Gaussian Model of Anti-Radar Properties for Coatings Based on Carbonyl Iron Powder

Abstract

1. Introduction

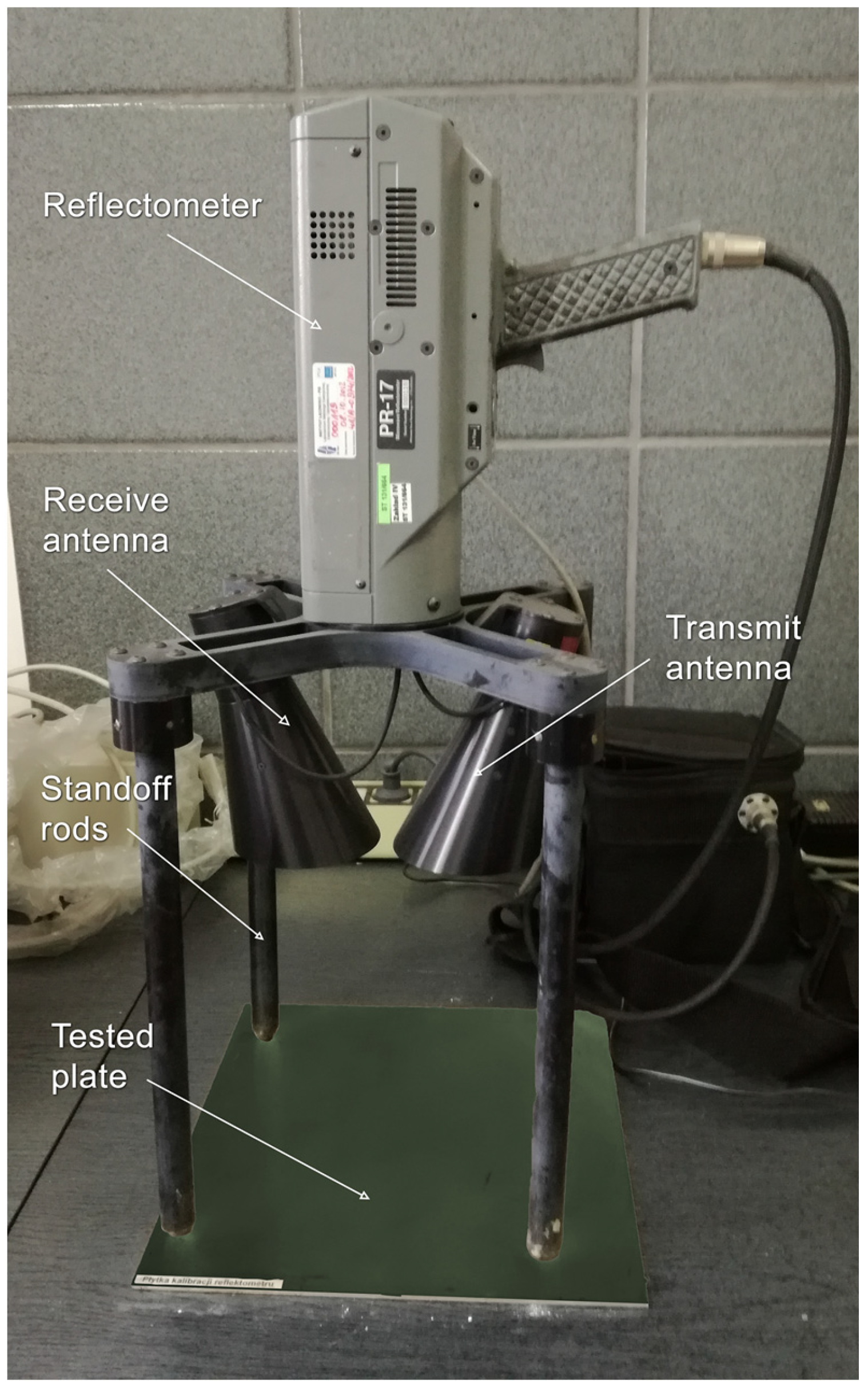

2. Materials and Methods

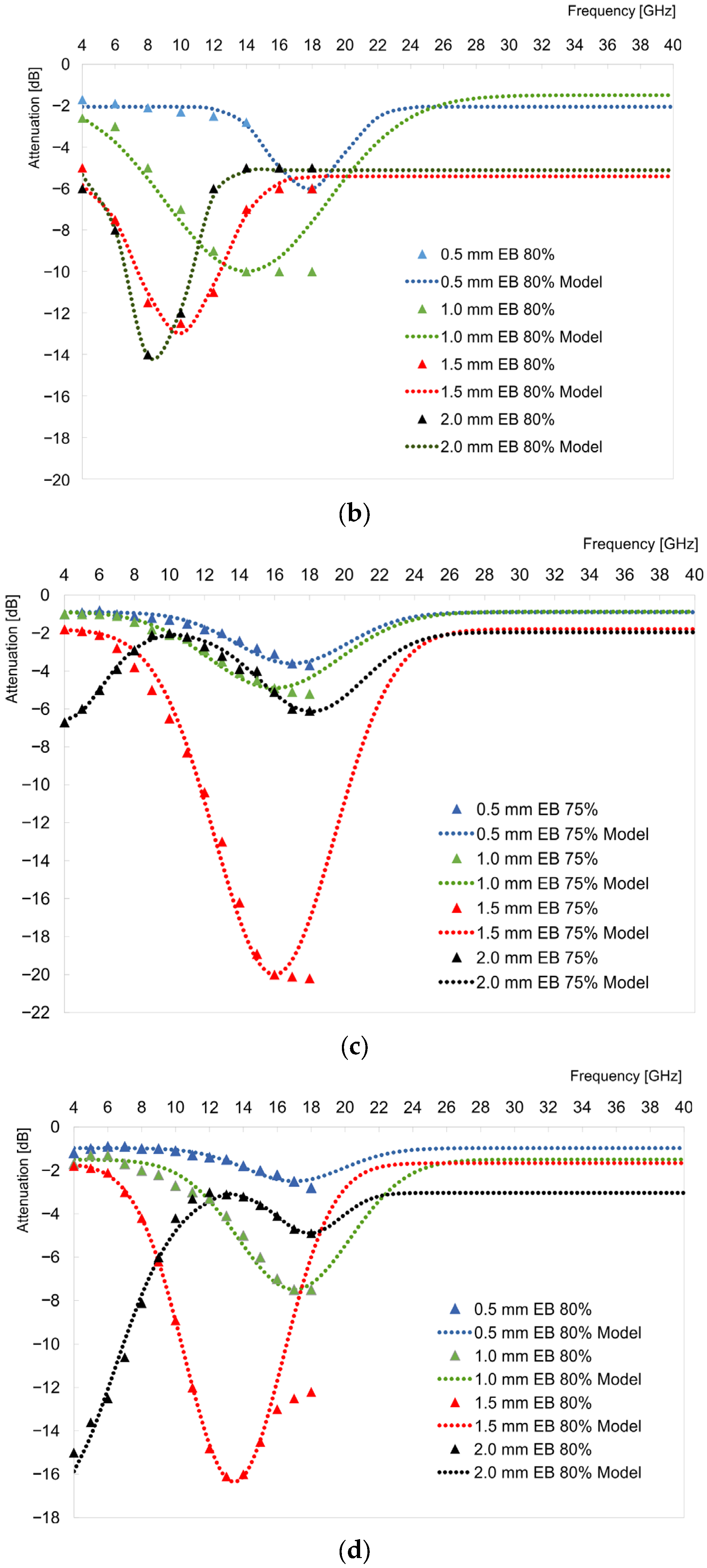

3. Results and Discussion

- A frequency range from 4 GHz to 40 GHz was adopted for the model attenuation calculations;

- Based on the experimental data, one dominant damping maximum was assumed for the simulated model;

- A damping model with Gaussian curve characteristics was adopted for each sample;

- A simulation was made for the maximum attenuation, preceded by the minimum recorded in the range from 4 to 18 GHz;

- Due to the location of the measurement points with maximum attenuation near the limits of the 4 GHz and 18 GHz measurement ranges for several samples, an additional approximation correction was introduced. The first point with the maximum attenuation level after the minimum was considered to be the maximum for which each subsequent point assumed an attenuation value equal to the maximum value with a tolerance of ±0.3 dB.

