Corrosion Behavior of Incoloy®800H, Hastelloy®G35® and 316L Stainless Steel in the Molten Eutectic Fluoride Mixture FLiNaK and Its Vapors

Abstract

:1. Introduction

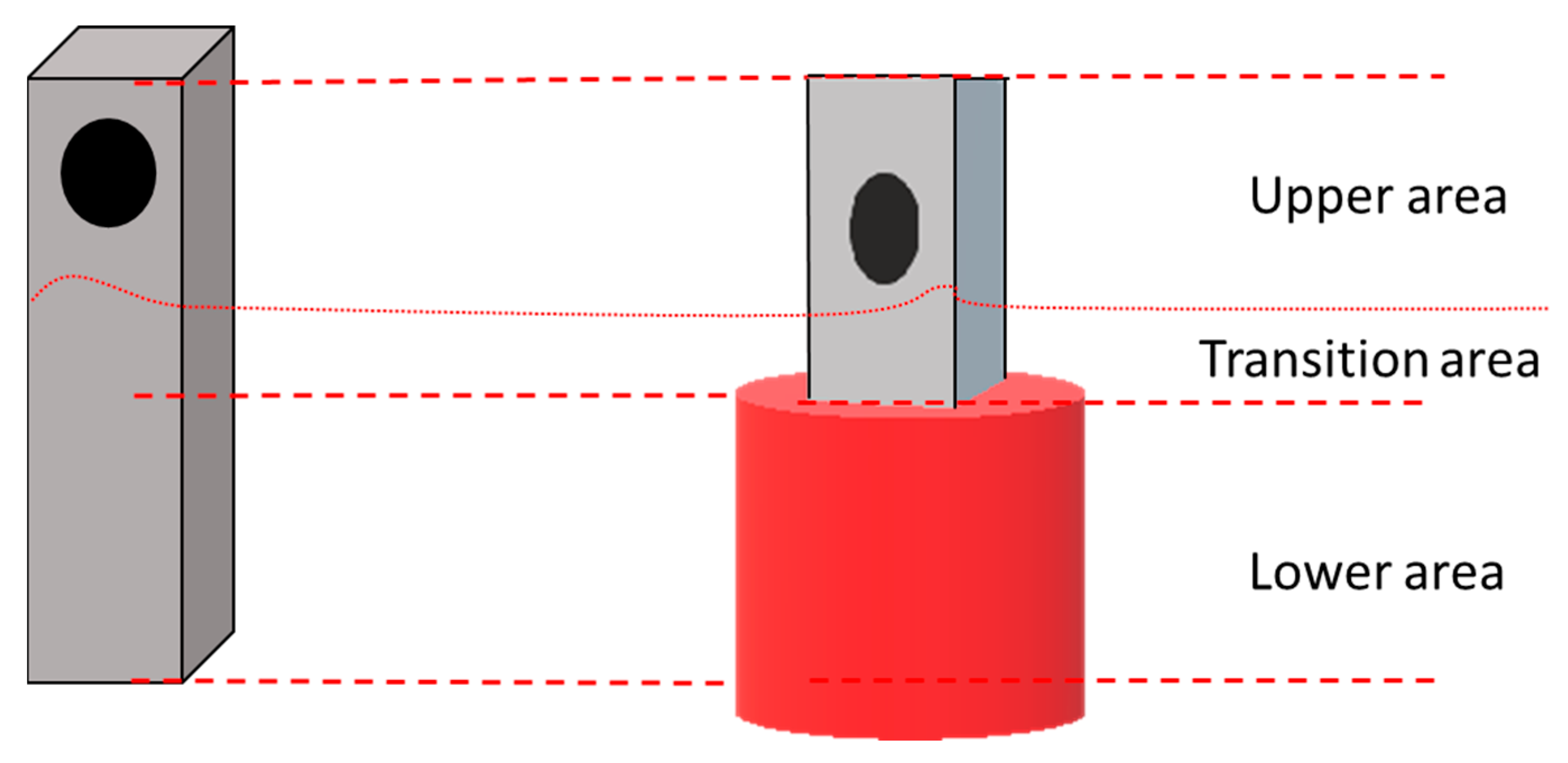

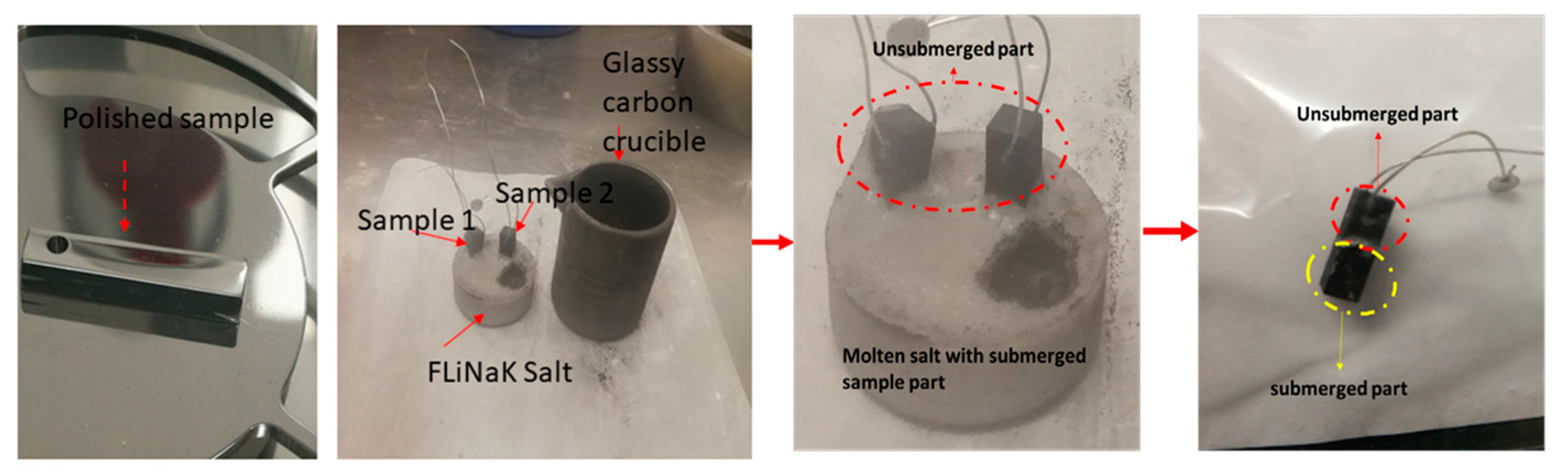

2. Materials and Methods

3. Results

3.1. Weight Loss

3.2. X-ray Data

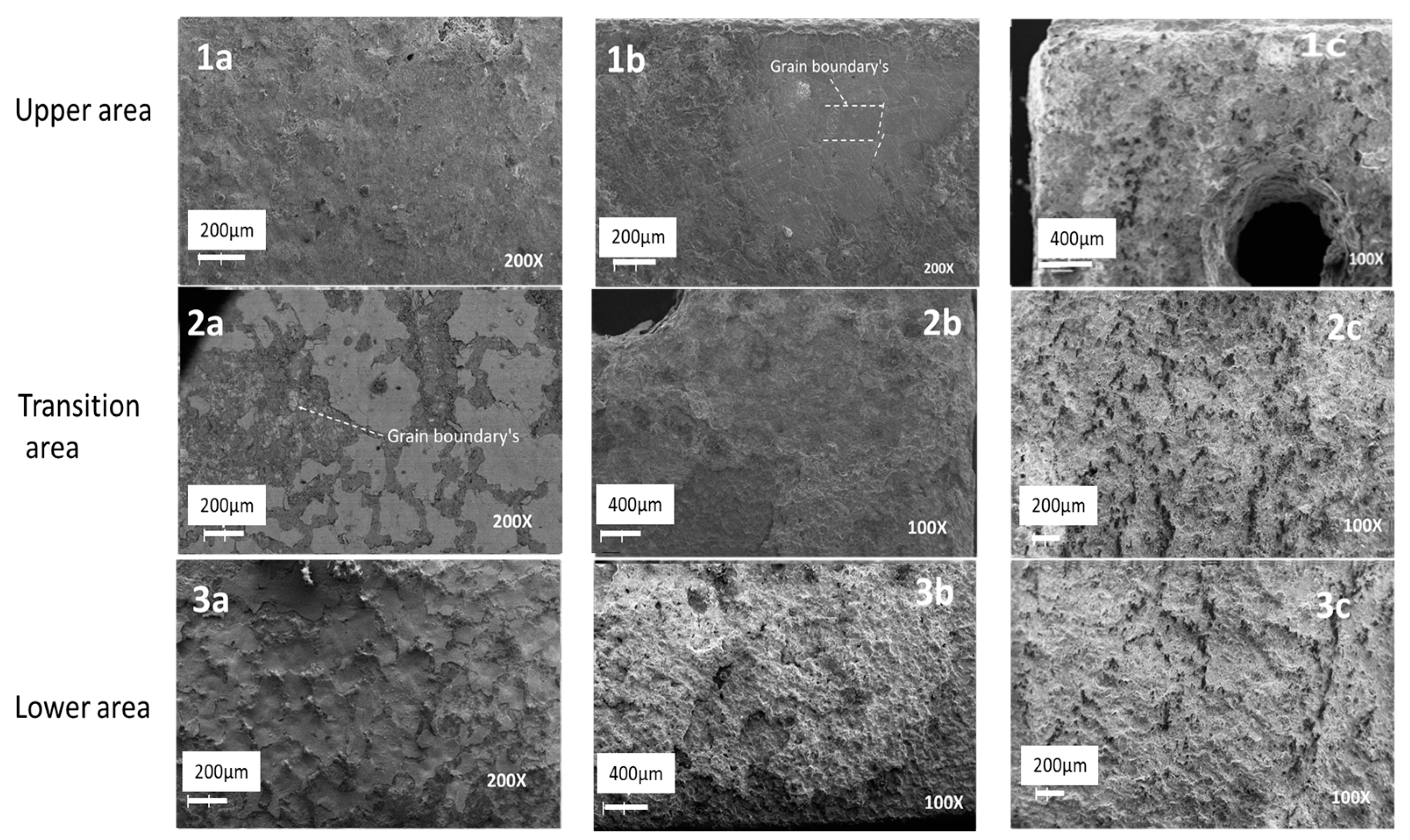

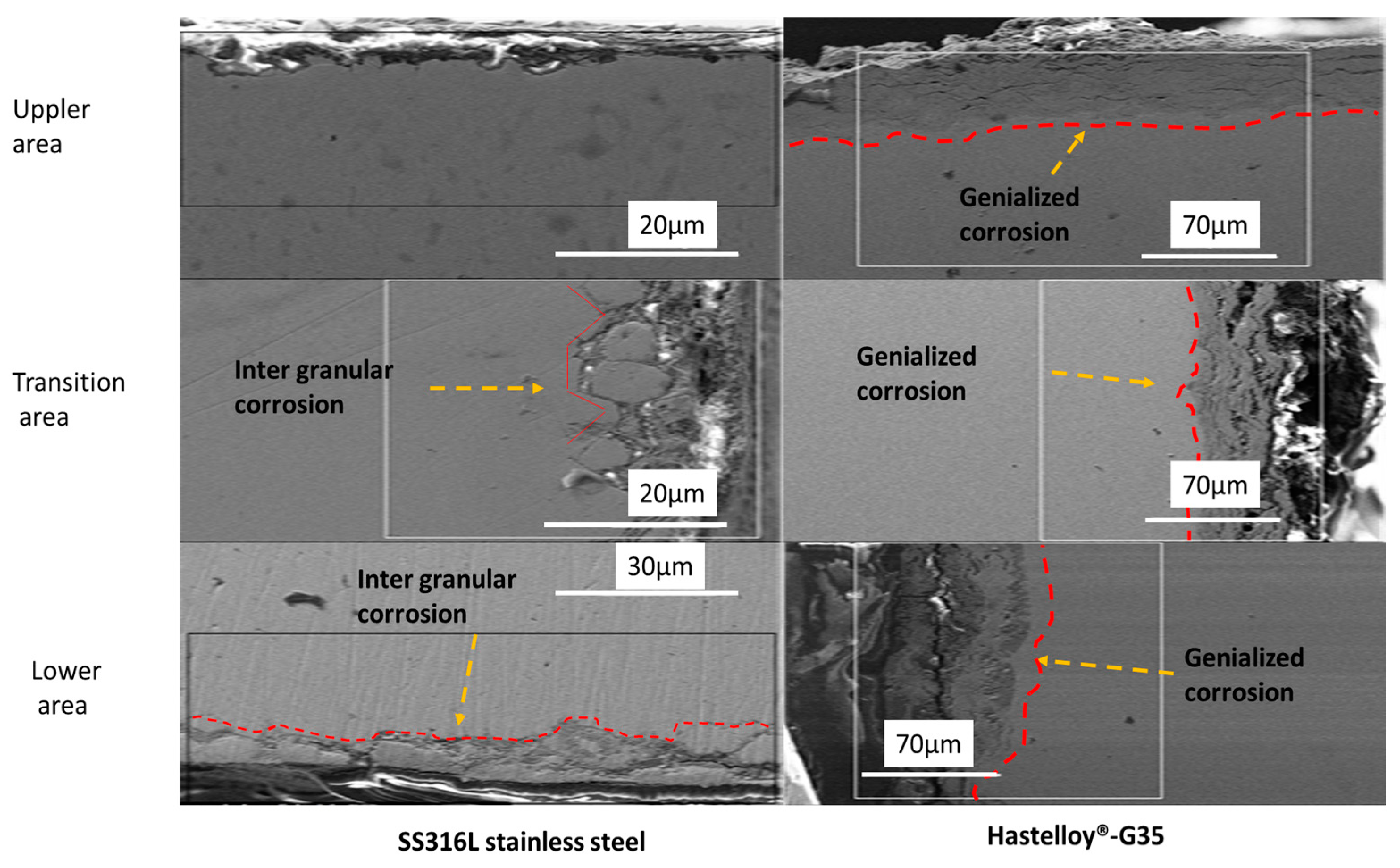

3.3. Surface Morphology

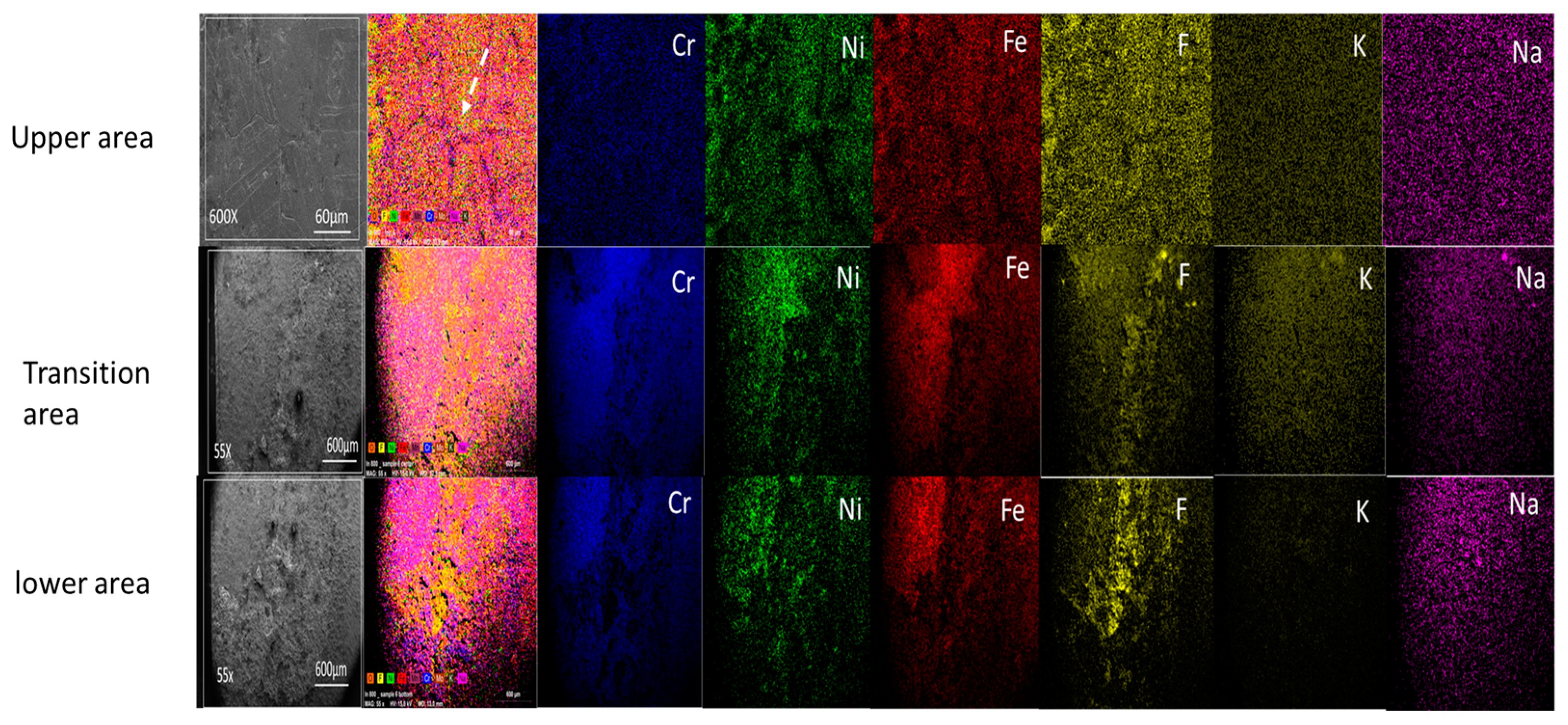

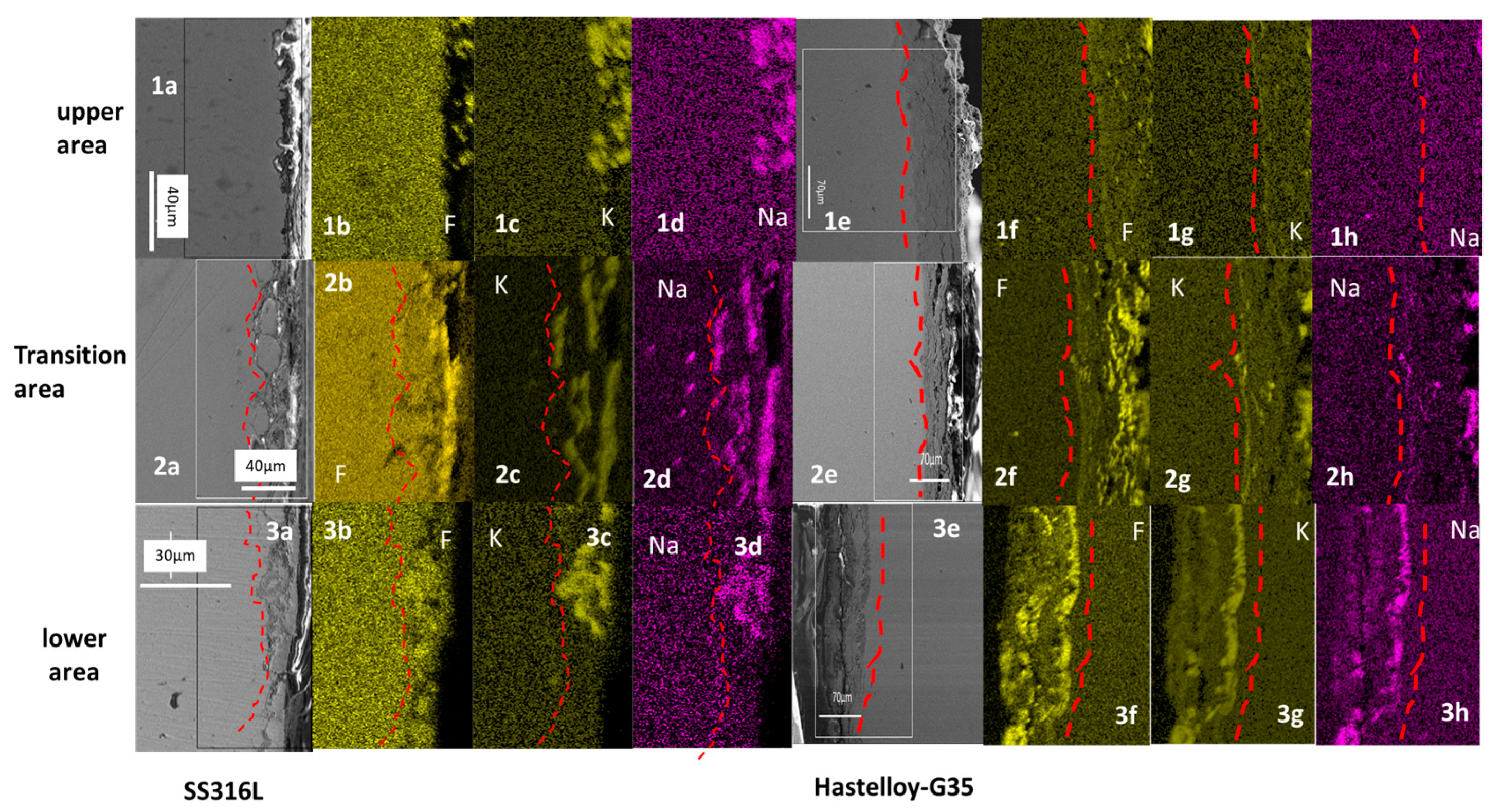

3.4. EDX Elemental Mapping

3.4.1. Elemental Mapping of SS316L Stainless Steel

3.4.2. Cross Section of SS316L Stainless Steel

3.4.3. Surface Mapping of Incoloy®-800H

3.4.4. Cross Section of Incoloy®-800H

