A Comparative Investigation of the Surface Properties of Corn-Starch-Microfibrillated Cellulose Composite Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Starch/MFC Composites

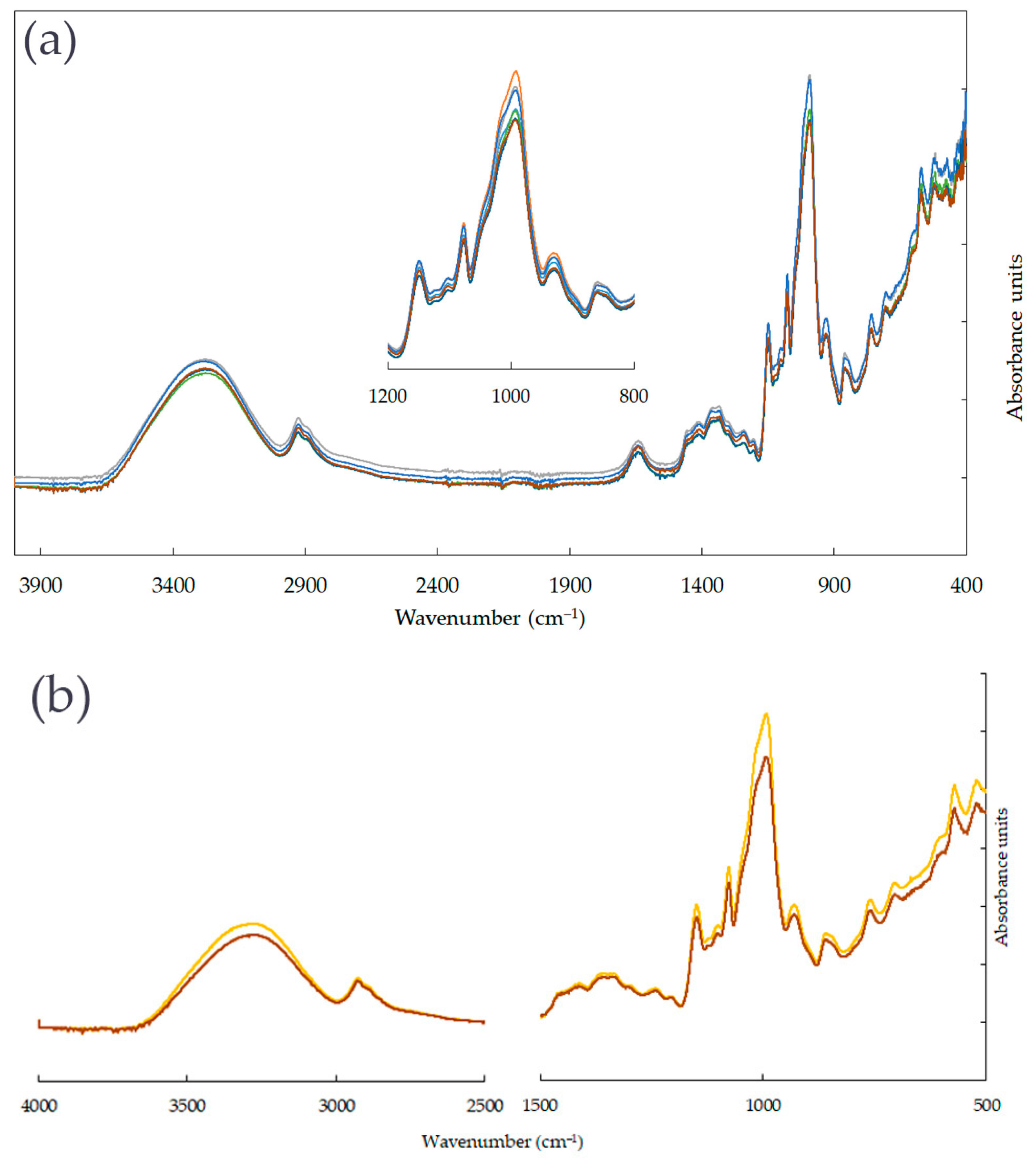

2.3. Infrared Spectroscopy (ATR FT-IR)

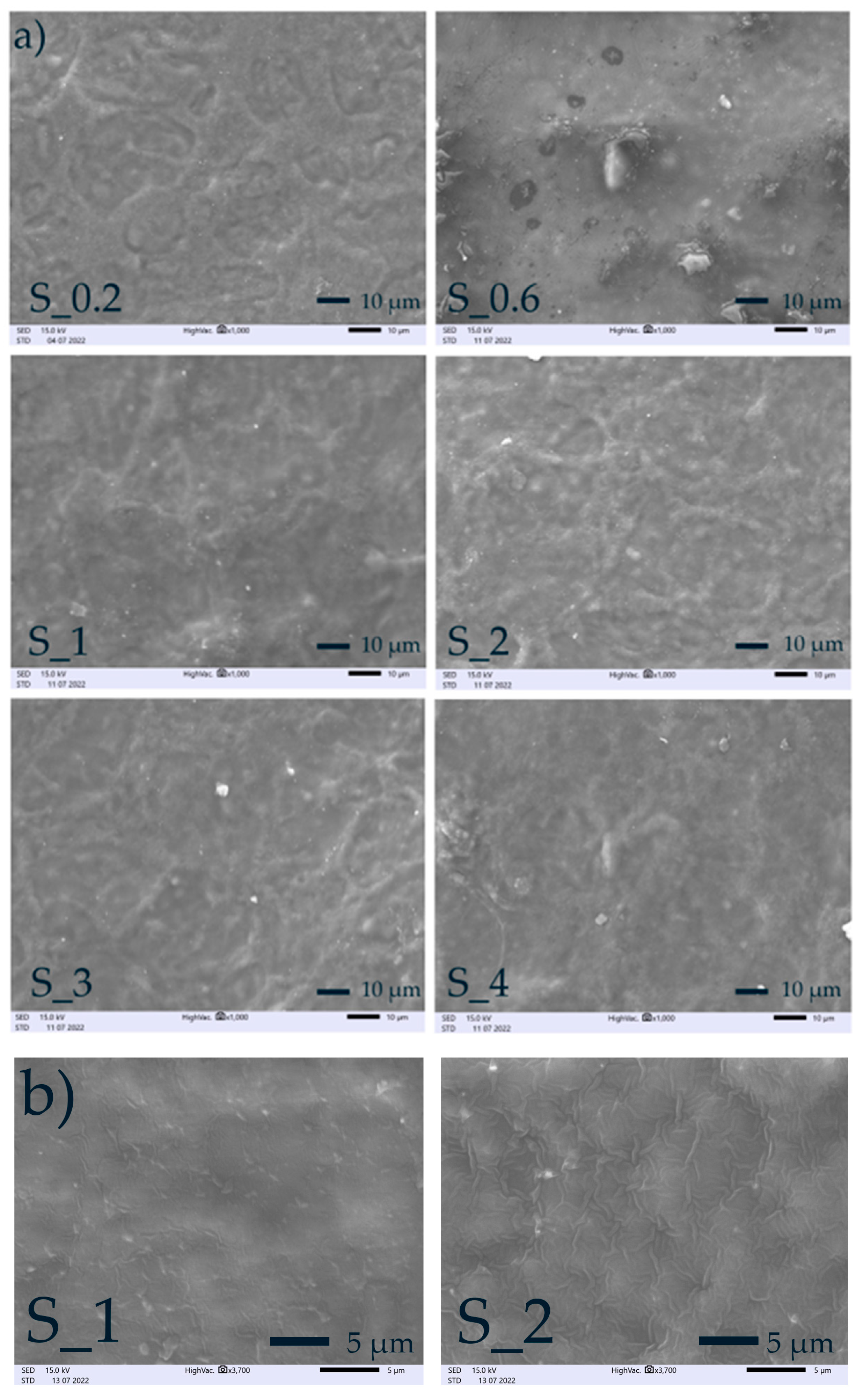

2.4. Surface Morphology

2.5. Statistical Analyses

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghanbarzadeh, B.; Oleyaei, S.A.; Almasi, H. Nanostructured Materials Utilized in Biopolymer-Based Plastics for Food Packaging Applications. Crit. Rev. Food Sci. Nutr. 2015, 55, 1699–1723. [Google Scholar] [CrossRef]

