Experimental Study on Reinforcement of Reef Limestone by Magnetic Anchoring System

Abstract

1. Introduction

2. Materials and Methods

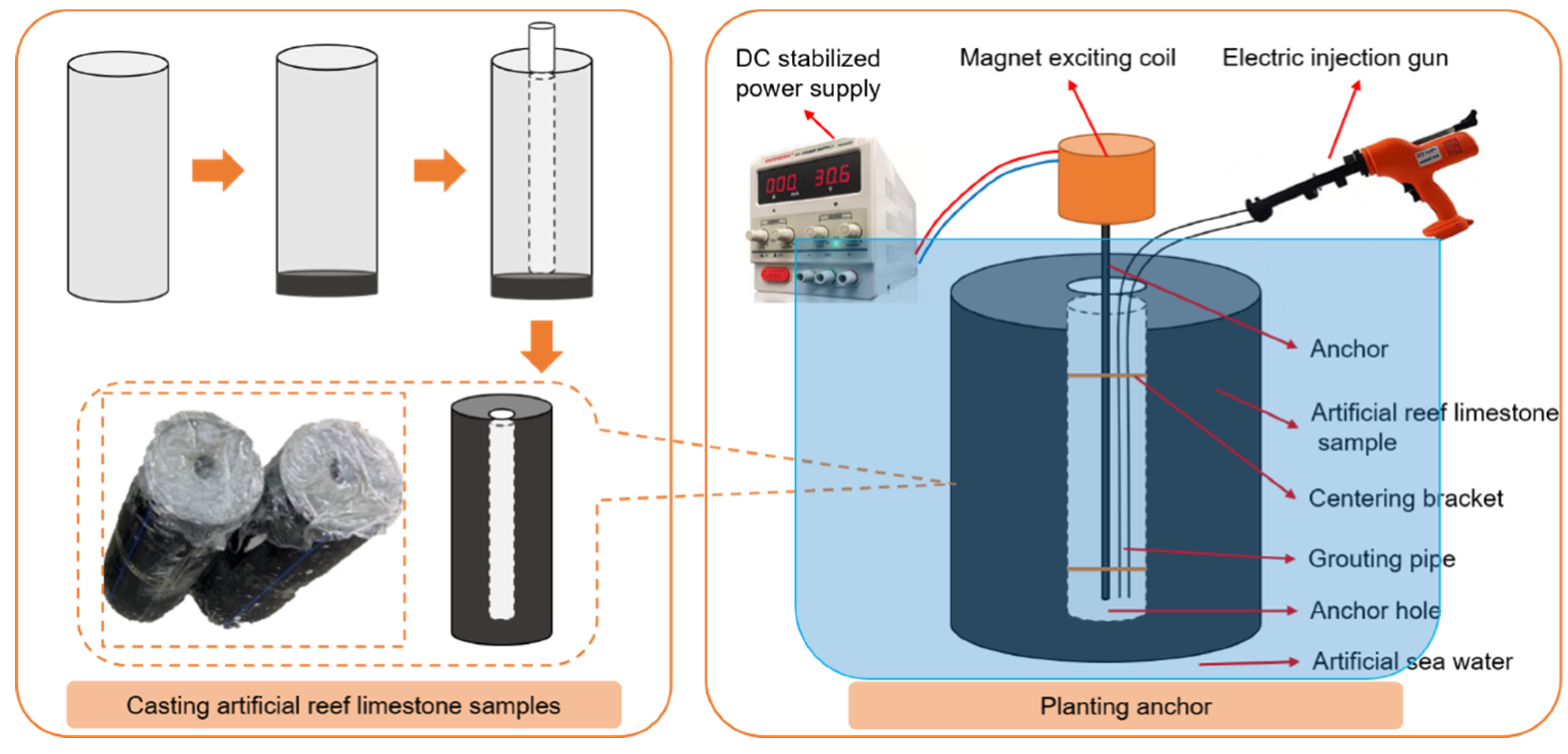

2.1. Preparation of Artificial Reef Limestone

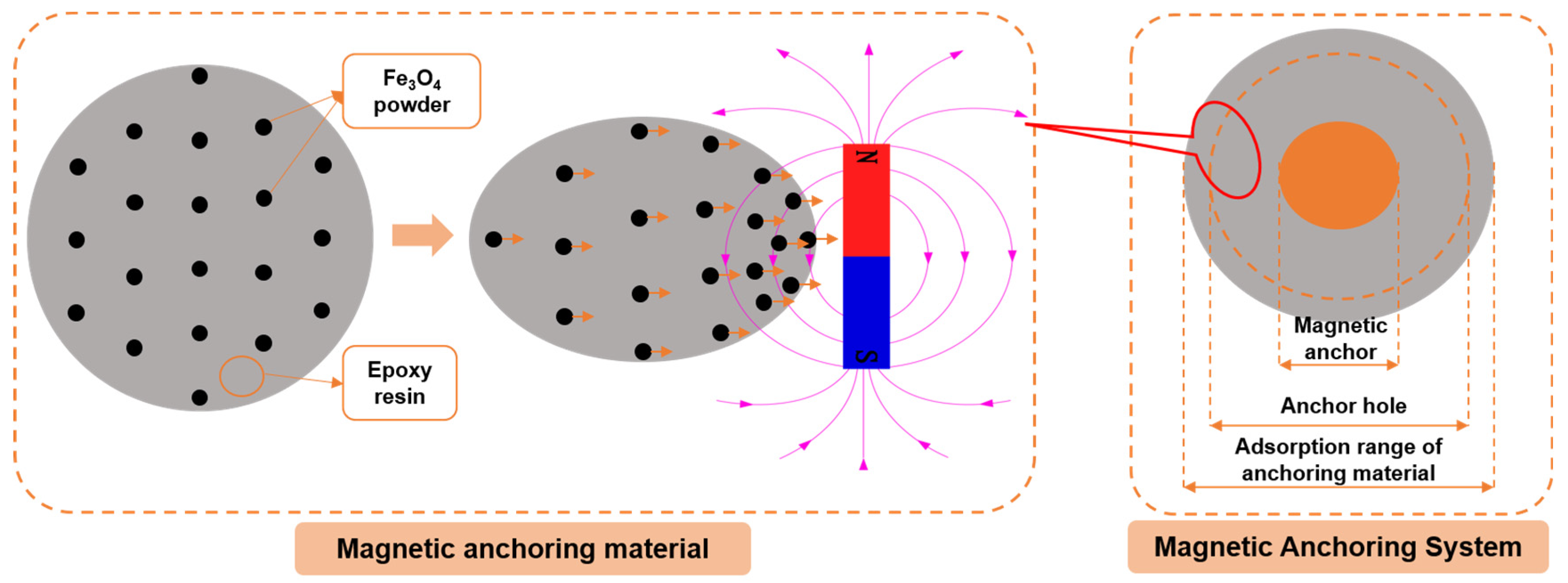

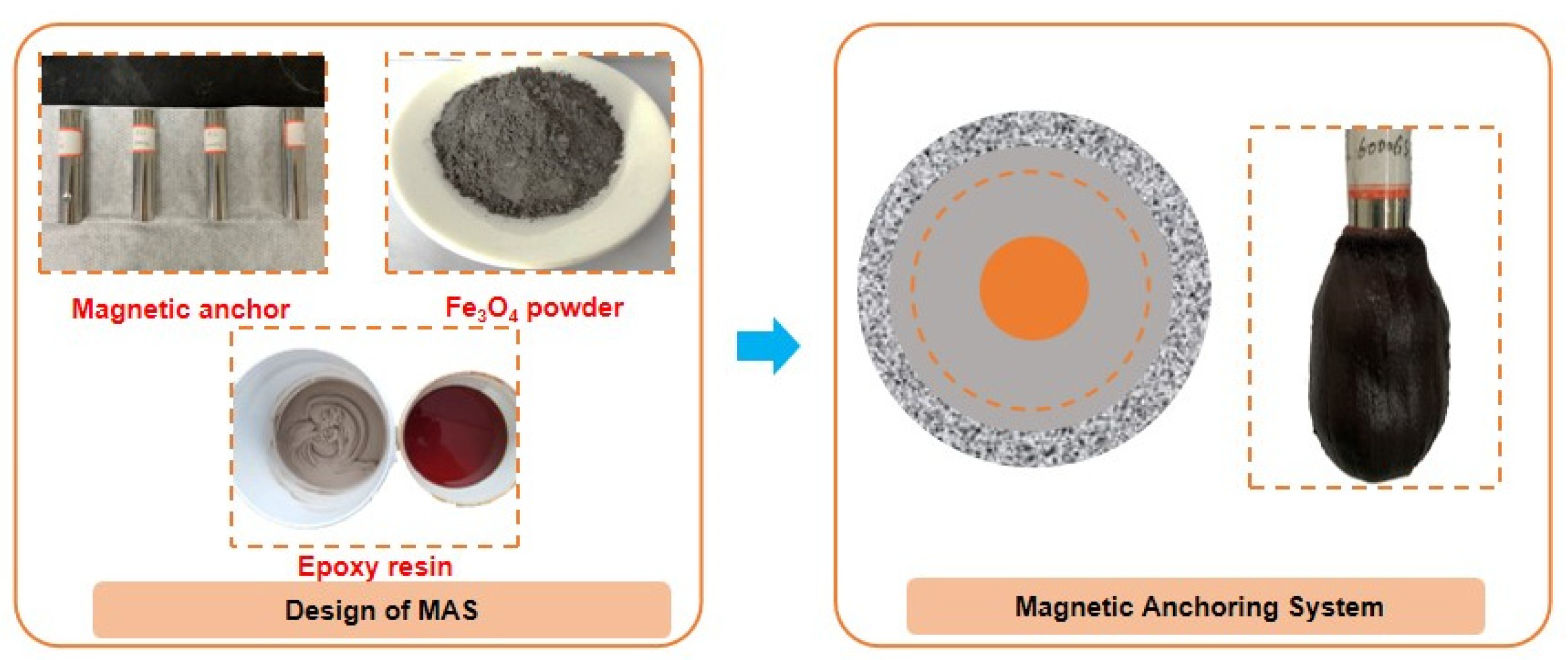

