Effect of Rolling Resistance Model Parameters on 3D DEM Modeling of Coarse Sand Direct Shear Test

Abstract

:1. Introduction

2. Model Calibration

2.1. Laboratory Direct Shear Tests

2.2. 3D DEM Simulation of DST

2.3. Contact Model

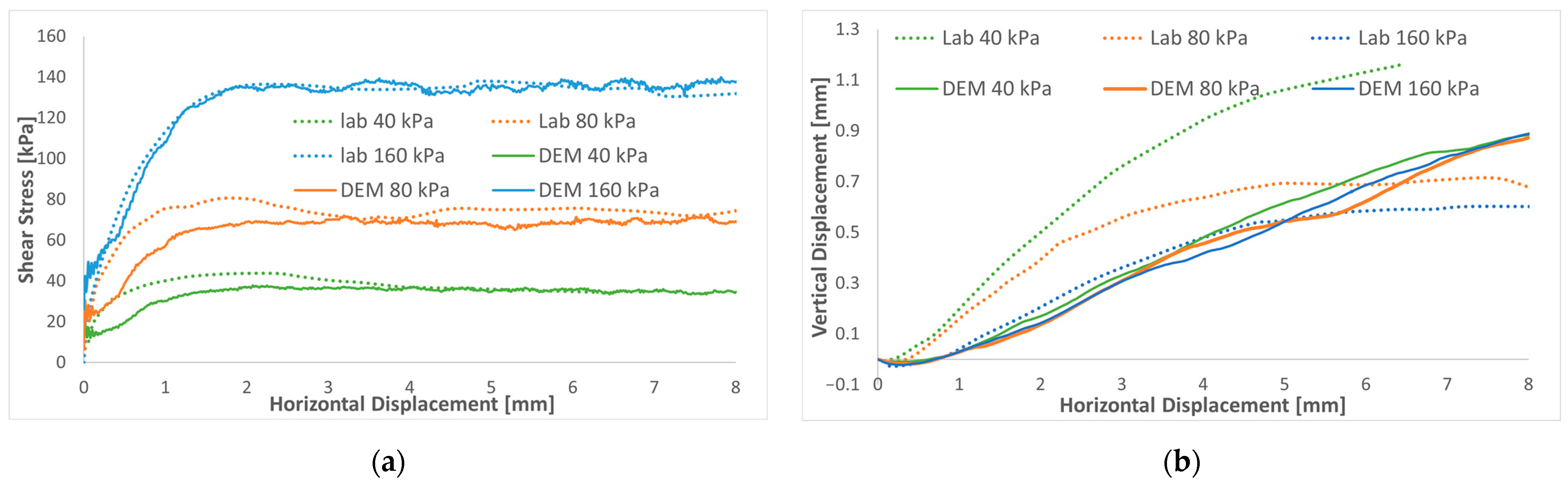

2.4. Calibration Results

3. Microscopic Observations

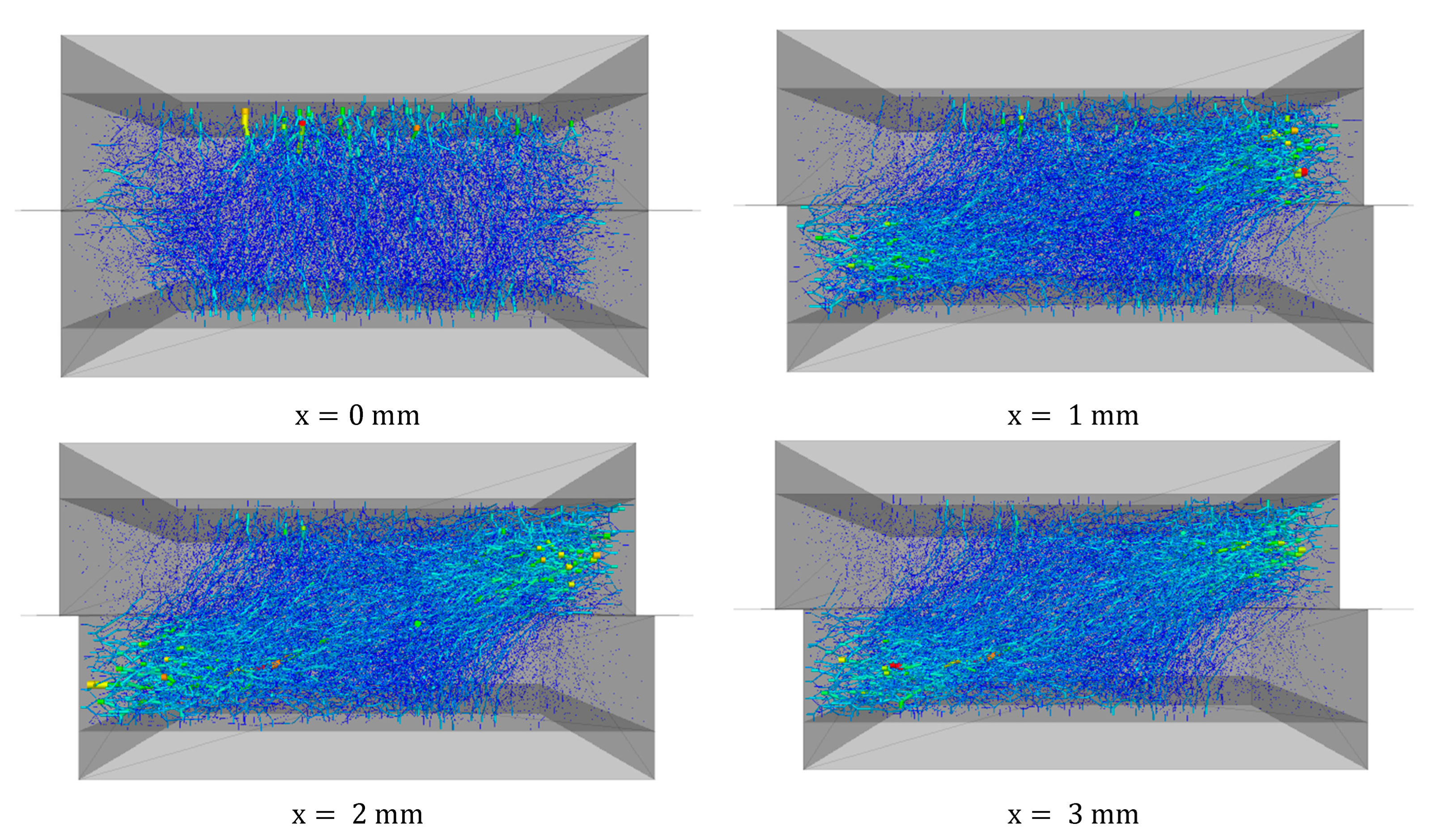

3.1. Inter-Particle Forces

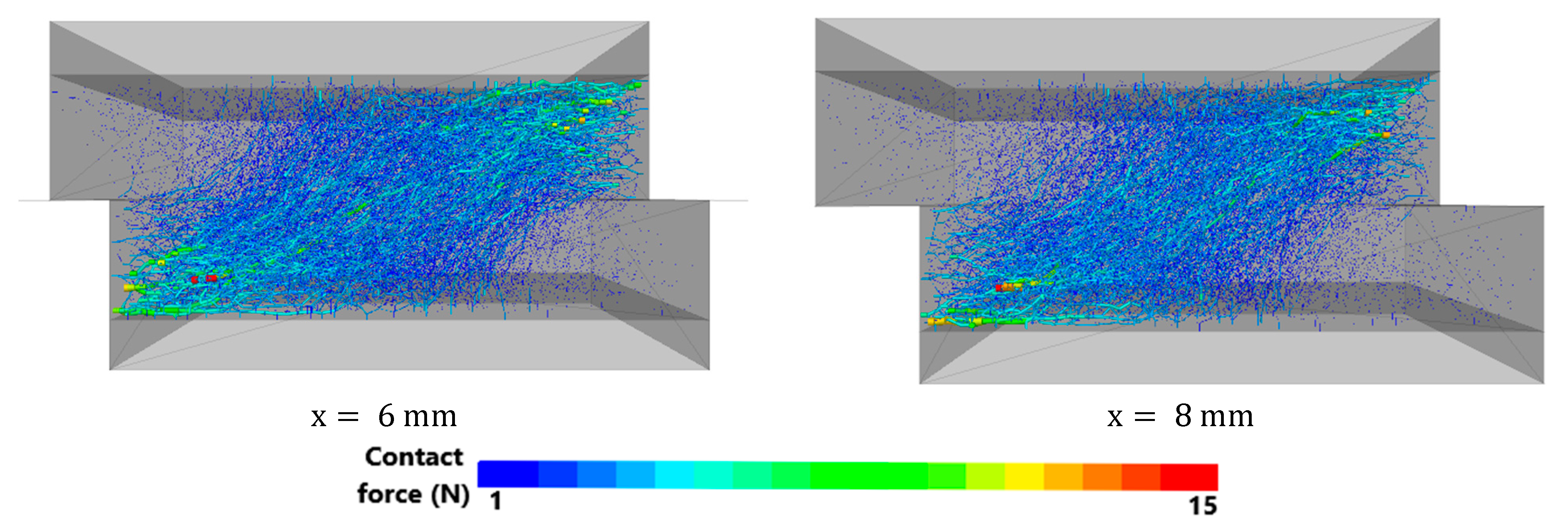

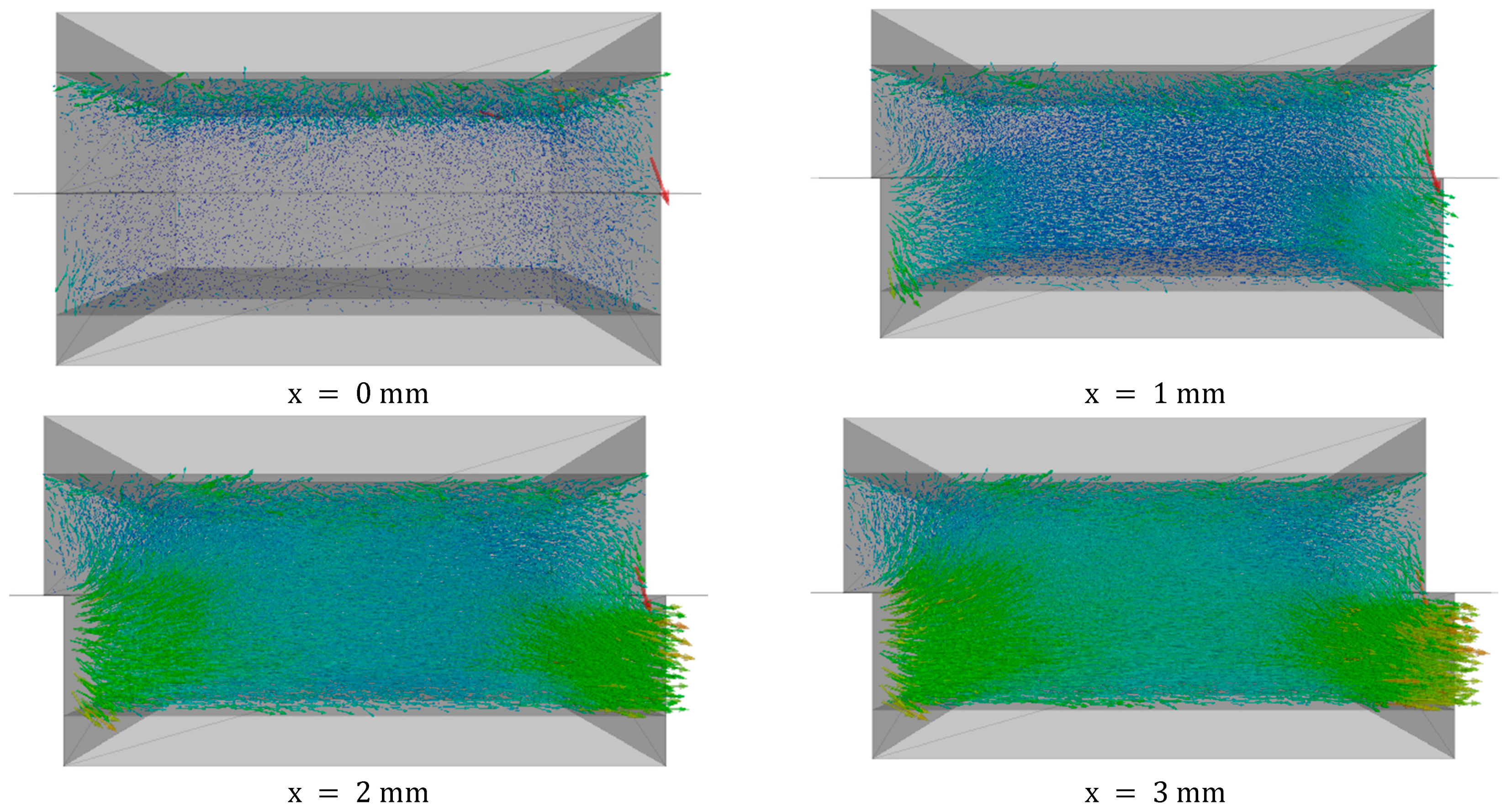

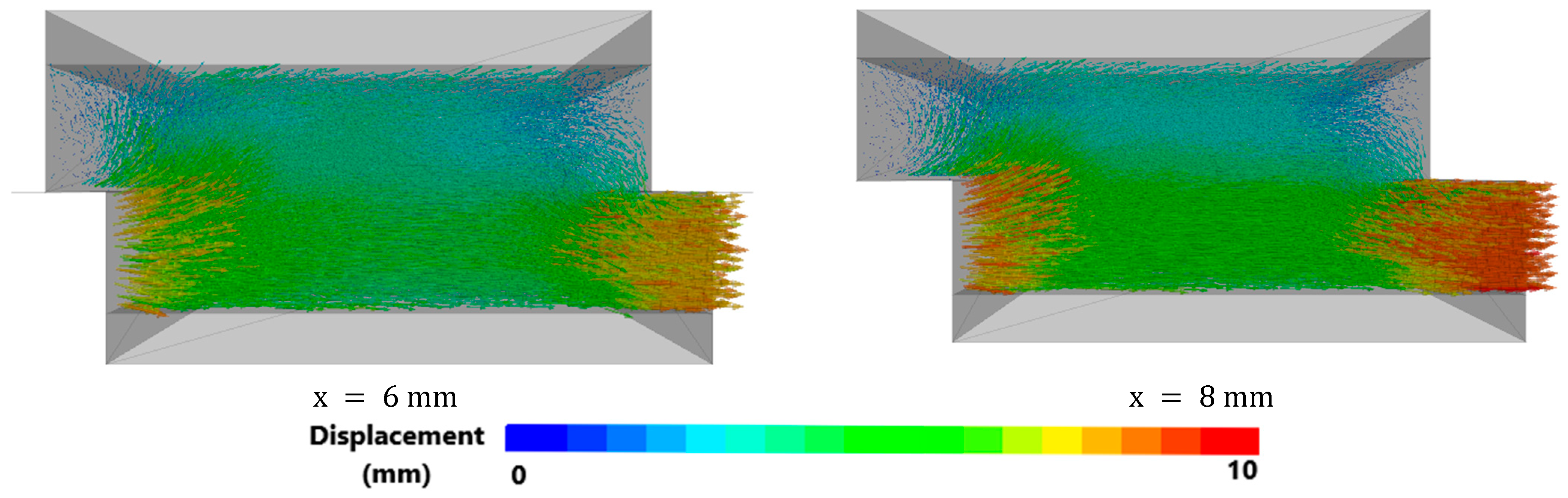

3.2. Particles Displacement Vector

4. Sensitivity Analysis

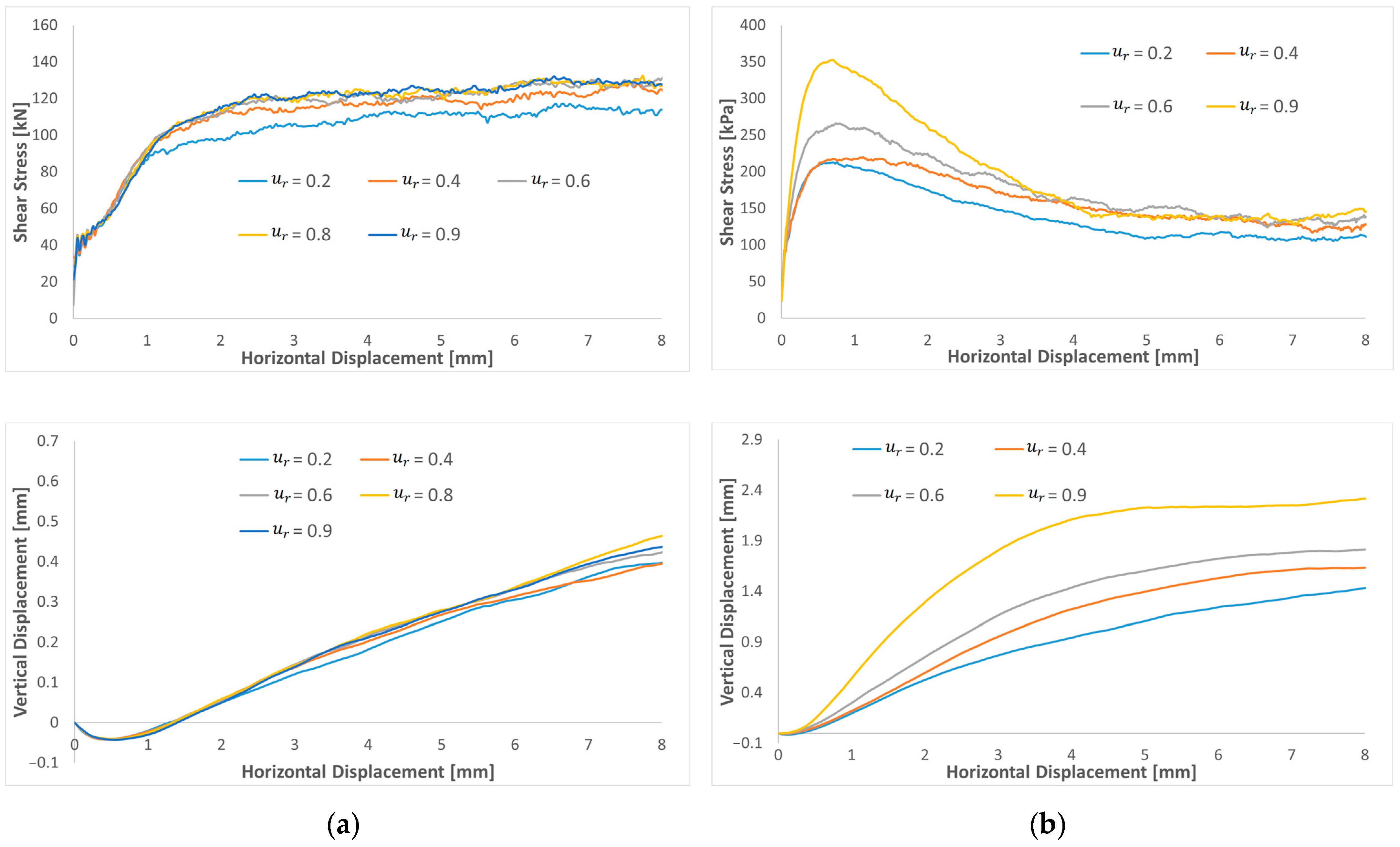

