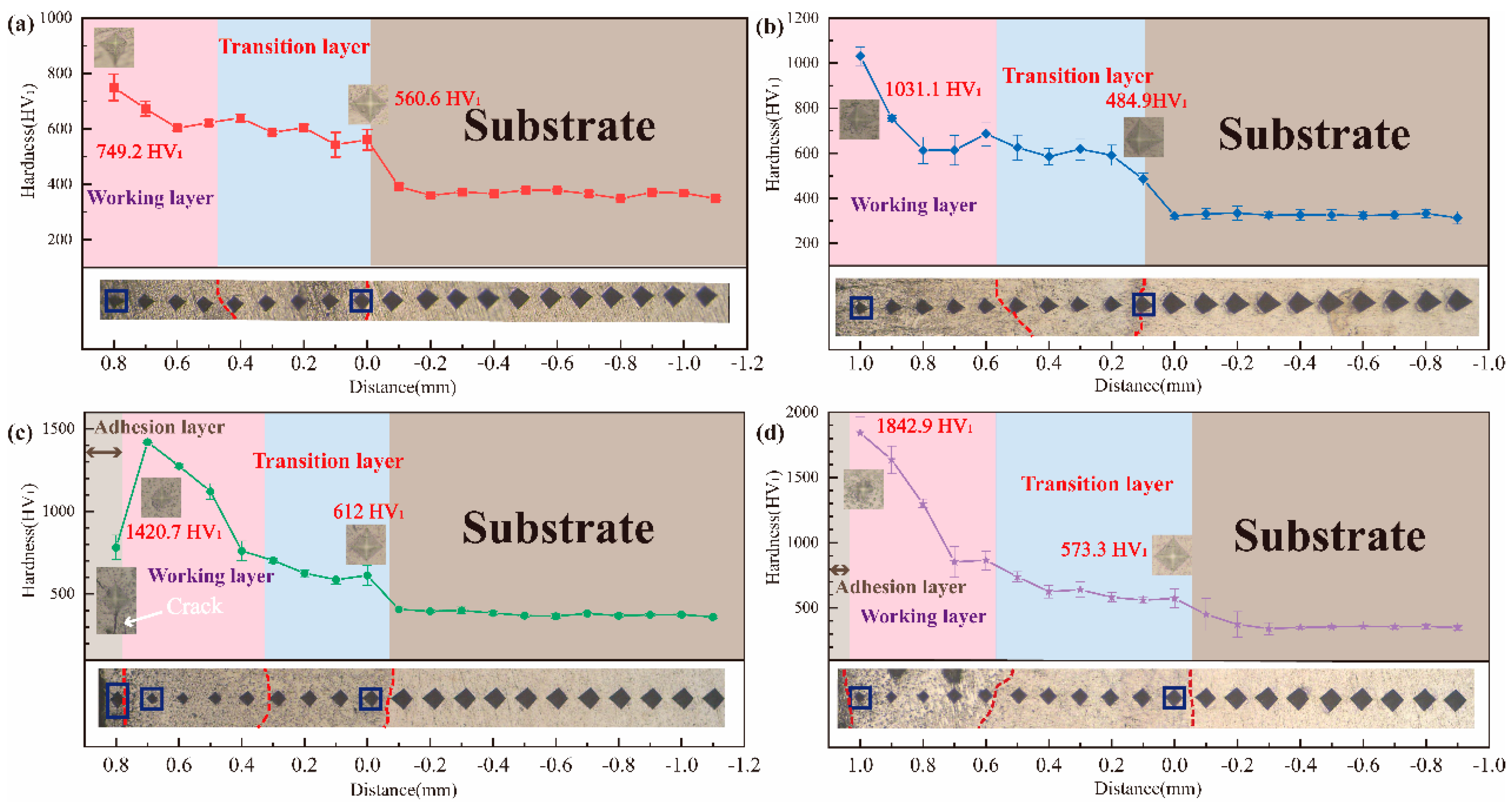

3.2.1. Vickers Hardness

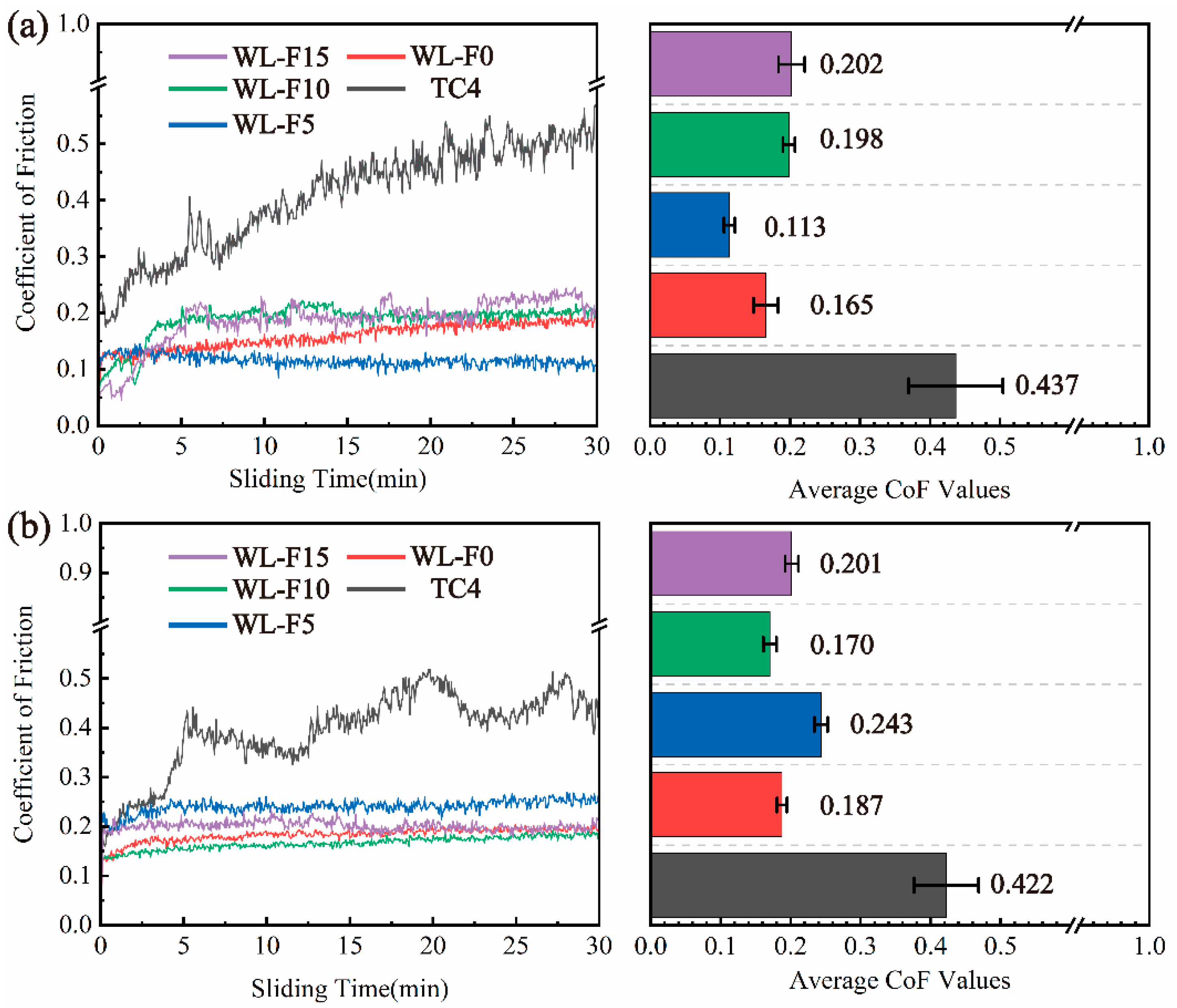

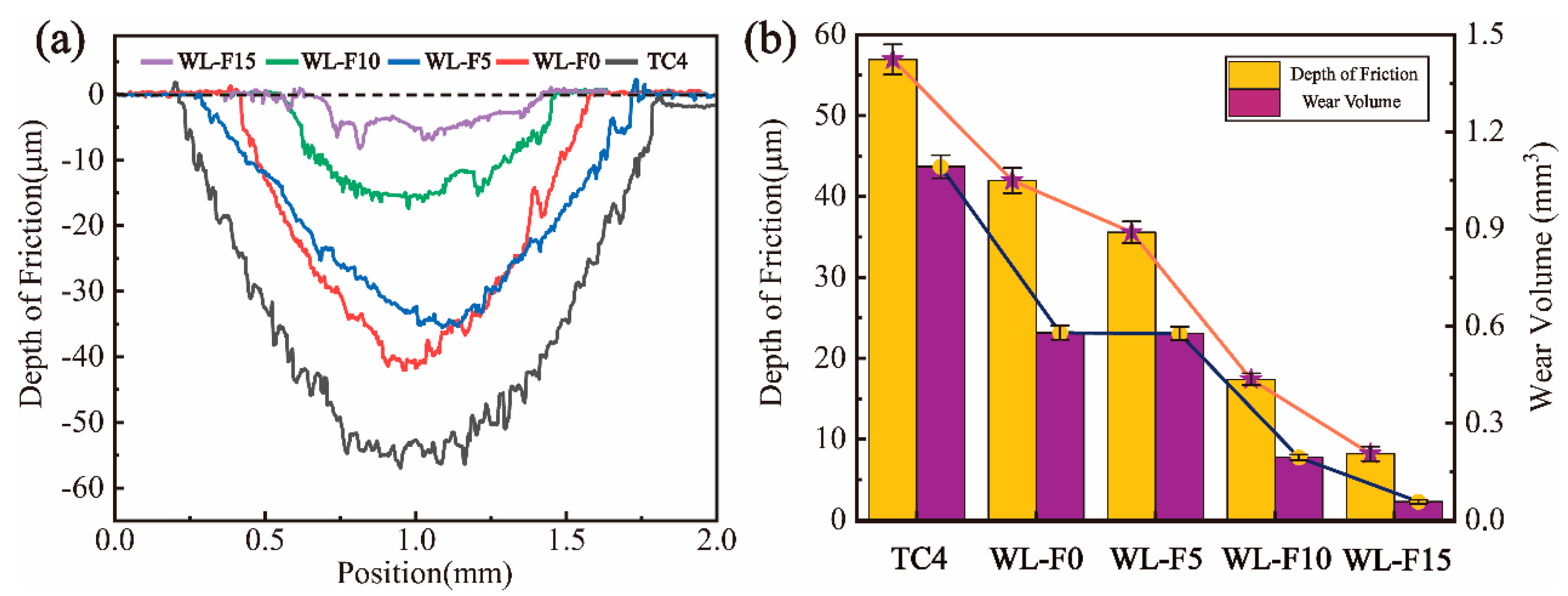

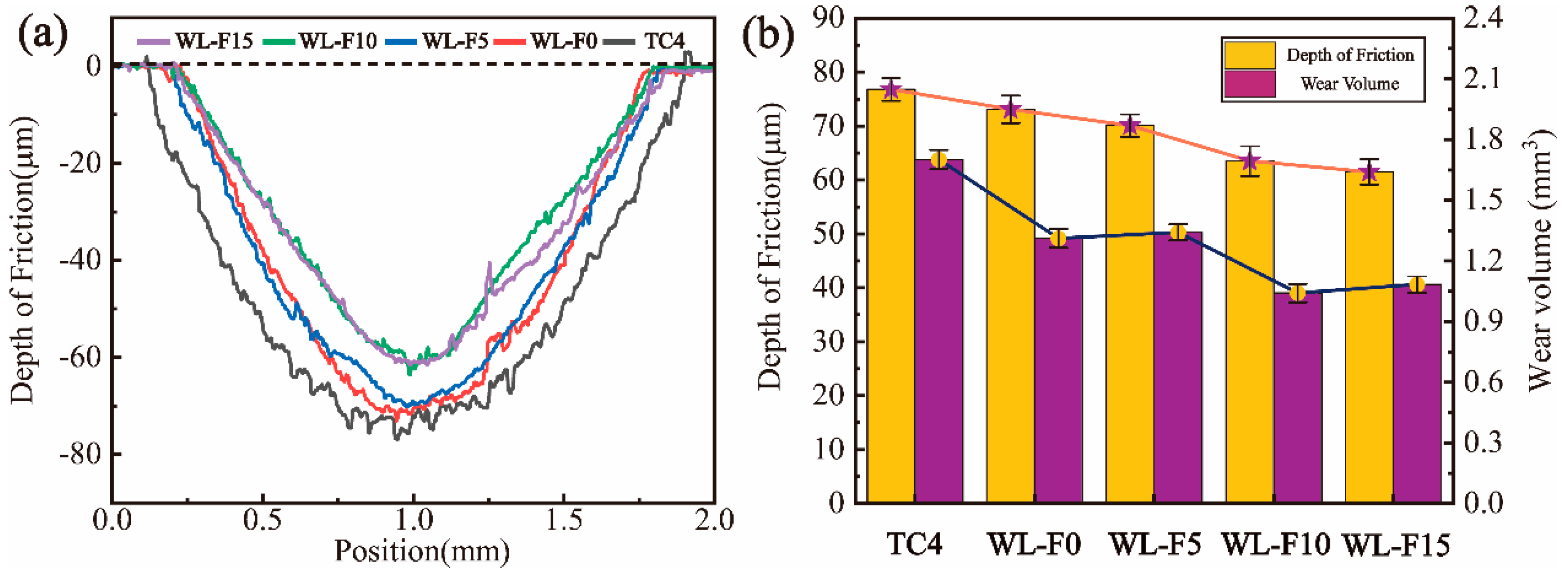

3.2.2. Frictional Wear Property

4. Discussion

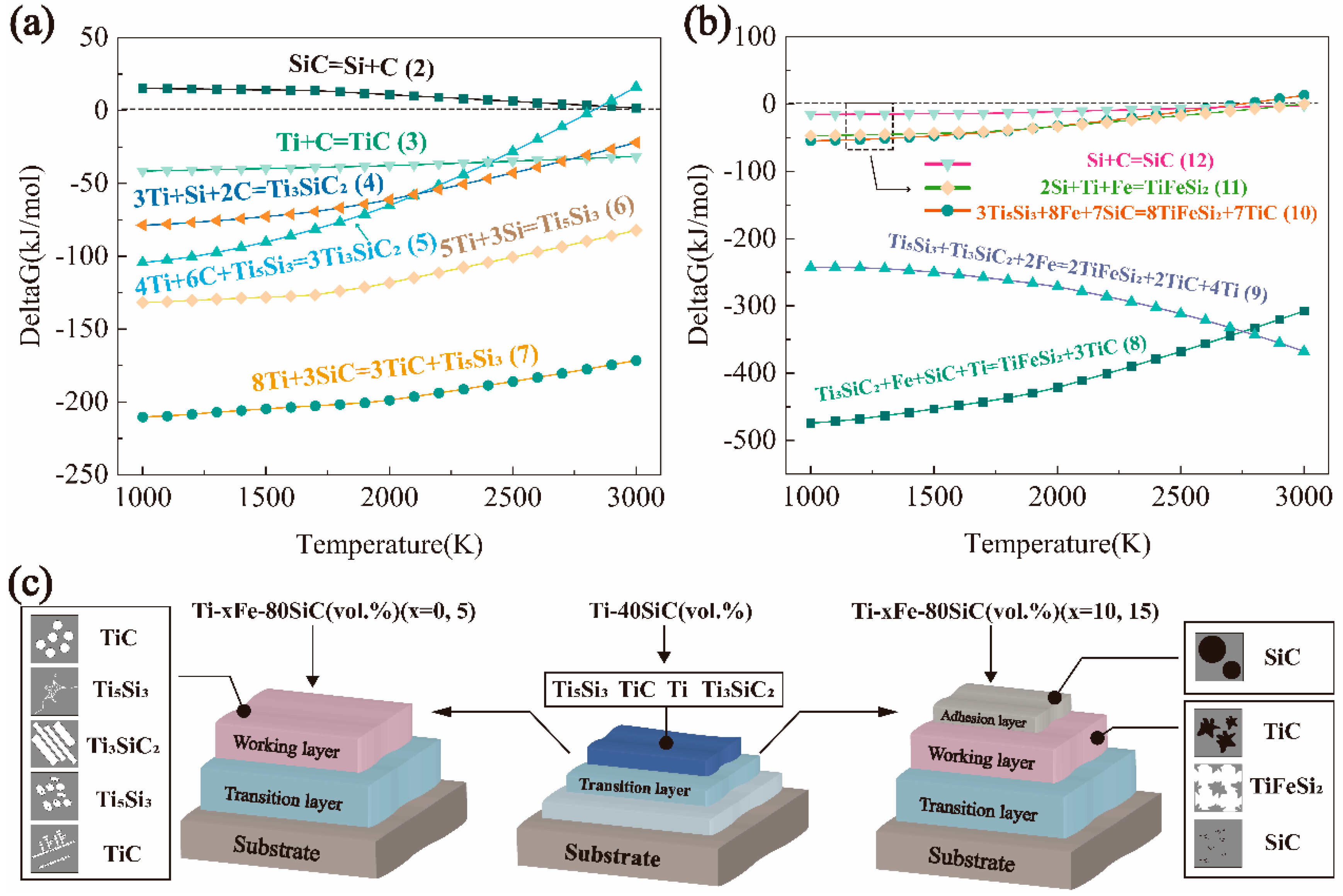

4.1. Mechanism of Phase Formation

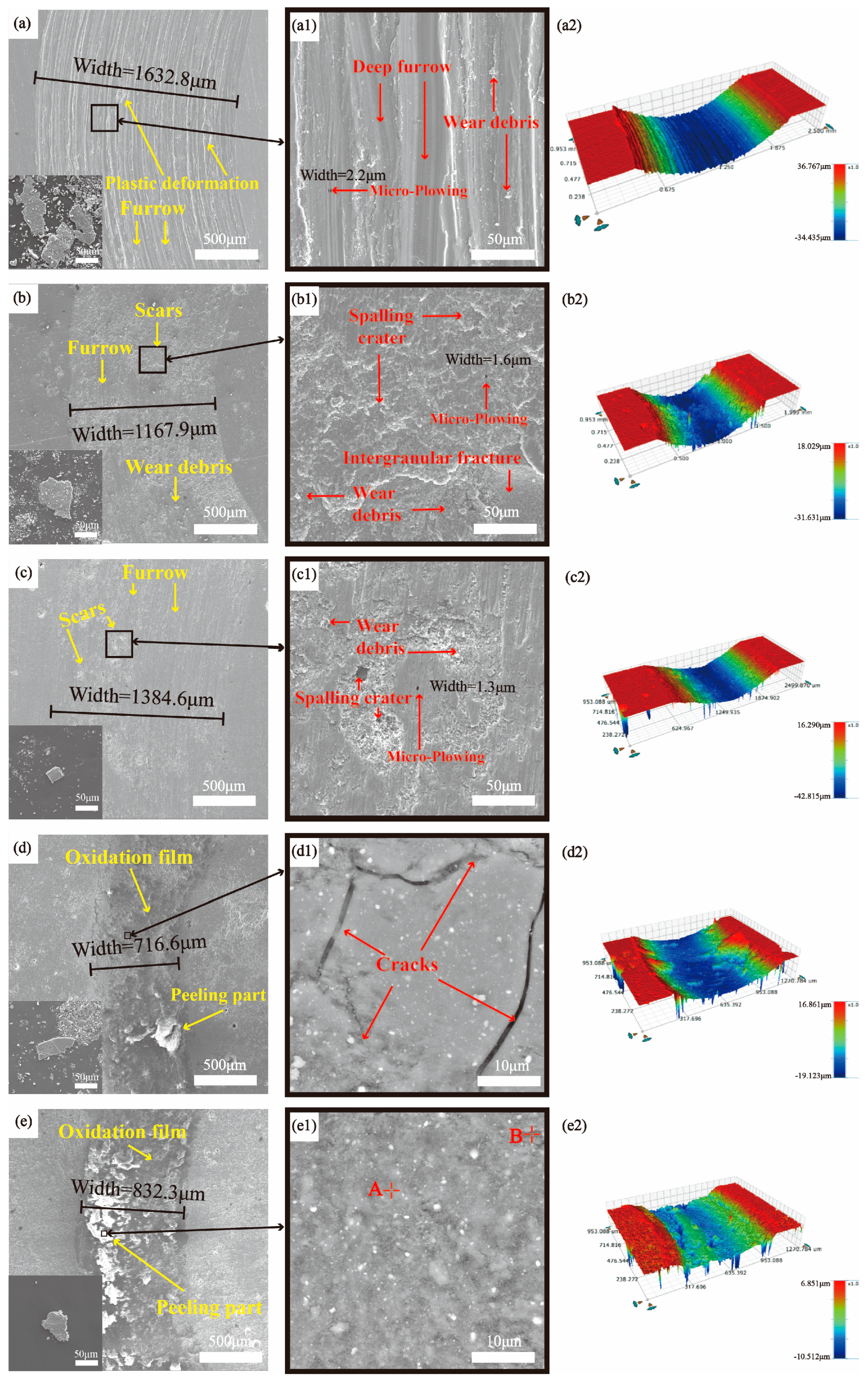

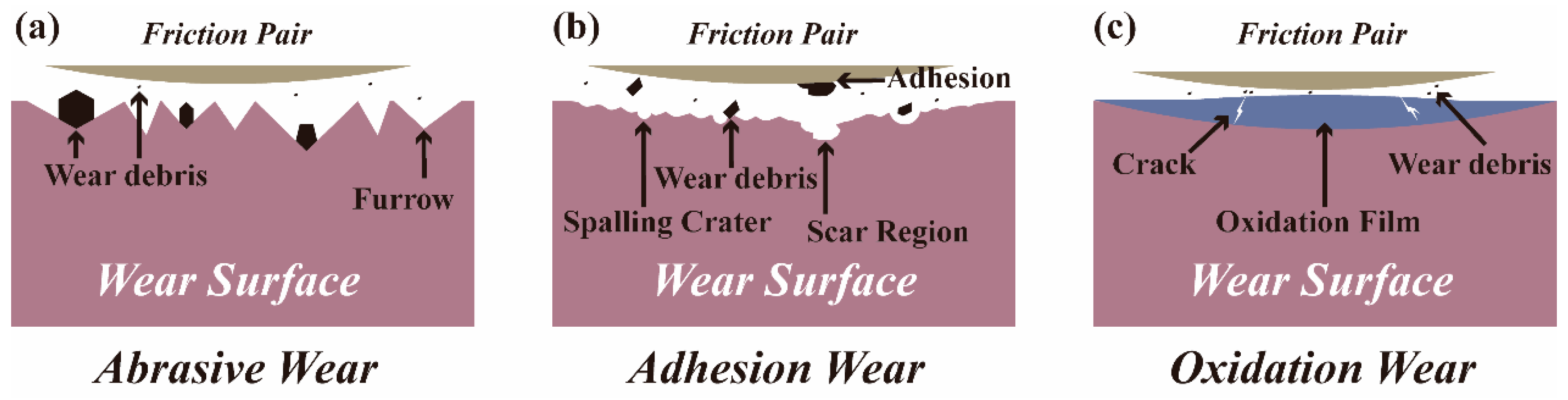

4.2. Wear Mechanism and Wear Transition

5. Conclusions

- The transition layer exhibits good metallurgical bonding with the substrate. It can effectively prevent the direct contact between the