Laboratory Experiments and Numerical Simulation on Dynamic Response of Island Reclamation Coral Sand under Aircraft Load

Abstract

1. Introduction

2. Laboratory Experiment

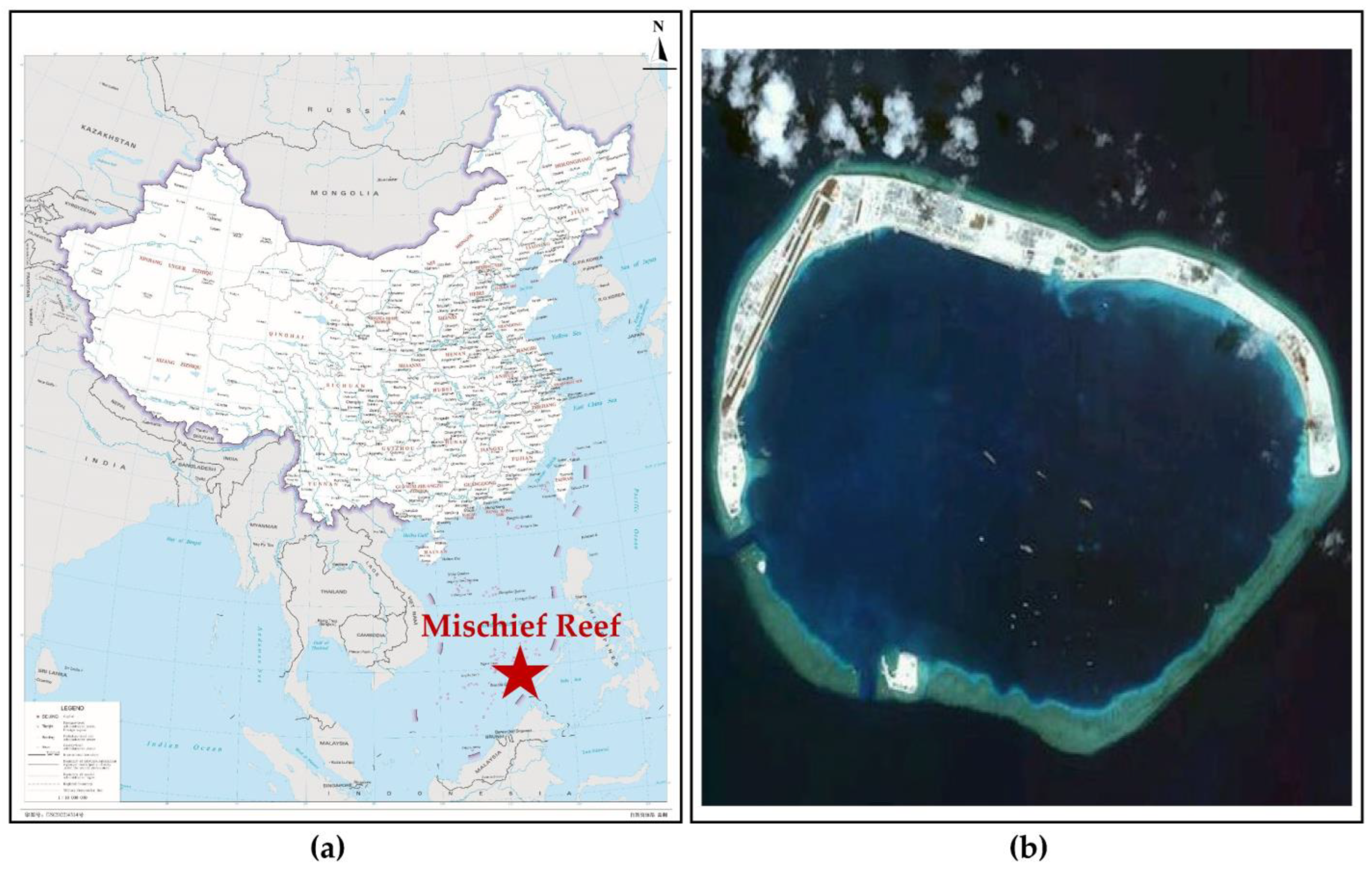

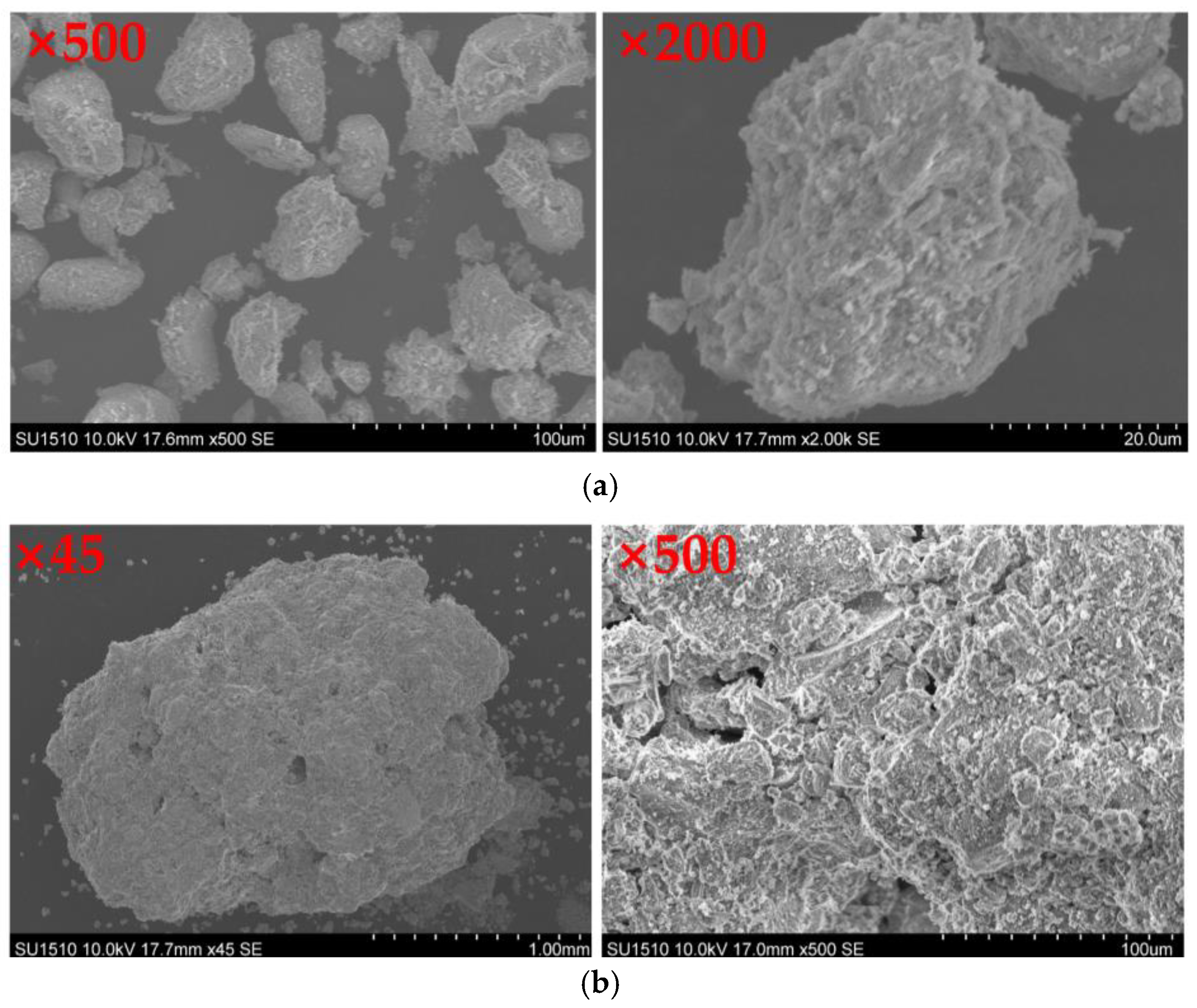

2.1. Coral Sand

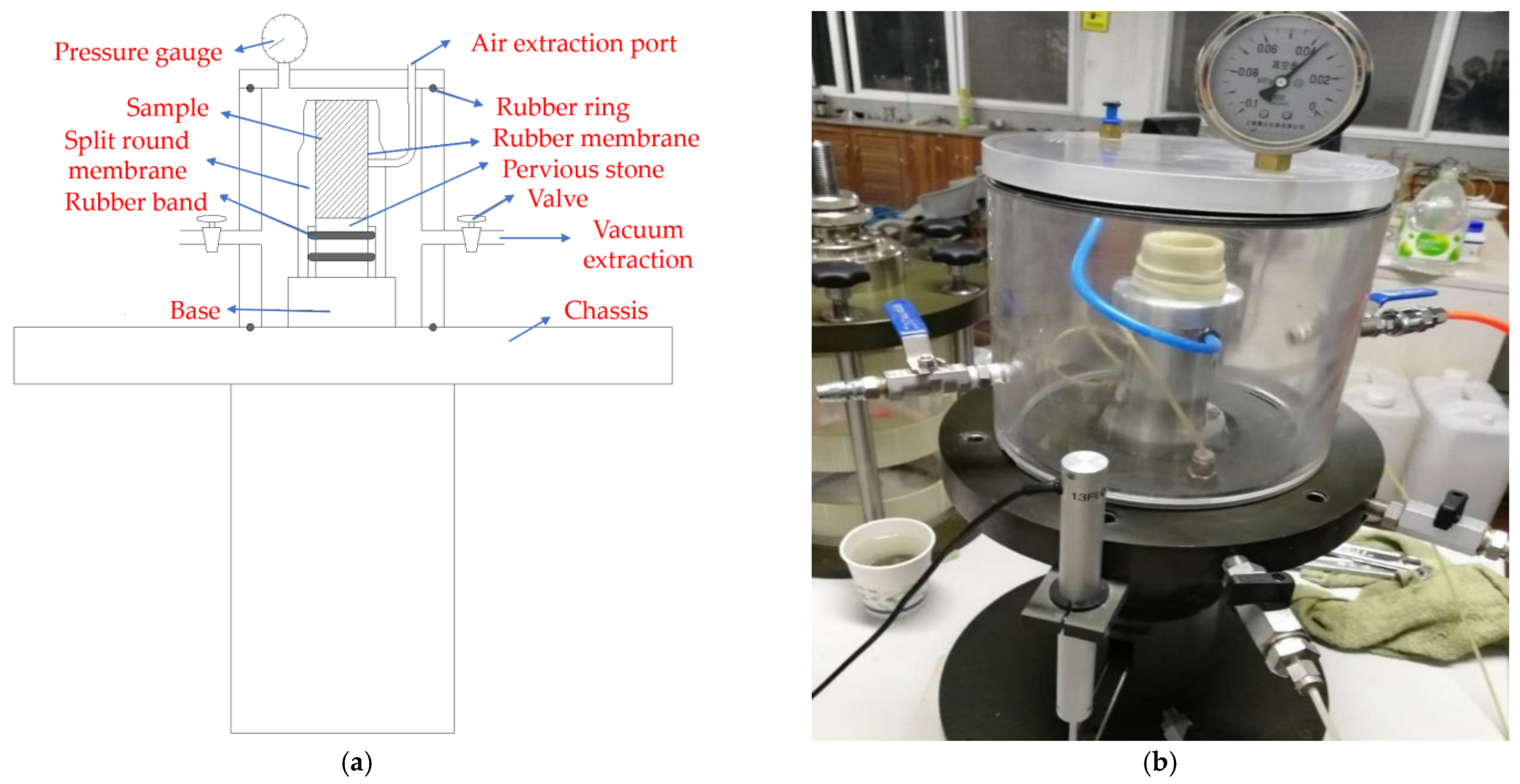

2.2. Sample Preparation

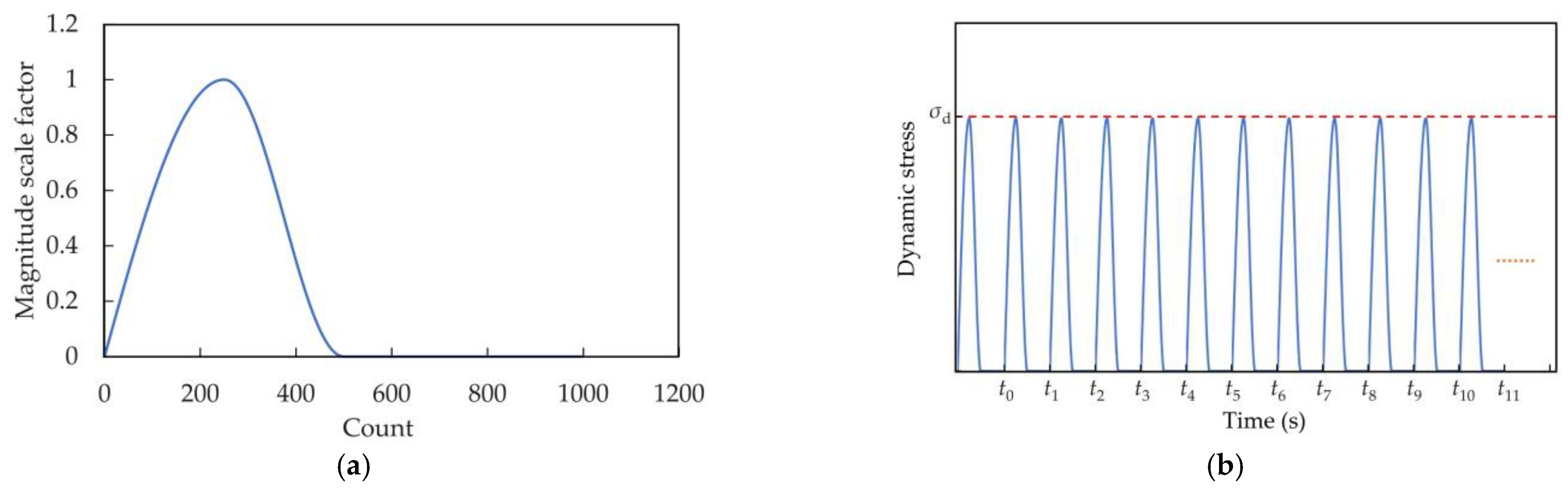

2.3. Aircraft Landing Load