3.4.5. Mapping the Surface of the Hastelloy®G35® Sample

3.4.6. Cross Section Mapping of Hastelloy®G35®

4. Discussion

5. Conclusions

- The experiment showed a single corrosion mechanism operating in each sample. Stainless steel 316L has intergranular corrosion and Hastelloy®G35® has generalized corrosion. However, the mechanics of the Incoloy®-800H corrosion were not discovered in this experiment.

- The cross section of each sample showed a different degree of degradation or corrosion.

- The experiment showed that, in the transition area, the corrosion is at an intermediate stage. As can be seen in the SS316L cross section, the lower area had highly degraded intergranular corrosion; in the transition area, the intergranular corrosion is clearly seen; and, in the upper area, the intergranular corrosion is shallow and barely visible.

- The cross section of the samples shows the different depth of penetration in each area of different elements into the base metal, as can be seen in Hastelloy®G35®.

- The experiment clearly shows that Cr plays a critical role in the corrosion process in all three areas (lower, transition and upper), which can be seen in the graph of mass loss vs. %Cr in Figure 4, where Hastelloy®G35®, with 33%Cr, had the highest mass loss, and SS316L stainless steel, with 17%Cr, had the lowest mass loss.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bahri, C.N.A.C.Z.; Al-Areqi, W.A.M.; Ruf, M.I.F.M.; Majid, A.A. Characteristic of molten