Enhancing Mechanical Properties of 3D Printing Metallic Lattice Structure Inspired by Bambusa Emeiensis

Abstract

:1. Introduction

2. Experiment of Bambusa Bionic Lattice Structure

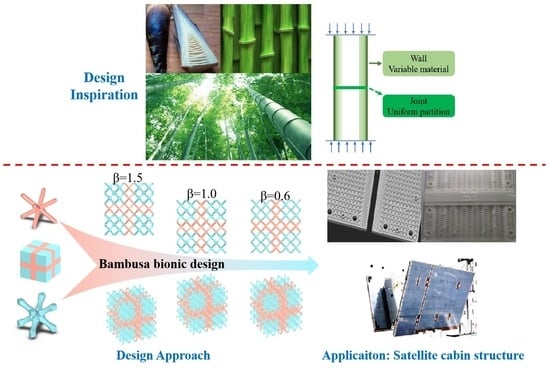

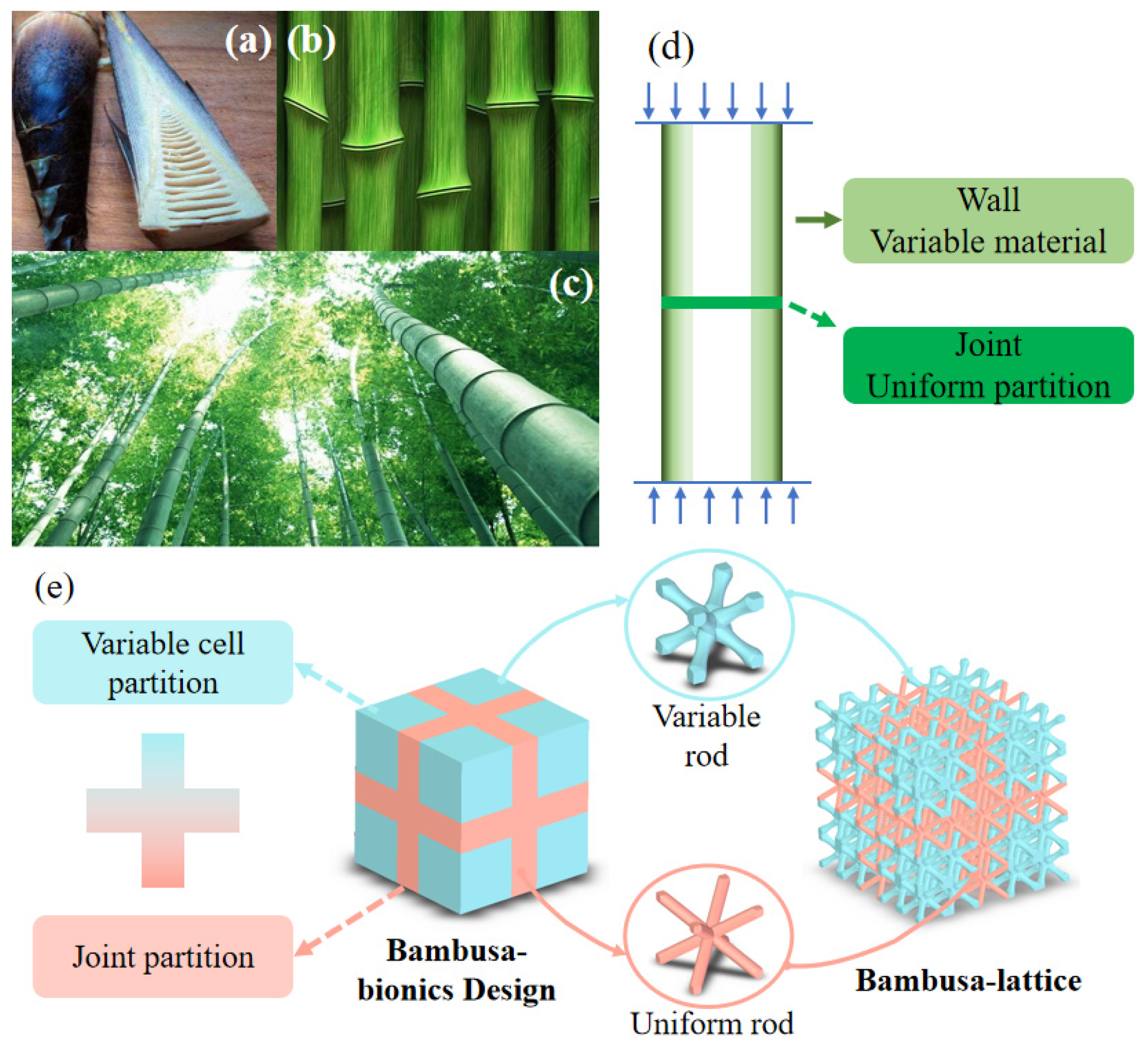

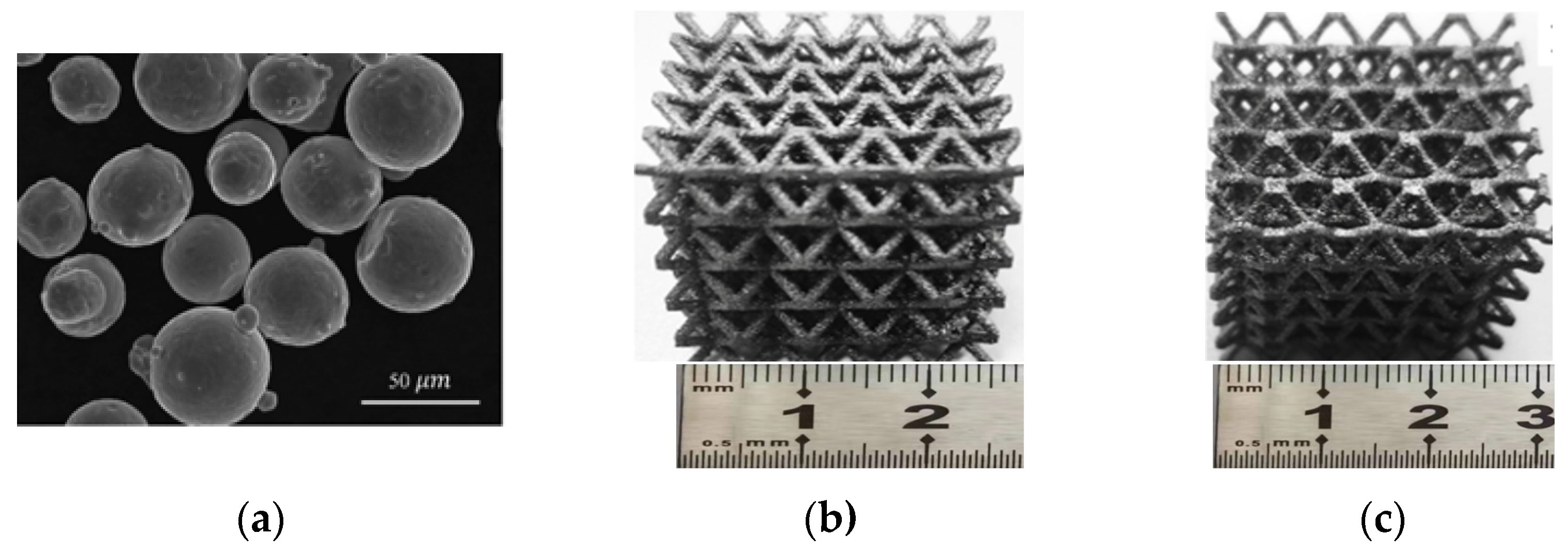

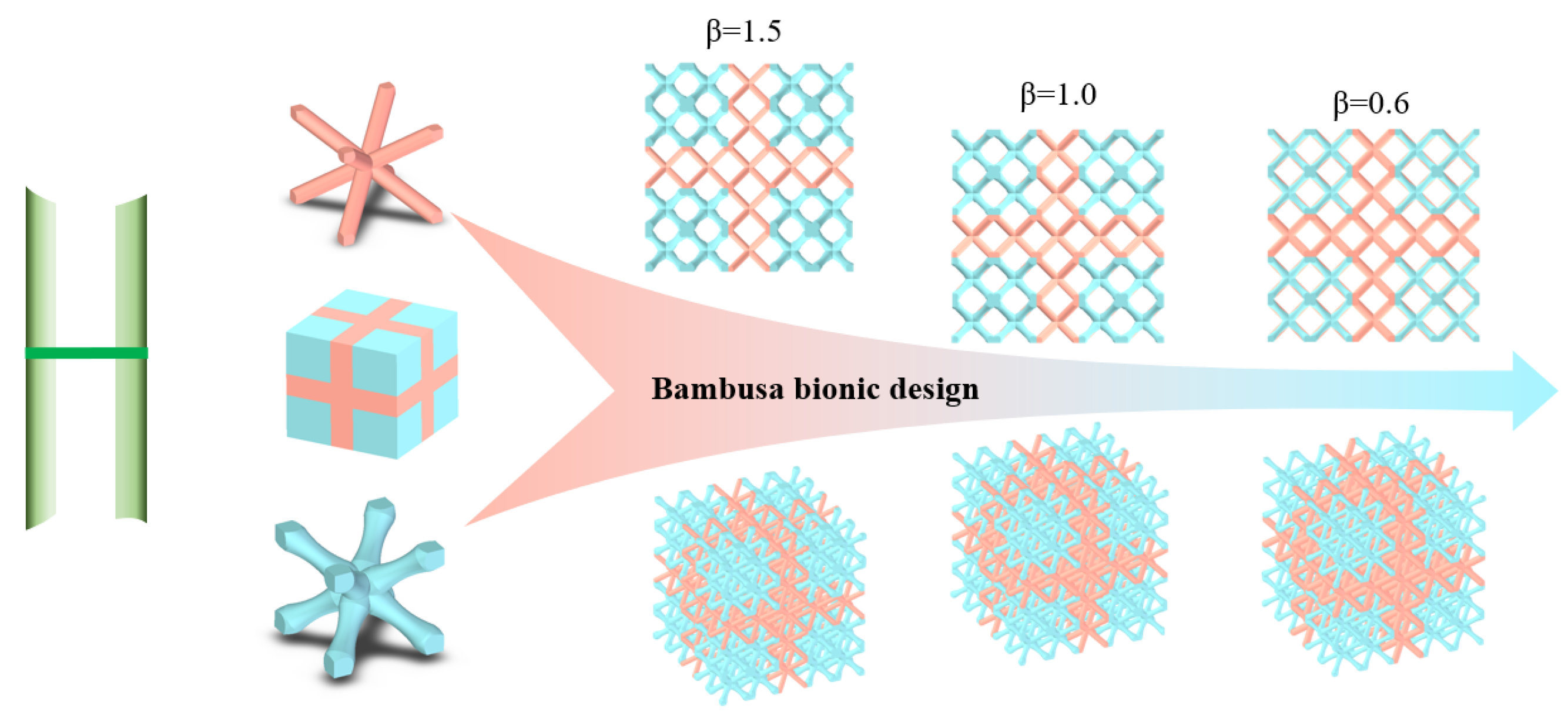