2.4. Experimental Scheme

2.5. Experimental Procedures

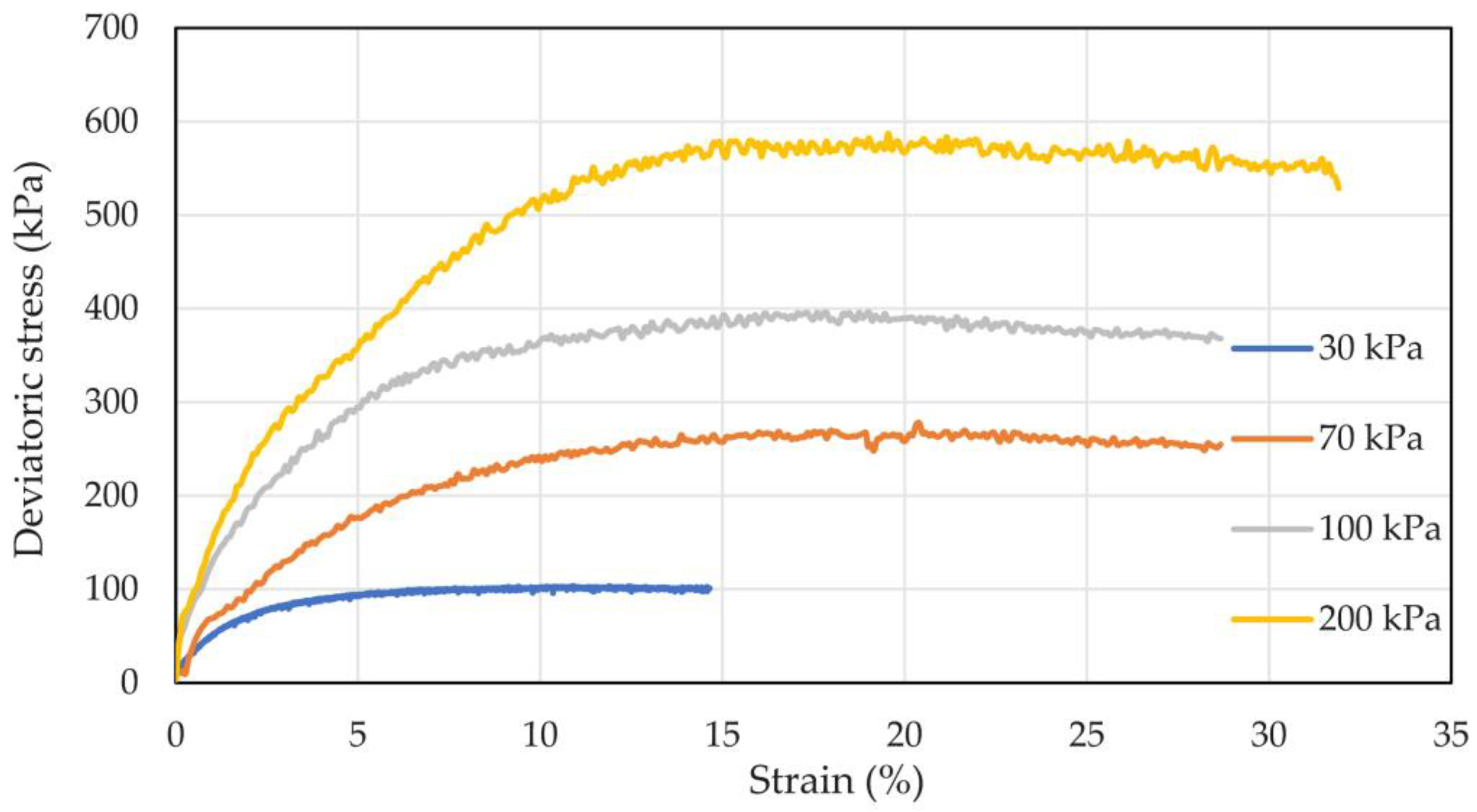

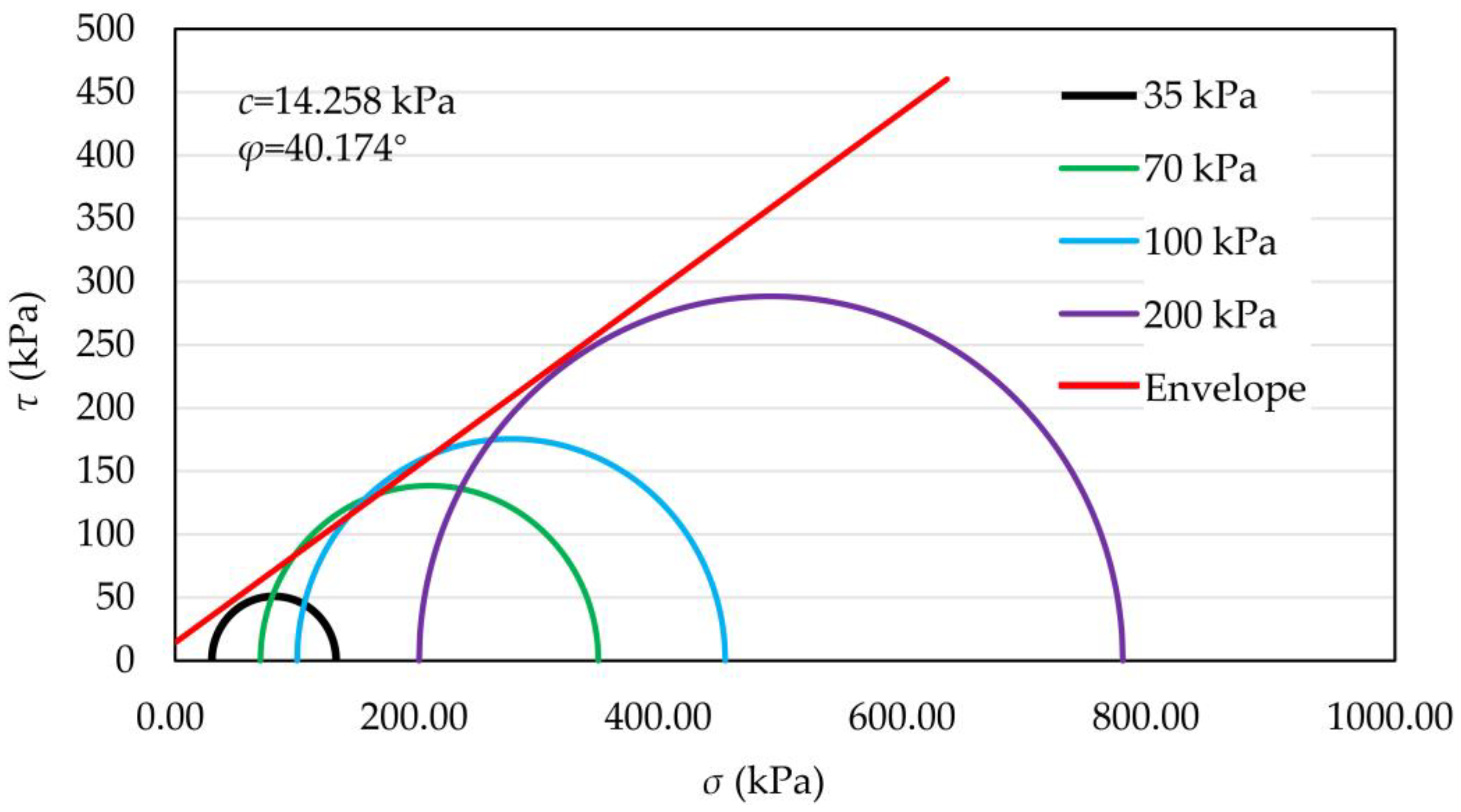

2.6. Results and Discussion

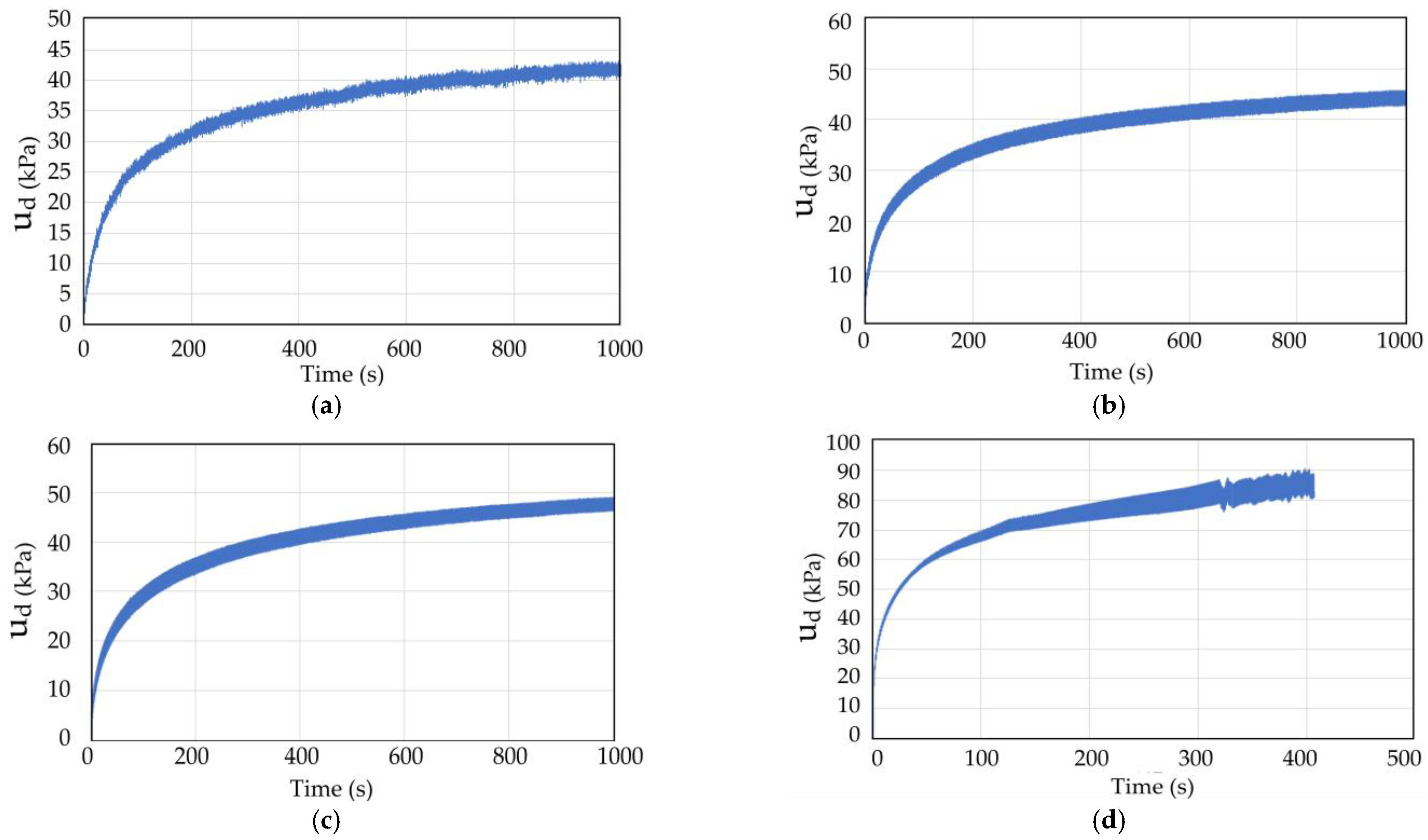

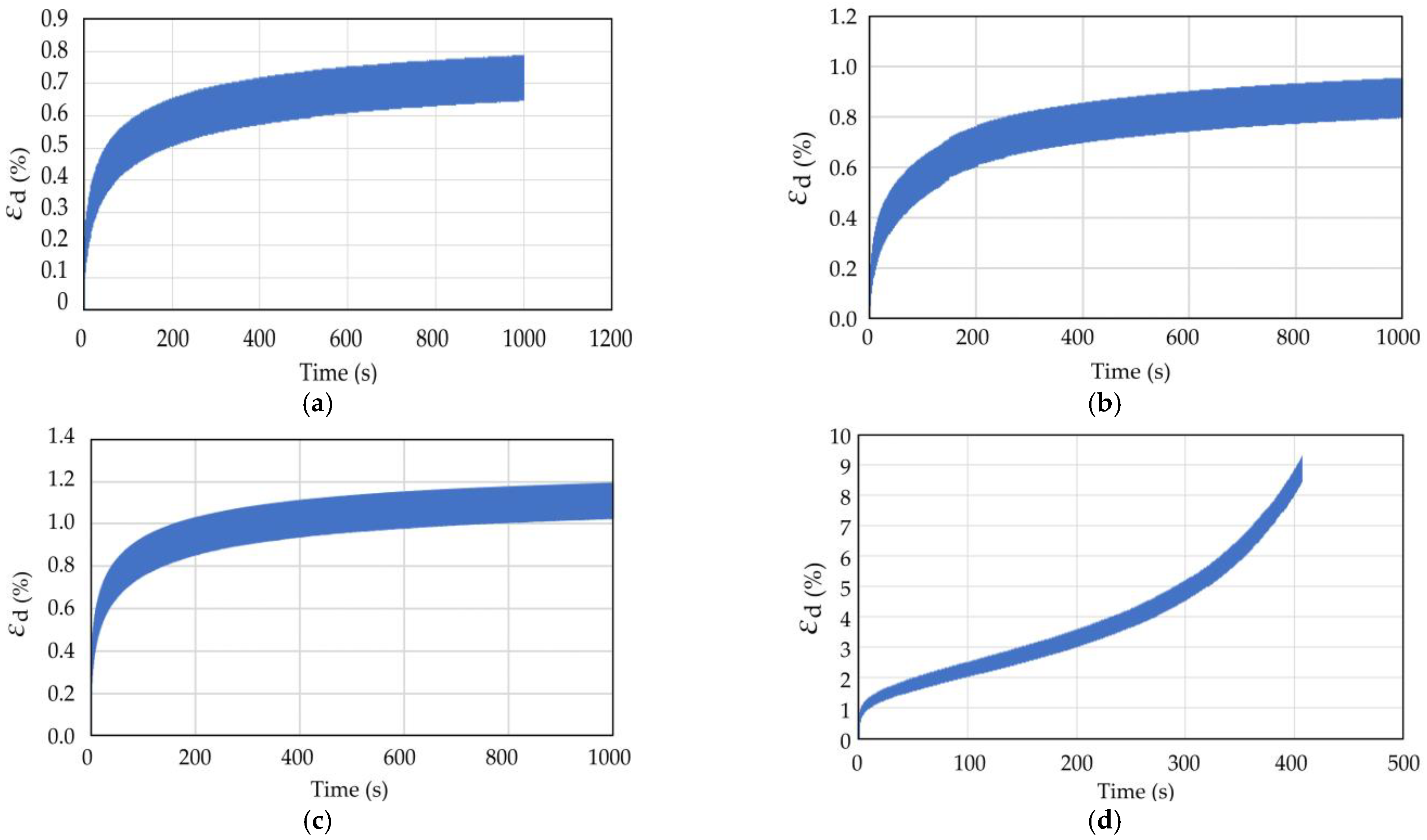

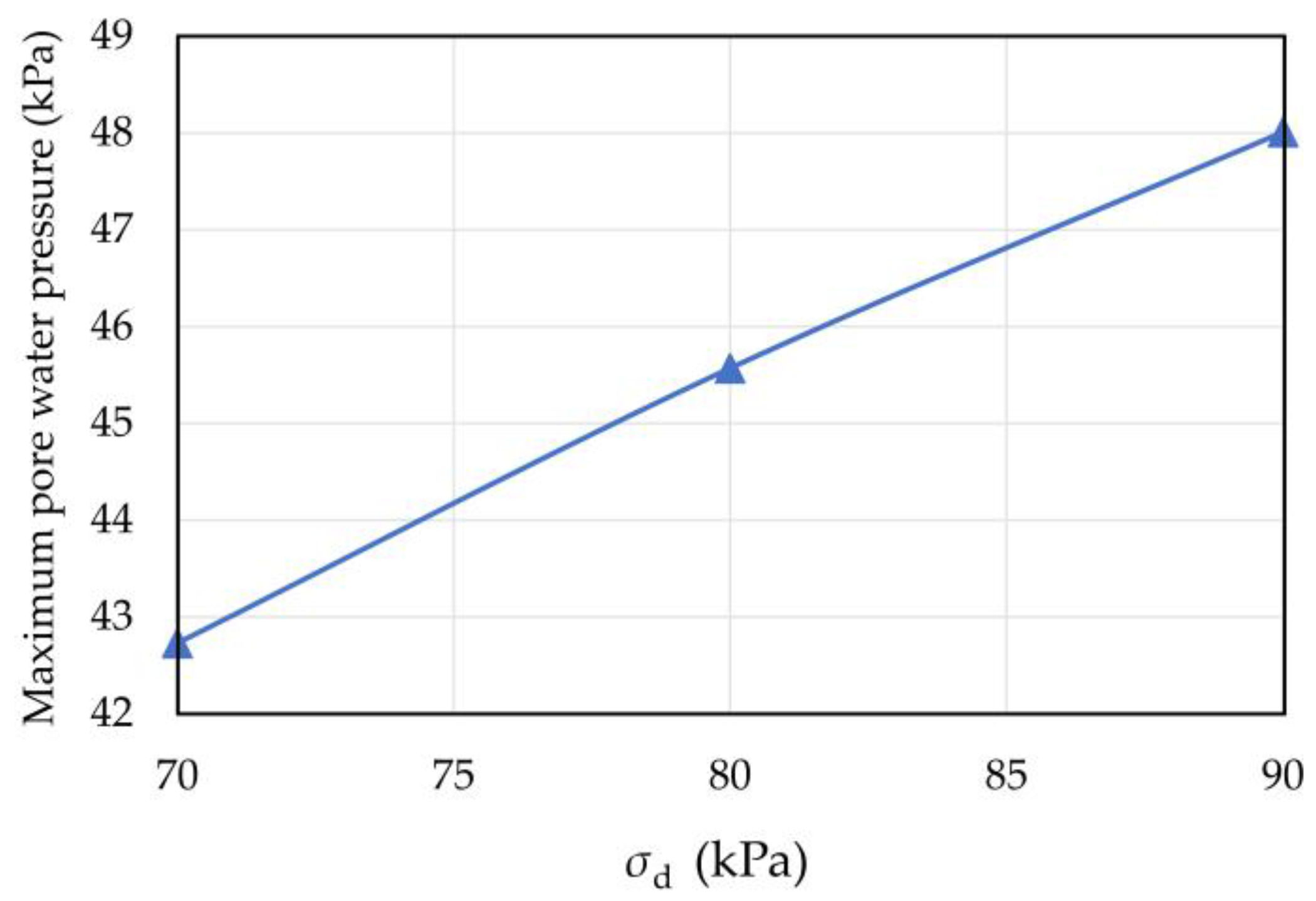

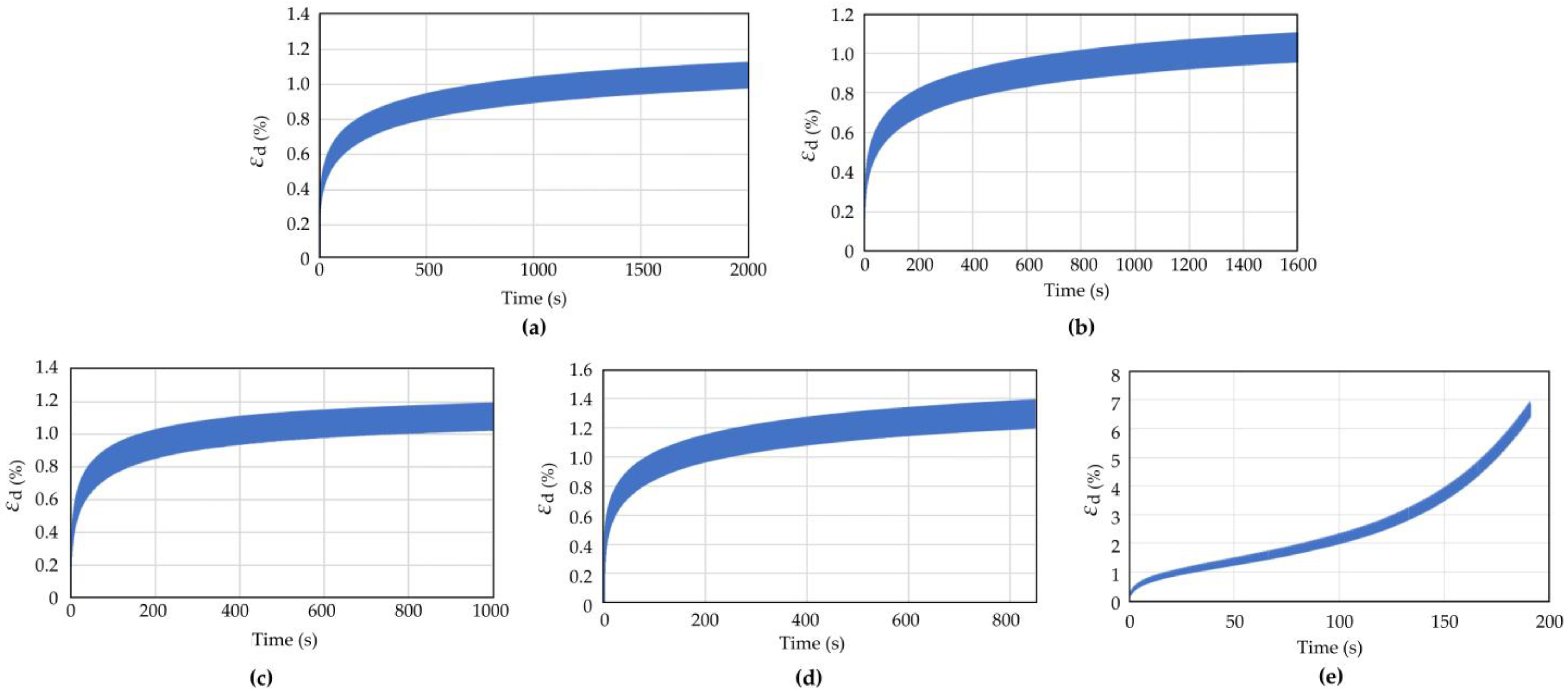

2.6.1. Influence of Dynamic Stress Amplitude on the Dynamic Response of Coral Sand

