Design Optimization of Additive Manufactured Edgeless Simple Cubic Lattice Structures under Compression

Abstract

1. Introduction

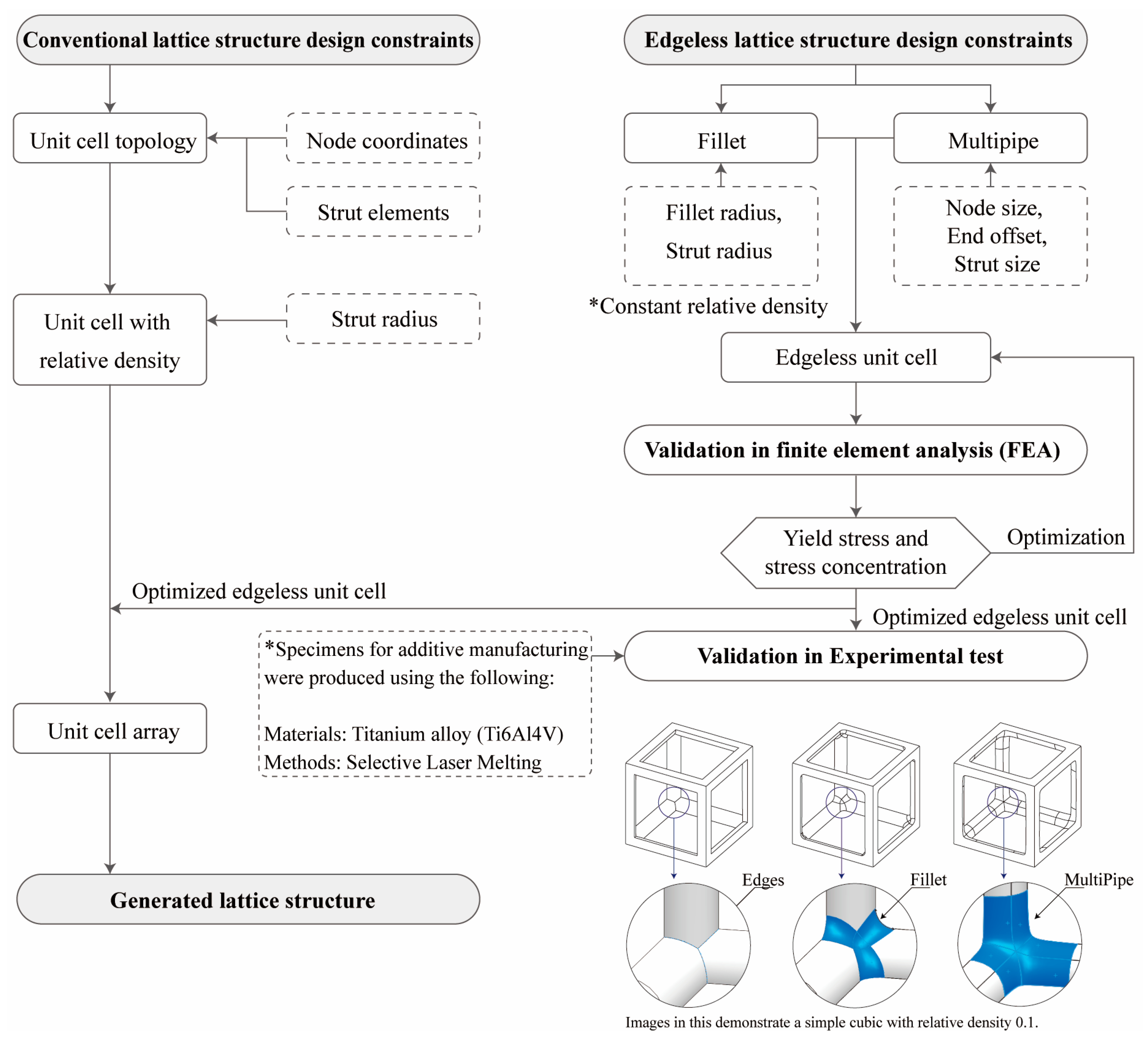

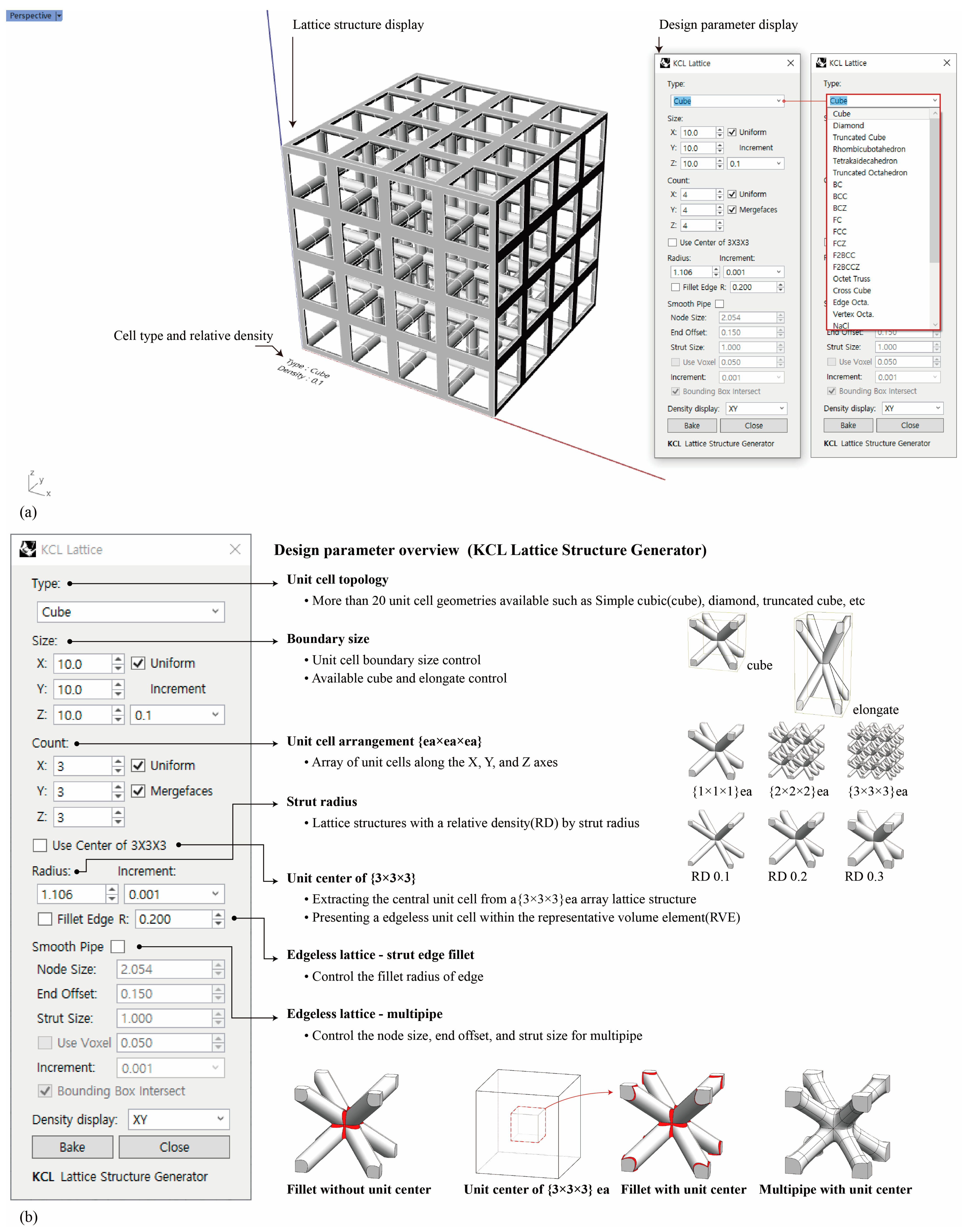

2. Methodologies

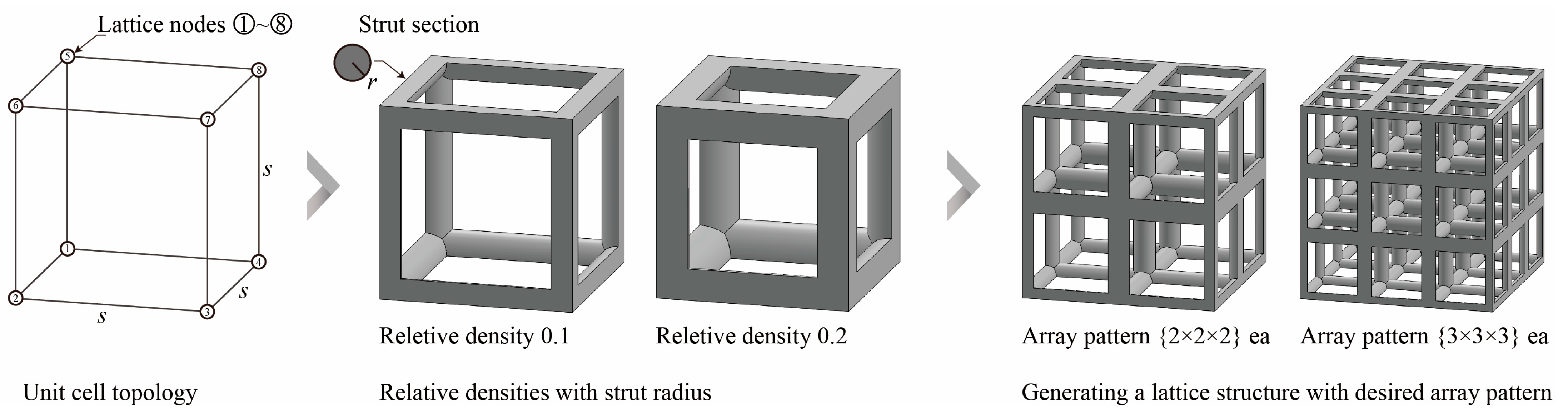

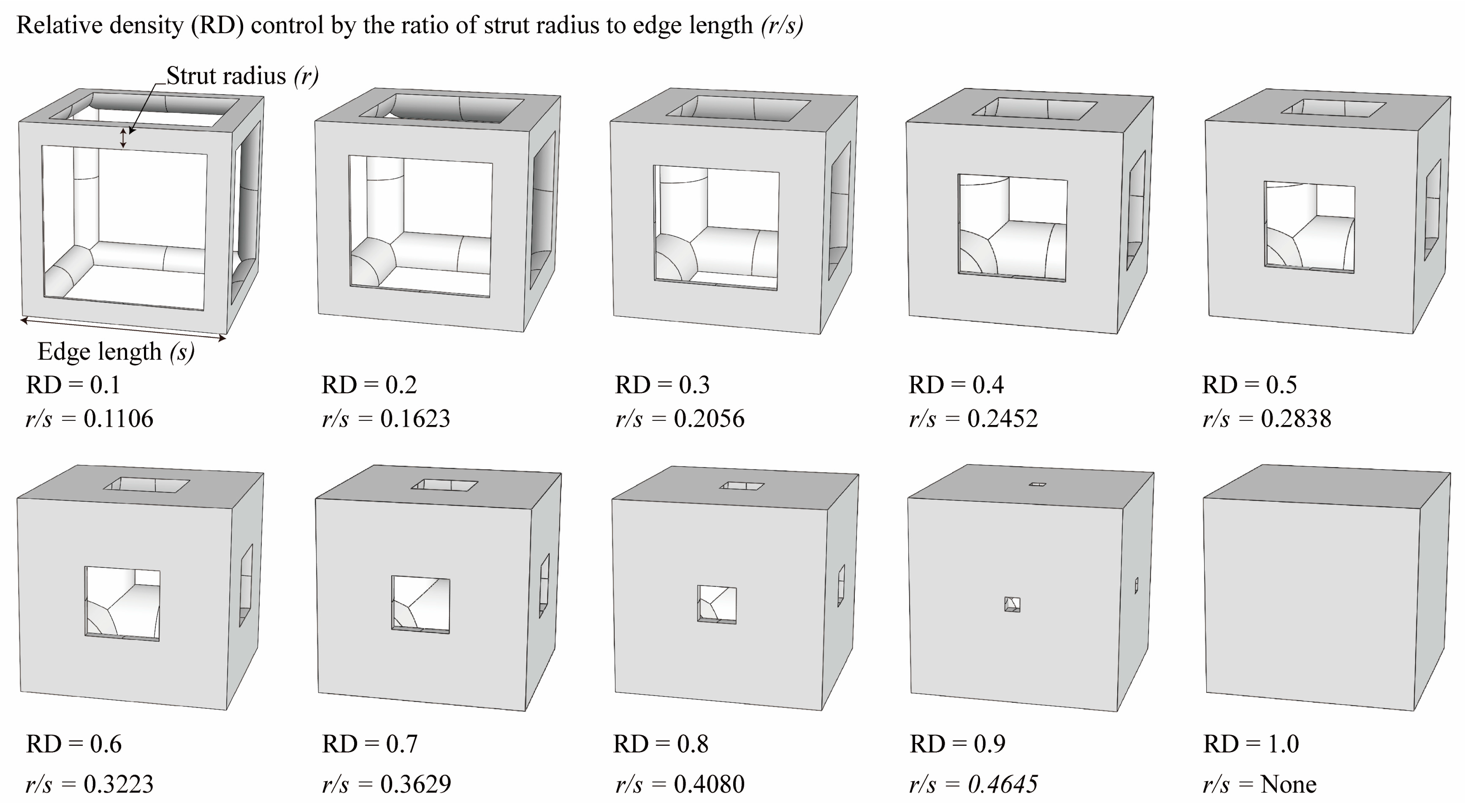

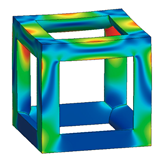

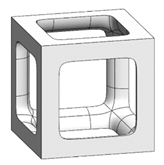

2.1. Conventional Lattice Configuration

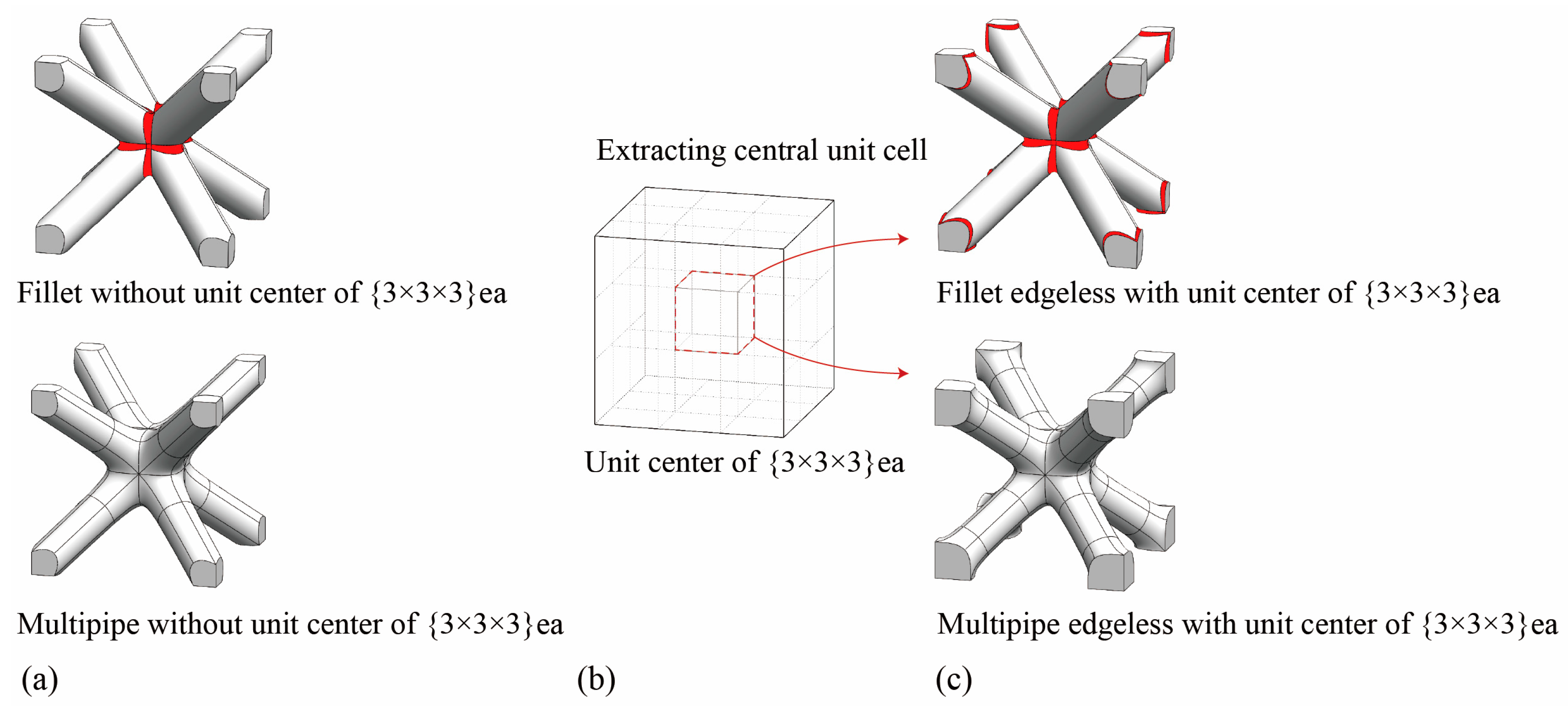

