Development of a Quartz-Based Photo-Mobile Polymer Film for Controlled Motion Triggered by Light or Heat

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the t-PMP-Mixture

2.3. Preparation of the t-PMP-Film

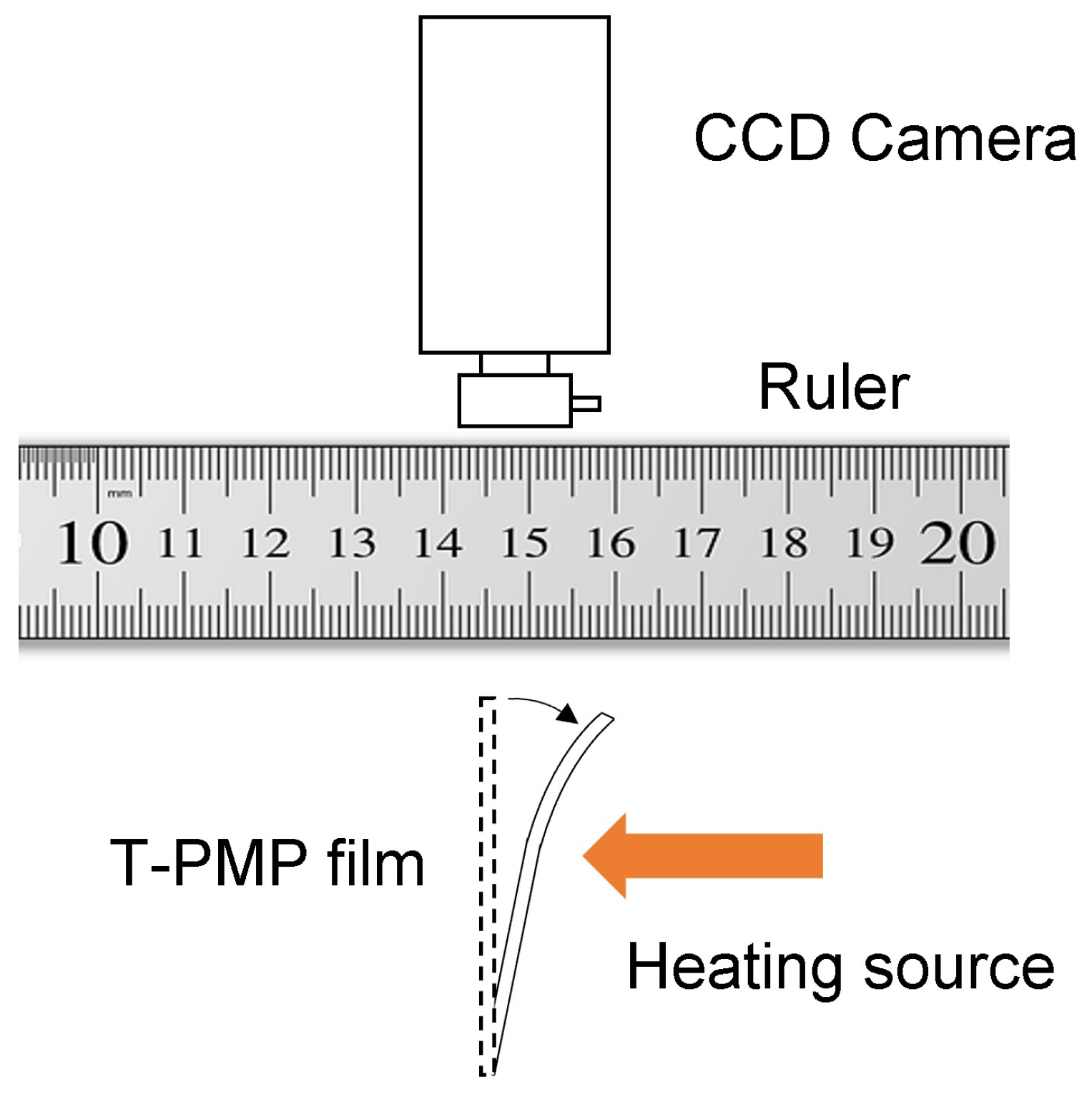

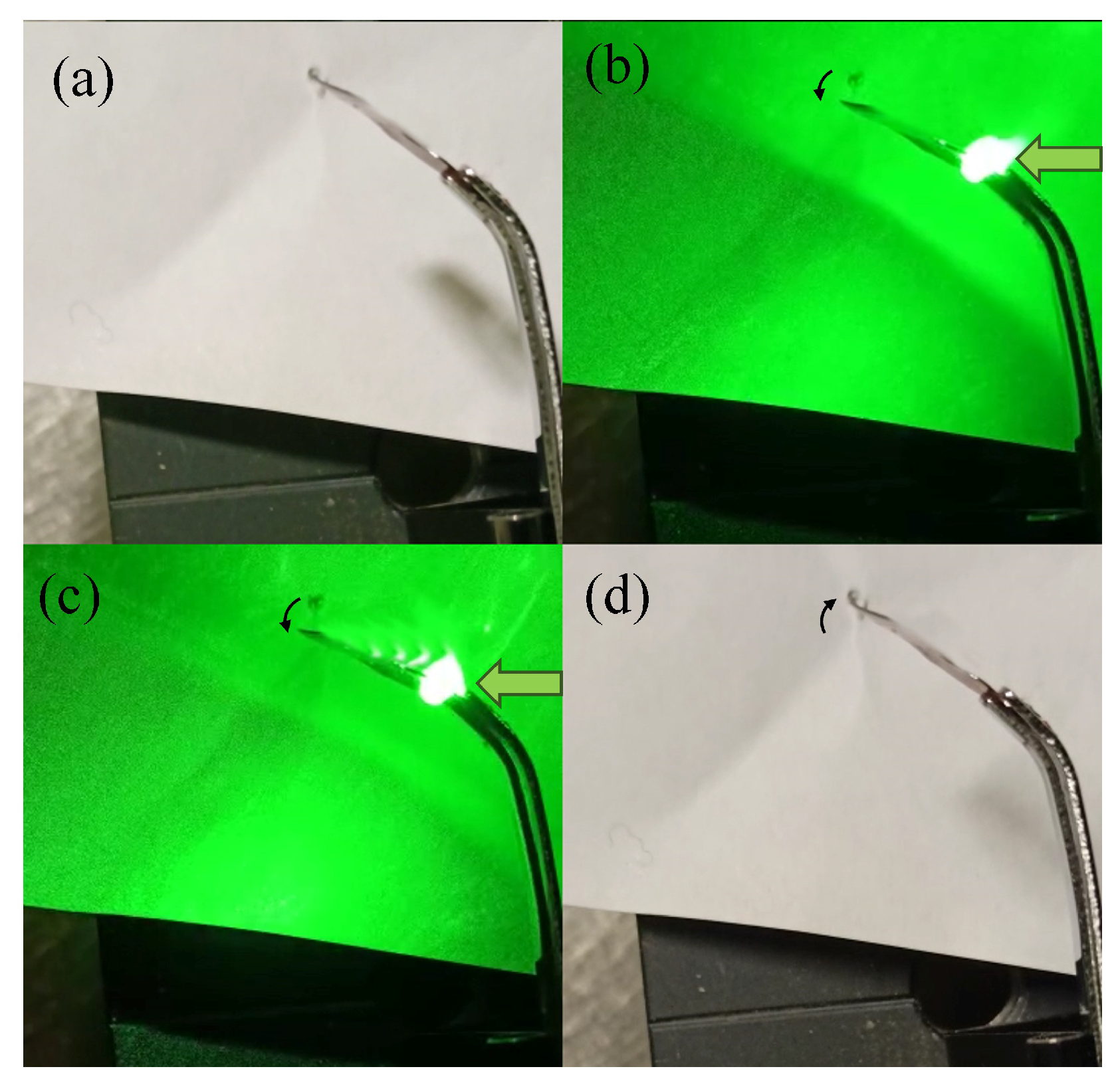

2.4. Set-Up