working layer and the substrate from causing an excessive dilution rate and ensure that there is a high content of ceramic phase in the working layer.

- With increasing content of Fe, the hardness of the working layer also increases obviously. The WL-F15 coating, exhibiting the most substantial increase in hardness, achieves a maximum hardness of 1842.9 HV1, which is five times higher than that of the substrate.

- Compared to the substrate, all the coatings exhibited a lower coefficient of friction (CoF), depth of friction, and wear volume. It was demonstrated that the coatings have a certain degree of wear-reducing and wear-resistance performances. The WL-F15 coating has the best wear resistance under a 10 N load. Under a load of 10 N, the wear volume and depth of friction of the WL-F15 coating was only 5.2% and 14.4% of that in the substrate. Under a load of 20 N, the WL-F10 coating has the lowest wear volume, and the WL-F15 coating has the lowest depth of friction. Overall, WL-F10 has the best wear resistance under a 20 N load. The experiments showed that the coatings have excellent wear-resistance properties at low loads, while the large gap in wear resistance between high and low loads can be attributed to the wear transition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.-C.; Chen, L.-Y.; Wang, L. Surface Modification of Titanium and Titanium Alloys: Technologies, Developments, and Future Interests. Adv. Eng. Mater. 2020, 22, 1901258. [Google Scholar] [CrossRef]

- Tabie, V.M.; Li, C.; Saifu, W.; Li, J.; Xu, X. Mechanical properties of near alpha titanium alloys for high-temperature applications—A review. AEAT 2020, 92, 521–540. [Google Scholar] [CrossRef]

- Gepreel, M.A.-H.; Niinomi, M. Biocompatibility of Ti-alloys for long-term implantation. J. Mech. Behav. Biomed. Mater. 2013, 20, 407–415. [Google Scholar] [CrossRef] [PubMed]

- Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. The present and future of additive manufacturing in the aerospace sector: A review of important aspects. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 2132–2147. [Google Scholar] [CrossRef]

- Attar, H.; Bönisch, M.; Calin, M.; Zhang, L.-C.; Scudino, S.; Eckert, J. Selective laser melting of in situ titanium–titanium boride composites: Processing, microstructure and mechanical properties. Acta Mater. 2014, 76, 13–22. [Google Scholar] [CrossRef]