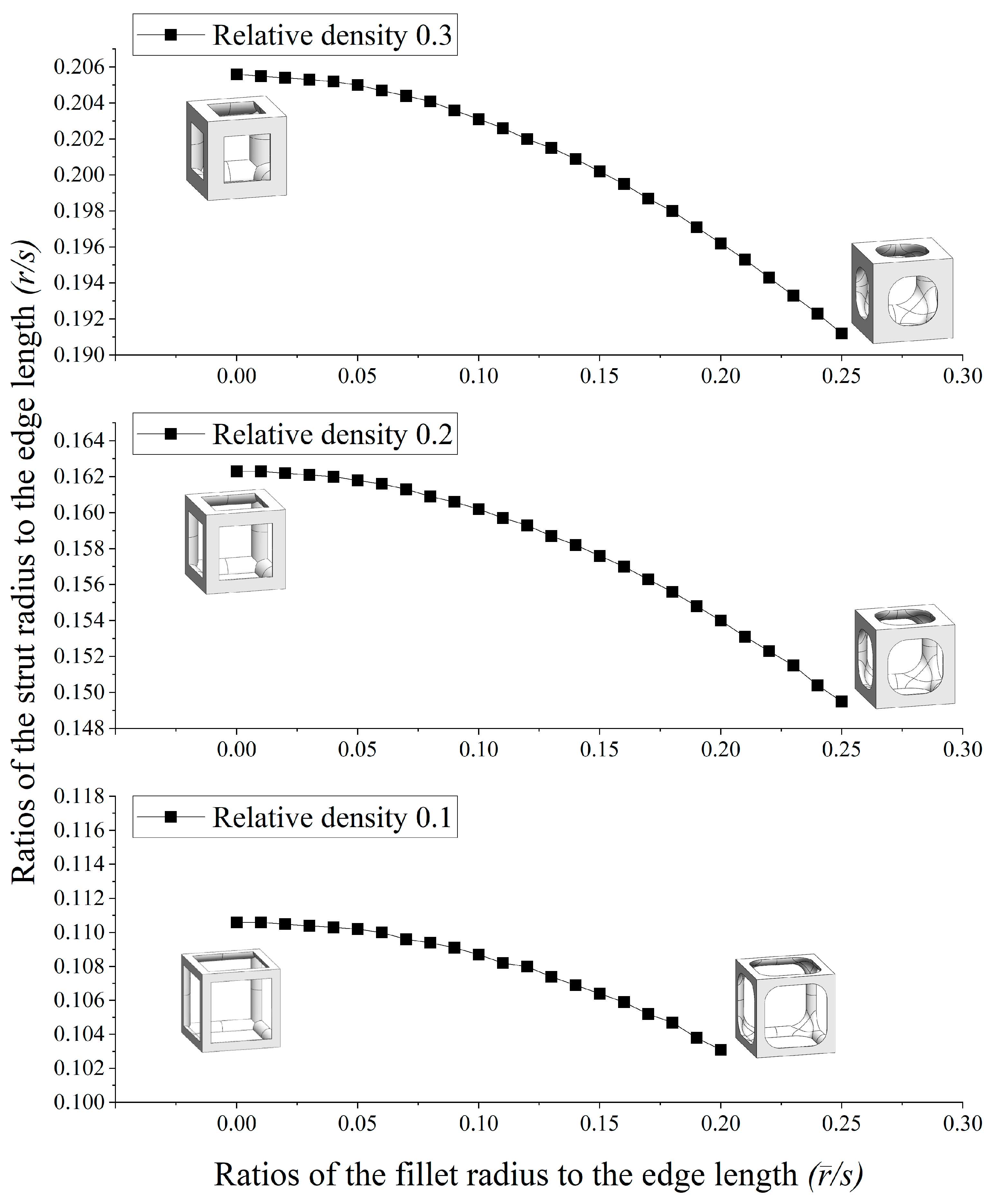

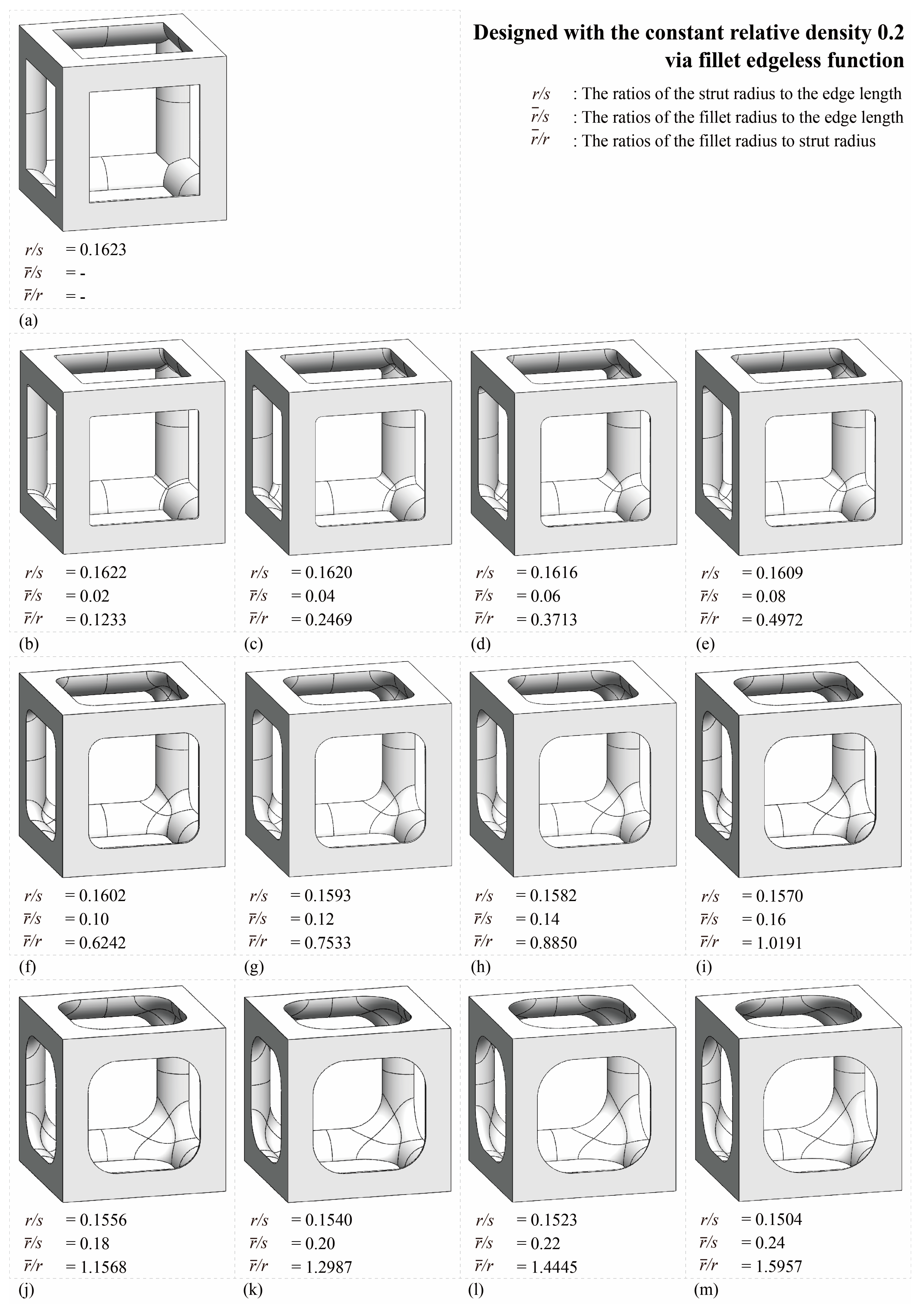

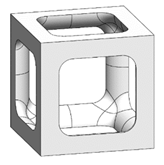

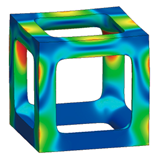

2.2. Fillet Edgeless Lattice Configuration

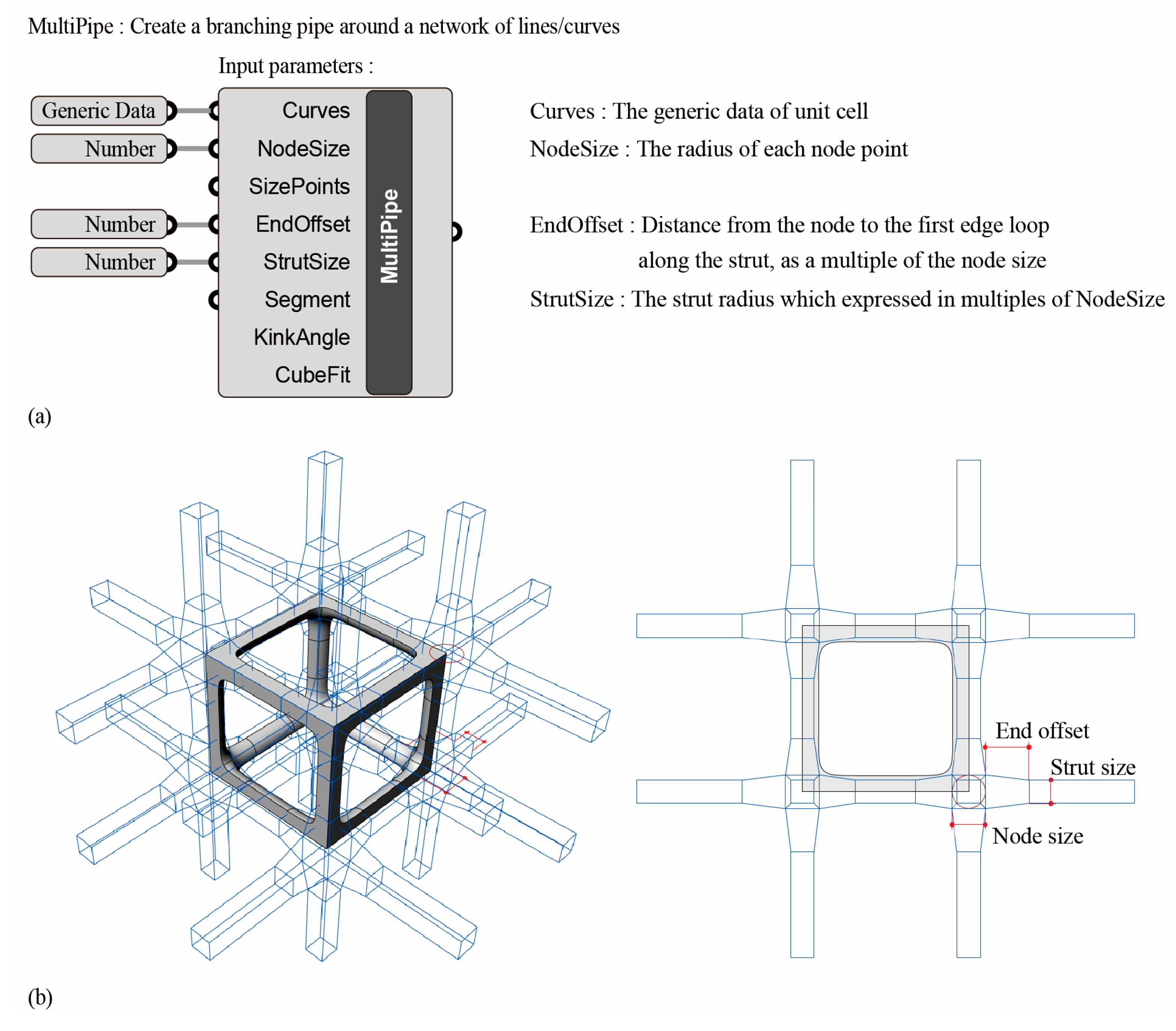

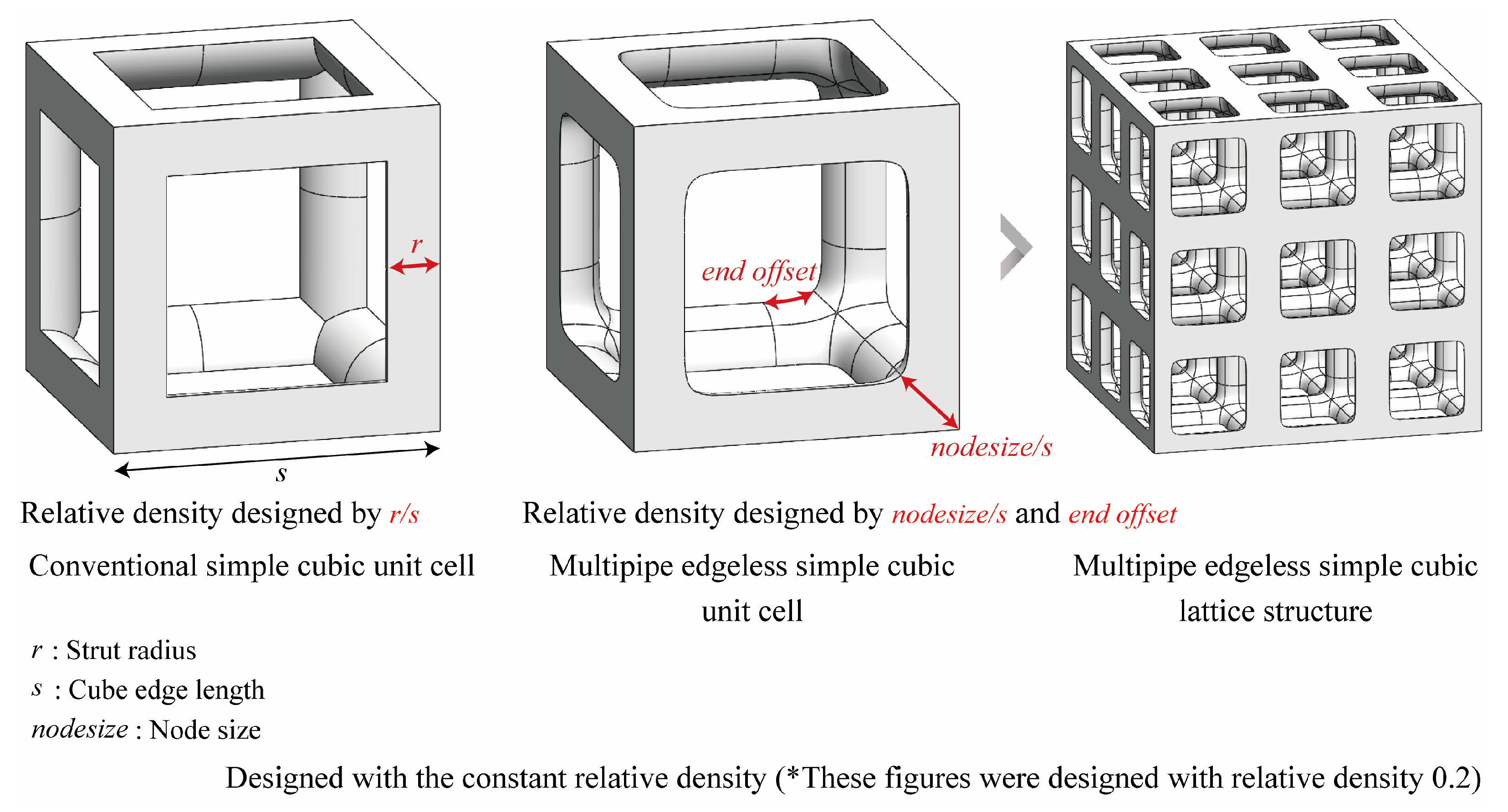

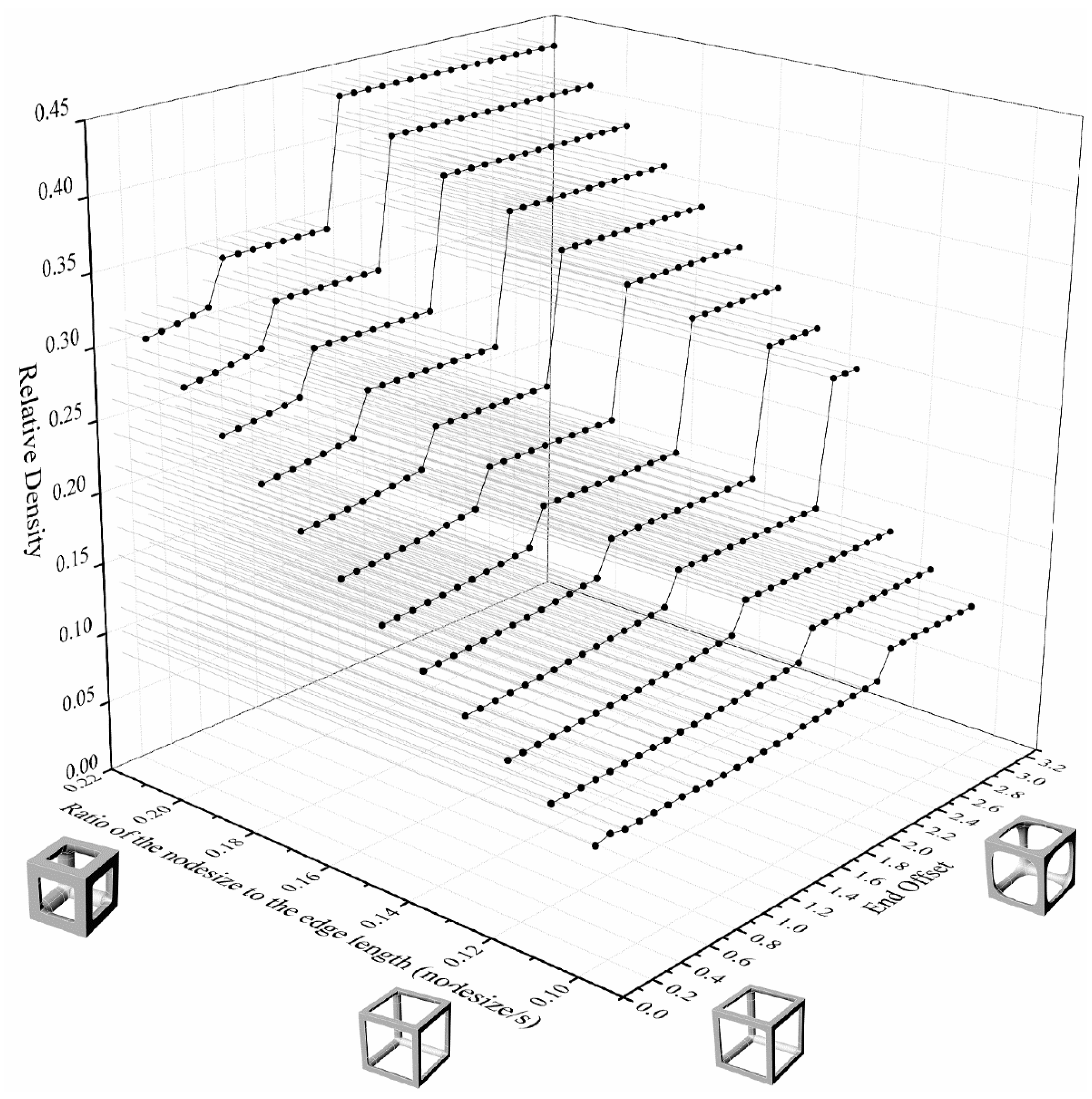

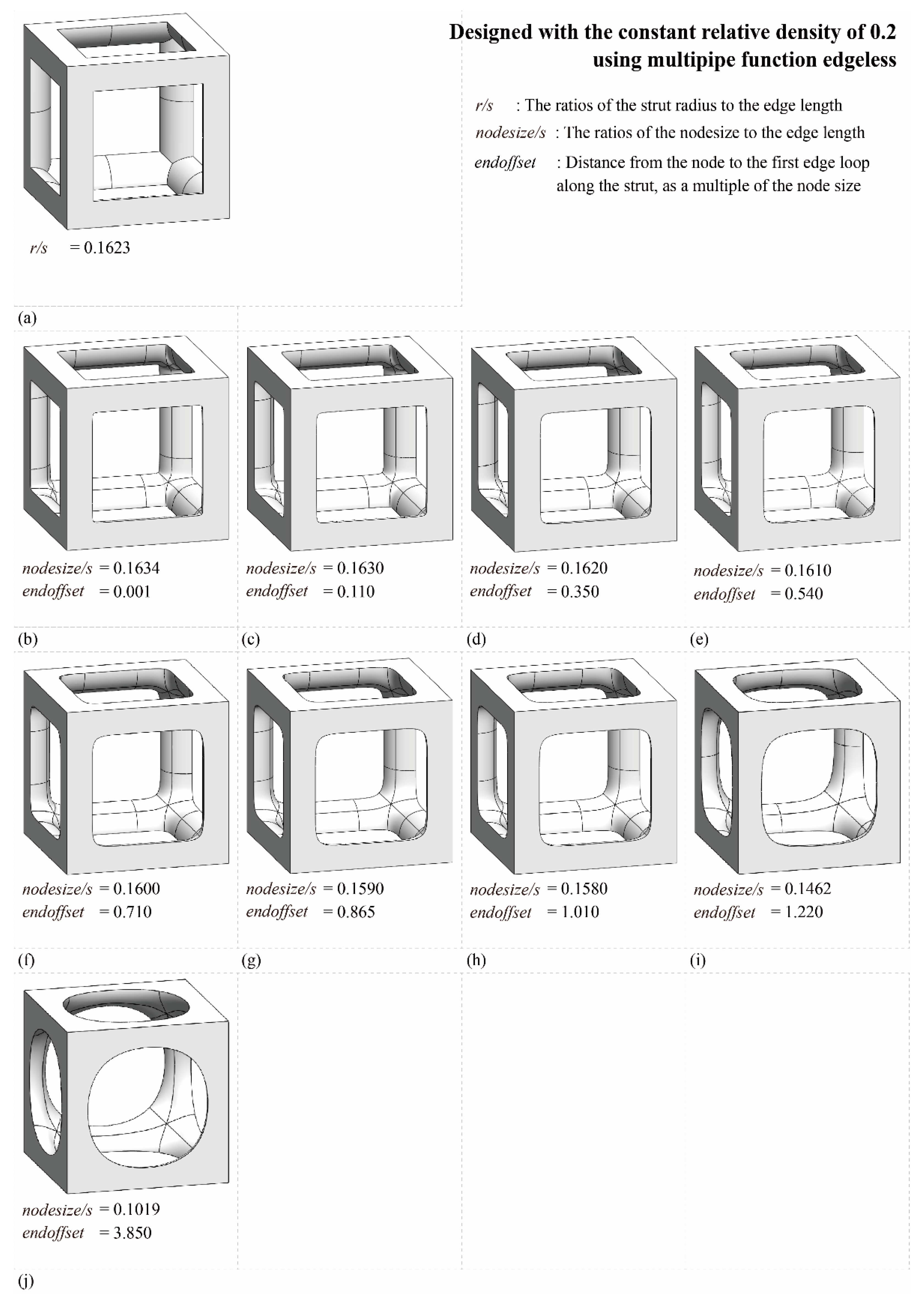

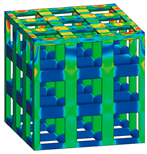

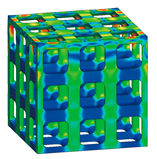

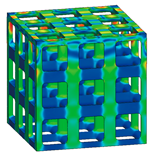