4.1. Rolling Resistance

4.2. Friction Coefficient

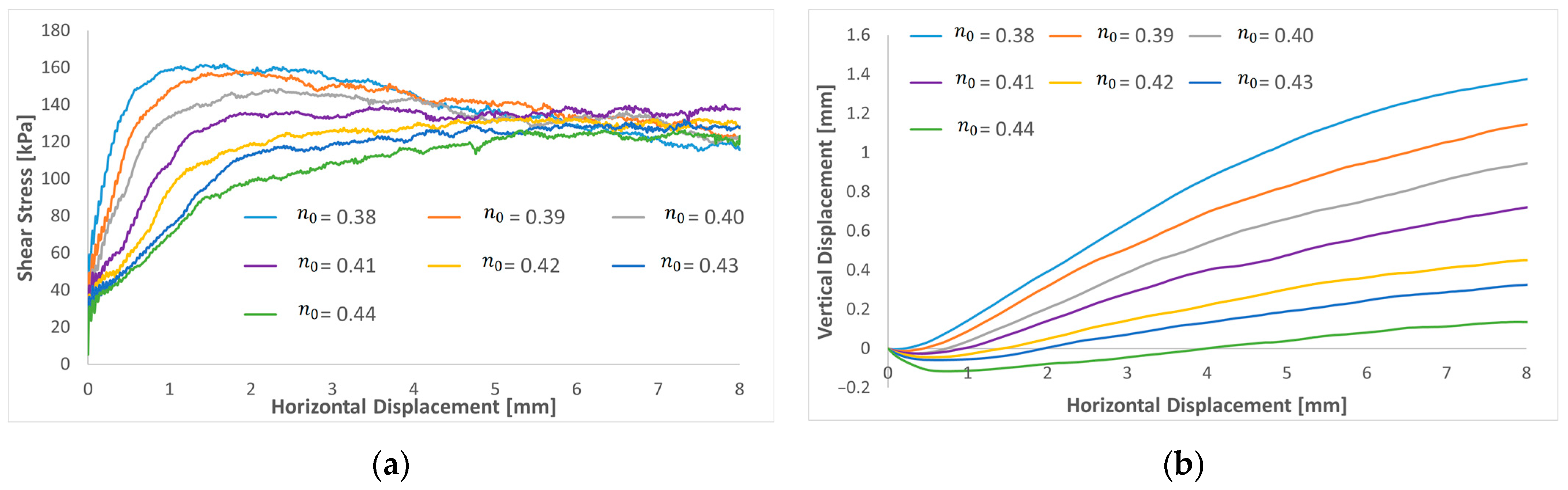

4.3. Porosity

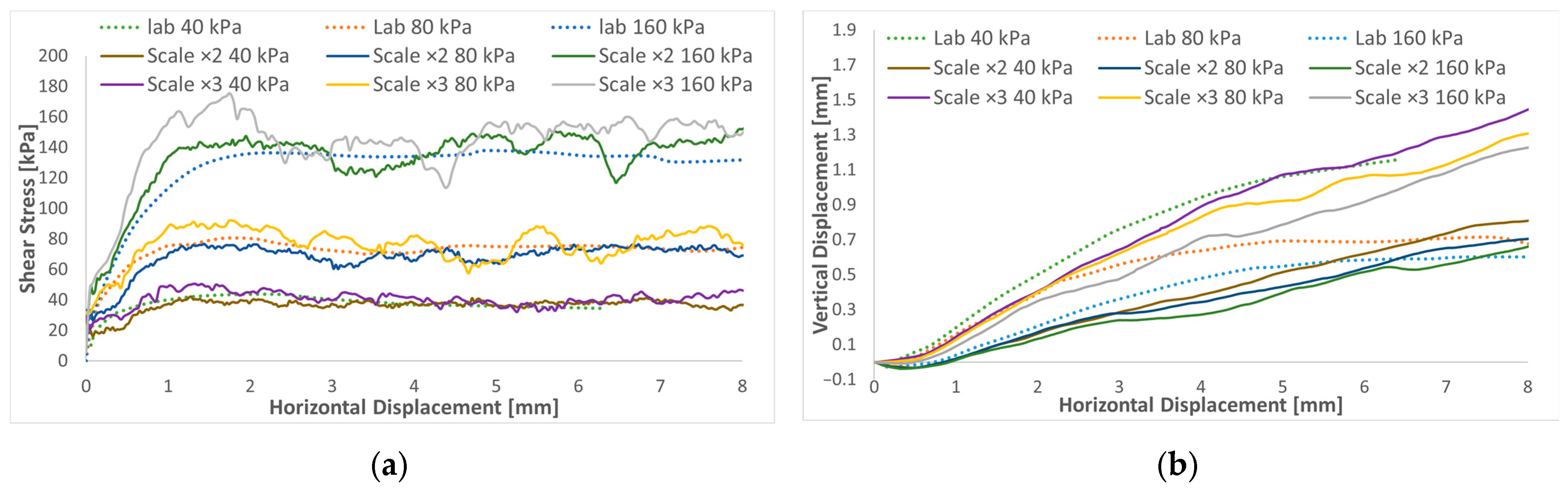

4.4. Up-Scaled Effect

5. Conclusions

- In direct shear, the shear stress paths (peak and residual) can be well represented and explored in-depth through the contact force chain and displacement.

- For a high coefficient of friction (), the peak shear stress and volume change are mainly affected by increasing the rolling resistance coefficient. However, for a low coefficient of friction (), the rolling resistance coefficient has a marginal effect on the shear stress and volume change during the shearing process.