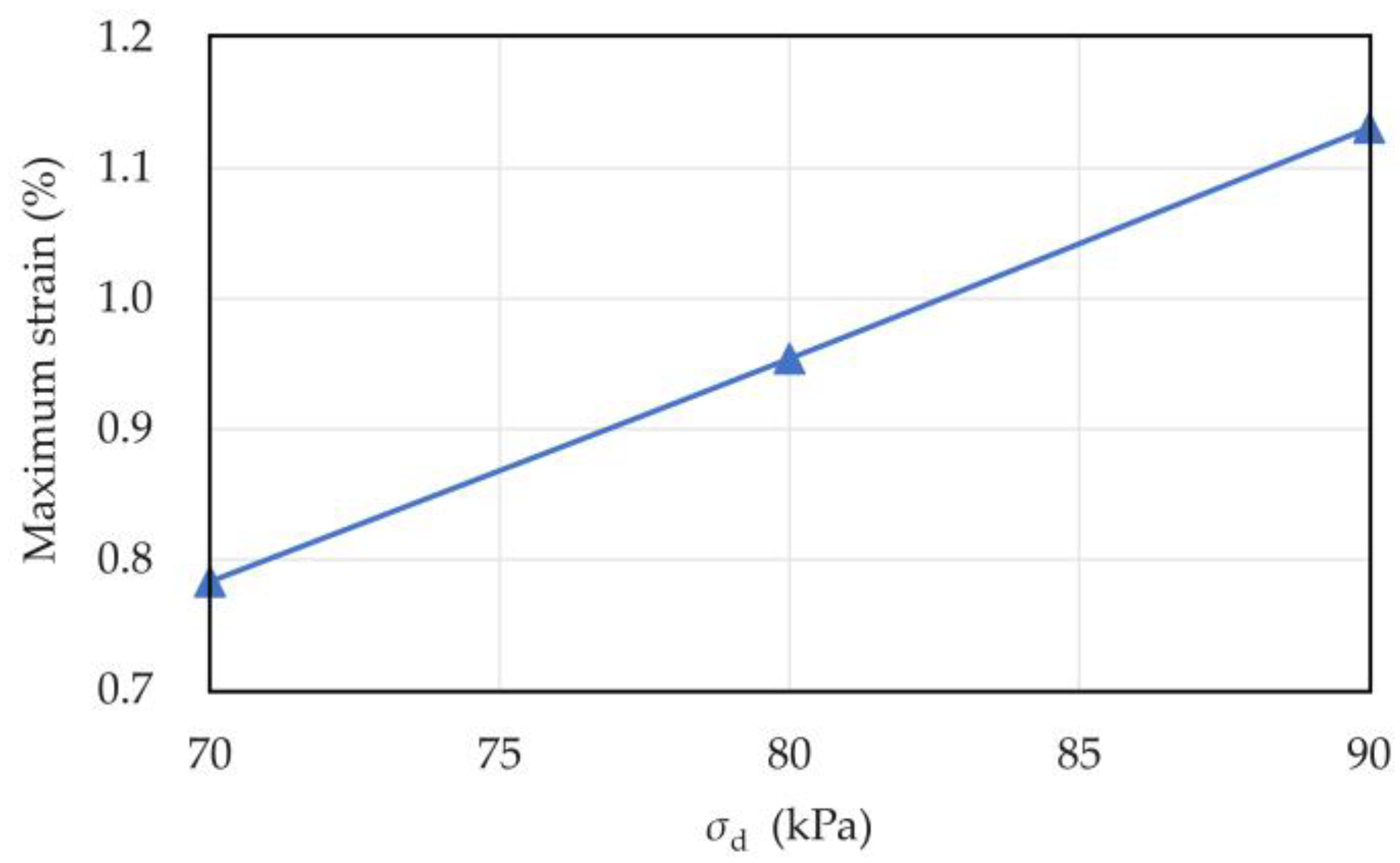

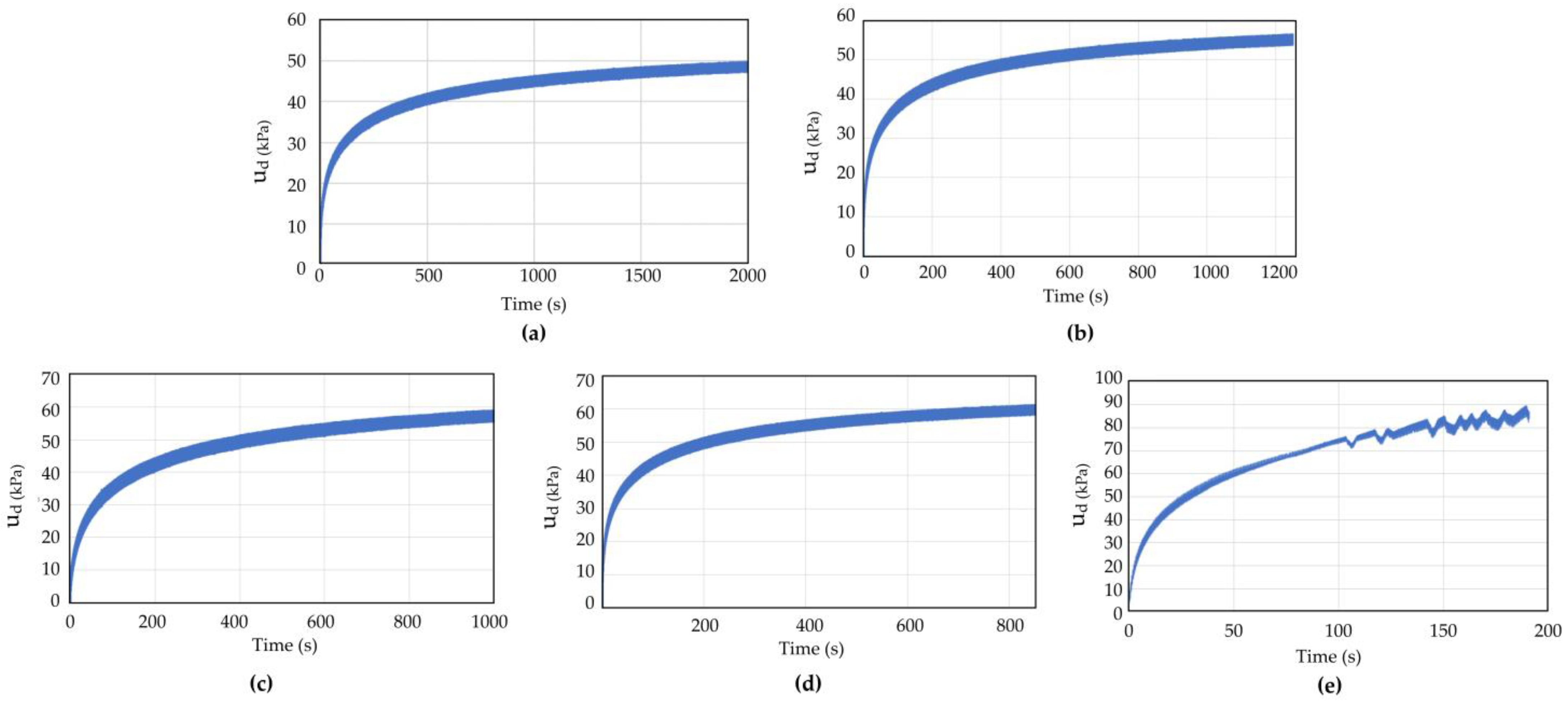

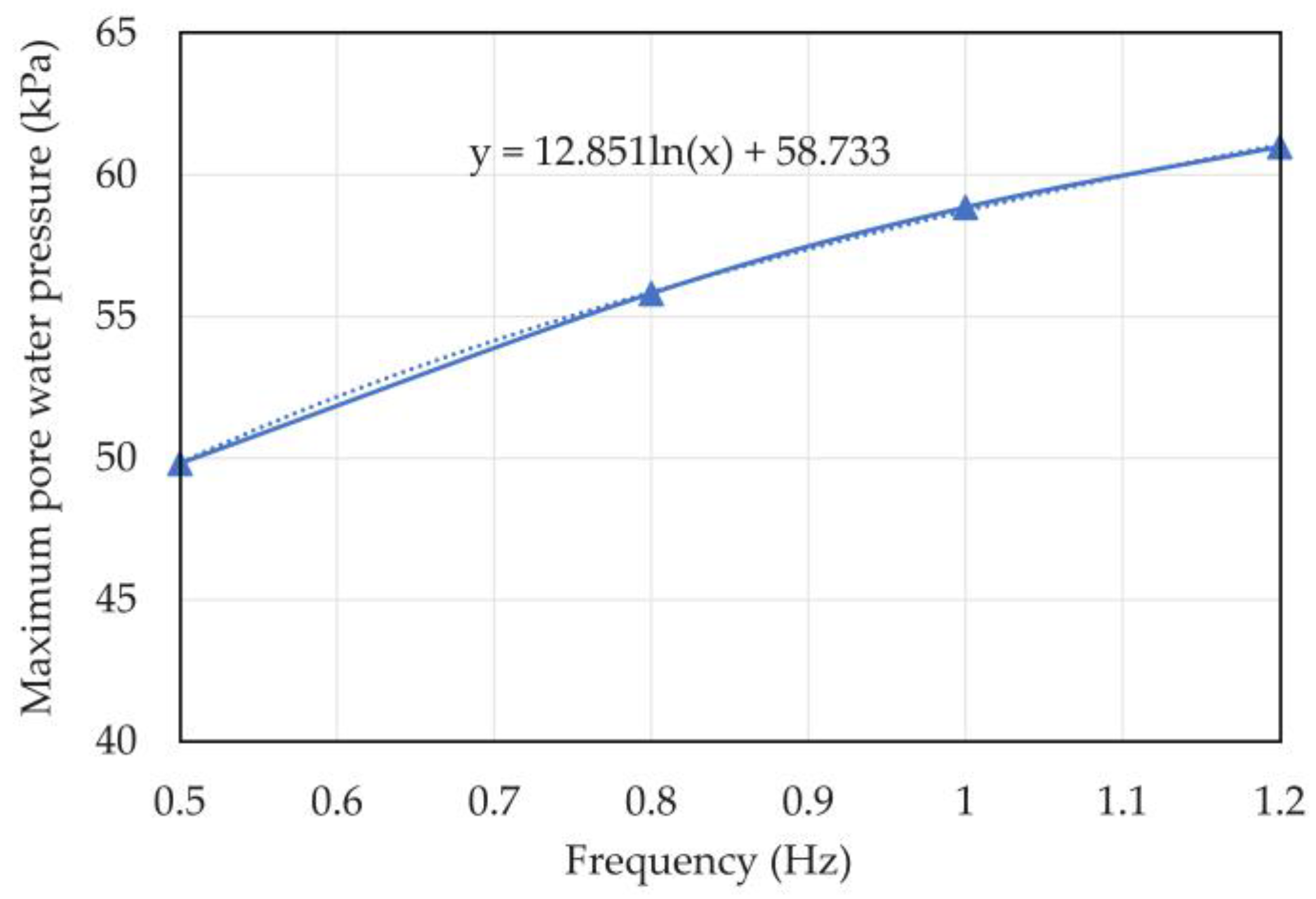

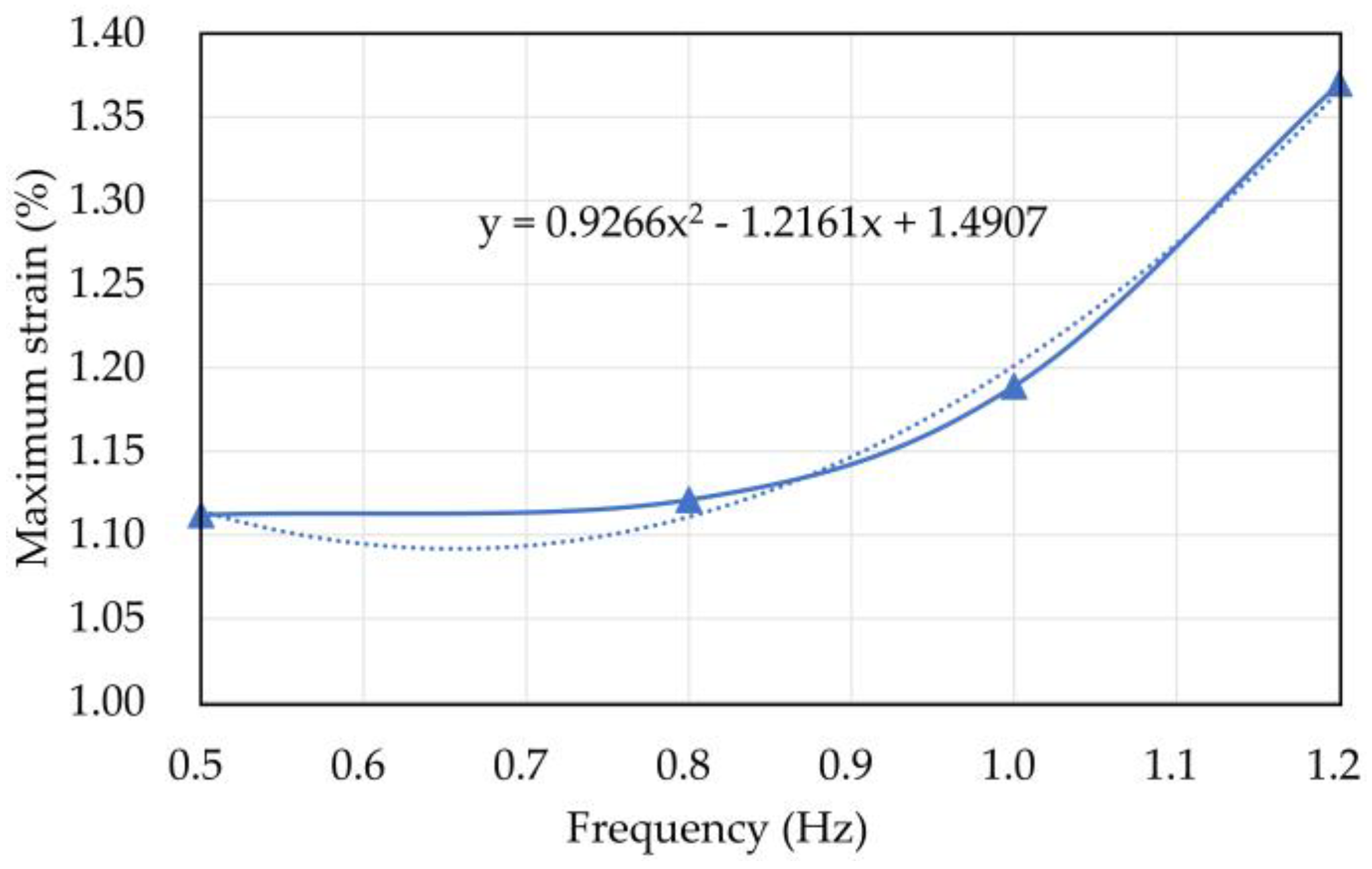

2.6.2. Influence of Cyclic Load Vibration Frequency on the Dynamic Response of Coral Sand

3. Numerical Simulations

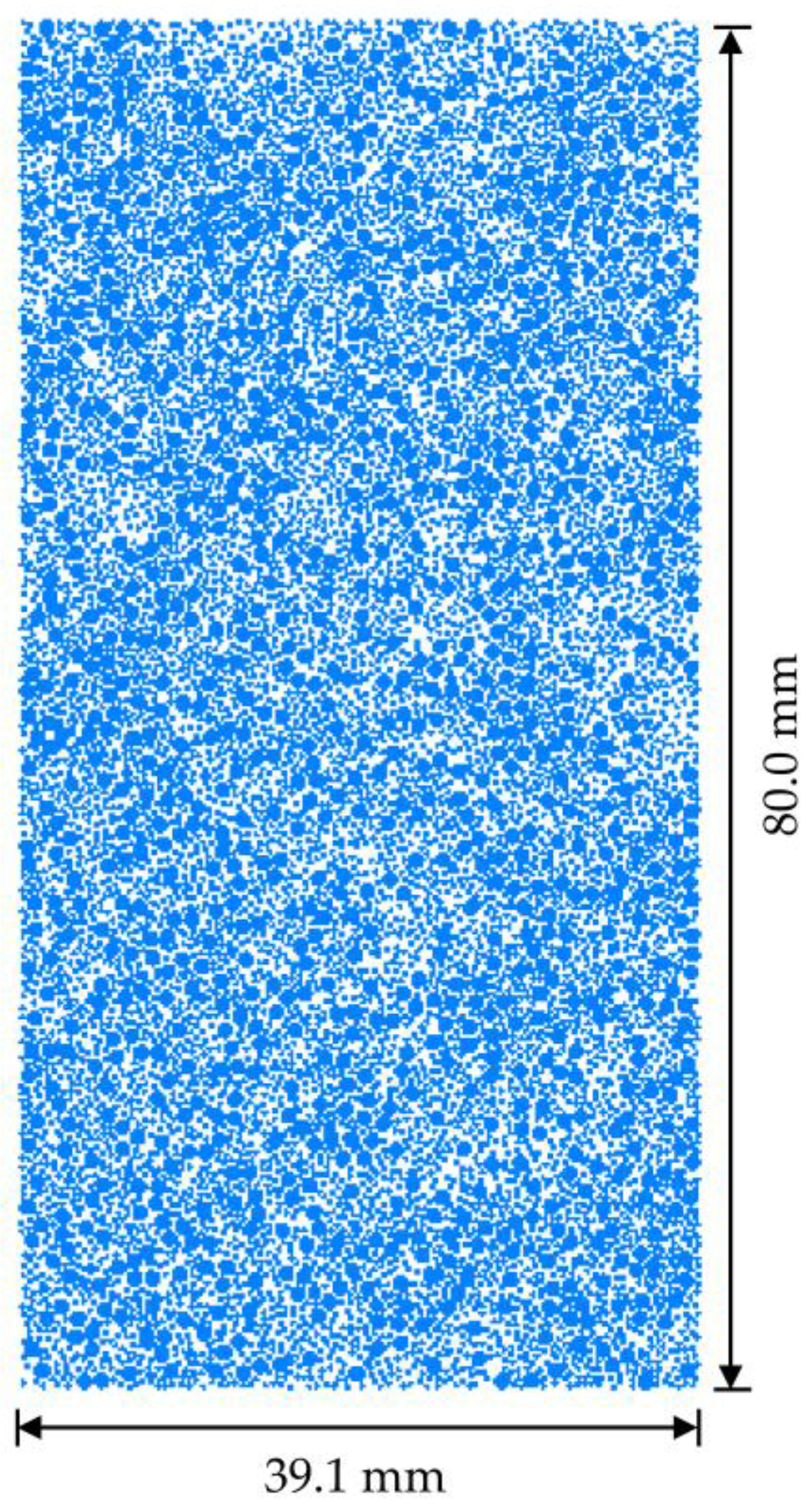

3.1. Modeling of the Numerical Model

3.2. Numerical Model Parameters