fluoride salt system LiF-BeF2 (Flibe) and LiF-NaF-KF (Flinak) as coolant and fuel carrier in molten salt reactor (MSR). In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2017; p. 040008. [Google Scholar]

- Magnussona, J.; Memmottb, M.; Munro, T. Review of thermophysical property methods applied to fueled and un-fueled molten salts. Ann. Nucl. Energy 2020, 146, 107608. [Google Scholar] [CrossRef]

- MacPherson, H.G. Molten-Salt Reactor Project Quarterly Progress Report for Period Ending APRIL 30, 1959; ORNL-2723; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 1959.

- LeBlanc, D. Molten salt reactors: A new beginning for an old idea. Nucl. Eng. Des. 2009, 240, 1644. [Google Scholar] [CrossRef]

- Sohal, M.S.; Ebner, M.A.; Sabharwall, P.; Sharpe, P. Engineering Database of Liquid Salt Thermophysical and Thermochemical Properties; INL/EXT-10-18297 TRN: US201012%%1219; Idaho National Laboratory (INL): Idaho Falls, ID, USA, 2010.

- Holcomb, D.E.C.; Sacit, M. An Overview of Liquid-Fluoride-Salt Heat Transport Systems; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2010.

- Serp, J.; Allibert, M.; Beneš, O.; Delpech, S.; Feynberg, O.; Ghetta, V.; Heuer, D.; Holcomb, D.; Ignatiev, V.; Kloosterman, J.L.; et al. The molten salt reactor (MSR) in generation IV. Prog. Nucl. Energy 2014, 77, 308. [Google Scholar] [CrossRef]

- Sridharan, K.; Allen, T.R. Corrosion in Molten Salts. In Molten Salts Chemistry; Elsevier: Amsterdam, The Netherlands, 2013; Volume 241. [Google Scholar]

- Devan, J.H.; Evans, R.B., III. Corrosion Behavior of Reactor Materials in Fluoride Salt Mixtures; ORNL-TM-328; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 1962.

- Adamson, G.M.C.R.S.; Manly, W.D. Interim Report on Corrosion by Alkali-Metal Fluorides; ORNL-2337; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 1959.

- MacPherson, H.G. Molten-Salt Reactor Project Quarterly Progress Report; ORNL-2684; Oak Ridge National Laboratory ORNL: Oak Ridge, TN, USA, 1959.

- Manly, W.D.G.M.; Adamson, J.; Coobs, J.H.; DeVan, J.H.; Douglas, D.A.; Hoffman, E.E.; Patriarca, P. Aircraft Reactor Experiment--Metallurgical Aspects; Oak Ridge National Laboratory ORNL: Oak Ridge, TN, USA, 1958; 57p.