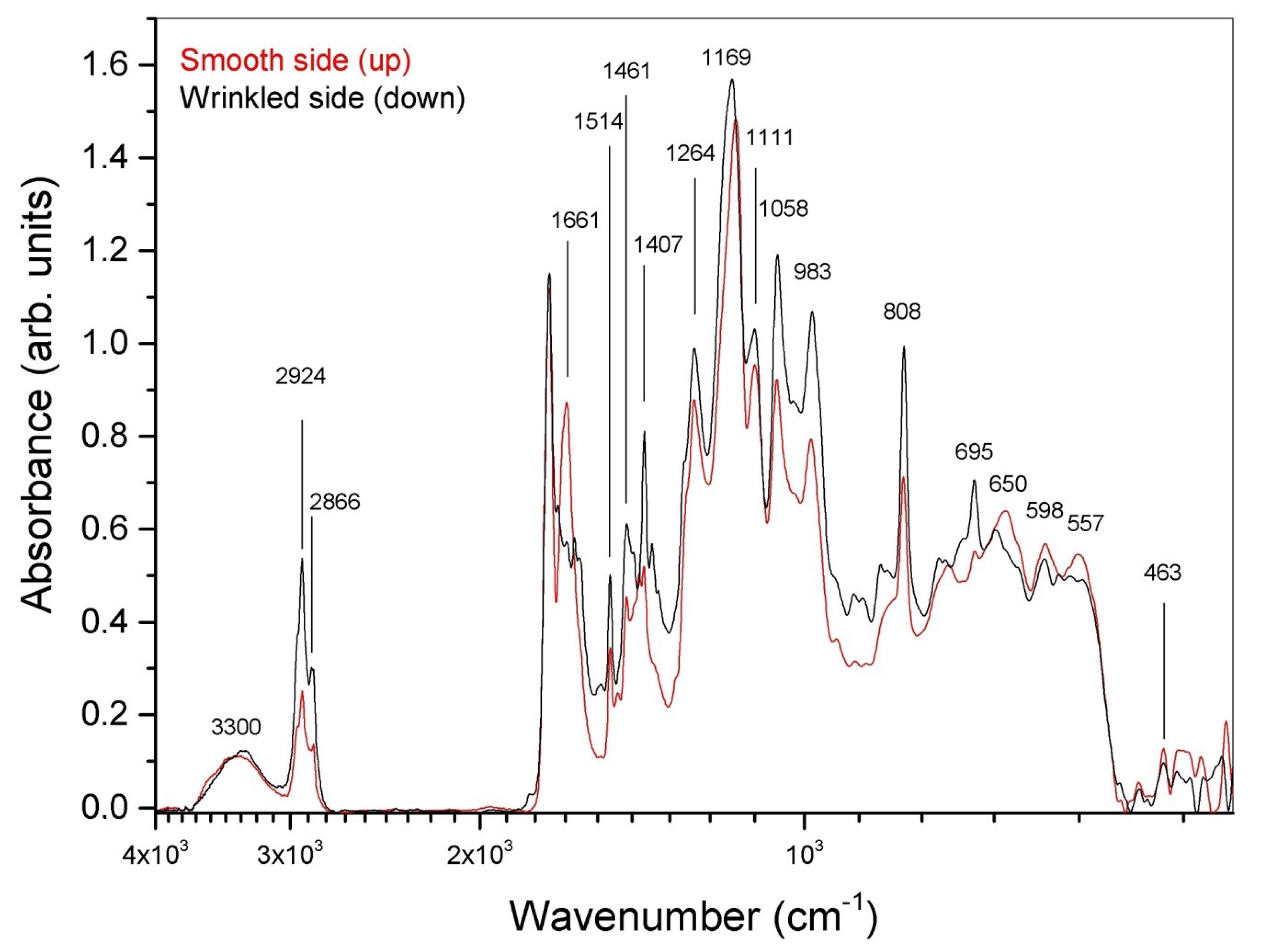

2.5. ATR-FTIR Measurements

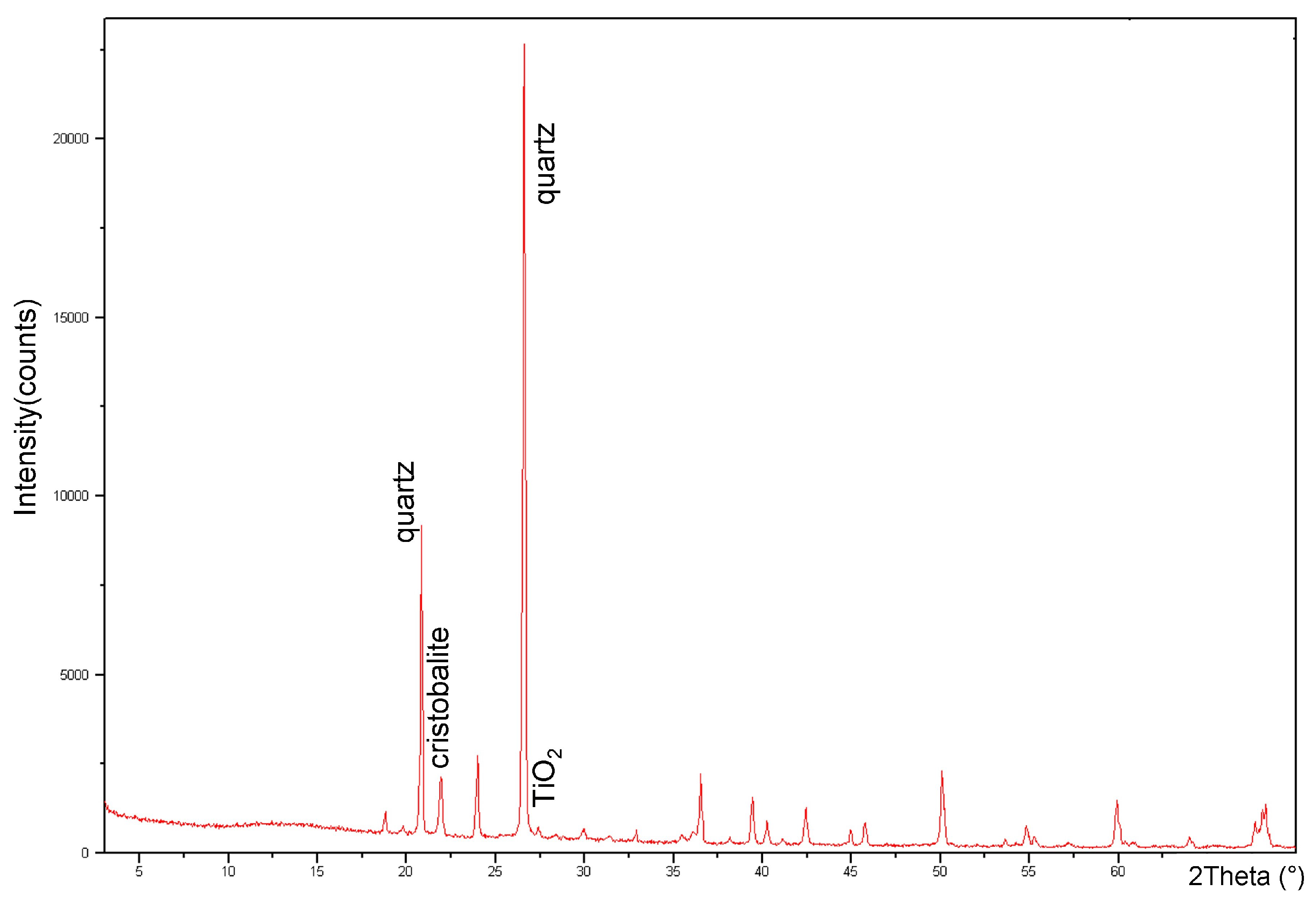

2.6. X-ray Measurements

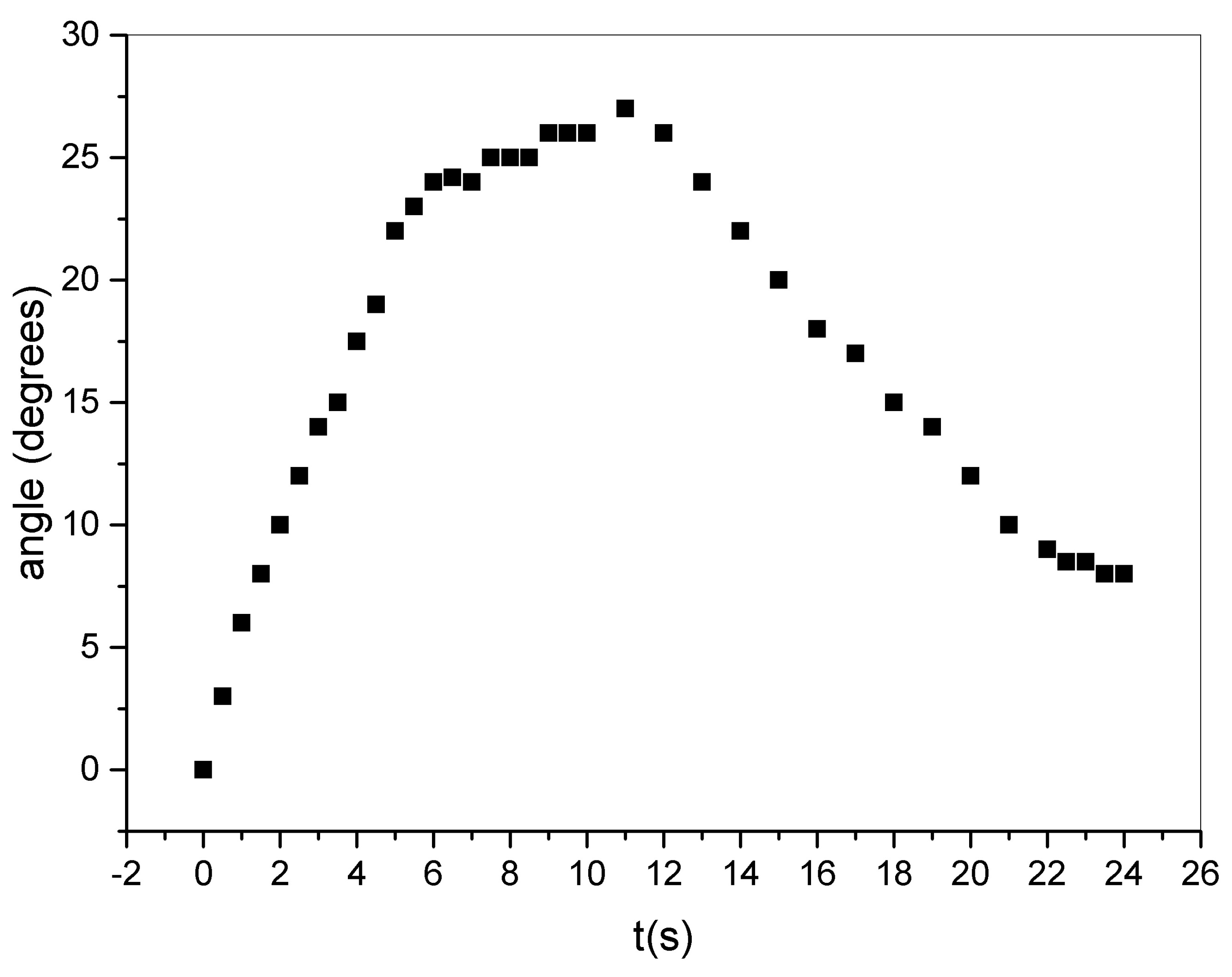

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Parameswarreddy, G.; Yadam, Y.R.; Arunachalam, K.; Sarathi, R.; Suematsu, H. Investigation on the enhancement of electromagnetic shielding with efficient use of short carbon fiber in MWCNT-epoxy nanocomposites. Polym. Compos. 2023, 44, 1522–1533. [Google Scholar] [CrossRef]

