Effect of Sustained Loading on the Direct Shear Behaviour of Recycled C&D Material–Geosynthetic Interfaces

Abstract

1. Introduction

2. Materials and Methods

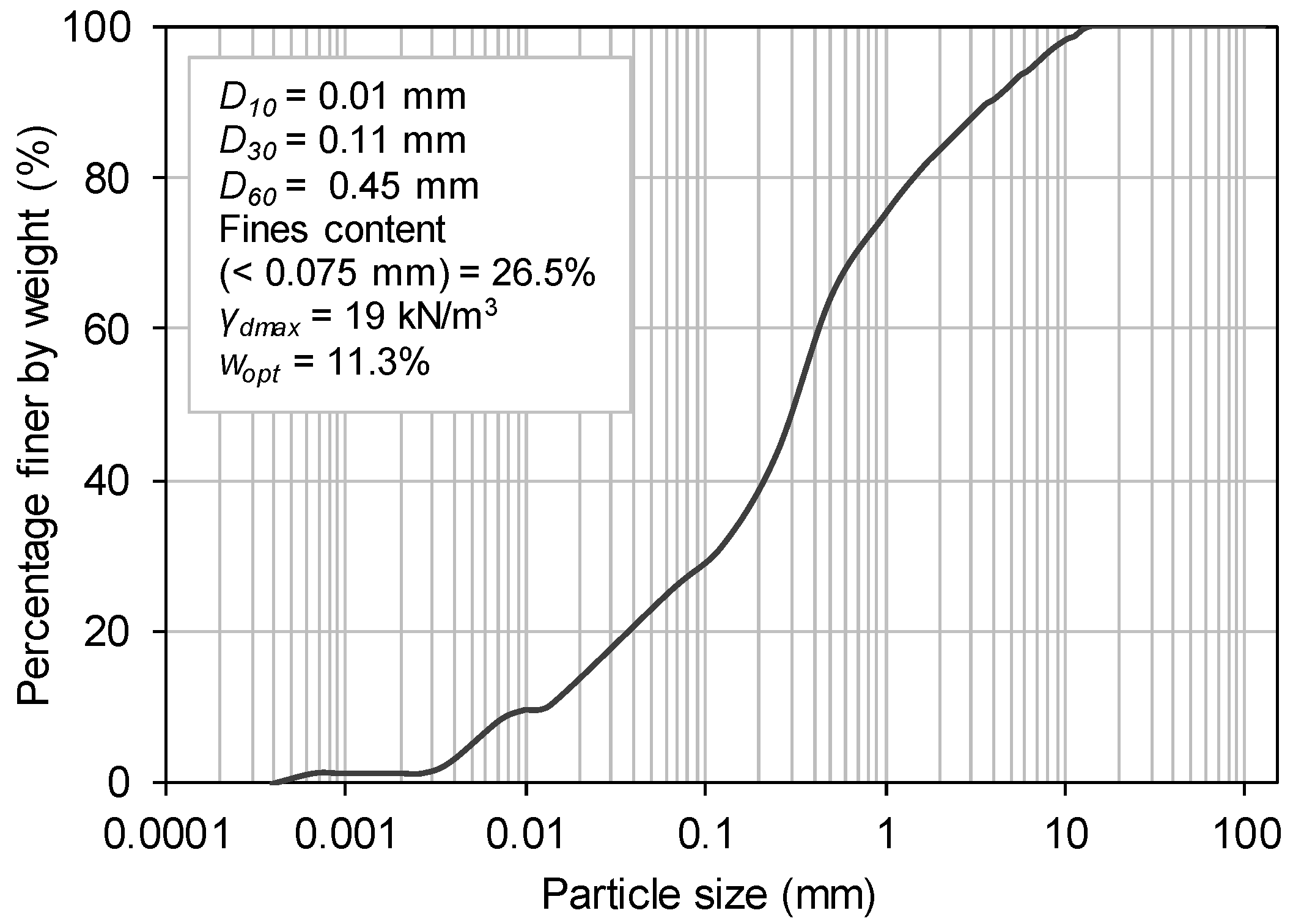

2.1. Recycled C&D Material

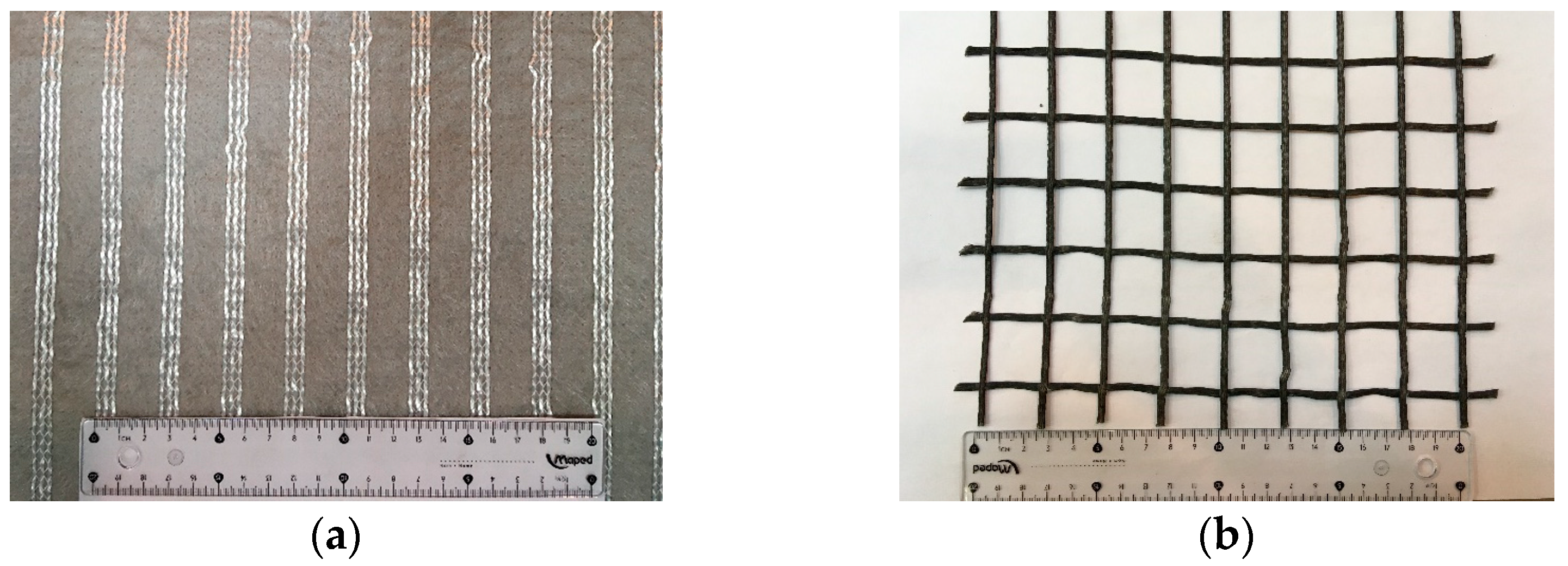

2.2. Geosynthetics

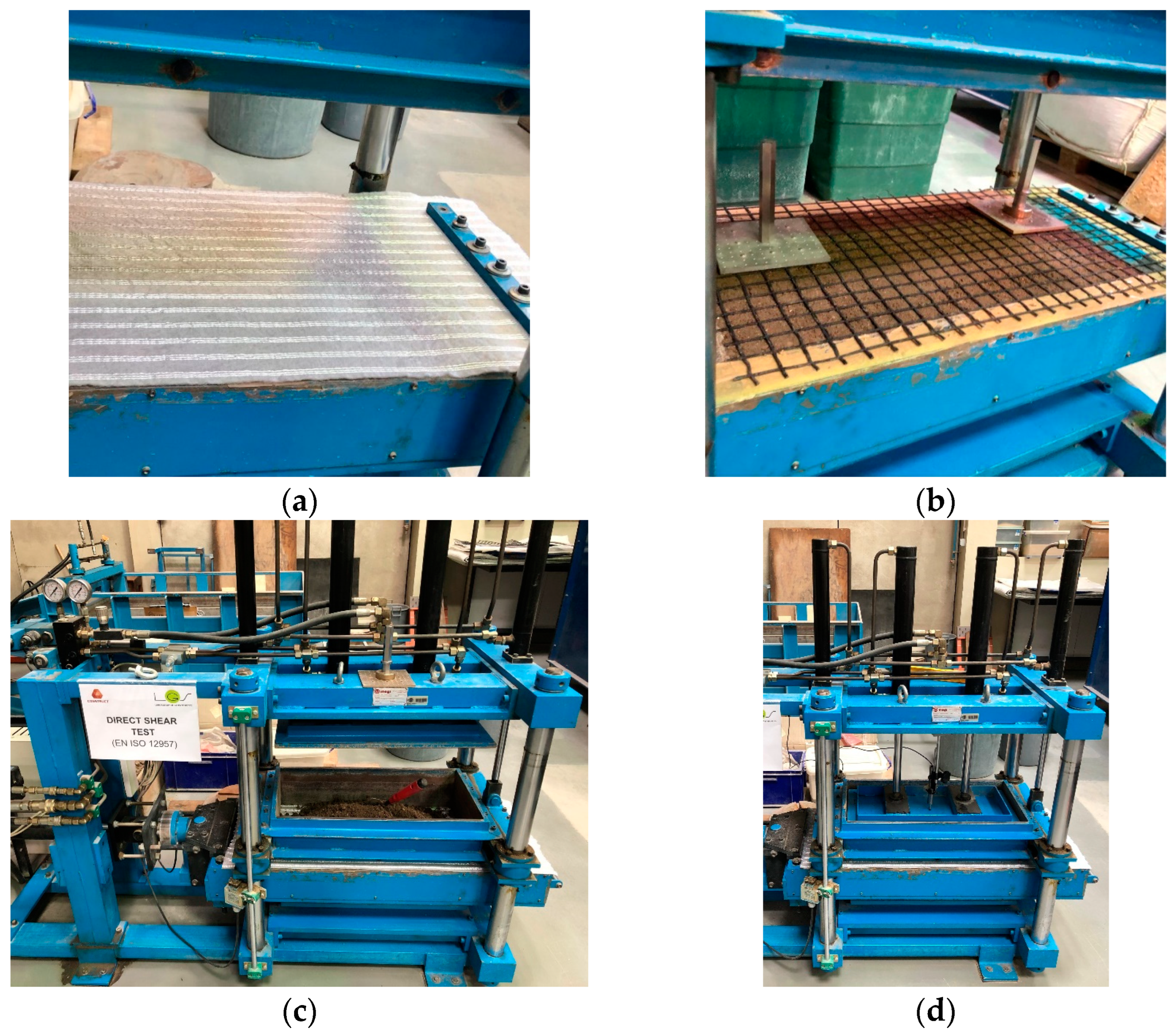

2.3. Direct Shear Test Device and Procedures

2.4. Experimental Programme

3. Results and Discussion

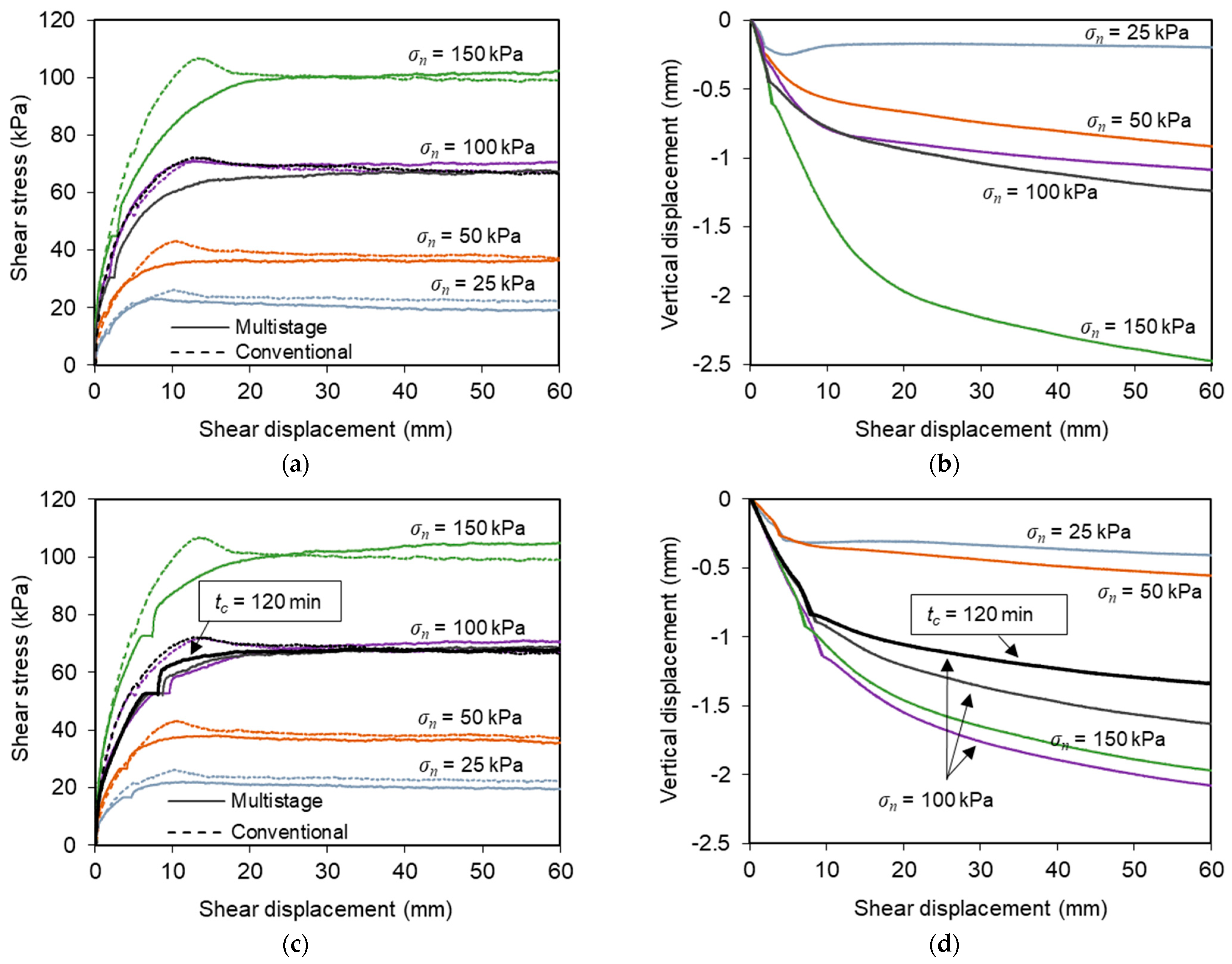

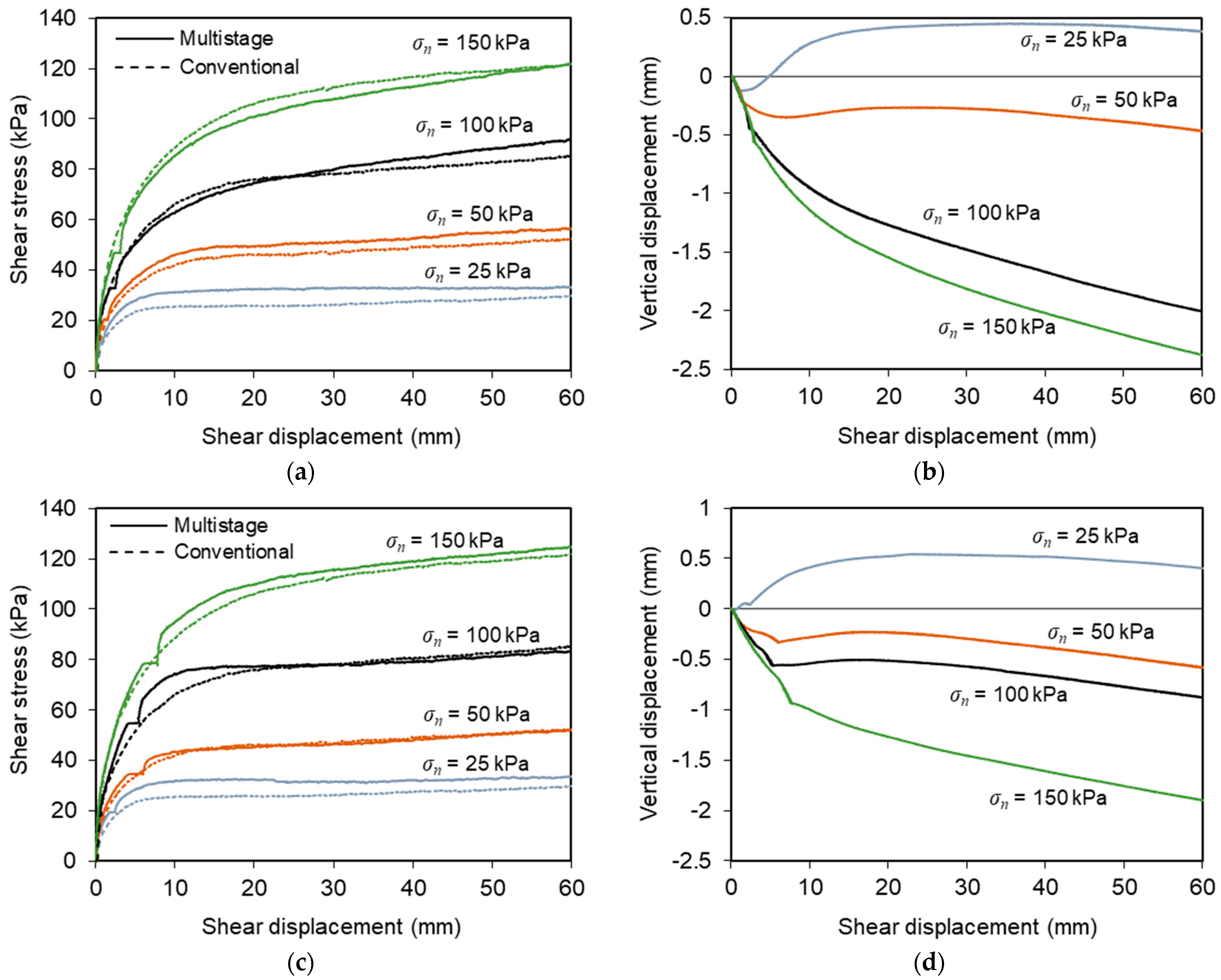

3.1. Conventional Interface Direct Shear Tests

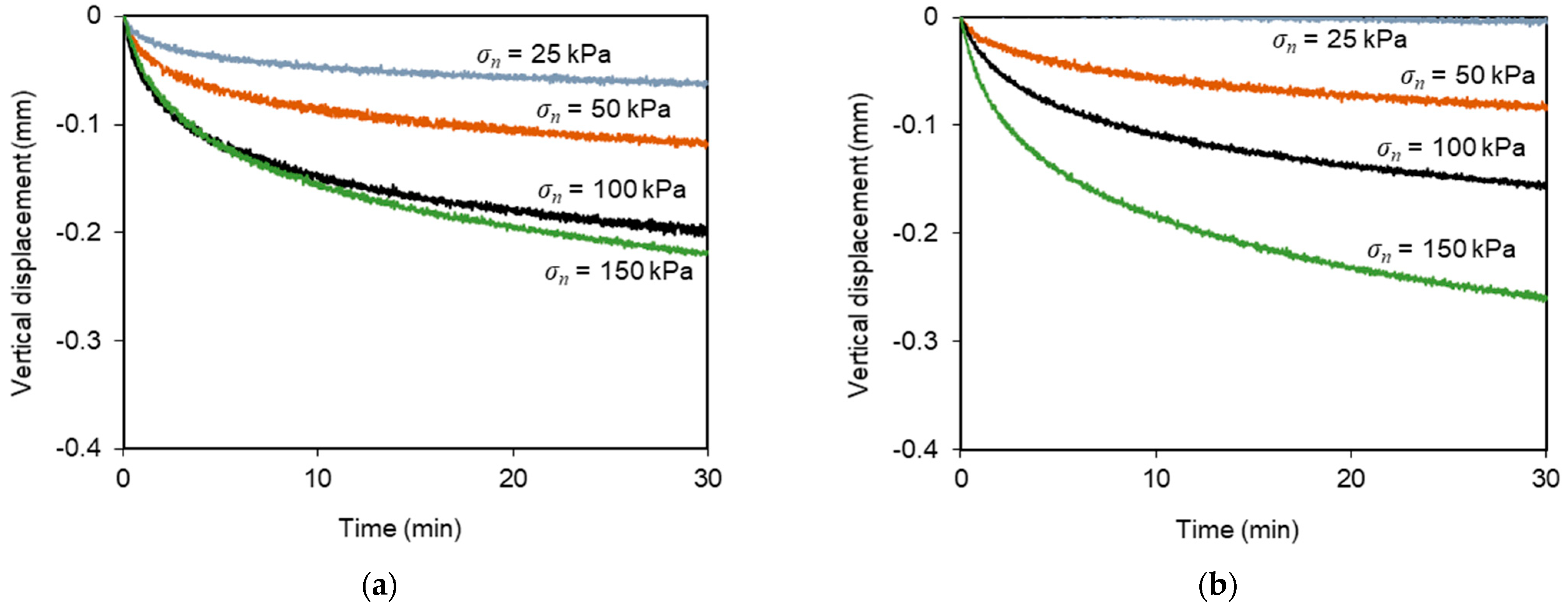

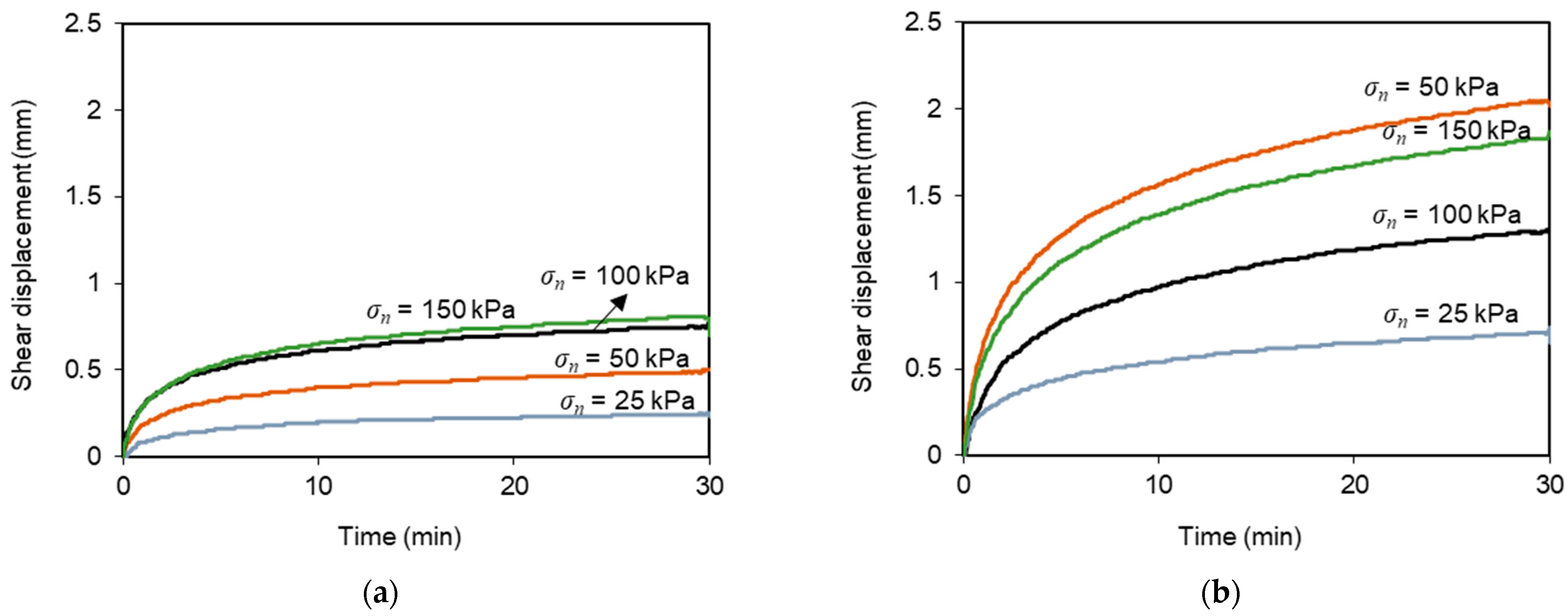