- Frye, J.H., Jr.; Manly, W.D.; Cunningham, J.E. Metallurgy Division Annual Progress Report; ORNL-2422(Del); Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 1957; p. 263.

- Wang, Y.; Goh, B.; Nelaturu, P.; Duong, T.; Hassan, N.; David, R.; Moorehead, M.; Chaudhuri, S.; Creuziger, A.; Hattrick-Simpers, J.; et al. Integrated High-Throughput and Machine Learning Methods to Accelerate Discovery of Molten Salt Corrosion-Resistant Alloys. Adv. Sci. 2022, 9, 2200370. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Sun, H.; Yin, H.; Guo, L.; Qiu, J.; Lin, J.; Tang, Z. Corrosion behaviour of 316H stainless steel in molten FLiNaK eutectic salt containing graphite particles. Corros. Sci. 2019, 160, 108174. [Google Scholar] [CrossRef]

- Ouyang, F.Y.; Chang, C.H.; You, B.C.; Yeh, T.K.; Kai, J.J. Effect of moisture on corrosion of Ni-based alloys in molten alkali fluoride FLiNaK salt environments. J. Nucl. Mater. 2013, 437, 201. [Google Scholar] [CrossRef]

- Yin, H.; Qiu, J.; Liu, H.; Liu, W.; Wang, Y.; Fei, Z.; Zhao, S.; An, X.; Cheng, J.; Chen, T.; et al. Effect of CrF3 on the corrosion behaviour of Hastelloy-N and 316L stainless steel alloys in FLiNaK molten salt. Corros. Sci. 2018, 131, 355. [Google Scholar] [CrossRef]

- Yin, H.; Zhang, P.; An, X.; Zhao, S.; Xie, L.; Wang, W. The effect of corrosion product CrF3 on thermo-physical properties of FLiNaK. J. Nucl. Sci. Technol. 2015, 53, 63. [Google Scholar]

- Yamazaki, G.; Nagasaka, T.; Tanaka, T.; Goto, T.; Shen, J.; Saito, K.; Kobayashi, M.I. Corrosion of pure Cr and W in molten FLiNaK with hydrogen fluoride solution. Fusion Eng. Des. 2021, 172, 112741. [Google Scholar] [CrossRef]

- Yoko, T.; Bailey, R.A. Electrochemical Studies of Chromium in Molten LiF-NaF-KF (FLINAK). J. Electrochem. Soc. 1984, 131, 2590. [Google Scholar] [CrossRef]

- Ramu, A.; Pavlik, V.; Sillikova, V.; Matselko, O.; Boca, M. Corrosion of Hastelloy-N and Hastelloy-G35 from vapors generated from FLiNaK salt with addition of 5% oxygen in argon atmosphere. Mater. Corros. 2022. [Google Scholar] [CrossRef]

- Riley, B.; DelCul, J.M.G.; Vienna, J.; Contescu, C.; Hay, L.; Savino, A.; Adkins, H. Identification of Potential Waste Processing and Waste Form Options for Molten Salt Reactors; ORNL/LTR-2018/907; Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2018.

- Mcfarlane, J.; Bull Ezell, N.D.; Del Cul, G.D.; Holcomb, D.E.; Myhre, K.; Lines, A.; Bryan, S.; Felmy, H.; Riley, B.; Chapel, A. Fission Product Volatility and Off-Gas Systems for Molten Salt Reactors; Oak Ridger-name>Oak Ridge National Laboratory (ORNL): Oak Ridge, TN, USA, 2019.

- Sekiguchi, Y.; Koyama, K.U.T.; Terai, T. Fundamental study on the vaporization of cesium and iodine dissolved in LiF-NaF-KF molten salt. J. Nucl. Mater. 2019, 522, 136–143. [Google Scholar] [CrossRef]

- Maxwell, C.I. Molecular dynamics study of fission gas behaviour and solubility in molten FLiNaK salt. J. Nucl. Mater. 2022, 563, 153633. [Google Scholar] [CrossRef]

- Wu, Y.; Leng, B.; Zhou, X. Corrosion behaviors of Ni-WC cemented carbide in high temperature molten fluoride salt and vapor. J. Nucl. Mater. 2022, 561, 153541. [Google Scholar] [CrossRef]