2.2. Design of Epoxy-Magnetic Powder-Magnetic Anchor System

2.3. Test Method

2.3.1. Absorption Range of the Anchoring Material

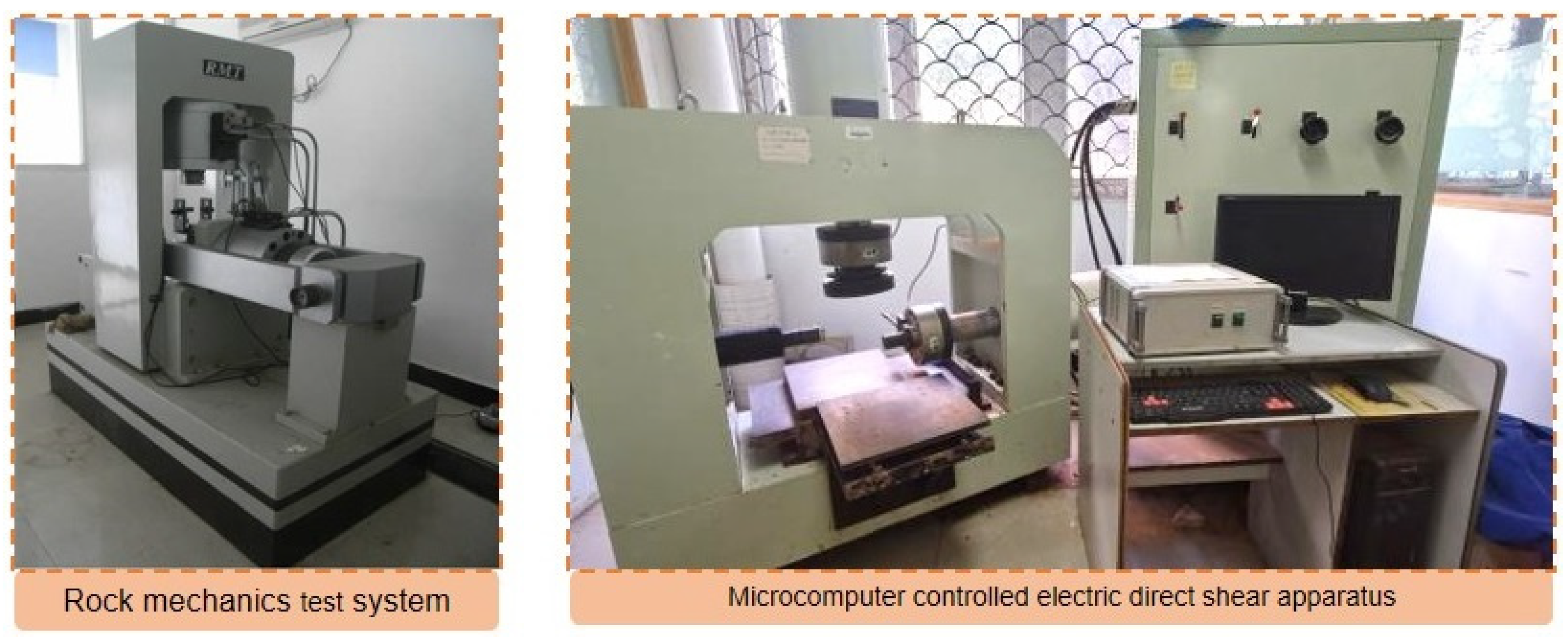

2.3.2. Mechanical Property

- (1)

- Uniaxial compression test

- (2)

- Indirect tensile test

- (3)