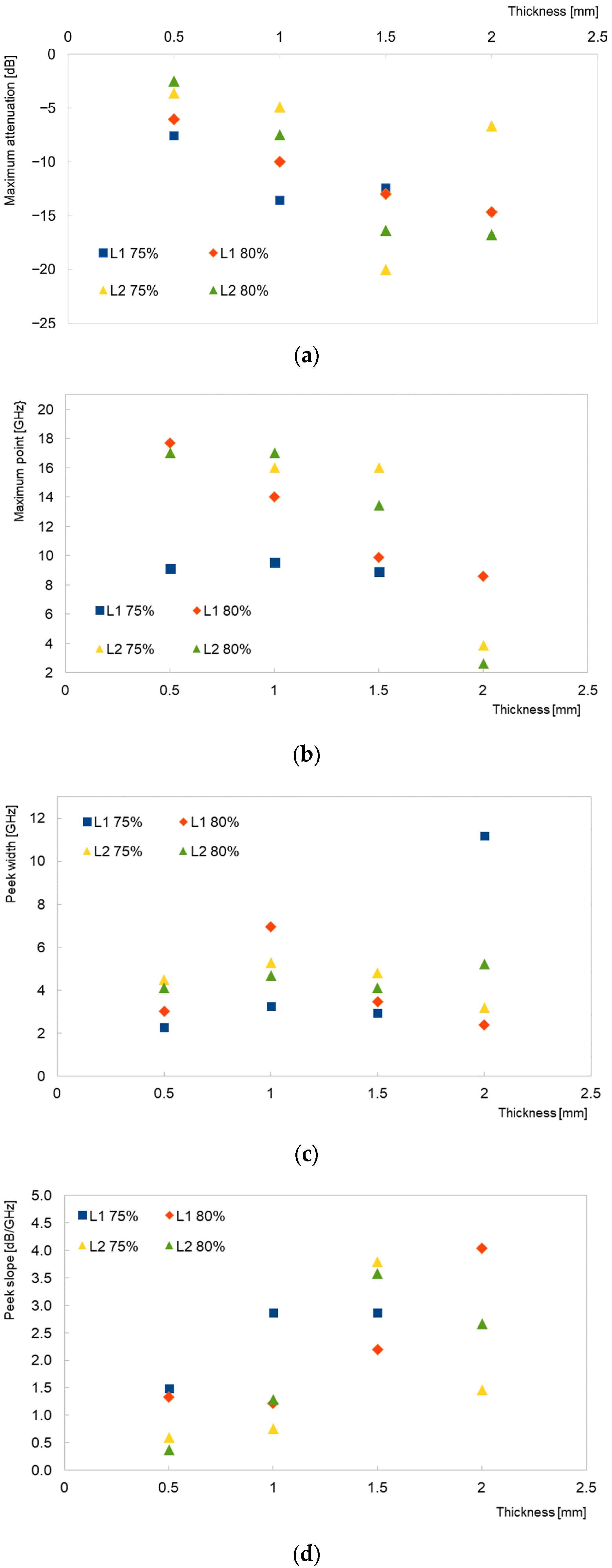

- Attenuation level exceeding 12 dB;

- Range with maximum attenuation in the range of 8–12 GHz (X band).

Mathematical Simulation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.; Tan, S.; Zhao, Y.; Liang, L.; Zhou, M.; Ji, G. Broadband multispectral compatible absorbers for radar, infrared and visible stealth application. Prog. Mater. Sci. 2023, 135, 101088. [Google Scholar] [CrossRef]

- Sista, K.S.; Dwarapudi, S.; Kumar, D.; Sinha, G.R.; Moon, A.P. Carbonyl iron powders as absorption material for microwave interference shielding: A review. J. Alloy. Compd. 2021, 853, 157251. [Google Scholar] [CrossRef]

- Luo, X.; Chung, D.D.L. Electromagnetic interference shielding reaching 130 dB using flexible graphite. Carbon 1996, 34, 1293–1294. [Google Scholar] [CrossRef]

- Deng, L.; Zhang, J.; Shu, R. Fabrication of three-dimensional nitrogen-doped reduced graphene oxide/tin oxide composite aerogels as high-performance electromagnetic wave absorbers. J. Colloid Interface Sci. 2021, 602, 282–290. [Google Scholar] [CrossRef] [PubMed]