- Singh, P.; Sharma, V.P. Integrated Plastic Waste Management: Environmental and Improved Health Approaches. Procedia Environ. Sci. 2016, 35, 692–700. [Google Scholar] [CrossRef]

- Fabijanski, M. Effect of Injection Parameters on the Mechanical Properties of Foamed Polylactide. Przem. Chem. 2021, 100, 750–753. [Google Scholar]

- Chatterjee, S.; Sharma, S. Microplastics in Our Oceans and Marine Health. J. Field Actions 2019, 19, 54–61. [Google Scholar]

- Nelms, S.E.; Galloway, T.S.; Godley, B.J.; Jarvis, D.S.; Lindeque, P.K. Investigating Microplastic Trophic Transfer in Marine Top Predators. Environ. Pollut. 2018, 238, 999–1007. [Google Scholar] [CrossRef]

- Mohamed Nor, N.H.; Kooi, M.; Diepens, N.J.; Koelmans, A.A. Lifetime Accumulation of Microplastic in Children and Adults. Environ. Sci. Technol. 2021, 55, 5084–5096. [Google Scholar] [CrossRef] [PubMed]

- Koelmans, A.A.; Redondo-Hasselerharm, P.E.; Nor, N.H.M.; de Ruijter, V.N.; Mintenig, S.M.; Kooi, M. Risk Assessment of Microplastic Particles. Nat. Rev. Mater. 2022, 7, 138–152. [Google Scholar] [CrossRef]

- OECD. Plastic Waste Projections to 2060; OECD Publishing: Paris, France, 2022; ISBN 9789264973640. [Google Scholar]

- Bertotto, C.; Bilck, A.P.; Yamashita, F.; Anjos, O.; Bakar Siddique, M.A.; Harrison, S.M.; Brunton, N.P.; Carpes, S.T. Development of a Biodegradable Plastic Film Extruded with the Addition of a Brazilian Propolis By-Product. LWT 2022, 157, 113124. [Google Scholar] [CrossRef]

- Fabijanski, M. Mechanical Properties of Polylactide Filled with Micronized Chalcedonite. J. Compos. Sci. 2022, 6, 387. [Google Scholar] [CrossRef]

- Colivet, J.; Carvalho, R.A. Hydrophilicity and Physicochemical Properties of Chemically Modified Cassava Starch Films. Ind. Crop. Prod. 2017, 95, 599–607. [Google Scholar] [CrossRef]

- Freitas, P.A.V.; González-Martínez, C.; Chiralt, A. Antioxidant Starch Composite Films Containing Rice Straw Extract and Cellulose Fibres. Food Chem. 2023, 400, 134073. [Google Scholar] [CrossRef] [PubMed]

- Ray, R.; Narayan Das, S.; Das, A. Mechanical, Thermal, Moisture Absorption and Biodegradation Behaviour of Date Palm Leaf Reinforced PVA/Starch Hybrid Composites. Mater. Today Proc. 2021, 41, 376–381. [Google Scholar] [CrossRef]

- Ojogbo, E.; Ogunsona, E.O.; Mekonnen, T.H. Chemical and Physical Modifications of Starch for Renewable Polymeric Materials. Mater. Today Sustain. 2020, 7–8, 100028. [Google Scholar] [CrossRef]