3.3. Numerical Simulation Scheme

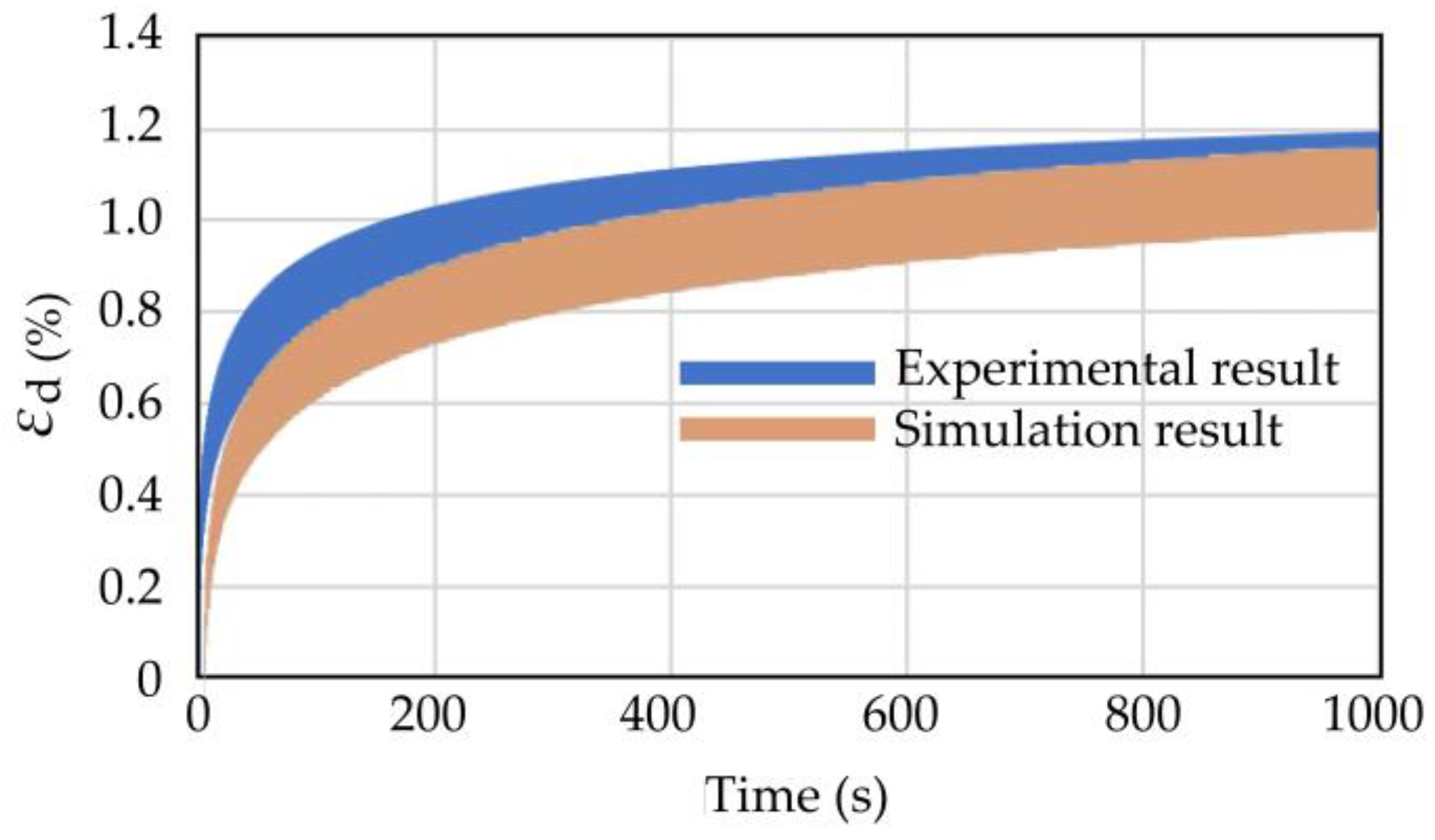

3.4. Numerical Reliability Analysis

3.5. Numerical Simulation Results and Discussion

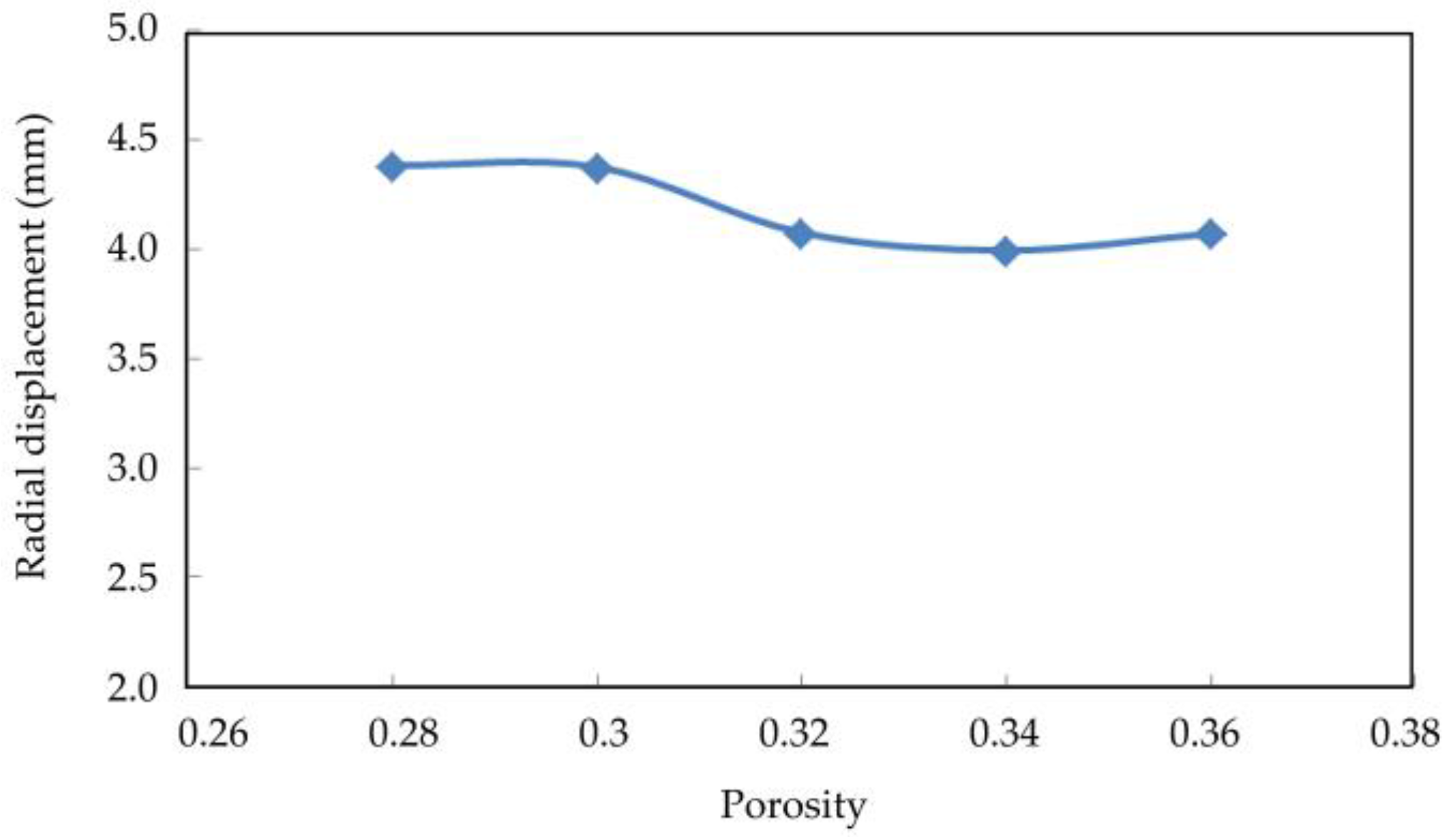

3.5.1. Influence of Porosity on the Dynamic Response of Coral Sand

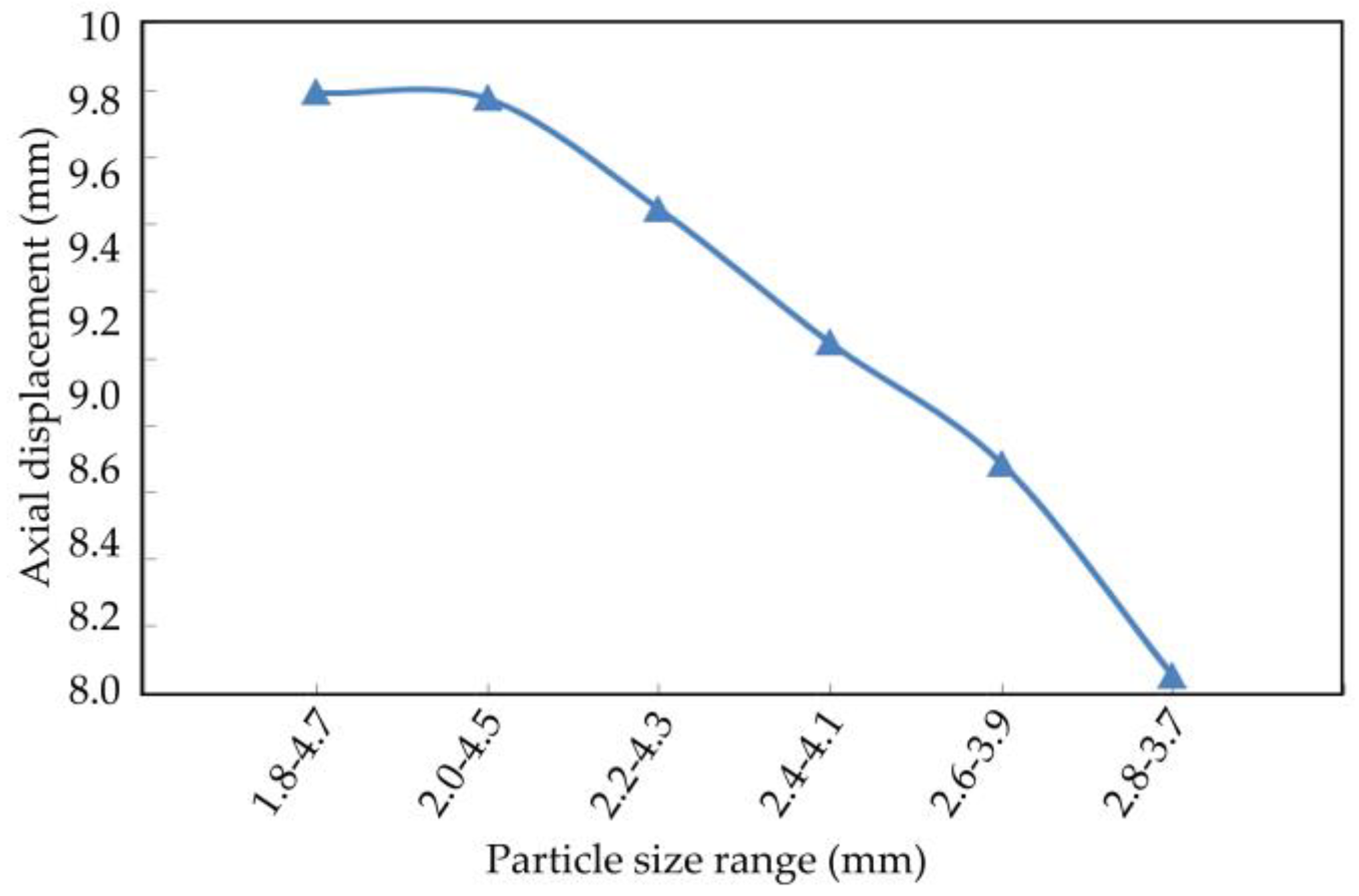

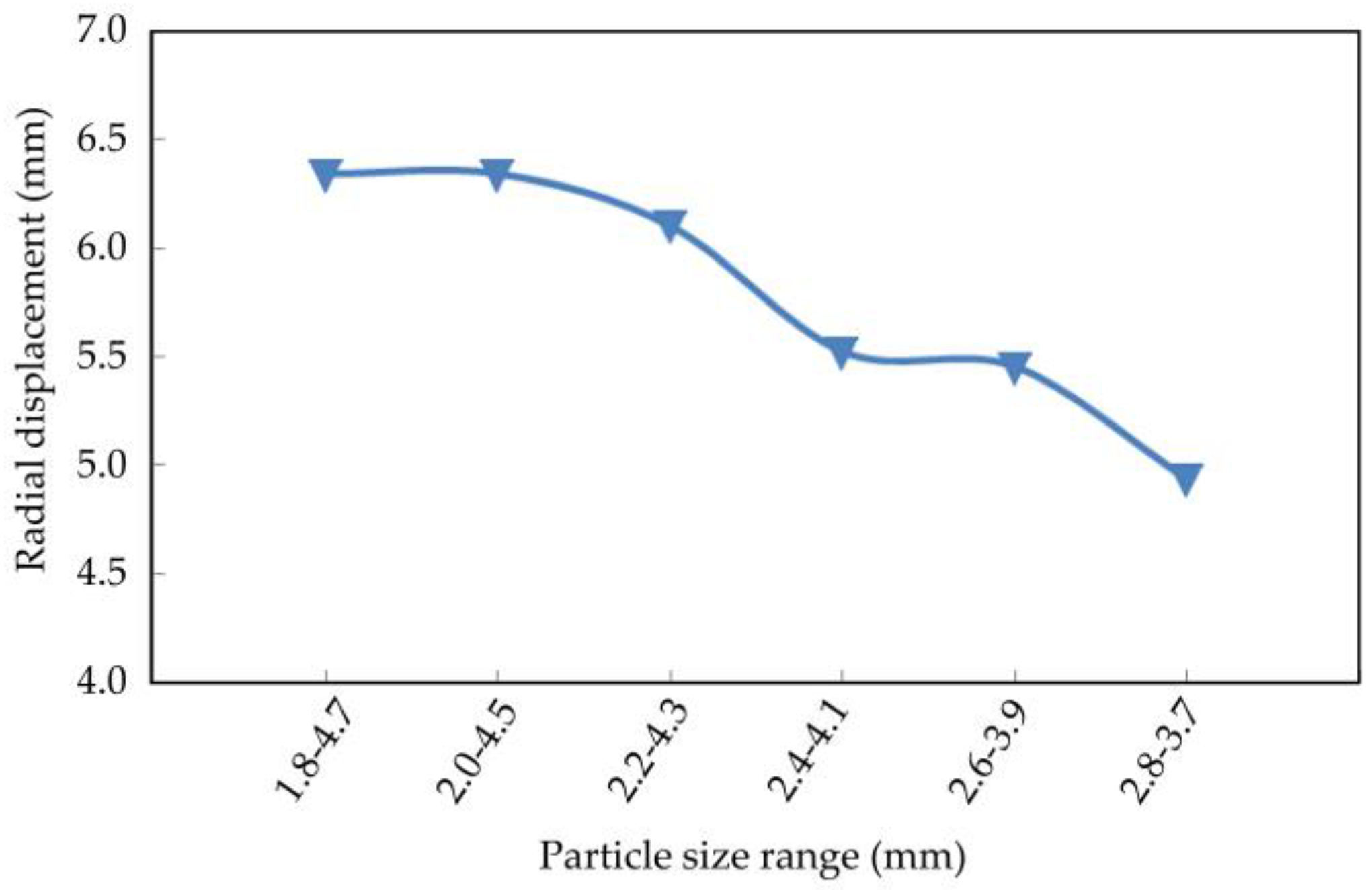

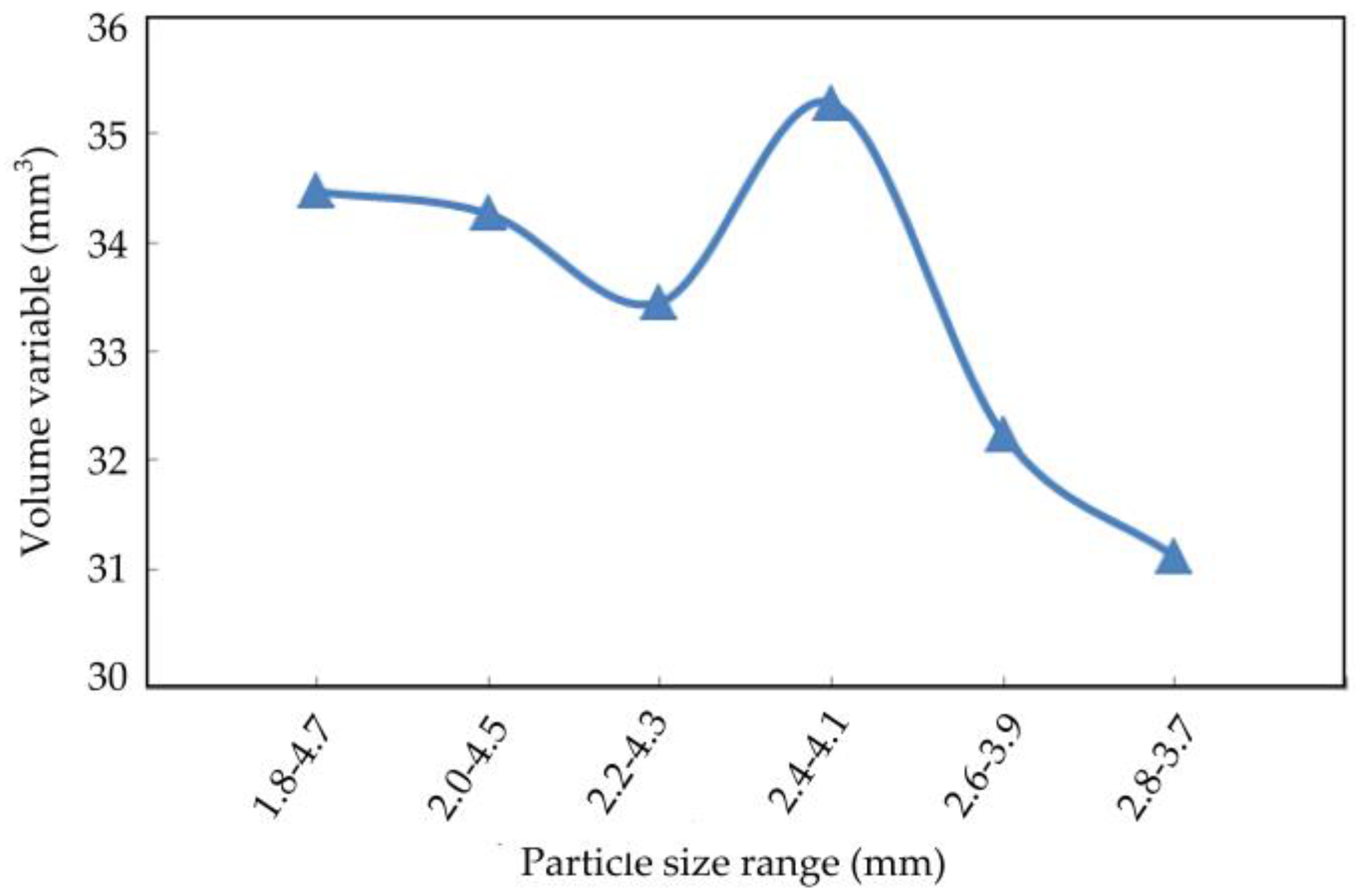

3.5.2. Influence of Particle Size on Dynamic Response of Coral Sand

4. Conclusions

- (1)

- When the amplitude of the aircraft cyclic load was small, the pore water pressure and strain of coral sand gradually increased with the number of load cycles, and the growth rate decreased gradually until it stabilized. When the amplitude of the aircraft cyclic load was large, the strain of coral sand increased with the number of load cycles, and the growth rate continuously increased.

- (2)

- When the frequency of the aircraft cyclic load was low, the pore water pressure and strain of coral sand gradually increased with the number of load cycles, but the growth rate gradually decreased. When the vibration frequency of the aircraft cyclic load was high, the strain of coral sand increased with the number of load cycles, and the growth rate increased.

- (3)

- Under the aircraft cyclic load, the maximum pore water pressure and strain of coral sand increased linearly with the dynamic load amplitude and increased nonlinearly with the vibration frequency.

- (4)

- The porosity of the coral sand particles considerably affected the deformation of coral sand under aircraft cyclic loading, and the deformation increased with porosity.