- Shu, X.; Yan, S.; Fang, B.; Song, Y.; Zhao, Z. A 3D multifunctional nitrogen-doped RGO-based aerogel with silver nanowires assisted self-supporting networks for enhanced electromagnetic wave absorption. Chem. Eng. J. 2023, 451, 138825. [Google Scholar] [CrossRef]

- Huang, L.; Liu, X.; Yu, R. Enhanced microwave absorption properties of rod-shaped Fe2O3/Fe3O4/MWCNTs composites. Prog. Nat. Sci. Mater. Int. 2018, 28, 288–295. [Google Scholar] [CrossRef]

- Zhou, Y.; Xie, H.; Zhou, W.; Ren, Z. Enhanced antioxidation and microwave absorbing properties of SiO 2 -coated flaky carbonyl iron particles. J. Magn. Magn. Mater. 2018, 446, 143–149. [Google Scholar] [CrossRef]

- Xia, Y.; Fang, J.; Li, P.; Zhang, B.; Yao, H.; Chen, J.; Ding, J.; Ouyang, J. Solution-processed highly superparamagnetic and conductive PEDOT:PSS/Fe3O4 nanocomposite films with high transparency and high mechanical flexibility. ACS Appl. Mater. Interfaces 2017, 9, 19001–19010. [Google Scholar] [CrossRef]

- Sankaran, S.; Deshmukh, K.; Ahamed, M.B.; Khadheer Pasha, S.K. Recent advances in electromagnetic interference shielding properties of metal and carbon filler reinforced flexible polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 49–71. [Google Scholar] [CrossRef]

- Pawar, S.P.; Biswas, S.; Kar, G.P.; Bose, S. High frequency millimetre wave absorbers derived from polymeric nanocomposites. Polymer 2016, 84, 398–419. [Google Scholar] [CrossRef]

- Ibrahim, I.R.; Matori, K.A.; Ismail, I.; Awang, Z.; Rusly, S.N.A.; Nazlan, R.; Idris, F.M.; Zulkimi, M.M.M.; Abdullah, N.H.; Mustaffa, M.S.; et al. A Study on Microwave Absorption Properties of Carbon Black and Ni0.6Zn0.4Fe2O4 Nanocomposites by Tuning the Matching-Absorbing Layer Structures. Sci. Rep. 2020, 10, 3135. [Google Scholar] [CrossRef] [PubMed]

- Raad, S.H.; Atlasbaf, Z.; Zapata, C.J. Broadband absorption using all-graphene grating-coupled nanoparticles on a reflector. Sci. Rep. 2020, 10, 19060. [Google Scholar] [CrossRef] [PubMed]

- Adenot-Engelvin, A.L.; Dudek, C.; Toneguzzo, P.; Acher, O. Microwave properties of ferromagnetic composites and metamaterials. J. Eur. Ceram. Soc. 2007, 27, 1029–1033. [Google Scholar] [CrossRef]

- Przybył, W.; Januszko, A.; Radek, N.; Szczepaniak, M.; Bogdanowicz, K.A.; Plebankiewicz, I.; Szczodrowska, B.; Mazurczuk, R. Microwave absorption properties of carbonyl iron-based paint coatings for military applications. Def. Technol. 2022. [Google Scholar] [CrossRef]

- More, J.J. The Levenberg-Marquardt Algorithm: Implementation and Theory. In Numerical Analysis; Watson, G.A., Ed.; Lecture Notes in Mathematics 630; Springer: Berlin/Heidelberg, Germany, 1977; pp. 105–116. [Google Scholar]

- Yuping, D.; Guangli, W.; Shuchao, G.; Shuqing, L.; Guojia, M. Study on microwave absorbing properties of carbonyl–iron composite coating based on PVC and Al sheet. Appl. Surf. Sci. 2012, 258, 5746–5752. [Google Scholar] [CrossRef]