- A’yun, A.Q.; Bintoro, N. The Effect of Starch Proportion in Coating Materials and Storage Temperatures on The Physical Qualities of Curly Green Chili (Capsicum annuum L). IOP Conf. Ser. Earth Environ. Sci. 2021, 828, 012040. [Google Scholar] [CrossRef]

- Castro, J.I.; Navia-Porras, D.P.; Arbeláez Cortés, J.A.; Mina Hernández, J.H.; Grande-Tovar, C.D. Synthesis, Characterization, and Optimization Studies of Starch/Chicken Gelatin Composites for Food-Packaging Applications. Molecules 2022, 27, 2264. [Google Scholar] [CrossRef]

- Cui, C.; Ji, N.; Wang, Y.; Xiong, L.; Sun, Q. Bioactive and Intelligent Starch-Based Films: A Review. Trends Food Sci. Technol. 2021, 116, 854–869. [Google Scholar] [CrossRef]

- Kurdziel, M.; Łabanowska, M.; Pietrzyk, S.; Pająk, P.; Królikowska, K.; Szwengiel, A. The Effect of UV-B Irradiation on Structural and Functional Properties of Corn and Potato Starches and Their Components. Carbohydr. Polym. 2022, 289, 119439. [Google Scholar] [CrossRef]

- Pająk, P.; Gałkowska, D.; Juszczak, L.; Khachatryan, G. Octenyl Succinylated Potato Starch-Based Film Reinforced by Honey-Bee Products: Structural and Functional Properties. Food Packag. Shelf Life 2022, 34, 100995. [Google Scholar] [CrossRef]

- da Fonseca de Albuquerque, M.D.; Bastos, D.C.; Ţălu, Ş.; Matos, R.S.; Pires, M.A.; Salerno, M.; da Fonseca Filho, H.D.; Simão, R.A. Vapor Barrier Properties of Cold Plasma Treated Corn Starch Films. Coatings 2022, 12, 1006. [Google Scholar] [CrossRef]

- Ramakrishnan, R.; Kulandhaivelu, S.V.; Roy, S.; Viswanathan, V.P. Characterisation of Ternary Blend Film of Alginate/Carboxymethyl Cellulose/Starch for Packaging Applications. Ind. Crop. Prod. 2023, 193, 116114. [Google Scholar] [CrossRef]

- Mascarenhas, A.R.P.; Scatolino, M.V.; dos Santos, A.D.A.; Norcino, L.B.; Duarte, P.J.; de Melo, R.R.; Dias, M.C.; de Faria, C.E.T.; Mendonça, M.C.; Tonoli, G.H.D. Does the Addition of Cellulosic Micro/Nanofibrils Improve the Properties of Hydroxypropyl Methylcellulose Films? Res. Sq. 2021, 1–35. [Google Scholar] [CrossRef]

- Vera-Loor, A.; Rigou, P.; Marlin, N.; Mortha, G.; Dufresne, A. Oxidation Treatments to Convert Paper-Grade Eucalyptus Kraft Pulp into Microfibrillated Cellulose. Carbohydr. Polym. 2022, 296, 119946. [Google Scholar] [CrossRef]

- Magdalena González-Pérez, M.; Manríquez-González, R.; Ramón Robledo-Ortíz, J.; Antonio Silva-Guzmán, J.; Bolzon de Muniz, G.I.; Guadalupe Lomelí-Ramírez, M.; Guadalupe Lomelí, M. Old Corrugated Container (OCC) Cardboard Material: An Alternative Source for Obtaining Microfibrillated Cellulose. J. Nat. Fibers 2022, 19, 9296–9308. [Google Scholar] [CrossRef]

- Dufresne, A. Preparation of Microfibrillated Cellulose. In Nanocellulose: From Nature to High Performance Tailored Materials; De Gruyter, Inc.: Grenoble, France, 2012; pp. 43–82. ISBN 9783110254600. [Google Scholar]