- Mohseni, E.; Zalnezhad, E.; Bushroa, A.R. Comparative investigation on the adhesion of hydroxyapatite coating on Ti–6Al–4V implant: A review paper. Int. J. Adhes. Adhes. 2014, 48, 238–257. [Google Scholar] [CrossRef]

- Siddiqui, A.A.; Dubey, A.K. Recent trends in laser cladding and surface alloying. Opt. Laser Technol. 2021, 134, 106619. [Google Scholar] [CrossRef]

- Poza, P.; Garrido-Maneiro, M.Á. Cold-sprayed coatings: Microstructure, mechanical properties, and wear behaviour. Prog. Mater. Sci. 2022, 123, 100839. [Google Scholar] [CrossRef]

- Asri, R.I.M.; Harun, W.S.W.; Samykano, M.; Lah, N.A.C.; Ghani, S.A.C.; Tarlochan, F.; Raza, M.R. Corrosion and surface modification on biocompatible metals: A review. Mater. Sci. Eng. C 2017, 77, 1261–1274. [Google Scholar] [CrossRef]

- Zhu, L.; Xue, P.; Lan, Q.; Meng, G.; Ren, Y.; Yang, Z.; Xu, P.; Liu, Z. Recent research and development status of laser cladding: A review. Opt. Laser Technol. 2021, 138, 106915. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Li, N.; Xiong, Y.; Xiong, H.; Shi, G.; Blackburn, J.; Liu, W.; Qin, R. Microstructure, formation mechanism and property characterization of Ti + SiC laser cladded coatings on Ti6Al4V alloy. Mater. Charact. 2019, 148, 43–51. [Google Scholar] [CrossRef]

- Yan, H.; Liu, K.; Zhang, P.; Zhao, J.; Qin, Y.; Lu, Q.; Yu, Z. Fabrication and tribological behaviors of Ti3SiC2/Ti5Si3/TiC/Ni-based composite coatings by laser cladding for self-lubricating applications. Opt. Laser Technol. 2020, 126, 106077. [Google Scholar] [CrossRef]

- Farotade, G.A.; Popoola, A.P.I.; Pityana, S.L. Influence of ZrB2 addition on microstructural development and microhardness of Ti-SiC clad coatings on Ti6Al4V substrate. Surf. Rev. Lett. 2018, 25, 1950005. [Google Scholar] [CrossRef]

- Du, Y.; Schuster, J.C.; Seifert, H.J.; Aldinger, F. Experimental Investigation and Thermodynamic Calculation of the Titanium–Silicon–Carbon System. J. Am. Ceram. Soc. 2000, 83, 197–203. [Google Scholar] [CrossRef]

- Mthisi, A.; Popoola, A.P.I. Influence of Al2O3 addition on the hardness and in vitro corrosion behavior of laser synthesized Ti-Al2O3 coatings on Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 100, 917–927. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.-C.; Meiners, W.; Wissenbach, K.; Poprawe, R. Selective Laser Melting of in-situ TiC/Ti5Si3 composites with novel reinforcement architecture and elevated performance. Surf. Coat. Technol. 2011, 205, 3285–3292. [Google Scholar] [CrossRef]

- Hamedi, M.J.; Torkamany, M.J.; Sabbaghzadeh, J. Effect of pulsed laser parameters on in-situ TiC synthesis in laser surface treatment. Opt. Lasers Eng. 2011, 49, 557–563. [Google Scholar] [CrossRef]

- Fan, J.; Li, X.; Su, Y.; Chen, R.; Guo, J.; Fu, H. Microstructure evolution of directionally solidified Ti–46Al–0.5W–0.5Si alloy. J. Cryst. Growth 2011, 337, 52–59. [Google Scholar] [CrossRef]

- Alhammad, M.; Esmaeili, S.; Toyserkani, E. Surface modification of Ti–6Al–4V alloy using laser-assisted deposition of a Ti–Si compound. Surf. Coat. Technol. 2008, 203, 1–8. [Google Scholar] [CrossRef]

- Zeng, L.; Liu, L.; Huang, S.; Zhang, L. Experimental investigation of phase equilibria in the Ti-Fe-Cr ternary system. Calphad 2017, 58, 58–69. [Google Scholar] [CrossRef]

- Bellen, P.; Kumar, K.C.H.; Wollants, P. Thermodynamic Assessment of the Ni-Ti Phase Diagram. Int. J. Mater. Res. 1996, 87, 972–978. [Google Scholar] [CrossRef]

- Yang, H.-Y.; Wang, Z.; Chen, L.-Y.; Shu, S.-L.; Qiu, F.; Zhang, L.-C. Interface formation and bonding control in high-volume-fraction (TiC+TiB2)/Al composites and their roles in enhancing properties. Compos. Part B Eng. 2021, 209, 108605. [Google Scholar] [CrossRef]

- Tobar, M.J.; Álvarez, C.; Amado, J.M.; Rodríguez, G.; Yáñez, A. Morphology and characterization of laser clad composite NiCrBSi–WC coatings on stainless steel. Surf. Coat. Technol. 2006, 200, 6313–6317. [Google Scholar] [CrossRef]

- Ghosh, N.C.; Harimkar, S.P. Phase analysis and wear behavior of in-situ spark plasma sintered Ti3SiC2. Ceram. Int. 2013, 39, 6777–6786. [Google Scholar] [CrossRef]