- Elmahaishi, M.F.; Azis, R.S.; Ismail, I.; Muhammad, F.D. A review on electromagnetic microwave absorption properties: Their materials and performance. J. Mater. Res. Technol. 2022, 20, 2188–2220. [Google Scholar] [CrossRef]

| Band Name | Frequency (GHz) | Wavelength (cm) | Band Symbol |

|---|---|---|---|

| VHF | 0.1–0.3 | 300–100 | A |

| UHF | 0.3–0.5 | 100–60 | B |

| 0.5–1.0 | 60–30 | C | |

| L | 1–2 | 30–15 | D |

| S | 2–3 | 15–10 | E |

| 3–4 | 10–7.5 | F | |

| C | 4–6 | 7.5–5 | G |

| 6–8 | 5–3.75 | H | |

| X | 8–10 | 3.75–3 | I |

| 10–12 | 3–2.5 | J | |

| Ku | 12–18 | 2.5–1.67 | J |

| K | 18–26.5 | 1.67–1.1 | J (to 20 GHz) |

| Ka | 26.5–40 | 1.1–0.75 | K |

| Millimeter waves | 40–100 | 0.75–0.3 | L (to 60 GHz) |

| M (>60 GHz) |

| No. | Resin | Chemical Hardener | Viscosity-Reducing Agent/ Plasticizer | Absorber Content |

|---|---|---|---|---|

| 1 | Shell Epikote 828 (L1) | Ancamine 1618 | AX-R/AX-S | 75% |

| 2 | Shell Epikote 828 (L1) | Ancamine 1618 | AX-R/AX-S | 80% |

| 3 | Epidian 112 (L2) | Saduramid 10/50 | —/— | 75% |

| 4 | Epidian 112 (L2) | Saduramid 10/50 | —/— | 80% |

| Frequency (GHz) | Absorber Content 75% | Absorber Content 80% | Resin | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.5 mm | 1.0 mm | 1.5 mm | 2.0 mm | 0.5 mm | 1.0 mm | 1.5 mm | 2.0 mm | ||

| 4 | −4.5 | −5 | −4.5 | −18 | −1.7 | −2.6 | −5 | −6 | L1 |

| 6 | −4.5 | −7 | −7 | −12.5 | −1.9 | −3 | −7.5 | −8 | L1 |

| 8 | −7 | −12 | −12 | −9 | −2.1 | −5 | −11.5 | −14 | L1 |

| 10 | −7 | −13 | −11 | −7 | −2.3 | −7 | −12.5 | −12 | L1 |

| 12 | −5 | −10 | −7 | −5 | −2.5 | −9 | −11 | −6 | L1 |

| 14 | −4.5 | −5 | −4.5 | −4 | −2.8 | −10 | −7 | −5 | L1 |

| 16 | −4 | −4.5 | −4 | −4 | −5 | −10 | −6 | −5 | L1 |

| 18 | −4 | −4.5 | −4 | −4 | −6 | −10 | −6 | −5 | L1 |

| 4 | −1 | −1 | −1.8 | −6.7 | −1.2 | −1.7 | −1.8 | −15 | L2 |

| 5 | −0.9 | −1 | −1.9 | −6 | −1 | −1.3 | −1.9 | −13.6 | L2 |

| 6 | −0.8 | −1 | −2.1 | −5 | −0.9 | −1.3 | −2.1 | −12.5 | L2 |

| 7 | −1 | −1.1 | −2.8 | −3.9 | −0.9 | −1.7 | −3 | −10.6 | L2 |

| 8 | −1.1 | −1.4 | −3.8 | −2.9 | −1 | −2 | −4.2 | −8.1 | L2 |

| 9 | −1.2 | −1.8 | −5 | −2.1 | −1 | −2.2 | −6.2 | −6 | L2 |

| 10 | −1.3 | −2.1 | −6.5 | −2 | −1.1 | −2.7 | −8.9 | −4.2 | L2 |

| 11 | −1.5 | −2.3 | −8.3 | −2.2 | −1.3 | −3 | −12 | −3.3 | L2 |

| 12 | −1.8 | −2.9 | −10.4 | −2.7 | −1.4 | −3.3 | −14.8 | −3 | L2 |

| 13 | −2 | −3.5 | −13 | −3.2 | −1.5 | −4.1 | −16.1 | −3.1 | L2 |

| 14 | −2.4 | −4.1 | −16.2 | −3.9 | −1.8 | −5 | −16 | −3.2 | L2 |

| 15 | −2.8 | −4.5 | −18.9 | −4 | −2 | −6 | −14.5 | −3.6 | L2 |

| 16 | −3.1 | −4.9 | −20 | −5.1 | −2.2 | −7 | −13 | −4.1 | L2 |

| 17 | −3.6 | −5.1 | −20.1 | −6 | −2.5 | −7.5 | −12.5 | −4.7 | L2 |

| 18 | −3.7 | −5.2 | −20.2 | −6.1 | −2.8 | −7.5 | −12.2 | −4.9 | L2 |

| Resin | Absorber Content (%) | Thickness (mm) | Noise B (dB) | Amplitude A (dB) | Maximum Value B + A (dB) | Width Δ (GHz) | Max. Frequency μ (GHz) | Slope A/δ (dB/GHz) | R2 Value |

