Investigation of Different Pre-Treatment Techniques and 3D Printed Turbulence Promoter to Mitigate Membrane Fouling in Dairy Wastewater Module

Abstract

1. Introduction

2. Material and Methods

2.1. Preparation of Dairy Wastewater Model

2.2. Examination of Pre-Treatments before Membrane Filtration

2.2.1. Physical Pre-Treatments

2.2.2. Chemical Pre-Treatments

2.3. Turbulence Promoter Application and Characteristics

2.4. Ultrafiltration after Laboratory Pre-Treatments

2.5. Post-Treatment

2.6. Membrane Performance Evaluation

2.7. Modelling

2.7.1. Resistance-in-Series Model

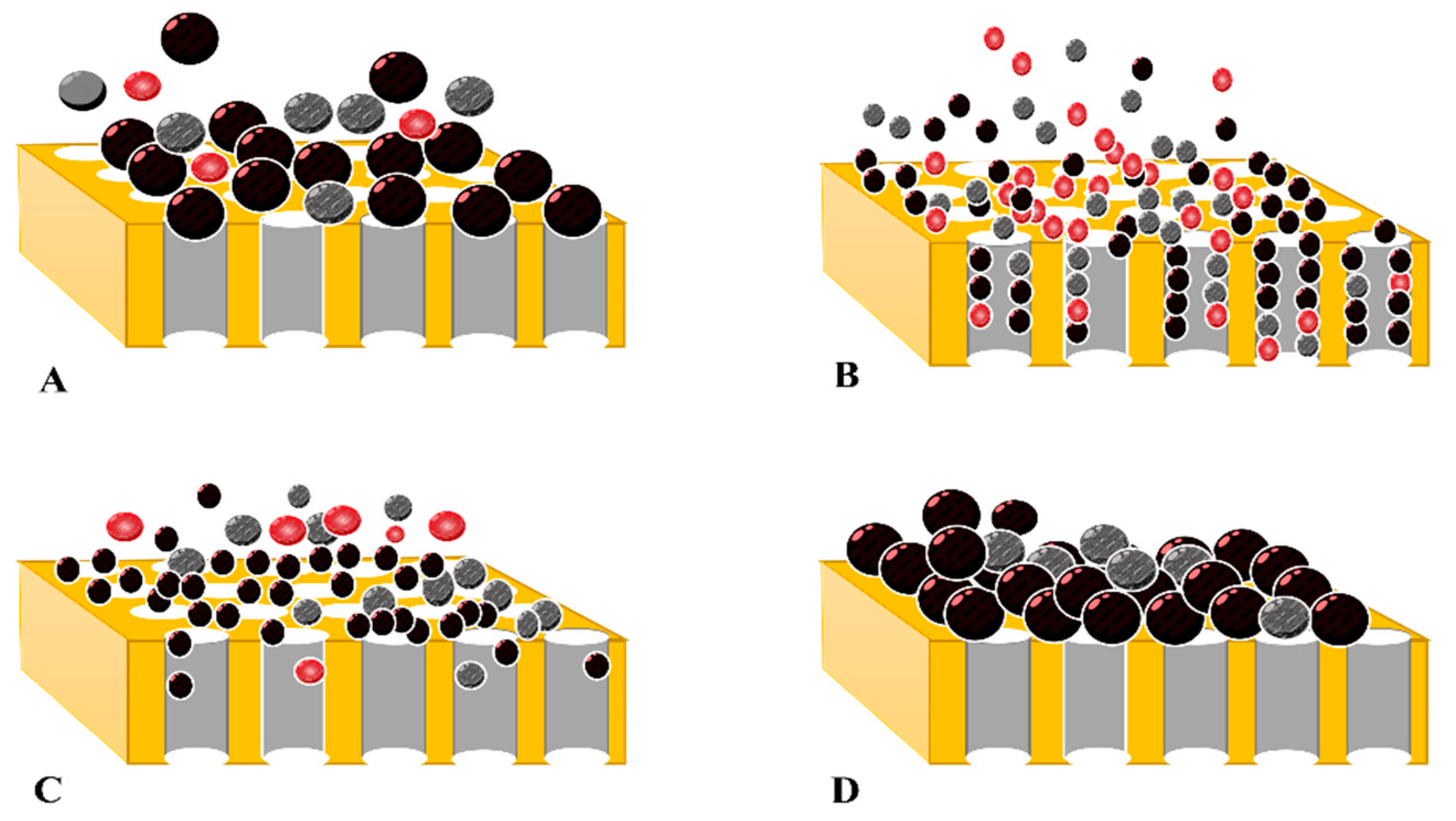

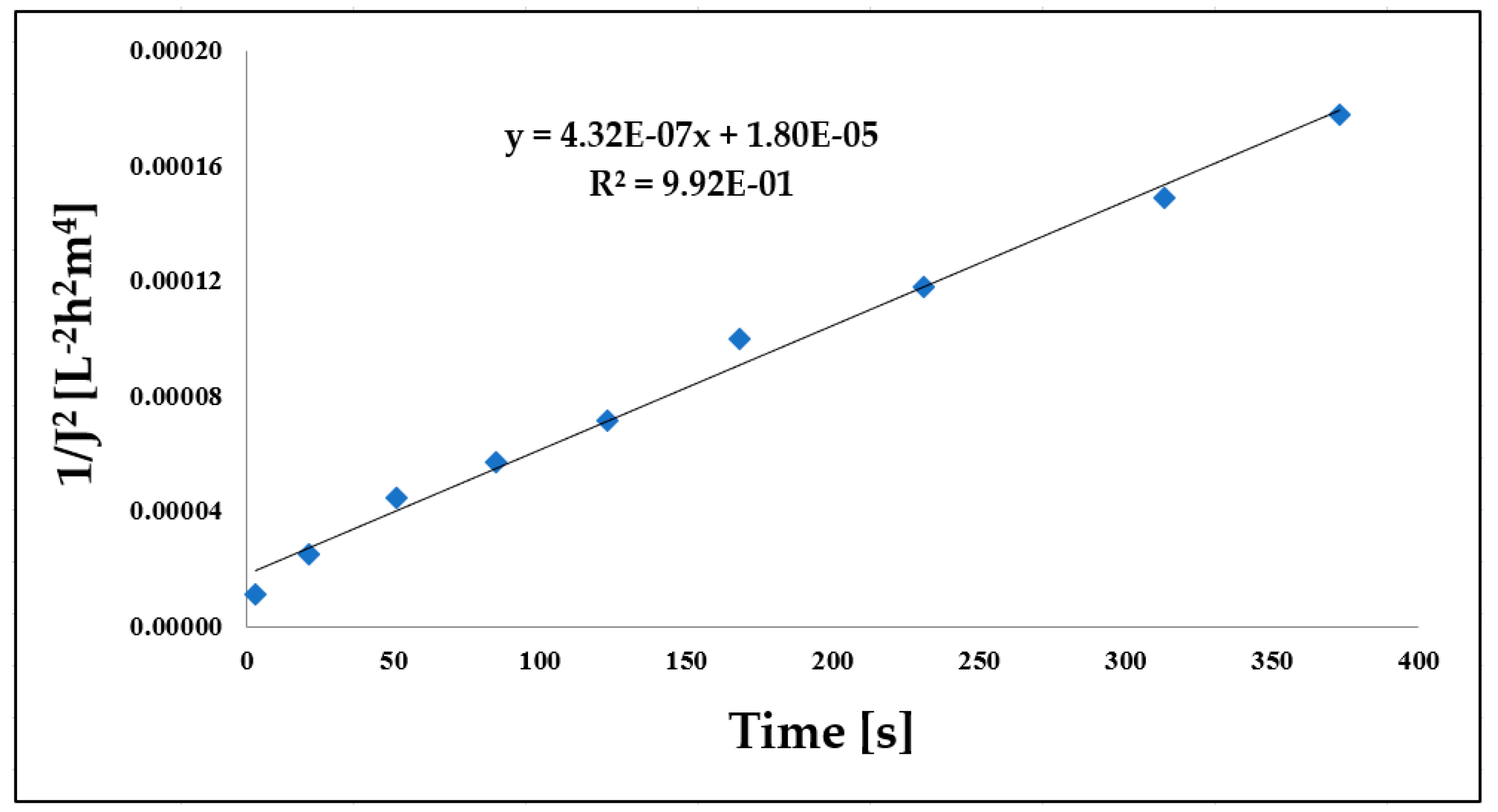

2.7.2. Hermia Module

3. Results and Discussion

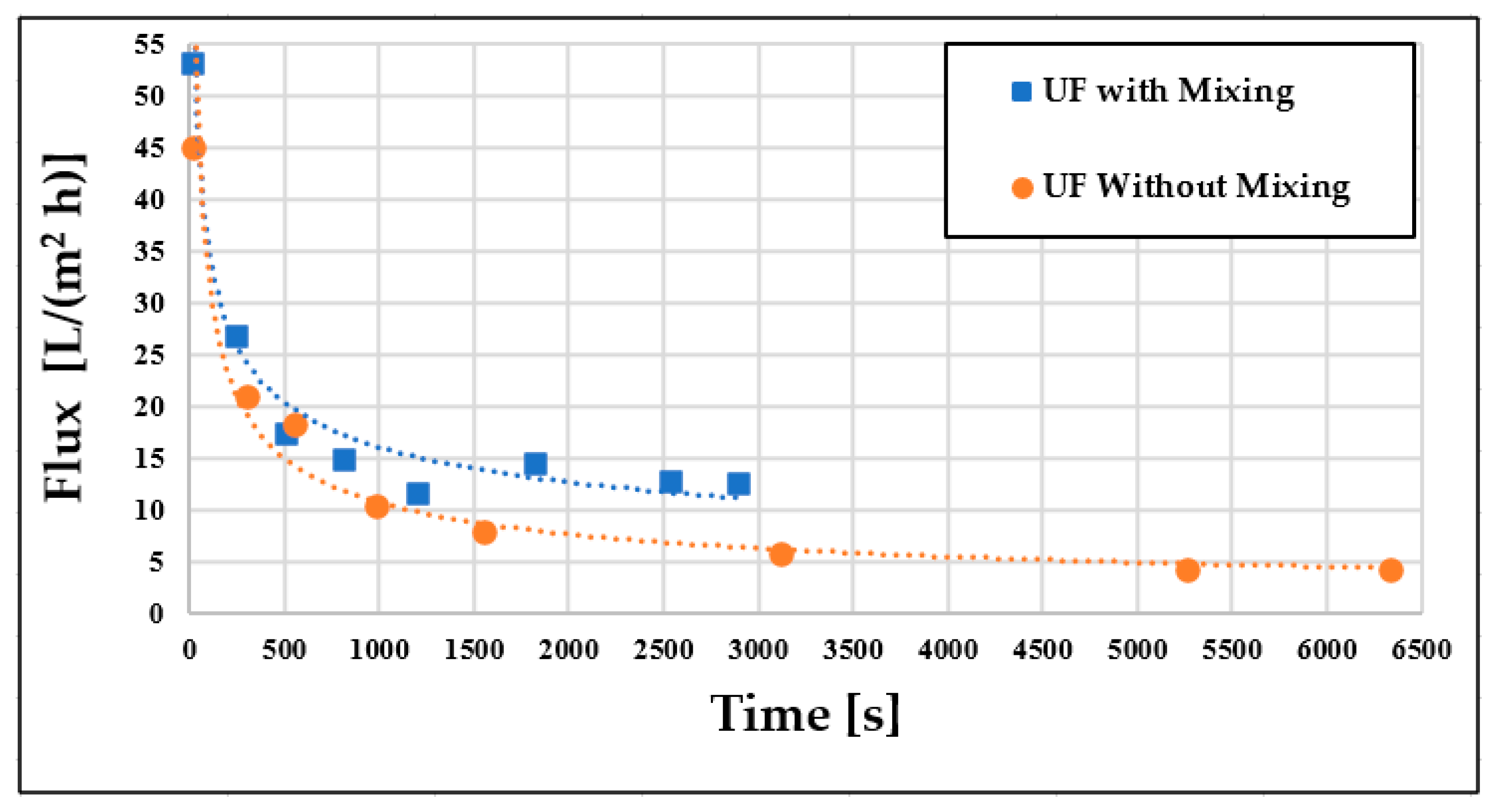

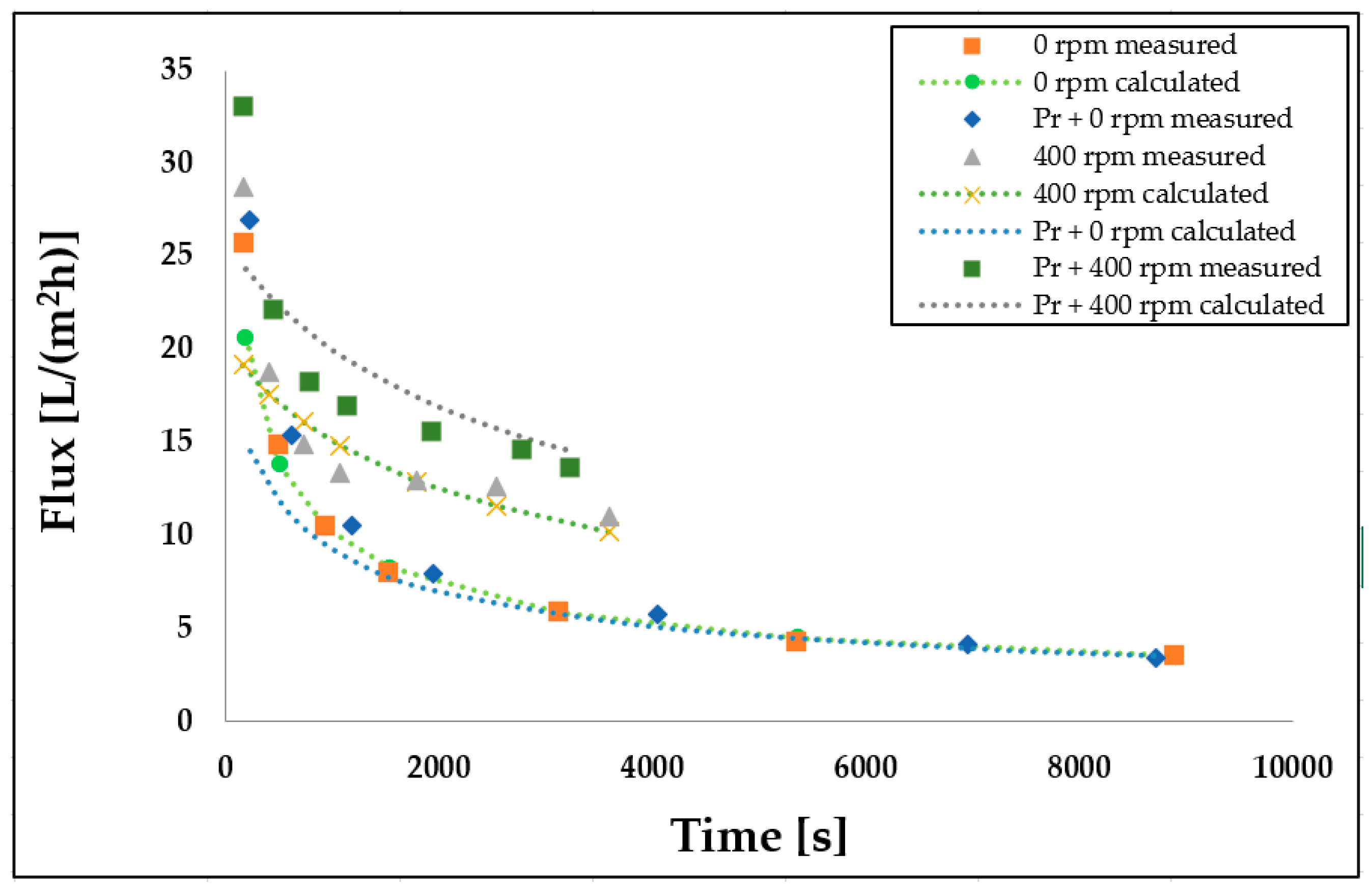

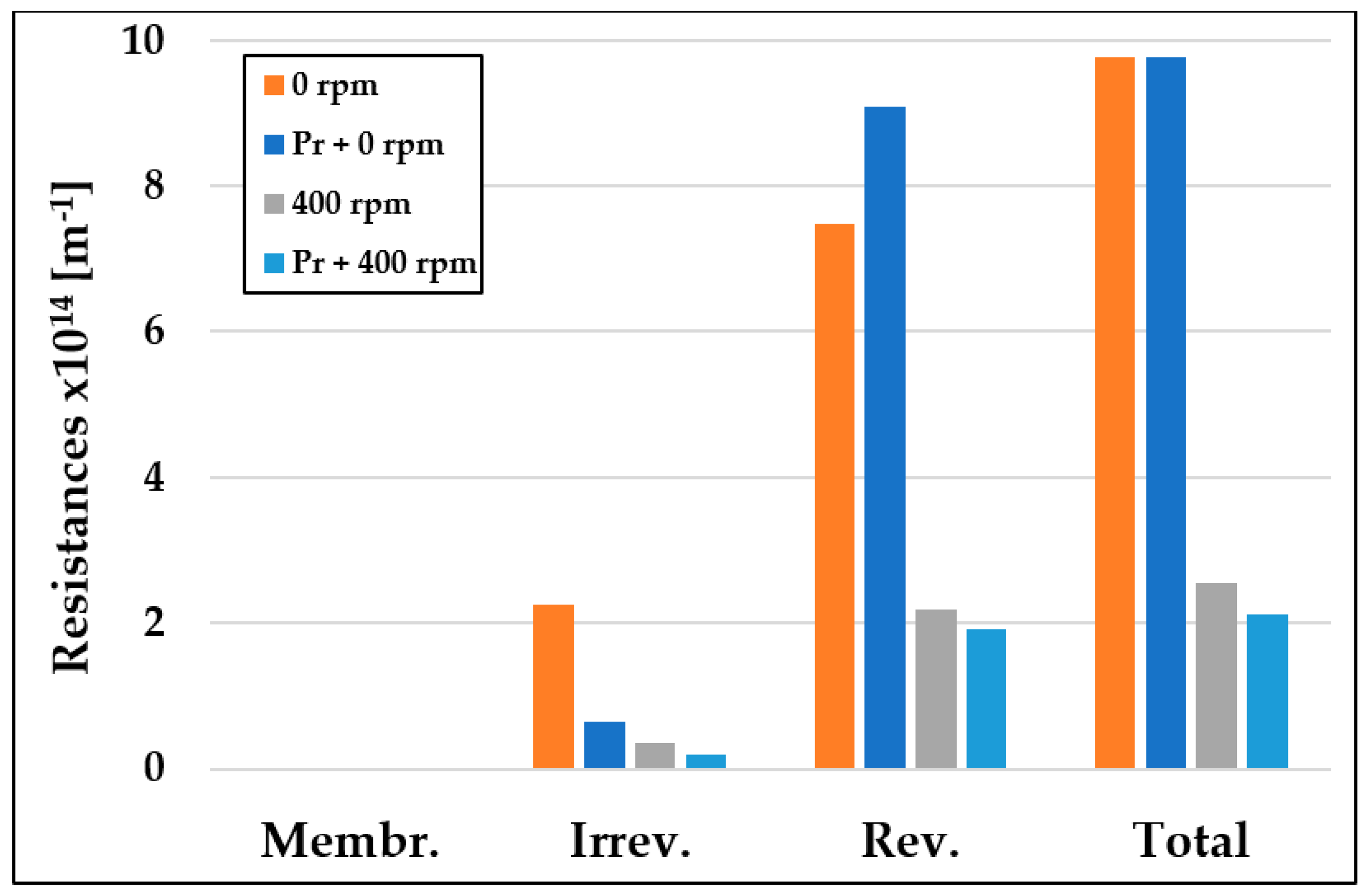