3.2. Effect of Sustained Loading on the Interface Behaviour

3.2.1. Recycled C&D Material–Geotextile Interface

3.2.2. Recycled C&D Material–Geogrid Interface

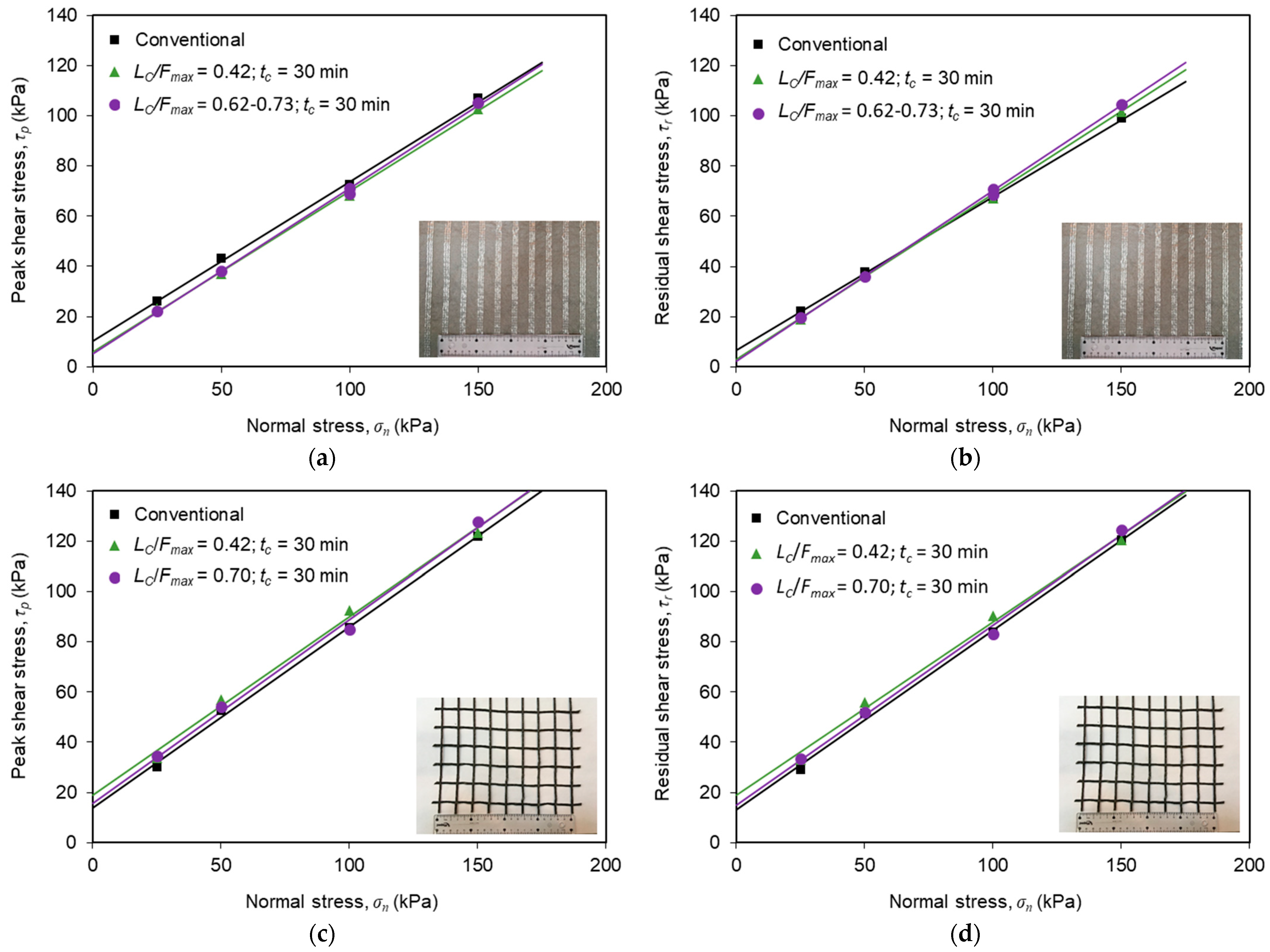

3.3. Interface Shear Strength Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wagih, A.M.; El-Karmoty, H.Z.; Ebid, M.; Okba, S.H. Recycled construction and demolition concrete waste as aggregate for structural concrete. HBRC J. 2013, 9, 193–200. [Google Scholar] [CrossRef]

- Kim, J.; Grabiec, A.M.; Ubysz, A. An experimental study on structural concrete containing recycled aggregates and powder from construction and demolition waste. Materials 2022, 15, 2458. [Google Scholar] [CrossRef] [PubMed]

