Oxidation Behavior of (Mo,Hf)Si2-Al2O3 Coating on Mo-Based Alloy at Elevated Temperature

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Oxidation Test and Characterization

3. Results and Discussion

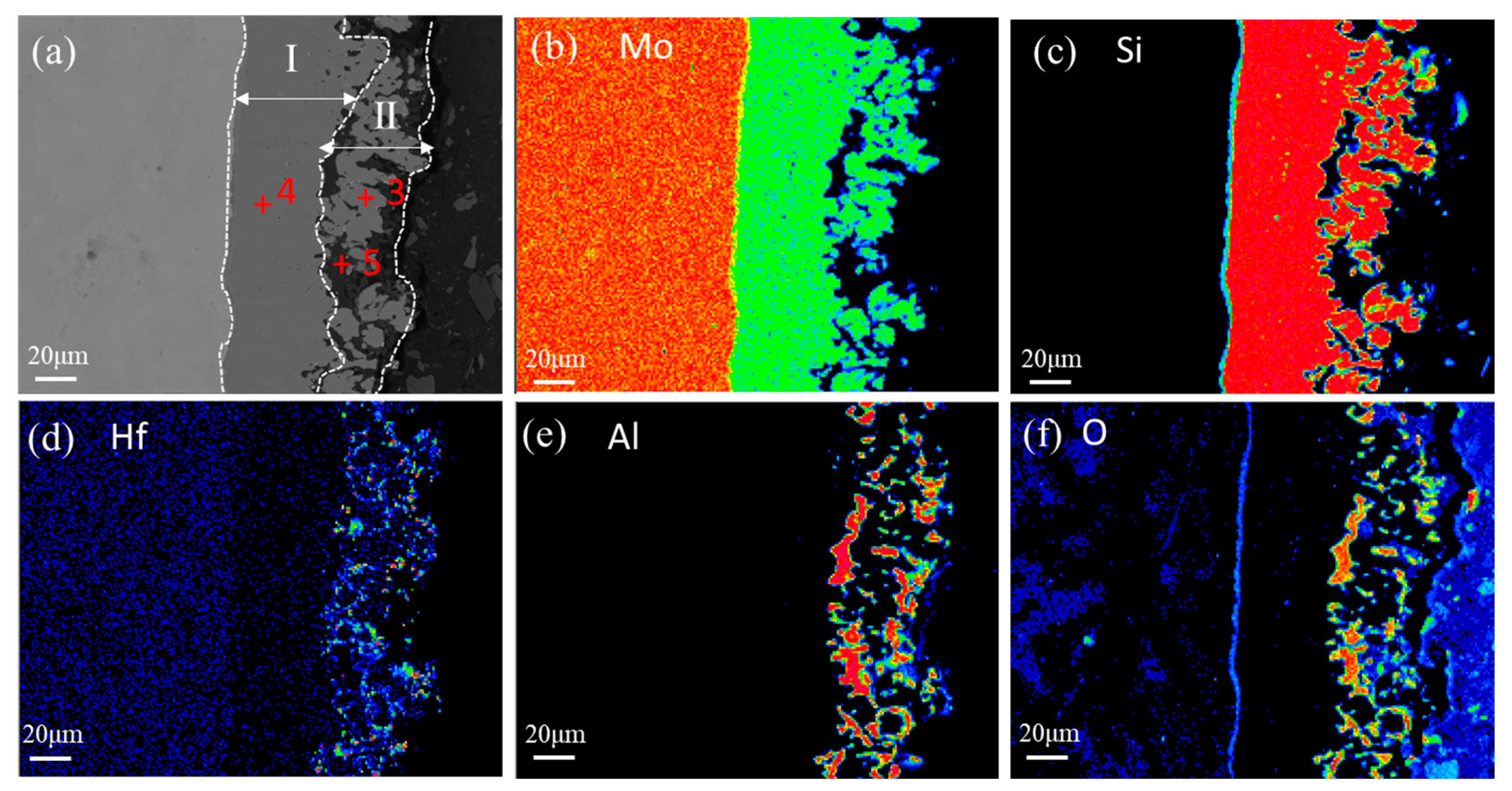

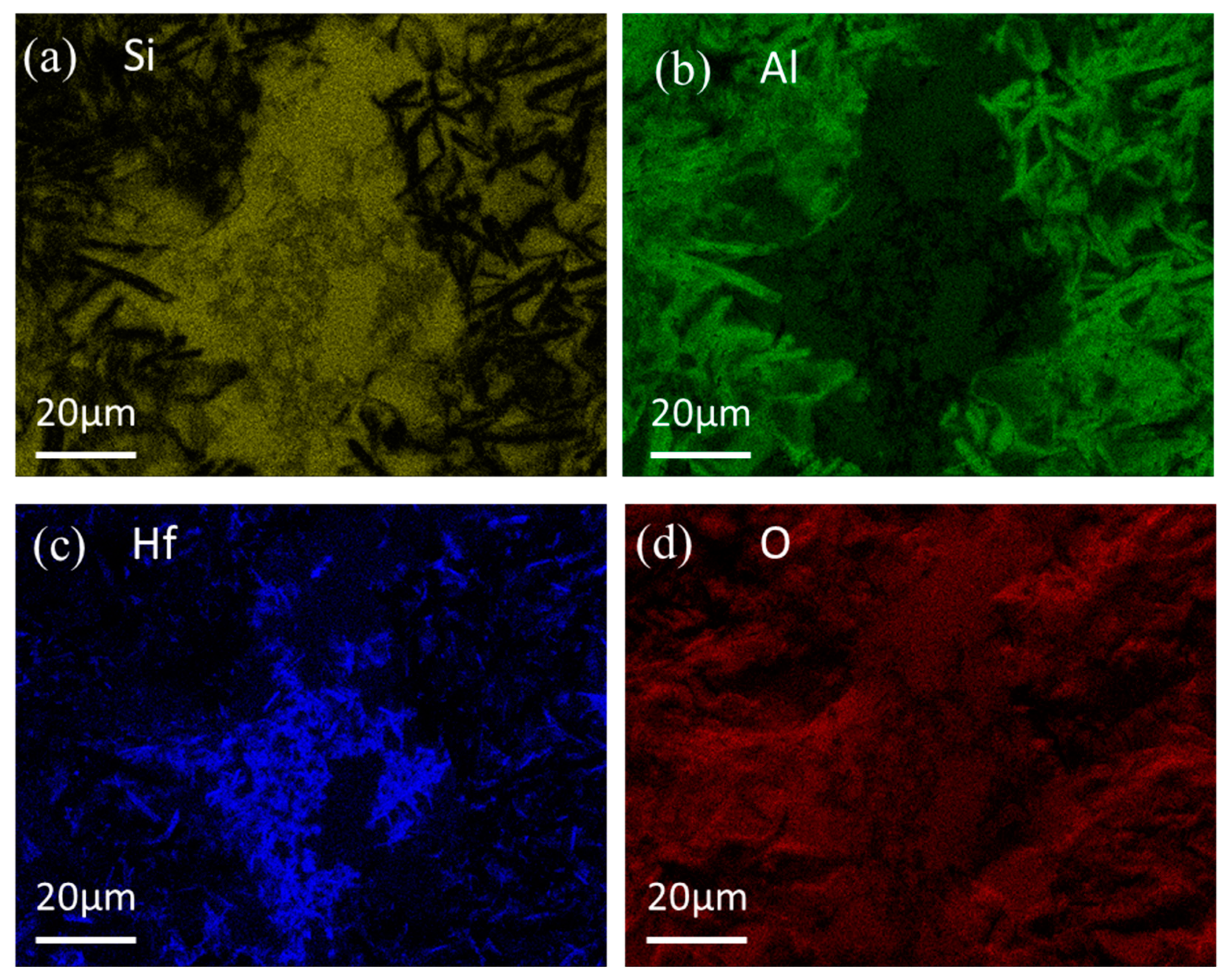

3.1. Microstructure and Phase Composition of the Coating

| Spot | Composition (at.%) | Main Phase | ||||

|---|---|---|---|---|---|---|

| Mo | Hf | Si | Al | O | ||

| 1 | 0.29 | 0.05 | 0.61 | 39.42 | 59.63 | Al2O3 |

| 2 | 30.83 | 2.09 | 63.06 | 1.17 | 2.85 | (Mo,Hf)Si2 |

| 3 | 31.55 | 1.62 | 64.43 | 0.83 | 1.57 | (Mo,Hf)Si2 |

| 4 | 32.32 | - | 67.25 | 0.15 | 0.28 | MoSi2 |

| 5 | 0.51 | 0.04 | 0.84 | 38.90 | 59.71 | Al2O3 |