3.1. Examination of Flux Changes

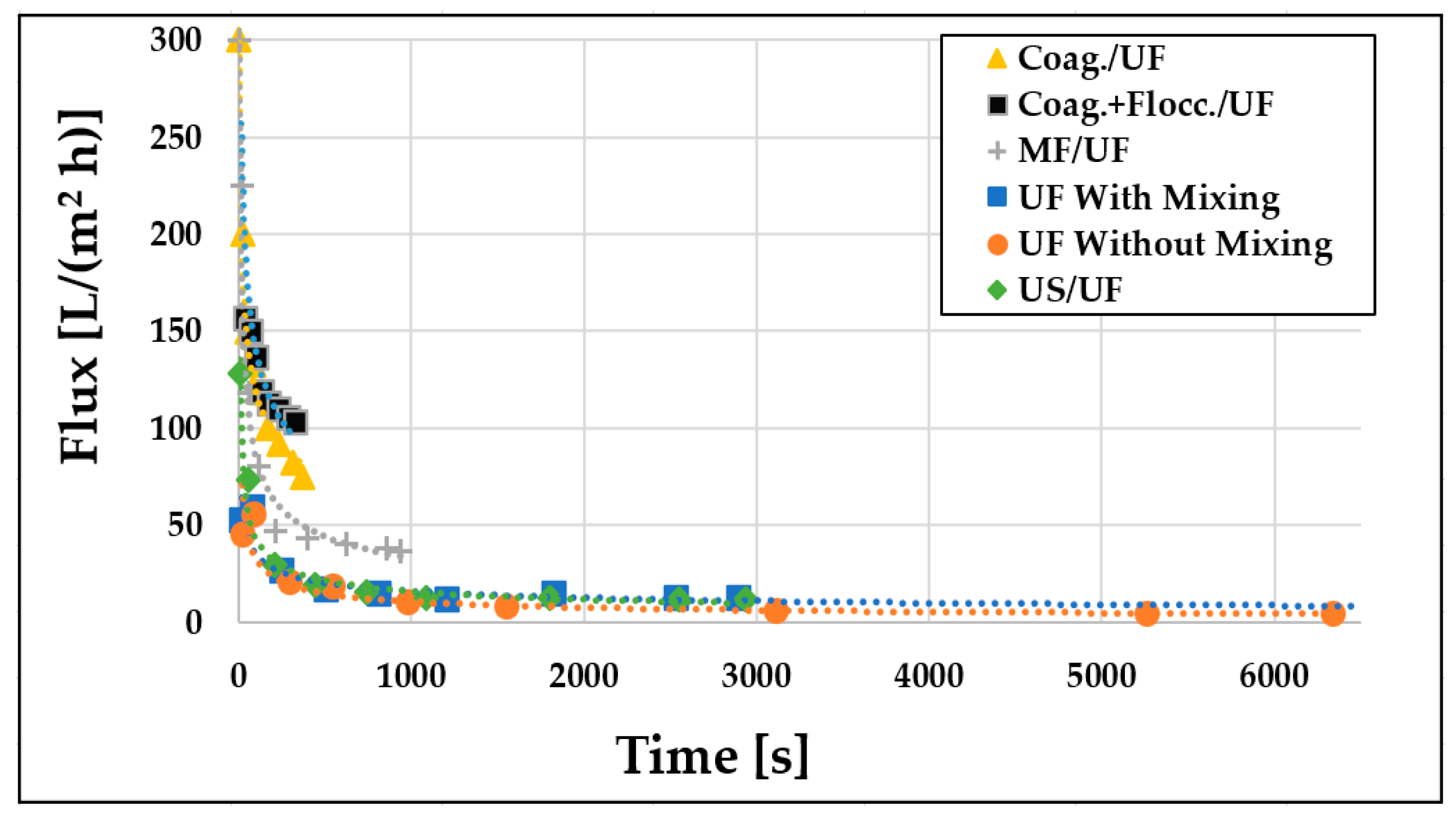

3.2. Examination of the Different Pre-Treatments

3.3. Comparison of Hermia Model Calculations

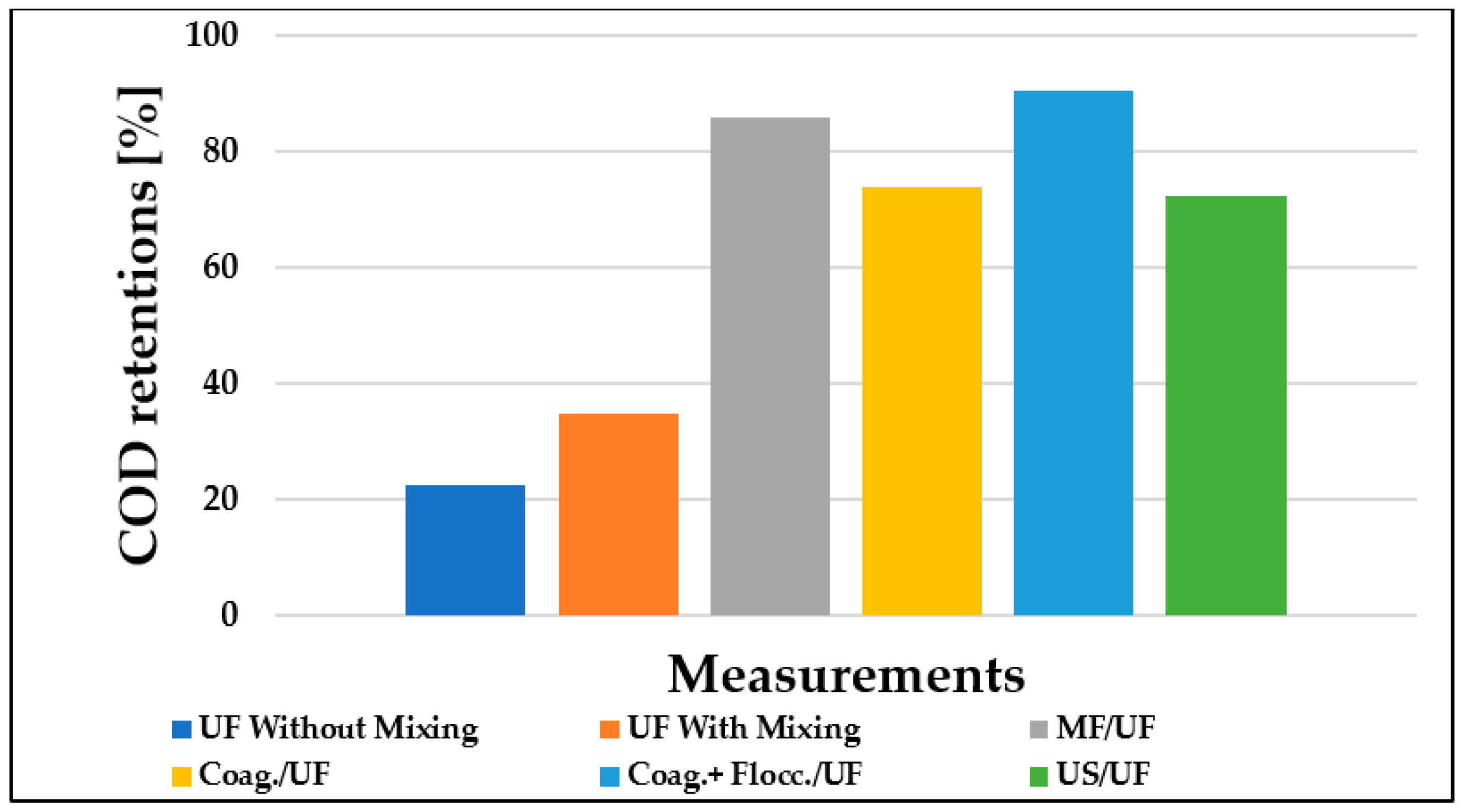

3.4. Evaluation of Membrane Retention

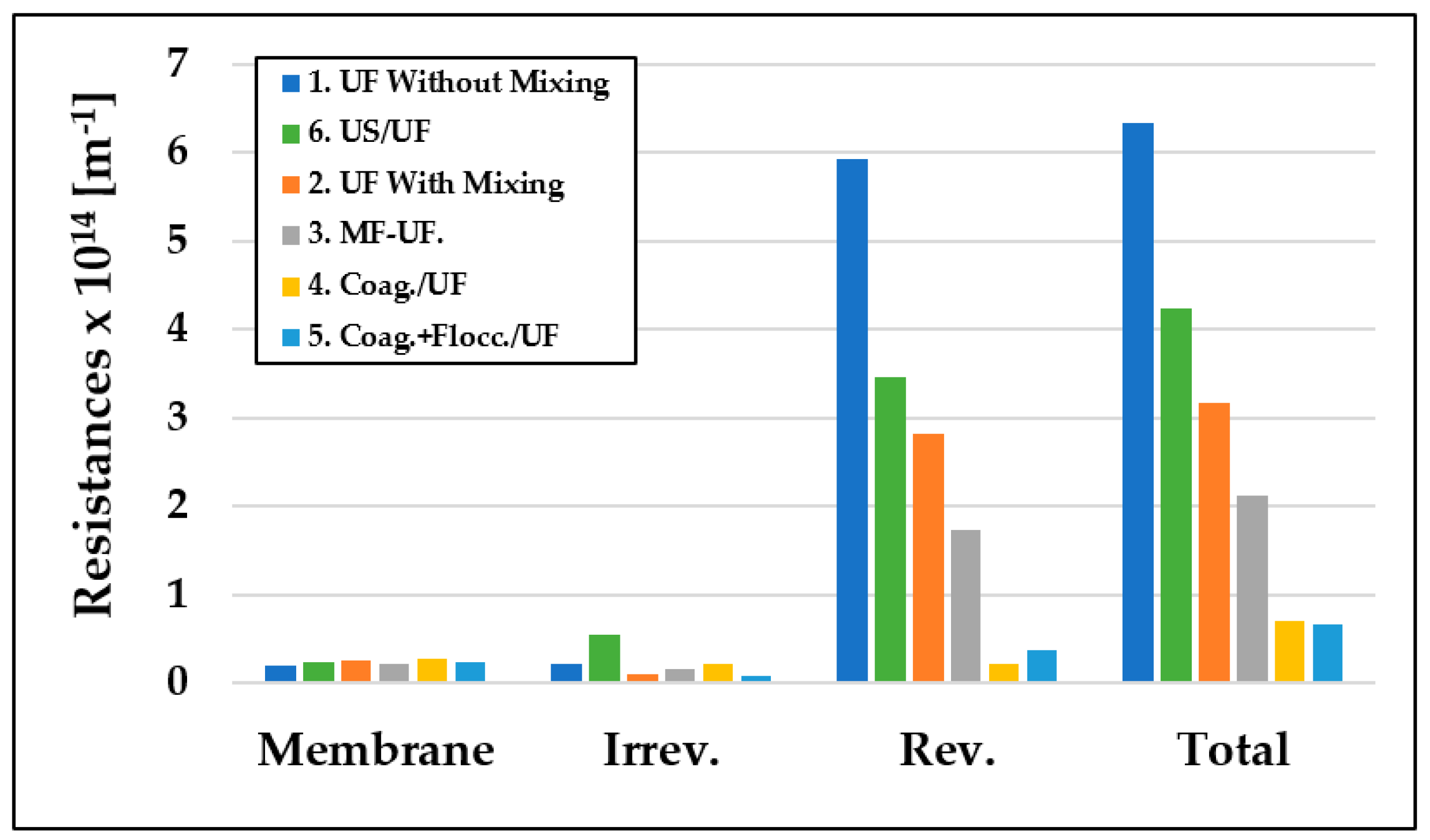

3.5. Membrane Resistances

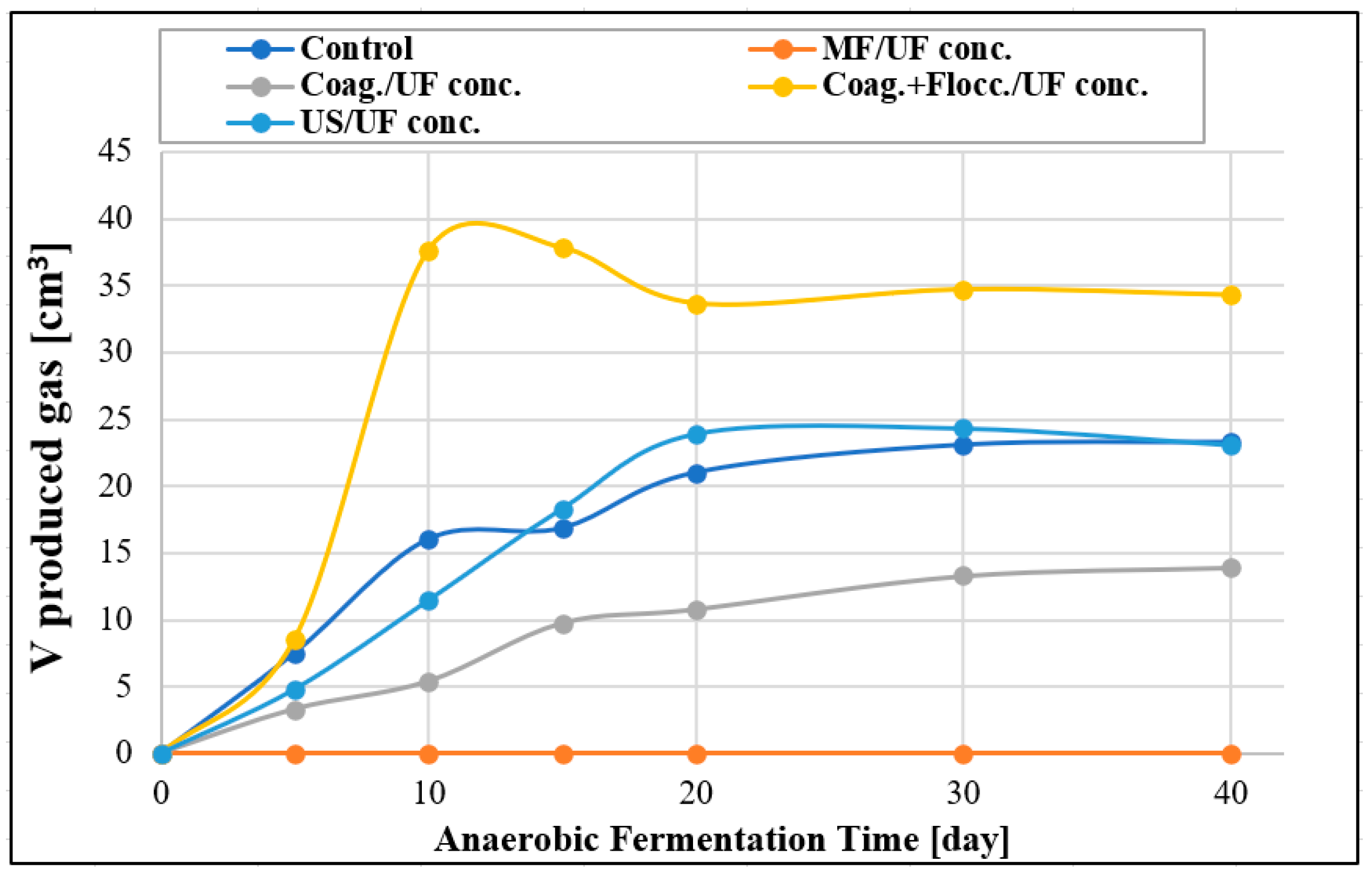

3.6. Results of Post-Treatment Gas Formation Determination

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bella, K.; Rao, P.V. Anaerobic Digestion of Dairy Wastewater: Effect of Different Parameters and Co-Digestion Options—A Review. Biomass Convers. Biorefin. 2023, 13, 2527–2552. [Google Scholar] [CrossRef]

- Kaur, N. Different Treatment Techniques of Dairy Wastewater. Groundw. Sustain. Dev. 2021, 14, 100640. [Google Scholar] [CrossRef]