- Leite, F.D.; Motta, R.D.; Vasconcelos, K.L.; Bernucci, L. Laboratory evaluation of recycled construction and demolition waste for pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M.; Bo, M.W. Geotechnical and geoenvironmental properties of recycled construction and demolition materials in pavement subbase applications. J. Mater. Civ. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Arulrajah, A.; Naeini, M.; Mohammadinia, A.; Horpibulsuk, S.; Leong, M. Recovered plastic and demolition waste blends as railway capping materials. Transp. Geotech. 2020, 22, 100320. [Google Scholar] [CrossRef]

- Naeini, M.; Mohammadinia, A.; Arulrajah, A.; Horpibulsuk, S. Recycled glass blends with recycled concrete aggregates in sustainable railway geotechnics. Sustainability 2021, 13, 2463. [Google Scholar] [CrossRef]

- Henzinger, C.; Heyer, D. Soil improvement using recycled aggregates from demolition waste. Proc. Inst. Civ. Eng. Ground Improv. 2018, 171, 74–81. [Google Scholar] [CrossRef]

- Santos, E.; Palmeira, E.; Bathurst, R. Performance of two geosynthetic reinforced walls with recycled construction waste backfill and constructed on collapsible ground. Geosynth. Int. 2014, 21, 256–269. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M.; Lopes, M.L. Recycled construction and demolition wastes as filling material for geosynthetic reinforced structures. Interface properties. J. Clean. Prod. 2016, 124, 299–311. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Pereira, P.M.; Lopes, M.L. Recycled construction and demolition waste as backfill material for geosynthetic-reinforced structures. In Sustainable Civil Engineering: Principles and Applications, 1st ed.; Kanwar, V.S., Shukla, S.K., John, S., Kandra, H.S., Eds.; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Hoboken, NJ, USA, 2023. [Google Scholar]

- Ferreira, F.B.; Pereira, P.M.; Vieira, C.S.; Lopes, M.L. Long-term tensile behavior of a high-strength geotextile after exposure to recycled construction and demolition materials. J. Mater. Civ. Eng. 2022, 34, 04022046. [Google Scholar] [CrossRef]

- Vieira, C.S.; Ferreira, F.B.; Pereira, P.M.; Lopes, M.L. Pullout behaviour of geosynthetics in a recycled construction and demolition material—Effects of cyclic loading. Transp. Geotech. 2020, 23, 100346. [Google Scholar] [CrossRef]

- European Commission. EU Circular Economy Action Plan. Available online: https://ec.europa.eu/environment/circular-economy/ (accessed on 1 December 2022).