2.1. Bambusa Bionic Design for Lattice Structure

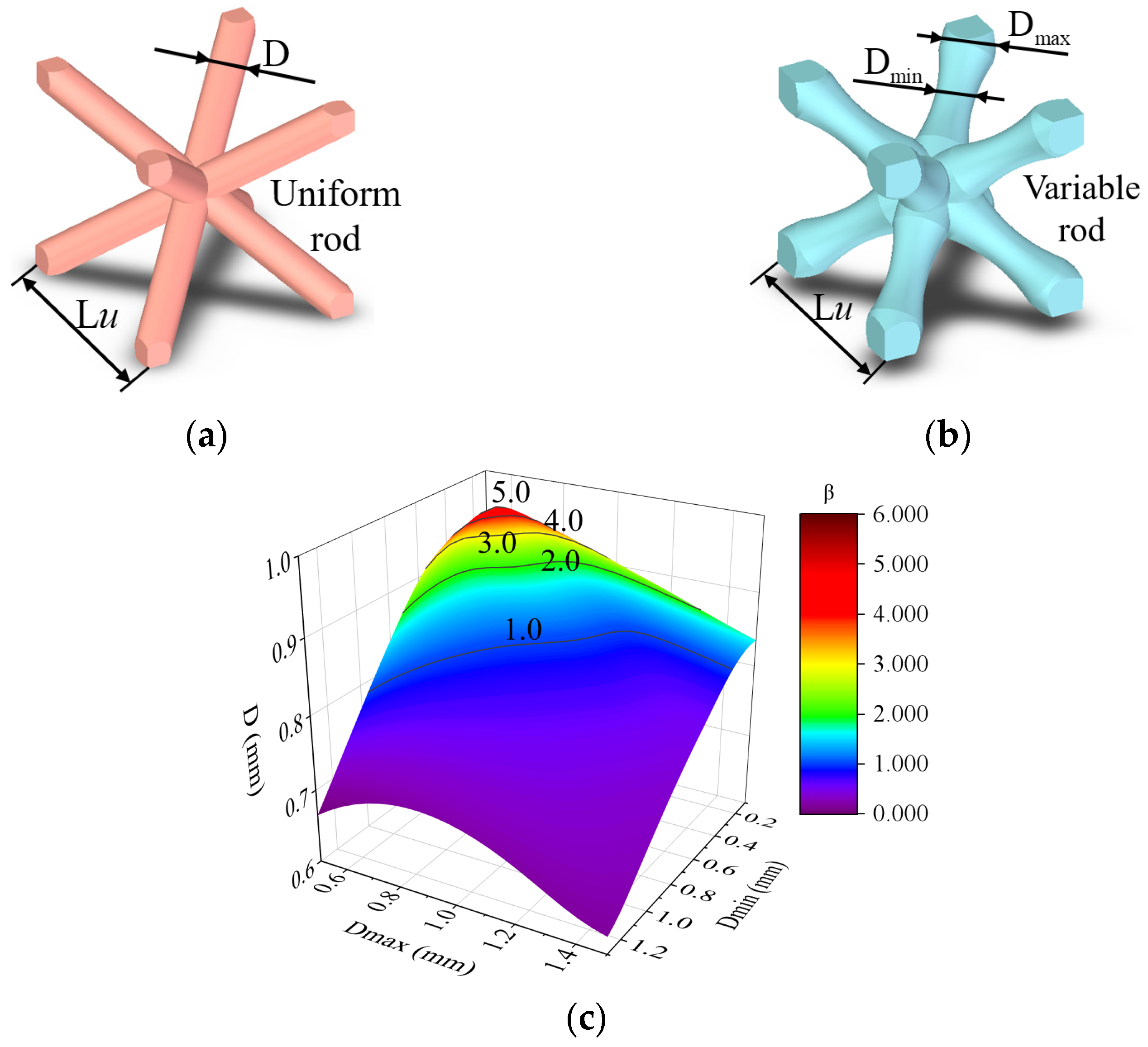

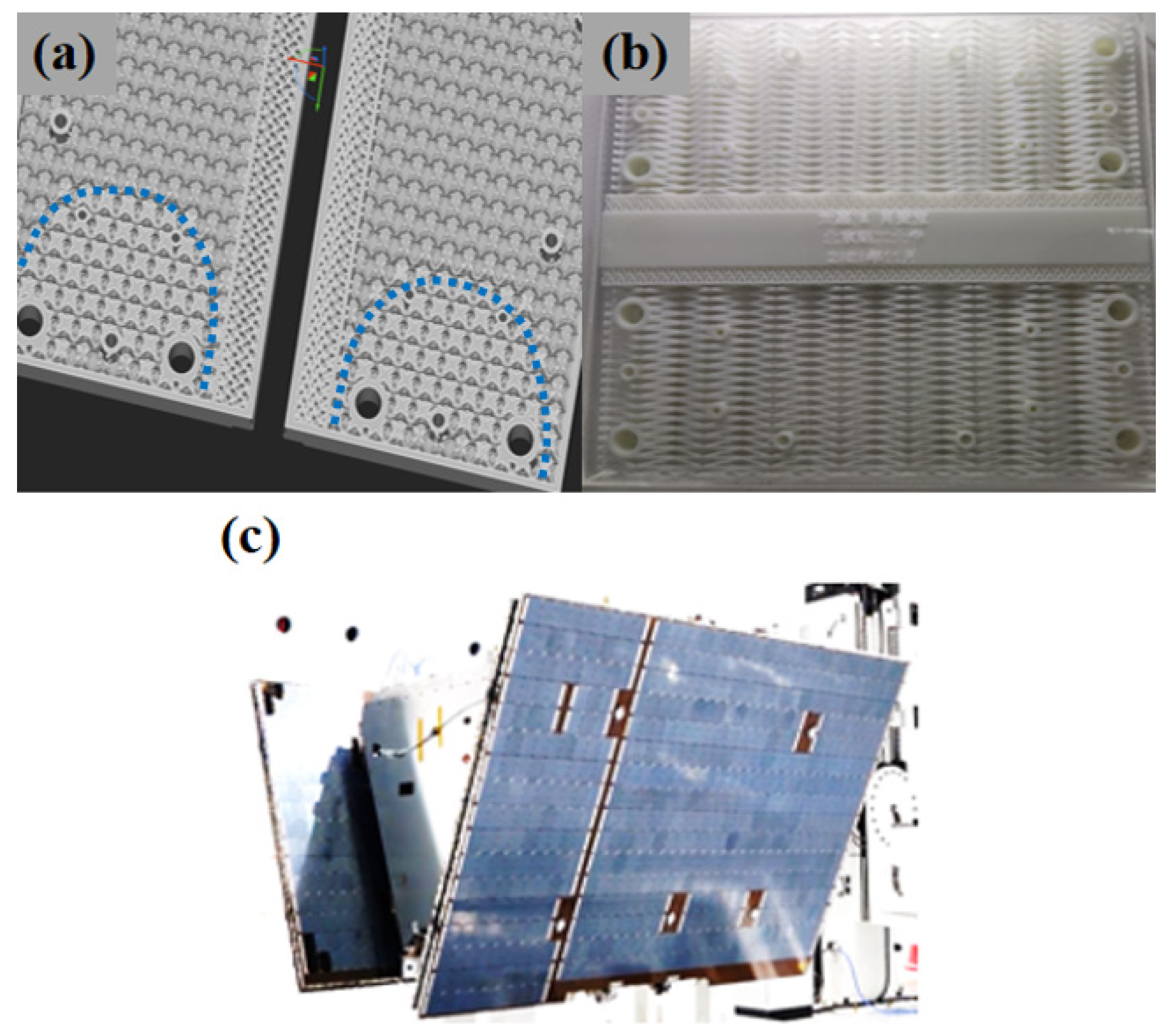

2.2. Sample Preparation and Experimental Procedure

