Degradation of Carbon Fiber-Reinforced Polymer Composites in Salt Water and Rapid Evaluation by Electrochemical Impedance Spectroscopy

Abstract

1. Introduction

2. Experimental

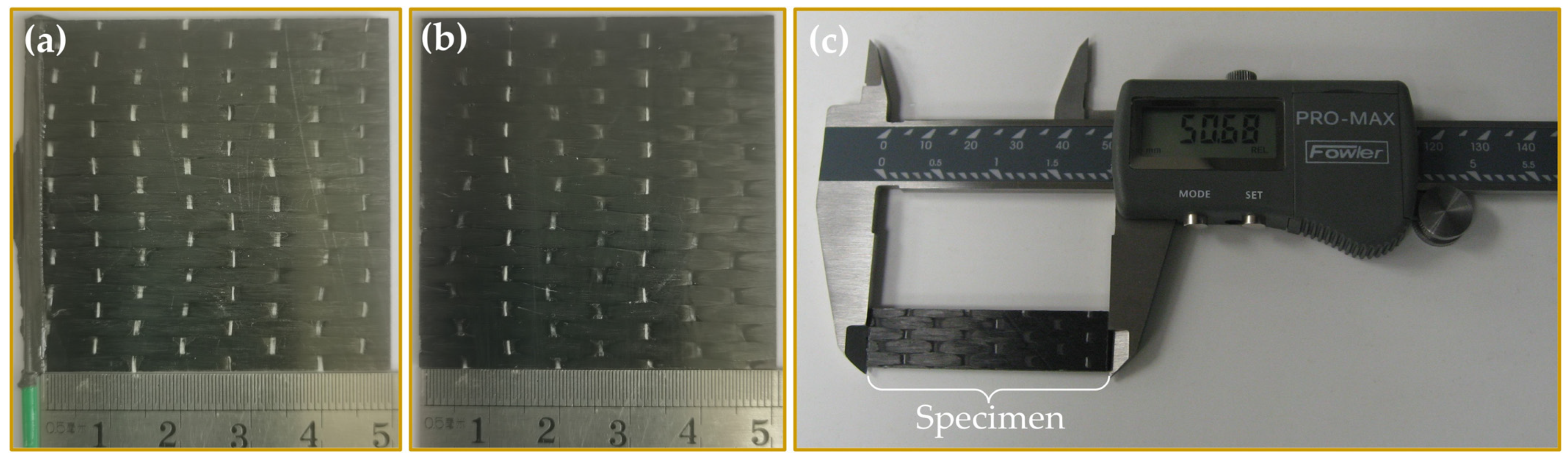

2.1. Materials and Preparation