- Li, K.; Mcgrady, D.; Zhao, X.; Ker, D.; Tekinalp, H.; He, X.; Qu, J.; Aytug, T.; Cakmak, E.; Phipps, J.; et al. Surface-Modified and Oven-Dried Microfibrillated Cellulose Reinforced Biocomposites: Cellulose Network Enabled High Performance. Carbohydr. Polym. 2021, 256, 117525. [Google Scholar] [CrossRef]

- Fotie, G.; Gazzotti, S.; Ortenzi, M.A.; Limbo, S.; Piergiovanni, L. Performance Comparison of Coatings Based on Cellulose Nanocrystals and Microfibrillated Cellulose for Food Packaging. Carbohydr. Polym. Technol. Appl. 2023, 5, 100264. [Google Scholar] [CrossRef]

- Wei, X.; Tang, J.; Tao, H.; Gao, W.; Guo, L.; Cui, B.; Liu, P.; Lu, L.; Wu, Z.; Fang, Y.; et al. Correlation between Interfacial Adhesion and Functional Properties of Corn Stalk Cellulose-Reinforced Corn Starch-Based Biodegradable Straws. Ind. Crop. Prod. 2022, 189, 115881. [Google Scholar] [CrossRef]

- Guan, Y.; Bai, M.; Li, Q.; Li, W.; Liu, G.; Liu, C.; Chen, Y.; Lin, Y.; Hui, Y.; Wei, R. A Plantar Wearable Pressure Sensor Based on Hybrid Lead Zirconate-Titanate/Microfibrillated Cellulose Piezoelectric Composite Films for Human Health Monitoring. Lab A Chip 2022, 22, 2376. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Kainuma, K.; French, D. Electron Microscopic Observations of Waxy Maize Starch. J. Ultrastruct. Res. 1979, 69, 249–261. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Gao, C.; Li, Y.; Meng, F.; Wang, S.; Kong, F. Investigating the Effect of Different Substitution Levels of Starch Carbamate on Composite Film Properties. Ind. Crop. Prod. 2023, 192, 116024. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Zeng, Y.; Hossen, M.A.; Dai, J.; Li, S.; Liu, Y.; Qin, W. Development and Characterization of Potato Starch/Lactucin/Nano-TiO2 Food Packaging for Sustained Prevention of Mealworms. Food Packag. Shelf Life 2022, 33, 100837. [Google Scholar] [CrossRef]

- Zhao, S.; Jia, R.; Yang, J.; Dai, L.; Ji, N.; Xiong, L.; Sun, Q. Development of Chitosan/Tannic Acid/Corn Starch Multifunctional Bilayer Smart Films as PH-Responsive Actuators and for Fruit Preservation. Int. J. Biol. Macromol. 2022, 205, 419–429. [Google Scholar] [CrossRef] [PubMed]

- Fitch-Vargas, P.R.; Aguilar-Palazuelos, E.; de Jesús Zazueta-Morales, J.; Vega-García, M.O.; Valdez-Morales, J.E.; Martínez-Bustos, F.; Jacobo-Valenzuela, N. Physicochemical and Microstructural Characterization of Corn Starch Edible Films Obtained by a Combination of Extrusion Technology and Casting Technique. J. Food Sci. 2016, 81, E2224–E2232. [Google Scholar] [CrossRef] [PubMed]

- Thiré, R.M.S.M.; Simão, R.A.; Andrade, C.T. High Resolution Imaging of the Microstructure of Maize Starch Films. Carbohydr. Polym. 2003, 54, 149–158. [Google Scholar] [CrossRef]

- Dai, L.; Zhang, J.; Cheng, F. Effects of Starches from Different Botanical Sources and Modification Methods on Physicochemical Properties of Starch-Based Edible Films. Int. J. Biol. Macromol. 2019, 132, 897–905. [Google Scholar] [CrossRef] [PubMed]