- Lopes, M.L.; Ladeira, M. Role of specimen geometry, soil height and sleeve length on the pull-out behaviour of geogrids. Geosynth. Int. 1996, 3, 701–719. [Google Scholar] [CrossRef]

- Moraci, N.; Recalcati, P. Factors affecting the pullout behaviour of extruded geogrids embedded in a compacted granular soil. Geotext. Geomembr. 2006, 24, 220–242. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L.; Carlos, D.M. Experimental investigation on the pullout behaviour of geosynthetics embedded in a granite residual soil. Eur. J. Environ. Civ. Eng. 2016, 20, 1147–1180. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L.; Ferreira, P.G. HDPE geogrid-residual soil interaction under monotonic and cyclic pullout loading. Geosynth. Int. 2020, 27, 79–96. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M.; Ferreira, F.B.; Lopes, M.L. Pullout behaviour of geogrids embedded in a recycled construction and demolition material. Effects of specimen size and displacement rate. Sustainability 2020, 12, 3825. [Google Scholar] [CrossRef]

- Cardile, G.; Pisano, M.; Recalcati, P.; Moraci, N. A new apparatus for the study of pullout behaviour of soil-geosynthetic interfaces under sustained load over time. Geotext. Geomembr. 2021, 49, 1519–1528. [Google Scholar] [CrossRef]

- Liu, C.-N.; Ho, Y.-H.; Huang, J.-W. Large scale direct shear tests of soil/PET-yarn geogrid interfaces. Geotext. Geomembr. 2009, 27, 19–30. [Google Scholar] [CrossRef]

- Arulrajah, A.; Rahman, M.A.; Piratheepan, J.; Bo, M.W.; Imteaz, M.A. Evaluation of interface shear strength properties of geogrid-reinforced construction and demolition materials using a modified large scale direct shear testing apparatus. J. Mater. Civ. Eng. 2014, 26, 974–982. [Google Scholar] [CrossRef]

- Ferreira, F.; Vieira, C.S.; Lopes, M. Direct shear behaviour of residual soil–geosynthetic interfaces–influence of soil moisture content, soil density and geosynthetic type. Geosynth. Int. 2015, 22, 257–272. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M. Interface shear properties of geosynthetics and construction and demolition waste from large-scale direct shear tests. Geosynth. Int. 2016, 23, 62–70. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L. Soil-geosynthetic interface strength properties from inclined plane and direct shear tests—A comparative analysis. In Proceedings of the 6th Asian Regional Conference on Geosynthetics: Geosynthetics for Infrastructure Development, New Delhi, India, 8–11 November 2016; pp. 925–937. [Google Scholar]

- Maghool, F.; Arulrajah, A.; Mirzababaei, M.; Suksiripattanapong, C.; Horpibulsuk, S. Interface shear strength properties of geogrid-reinforced steel slags using a large-scale direct shear testing apparatus. Geotext. Geomembr. 2020, 48, 625–633. [Google Scholar] [CrossRef]

- Chao, Z.; Fowmes, G. Modified stress and temperature-controlled direct shear apparatus on soil-geosynthetics interfaces. Geotext. Geomembr. 2021, 49, 825–841. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Pereira, P.M.; Vieira, C.S.; Lopes, M.L. Time-dependent response of a recycled C&D material-geotextile interface under direct shear mode. Materials 2021, 14, 3070. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Martinez, J. Creep behaviour of sand-geomembrane interfaces. Geosynth. Int. 2014, 21, 83–88. [Google Scholar] [CrossRef]

- Yang, W.; He, J.; Liu, L.; Yang, H. Testing the shearing creep of composite geomembranes-cushion interface and its empirical model. Soils Found. 2022, 62, 101236. [Google Scholar] [CrossRef]

- Helwany, S.M.B.; Shih, S. Creep and stress relaxation of geotextile-reinforced soils. Geosynth. Int. 1998, 5, 425–434. [Google Scholar] [CrossRef]

- Lu, Y.; Abuel-Naga, H.; Leong, E.-C.; Jiao, W.-G.; Wang, X. Characterisation of geomembrane and geotextile interface short-term creep behaviour in a dry condition. Geotext. Geomembr. 2022, 50, 312–322. [Google Scholar] [CrossRef]

- BS 1377-2; Methods of Test for Soils for Civil Engineering Purposes—Classification Tests. BSI: London, UK, 1990.

- EN 13286-2; Unbound and Hydraulically Bound Mixtures—Part 2: Test Methods for Laboratory Reference Density and Water Content—Proctor Compaction. CEN.: Brussels, Belgium, 2010.

- EN 933-11; Tests for Geometrical Properties of Aggregates—Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate. CEN: Brussels, Belgium, 2009.

- EN 12457-4; Characterisation of Waste—Leaching—Compliance Test for Leaching of Granular Waste Material and Sludges—Part 4. CEN: Brussels, Belgium, 2002.

- European Commission. Council Decision 2003/33/EC establishing criteria and procedures for the acceptance of waste at landfills pursuant to Article 16 of and Annex II to Directive 1999/31/EC. Off. J. Eur. Union 2003, L11/27, 27–49. [Google Scholar]

- Jang, Y.-C.; Townsend, T. Sulfate leaching from recovered construction and demolition debris fines. Adv. Environ. Res. 2001, 5, 203–217. [Google Scholar] [CrossRef]

- Vieira, C.S.; Lopes, M.L.; Caldeira, L.M. Sand-geotextile interface characterisation through monotonic and cyclic direct shear tests. Geosynth. Int. 2013, 20, 26–38. [Google Scholar] [CrossRef]

- EN ISO 12957-1; Geosynthetics—Determination of Friction Characteristics—Part 1: Direct Shear Test. CEN: Brussels, Belgium, 2018.