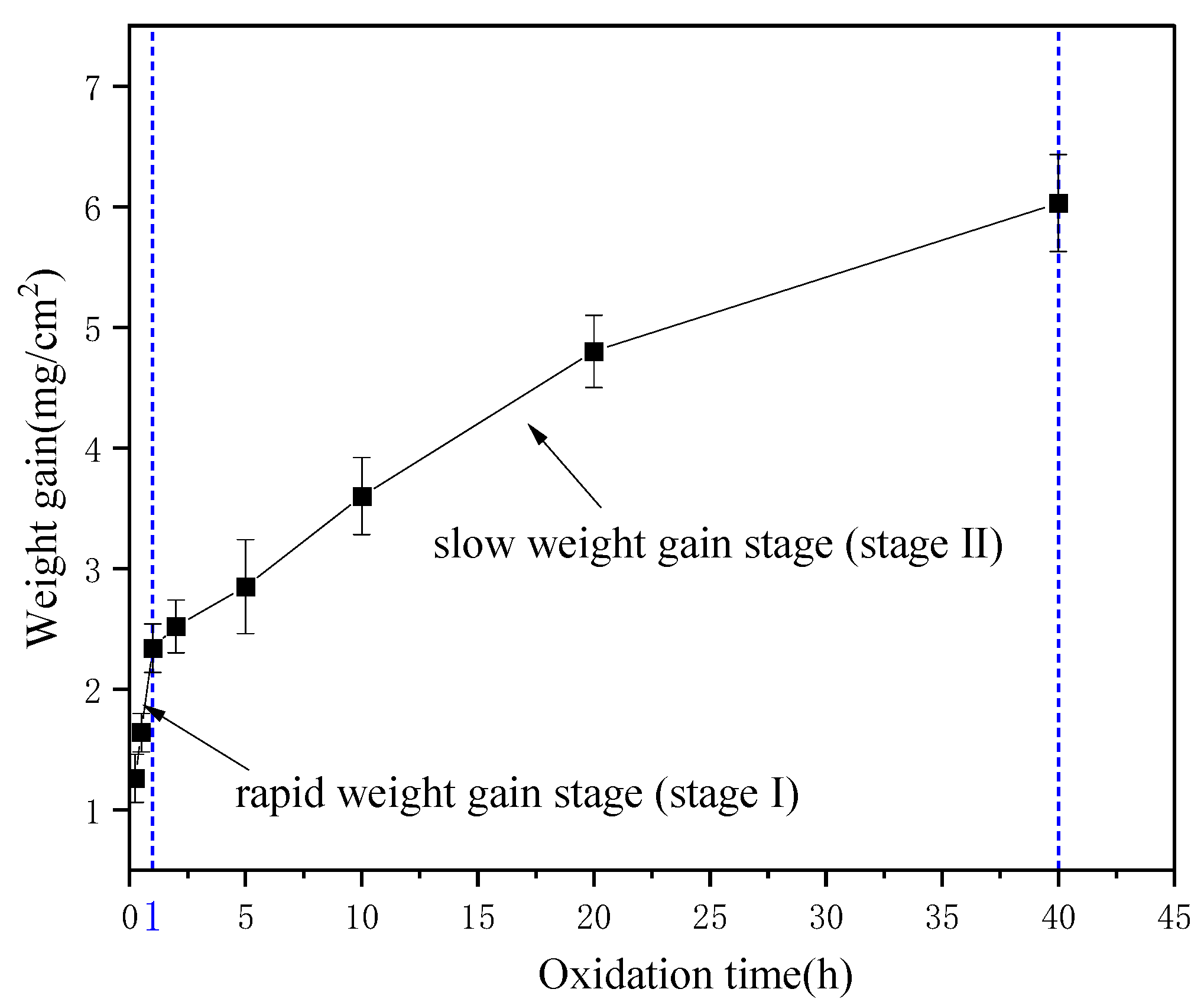

3.2. Oxidation Behavior of the Coating

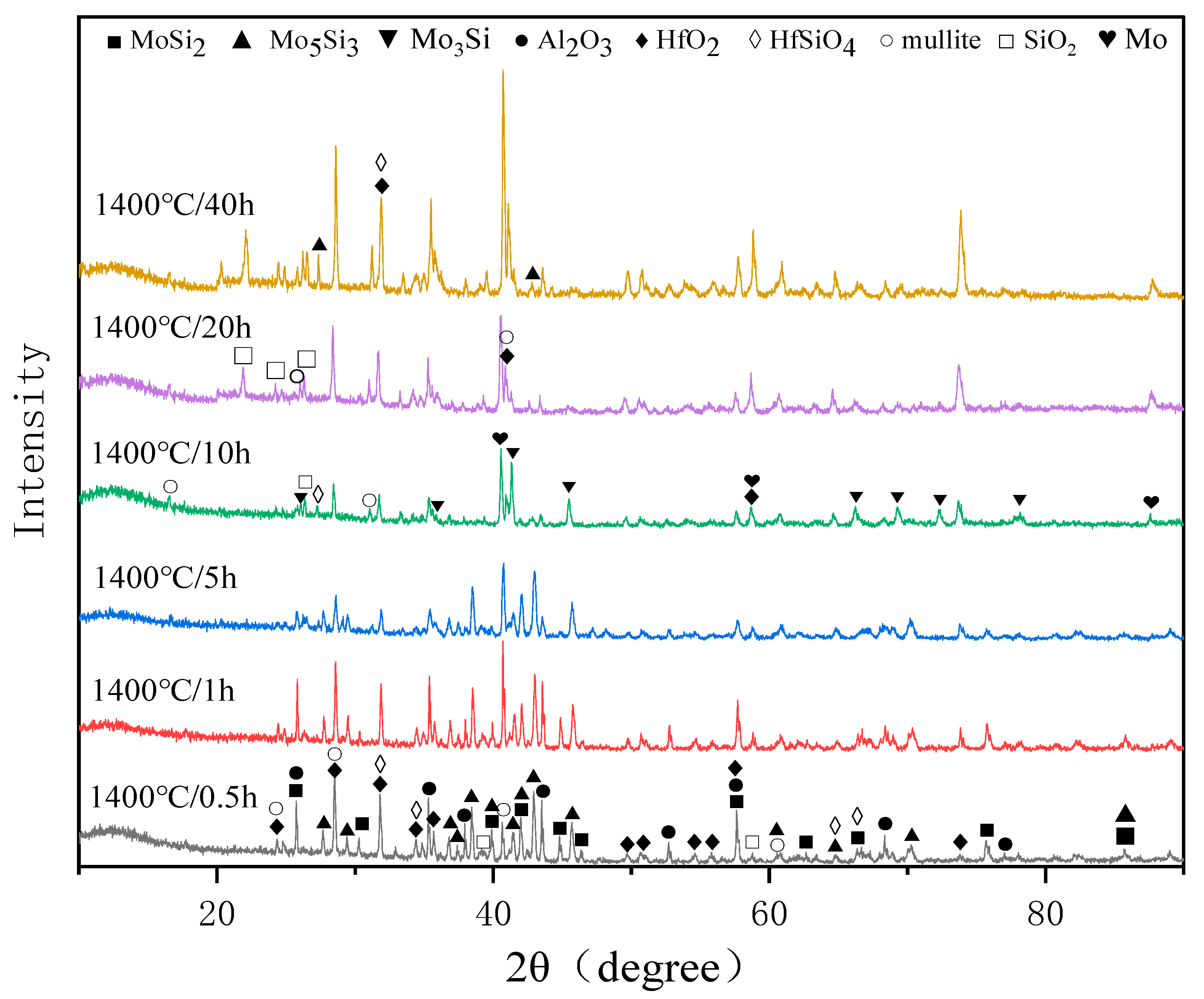

3.3. Phase Composition of the Oxidized Coating

3.4. Microstructure Evolution of the Coating during Oxidation

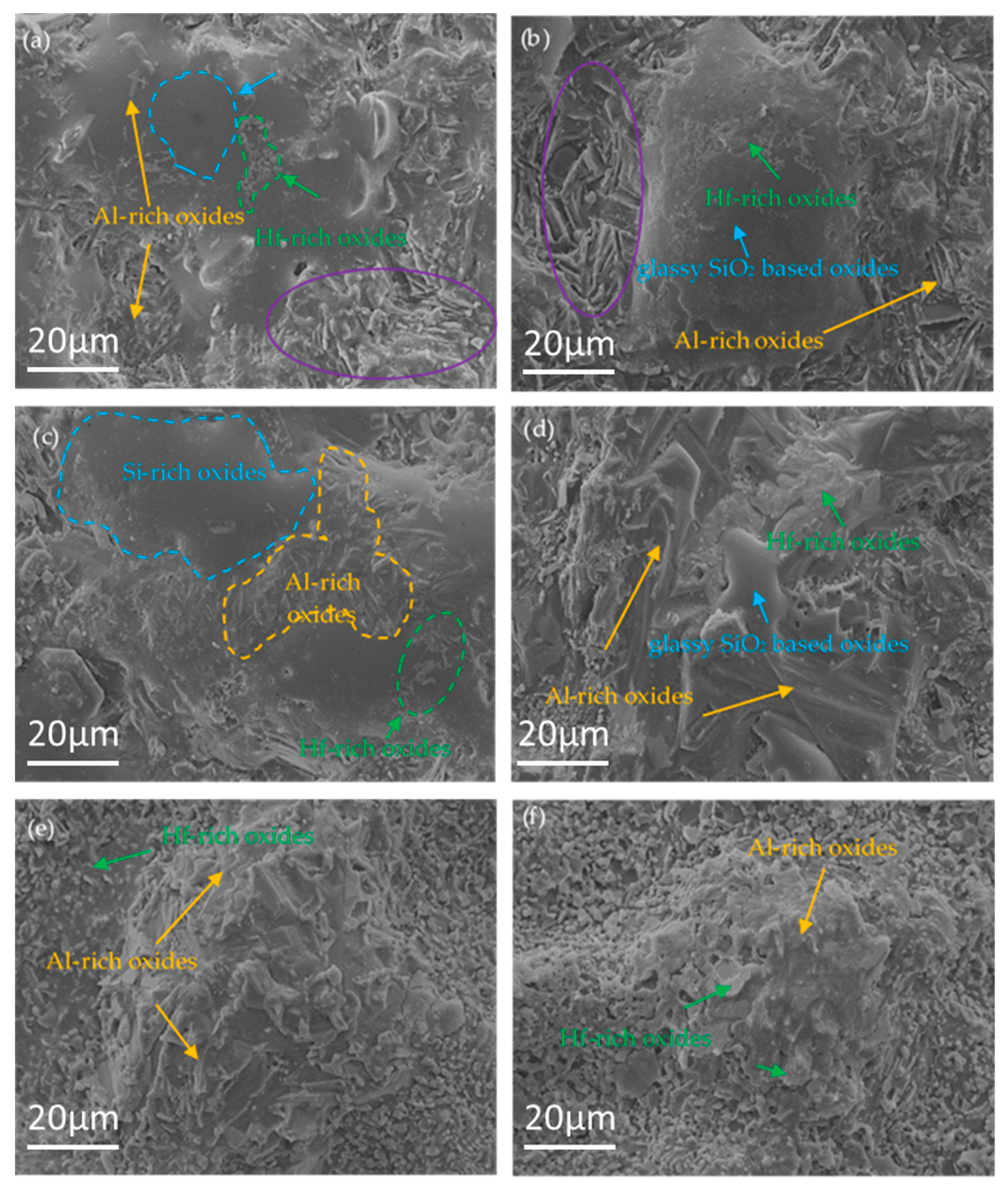

3.4.1. Surface Morphology

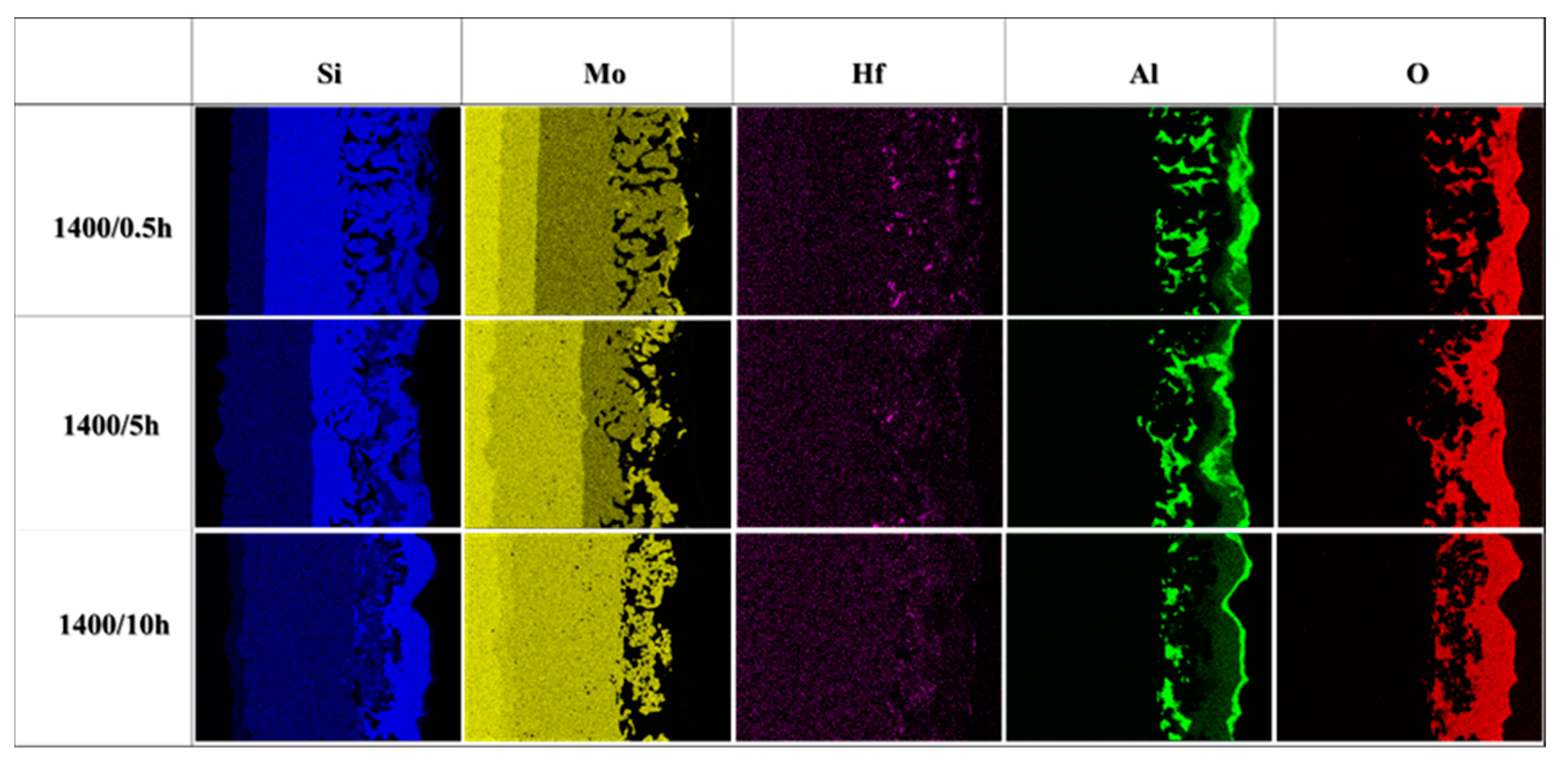

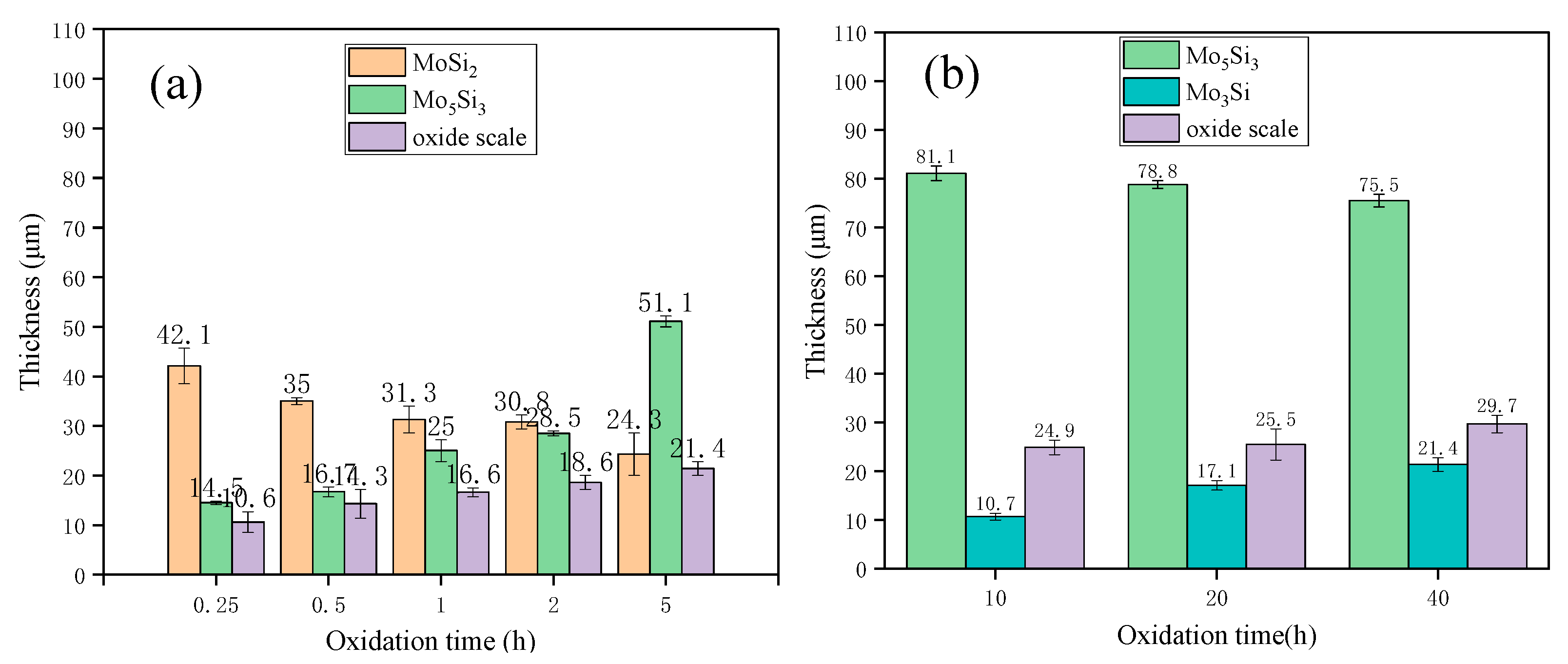

3.4.2. Cross-Sectional Microstructure

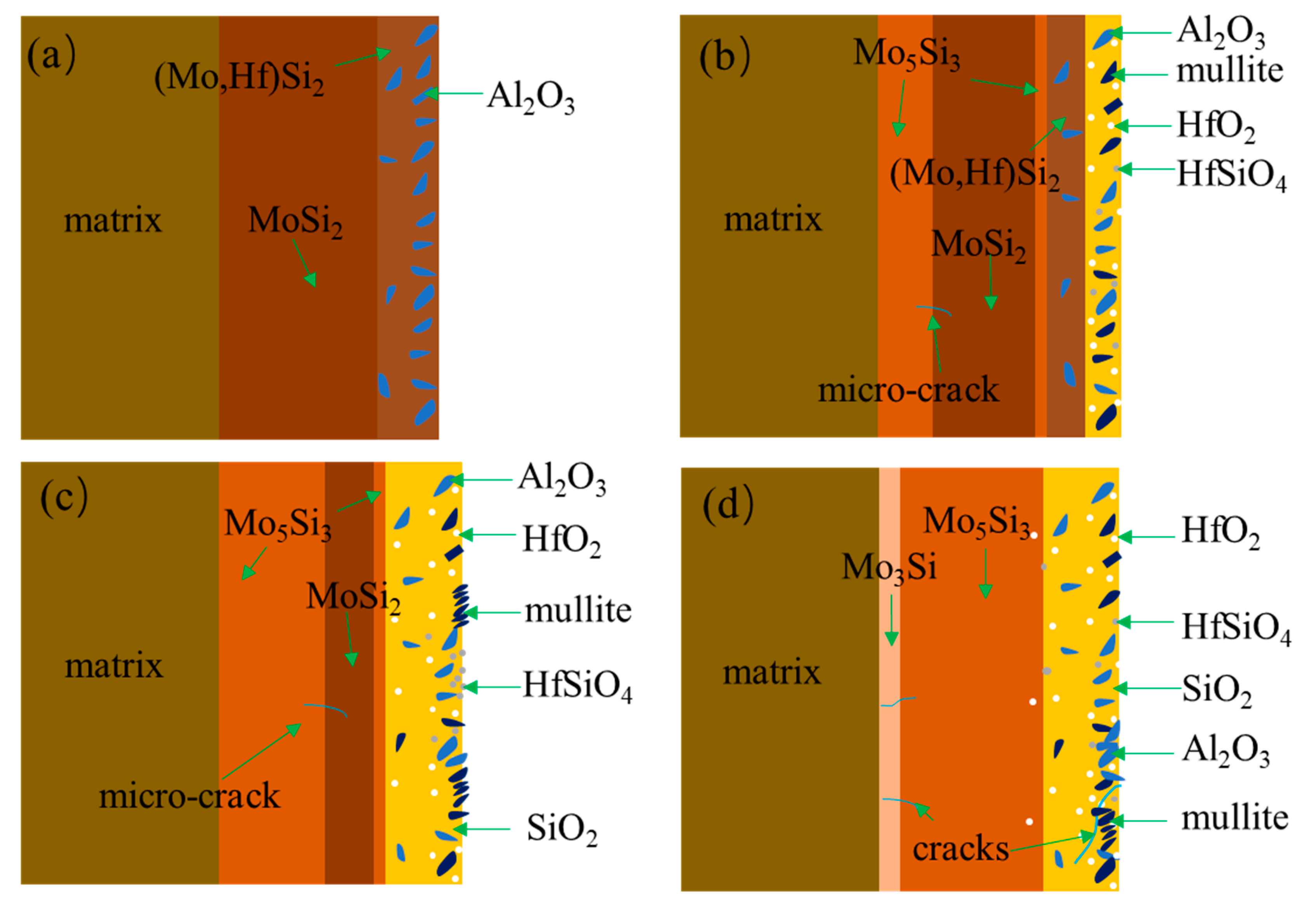

3.5. Antioxidation Mechanism of the Composite Coating

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jing, K.; Cheng, X.; Liu, R.; Xie, X.; Xie, Z.; Wu, X.; Wang, H.; Li, G.; Fang, Q.; Liu, C.; et al. Enhanced mechanical