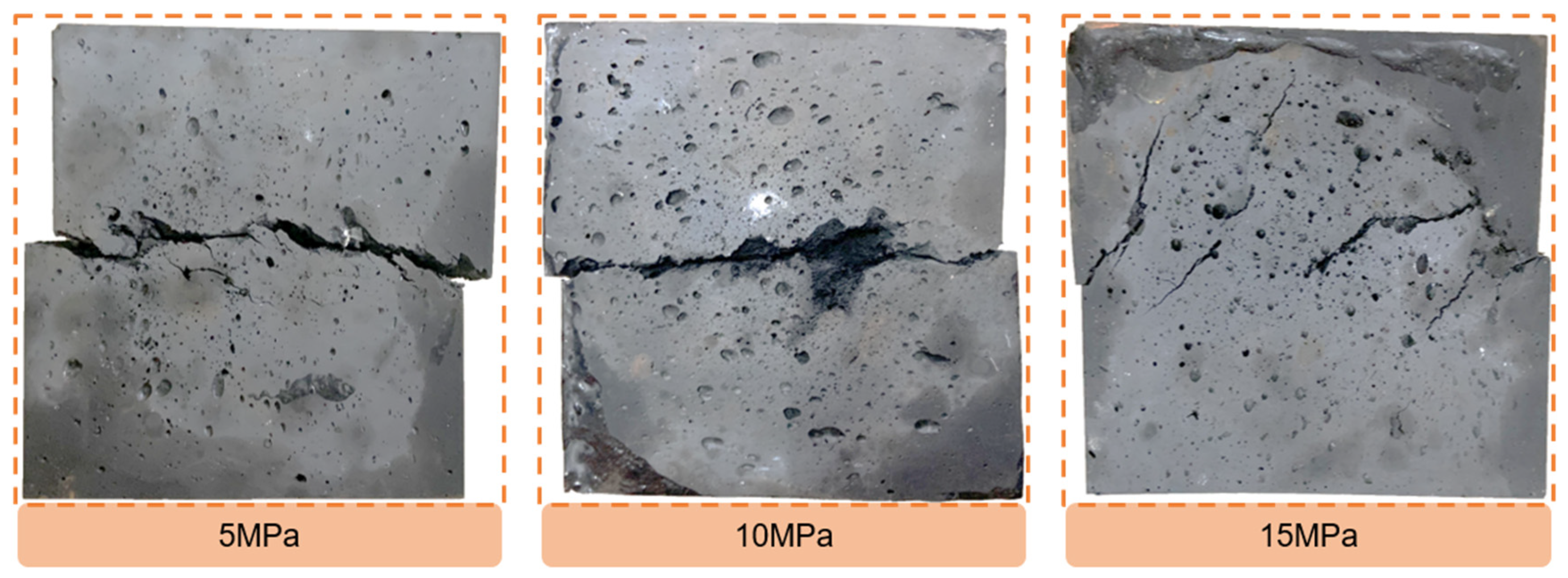

- Direct shear test

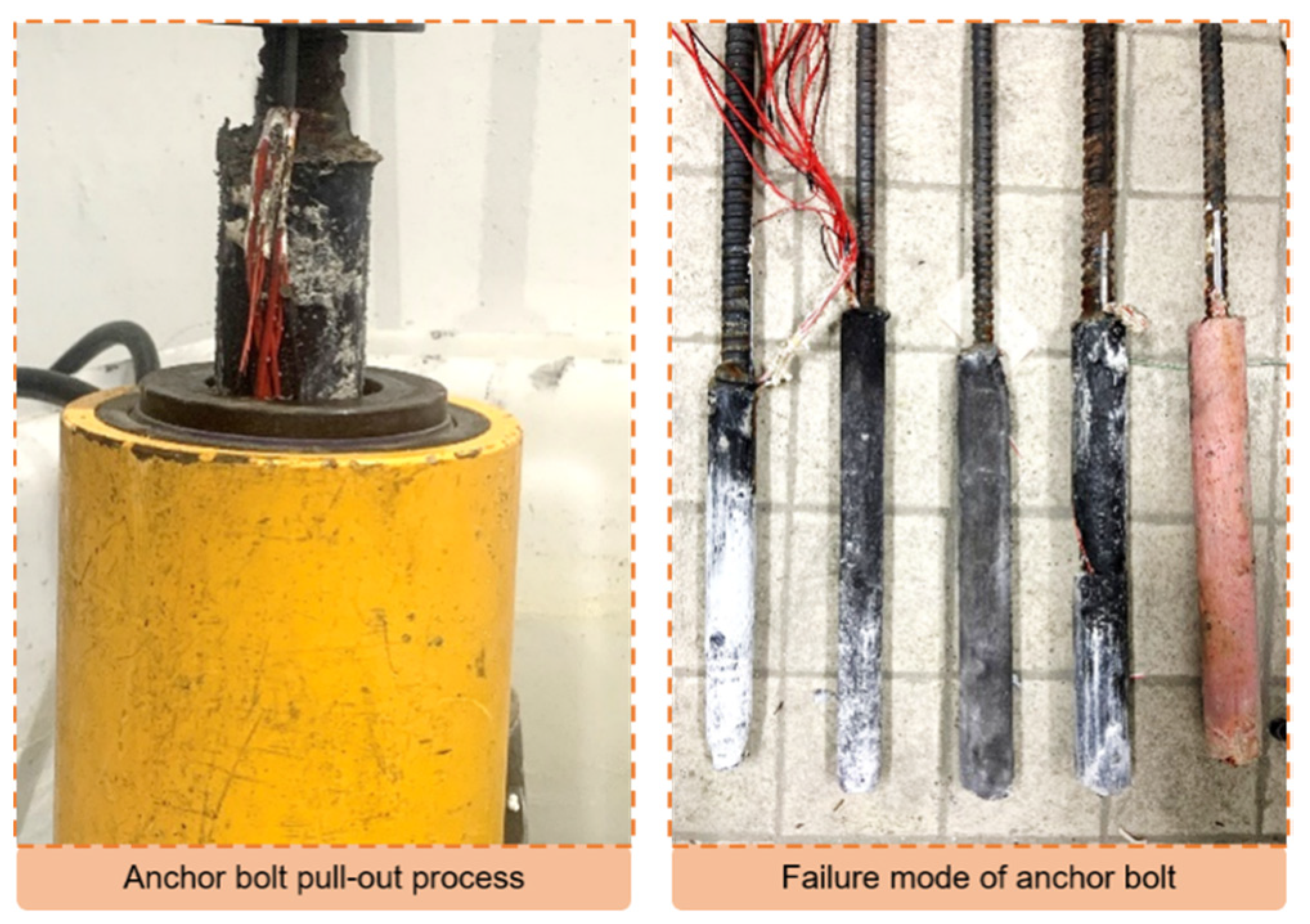

2.3.3. Pull-Out Test

- (1)

- Samples preparation

- (2)