- Bhuvaneshwari, S.; Majeed, F.; Jose, E.; Mohan, A. Different Treatment Methodologies and Reactors Employed for Dairy Effluent Treatment—A Review. J. Water Process Eng. 2022, 46, 102622. [Google Scholar]

- Zieliński, M.; Dębowski, M.; Kazimierowicz, J. Performance of an Innovative Low-Cost Recycled Filling (LCRF) in Anaerobic Treatment of Dairy Effluent—A Pilot-Scale Study. Materials 2022, 15, 7815. [Google Scholar] [CrossRef]

- Deka, A.; Rasul, A.; Baruah, A.; Malakar, H.; Basumatary, A.K. Treatment of Dairy Wastewater with Tubular Ceramic Membrane. Mater. Today Proc. 2023, 72, 2773–2779. [Google Scholar] [CrossRef]

- Zainith, S.; Ferreira, L.F.R.; Saratale, G.D.; Mulla, S.I.; Bharagava, R.N. Membrane-Based Hybrid Processes in Industrial Waste Effluent Treatment. In Membrane-Based Hybrid Processes for Wastewater Treatment; Elsevier: Amsterdam, The Netherlands, 2021; pp. 205–226. [Google Scholar]

- El machtani Idrissi, D.; Elidrissi, Z.C.; Achiou, B.; Ouammou, M.; Younssi, S.A. Fabrication of Low-Cost Kaolinite/Perlite Membrane for Microfiltration of Dairy and Textile Wastewaters. J. Environ. Chem. Eng. 2023, 11, 109281. [Google Scholar] [CrossRef]

- Charcosset, C. Classical and Recent Applications of Membrane Processes in the Food Industry. Food Eng. Rev. 2021, 13, 322–343. [Google Scholar] [CrossRef]

- Tanudjaja, H.J.; Anantharaman, A.; Ng, A.Q.Q.; Ma, Y.; Tanis-Kanbur, M.B.; Zydney, A.L.; Chew, J.W. A Review of Membrane Fouling by Proteins in Ultrafiltration and Microfiltration. J. Water Process Eng. 2022, 50, 103294. [Google Scholar] [CrossRef]