properties and thermal stability of hot-rolled Mo-0.5%ZrC alloy. Mater. Sci. Eng. A 2022, 854, 143803. [Google Scholar] [CrossRef]

- Hu, P.; Zhou, Y.; Chang, T.; Yu, Z.; Wang, K.; Yang, F.; Hu, B.; Cao, W.; Yu, H. Investigation on compression behavior of TZM and La 2 O 3 doped TZM Alloys at high temperature. Mater. Sci. Eng. A 2017, 687, 276–280. [Google Scholar] [CrossRef]

- Zhai, R.; Song, P.; Huang, T.; Li, C.; Hua, C.; Huang, W.; Li, Q.; Zheng, B.; Lu, J. Microstructure and oxidation behaviour of MoSi2 coating combined MoB diffusion barrier layer on Mo substrate at 1300 °C. Ceram. Int. 2022, 47, 10137–10146. [Google Scholar] [CrossRef]

- Zhang, Y.; Tu, T.; Yu, L.; Shen, F.; Wang, J.; Cui, K. Improving oxidation resistance of TZM alloy by deposited Si-MoSi2 composite coating with high silicon concentration. Ceram. Int. 2022, 48, 20895–20904. [Google Scholar] [CrossRef]

- Liu, Z.; Li, W.; Fan, J.; Lv, Y.; Wang, Z.; Zhao, X. High temperature oxidation behavior of MoSi2–Al2O3 composite coating on TZM alloy. Ceram. Int. 2022, 48, 10911–10920. [Google Scholar] [CrossRef]

- Smolik, G.R.; Petti, D.A.; Schuetz, S.T. Oxidation and volatilization of TZM alloy in air. J. Nucl. Mater. 2000, 283, 1458–1462. [Google Scholar] [CrossRef]

- Yang, F.; Wang, K.-S.; Hu, P.; He, H.-C.; Kang, X.-Q.; Wang, H.; Liu, R.-Z.; Volinsky, A.A. La doping effect on TZM alloy oxidation behavior. J. Alloys Compd. 2014, 593, 196–201. [Google Scholar] [CrossRef]