- Test procedure

3. Results and Discussions

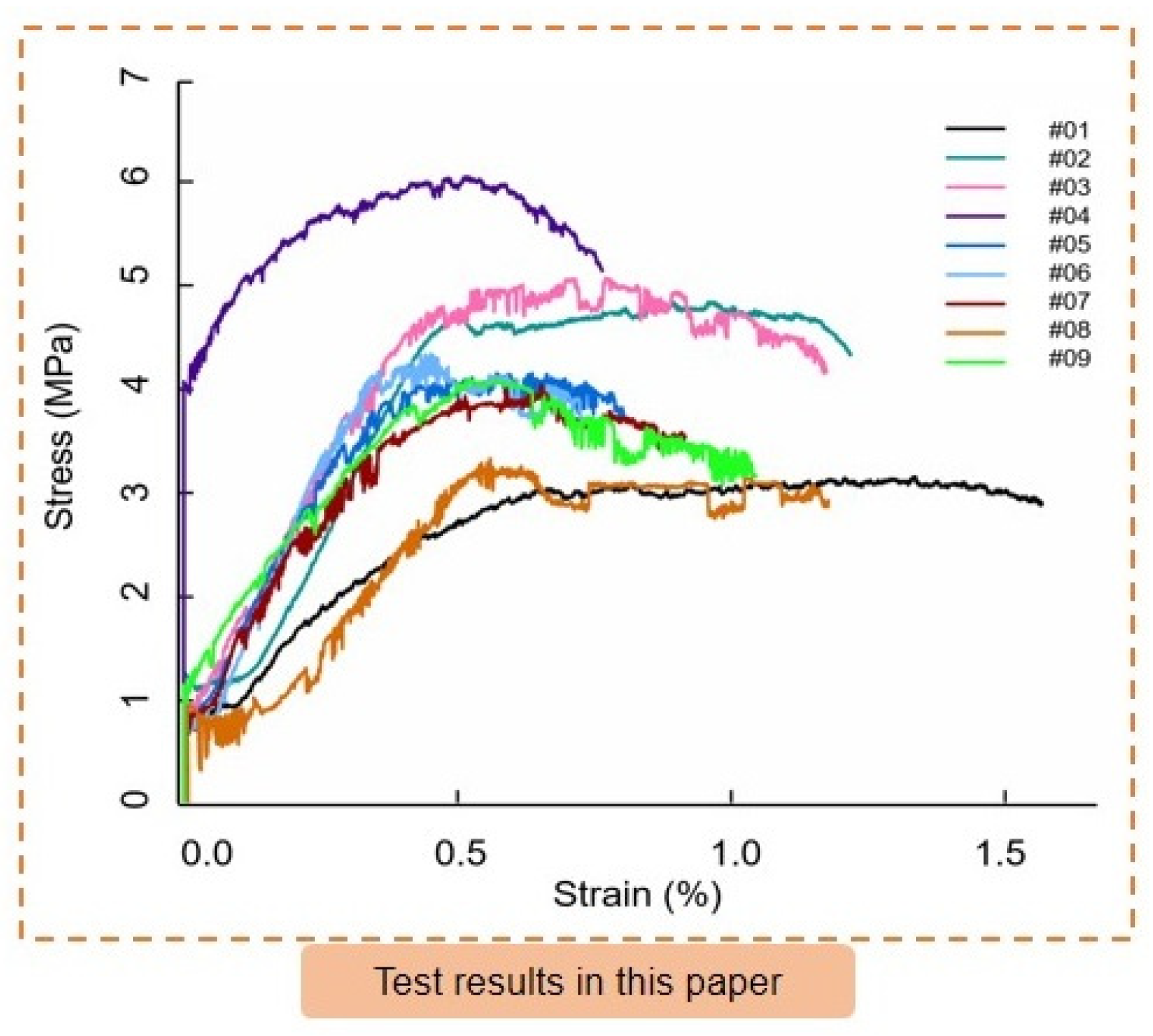

3.1. Mix Design of Artificial Reef Limestone

3.2. Design of MAS

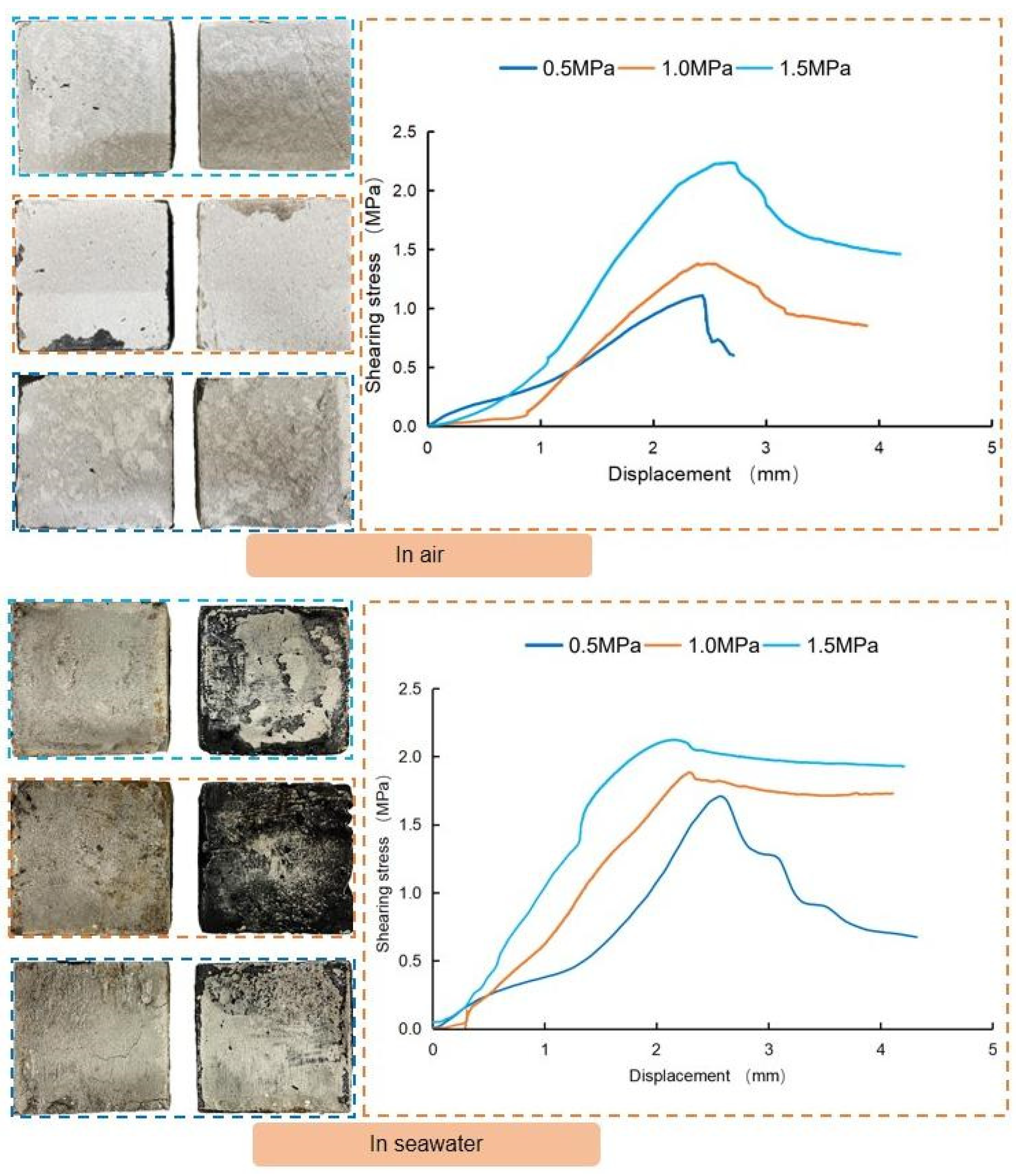

3.3. Bond Performance between Anchoring Material and Reef Limestone

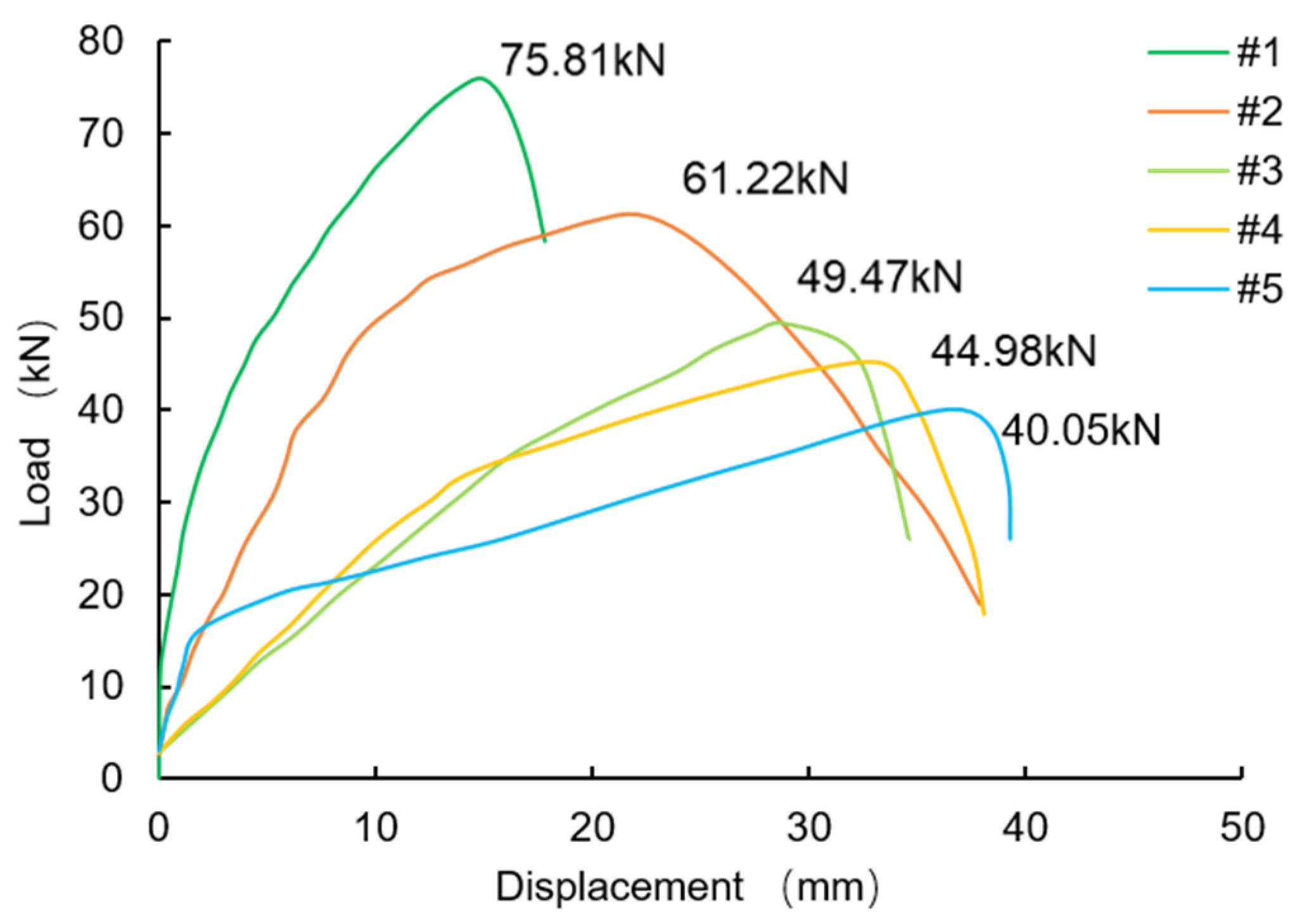

3.4. Results of Pull-Out Test

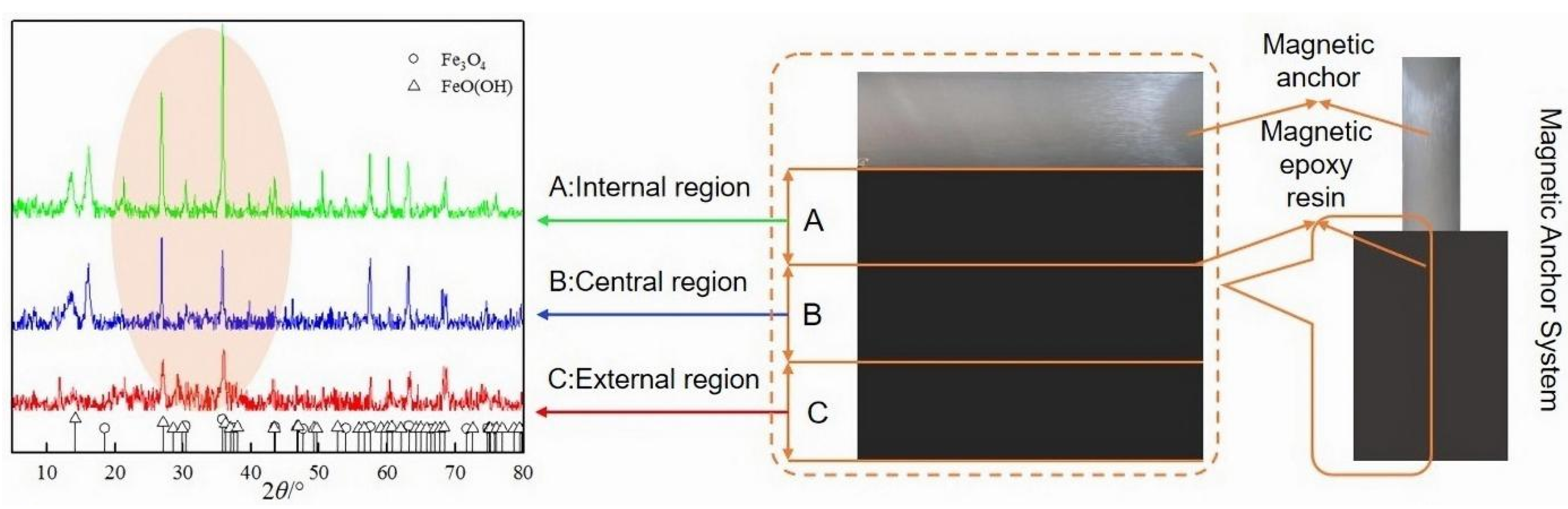

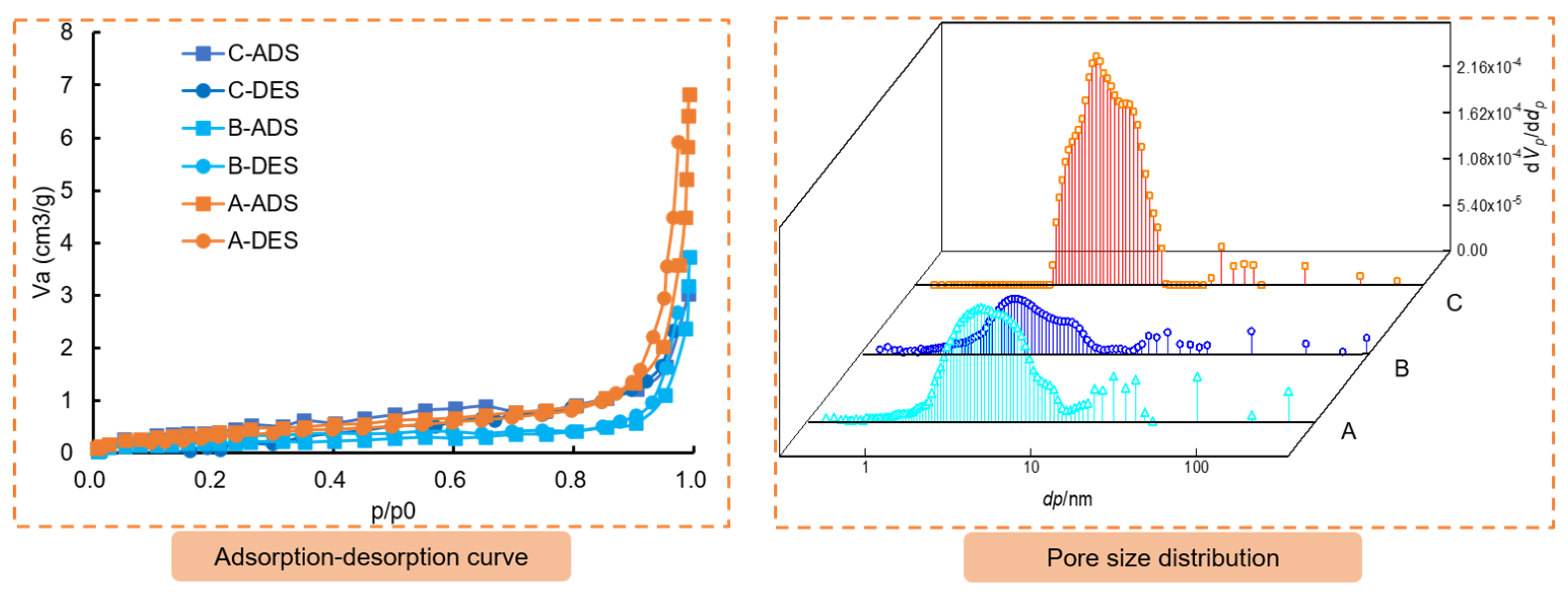

3.5. Micro Analysis

4. Conclusions

- (1)

- The orthogonal test of the relative ratio of the reef limestone was carried out. The concept of a magnetic anchorage system (MAS) in reef limestone was proposed.

- (2)

- In the pull-out test, it was observed that the interface failure between the anchoring material and the rock mass occurred in the reef limestone specimen that was reinforced by the bolt. The peak load of the pull test was 12.3% higher than that of the traditional anchoring method. The feature that the magnetic anchor bolt adsorbing the anchoring material can improve the density of the anchoring material, and squeeze out the free water in the anchor hole, improved the bonding effect of the interface.

- (3)