- Guan, Q.L.; Wang, H.Y.; Li, S.L.; Zhang, W.N.; Lü, S.J.; Jiang, Q.C. Effect of Fe addition on self-propagating high-temperature synthesis of Ti5Si3 in Fe–Ti–Si system. J. Alloys Compd. 2008, 456, 79–84. [Google Scholar] [CrossRef]

- Emamian, A.; Corbin, S.F.; Khajepour, A. Effect of laser cladding process parameters on clad quality and in-situ formed microstructure of Fe–TiC composite coatings. Surf. Coat. Technol. 2010, 205, 2007–2015. [Google Scholar] [CrossRef]

- Yanan, L.; Ronglu, S.; Wei, N.; Tiangang, Z.; Yiwen, L. Effects of CeO2 on microstructure and properties of TiC/Ti2Ni reinforced Ti-based laser cladding composite coatings. Opt. Lasers Eng. 2019, 120, 84–94. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Q.Y.; Li, X.X.; Cui, X.H.; Wang, S.Q. Severe-to-Mild Wear Transition of Titanium Alloys as a Function of Temperature. Tribol. Lett. 2014, 53, 511–520. [Google Scholar] [CrossRef]

- Sahoo, R.; Jha, B.B.; Sahoo, T.K. Dry Sliding Wear Behaviour of Ti–6Al–4V Alloy Consisting of Bimodal Microstructure. Trans. Indian Inst. Met. 2014, 67, 239–245. [Google Scholar] [CrossRef]

- Zhou, K.-C.; Pei, H.-L.; Xiao, J.-K.; Zhang, L. Micro-scratch behavior of WC particle-reinforced copper matrix composites. Rare Met. 2022, 41, 2337–2342. [Google Scholar] [CrossRef]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Li, J.; Luo, X.; Li, G.J. Effect of Y2O3 on the sliding wear resistance of TiB/TiC-reinforced composite coatings fabricated by laser cladding. Wear 2014, 310, 72–82. [Google Scholar] [CrossRef]

- Tsuchiyama, T.; Fujii, Y.; Terazawa, Y.; Nakashima, K.; Ando, T.; Takaki, S. Factors Inducing Intergranular Fracture in Nickel-free High Nitrogen Austenitic Stainless Steel Produced by Solution Nitriding. ISIJ Int. 2008, 48, 861–867. [Google Scholar] [CrossRef]

- Yun, J.Y.; Lee, H.S.; Hur, D.H.; Kang, W.S.; Bae, C.H.; Kim, S.J. Effect of oxidation film on the fretting wear behavior of Alloy 690 steam generator tube mated with SUS 409. Wear 2016, 368–369, 344–349. [Google Scholar] [CrossRef]

- Storozhenko, M.S.; Umanskii, A.P.; Lavrenko, V.A.; Chuprov, S.S.; Kostenko, A.D. Composites based on TiB2–SiC with a nickel–chromium matrix. Powder Met. Met. Ceram. 2012, 50, 719–725. [Google Scholar] [CrossRef]

- Fu, L.; Yang, J.; Bi, Q.; Liu, W. Improved Wear Resistance of Dendrite Composite Eutectic Fe-B Alloy. J. Tribol. 2011, 133, 041602. [Google Scholar] [CrossRef]

- Potekhin, B.A.; Khristolyubov, A.S.; Zhilyakov, A.Y. Development of Composite Bronzes Reinforced by Steel Dendrites. Russ. J. Non. Ferr. Met. 2018, 59, 527–532. [Google Scholar] [CrossRef]

- Jalali, M.; Zarei-Hanzaki, A.; Mosayebi, M.; Abedi, H.R.; Malekan, M.; Kahnooji, M.; Farabi, E.; Kim, S.-H. Unveiling the influence of dendrite characteristics on the slip/twinning activity and the strain hardening capacity of Mg-Sn-Li-Zn cast alloys. J. Magnes. Alloys 2023, 11, 329–347. [Google Scholar] [CrossRef]

- Xue, P.; Meng, Q.; Chen, S.; Liang, L.; Liu, Z.; Chen, R. Tribological property of (TiC-TiB2)pNi ceramics prepared by field-activated and pressure-assisted synthesis. Rare Met. 2011, 30, 599–603. [Google Scholar] [CrossRef]

- Zhou, K.; Xiao, G.; Xu, J.; Huang, Y. Wear evolution of electroplated diamond abrasive belt and corresponding surface integrity of Inconel 718 during grinding. Tribol. Int. 2023, 177, 107972. [Google Scholar] [CrossRef]

- Mishina, H.; Hase, A. Effect of the adhesion force on the equation of adhesive wear and the generation process of wear elements in adhesive wear of metals. Wear 2019, 433, 202936. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Gupta, M.K.; Tomaz, I.; Pimenov, D.Y.; Kuntoğlu, M.; Khanna, N.; Yıldırım, Ç.V.; Krolczyk, G.M. A state-of-the-art review on tool wear and surface integrity characteristics in machining of superalloys. CIRP J. Manuf. Sci. Technol. 2021, 35, 624–658. [Google Scholar] [CrossRef]

- Xiong, F.; Manory, R.R. The effect of test parameters on alumina wear under low contact stress. Wear 1999, 236, 240–245. [Google Scholar] [CrossRef]