|---|---|---|---|---|---|---|---|---|---|

| L1 | 75 | 0.5 | −4.21 | −3.38 | −7.59 | 2.27 | 9.10 | 1.49 | 0.970 |

| L1 | 75 | 1 | −4.30 | −9.28 | −13.58 | 3.24 | 9.51 | 2.86 | 0.988 |

| L1 | 75 | 1.5 | −4.01 | −8.42 | −12.44 | 2.94 | 8.88 | 2.87 | 0.996 |

| L1 | 75 | 2 | −3.62 | −59.77 | −63.39 | 11.18 | −9.36 | 5.35 | 0.998 |

| L1 | 80 | 0.5 | −2.06 | −3.99 | −6.05 | 3.00 | 17.70 | 1.33 | 0.980 |

| L1 | 80 | 1 | −1.50 | −8.50 | −10.00 | 6.95 | 14.00 | 1.22 | 0.901 |

| L1 | 80 | 1.5 | −5.42 | −7.58 | −12.99 | 3.46 | 9.89 | 2.19 | 0.971 |

| L1 | 80 | 2 | −5.11 | −9.56 | −14.67 | 2.37 | 8.59 | 4.03 | 0.993 |

| L2 | 75 | 0.5 | −0.89 | −2.71 | −3.60 | 4.50 | 17.00 | 0.60 | 0.973 |

| L2 | 75 | 1 | −0.87 | −4.03 | −4.90 | 5.29 | 16.00 | 0.76 | 0.967 |

| L2 | 75 | 1.5 | −1.80 | −18.20 | −20.00 | 4.80 | 16.00 | 3.79 | 0.981 |

| L2 | 75 | 2 | −1.97 | −4.68 | −6.65 | 3.19 | 3.88 | 1.47 | 0.985 |

| −1.95 | −4.19 | −6.14 | 4.14 | 18.11 | 1.47 | 0.985 | |||

| L2 | 80 | 0.5 | −0.98 | −1.52 | −2.50 | 4.10 | 17.00 | 0.37 | 0.939 |

| L2 | 80 | 1 | −1.50 | −6.00 | −7.50 | 4.67 | 17.00 | 1.29 | 0.983 |

| L2 | 80 | 1.5 | −1.67 | −14.70 | −16.36 | 4.11 | 13.45 | 3.57 | 0.891 |

| L2 | 80 | 2 | −2.87 | −13.90 | −16.77 | 5.22 | 2.65 | 2.66 | 0.989 |

| 2 | −3.03 | −1.87 | −4.91 | 2.61 | 17.92 | 2.66 | 0.989 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Przybył, W.; Mazurczuk, R.; Kalinowski, A.; Bogdanowicz, K.A. Gaussian Model of Anti-Radar Properties for Coatings Based on Carbonyl Iron Powder. Materials 2023, 16, 3050. https://doi.org/10.3390/ma16083050

Przybył W, Mazurczuk R, Kalinowski A, Bogdanowicz KA. Gaussian Model of Anti-Radar Properties for Coatings Based on Carbonyl Iron Powder. Materials. 2023; 16(8):3050. https://doi.org/10.3390/ma16083050

Chicago/Turabian StylePrzybył, Wojciech, Robert Mazurczuk, Artur Kalinowski, and Krzysztof A. Bogdanowicz. 2023. "Gaussian Model of Anti-Radar Properties for Coatings Based on Carbonyl Iron Powder" Materials 16, no. 8: 3050. https://doi.org/10.3390/ma16083050

APA StylePrzybył, W., Mazurczuk, R., Kalinowski, A., & Bogdanowicz, K. A. (2023). Gaussian Model of Anti-Radar Properties for Coatings Based on Carbonyl Iron Powder. Materials, 16(8), 3050. https://doi.org/10.3390/ma16083050