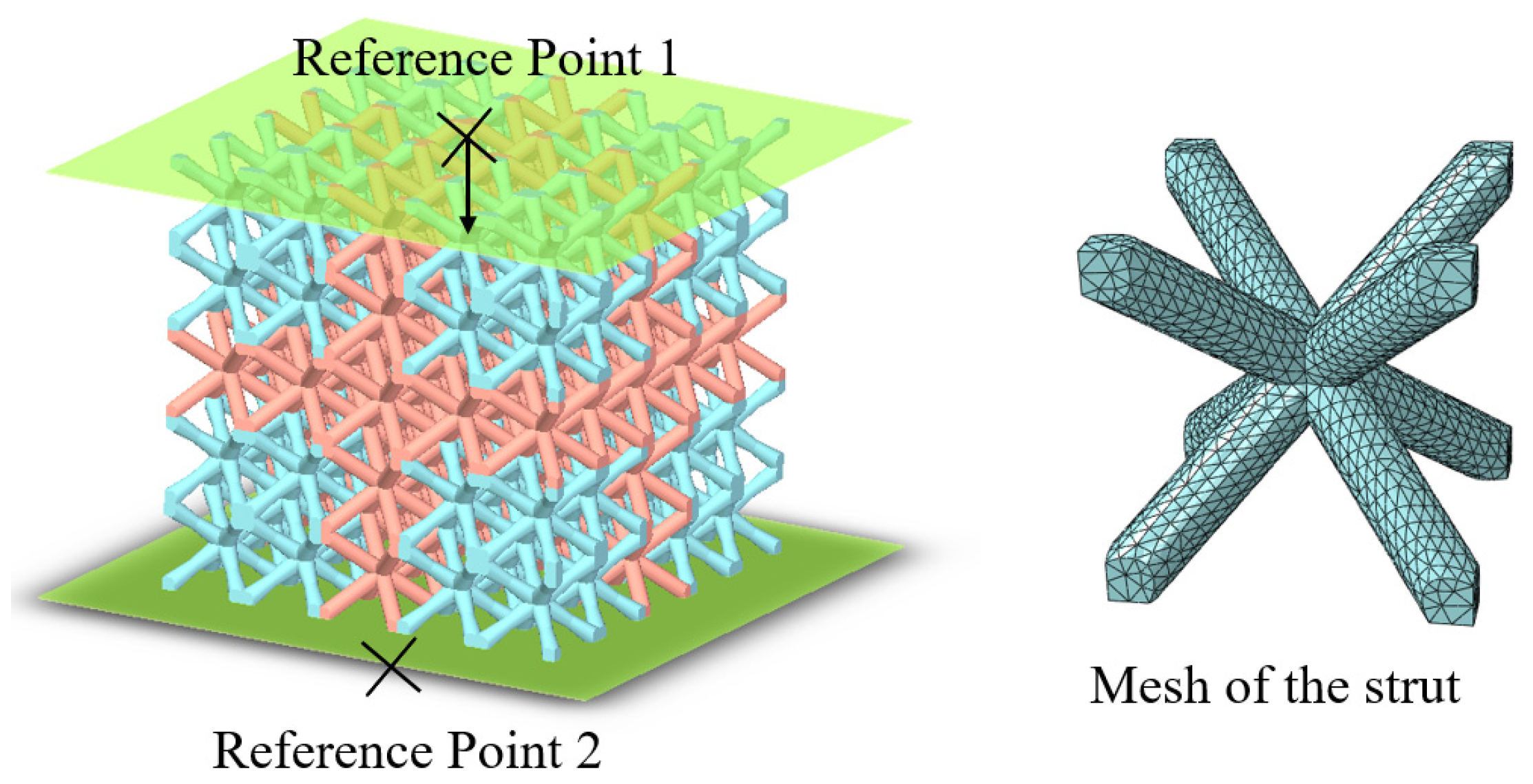

2.3. Finite Element Analysis

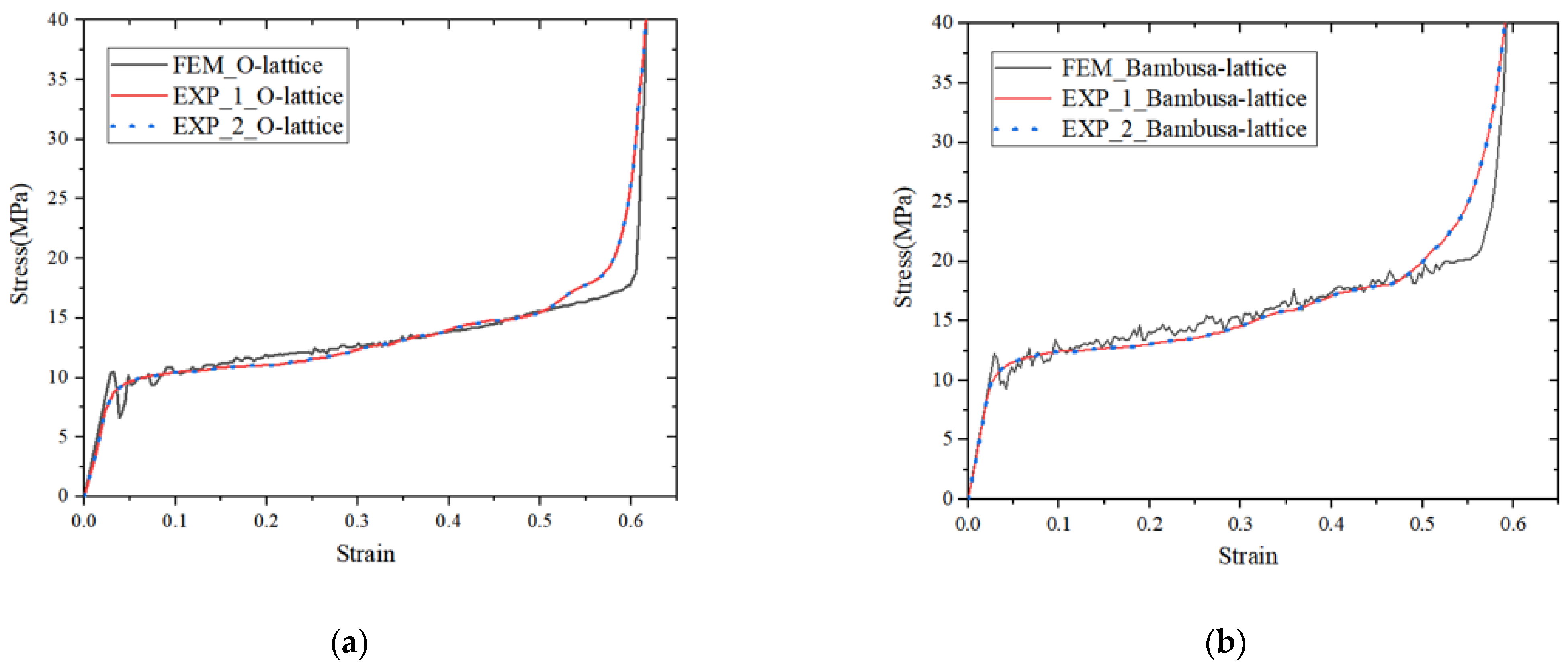

3. Results and Discussion

3.1. Parametric Analysis for Mechanical Properties