2.3. Multipipe Edgeless Lattice Configuration

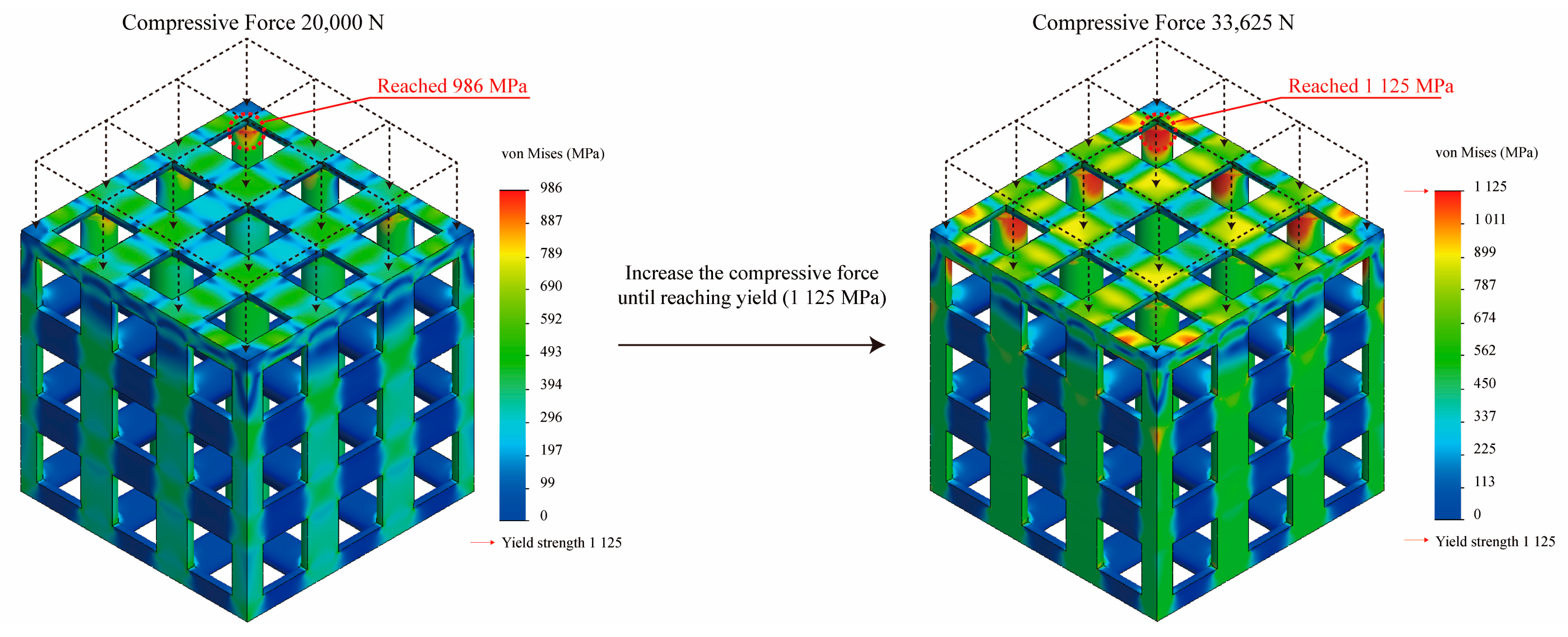

2.4. Finite Element Analysis

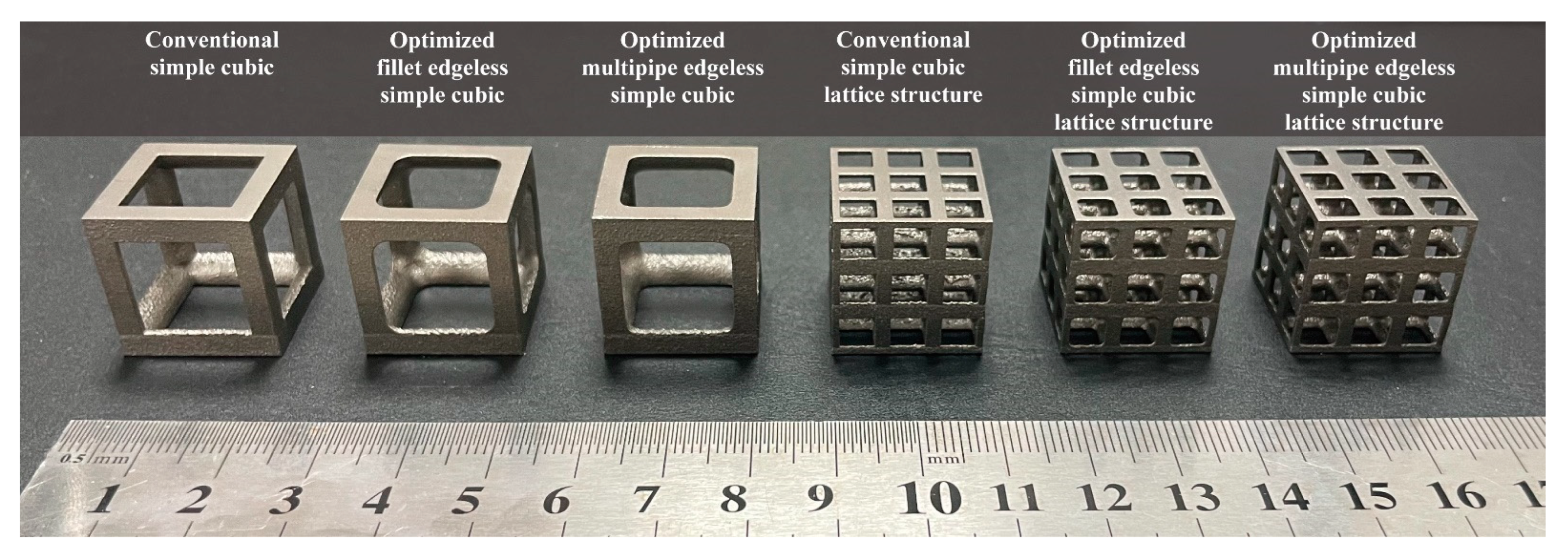

2.5. Specimens for Additive Manufacturing and Experimental Compressive Tests

3. Results and Discussion

3.1. Fillet Edgeless Simple Cubic Unit Cell

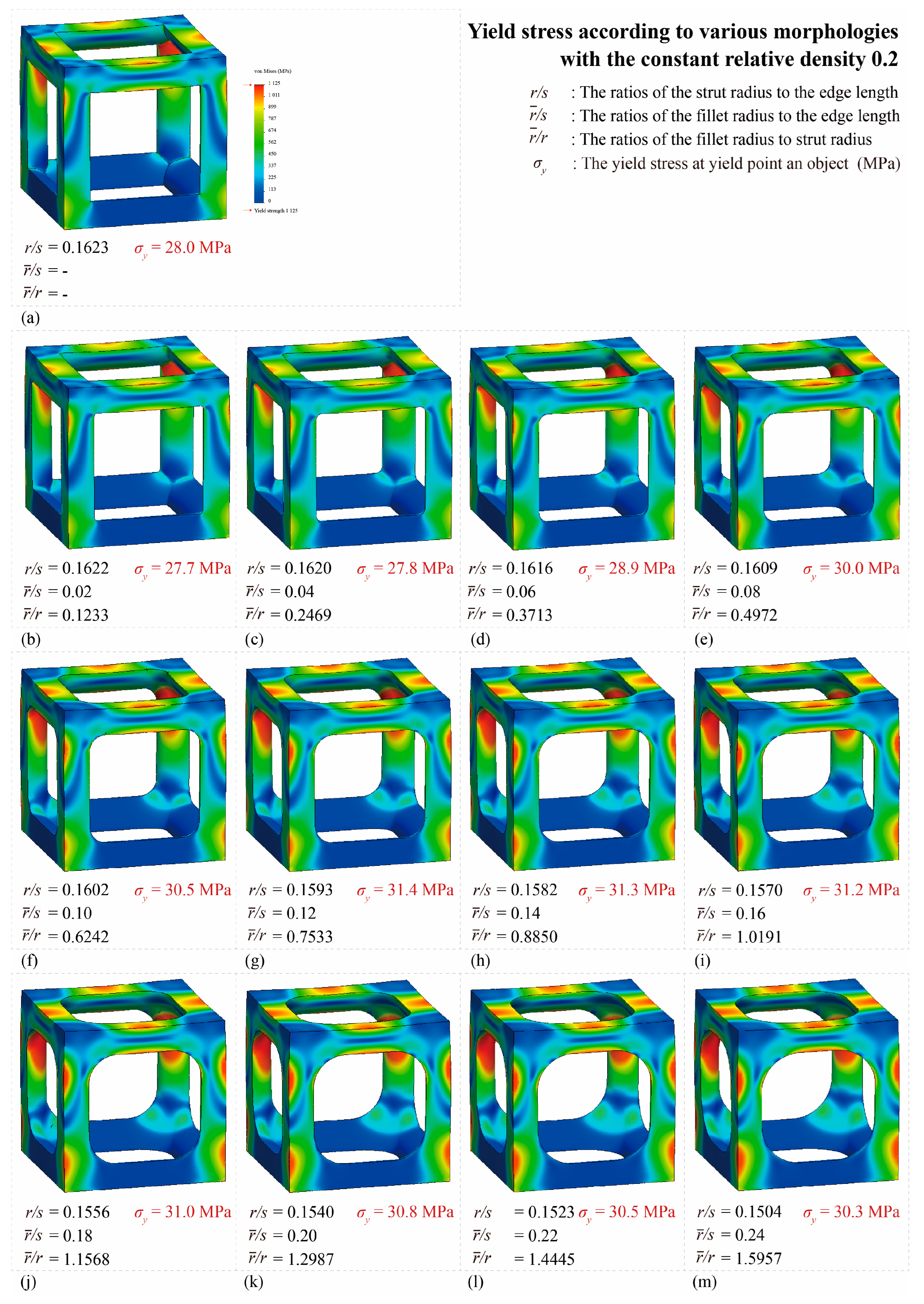

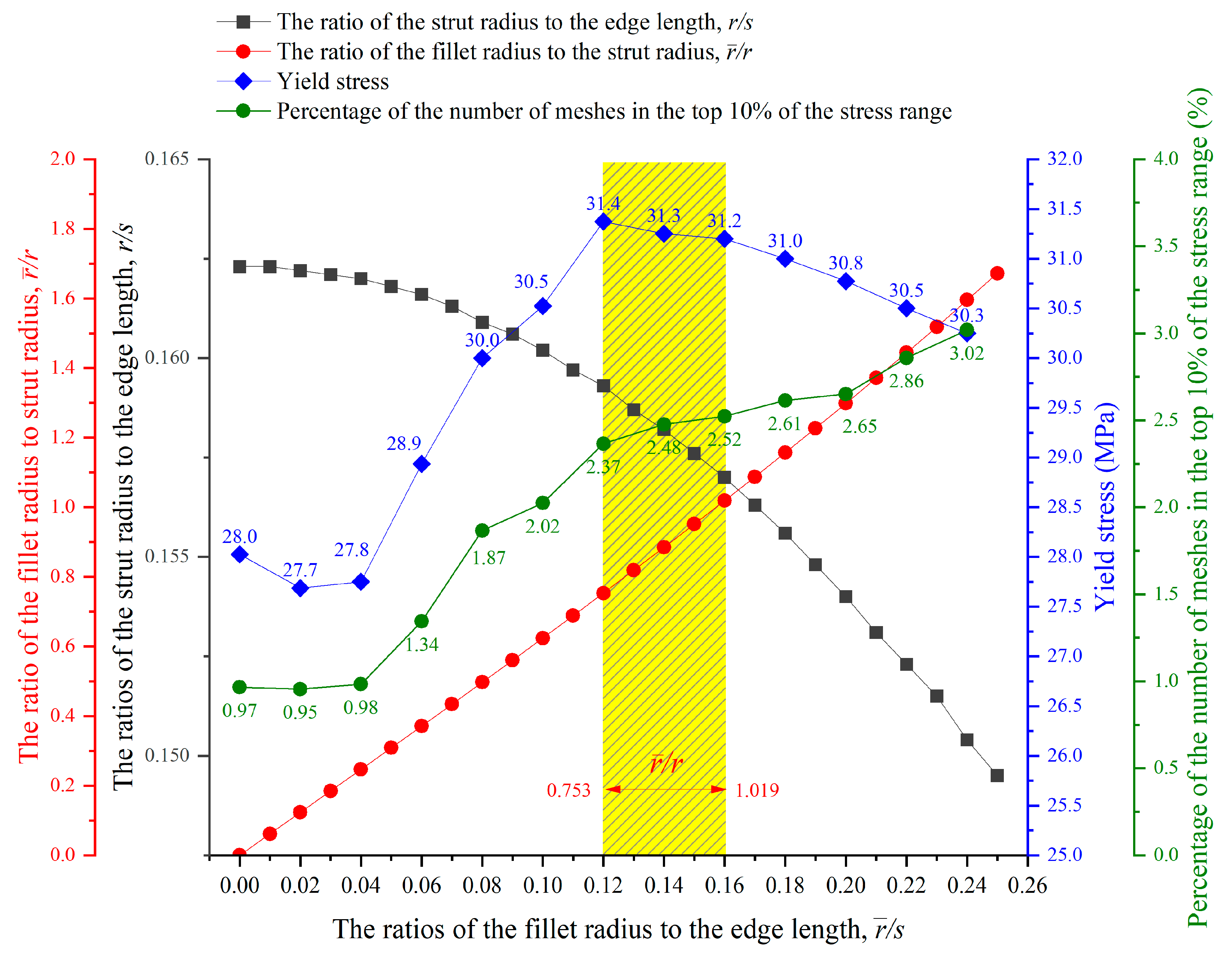

3.1.1. Yield Stress Improvement Effect with Fillet Edgeless Function

3.1.2. Reducing Stress Concentration with the Edgeless Unit Cell Design