- Zsirai, T.; Buzatu, P.; Aerts, P.; Judd, S. Efficacy of Relaxation, Backflushing, Chemical Cleaning and Clogging Removal for an Immersed Hollow Fibre Membrane Bioreactor. Water Res. 2012, 46, 4499–4507. [Google Scholar] [CrossRef]

- Burts, K.S.; Plisko, T.V.; Sjölin, M.; Rodrigues, G.; Bildyukevich, A.V.; Lipnizki, F.; Ulbricht, M. Development of Antifouling Polysulfone Membranes by Synergistic Modification with Two Different Additives in Casting Solution and Coagulation Bath: Synperonic F108 and Polyacrylic Acid. Materials 2022, 15, 359. [Google Scholar] [CrossRef]

- AlSawaftah, N.; Abuwatfa, W.; Darwish, N.; Husseini, G. A Comprehensive Review on Membrane Fouling: Mathematical Modelling, Prediction, Diagnosis, and Mitigation. Water 2021, 13, 1327. [Google Scholar] [CrossRef]

- She, Q.; Wang, R.; Fane, A.G.; Tang, C.Y. Membrane Fouling in Osmotically Driven Membrane Processes: A Review. J. Membr. Sci. 2016, 499, 201–233. [Google Scholar] [CrossRef]

- Tomczak, W.; Gryta, M. Long-Term Performance of Ultrafiltration Membranes: Corrosion Fouling Aspect. Materials 2023, 16, 1673. [Google Scholar] [CrossRef]

- Gamage, N.P.; Chellam, S. Aluminum Electrocoagulation Pretreatment Reduces Fouling during Surface Water Microfiltration. J. Membr. Sci. 2011, 379, 97–105. [Google Scholar] [CrossRef]

- Landsman, M.R.; Lawler, D.F.; Katz, L.E. Application of Electrodialysis Pretreatment to Enhance Boron Removal and Reduce Fouling during Desalination by Nanofiltration/Reverse Osmosis. Desalination 2020, 491, 114563. [Google Scholar] [CrossRef]

- Sun, W.; Liu, J.; Chu, H.; Dong, B. Pretreatment and Membrane Hydrophilic Modification to Reduce Membrane Fouling. Membranes 2013, 3, 226–241. [Google Scholar] [CrossRef] [PubMed]