- Under the attraction of magnetic force, the Fe3O4 powder migrated to the anchor (but not all concentrated near the anchor). Additionally, the mesoporous near the anchor was extruded and separated into microspores, so as to improve the compactness of the anchoring material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, L.J.; Wu, J.W.; Wang, M.Y.; Dong, L.; Wei, H. Dynamic compressive properties of dry and saturated coral rocks at high strain rates. Eng. Geol. 2020, 272, 105615. [Google Scholar] [CrossRef]

- Al-Kahtany, K.M. Facies development of the Middle Miocene reefal limestone in northwest Saudi Arabia. J. Afr. Earth Sci. 2017, 130, 134–140. [Google Scholar] [CrossRef]

- Deshmukh, A.M.; Gulhati, S.K.; Venkatappa Rao, G.; Agarwal, S.L. Influence of geological aspects on behaviour of coral rock. In Proceedings of the 11th International Conference on Soil Mechanics and Foundation Engineering, San Francisco, CA, USA, 12–16 August 1985; pp. 2397–2400. [Google Scholar]

- Zhao, H.T.; Wang, L.R. Review on the study of freshwater lens in the coral reef island. Trop. Geogr. 2015, 35, 120–129. [Google Scholar]

- Liu, H.F.; Zhu, C.Q.; Zheng, K.; Ma, C.; Yi, M. Crack Initiation and Damage Evolution of Micritized Framework Reef Limestone in the South China Sea. Rock Mech. Rock Eng. 2021, 54, 5591–5601. [Google Scholar] [CrossRef]