of Bamboo-Lattice Structure

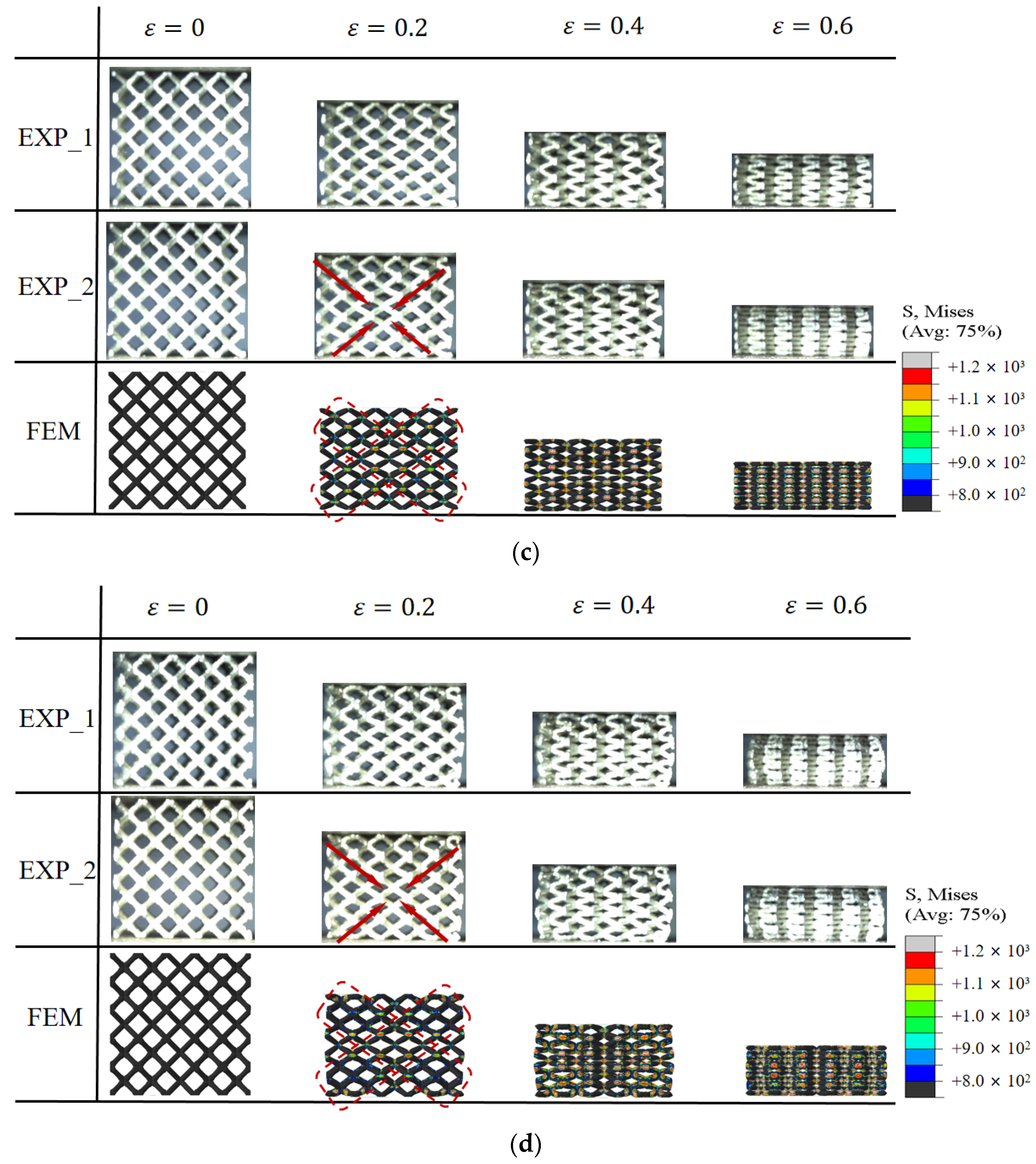

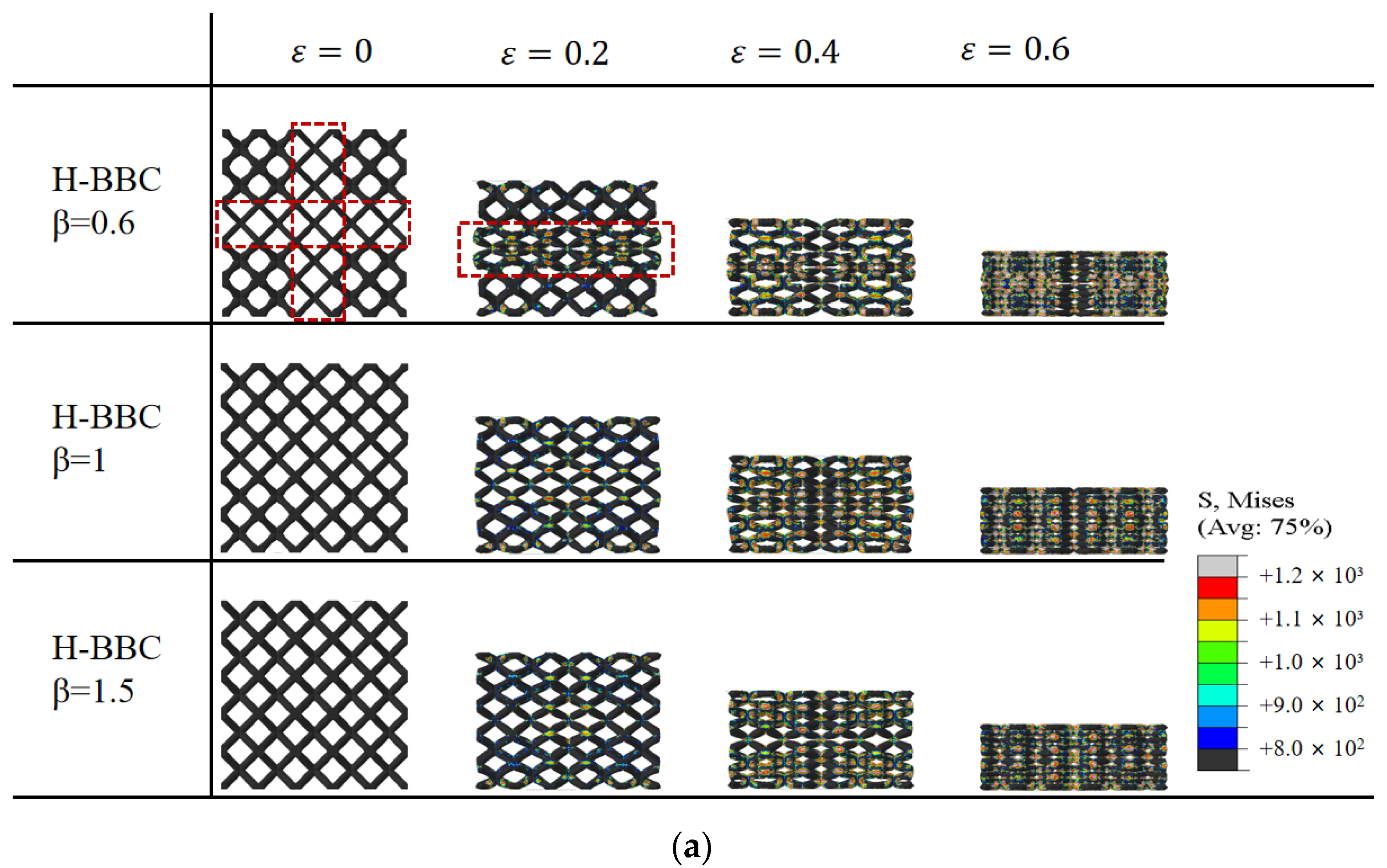

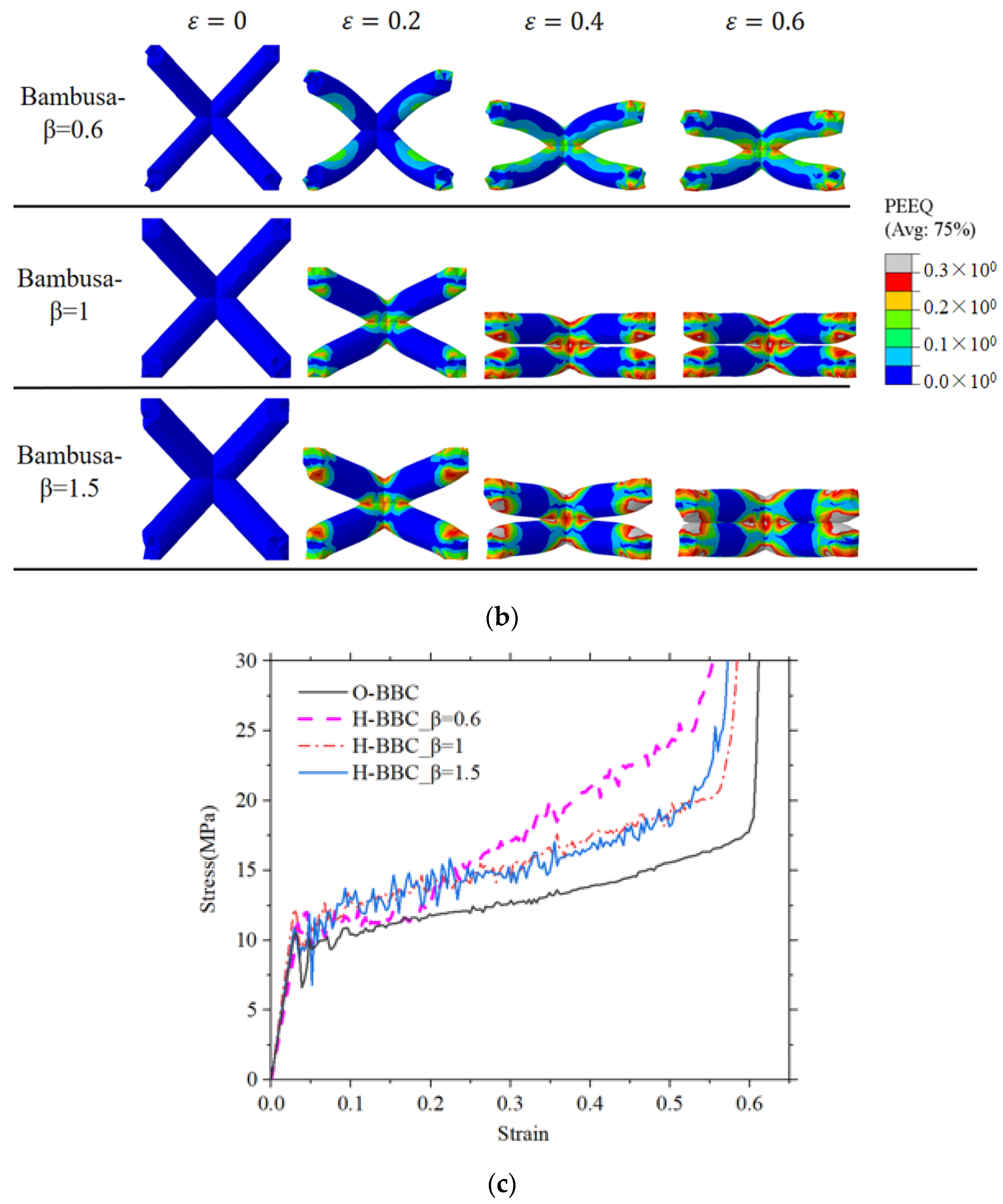

3.2. Compression Deformation Characteristics

3.3. Shear Deformation Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties; Cambridge University Press: Cambridge, UK, 1997; pp. 15–29. [Google Scholar]