3.2. Multipipe Edgeless Simple Cubic Unit Cell

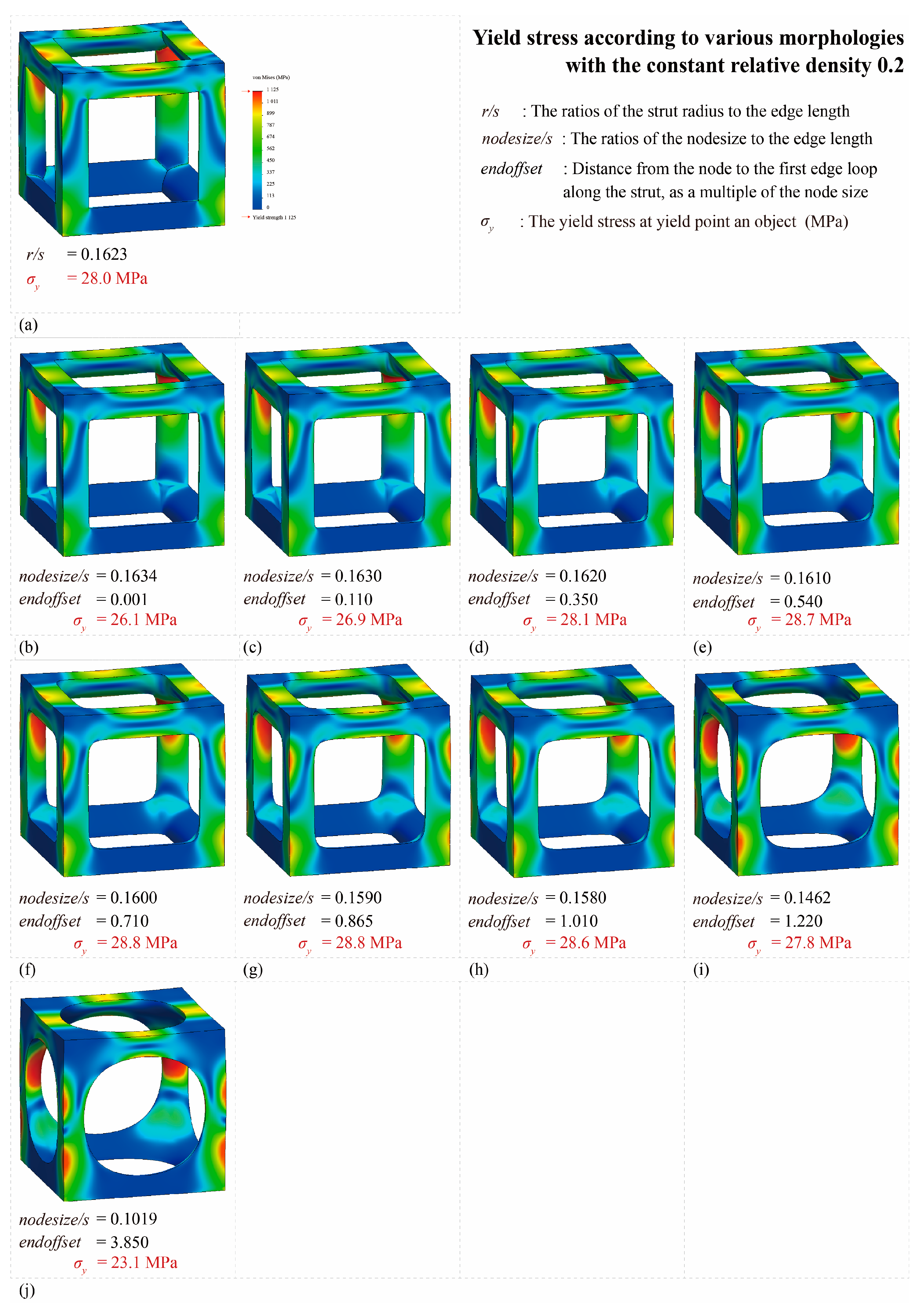

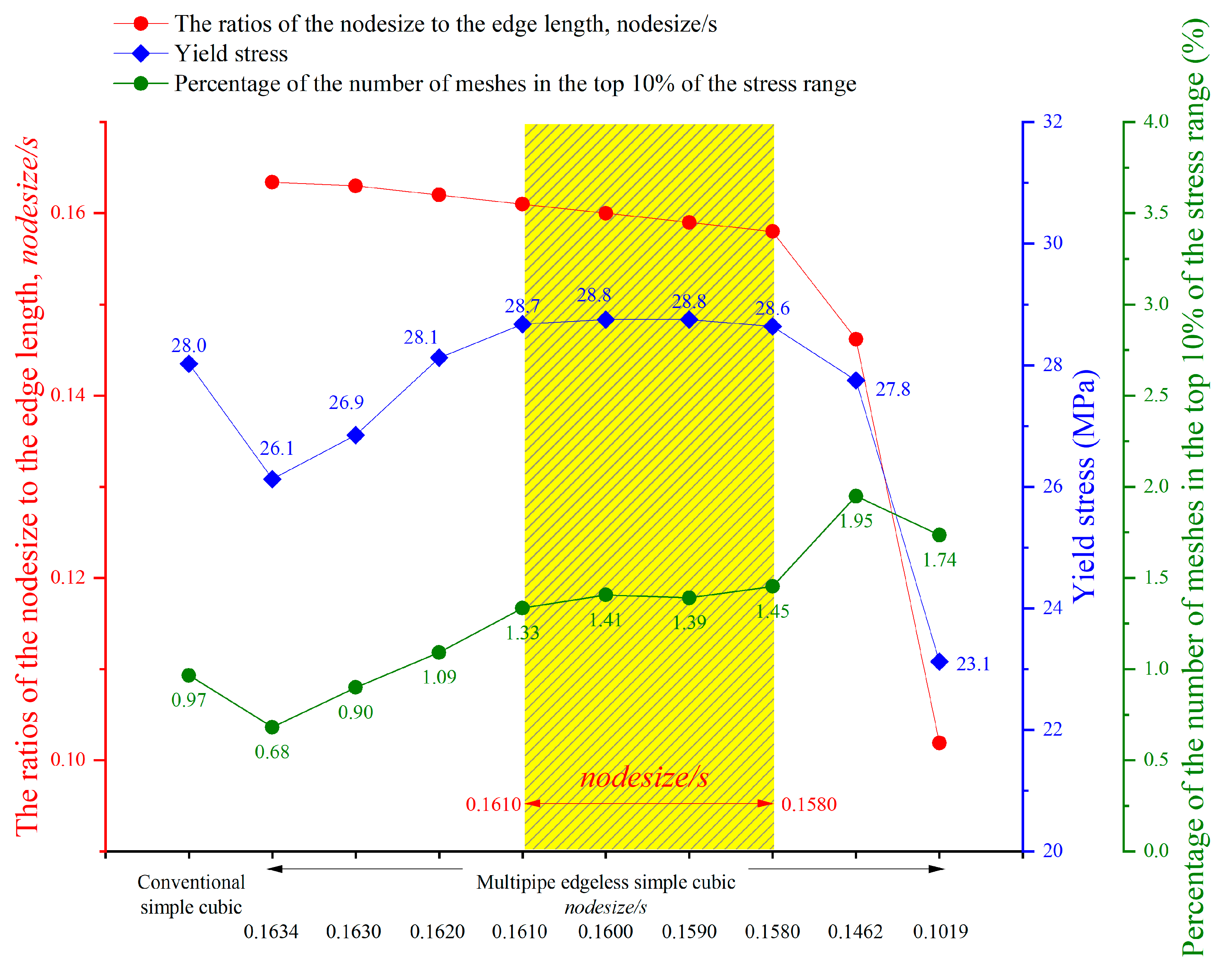

3.2.1. Yield Stress Improvement Effect with Multipipe Edgeless Function

3.2.2. Reducing Stress Concentration with Edgeless Unit Cell Function

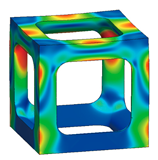

3.3. Optimized Edgeless Lattice Structure

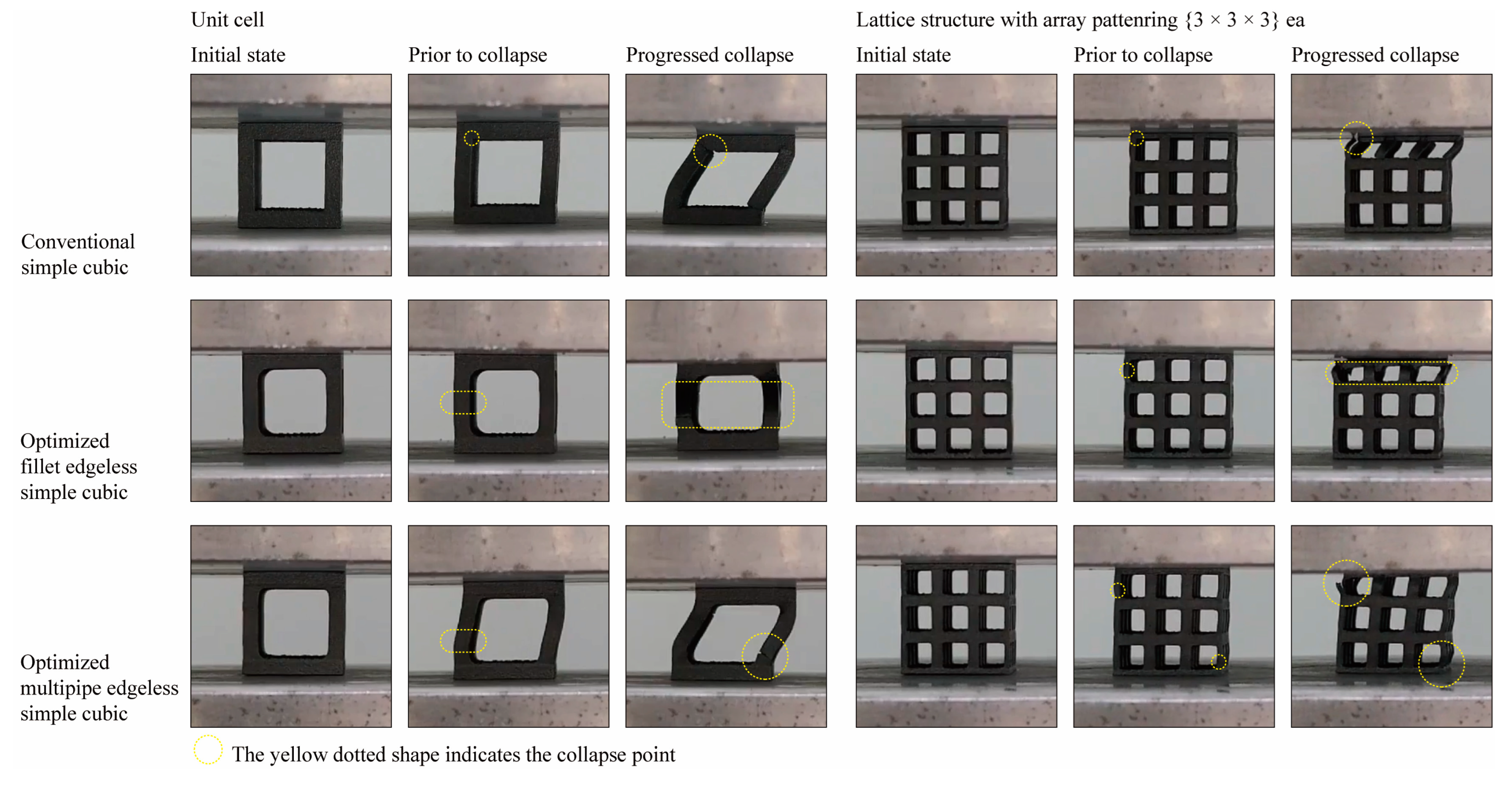

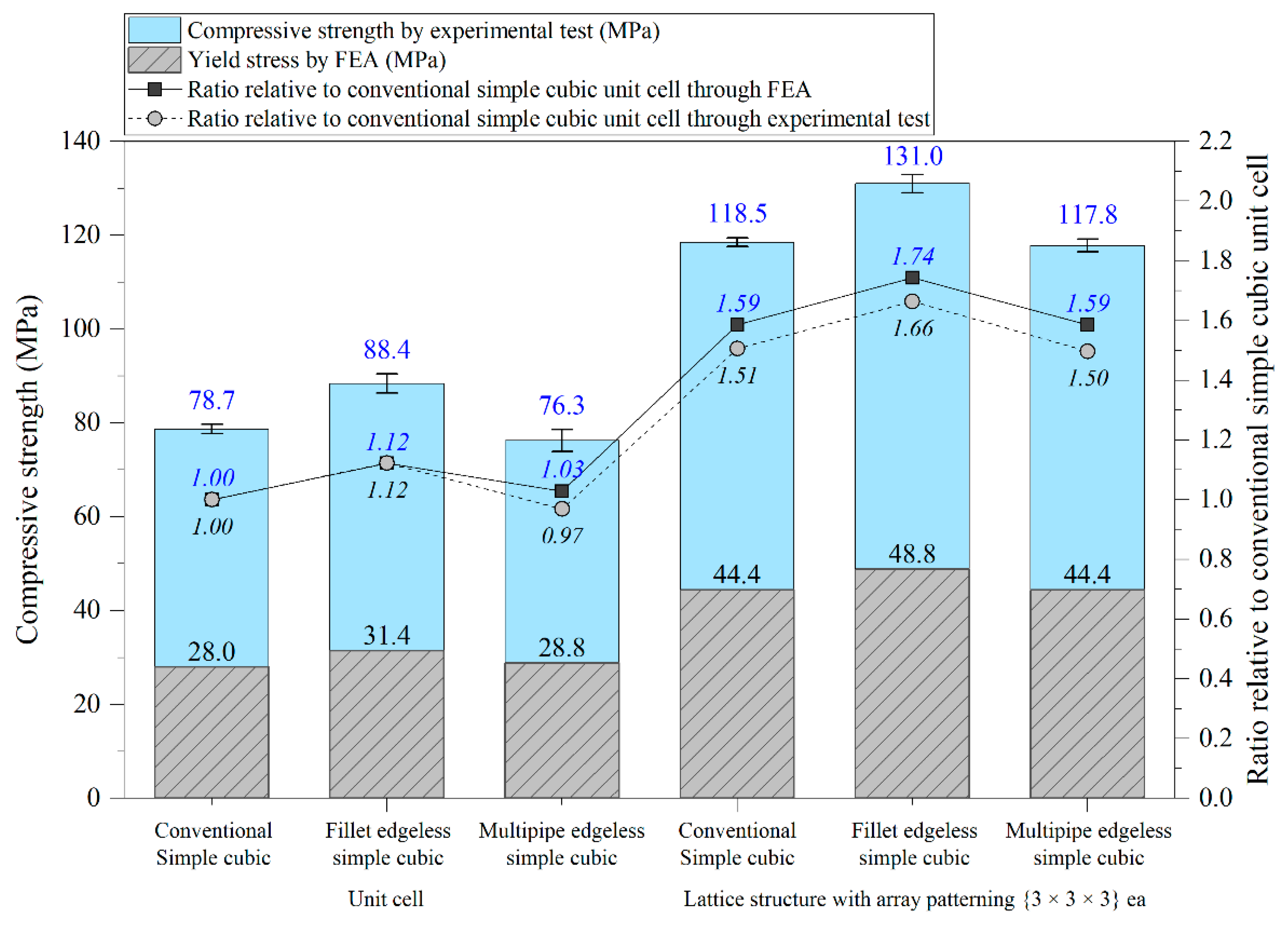

3.4. Validation through Experimental Compressive Test

3.5. Limitations of the Study

4. Conclusions

- Methodologies and frameworks for design optimization were established to achieve optimized edgeless lattice structures assisted by the lattice structure generator plugin for Rhinoceros, which is called the KCL lattice structure generator. The results were achieved by: (i) introducing the derivation of the representative relative density of the edgeless unit cell by extracting the central unit cell from the {3 × 3 × 3} ea arranged lattice structure; (ii) introducing fillet edgeless function by design variable parameters (i.e., the ratio of the fillet radius to the strut radius (); (iii) introducing multipipe edgeless function by design variable parameters (i.e., the ratio of the node size to the edge length () and ); and (iv) introducing a new method for evaluating the degree of stress concentration by the number of meshes subjected to stress, which corresponds to the top 10% of the von Mises stress distribution.