- Pan, Y.; Wang, S.; Zhang, X.; Jia, L. First-principles investigation of new structure, mechanical and electronic properties of Mo-based silicides. Ceram. Int. 2018, 44, 1744–1750. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, L.; Qiao, Y.; Gao, Q.; Xiao, Z. A new C11b-type high entropy refractory metal silicide to improve MoSi2 mechanical properties more easily. Scr. Mater. 2022, 218, 114798. [Google Scholar] [CrossRef]

- Pinto, B.A.; D’Oliveira, A.S.C. Nb silicide coatings processed by double pack cementation: Formation mechanisms and stability. Surf. Coat. Technol. 2021, 409, 126913. [Google Scholar] [CrossRef]

- Sun, J.; Li, T.; Zhang, G.-P.; Fu, Q.-G. Different oxidation protection mechanisms of HAPC silicide coating on niobium alloy over a large temperature range. J. Alloys Compd. 2019, 790, 1014–1022. [Google Scholar] [CrossRef]

- Xiao, L.; Xu, X.; Liu, S.; Shen, Z.; Huang, S.; Liu, W.; Peng, Y.; Huang, Y.; Liu, J.; Nie, Y.; et al. Oxidation behaviour and microstructure of a dense MoSi2 ceramic coating on Ta substrate prepared using a novel two-step process. J. Eur. Ceram. Soc. 2020, 40, 3555–3561. [Google Scholar] [CrossRef]

- Fu, T.; Zhang, Y.; Shen, F.; Cui, K.; Chen, L. Microstructure and oxidation behavior of Si-MoSi2 coating deposited on Mo substrate at 600 °C and 900 °C in static air. Mater. Charact. 2022, 192, 112192. [Google Scholar] [CrossRef]