- Olson, L.C.; Ambrosek, J.W.; Sridharan, K.; Anderson, M.H.; Anderson, M.H. Materials corrosion in molten LiF-NaF-KF salt. J. Fluor. Chem. 2009, 130, 67–73. [Google Scholar] [CrossRef]

- Forsberg, C.; Peterson, L.H.P.; Sridharan, K. Fluoride-Salt-Cooled High-Temperature Reactor (FHR) for Power and Process Heat; DOE/NEUP-11-3272; Massachusetts Inst. of Technology (MIT): Cambridge, MA, USA, 2018. [Google Scholar]

- Kubíková, B.; Mlynáriková, J.; Boča, M.; Shi, Z.; Gao, B.; Patel, N. Temperatures of Primary Crystallization and Density of the KF + AlF3 + LiF + Al2O3 Molten System. J. Chem. Eng. Data 2018, 63, 3047. [Google Scholar] [CrossRef]

- McAlpine, S.W.; Skowronski, N.C.; Zhou, W.; Zheng, G.; Short, M.P. Corrosion of commercial alloys in FLiNaK molten salt containing EuF3 and simulant fission product additives. J. Nucl. Mater. 2020, 532, 151994. [Google Scholar] [CrossRef]

- Qiu, J.; Wu, A.; Li, Y.; Xu, Y.; Scarlat, R.; Macdonald, D.D. Galvanic corrosion of Type 316L stainless steel and Graphite in molten fluoride salt. Corros. Sci. 2020, 170, 108677. [Google Scholar] [CrossRef]

- Olson, L.; Sridharan, K.; Anderson, M.; Allen, T. Intergranular corrosion of high temperature alloys in molten fluoride salts. Mater. High Temp. 2010, 27, 145. [Google Scholar] [CrossRef]

- Sandhi, K.K.; Szpunar, J. Analysis of Corrosion of Hastelloy-N, Alloy X750, SS316 and SS304 in Molten Salt High-Temperature Environment. Energies 2021, 14, 543. [Google Scholar] [CrossRef]

- Dai, Q.; Ye, X.-X.; Ai, H.; Chen, S.; Jiang, L.; Liang, J.; Yu, K.; Leng, B.; Li, Z.; Zhou, X. Corrosion of Incoloy 800H alloys with nickel cladding in FLiNaK salts at 850 °C. Corros. Sci. 2018, 133, 349–357. [Google Scholar] [CrossRef]

- Olson, L.; Sridharan, K.; Anderson, M.; Allen, T. Nickel-plating for active metal dissolution resistance in molten fluoride salts. J. Nucl. Mater. 2011, 411, 51–59. [Google Scholar] [CrossRef]

| Alloy | Ni wt% | Cr wt% | Fe wt% | Mo wt% | Mn wt% |

|---|---|---|---|---|---|

| Incoloy®-800H | 31.59 | 20.42 | 47.99 | - | 0.8 |

| SS316L Stainless Steel | 12 | 17 | 65 | 3 | 2 |

| Hastelloy®-G35® | 56 | 33 | 2 | 8 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramu, A.; Pavlik, V.; Sillikova, V.; Boca, M. Corrosion Behavior of Incoloy®800H, Hastelloy®G35® and 316L Stainless Steel in the Molten Eutectic Fluoride Mixture FLiNaK and Its Vapors. Materials 2023, 16, 2679. https://doi.org/10.3390/ma16072679

Ramu A, Pavlik V, Sillikova V, Boca M. Corrosion Behavior of Incoloy®800H, Hastelloy®G35® and 316L Stainless Steel in the Molten Eutectic Fluoride Mixture FLiNaK and Its Vapors. Materials. 2023; 16(7):2679. https://doi.org/10.3390/ma16072679

Chicago/Turabian StyleRamu, Ambati, Viliam Pavlik, Veronika Sillikova, and Miroslav Boca. 2023. "Corrosion Behavior of Incoloy®800H, Hastelloy®G35® and 316L Stainless Steel in the Molten Eutectic Fluoride Mixture FLiNaK and Its Vapors" Materials 16, no. 7: 2679. https://doi.org/10.3390/ma16072679

APA StyleRamu, A., Pavlik, V., Sillikova, V., & Boca, M. (2023). Corrosion Behavior of Incoloy®800H, Hastelloy®G35® and 316L Stainless Steel in the Molten Eutectic Fluoride Mixture FLiNaK and Its Vapors. Materials, 16(7), 2679. https://doi.org/10.3390/ma16072679