- (5)

- The smaller the variation range of the coral sand particle size was, the smaller the coral sand settlement caused by aircraft takeoff and landing loads was.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, Z.X. Engineering Properties of Coral Sands in Nansha Islands. Trop. Ocean. 2000, 19, 1–8. [Google Scholar]

- Fang, X.; Yang, Y.; Chen, Z.; Liu, H.; Xiao, Y.; Shen, C. Influence of Fiber Content and Length on Engineering Properties of MICP-Treated Coral Sand. Geomicrobiol. J. 2020, 37, 582–594. [Google Scholar] [CrossRef]

- Coop, M.R. The mechanics of uncemented carbonate sands. Geotechnique 1990, 40, 607–626. [Google Scholar] [CrossRef]

- O’Sullivan, C.; Coop, M.; Cavarretta, I. The influence of particle characteristics on the behaviour of coarse grained soils. Geotechnique 2010, 60, 413–423. [Google Scholar] [CrossRef]

- Lv, Y.; Wang, Y.; Zuo, D. Effects of particle size on dynamic constitutive relation and energy absorption of calcareous sand. Powder Technol. 2019, 356, 21–30. [Google Scholar] [CrossRef]

- Wu, Q.; Ding, X.; Zhang, Y. Microfabric evolution of coral sand foundations during seismic liquefaction using 3D images. Soil Dyn. Earthq. Eng. 2022, 162, 107445. [Google Scholar] [CrossRef]

- Altuhafi, F.N.; Coop, M.R.; Georgiannou, V.N. Effect of Particle Shape on the Mechanical Behavior of Natural Sands. J. Geotech. Geoenviron. 2016, 142, 1–15. [Google Scholar] [CrossRef]

- Lv, Y.R.; Wang, C.; Huang, H.X.; Zuo, D.J. Study on particle structure and crushing behaviors of coral sand. Rock Soil Mech. 2021, 42, 352–360. [Google Scholar] [CrossRef]

- Wood, D.M.; Maeda, K. Changing grading of soil: Effect on critical states. Acta Geotech. 2008, 3, 3–14. [Google Scholar] [CrossRef]

- Indraratna, B.; Salim, W. Modelling of particle breakage of coarse aggregates incorporating strength and dilatancy. Geotech. Eng. 2002, 155, 243–252. [Google Scholar] [CrossRef]

- de Bono, J.P.; McDowell, G.R. Discrete element modelling of one-dimensional compression of cemented sand. Granul. Matter 2013, 16, 79–90. [Google Scholar] [CrossRef]

- Ciantia, M.O.; Arroyo, M.; O’Sullivan, C.; Gens, A.; Liu, T. Grading evolution and critical state in a discrete numerical model of Fontainebleau sand. Geotechnique 2019, 69, 1–15. [Google Scholar] [CrossRef]

- Sharma, S.S.; Ismail, M.A. Monotonic and Cyclic Behavior of Two Calcareous Soils of Different Origins. J. Geotech. Geoenviron. 2006, 132, 1581–1591. [Google Scholar] [CrossRef]

- Wang, X.-Z.; Wang, X.; Chen, J.-W.; Wang, R.; Hu, M.-J.; Meng, Q.-S. Experimental study on permeability characteristics of calcareous soil. Bull. Eng. Geol. Environ. 2017, 77, 1753–1762. [Google Scholar] [CrossRef]

- Rui, S.; Guo, Z.; Si, T.; Li, Y. Effect of particle shape on the liquefaction resistance of calcareous sands. Soil Dyn. Earthq. Eng. 2020, 137, 106302. [Google Scholar] [CrossRef]

- Aissa, Y.H.; Goual, I.; Benabed, B. Mix-design and properties of self-compacting concrete made with calcareous tuff. J. Build. Eng. 2020, 27, 100997. [Google Scholar] [CrossRef]

- Sandoval, E.A.; Pando, M.A. Experimental assessment of the liquefaction resistance of calcareous biogenous sands. Earth. Sci. Res. J. 2012, 16, 55–63. [Google Scholar]

- Shahnazari, H.; Rezvani, R. Effective parameters for the particle breakage of calcareous sands. Eng. Geol. 2013, 159, 98–105. [Google Scholar] [CrossRef]

- Coop, M.R.; Sorensen, K.K.; Freitas, T.M.B. Particle breakage during shearing of a carbonate sand. Geotechnique 2004, 54, 157–163. [Google Scholar] [CrossRef]

- Wang, X.-Z.; Wang, X.; Jin, Z.-C.; Meng, Q.-S.; Zhu, C.-Q.; Wang, R. Shear characteristics of calcareous gravelly soil. Bull. Eng. Geol. Environ. 2016, 76, 561–573. [Google Scholar] [CrossRef]

- Rezvani, R.; Nabizadeh, A.; Tutunchian, M.A. The effect of particle size distribution on shearing response and particle breakage of two different calcareous soils. Eur. Phys. J. Plus 2021, 136, 1008. [Google Scholar] [CrossRef]

- Dong, K.; Ren, H.Q.; Ruan, W.J.; Ning, H.J.; Guo, R.Q.; Huang, K. Study on strain rate effect of coral sand. Explos. Shock. Waves 2020, 40, 32–41. [Google Scholar] [CrossRef]

- Salem, M.; Elmamlouk, H.; Agaiby, S. Static and cyclic behavior of North Coast calcareous sand in Egypt. Soil Dyn. Earthq. Eng. 2013, 55, 83–91. [Google Scholar] [CrossRef]

- Hemmat, A.; Aghilinategh, N.; Sadeghi, M. Shear strength of repacked remoulded samples of a calcareous soil as affected by long-term incorporation of three organic manures in central Iran. Biosyst. Eng. 2010, 107, 251–261. [Google Scholar] [CrossRef]

- Airey, D.W.; Fahey, M. Cyclic response of calcareous soil from the North-West Shelf of Australia. Geotechnique 1991, 41, 101–121. [Google Scholar] [CrossRef]

- Sadrekarimi, A.; Olson, S.M. Particle damage observed in ring shear tests on sands. Can. Geotech. J. 2010, 47, 497–515. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Shen, J.; Zhu, C. Particle size and confining-pressure effects of shear characteristics of coral sand: An experimental study. Bull. Eng. Geol. Environ. 2022, 81, 1–19. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, Z.; Qin, Y.; Liu, T.; Cheng, Z. Effect of particle size distribution on dynamic properties of cemented coral sand under SHPB impact loading. Soil Dyn. Earthq. Eng. 2022, 162, 107438. [Google Scholar] [CrossRef]

- Alshibli, K.A.; Sture, S. Shear Band Formation in Plane Strain Experiments of Sand. J. Geotech. Geoenviron. Eng. 2000, 126, 495–503. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Hai, Y.; Zhang, S.-H.; Wei, P.-S. Mechanics properties of sand under triaxial test simulated by particle flow code. Mech. Archit. Des. 2017, 205–210. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Tai, P.; Zeng, Q.; Bai, Q. Numerical Investigation of Triaxial Shear Behaviors of Cemented Sands with Different Sampling Conditions Using Discrete Element Method. Materials 2022, 15, 3337. [Google Scholar] [CrossRef]

- Shamy, U.E.; Zeghal, M.A. A micro-mechanical investigation of the dynamic response and liquefaction of saturated granular soils. Soil. Dyn. Earthq. Eng. 2007, 27, 712–729. [Google Scholar] [CrossRef]

- Jiang, M.; Li, T.; Thornton, C.; Hu, H. Wetting-Induced Collapse Behavior of Unsaturated and Structural Loess under Biaxial Tests Using Distinct Element Method. Int. J. Géoméch. 2017, 17, 1–12. [Google Scholar] [CrossRef]

- GB/T50123-2019; Ministry of Water Resources of the People’s Republic of China. Standard for Soil Test Method. China Planning Press: Beijing, China, 2019.

- Zhang, Z.F.; Fu, H.L.; Li, C.W.; Yu, G. Analysis of Additional Stress of Soils under Airport Runway Caused by Aireraft Moving Load. Mod. Tunn. Technol. 2022, 59, 1111–1119. [Google Scholar]

- Wang, W.S. Dynamic Strength and Liquefaction Characteristics of Soil; China Electric Power Press: Beijing, China, 1996. [Google Scholar]

- Peng, J. Dynamic Triaxial Test and DEM Simulation of Transparent Sand. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2019. [Google Scholar]

- Zhang, K.F.; Zhang, S.; Teng, J.D.; Sheng, Y.C. 3D Numerical Simulation of Particle Breakage Using Discrete Element Method. Rock Soil Mech. 2017, 38, 2119–2127. [Google Scholar] [CrossRef]

- Ciantia, M.; Arroyo, M.; Calvetti, F.; Gens, A. An approach to enhance efficiency of DEM modelling of soils with crushable grains. Geotechnique 2015, 65, 91–110. [Google Scholar] [CrossRef]

| Particle Diameter (mm) | 1–2 | 0.5–1 | 0.25–0.5 | 0.1–0.25 | 0.075–0.1 | <0.075 |

|---|---|---|---|---|---|---|

| Percentage | 6.47% | 13.80% | 28.73% | 17.14% | 8.43% | 25.43% |

| Working Condition | Consolidation Pressure (kPa) | Relative Compactness | Vibration Frequency (Hz) | Dynamic Stress Amplitude (kPa) |

|---|---|---|---|---|

| Working condition 1 | 100 | 60 | 1 | 70 |

| 1 | 80 | |||

| 1 | 90 | |||

| 1 | 145 | |||

| Working condition 2 | 100 | 60 | 0.5 | 100 |

| 0.8 | 100 | |||

| 1.0 | 100 | |||

| 1.2 | 100 | |||

| 2 | 100 |

| Dynamic Stress Amplitudes (kPa) | Pore Water Pressure (kPa) | Strain (%) |

|---|---|---|

| 70 | 42.73 | 0.783 |

| 80 | 45.57 | 0.954 |

| 90 | 48.01 | 1.189 |

| Vibration Frequency (Hz) | Pore Water Pressure (kPa) | Strain (%) |

|---|---|---|

| 0.5 | 49.82 | 1.112 |

| 0.8 | 55.82 | 1.121 |

| 1.0 | 58.86 | 1.189 |

| 1.2 | 61.01 | 1.371 |

| Parameter | Density (g/cm3) | Internal Friction Angle (°) | Poisson’s Ratio | Elasticity Modulus (MPa) |

|---|---|---|---|---|

| Value | 1.41 | 40 | 0.25 | 18 |

| Parameter | Normal Stiffness kn (N/m) | Tangential Stiffness ks (N/m) | Friction Coefficient μ | Porosity n |

|---|---|---|---|---|

| Value | 2 × 106 | 2 × 106 | 0.5 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Cao, A.; Song, D.; Feng, B.; Li, H.; Long, Y.; Ye, Z. Laboratory Experiments and Numerical Simulation on Dynamic Response of Island Reclamation Coral Sand under Aircraft Load. Materials 2023, 16, 3465. https://doi.org/10.3390/ma16093465

Wang J, Cao A, Song D, Feng B, Li H, Long Y, Ye Z. Laboratory Experiments and Numerical Simulation on Dynamic Response of Island Reclamation Coral Sand under Aircraft Load. Materials. 2023; 16(9):3465. https://doi.org/10.3390/ma16093465

Chicago/Turabian StyleWang, Jianxiu, Ansheng Cao, Dongsheng Song, Bo Feng, Huboqiang Li, Yanxia Long, and Zhenhua Ye. 2023. "Laboratory Experiments and Numerical Simulation on Dynamic Response of Island Reclamation Coral Sand under Aircraft Load" Materials 16, no. 9: 3465. https://doi.org/10.3390/ma16093465

APA StyleWang, J., Cao, A., Song, D., Feng, B., Li, H., Long, Y., & Ye, Z. (2023). Laboratory Experiments and Numerical Simulation on Dynamic Response of Island Reclamation Coral Sand under Aircraft Load. Materials, 16(9), 3465. https://doi.org/10.3390/ma16093465