- Wang, X.; Wang, R.; Meng, Q.; Chen, J. Research on characteristics of coral reef calcareous rock in Nansha Islands. Chin. J. Rock Mech. Eng. 2008, 27, 2221–2226. [Google Scholar]

- Da, B.; Yu, H.; Ma, H.; Tan, Y.; Mi, R.; Dou, X. Experimental investigation of whole stress-strain curves of coral concrete. Constr. Build. Mater. 2016, 122, 81–89. [Google Scholar] [CrossRef]

- Elhakim, A.F. The use of point load test for Dubai weak calcareous sandstones. J. Rock Mech. Geotech. Eng. 2015, 7, 452–457. [Google Scholar] [CrossRef]

- Pappalardo, G. Correlation between P-wave velocity and physical-mechanical properties of intensely jointed dolostones, Pelori-tani mounts, NE Sicily. Rock Mech. Rock Eng. 2015, 48, 1711–1721. [Google Scholar] [CrossRef]

- Li, D.-J.; Shi, C.; Ruan, H.-N.; Li, B.-Y.; Li, W.-Y.; Yao, X.-C. Study on shear behavior of coral reef limestone–concrete interface. Mar. Georesour. Geotechnol. 2021, 40, 438–447. [Google Scholar] [CrossRef]

- Yan, M.; Zhao, Y.; Zhang, N. Creep behavior of epoxy-bonded anchor system. Int. J. Rock Mech. Min. Sci. 2014, 67, 96–103. [Google Scholar]

- Caliskan, O.; Yilmaz, S.; Kaplan, H.; Kıraç, N. Shear strength of epoxy anchors embedded into low strength concrete. Constr. Build. Mater. 2013, 38, 723–730. [Google Scholar] [CrossRef]