- Zhang, Q.; Yang, X.; Li, P.; Huang, G.; Feng, S.; Shen, C.; Han, B.; Zhang, X.; Jin, F.; Xu, F.; et al. Bioinspired engineering of honeycomb structure—Using nature to inspire human innovation. Prog. Mater. Sci. 2015, 74, 332–400. [Google Scholar] [CrossRef]

- Davoodi, E.; Montazerian, H.; Mirhakimi, A.S.; Zhianmanesh, M.; Ibhadode, O.; Shahabad, S.I.; Esmaeilizadeh, R.; Sarikhani, E.; Toorandaz, S.; Sarabi, S.A.; et al. Additively manufactured metallic biomaterials. Bioact. Mater. 2022, 15, 214–249. [Google Scholar] [CrossRef]

- Maskery, I.; Parry, L.A.; Padrão, D.; Hague, R.J.M.; Ashcroft, I.A. FLatt Pack: A research-focussed lattice design program. Addit. Manuf. 2022, 49, 102510. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Amani, Y.; Dancette, S.; Delroisse, P.; Simar, A.; Maire, E. Compression behavior of lattice structures produced by selective laser melting: X-ray tomography based experimental and finite element approaches. Acta Mater. 2018, 159, 395–407. [Google Scholar] [CrossRef]

- Gungor, O.U.; Gorguluarslan, R.M. Experimental characterization of spatial variability for random field modeling on struts of additively manufactured lattice structures. Addit. Manuf. 2020, 36, 101471. [Google Scholar] [CrossRef]

- Doroszko, M.; Falkowska, A.; Seweryn, A. Image-based numerical modeling of the tensile deformation behavior and mechanical properties of additive manufactured Ti-6Al-4V diamond lattice structures. Mat. Sci. Eng. A 2021, 818, 141362. [Google Scholar] [CrossRef]

- Liu, L.; Kamm, P.; García-Moreno, F.; Banhart, J.; Pasini, D. Elastic and failure response of imperfect three-dimensional metallic lattices: The role of geometric defects induced by Selective Laser Melting. J. Mech. Phys. Solids 2017, 107, 160–184. [Google Scholar] [CrossRef]

- Jiang, P.; De Meter, E.C.; Basu, S. The influence of defects on the elastic response of lattice structures resulting from additive manufacturing. Comp. Mater. Sci. 2021, 199, 110716. [Google Scholar] [CrossRef]

- Echeta, I.; Dutton, B.; Leach, R.K.; Piano, S. Finite element modelling of defects in additively manufactured strut-based lattice structures. Addit. Manuf. 2021, 47, 102301. [Google Scholar] [CrossRef]

- Prathyusha, A.L.R.; Babu, G.R. A review on additive manufacturing and topology optimization process for weight reduction studies in various industrial applications. Mater. Today Proc. 2022, 62, 109–117. [Google Scholar] [CrossRef]

- Lian, Y.P.; Wang, P.D.; Gao, J.; Liu, J.K.; Li, Q.H.; Liu, C.M.; He, X.F.; Gao, L.; Li, H.; Lei, H.S.; et al. Fundamental mechanics problems in metal additive manufacturing: A state-of-art review. Adv. Mech. 2021, 51, 648–701. [Google Scholar]

- Khosravani, M.R.; Rezaei, S.; Ruan, H.; Reinicke, T. Fracture behavior of anisotropic 3D-printed parts: Experiments and numerical simulations. J. Mater. Res. Technol. 2022, 19, 1260–1270. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Frohn-Sörensen, P.; Reuter, J.; Engel, B.; Reinicke, T. Fracture studies of 3D-printed continuous glass fiber reinforced composites. Theor. Appl. Fract. Mech. 2022, 119, 103317. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Soltani, P.; Reinicke, T. Effects of steps on the load bearing capacity of 3D-printed single lap joints. J. Mater. Res. Technol. 2023, 23, 1834–1847. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Berto, F.; Ayatollahi, M.R.; Reinicke, T. Characterization of 3D-printed PLA parts with different raster orientations and printing speeds. Sci. Rep. 2022, 12, 1016. [Google Scholar] [CrossRef]

- Sun, M.; Wang, B.; Zhang, J.; Lu, B. In-situ synthesis of CoCrFeMnNi high-entropy alloy by selective laser melting. Intermetallic 2023, 156, 107866. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Robak, G.; Moj, K.; Krolczyk, G.M.; Kuntoğlu, M. Development of lattice structure with selective laser melting process: A state of the art on properties, future trends and challenges. J. Manuf. Processes 2022, 81, 1040–1063. [Google Scholar] [CrossRef]

- Pham, M.S.; Liu, C.; Todd, I.; Lertthanasarn, J. Damage-tolerant architected materials inspired by crystal microstructure. Nature 2019, 565, 305–311. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Lertthanasarn, J.; Pham, M.S. The origin of the boundary strengthening in polycrystal-inspired architected materials. Nat. Commun. 2021, 12, 4600. [Google Scholar] [CrossRef]

- Yin, S.; Guo, W.; Wang, H.; Huang, Y.; Yang, R.; Hu, Z.; Chen, D.; Xu, J.; Ritchie, R.O. Strong and Tough Bioinspired Additive-Manufactured Dual-Phase Mechanical Metamaterial Composites. J. Mech. Phys. Solids 2021, 149, 104341. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Zhou, H.; Cao, X.Y.; Li, C.L.; Zhang, X.; Fan, H.; Lei, H.; Fang, D. Design of self-supporting lattices for additive manufacturing. J. Mech. Phys. Solids 2021, 148, 104298. [Google Scholar] [CrossRef]