2.2. Measurements

3. Results and Discussion

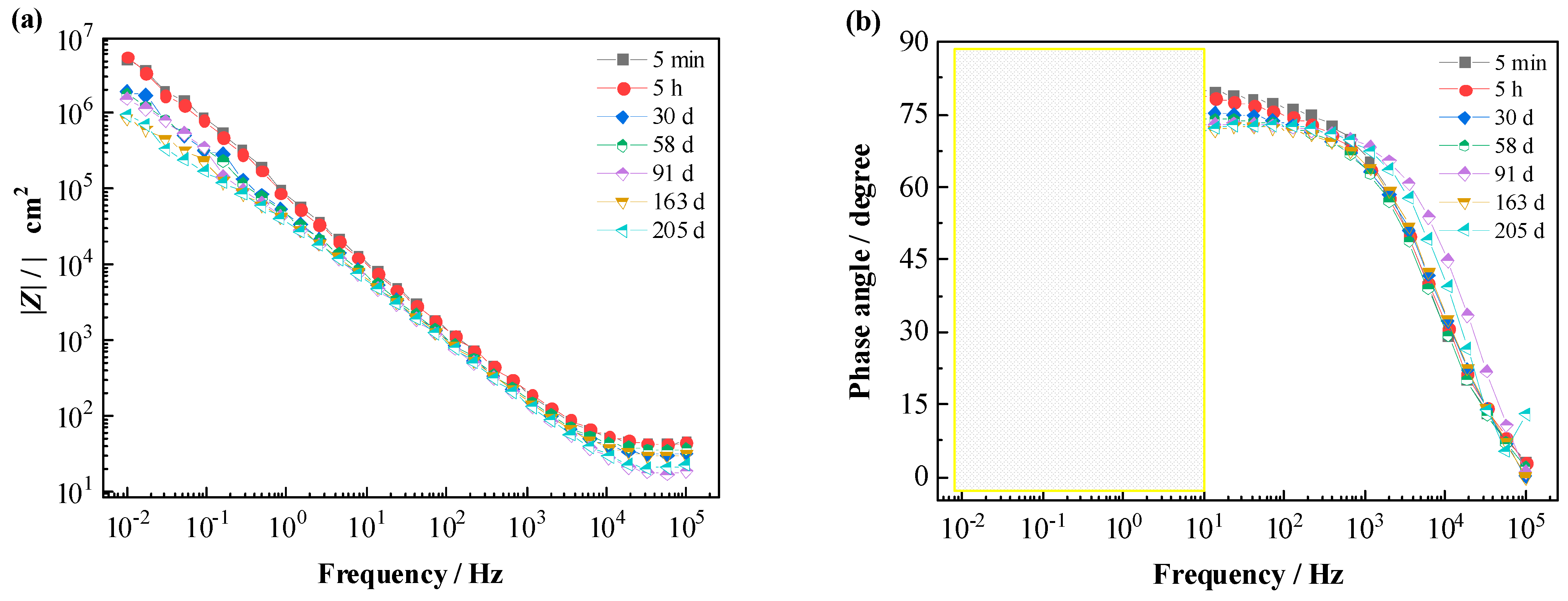

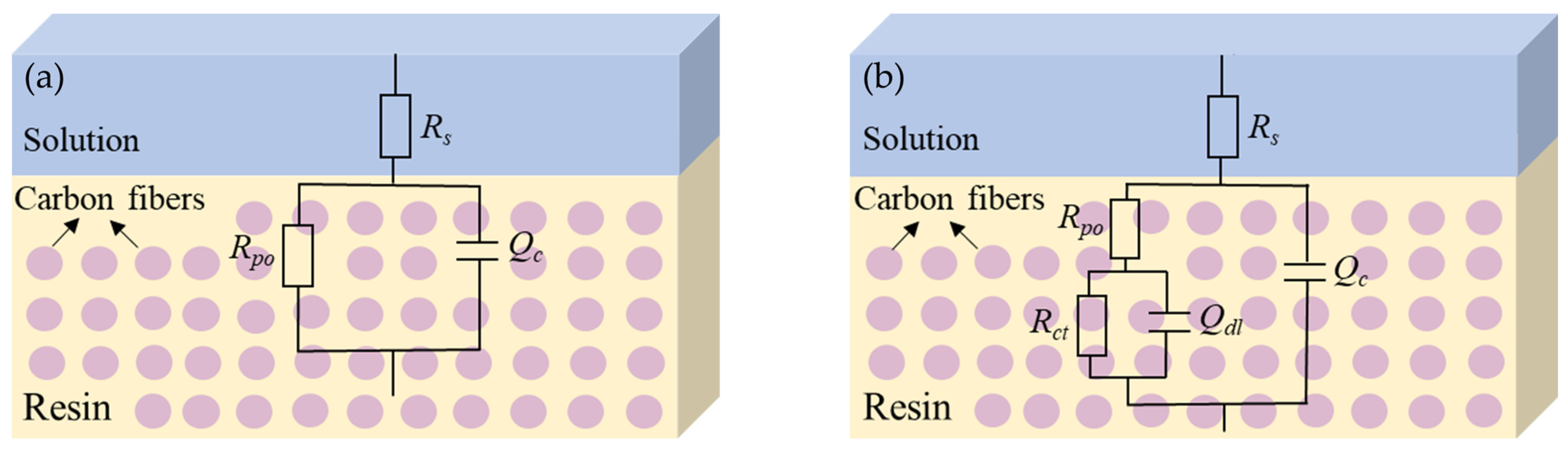