- Contrafattoa, L.; Cosenza, R. Behaviour of post-installed adhesive anchors in natural stone. Constr. Build. Mater. 2014, 68, 355–369. [Google Scholar] [CrossRef]

- Upadhyaya, P.; Kumar, S. Pull-out capacity of adhesive anchors: An analytical Solution. Int. J. Adhes. Adhes. 2015, 60, 54–62. [Google Scholar] [CrossRef]

- Boumaza, M.; Khan, R.; Zahrani, S. An experimental investigation of the effects of nanoparticles on the mechanical properties of epoxy coating. Thin Solid Films 2016, 620, 160–164. [Google Scholar] [CrossRef]

- Nayak, R.K.; Dash, A.; Ray, B.C. Effect of Epoxy Modifiers (Al2O3/SiO2/TiO2) on Mechanical Performance of epoxy/glass Fiber Hybrid Composites. Procedia Mater. Sci. 2014, 6, 1359–1364. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A. The role of alumina nanoparticles in epoxy adhesives. J. Nanoparticle Res. 2011, 13, 2429–2441. [Google Scholar] [CrossRef]

- Bagherzadeh, A.; Jamshidi, M.; Monemian, F. Investigating mechanical and bonding properties of micro/nano filler containing epoxy adhesives for anchoring steel bar in concrete. Constr. Build. Mater. 2020, 240, 117979. [Google Scholar] [CrossRef]

- Ahmad, Z.; Ansell, M.P.; Smedley, D. Epoxy adhesives modified with nano and micro particles for in situ timber bonding: Effect of microstructure on bond integrity. Int. J. Mech. Mater. Eng. 2010, 5, 59–67. [Google Scholar]

- Matuszewski, L. New Designs of Centrifugal Magnetic Fluid Seals for Rotating Shafts in Marine Technology. Pol. Marit. Res. 2019, 26, 33–46. [Google Scholar] [CrossRef]

- Jeoffroy, E.; Bouville, F.; Bueno, M.; Studart, A.R.; Partl, M.N. Iron-based particles for the magnetically-triggered crack healing of bituminous materials. Constr. Build. Mater. 2018, 164, 775–782. [Google Scholar] [CrossRef]

- Villar, V.P.; Medina, N.F.; Hernández-Olivares, F. A model about dynamic parameters through magnetic fields during the alignment of steel fibres reinforcing cementitious composites. Constr. Build. Mater. 2019, 201, 340–349. [Google Scholar] [CrossRef]

- Javahershenas, F.; Gilani, M.S.; Hajforoush, M. Effect of magnetic field exposure time on mechanical and microstructure properties of steel fiber-reinforced concrete (SFRC). J. Build. Eng. 2021, 35, 101975. [Google Scholar] [CrossRef]

- Kang, D.; Moon, D.; Kim, W. Changes in Rheological Properties of Mortars with Steel Slags and Steel Fibers by Magnetic Field. Materials 2021, 14, 4005. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wang, J.; Jin, W.L. Study of magnetically driven concrete. Constr. Build. Mater. 2016, 121, 53–59. [Google Scholar] [CrossRef]

- Xue, W.; Chen, J.; Xie, F.; Feng, B. Orientation of Steel Fibers in Magnetically Driven Concrete and Mortar. Materials 2018, 11, 170–182. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, X.Y.; Wang, X.Z.; Zhang, L.W.; Fu, H.; Zhao, D.K.; Di, S.T.; Sun, M.H.; Li, J.R.; Zhao, S.Q. Preparation and Application of the Similar Materials of Coral Sandstone and Coral Gravel Limestone. CN110642583A, 3 January 2020. (In Chinese). [Google Scholar]

- Zhu, C.Q.; Liu, H.F.; Zhou, B. Micro-structures and the basic engineering properties of beach calcarenites in South China Sea. Ocean. Eng. 2016, 114, 224–235. [Google Scholar]

- Rouquérol, J.; Avnir, D.; Fairbridge, C.W.; Everett, D.H.; Haynes, J.M.; Pernicone, N.; Ramsay, J.D.F.; Sing, K.S.W.; Unger, K.K. Recommendations for the characterization of porous solids. Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

| Calcareous Sand | Cement | Barite Powder | Quartz Sand | Gypsum Powder |

|---|---|---|---|---|

| Original calcareous sand from south China sea. | Portland cement; NO.42.5. | White powder; Diameter: 20 μm. | White translucent; Diameter: 0.45~0.2 mm. | White powder; Diameter: 9 μm. |

| Level | Quartz Sand | Gypsum | Cement | Water |

|---|---|---|---|---|

| 1 | 10 | 8 | 17 | 25 |

| 2 | 8 | 9 | 19 | 24 |

| 3 | 6 | 10 | 21 | 23 |

| Code | Quartz Sand | Gypsum | Cement | Water |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 3 | 2 |

| 3 | 1 | 3 | 2 | 3 |

| 4 | 2 | 1 | 3 | 3 |

| 5 | 2 | 2 | 2 | 1 |

| 6 | 2 | 3 | 1 | 2 |

| 7 | 3 | 1 | 2 | 2 |

| 8 | 3 | 2 | 1 | 3 |

| 9 | 3 | 3 | 3 | 1 |

| Epoxy | Fe3O4 Powder | Diluent | Magnetic Anchor |

|---|---|---|---|

| Density:1.50 g/cm3; Viscosity:20 Pa·s; Solid content: 99.5%; Compressive strength: 92.9 MPa; Bending strength: 61.7 MPa; Split tensile strength: 17.7 MPa. | Diameter: 1~3 μm. | 98° Industrial alcohol. | Material: NdFeB cylindrical magnet; Diameter: 19~32 mm; Magnetic field intensity: 6000~12,000 Gs. |

| Level | Magnetic Field Intensity (Gs) | Epoxy/Fe3O4 Powder Ratio | Diameter of Magnetic Anchor (mm) |

|---|---|---|---|

| 1 | 6000 | 2 | 19 |

| 2 | 8000 | 1 | 22 |

| 3 | 10,000 | 1/1.5 | 25 |

| 4 | 12,000 | 0.5 | 32 |

| Code | Magnetic Field Intensity | Epoxy/Fe3O4 Powder Ratio | Diameter of Magnetic Anchor |