- Żołek-Tryznowska, Z.; Holica, J. Starch Films as an Environmentally Friendly Packaging Material: Printing Performance. J. Clean. Prod. 2020, 276, 124265. [Google Scholar] [CrossRef]

- Kruszewski, S.; Kobiela, T. AFM and Optical Investigations of SERS-Active Silver Electrodes. Vacuum 1999, 54, 245–249. [Google Scholar] [CrossRef]

- De Albuquerque, M.D.F.; Bastos, D.C.; Simão, R.A. Surface Modification of Starch Films by Plasma. Macromol. Symp. 2014, 343, 96–101. [Google Scholar] [CrossRef]

- Popa, M.S.; Frone, A.N.; Radu, I.C.; Stanescu, P.O.; Truşcă, R.; Rădiţoiu, V.; Nicolae, C.A.; Gabor, A.R.; Panaitescu, D.M. Microfibrillated Cellulose Grafted with Metacrylic Acid as a Modifier in Poly(3-Hydroxybutyrate). Polymers 2021, 13, 3970. [Google Scholar] [CrossRef] [PubMed]

- Sudheesh, C.; Valiyapeediyekkal Sunooj, K.; Aaliya, B.; Navaf, M.; Parambil Akhila, P.; Ahmad Mir, S.; Sabu, S.; Sasidharan, A.; Pulissery Sudheer, K.; Kumar Sinha, S.; et al. Effect of Energetic Neutrals on the Kithul Starch Retrogradation; Potential Utilization for Improving Mechanical and Barrier Properties of Films. Food Chem. 2023, 398, 133881. [Google Scholar] [CrossRef] [PubMed]

- Woch, J.; Małachowska, E.; Korasiak, K.; Lipkiewicz, A.; Dubowik, M.; Chrobak, J.; Iłowska, J.; Przybysz, P. Barrier Dispersion-Based Coatings Containing Natural and Paraffin Waxes. Molecules 2022, 27, 930. [Google Scholar] [CrossRef]

- Ollé Resa, C.P.; Jagus, R.J.; Gerschenson, L.N. Effect of Natamycin, Nisin and Glycerol on the Physicochemical Properties, Roughness and Hydrophobicity of Tapioca Starch Edible Films. Mater. Sci. Eng. C 2014, 40, 281–287. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Zong, L.; Wang, J.; Xie, J. Microfibrillated Cellulose Reinforced Starch/Polyvinyl Alcohol Antimicrobial Active Films with Controlled Release Behavior of Cinnamaldehyde. Carbohydr. Polym. 2021, 272, 118448. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Jiang, S.; Zhang, S.; Xi, T.; Sun, Q.; Xiong, L. Characterization of Edible Corn Starch Nanocomposite Films: The Effect of Self-Assembled Starch Nanoparticles. Starch-Stärke 2016, 68, 239–248. [Google Scholar] [CrossRef]

- Chavan, P.; Sinhmar, A.; Sharma, S.; Dufresne, A.; Thory, R.; Kaur, M.; Sandhu, K.S.; Nehra, M.; Nain, V. Nanocomposite Starch Films: A New Approach for Biodegradable Packaging Materials. Starch-Stärke 2022, 74, 2100302. [Google Scholar] [CrossRef]

- Dastidar, T.G.; Netravali, A. Cross-Linked Waxy Maize Starch-Based “Green” Composites. ACS Sustain. Chem. Eng. 2013, 1, 1537–1544. [Google Scholar] [CrossRef]