- Castagna, R.; Lucchetta, D.E.; Rippa, M.; Xu, J.H.; Donato, A.D. Near-frequency photons Y-splitter. Appl. Mater. Today 2020, 19, 100636. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Huan, D.; Li, L.; Liu, H.; Wang, W.; Wang, J.; Zhu, C.; Zhao, N. The effect of nanoparticle fillers on glass fiber/poly-ether-ether-ketone prepreg laser absorbance, thermal conductivity and interlayer performance. Polym. Compos. 2023, 44, 1836–1848. [Google Scholar] [CrossRef]

- Lucchetta, D.; Simoni, F.; Hernandez, R.; Mazzulla, A.; Cipparrone, G. Lasing from chiral doped nematic liquid crystal droplets generated in a microfluidic device. Mol. Cryst. Liq. Cryst. 2017, 649, 11–19. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, P.; Luo, J.; Li, B.; Liu, G.; Zhan, X. Effect of heat input on temperature characteristics and fusion behavior at bonding interface of CFRTP induction welded joint with carbon fiber susceptor. Polym. Compos. 2023, 44, 1586–1602. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Castagna, R.; Simoni, F. Light-actuated contactless macro motors exploiting Bénard–Marangoni convection. Opt. Express 2019, 27, 13574–13580. [Google Scholar] [CrossRef] [PubMed]

- Pinto, G.M.; Cremonezzi, J.M.O.; Ribeiro, H.; Andrade, R.J.E.; Demarquette, N.R.; Fechine, G.J.M. From two-dimensional materials to polymer nanocomposites with emerging multifunctional applications: A critical review. Polym. Compos. 2023, 44, 1438–1470. [Google Scholar] [CrossRef]

- Xiong, X.; del Campo, A.; Cui, J. Chapter 4—Photoresponsive Polymers. In Smart Polymers and Their Applications, 2nd ed.; Aguilar, M.R., San Román, J., Eds.; Woodhead Publishing in Materials; Woodhead Publishing: Oxford, UK, 2019; pp. 87–153. [Google Scholar] [CrossRef]

- Kumar, G.S.; Neckers, D.C. Photochemistry of azobenzene-containing polymers. Chem. Rev. 1989, 89, 1915–1925. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, L.; Ma, S.; Zhang, H. Fully Room-Temperature Reprogrammable, Reprocessable, and Photomobile Soft Actuators from a High-Molecular-Weight Main-Chain Azobenzene Crystalline Poly(ester-amide). ACS Appl. Mater. Interfaces 2022, 14, 3264–3273. [Google Scholar] [CrossRef]

- Castagna, R.; Rippa, M.; Simoni, F.; Villani, F.; Nenna, G.; Petti, L. Plasmonic Photomobile Polymer Films. Crystals 2020, 10, 660. [Google Scholar] [CrossRef]

- Lyu, X.; Xiao, A.; Shi, D.; Li, Y.; Shen, Z.; Chen, E.Q.; Zheng, S.; Fan, X.H.; Zhou, Q.F. Liquid crystalline polymers: Discovery, development, and the future. Polymer 2020, 202, 122740. [Google Scholar] [CrossRef]

- Castagna, R.; Di Donato, A.; Strangi, G.; Lucchetta, D.E. Light controlled bending of a holographic transmission phase grating. Smart Mater. Struct. 2022, 31, 03LT02. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Di Donato, A.; Singh, G.; Tombesi, A.; Castagna, R. Optically tunable diffraction efficiency by photo-mobile holographic composite polymer material. Opt. Mater. 2021, 121, 111612. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Di Donato, A.; Francescangeli, O.; Singh, G.; Castagna, R. Light-Controlled Direction of Distributed Feedback Laser Emission by Photo-Mobile Polymer Films. Nanomaterials 2022, 12, 2890. [Google Scholar] [CrossRef]