- Knittel, S.; Mathieu, S.; Vilasi, M. The oxidation behaviour of uniaxial hot pressed MoSi2 in air from 400 to 1400 °C. Intermetallics 2011, 19, 1207–1215. [Google Scholar] [CrossRef]

- Zhu, L.; Ren, X.; Wang, G.; Kang, X.; Zhang, P.; Wang, X.; Feng, P. Preparation and 1500 °C oxidation behavior of crack-free bentonite doped MoSi2 protective coating on molybdenum. Corros. Sci. 2021, 184, 109379. [Google Scholar] [CrossRef]

- Zhang, C.; Feng, H.; Zheng, Z.; Ning, L.; Tong, J.; Tan, Z.; Liu, E. Preparation and corrosion behavior of the Al-modified MoSi2/Al2O3 coating on the surface of molybdenum metal core. Corros. Sci. 2021, 193, 109879. [Google Scholar] [CrossRef]

- Fei, X.; Niu, Y.; Ji, H.; Huang, L.; Zheng, X. Oxidation behavior of Al2O3 reinforced MoSi2 composite coatings fabricated by vacuum plasma spraying. Ceram. Int. 2010, 36, 2235–2239. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.; Sytchenko, A.D.; Sviridova, T.A.; Sidorenko, D.A.; Andreev, N.V.; Klechkovskaya, V.V.; Polčak, J.; Levashov, E.A. Effects of doping with Zr and Hf on the structure and properties of Mo-Si-B coatings obtained by magnetron sputtering of composite targets. Surf. Coat. Technol. 2022, 442, 128141. [Google Scholar] [CrossRef]

- Zhu, L.; Ren, X.; Wang, X.; Kang, X.; Zheng, R.; Feng, P. Microstructure and high-temperature oxidation resistance of MoSi2-ZrO2 composite coatings for Niobium substrate. J. Eur. Ceram. Soc. 2021, 41, 1197–1210. [Google Scholar] [CrossRef]

- Wang, J.; Yang, K.; Wang, J.; Yang, S.; Zhang, X. The enhanced structure stability and the reinforcement mechanism of 0.1Al2O3-ZrO2 reinforced MoSi2 composite coating. Surf. Coat. Technol. 2020, 403, 126438. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, X.; Ren, X.; Zhang, P.; Akhtar, F.; Feng, P. Preparation, properties and high-temperature oxidation resistance of MoSi2-HfO2 composite coating to protect niobium using spent MoSi2-based materials. Ceram. Int. 2021, 47, 27091–27099. [Google Scholar] [CrossRef]

- Cai, Z.; Wu, Y.; Liu, H.; Tian, G.; Pu, R.; Piao, S.; Tang, X.; Liu, S.; Zhao, X.; Xiao, L. Formation and oxidation resistance of a new YSZ modified silicide coating on Mo-based alloy. Mater. Des. 2018, 155, 463–474. [Google Scholar] [CrossRef]

- Zheng, J.; Hou, X.; Wang, X.; Meng, Y.; Zheng, X.; Zheng, L. Isothermal oxidation mechanism of a newly developed Nb-Ti-V-Cr-Al-W-Mo-Hf alloy at 800–1200 °C. Int. J. Refract. Met. Hard Mater. 2016, 54, 322–329. [Google Scholar] [CrossRef]

- Li, L.; Saber, M.; Xu, W.; Zhu, Y.; Koch, C.C.; Scattergood, R.O. High-temperature grain size stabilization of nanocrystalline Fe–Cr alloys with Hf additions. Mater. Sci. Eng. A 2014, 613, 289–295. [Google Scholar] [CrossRef]

- Taghvaei, A.H.; Shirazifard, N.G.; Ramasamy, P.; Bednarčik, J.; Eckert, J. Thermal behavior, structural relaxation and magnetic study of a new Hf-microalloyed Co-based glassy alloy with high thermal stability. J. Alloys Compd. 2018, 748, 553–560. [Google Scholar] [CrossRef]

- Grammenos, I.; Tsakiropoulos, P. Study of the role of Hf, Mo and W additions in the microstructure of Nb-20Si silicde based alloys. Intermetallics 2011, 19, 1612–1621. [Google Scholar] [CrossRef]

- Wei, L.; Peng, H.; Jia, F.; Zheng, L.; Gong, S.; Guo, H. Cyclic oxidation behavior of Hf/Zr co-doped EB-PVD β-NiAl coatings at 1200 °C. Surf. Coat. Technol. 2015, 276, 721–725. [Google Scholar] [CrossRef]

- Pint, B.A.; Haynes, J.A.; Besmann, T.M. Effect of Hf and Y alloy additions on aluminide coating performance. Surf. Coat. Technol. 2010, 204, 3287–3293. [Google Scholar] [CrossRef]

- Lu, J.; Li, L.; Chen, Y.; Liu, X.; Zhao, X.; Guo, F.; Xiao, P. Y-Hf co-doped AlCoCrFeNi high-entropy alloy coating with superior oxidation and spallation resistance at 1100 °C. Corros. Sci. 2021, 182, 109267. [Google Scholar] [CrossRef]

- Yue, G.; Guo, X.; Qiao, Y.; Luo, F. Isothermal oxidation and interdiffusion behavior of MoSi2/WSi2 compound coating on Nb-Ti-Si based alloy. Appl. Surf. Sci. 2020, 504, 144477. [Google Scholar] [CrossRef]

- Potanin, A.Y.; Vorotilo, S.; Pogozhev, Y.S.; Rupasov, S.I.; Loginov, P.A.; Shvyndina, N.V.; Sviridova, T.A.; Levashov, E.A. High-temperature oxidation and plasma torch testing of MoSi2–HfB2–MoB ceramics with single-level and two-level structure. Corros. Sci. 2019, 158, 108074. [Google Scholar] [CrossRef]