- Through nonlinear static FEA, it was confirmed that the optimized fillet edgeless simple cubic unit cell improved the properties of yield stress and stress concentration. The yield stress of the fillet edgeless simple cubic unit cell with 0.753 ≤ ≤ 1.109 was improved by approximately 12.1% compared to the conventional simple cubic unit cell. When 0.753 ≤ ≤ 1.109, the percentage of the number of meshes in the top 10% of the stress range ranged from 2.37% to 2.52%, which means that it was effective in reducing stress concentration, compared to that of the conventional simple cubic at 0.97%.

- Through nonlinear static FEA, it was confirmed that the optimized multipipe edgeless simple cubic unit cell improved the properties of yield stress and stress concentration. In the optimized multipipe edgeless parameters presented in this study, the yield stress of multipipe edgeless simple cubic unit cell with 0.1610 ≤ ≤ 1.1580 was improved by approximately 2.9% compared to that of the conventional simple cubic unit cell. However, it was observed that the improvement was less effective than the fillet edgeless function.

- The experimental compressive tests confirmed that the introduction of edgeless functions to lattice structures improved their compressive strength. The optimized fillet edgeless simple cubic structure showed the most significant improvement compared to conventional simple cubic and multipipe edgeless structures. The results of the compressive strength tests were consistent with the FEA results, and initial fractures occurred at stress concentration locations derived from FEA. However, further FEA and experimental tests are needed to study the detailed deformation beyond the elastic region into the plastic region and final fracture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mazur, M.; Leary, M.; McMillan, M.; Sun, S.; Shidid, D.; Brandt, D. Mechanical Properties of Ti6Al4V and AlSi12Mg Lattice Structures Manufactured by Selective Laser Melting (SLM). In Woodhead Publishing Series in Electronic and Optical Materials; Laser Additive Manufacturing; Woodhead Publishing: Cambridge, UK, 2017; Volume 5, pp. 119–161. [Google Scholar] [CrossRef]

- Cao, X.; Duan, S.; Liang, J.; Wen, W.; Fang, D. Mechanical properties of an improved 3D-printed rhombic dodecahedron stainless steel lattice structure of variable cross section. Int. J. Mech. Sci. 2018, 145, 53–63. [Google Scholar] [CrossRef]

- Xiao, D.; Dong, Z.; Li, Y.; Wu, W.; Fang, D. Compression behavior of the graded metallic auxetic reentrant honeycomb: Experiment and finite element analysis. Mater. Sci. Eng. A 2019, 758, 163–171. [Google Scholar] [CrossRef]

- Pan, C.; Han, Y.; Lu, J. Design and Optimization of Lattice Structures: A Review. Appl. Sci. 2020, 10, 6374. [Google Scholar] [CrossRef]

- Vasiliev, V.V.; Barynin, V.A.; Razin, A.F. Anisogrid composite lattice structures—Development and aerospace applications. Compos. Struct. 2012, 94, 1117–1127. [Google Scholar] [CrossRef]

- Zhu, J.-H.; Zhang, W.-H.; Xia, L. Topology Optimization in Aircraft and Aerospace Structures Design. Arch. Comput. Methods Eng. 2016, 23, 595–622. [Google Scholar] [CrossRef]

- Zhu, L.; Li, N.; Childs, P.R.N. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Yin, S.; Chen, H.; Wu, Y.; Li, Y.; Xu, J. Introducing composite lattice core sandwich structure as an alternative proposal for engine hood. Compos. Struct. 2018, 201, 131–140. [Google Scholar] [CrossRef]

- Magerramova, L.; Volkov, M.; Afonin, A.; Svinareva, M.; Kalinin, D. Application of light lattice structures for gas turbine engine fan blades. In Proceedings of the 31st Congress of the International Council of the Aeronautical Sciences (ICAS), Belo Horizonte, Brazil, 9–14 September 2018; pp. 1–10. [Google Scholar]

- Moon, S.K.; Tan, Y.E.; Hwang, J.; Yoon, Y.-J. Application of 3D printing technology for designing light-weight unmanned aerial vehicle wing structures. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 223–228. [Google Scholar] [CrossRef]

- Jetté, B.; Brailovski, V.; Dumas, M.; Simoneau, C.; Terriault, P. Femoral stem incorporating a diamond cubic lattice structure: Design, manufacture and testing. J. Mech. Behav. Biomed. Mater. 2018, 77, 58–72. [Google Scholar] [CrossRef]

- Dumas, M.; Terriault, P.; Brailovski, V. Modelling and characterization of a porosity graded lattice structure for additively manufactured biomaterials. Mater. Des. 2017, 121, 383–392. [Google Scholar] [CrossRef]

- Gorguluarslan, R.M.; Choi, S.-K.; Saldana, C.J. Uncertainty quantification and validation of 3D lattice scaffolds for computer-aided biomedical applications. J. Mech. Behav. Biomed. Mater. 2017, 71, 428–440. [Google Scholar] [CrossRef] [PubMed]

- Gibson, L.J.; Ashby, M.F.; Brendan, A.H. Cellular Materials in Nature and Medicine, 1st ed.; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Zadpoor, A.A. Mechanical performance of additively manufactured meta-biomaterials. Acta Biomater. 2019, 85, 41–59. [Google Scholar] [CrossRef] [PubMed]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Yavari, S.A.; Ahmadi, S.M.; Wauthle, R.; Pouran, B.; Schrooten, J.; Weinans, H.; Zadpoor, A.A. Relationship between unit cell type and porosity and the fatigue behavior of selective laser melted meta-biomaterials. J. Mech. Behav. Biomed. Mater. 2015, 43, 91–100. [Google Scholar] [CrossRef] [PubMed]

- Park, K.-M.; Min, K.-S.; Roh, Y.-S. Design Optimization of Lattice Structures under Compression: Study of Unit Cell Types and Cell Arrangements. Materials 2021, 15, 97. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mater. Process. Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology: Bending versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Queheillalt, D.T.; Murty, Y.; Wadley, H.N.G. Mechanical properties of an extruded pyramidal lattice truss sandwich structure. Scr. Mater. 2008, 58, 76–79. [Google Scholar] [CrossRef]

- ASTM F2792-12; Standard Terminology for Additive Manufacturing Technologies. ASTM: West Conshohocken, PA, USA, 2012.

- Yeong, W.; Sudarmadji, N.; Yu, H.; Chua, C.; Leong, K.; Venkatraman, S.; Boey, Y.; Tan, L. Porous polycaprolactone scaffold for cardiac tissue engineering fabricated by selective laser sintering. Acta Biomater. 2010, 6, 2028–2034. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Bhavar, V.; Kattire, P.; Patil, V.; Khot, S.; Gujar, K.; Singh, R. A review on powder bed fusion technology of metal additive manufacturing. In Additive Manufacturing Handbook; CRC Press: Boca Raton, FL, USA, 2017; pp. 251–253. [Google Scholar]

- Bai, L.; Zhang, J.; Chen, X.; Yi, C.; Chen, R.; Zhang, Z. Configuration Optimization Design of Ti6Al4V Lattice Structure Formed by SLM. Materials 2018, 11, 1856. [Google Scholar] [CrossRef]

- Chen, L.-Y.; Zhang, H.-Y.; Zheng, C.; Yang, H.-Y.; Qin, P.; Zhao, C.; Lu, S.; Liang, S.-X.; Chai, L.; Zhang, L.-C. Corrosion behavior and characteristics of passive films of laser powder bed fusion produced Ti–6Al–4V in dynamic Hank’s solution. Mater. Des. 2021, 208, 109907. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Y.; Zhang, J.; Gu, X.; Qin, P.; Dai, N.; Li, X.; Kruth, J.-P.; Zhang, L.-C. Improved corrosion behavior of ultrafine-grained eutectic Al-12Si alloy produced by selective laser melting. Mater. Des. 2018, 146, 239–248. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Williams, H.; Yang, E.; Alghamdi, A.; Lozanovski, B.; Zhang, X.; Shidid, D.; Farahbod-Sternahl, L.; Witt, G.; et al. Inconel 625 lattice structures manufactured by selective laser melting (SLM): Mechanical properties, deformation and failure modes. Mater. Des. 2018, 157, 179–199. [Google Scholar] [CrossRef]

- Park, S.-I.; Rosen, D.W. Homogenization of Mechanical Properties for Material Extrusion Periodic Lattice Structures Considering Joint Stiffening Effects. J. Mech. Des. 2018, 140, 111414. [Google Scholar] [CrossRef]

- Bai, L.; Yi, C.Y.; Chen, X.H.; Sun, Y.X.; Zhang, J.F. Effective Design of the Graded Strut of BCC Lattice Structure for Improving Mechanical Properties. Materials 2019, 12, 2192. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.-H.; Nie, Y.-F.; Liu, B.; Kuai, Z.-Z.; Zhao, M.; Liu, F. Mechanical properties of AlSi10Mg lattice structures fabricated by selective laser melting. Mater. Des. 2020, 192, 108709. [Google Scholar] [CrossRef]

- Nazir, A.; Arshad, A.-B.; Hsu, C.-P.; Jeng, J.-Y. Effect of Fillets on Mechanical Properties of Lattice Structures Fabricated Using Multi-Jet Fusion Technology. Materials 2021, 14, 2194. [Google Scholar] [CrossRef] [PubMed]

- Latture, R.M.; Rodriguez, R.X.; Holmes, L.R., Jr.; Zok, F.W. Effects of nodal fillets and external boundaries on compressive response of an octet truss. Acta Mater. 2018, 149, 78–87. [Google Scholar] [CrossRef]

- Zhao, M.; Liu, F.; Fu, G.; Zhang, D.Z.; Zhang, T.; Zhou, H. Improved Mechanical Properties and Energy Absorption of BCC Lattice Structures with Triply Periodic Minimal Surfaces Fabricated by SLM. Materials 2018, 11, 2411. [Google Scholar] [CrossRef]

- Amani, Y.; Dancette, S.; Delroisse, P.; Simar, A.; Maire, E. Compression behavior of lattice structures produced by selective laser melting: X-ray tomography based experimental and finite element approaches. Acta Mater. 2018, 159, 395–407. [Google Scholar] [CrossRef]

- Červinek, O.; Werner, B.; Koutný, D.; Vaverka, O.; Pantělejev, L.; Paloušek, D. Computational Approaches of Quasi-Static Compression Loading of SS316L Lattice Structures Made by Selective Laser Melting. Materials 2021, 14, 2462. [Google Scholar] [CrossRef]

- Jiang, C.-P.; Wibisono, A.T.; Pasang, T. Selective Laser Melting of Stainless Steel 316L with Face-Centered-Cubic-Based Lattice Structures to Produce Rib Implants. Materials 2021, 14, 5962. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Gong, C.; Chen, X.; Zheng, J.; Yang, J.; Li, K.; Sun, Y. Heterogeneous compressive responses of additively manufactured Ti-6Al-4V lattice structures by varying geometric parameters of cells. Int. J. Mech. Sci. 2022, 214, 106922. [Google Scholar] [CrossRef]

- Bi, J.; Wu, L.; Liu, Z.; Wang, H.; Jia, X.; Chen, X.; Starostenkov, M.D.; Dong, G. Formability, surface quality and compressive fracture behavior of AlMgScZr alloy lattice structure fabricated by selective laser melting. J. Mater. Res. Technol. 2022, 19, 391–403. [Google Scholar] [CrossRef]

- Sanglikar, M.; Koparkar, P.; Joshi, V. Modelling rolling ball blends for computer aided geometric design. Comput. Aided Geom. Des. 1990, 7, 399–414. [Google Scholar] [CrossRef]

- Choy, S.Y.; Sun, C.-N.; Leong, K.F.; Wei, J. Compressive properties of Ti-6Al-4V lattice structures fabricated by selective laser melting: Design, orientation and density. Addit. Manuf. 2017, 16, 213–224. [Google Scholar] [CrossRef]

- Cutolo, A.; Engelen, B.; Desmet, W.; Van Hooreweder, B. Mechanical properties of diamond lattice Ti–6Al–4V structures produced by laser powder bed fusion: On the effect of the load direction. J. Mech. Behav. Biomed. Mater. 2020, 104, 103656. [Google Scholar] [CrossRef]

- Geng, X.; Lu, Y.; Liu, C.; Li, W.; Yue, Z. Fracture characteristic analysis of cellular lattice structures under tensile load. Int. J. Solids Struct. 2019, 163, 170–177. [Google Scholar] [CrossRef]

- Nasrullah, A.I.H.; Santosa, S.P.; Dirgantara, T. Design and optimization of crashworthy components based on lattice structure configuration. Structures 2020, 26, 969–981. [Google Scholar] [CrossRef]

- Chmelko, V.; Harakaľ, M.; Žlábek, P.; Margetin, M.; Ďurka, R. Simulation of Stress Concentrations in Notches. Metals 2022, 12, 43. [Google Scholar] [CrossRef]

- ISO 13314:2011; Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals. The International Organization for Standardization: Geneva, Switzerland, 2011.