|---|---|---|---|

| 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 |

| 3 | 1 | 3 | 3 |

| 4 | 1 | 4 | 4 |

| 5 | 2 | 1 | 2 |

| 6 | 2 | 2 | 1 |

| 7 | 2 | 3 | 4 |

| 8 | 2 | 4 | 3 |

| 9 | 3 | 1 | 3 |

| 10 | 3 | 2 | 4 |

| 11 | 3 | 3 | 1 |

| 12 | 3 | 4 | 2 |

| 13 | 4 | 1 | 4 |

| 14 | 4 | 2 | 3 |

| 15 | 4 | 3 | 2 |

| 16 | 4 | 4 | 1 |

| Code | Density (N·m−3) | Compressive Strength (MPa) | Elastic Modulus (MPa) |

|---|---|---|---|

| 1 | 19.83 | 3.51 | 797.50 |

| 2 | 20.79 | 4.84 | 1130.08 |

| 3 | 21.06 | 5.07 | 1002.30 |

| 4 | 20.82 | 6.04 | 950.91 |

| 5 | 20.69 | 4.15 | 1053.96 |

| 6 | 20.46 | 4.34 | 1295.49 |

| 7 | 20.46 | 3.88 | 974.80 |

| 8 | 20.76 | 3.3291 | 647.738 |

| 9 | 20.24 | 4.0991 | 718.489 |

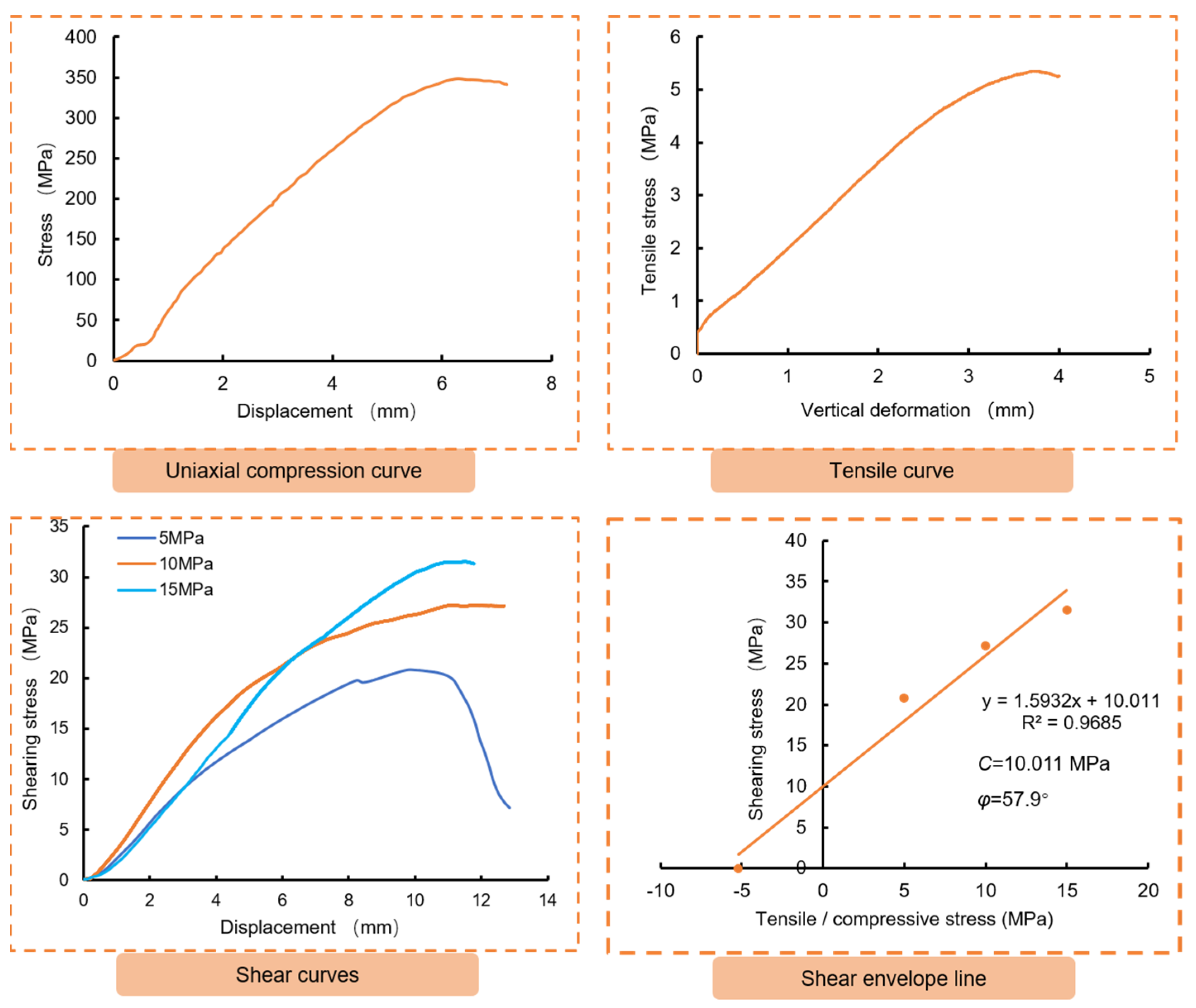

| Compressive Strength (MPa) | Tensile Strength (MPa) | Elastic Modulus (GPa) | |

|---|---|---|---|

| Artificial reef limestone | 6.70 | 0.66 | 1.20 |

| Original sample [8,10] | 1.07~38.60, (most of them are 6~9) | 0.64~4.4 | 0.61~14.08 |

| Volumetric Weight (N·m−3) | Compressive Strength (MPa) | Tensile Strength (MPa) | Elastic Modulus (MPa) | Poisson Ratio | Cohesion (MPa) | Angle of Internal Friction (°) |

|---|---|---|---|---|---|---|

| 21.02 | 36.31 | 5.33 | 393.60 | 0.19 | 10.01 | 57.9 |

| Code | Anchor Bolt Diameter | Magnetic Field Strength | Anchor Hole Diameter | Anchoring Material | |

|---|---|---|---|---|---|

| Orthogonal test | #1 | 1; (25 mm) | 1; (4000 GS) | 1; (50 mm) | Epoxy + Fe3O4 powder |

| #2 | 1; (25 mm) | 2; (2000 GS) | 2; (40 mm) | ||

| #3 | 2; (19 mm) | 1; (4000 GS) | 2; (40 mm) | ||

| #4 | 2; (19 mm) | 2; (2000 GS) | 1; (50 mm) | ||

| Control group | #5 | 19 mm | —— | 50 mm | Epoxy |

| Region | BET Surface Area (m2·g−1) | Total Pore Volume (cm3(STP) g−1) |

|---|---|---|

| A | 0.66506 | 0.1528 |

| B | 1.4494 | 0.333 |

| C | 1.6831 | 0.3867 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Guo, J.; Yu, F.; Li, Z. Experimental Study on Reinforcement of Reef Limestone by Magnetic Anchoring System. Materials 2023, 16, 3519. https://doi.org/10.3390/ma16093519

Liu J, Guo J, Yu F, Li Z. Experimental Study on Reinforcement of Reef Limestone by Magnetic Anchoring System. Materials. 2023; 16(9):3519. https://doi.org/10.3390/ma16093519

Chicago/Turabian StyleLiu, Jie, Jianxiang Guo, Fan Yu, and Zheng Li. 2023. "Experimental Study on Reinforcement of Reef Limestone by Magnetic Anchoring System" Materials 16, no. 9: 3519. https://doi.org/10.3390/ma16093519

APA StyleLiu, J., Guo, J., Yu, F., & Li, Z. (2023). Experimental Study on Reinforcement of Reef Limestone by Magnetic Anchoring System. Materials, 16(9), 3519. https://doi.org/10.3390/ma16093519