- Sciti, D.; Balbo, A.; Bellosi, A. Oxidation behaviour of a pressureless sintered HfB2–MoSi2 composite. J. Eur. Ceram. Soc. 2009, 29, 1809–1815. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sytchenko, A.D.; Potanin, A.Y.; Vorotilo, S.A.; Levashov, E.A. Mechanical properties and oxidation resistance of Mo-Si-B and Mo-Hf-Si-B coatings obtained by magnetron sputtering in DC and pulsed DC modes. Surf. Coat. Technol. 2020, 403, 126373. [Google Scholar]

- Wang, L.; Fu, Q.G.; Zhao, F. Improving oxidation resistance of MoSi2 coating by reinforced with Al2O3 whiskers. Intermetallics 2018, 94, 106–113. [Google Scholar] [CrossRef]

- Li, L.; Guo, X.; Qiao, Y. Formation and oxidation resistance of MoSi2 coating for Nb-Si based alloy prepared by slurry sintering method. J. Alloys Compd. 2023, 938, 168456. [Google Scholar] [CrossRef]

- Tian, X.; Guo, X.; Sun, Z.; Li, M.; Wang, L. Effects of Y2O3/Y on Si-B co-deposition coating prepared through HAPC method on pure molybdenum. J. Rare Earths 2016, 34, 952–957. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, X.; Feng, P.; Li, D.; Yang, T.; Akhta, F. Synthesis, microstructure and mechanical properties of (Mo,Ti)Si2/Al2O3 composites prepared by thermite-reaction-assisted combustion synthesis. J. Alloys Compd. 2016, 688, 870–877. [Google Scholar] [CrossRef]

- Cai, Z.; Liu, S.; Xiao, L.; Fang, Z.; Li, W.; Zhang, B. Oxidation behavior and microstructural evolution of a slurry sintered Si-Mo coating on Mo alloy at 1650 °C. Surf. Coat. Technol. 2017, 324, 182–189. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Zhou, X.; Zhao, G.; Liu, J.; Shen, H.; Cai, Z.; Zhao, X.; Xiao, L. Ultra-high temperature oxidation behavior of ZrB2/YSZ modified Si-Mo-W coating with a diffusion barrier on niobium alloy. Corros. Sci. 2022, 195, 109977. [Google Scholar] [CrossRef]

- Li, S.; Xiao, L.; Liu, S.; Zhang, Y.; Xu, J.; Zhou, X.; Zhao, G.; Cai, Z. Ultra-high temperature oxidation resistance of a novel (Mo,Hf,W,Ti)Si2 ceramic coating with Nb interlayer on Ta substrate. J. Eur. Ceram. Soc. 2022, 42, 4866–4880. [Google Scholar] [CrossRef]

- Hou, Q.; Shao, W.; Li, M.; Zhou, C. Interdiffusion behavior of Mo-Si-B/Al2O3 composite coating on Nb-Si based alloy. Surf. Coat. Technol. 2020, 401, 126243. [Google Scholar] [CrossRef]

- Su, L.; Lu-Steffes, O.; Zhang, H.; Perepezko, J.H. An ultra-high temperature Mo–Si–B based coating for oxidation protection of NbSS/Nb5Si3 composites. Appl. Surf. Sci. 2015, 337, 38–44. [Google Scholar] [CrossRef]

- Yue, G.; Guo, X.; Qiao, Y. Oxidation resistance and diffusion behavior of MoSi2/WSi2/(Nb,X)Si2 compound coating at 1400 °C. J. Alloys Compd. 2021, 870, 159498. [Google Scholar] [CrossRef]

| Time (h) | Phase Composition |

|---|---|

| 0.5, 1, 5 | MoSi2, Mo5Si3, mullite, Al2O3, HfO2, SiO2, HfSiO4 |

| 10, 20, 40 | Mo, Mo5Si3, Mo3Si, HfO2, Al2O3, SiO2, mullite, HfSiO4 |

| Spot | Composition (at.%) | Main Phase | ||||

|---|---|---|---|---|---|---|

| Mo | Hf | Si | Al | O | ||

| 1 | 58.92 | - | 39.84 | - | 1.24 | Mo5Si3 |

| 2 | 31.68 | 0.12 | 66.91 | - | 1.29 | MoSi2 |

| 3 | 29.69 | 0.26 | 66.93 | - | 3.12 | MoSi2 (Hf) |

| 4 | 55.87 | - | 40.02 | - | 4.11 | Mo5Si3 |

| 5 | - | 0.95 | 12.14 | 32.98 | 53.93 | SiO2, Al2O3, HfO2 |

| 6 | 62.20 | 23.88 | - | 13.92 | Mo3Si | |

| 7 | 53.65 | - | 36.46 | - | 09.89 | Mo5Si3 |

| 8 | 65.81 | - | 25.54 | - | 08.65 | Mo3Si |

| 9 | - | 0.54 | 35.73 | 6.97 | 56.76 | SiO2, Al2O3, HfO2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Cheng, H.; Geng, Z.; Li, W. Oxidation Behavior of (Mo,Hf)Si2-Al2O3 Coating on Mo-Based Alloy at Elevated Temperature. Materials 2023, 16, 3215. https://doi.org/10.3390/ma16083215

Lv Y, Cheng H, Geng Z, Li W. Oxidation Behavior of (Mo,Hf)Si2-Al2O3 Coating on Mo-Based Alloy at Elevated Temperature. Materials. 2023; 16(8):3215. https://doi.org/10.3390/ma16083215

Chicago/Turabian StyleLv, Yongqi, Huichao Cheng, Zhanji Geng, and Wei Li. 2023. "Oxidation Behavior of (Mo,Hf)Si2-Al2O3 Coating on Mo-Based Alloy at Elevated Temperature" Materials 16, no. 8: 3215. https://doi.org/10.3390/ma16083215

APA StyleLv, Y., Cheng, H., Geng, Z., & Li, W. (2023). Oxidation Behavior of (Mo,Hf)Si2-Al2O3 Coating on Mo-Based Alloy at Elevated Temperature. Materials, 16(8), 3215. https://doi.org/10.3390/ma16083215