- Callister, W.D., Jr.; Rethwisch, D.G. Callister’s Materials Science and Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

| Constituents | According to [34] * | Global Value |

|---|---|---|

| Concrete, concrete products, mortar, concrete masonry units, Rc (%) | 16.0 | 1.6 |

| Unbound aggregate, natural stone, hydraulically bound aggregate, Ru (%) | 45.7 | 4.6 |

| Clay masonry units, calcium silicate masonry units, aerated non-floating concrete, Rb (%) | 3.7 | 0.4 |

| Bituminous materials, Ra (%) | 2.2 | 0.2 |

| Glass, Rg (%) | 0.3 | 0.0 |

| Other materials, X ** (%) | 32.1 | 3.2 |

| Unsorted particles (<4 mm) (%) | - | 90 |

| Floating particles, FL (cm3/kg) | 3.8 | - |

| Test Number | Geosynthetic Type | Test Method | Normal Stress, σn (kPa) | Sustained Shear Load, LC (kN) | Load Level, LC/Fmax | Time, tc (min) |

|---|---|---|---|---|---|---|

| T1 | Geotextile | Conventional | 25 | - | - | - |

| T2 | Geotextile | Conventional | 50 | - | - | - |

| T3 | Geotextile | Conventional | 100 | - | - | - |

| T4 | Geotextile | Conventional | 100 | - | - | - |

| T5 | Geotextile | Conventional | 150 | - | - | - |

| T6 | Geotextile | Multistage | 25 | 2.0 | 0.42 | 30 |

| T7 | Geotextile | Multistage | 50 | 3.3 | 0.42 | 30 |

| T8 | Geotextile | Multistage | 100 | 5.5 | 0.42 | 30 |

| T9 | Geotextile | Multistage | 100 | 5.5 | 0.42 | 30 |

| T10 | Geotextile | Multistage | 150 | 8.1 | 0.42 | 30 |

| T11 | Geotextile | Multistage | 25 | 3.4 | 0.72 | 30 |

| T12 | Geotextile | Multistage | 50 | 4.8 | 0.62 | 30 |

| T13 | Geotextile | Multistage | 100 | 9.5 | 0.73 | 30 |

| T14 | Geotextile | Multistage | 100 | 9.5 | 0.73 | 30 |

| T15 | Geotextile | Multistage | 150 | 13.1 | 0.68 | 30 |

| T16 | Geotextile | Multistage | 100 | 9.5 | 0.73 | 120 |

| T17 | Geogrid | Conventional | 25 | - | - | - |

| T18 | Geogrid | Conventional | 50 | - | - | - |

| T19 | Geogrid | Conventional | 100 | - | - | - |

| T20 | Geogrid | Conventional | 150 | - | - | - |

| T21 | Geogrid | Multistage | 25 | 2.1 | 0.42 | 30 |

| T22 | Geogrid | Multistage | 50 | 3.7 | 0.42 | 30 |

| T23 | Geogrid | Multistage | 100 | 5.9 | 0.42 | 30 |

| T24 | Geogrid | Multistage | 150 | 8.4 | 0.42 | 30 |

| T25 | Geogrid | Multistage | 25 | 3.5 | 0.70 | 30 |

| T26 | Geogrid | Multistage | 50 | 6.2 | 0.70 | 30 |

| T27 | Geogrid | Multistage | 100 | 9.8 | 0.70 | 30 |

| T28 | Geogrid | Multistage | 150 | 14.0 | 0.70 | 30 |

| Interface | Test Method | LC/Fmax | tc (min) | Peak | Residual | ||

|---|---|---|---|---|---|---|---|

| δ (°) | ca (kPa) | δ (°) | ca (kPa) | ||||

| C&D material–geotextile | Conventional | - | - | 32.4 | 10.3 | 31.4 | 6.9 |

| Multistage | 0.42 | 30 | 32.6 | 6.0 | 33.4 | 2.9 | |

| Multistage | 0.62–0.73 | 30 | 33.4 | 5.0 | 34.2 | 2.2 | |

| C&D material–geogrid | Conventional | - | - | 35.8 | 13.9 | 35.6 | 13.0 |

| Multistage | 0.42 | 30 | 35.4 | 19.0 | 34.6 | 18.8 | |

| Multistage | 0.70 | 30 | 36.2 | 15.8 | 35.7 | 14.9 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, F.B.; Vieira, C.S.; Mendonça, G.; Lopes, M.d.L. Effect of Sustained Loading on the Direct Shear Behaviour of Recycled C&D Material–Geosynthetic Interfaces. Materials 2023, 16, 1722. https://doi.org/10.3390/ma16041722

Ferreira FB, Vieira CS, Mendonça G, Lopes MdL. Effect of Sustained Loading on the Direct Shear Behaviour of Recycled C&D Material–Geosynthetic Interfaces. Materials. 2023; 16(4):1722. https://doi.org/10.3390/ma16041722

Chicago/Turabian StyleFerreira, Fernanda Bessa, Castorina Silva Vieira, Guilherme Mendonça, and Maria de Lurdes Lopes. 2023. "Effect of Sustained Loading on the Direct Shear Behaviour of Recycled C&D Material–Geosynthetic Interfaces" Materials 16, no. 4: 1722. https://doi.org/10.3390/ma16041722

APA StyleFerreira, F. B., Vieira, C. S., Mendonça, G., & Lopes, M. d. L. (2023). Effect of Sustained Loading on the Direct Shear Behaviour of Recycled C&D Material–Geosynthetic Interfaces. Materials, 16(4), 1722. https://doi.org/10.3390/ma16041722