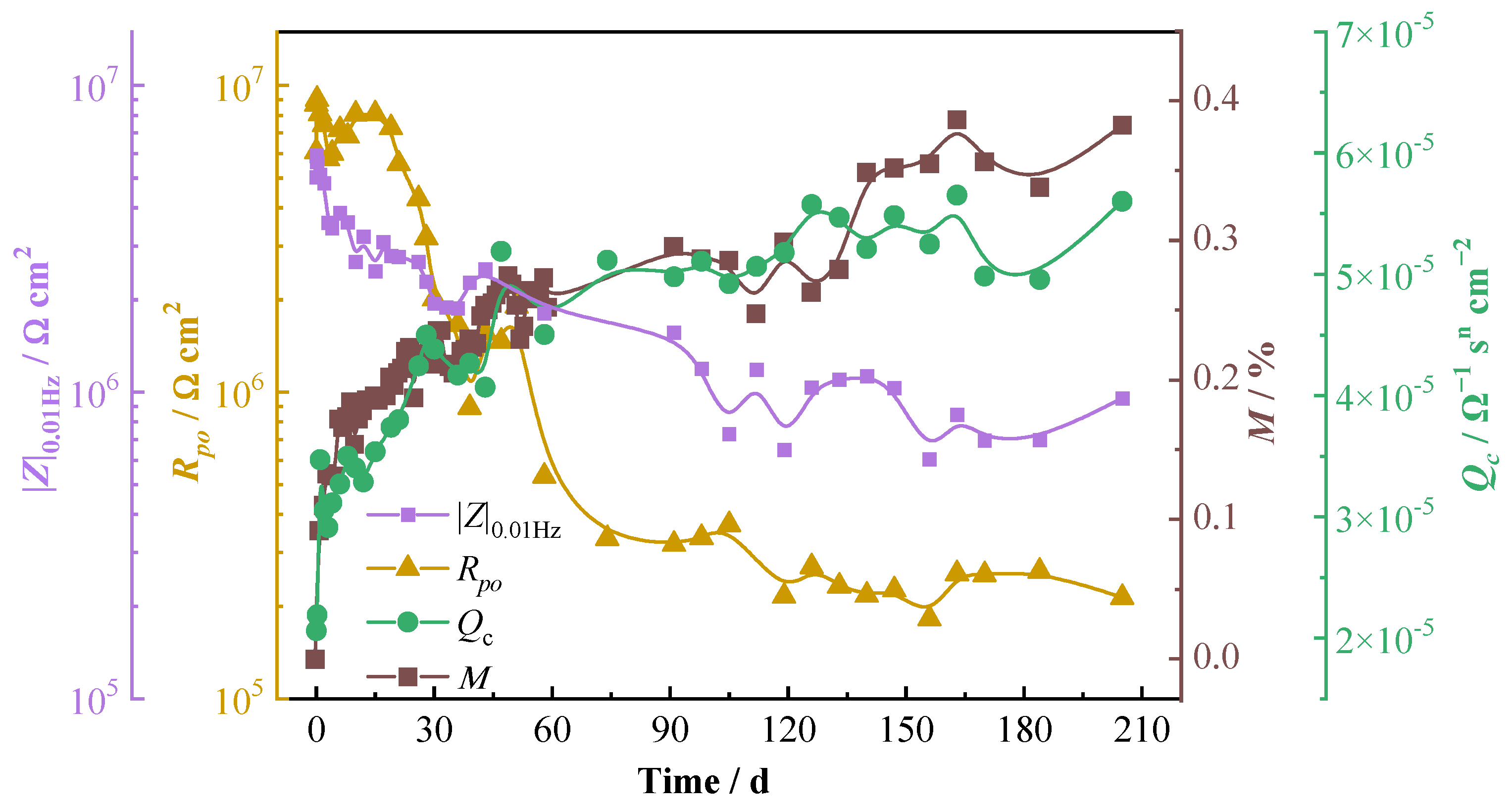

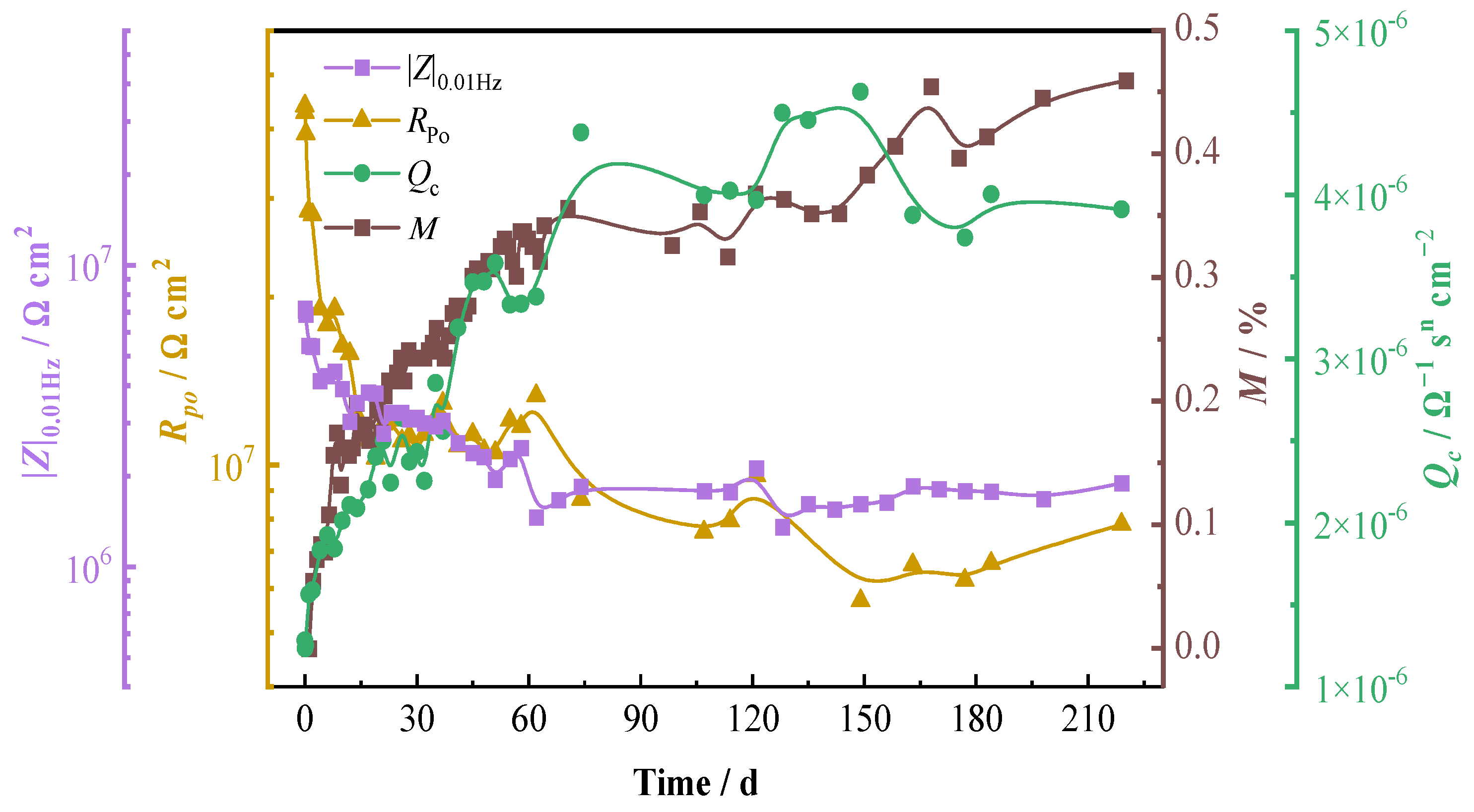

3.1. EIS Spectra of T700/VE Composite