- Sganzerla, W.G.; Rosa, G.B.; Ferreira, A.L.A.; da Rosa, C.G.; Beling, P.C.; Xavier, L.O.; Hansen, C.M.; Ferrareze, J.P.; Nunes, M.R.; Barreto, P.L.M.; et al. Bioactive Food Packaging Based on Starch, Citric Pectin and Functionalized with Acca Sellowiana Waste by-Product: Characterization and Application in the Postharvest Conservation of Apple. Int. J. Biol. Macromol. 2020, 147, 295–303. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the Surface Free Energy of Polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Velásquez-Castillo, L.E.; Leite, M.A.; Tisnado, V.J.A.; Ditchfield, C.; Sobral, P.J.D.A.; Moraes, I.C.F. Cassava Starch Films Containing Quinoa Starch Nanocrystals: Physical and Surface Properties. Foods 2023, 12, 576. [Google Scholar] [CrossRef]

| Run | Film Abbreviation | Starch (g) | MFC (g) |

|---|---|---|---|

| 1 | S_0 | 10.00 | − |

| 2 | S_0.2 | 10.04 | 0.22 |

| 3 | S_0.6 | 10.02 | 0.66 |

| 4 | S_1 | 10.04 | 1.02 |

| 5 | S_2 | 10.06 | 2.06 |

| 6 | S_3 | 10.06 | 3.01 |

| 7 | S_4 | 10.02 | 4.04 |

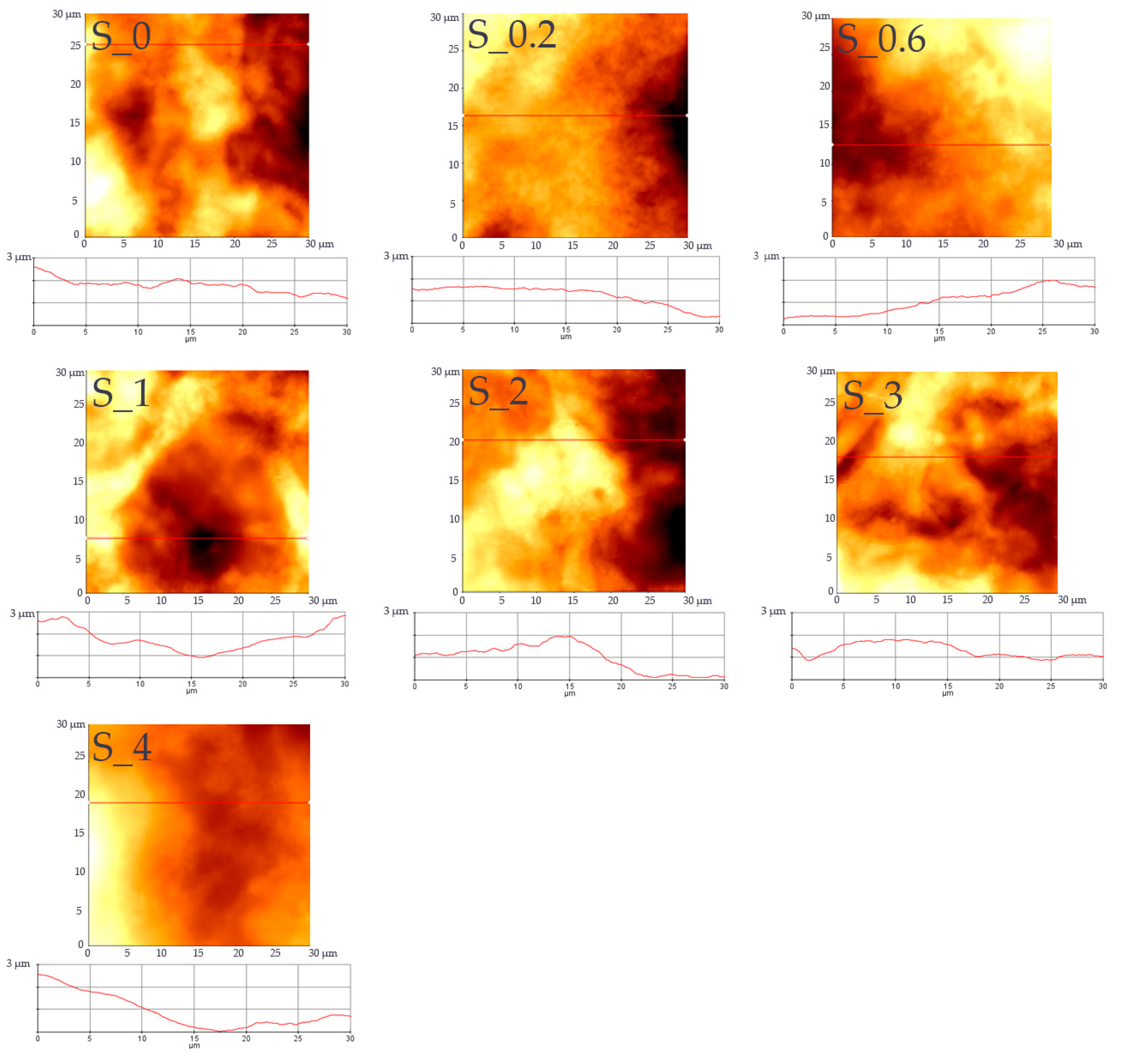

| Film | Ra in μm |

|---|---|

| S_0 | 1.44 ± 0.59 ab |

| S_0.2 | 2.07 ± 1.05 abc |

| S_0.6 | 2.89 ± 1.27 a |

| S_1 | 1.14 ± 0.42 a |

| S_2 | 2.89 ± 0.59 bc |

| S_3 | 2.52 ± 1.19 abc |

| S_4 | 2.32 ± 1.13 c |

| Film | WCA * (°) | Surface Free Energy (mJ·m−2) | ||

|---|---|---|---|---|

| Polar | Dispersive | Total | ||

| S_0 | 70.3 ± 2.4 c | 7.8 ± 2.8 a | 38.3 ± 2.1 a | 46.2 ± 3.4 a |