- Farahbakhsh, K.; Svrcek, C.; Guest, R.K.; Smith, D.W. A Review of the Impact of Chemical Pretreatment on Low-Pressure Water Treatment Membranes. J. Environ. Eng. Sci. 2004, 3, 237–253. [Google Scholar] [CrossRef]

- Konieczny, K.; Sąkol, D.; Płonka, J.; Rajca, M.; Bodzek, M. Coagulation—Ultrafiltration System for River Water Treatment. Desalination 2009, 240, 151–159. [Google Scholar] [CrossRef]

- Yu, W.; Graham, N.; Liu, H.; Qu, J. Comparison of FeCl3 and Alum Pre-Treatment on UF Membrane Fouling. Chem. Eng. J. 2013, 234, 158–165. [Google Scholar] [CrossRef]

- Wang, J.; Yang, J.; Zhang, H.; Guo, W.; Ngo, H.-H. Feasibility Study on Magnetic Enhanced Flocculation for Mitigating Membrane Fouling. J. Ind. Eng. Chem. 2015, 26, 37–45. [Google Scholar] [CrossRef]

- Ohno, K.; Matsui, Y.; Itoh, M.; Oguchi, Y.; Kondo, T.; Konno, Y.; Matsushita, T.; Magara, Y. NF Membrane Fouling by Aluminum and Iron Coagulant Residuals after Coagulation–MF Pretreatment. Desalination 2010, 254, 17–22. [Google Scholar] [CrossRef]

- Gayathri, T.; Kavitha, S.; Kumar, S.A.; Kaliappan, S.; Yeom, I.T.; Banu, J.R. Effect of Citric Acid Induced Deflocculation on the Ultrasonic Pretreatment Efficiency of Dairy Waste Activated Sludge. Ultrason. Sonochem. 2015, 22, 333–340. [Google Scholar] [CrossRef]

- Kurup, G.G.; Adhikari, B.; Zisu, B. Application of High-Frequency Ultrasound Standing Waves for the Recovery of Lipids from High-Fat Dairy Effluent. Ultrason. Sonochem. 2020, 63, 104944. [Google Scholar] [CrossRef]

- Li, F.; Meng, J.; Ye, J.; Yang, B.; Tian, Q.; Deng, C. Surface Modification of PES Ultrafiltration Membrane by Polydopamine Coating and Poly (Ethylene Glycol) Grafting: Morphology, Stability, and Anti-Fouling. Desalination 2014, 344, 422–430. [Google Scholar] [CrossRef]

- Zhang, Y.; Chong, J.Y.; Zhao, Y.; Xu, R.; Asakawa, A.; Wang, R. Facile Hydrophobic Modification of Hydrophilic Membranes by Fluoropolymer Coating for Direct Contact Membrane Distillation. J. Membr. Sci. 2023, 672, 121432. [Google Scholar] [CrossRef]

- Damavandi, F.; Aroujalian, A.; Salimi, P. TiO2 Nanoparticle Stability via Polyacrylic Acid-Binding on the Surface of Polyethersulfone Membrane: Long-Term Evaluation. J. Ind. Eng. Chem. 2023, 117, 307–318. [Google Scholar] [CrossRef]

- Maziya, K.; Dlamini, B.C.; Malinga, S.P. Hyperbranched Polymer Nanofibrous Membrane Grafted with Silver Nanoparticles for Dual Antifouling and Antibacterial Properties against Escherichia Coli, Staphylococcus Aureus and Pseudomonas Aeruginosa. React. Funct. Polym. 2020, 148, 104494. [Google Scholar] [CrossRef]

- Kochkodan, V.; Johnson, D.J.; Hilal, N. Polymeric Membranes: Surface Modification for Minimizing (Bio) Colloidal Fouling. Adv. Colloid Interface Sci. 2014, 206, 116–140. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, Y.; Hilal, N. The Potentials of 3D-Printed Feed Spacers in Reducing the Environmental Footprint of Membrane Separation Processes. J. Environ. Chem. Eng. 2023, 11, 109249. [Google Scholar] [CrossRef]

- Qian, X.; Anvari, A.; Hoek, E.M.V.; McCutcheon, J.R. Advancements in Conventional and 3D Printed Feed Spacers in Membrane Modules. Desalination 2023, 556, 116518. [Google Scholar] [CrossRef]

- Kertész, S.; Gulyás, N.S.; Al-Tayawi, A.N.; Huszár, G.; Lennert, J.R.; Csanádi, J.; Beszédes, S.; Hodúr, C.; Szabó, T.; László, Z. Modeling of Organic Fouling in an Ultrafiltration Cell Using Different Three-Dimensional Printed Turbulence Promoters. Membranes 2023, 13, 262. [Google Scholar] [CrossRef]

- Yanar, N.; Son, M.; Park, H.; Choi, H. Toward Greener Membranes with 3D Printing Technology. Environ. Eng. Res. 2021, 26, 200027. [Google Scholar] [CrossRef]

- Shete, B.S.; Shinkar, N.P. Dairy Industry Wastewater Sources, Characteristics & Its Effects on Environment. Int. J. Curr. Eng. Technol. 2013, 3, 1611–1615. [Google Scholar]

- Bortoluzzi, A.C.; Faitão, J.A.; Di Luccio, M.; Dallago, R.M.; Steffens, J.; Zabot, G.L.; Tres, M.V. Dairy Wastewater Treatment Using Integrated Membrane Systems. J. Environ. Chem. Eng. 2017, 5, 4819–4827. [Google Scholar] [CrossRef]

- Prazeres, A.R.; Fernandes, F.; Luz, S.; Jerónimo, E. Simple Processes for Contamination Removal in Cheesemaking Wastewater: CaCO3, Mg(OH)2, FeSO4 and FeCl3. J. Environ. Chem. Eng. 2020, 8, 104034. [Google Scholar] [CrossRef]

- San Andrés, M.; Chércoles, R.; Navarro, E.; de la Roja, J.M.; Gorostiza, J.; Higueras, M.; Blanch, E. Use of 3D Printing PLA and ABS Materials for Fine Art. Analysis of Composition and Long-Term Behaviour of Raw Filament and Printed Parts. J. Cult. Herit. 2023, 59, 181–189. [Google Scholar] [CrossRef]

- Atakok, G.; Kam, M.; Koc, H.B. Tensile, Three-Point Bending and Impact Strength of 3D Printed Parts Using PLA and Recycled PLA Filaments: A Statistical Investigation. J. Mater. Res. Technol. 2022, 18, 1542–1554. [Google Scholar] [CrossRef]

- Szczepanik, S.; Nikiel, P. Influence of Structural Characteristics on the Mechanical Properties of FDM Printed PLA Material. J. Cast. Mater. Eng. 2020, 4, 1–8. [Google Scholar] [CrossRef]