- Varying the friction and rolling resistance coefficients seems to have a negligible influence on the residual shear stress (the contact model parameters interactions lightly affect the residual shear stress).

- To represent the typical response of relatively dense sand characterized by peak shear stress and residual shear stress close to the shear stress of loose sand, choosing dense sand with a high coefficient of friction is necessary.

- Using a high rolling resistance, the effect of increasing the friction coefficient is more pronounced for the peak stress and volume change values.

- The use of the scaling method is the best alternative to reach a reasonable computing time, but it raises the fluctuation of results. This methodology allows for making bigger and more complex models.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Frydman, S.; Talesnick, M. Simple shear of isotropic elasto–plastic soil. Int. J. Numer. Anal. Methods Geomech. 1991, 15, 251–270. [Google Scholar] [CrossRef]

- Gutierrez, M.; Wang, J.; Yoshimine, M. Modeling of the simple shear deformation of sand: Effects of principal stress rotation. Acta Geotech. 2009, 3, 193–201. [Google Scholar] [CrossRef]

- Tejchman, J.; Bauer, E. FE-simulations of a direct and a true simple shear test within a polar hypoplasticity. Comput. Geotech. 2005, 32, 1–16. [Google Scholar] [CrossRef]

- Cui, L.; O’sullivan, C. Exploring the macro-and micro-scale response of an idealised granular material in the direct shear apparatus. Geotechnique 2006, 56, 455–468. [Google Scholar] [CrossRef]

- Wang, J.; Gutierrez, M.S.; Dove, J.E. Numerical studies of shear banding in interface shear tests using a new strain calculation method. Int. J. Numer. Anal. Methods Geomech. 2007, 31, 1349–1366. [Google Scholar] [CrossRef]

- Zhou, Q.; Shen, H.; Helenbrook, B.; Zhang, H.W. Scale dependence of direct shear tests. Chin. Sci. Bull. 2009, 54, 4337–4348. [Google Scholar] [CrossRef] [Green Version]

- Kozicki, J.; Niedostatkiewicz, M.; Tejchman, J.; Mühlhaus, H.-B. Discrete modelling results of a direct shear test for granular materials versus FE results. Granul. Matter 2013, 15, 607–627. [Google Scholar] [CrossRef]

- Salazar, A.; Sáez, E.; Pardo, G. Modeling the direct shear test of a coarse sand using the 3D discrete element method with a rolling friction model. Comput. Geotech. 2015, 67, 83–93. [Google Scholar] [CrossRef]