| S_0.2 | 55.9 ± 1.3 b | 13.5 ± 1.6 b | 42.8 ± 1.5 bc | 56.4 ± 2.2 b |

| S_0.6 | 52.2 ± 1.5 b | 16.2 ± 2.0 b | 41.3 ± 1.0 b | 57.5° ± 2.2 b |

| S_1 | 51.9 ± 0.9 b | 15.7 ± 1.4 b | 42.9 ± 0.9 bc | 58.6 ± 1.2 b |

| S_2 | 52.8 ± 1.3 b | 16.0 ± 2.4 b | 41.0 ± 2.0 b | 57.0 ± 1.4 b |

| S_3 | 40.3 ± 0.4 a | 22.8 ± 0.7 c | 41.4 ± 0.5 b | 64.2 ± 0.5 c |

| S_4 | 39.1 ± 1.0 a | 22.2 ± 1.1 c | 44.0 ± 0.6 c | 66.2 ± 1.5 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żołek-Tryznowska, Z.; Bednarczyk, E.; Tryznowski, M.; Kobiela, T. A Comparative Investigation of the Surface Properties of Corn-Starch-Microfibrillated Cellulose Composite Films. Materials 2023, 16, 3320. https://doi.org/10.3390/ma16093320

Żołek-Tryznowska Z, Bednarczyk E, Tryznowski M, Kobiela T. A Comparative Investigation of the Surface Properties of Corn-Starch-Microfibrillated Cellulose Composite Films. Materials. 2023; 16(9):3320. https://doi.org/10.3390/ma16093320

Chicago/Turabian StyleŻołek-Tryznowska, Zuzanna, Ewa Bednarczyk, Mariusz Tryznowski, and Tomasz Kobiela. 2023. "A Comparative Investigation of the Surface Properties of Corn-Starch-Microfibrillated Cellulose Composite Films" Materials 16, no. 9: 3320. https://doi.org/10.3390/ma16093320

APA StyleŻołek-Tryznowska, Z., Bednarczyk, E., Tryznowski, M., & Kobiela, T. (2023). A Comparative Investigation of the Surface Properties of Corn-Starch-Microfibrillated Cellulose Composite Films. Materials, 16(9), 3320. https://doi.org/10.3390/ma16093320