- Castagna, R.; Nucara, L.; Simoni, F.; Greci, L.; Rippa, M.; Petti, L.; Lucchetta, D.E. An Unconventional Approach to Photomobile Composite Polymer Films. Adv. Mater. 2017, 29, 1604800. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Di Donato, A.; Paturzo, M.; Singh, G.; Castagna, R. Light-Induced Dynamic Holography. Micromachines 2022, 13, 297. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Castellini, P.; Martarelli, M.; Scalise, L.; Pandarese, G.; Riminesi, C.; Singh, G.; Di Donato, A.; Francescangeli, O.; Castagna, R. Light-Controlled Rotational Speed of an Acoustically Levitating Photomobile Polymer Film. Materials 2023, 16, 553. [Google Scholar] [CrossRef]

- Wells, L.A.; Lasowski, F.; Fitzpatrick, S.D.; Sheardown, H. Responding to Change: Thermo- and Photoresponsive Polymers as Unique Biomaterials. Crit. Rev. Trade Biomed. Eng. 2010, 38, 487–509. [Google Scholar] [CrossRef]

- Teotia, A.; Sami, H.; Kumar, A. 1—Thermo-responsive polymers: Structure and design of smart materials. In Switchable and Responsive Surfaces and Materials for Biomedical Applications; Zhang, Z., Ed.; Woodhead Publishing: Oxford, UK, 2015; pp. 3–43. [Google Scholar] [CrossRef]

- Hirayama, R.; Plasencia, D.M.; Masuda, N.; Subramanian, S. A volumetric display for visual, tactile and audio presentation using acoustic trapping. Nature 2019, 575, 320–323. [Google Scholar] [CrossRef]

- Ochiai, Y.; Hoshi, T.; Rekimoto, J. Three-Dimensional Mid-Air Acoustic Manipulation by Ultrasonic Phased Arrays. PLoS ONE 2014, 9, e097590. [Google Scholar] [CrossRef]

- Marzo, A.; Barnes, A.; Drinkwater, B.W. TinyLev: A multi-emitter single-axis acoustic levitator. Rev. Sci. Instrum. 2017, 88, 085105. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castagna, R.; Riminesi, C.; Pianesi, M.S.; Sabbatini, S.; Di Donato, A.; Singh, G.; Francescangeli, O.; Cantisani, E.; Castellini, P.; Lucchetta, D.E. Development of a Quartz-Based Photo-Mobile Polymer Film for Controlled Motion Triggered by Light or Heat. Materials 2023, 16, 3046. https://doi.org/10.3390/ma16083046

Castagna R, Riminesi C, Pianesi MS, Sabbatini S, Di Donato A, Singh G, Francescangeli O, Cantisani E, Castellini P, Lucchetta DE. Development of a Quartz-Based Photo-Mobile Polymer Film for Controlled Motion Triggered by Light or Heat. Materials. 2023; 16(8):3046. https://doi.org/10.3390/ma16083046

Chicago/Turabian StyleCastagna, Riccardo, Cristiano Riminesi, Maria Savina Pianesi, Simona Sabbatini, Andrea Di Donato, Gautam Singh, Oriano Francescangeli, Emma Cantisani, Paolo Castellini, and Daniele Eugenio Lucchetta. 2023. "Development of a Quartz-Based Photo-Mobile Polymer Film for Controlled Motion Triggered by Light or Heat" Materials 16, no. 8: 3046. https://doi.org/10.3390/ma16083046

APA StyleCastagna, R., Riminesi, C., Pianesi, M. S., Sabbatini, S., Di Donato, A., Singh, G., Francescangeli, O., Cantisani, E., Castellini, P., & Lucchetta, D. E. (2023). Development of a Quartz-Based Photo-Mobile Polymer Film for Controlled Motion Triggered by Light or Heat. Materials, 16(8), 3046. https://doi.org/10.3390/ma16083046