- Jákói, Z.; Hodúr, C.; Beszédes, S. Monitoring the Process of Anaerobic Digestion of Native and Microwave Pre-Treated Sludge by Dielectric and Rheological Measurements. Water 2022, 14, 1294. [Google Scholar] [CrossRef]

- Ni, T.; Kong, L.; Xie, Z.; Lin, J.; Zhao, S. Flux vs. Permeability: How to Effectively Evaluate Mass Transfer Performance of Membranes in Oil-Water Separation. J. Water Process Eng. 2022, 49, 103119. [Google Scholar] [CrossRef]

- Lahnafi, A.; Elgamouz, A.; Tijani, N.; Jaber, L.; Kawde, A.-N. Hydrothermal Synthesis and Electrochemical Characterization of Novel Zeolite Membranes Supported on Flat Porous Clay-Based Microfiltration System and Its Application of Heavy Metals Removal of Synthetic Wastewaters. Microporous Mesoporous Mater. 2022, 334, 111778. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Ismail, S.; Bhatia, S. Membrane Treatment for Palm Oil Mill Effluent: Effect of Transmembrane Pressure and Crossflow Velocity. Desalination 2005, 179, 245–255. [Google Scholar] [CrossRef]

- Zhu, Z.; Mhemdi, H.; Ding, L.; Bals, O.; Jaffrin, M.Y.; Grimi, N.; Vorobiev, E. Dead-End Dynamic Ultrafiltration of Juice Expressed from Electroporated Sugar Beets. Food Bioproc. Tech. 2015, 8, 615–622. [Google Scholar] [CrossRef]

- Dippel, J.; Handt, S.; Stute, B.; von Lieres, E.; Loewe, T. Fluid Dynamics in Pleated Membrane Filter Devices. Sep. Purif. Technol. 2021, 267, 118580. [Google Scholar] [CrossRef]

- Xu, C.; Chen, Y. Understanding Water and Solute Transport in Thin Film Nanocomposite Membranes by Resistance-in-Series Theory Combined with Monte Carlo Simulation. J. Membr. Sci. 2021, 626, 119106. [Google Scholar] [CrossRef]

- Szerencsés, S.G.; Beszédes, S.; László, Z.; Veréb, G.; Szegedi, B.; Horváth, Z.H.; Hodúr, C.; Rákhely, G.; Kertész, S. Effect of Vibration on the Efficiency of Ultrafiltration. Analecta Tech. Szeged. 2021, 15, 37–44. [Google Scholar] [CrossRef]

- Kertész, S.; László, Z.; Forgács, E.; Szabó, G.; Hodúr, C. Dairy Wastewater Purification by Vibratory Shear Enhanced Processing. Desalination Water Treat. 2011, 35, 195–201. [Google Scholar] [CrossRef]

- Sreedhar, N.; Mavukkandy, M.O.; Aminabhavi, T.M.; Hong, S.; Arafat, H.A. Fouling Mechanisms in Ultrafiltration under Constant Flux: Effect of Feed Spacer Design. Chem. Eng. J. 2022, 446, 136563. [Google Scholar] [CrossRef]

- Hermia, J. Constant Pressure Blocking Filtration Laws: Application to Power-Law Non-Newtonian Fluids. 1982. Available online: https://www.semanticscholar.org/paper/Constant-Pressure-Blocking-Filtration-Laws-To-Hermia/a2d8fcd52e97e4a1d1b82c16f5b977f2bd7ee6a2 (accessed on 22 June 2022).

- Ferreira, F.B.; Ullmann, G.; Vieira, L.G.M.; Cardoso, V.L.; Reis, M.H.M. Hydrodynamic Performance of 3D Printed Turbulence Promoters in Cross-Flow Ultrafiltrations of Psidium Myrtoides Extract. Chem. Eng. Process.-Process Intensif. 2020, 154, 108005. [Google Scholar] [CrossRef]

- Wang, S.; Yuan, R.; Liu, C.; Zhou, B. Effect of Fe2+ Adding Period on the Biogas Production and Microbial Community Distribution during the Dry Anaerobic Digestion Process. Process Saf. Environ. Prot. 2020, 136, 234–241. [Google Scholar] [CrossRef]

| Measurements | Distribution of Resistance Values | ||||

|---|---|---|---|---|---|

| Rm | Rirrev | Rrev | Rirrev/Rrev | Rtotal | |

| Coag./UF | 38.33 | 30.67 | 30.99 | 0.9896 | 100.00 |

| Coag.+Flocc./UF | 35.07 | 10.79 | 54.14 | 0.1992 | 100.00 |

| US/UF | 5.54 | 12.78 | 81.68 | 0.1564 | 100.00 |

| MF/UF | 10.22 | 7.67 | 82.11 | 0.0934 | 100.00 |

| UF with mixing | 7.95 | 3.41 | 88.64 | 0.0384 | 100.00 |

| UF without mixing | 3.15 | 3.38 | 93.47 | 0.0361 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kertész, S.; Al-Tayawi, A.N.; Gergely, G.; Ott, B.; Gulyás, N.S.; Jákói, Z.; Beszédes, S.; Hodúr, C.; Szabó, T.; László, Z. Investigation of Different Pre-Treatment Techniques and 3D Printed Turbulence Promoter to Mitigate Membrane Fouling in Dairy Wastewater Module. Materials 2023, 16, 3117. https://doi.org/10.3390/ma16083117

Kertész S, Al-Tayawi AN, Gergely G, Ott B, Gulyás NS, Jákói Z, Beszédes S, Hodúr C, Szabó T, László Z. Investigation of Different Pre-Treatment Techniques and 3D Printed Turbulence Promoter to Mitigate Membrane Fouling in Dairy Wastewater Module. Materials. 2023; 16(8):3117. https://doi.org/10.3390/ma16083117

Chicago/Turabian StyleKertész, Szabolcs, Aws N. Al-Tayawi, Gréta Gergely, Bence Ott, Nikolett Sz. Gulyás, Zoltán Jákói, Sándor Beszédes, Cecilia Hodúr, Tamás Szabó, and Zsuzsanna László. 2023. "Investigation of Different Pre-Treatment Techniques and 3D Printed Turbulence Promoter to Mitigate Membrane Fouling in Dairy Wastewater Module" Materials 16, no. 8: 3117. https://doi.org/10.3390/ma16083117

APA StyleKertész, S., Al-Tayawi, A. N., Gergely, G., Ott, B., Gulyás, N. S., Jákói, Z., Beszédes, S., Hodúr, C., Szabó, T., & László, Z. (2023). Investigation of Different Pre-Treatment Techniques and 3D Printed Turbulence Promoter to Mitigate Membrane Fouling in Dairy Wastewater Module. Materials, 16(8), 3117. https://doi.org/10.3390/ma16083117