- Sharma, S.K.; Kumar, B.V.M.; Kim, Y.-W. Tribological Behavior of Silicon Carbide Ceramics—A Review. J. Korean Ceram. Soc. 2016, 53, 581–596. [Google Scholar] [CrossRef]

- Kim, J.-H.; Choi, S.-G.; Kim, S.-S. A Fracture Mechanics Approach to Wear Mechanism of Ceramics Under Non-conformal Rolling Friction. Int. J. Precis. Eng. Manuf. 2019, 20, 983–991. [Google Scholar] [CrossRef]

- Lou, M.; Chen, X.; Xu, K.; Deng, Z.; Chen, L.; Lv, J.; Chang, K.; Wang, L. Temperature-induced wear transition in ceramic-metal composites. Acta Mater. 2021, 205, 116545. [Google Scholar] [CrossRef]

- Bosman, R.; Schipper, D.J. On the transition from mild to severe wear of lubricated, concentrated contacts: The IRG (OECD) transition diagram. Wear 2010, 269, 581–589. [Google Scholar] [CrossRef]

| Coatings | Compositions | Content (vol.%) | ||

|---|---|---|---|---|

| SiC | Ti | Fe-Based Alloy | ||

| TL | Ti-40SiC | 40 | 60 | 0 |

| WL-F0 | Ti-80SiC | 80 | 20 | 0 |

| WL-F5 | Ti-5Fe-80SiC | 80 | 15 | 5 |

| WL-F10 | Ti-10Fe-80SiC | 80 | 10 | 10 |

| WL-F15 | Ti-15Fe-80SiC | 80 | 5 | 15 |

| Point | Element | Possible Phase | ||||

|---|---|---|---|---|---|---|

| Ti | Si | C | Al | Others | ||

| A | 49.57 | 1.05 | 48 | 0.84 | 0.54 | TiC |

| B | 67.65 | 11.53 | 13.49 | 5.17 | 2.16 | Ti5Si3 |

| C | 49.73 | 0.18 | 48.92 | 0.14 | 1.03 | TiC |

| D | 58.69 | 30.25 | 7.32 | 3.2 | 0.54 | Ti5Si3 |

| Point | Elements | Possible Phase | |||||

|---|---|---|---|---|---|---|---|

| Ti | Si | C | Fe | Al | Others | ||

| A | 57.63 | 15.01 | 24.32 | - | 2.38 | 0.66 | Ti3SiC2 |

| B | 47.22 | 0.8 | 50.99 | 0.21 | 0.37 | 0.41 | TiC |

| C | 58.58 | 31.53 | 6.36 | 0.23 | 1.93 | 1.37 | Ti5Si3 |

| D | 18.6 | 35.4 | 26.75 | 14.1 | 1.16 | 3.99 | TiFeSi2 |

| E | 38.83 | 2.09 | 57.48 | 0.15 | 0.31 | 1.14 | TiC |

| F | 12.94 | 25.36 | 53.47 | 2.22 | 4.9 | 1.11 | SiC |

| G | 42.4 | 0.34 | 55.55 | 0.18 | 0.09 | 1.44 | TiC |

| H | 1.78 | 43.4 | 53.86 | 0.24 | 0.44 | 0.28 | SiC |

| Point | Element | Possible Phase | |||||

|---|---|---|---|---|---|---|---|

| Ti | Si | O | C | Al | Others | ||

| A | 10.37 | 20.1 | 55.51 | 10.31 | 1.62 | 2.09 | SiO2 + TiO2 |

| B | 12.33 | 19.9 | 48.26 | 16 | 1.55 | 1.96 | SiO2 + TiO2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Lyu, P.; Fang, S.; Li, S.; Tu, X.; Ren, P.; Liu, D.; Chen, L.; Xiao, L.; Liu, S. Microstructure and Wear Behavior of Ti-xFe-SiC In Situ Composite Ceramic Coatings on TC4 Substrate from Laser Cladding. Materials 2024, 17, 100. https://doi.org/10.3390/ma17010100

Zhao X, Lyu P, Fang S, Li S, Tu X, Ren P, Liu D, Chen L, Xiao L, Liu S. Microstructure and Wear Behavior of Ti-xFe-SiC In Situ Composite Ceramic Coatings on TC4 Substrate from Laser Cladding. Materials. 2024; 17(1):100. https://doi.org/10.3390/ma17010100

Chicago/Turabian StyleZhao, Xiaojun, Peize Lyu, Shenqin Fang, Shaohao Li, Xiaoxuan Tu, Penghe Ren, Dian Liu, Lyuming Chen, Lairong Xiao, and Sainan Liu. 2024. "Microstructure and Wear Behavior of Ti-xFe-SiC In Situ Composite Ceramic Coatings on TC4 Substrate from Laser Cladding" Materials 17, no. 1: 100. https://doi.org/10.3390/ma17010100

APA StyleZhao, X., Lyu, P., Fang, S., Li, S., Tu, X., Ren, P., Liu, D., Chen, L., Xiao, L., & Liu, S. (2024). Microstructure and Wear Behavior of Ti-xFe-SiC In Situ Composite Ceramic Coatings on TC4 Substrate from Laser Cladding. Materials, 17(1), 100. https://doi.org/10.3390/ma17010100