- Bernhardt, M.L.; Biscontin, G.; O’Sullivan, C. Experimental validation study of 3D direct simple shear DEM simulations. Soils Found. 2016, 56, 336–347. [Google Scholar] [CrossRef]

- Wang, C.; Deng, A.; Taheri, A. Three-dimensional discrete element modeling of direct shear test for granular rubber–sand. Comput. Geotech. 2018, 97, 204–216. [Google Scholar] [CrossRef]

- Grabowski, A.; Nitka, M. 3D DEM simulations of basic geotechnical tests with early detection of shear localization. Stud. Geotech. Mech. 2020, 43, 48–64. [Google Scholar] [CrossRef]

- Pirhooshyaran, M.R.; Nikkhah, M. Hydraulic fracture patterns in fractured rock mass using coupled hydromechanical modeling in the bonded particle model. Model. Earth Syst. Environ. 2022, 8, 2277–2290. [Google Scholar] [CrossRef]

- Jensen, R.P.; Bosscher, P.J.; Plesha, M.E.; Edil, T.B. DEM simulation of granular media structure interface: Effects of surface roughness and particle shape. Int. J. Numer. Anal. Methods Geomech. 1999, 23, 531–547. [Google Scholar] [CrossRef]

- Frost, J.D.; Dejong, J.T.; Recalde, M. Shear failure behavior of granular-continuum interfaces. Eng. Fract. Mech. 2002, 69, 2029–2048. [Google Scholar] [CrossRef]

- Frost, J.D.; DeJong, J.T. In situ assessment of role of surface roughness on interface response. J. Geotech. Geoenviron. Eng. 2005, 131, 498–511. [Google Scholar] [CrossRef]

- Wang, J.; Dove, J.E.; Gutierrez, M.S. Discrete-continuum analysis of shear banding in the direct shear test. Geotechnique 2007, 57, 513–526. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, M. Unified soil behavior of interface shear test and direct shear test under the influence of lower moving boundaries. Granul. Matter 2011, 13, 631–641. [Google Scholar] [CrossRef]

- Gu, X.; Chen, Y.; Huang, M. Critical state shear behavior of the soil-structure interface determined by discrete element modelling. Particuology 2017, 35, 68–77. [Google Scholar] [CrossRef]

- Zhu, H.; Zhou, W.H.; Yin, Z.Y. Deformation mechanism of strain localization in 2D numerical interface tests. Acta Geotech. 2018, 13, 557–573. [Google Scholar] [CrossRef]

- Jing, X.Y.; Zhou, W.H.; Li, Y. Interface direct shearing behavior between soil and saw tooth surfaces by DEM simulation. Procedia Eng. 2017, 175, 36–42. [Google Scholar] [CrossRef]

- Jing, X.Y.; Zhou, W.H.; Zhu, H.X.; Yin, Z.Y.; Li, Y. Analysis of soil-structural interface behavior using three-dimensional DEM simulations. Int. J. Numer. Anal. Methods Geomech. 2018, 42, 339–357. [Google Scholar] [CrossRef]

- Zhou, W.H.; Jing, X.Y.; Yin, Z.Y.; Geng, X. Effects of particle sphericity and initial fabric on the shearing behavior of soil-rough structural interface. Acta Geotech. 2019, 14, 1699–1716. [Google Scholar] [CrossRef]

- Zhang, N.; Evans, T.M. Three dimensional discrete element method simulations of interface shear. Soils Found. 2018, 58, 941–956. [Google Scholar] [CrossRef]

- Grabowski, A.; Nitka, M.; Tejchman, J. 3D DEM simulations of monotonic interface behaviour between cohesionless sand and rigid wall of different roughness. Acta Geotech. 2020, 16, 1001–1026. [Google Scholar] [CrossRef]

- Terzaghi, K.; Peck, R.B. Soil Mechanics in Engineering Practice; Wiley: New York, NY, USA, 1948. [Google Scholar]

- Potyondy, J.G. Skin friction between various soils and construction materials. Geotechnique 1961, 4, 339–353. [Google Scholar] [CrossRef]

- Saada, A.S.; Townsend, F.C. State of the art: Laboratory strength testing of soils. Laboratory shear strength of soil. ASTM Spec. Tech. Publ. 1981, 740, 7–77. [Google Scholar] [CrossRef]

- Desai, C.S.; Drumm, E.C.; Zama, M.M. Cyclic testing and modeling of interfaces. J. Geotech. Eng. ASCE 1985, 111, 793–815. [Google Scholar] [CrossRef]

- Jewell, R.A.; Wroth, C.P. Direct shear tests on reinforced sand. Geotechnique 1987, 37, 53–68. [Google Scholar] [CrossRef]