- Song, J.F.; Xu, S.C.; Wang, H.X.; Wu, X.Q.; Zou, M. Bionic design and multi-objective optimization for variable wall thickness tube inspired bamboo structures. Thin Walled Struct. 2018, 125, 76–88. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Fang, G.; Leeflang, S.; Zadpoor, A.A.; Zhou, J. Topological design, permeability and mechanical behavior of additively manufactured functionally graded porous metallic biomaterials. Acta Biomater. 2019, 84, 437–452. [Google Scholar] [CrossRef] [PubMed]

- Ha, N.S.; Lu, G.X. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B Eng. 2020, 18, 107496. [Google Scholar] [CrossRef]

- Wu, Y.C.; Kuo, C.N.; Wu, T.H.; Liu, T.Y.; Chen, Y.W.; Guo, X.H.; Huang, J.C. Empirical rule for predicting mechanical properties of Ti-6Al-4V bone implants with radial-gradient porosity bionic structures. Mater. Today Commun. 2021, 27, 102346. [Google Scholar] [CrossRef]

- Cao, X.F.; Duan, S.Y.; Liang, J.; Wen, W.; Fang, D. Mechanical properties of an improved 3D-printed rhombic dodecahedron stainless steel lattice structure of variable cross section. Int. J. Mech. Sci. 2018, 145, 53–63. [Google Scholar] [CrossRef]

- Liu, X.; Wada, T.; Suzki, A.; Takata, N.; Kobashi, M.; Kato, M. Understanding and suppressing shear band formation in strut-based lattice structures manufactured by laser powder bed fusion. Mater. Des. 2021, 199, 109416. [Google Scholar] [CrossRef]

| Sample | Relative Density | Cell Size (mm) | Dimensions (mm3) | Diameter (mm) |

|---|---|---|---|---|

| O-lattice | 0.1634 | Lu: 5 | 25 × 25 × 25 | D: 0.952 |

| Bambusa-lattice (β = 1.0) | 0.1634 | Lu: 5 | 25 × 25 × 25 | Dmax: 1.130 Dmin: 0.794 |

| Laser Power | Laser Exposure Time | Scanning Speed | Layer Thickness | Hatch Spacing |

|---|---|---|---|---|

| 400 W | 200 μs | 0.15 m/s | 30 μm | 120 μm |

| Designed mass (g) | Measured mass (g) | Average (g) | Error (%) | |

| O-lattice | 19.91 | 19.16 19.20 | 19.18 | 3.67 |

| Bambusa-lattice | 19.91 | 19.44 19.42 | 19.43 | 2.41 |

| Sample | Density (g/cm3) | Elastic Modulus (GPa) | Initial Yield Stress (MPa) | Ultimate Stress (MPa) | Ultimate Strain |

|---|---|---|---|---|---|

| 1 | - | 95 | 516 | 927 | 0.2365 |

| 2 | - | 91 | 509 | 937 | 0.2374 |

| Average | 7.96 | 93 | 512.5 | 932 | 0.237 |

| Lattice Configuration | E (MPa) | σys (MPa) | σp (MPa) | ||

|---|---|---|---|---|---|

| O-lattice | Experiment | 1st test 2nd test | 426.85 424.38 | 8.912 8.868 | 10.575 10.870 |

| Average | 425.62 | 8.89 | 10.72 | ||

| Exp Error(%) | 0.58 | 0.49 | 2.71 | ||

| Simulation | 402.77 | 9.147 | 11.188 | ||

| Error (%) | 5.37 | 2.89 | 4.34 | ||

| Bambusa-lattice | Experiment | 1st test 2nd test | 510.68 522.40 | 10.528 10.608 | 12.478 12.450 |

| Average | 516.54 | 10.568 | 12.464 | ||

| Exp Error(%) | 2.244 | 0.754 | 0.225 | ||

| Simulation | 541.53 | 10.354 | 12.491 | ||

| Error (%) | 4.84 | 2.02 | 0.22 | ||

| β | E (MPa) | G (MPa) | σys (MPa) | σm (MPa) |

|---|---|---|---|---|

| 0.6 | 402.77 | 980 | 9.147 | 11.188 |

| 1.0 | 541.53 | 900 | 10.354 | 12.491 |

| 1.5 | 609.83 | 780 | 5.713 | 11.941 |

| O-lattice | 402.77 | 820 | 9.147 | 11.188 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, S.; Li, W.; Ma, G.; Cao, X.; Zhang, L.; Fang, L.; Meng, J.; Shao, Y.; Shen, B.; Zhang, C.; et al. Enhancing Mechanical Properties of 3D Printing Metallic Lattice Structure Inspired by Bambusa Emeiensis. Materials 2023, 16, 2545. https://doi.org/10.3390/ma16072545

Jing S, Li W, Ma G, Cao X, Zhang L, Fang L, Meng J, Shao Y, Shen B, Zhang C, et al. Enhancing Mechanical Properties of 3D Printing Metallic Lattice Structure Inspired by Bambusa Emeiensis. Materials. 2023; 16(7):2545. https://doi.org/10.3390/ma16072545

Chicago/Turabian StyleJing, Shikai, Wei Li, Guanghao Ma, Xiaofei Cao, Le Zhang, Liu Fang, Jiaxu Meng, Yujie Shao, Biwen Shen, Changdong Zhang, and et al. 2023. "Enhancing Mechanical Properties of 3D Printing Metallic Lattice Structure Inspired by Bambusa Emeiensis" Materials 16, no. 7: 2545. https://doi.org/10.3390/ma16072545

APA StyleJing, S., Li, W., Ma, G., Cao, X., Zhang, L., Fang, L., Meng, J., Shao, Y., Shen, B., Zhang, C., Li, H., Wan, Z., & Xiao, D. (2023). Enhancing Mechanical Properties of 3D Printing Metallic Lattice Structure Inspired by Bambusa Emeiensis. Materials, 16(7), 2545. https://doi.org/10.3390/ma16072545