- Molski, K.L.; Tarasiuk, P.; Glinka, G. Stress concentration at cruciform welded joints under axial and bending loading modes. Weld. World 2020, 64, 1867–1876. [Google Scholar] [CrossRef]

- Singh, A.P.; Vidya, S.; Suresh, P.; Kumar, A.; Srikanth, K. Comparative stress analysis of round shaft with shoulder fillet using finite element and analytical method. Mater. Today Proc. 2020, 56, 497–501. [Google Scholar] [CrossRef]

| Relative Density = 0.1 | Relative Density = 0.2 | Relative Density = 0.3 | ||||||

|---|---|---|---|---|---|---|---|---|

| *1 | *2 | *3 | ||||||

| 0.1106 | - | - | 0.1623 | - | - | 0.2056 | - | - |

| 0.1106 | 0.01 | 0.0904 | 0.1623 | 0.01 | 0.0616 | 0.2055 | 0.01 | 0.0487 |

| 0.1105 | 0.02 | 0.1810 | 0.1622 | 0.02 | 0.1233 | 0.2054 | 0.02 | 0.0974 |

| 0.1104 | 0.03 | 0.2717 | 0.1621 | 0.03 | 0.1851 | 0.2053 | 0.03 | 0.1461 |

| 0.1103 | 0.04 | 0.3626 | 0.1620 | 0.04 | 0.2469 | 0.2052 | 0.04 | 0.1949 |

| 0.1102 | 0.05 | 0.4537 | 0.1618 | 0.05 | 0.3090 | 0.2050 | 0.05 | 0.2439 |

| 0.1100 | 0.06 | 0.5455 | 0.1616 | 0.06 | 0.3713 | 0.2047 | 0.06 | 0.2931 |

| 0.1096 | 0.07 | 0.6387 | 0.1613 | 0.07 | 0.4340 | 0.2044 | 0.07 | 0.3425 |

| 0.1094 | 0.08 | 0.7313 | 0.1609 | 0.08 | 0.4972 | 0.2041 | 0.08 | 0.3920 |

| 0.1091 | 0.09 | 0.8249 | 0.1606 | 0.09 | 0.5604 | 0.2036 | 0.09 | 0.4420 |

| 0.1087 | 0.10 | 0.9200 | 0.1602 | 0.10 | 0.6242 | 0.2031 | 0.10 | 0.4924 |

| 0.1082 | 0.11 | 1.0166 | 0.1597 | 0.11 | 0.6888 | 0.2026 | 0.11 | 0.5429 |

| 0.1080 | 0.12 | 1.1111 | 0.1593 | 0.12 | 0.7533 | 0.2020 | 0.12 | 0.5941 |

| 0.1074 | 0.13 | 1.2104 | 0.1587 | 0.13 | 0.8192 | 0.2015 | 0.13 | 0.6452 |

| 0.1069 | 0.14 | 1.3096 | 0.1582 | 0.14 | 0.8850 | 0.2009 | 0.14 | 0.6969 |

| 0.1064 | 0.15 | 1.4098 | 0.1576 | 0.15 | 0.9518 | 0.2002 | 0.15 | 0.7493 |

| 0.1059 | 0.16 | 1.5109 | 0.1570 | 0.16 | 1.0191 | 0.1955 | 0.16 | 0.8020 |

| 0.1052 | 0.17 | 1.6160 | 0.1563 | 0.17 | 1.0877 | 0.1987 | 0.17 | 0.8556 |

| 0.1047 | 0.18 | 1.7192 | 0.1556 | 0.18 | 1.1568 | 0.1980 | 0.18 | 0.9091 |

| 0.1038 | 0.19 | 1.8304 | 0.1548 | 0.19 | 1.2274 | 0.1971 | 0.19 | 0.9640 |

| 0.1031 | 0.20 | 1.9399 | 0.1540 | 0.20 | 1.2987 | 0.1962 | 0.20 | 1.0194 |

| N/A *4 | N/A | N/A | 0.1531 | 0.21 | 1.3717 | 0.1953 | 0.21 | 1.0753 |

| N/A | N/A | N/A | 0.1523 | 0.22 | 1.4445 | 0.1943 | 0.22 | 1.1323 |

| N/A | N/A | N/A | 0.1515 | 0.23 | 1.5182 | 0.1933 | 0.23 | 1.1899 |

| N/A | N/A | N/A | 0.1504 | 0.24 | 1.5957 | 0.1923 | 0.24 | 1.2480 |

| N/A | N/A | N/A | 0.1495 | 0.25 | 1.6722 | 0.1912 | 0.25 | 1.3075 |

| Design Parameters for Fillet Edgeless Simple Cubic with a Relative Density of 0.2 | Results of FEA | |||||

|---|---|---|---|---|---|---|

| *1 | *2 | *3 | Yield Stress of Unit Cell (MPa) | Stress Concentration | ||

| Total Number of Meshes (ea) | Number of Meshes in the Top 10% of Stress Range (ea) | Percentage of the Number of Meses in the Top 10% of the Stress Range (%) | ||||

| 0.1623 | - | - | 28.0 | 521,249 | 5032 | 0.97 |

| 0.1622 | 0.02 | 0.1233 | 27.7 | 524,870 | 5010 | 0.95 |

| 0.1620 | 0.04 | 0.2469 | 27.8 | 529,862 | 5206 | 0.98 |

| 0.1616 | 0.06 | 0.3713 | 28.9 | 522,764 | 7027 | 1.34 |

| 0.1609 | 0.08 | 0.4972 | 30.0 | 528,825 | 9867 | 1.87 |

| 0.1602 | 0.10 | 0.6242 | 30.5 | 543,516 | 11,003 | 2.02 |

| 0.1593 | 0.12 | 0.7533 | 31.4 | 538,276 | 12,731 | 2.37 |

| 0.1582 | 0.14 | 0.8850 | 31.3 | 537,120 | 13,300 | 2.48 |

| 0.1570 | 0.16 | 1.0191 | 31.2 | 524,071 | 13,218 | 2.52 |

| 0.1556 | 0.18 | 1.1568 | 31.0 | 523,350 | 13,681 | 2.61 |

| 0.1540 | 0.20 | 1.2987 | 30.8 | 521,775 | 13,831 | 2.65 |

| 0.1523 | 0.22 | 1.4445 | 30.5 | 531,064 | 15,180 | 2.86 |

| 0.1504 | 0.24 | 1.5957 | 30.3 | 531,067 | 16,031 | 3.02 |

| Design Parameters for Fillet Edgeless Simple Cubic with a Relative Density of 0.2 | Results of FEA | |||||

|---|---|---|---|---|---|---|

| *1 | *2 | Yield Stress of Unit Cell (MPa) | Stress Concentration | |||

| Total Number of Meshes (ea) | Number of Meshes in the Top 10% of Stress Range (ea) | Percentage of the Number of Meses in the Top 10% of the Stress Range (%) | ||||

| 0.1623 | - | - | 28.0 | 521,249 | 5032 | 0.97 |

| - | 0.1634 | 0.001 | 26.1 | 530,116 | 3613 | 0.68 |

| - | 0.1630 | 0.110 | 26.9 | 537,315 | 4831 | 0.90 |

| - | 0.1620 | 0.350 | 28.1 | 531,025 | 5795 | 1.09 |

| - | 0.1610 | 0.540 | 28.7 | 522,250 | 6970 | 1.33 |

| - | 0.1600 | 0.710 | 28.8 | 523,742 | 7365 | 1.41 |

| - | 0.1590 | 0.865 | 28.8 | 516,855 | 7189 | 1.39 |

| - | 0.1580 | 1.010 | 28.6 | 520,981 | 7570 | 1.45 |

| - | 0.1462 | 1.220 | 27.8 | 513,029 | 9995 | 1.95 |

| - | 0.1019 | 3.850 | 23.1 | 479,168 | 8314 | 1.74 |

| Types | Conditions | Unit Cell with Dimensions of 20 mm × 20 mm × 20 mm | Lattice Structure Dimensions of 20 mm × 20 mm × 20 mm with Array Patterning {3 × 3 × 3} ea | ||

|---|---|---|---|---|---|

| Design | FEA | Design | FEA | ||

| Conventional simple cubic | Morphology |  |  |  |  |

| Design parameter | *1 = 0.1623 | ||||

| Yield stress (MPa) | 28.0 | 44.4 | |||

| Optimized fillet edgeless simple cubic | Morphology |  |  |  |  |

| Design parameter | *3 = 0.7533 | ||||

| Yield stress (MPa) | 31.4 | 48.8 | |||

| Optimized Multipipe edgeless simple cubic | Morphology |  |  |  |  |

| Design parameter | *4 = 0.1600, endoffset = 0.710 | ||||

| Yield stress (MPa) | 28.8 | 44.4 | |||

| Type | Morphology | FEA | Experimental Test | ||

|---|---|---|---|---|---|

| Yield Stress by FEA (MPa) | Ratio Relative to Conventional Simple Cubic Unit Cell | Compressive Strength by Experimental Test (MPa) | Ratio Relative to Conventional Simple Cubic Unit Cell | ||

| Unit cell | Conventional Simple cubic | 28.0 | 1.00 | 78.7 | 1.00 |

| Fillet edgeless simple cubic | 31.4 | 1.12 | 88.4 | 1.12 | |

| Multipipe edgeless simple cubic | 28.8 | 1.03 | 76.3 | 0.97 | |

| Lattice structure | Conventional Simple cubic | 44.4 | 1.59 | 118.5 | 1.51 |

| Fillet edgeless simple cubic | 48.8 | 1.74 | 131.0 | 1.66 | |

| Multipipe edgeless simple cubic | 44.4 | 1.59 | 117.8 | 1.50 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, K.-M.; Roh, Y.-S. Design Optimization of Additive Manufactured Edgeless Simple Cubic Lattice Structures under Compression. Materials 2023, 16, 2870. https://doi.org/10.3390/ma16072870

Park K-M, Roh Y-S. Design Optimization of Additive Manufactured Edgeless Simple Cubic Lattice Structures under Compression. Materials. 2023; 16(7):2870. https://doi.org/10.3390/ma16072870

Chicago/Turabian StylePark, Kwang-Min, and Young-Sook Roh. 2023. "Design Optimization of Additive Manufactured Edgeless Simple Cubic Lattice Structures under Compression" Materials 16, no. 7: 2870. https://doi.org/10.3390/ma16072870

APA StylePark, K.-M., & Roh, Y.-S. (2023). Design Optimization of Additive Manufactured Edgeless Simple Cubic Lattice Structures under Compression. Materials, 16(7), 2870. https://doi.org/10.3390/ma16072870