- Tejchman, J.; Wu, W. Experimental and numerical study of sand-steel interfaces. Int. J. Numer. Anal. Methods Geomech. 1995, 19, 513–537. [Google Scholar] [CrossRef]

- Shibuya, S.; Mitachi, T.; Tamate, S. Interpretation of direct shear box testing of sands as quasi-simple shear. Geotechnique 1997, 47, 769–790. [Google Scholar] [CrossRef]

- Chandler, R.J.; Hamilton, P.S. On the measurement of the undrained strength of discontinuities in the direct shear box. Geotechnique 1999, 49, 615–620. [Google Scholar] [CrossRef]

- Schwedes, J. Testers for measuring flow properties of particulate solids. Powder Handl. Process. 2000, 12, 337–385. [Google Scholar]

- Fischer, S. Breakage Test of Railway Ballast Materials with New Laboratory Method. Period. Polytech. Civ. Eng. 2017, 61, 794–802. [Google Scholar] [CrossRef] [Green Version]

- Cerato, A.B.; Lutenegger, A.J. Specimen size and scale effects of direct shear box tests of sands. Geotech. Test. J. 2006, 29, 507–516. [Google Scholar] [CrossRef]

- Yan, Y.; Ji, S. Discrete element modeling of direct shear tests for a granular material. Int. J. Numer. Anal. Methods Geomech. 2010, 34, 978–990. [Google Scholar] [CrossRef]

- Härtl, J.; Ooi, J.Y. Numerical investigation of particle shape and particle friction on limiting bulk friction in direct shear tests and comparison with experiments. Powder Technol. 2011, 212, 231–239. [Google Scholar] [CrossRef]

- Kim, B.S.; Shibuya, S.; Park, S.W.; Kato, S. Effect of the opening between shear boxes on the shear behavior of granular materials in direct shear box test. KSCE J. Civ. Eng. 2012, 16, 1132–1142. [Google Scholar] [CrossRef]

- Nitka, M.; Grabowski, A. Shear band evolution phenomena in direct shear test modelled with DEM. Powder Technol. 2021, 391, 369–384. [Google Scholar] [CrossRef]

- Moncada, M.; Betancourt, F.; Rodríguez, C.G.; Toledo, P. Effect of Particle Shape on Parameter Calibration for a Discrete Element Model for Mining Applications. Minerals 2023, 13, 40. [Google Scholar] [CrossRef]

- Wang, L.; Yao, Y.; Li, J.; Tao, Y.; Liu, K. Review of Visualization Technique and Its Application of Road Aggregates Based on Morphological Features. Appl. Sci. 2022, 12, 10571. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Yang, X.; Zhang, A.; Yu, M. Monte Carlo simulations of deformation behaviour of unbound granular materials based on a real aggregate library. Int. J. Pavement Eng. 2023, 24, 2165650. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, C.; Markine, V.; Shi, C.; Jing, G.; Zhai, W. Discrete element modelling of railway ballast performance considering particle shape and rolling resistance. Rail. Eng. Sci. 2020, 28, 382–407. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| 1578 | |

| 0.679 | |

| 0.405 | |

| Angle of internal friction: [°] | 35 |

| 8 |

| Particles Properties | ||

|---|---|---|

| Elementary particles size, | 1.2–2.15 | |

| 2 | ||

| - | 1 | |

| Density | kg/m3 | 2600 |

| Damping coefficient | - | 0.5 |

| Friction coefficient between sand particles, | - | 0.3 |

| Porosity | - | 0.41 |

| Friction coefficient between sand particle and wall, | - | 0.0 |

| - | 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benmebarek, M.A.; Movahedi Rad, M. Effect of Rolling Resistance Model Parameters on 3D DEM Modeling of Coarse Sand Direct Shear Test. Materials 2023, 16, 2077. https://doi.org/10.3390/ma16052077

Benmebarek MA, Movahedi Rad M. Effect of Rolling Resistance Model Parameters on 3D DEM Modeling of Coarse Sand Direct Shear Test. Materials. 2023; 16(5):2077. https://doi.org/10.3390/ma16052077

Chicago/Turabian StyleBenmebarek, Mohamed Amine, and Majid Movahedi Rad. 2023. "Effect of Rolling Resistance Model Parameters on 3D DEM Modeling of Coarse Sand Direct Shear Test" Materials 16, no. 5: 2077. https://doi.org/10.3390/ma16052077

APA StyleBenmebarek, M. A., & Movahedi Rad, M. (2023). Effect of Rolling Resistance Model Parameters on 3D DEM Modeling of Coarse Sand Direct Shear Test. Materials, 16(5), 2077. https://doi.org/10.3390/ma16052077