in 3.5% NaCl Solution

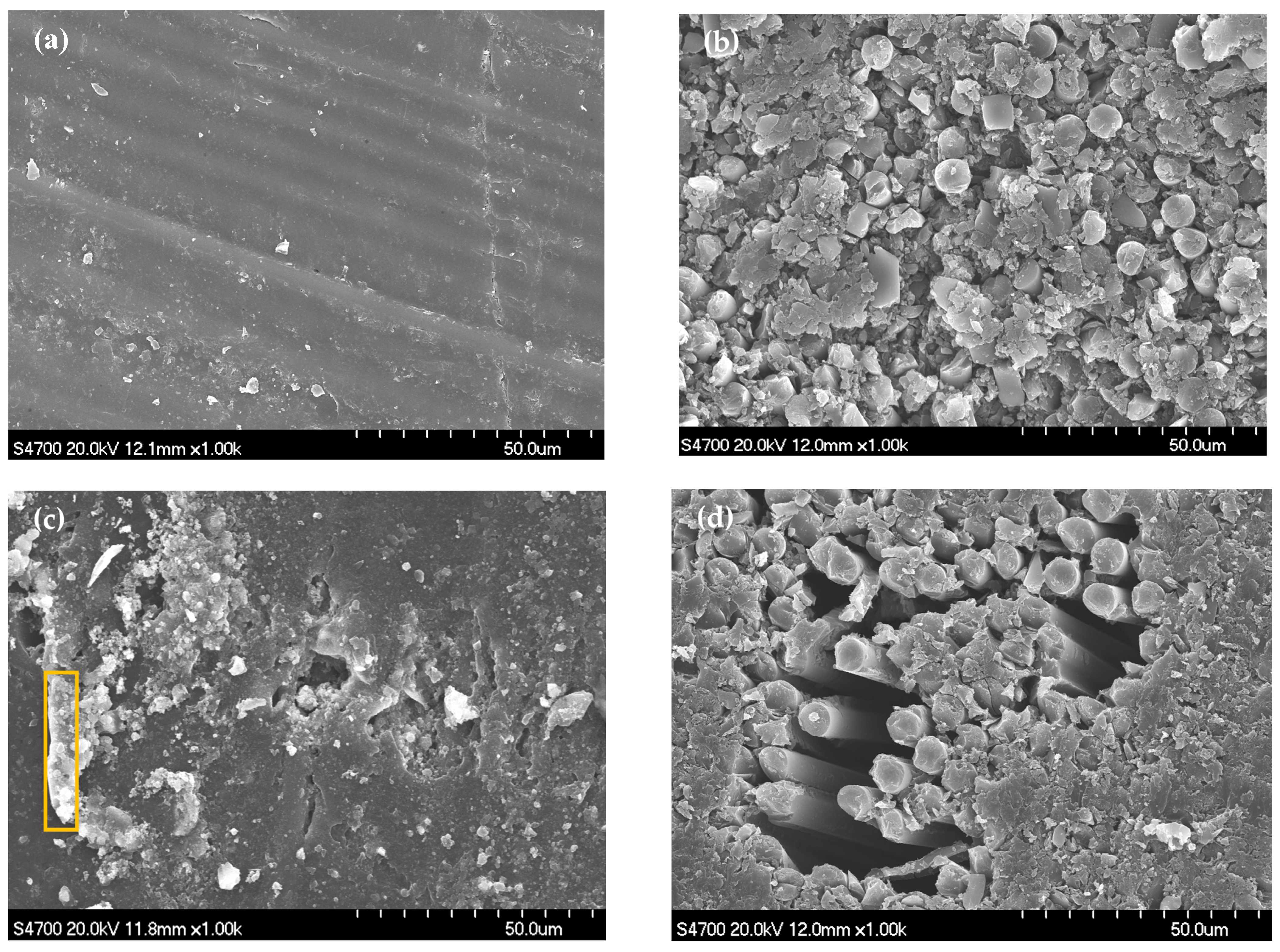

3.2. SEM-EDS and Bending Test Results of 700/VE Composite

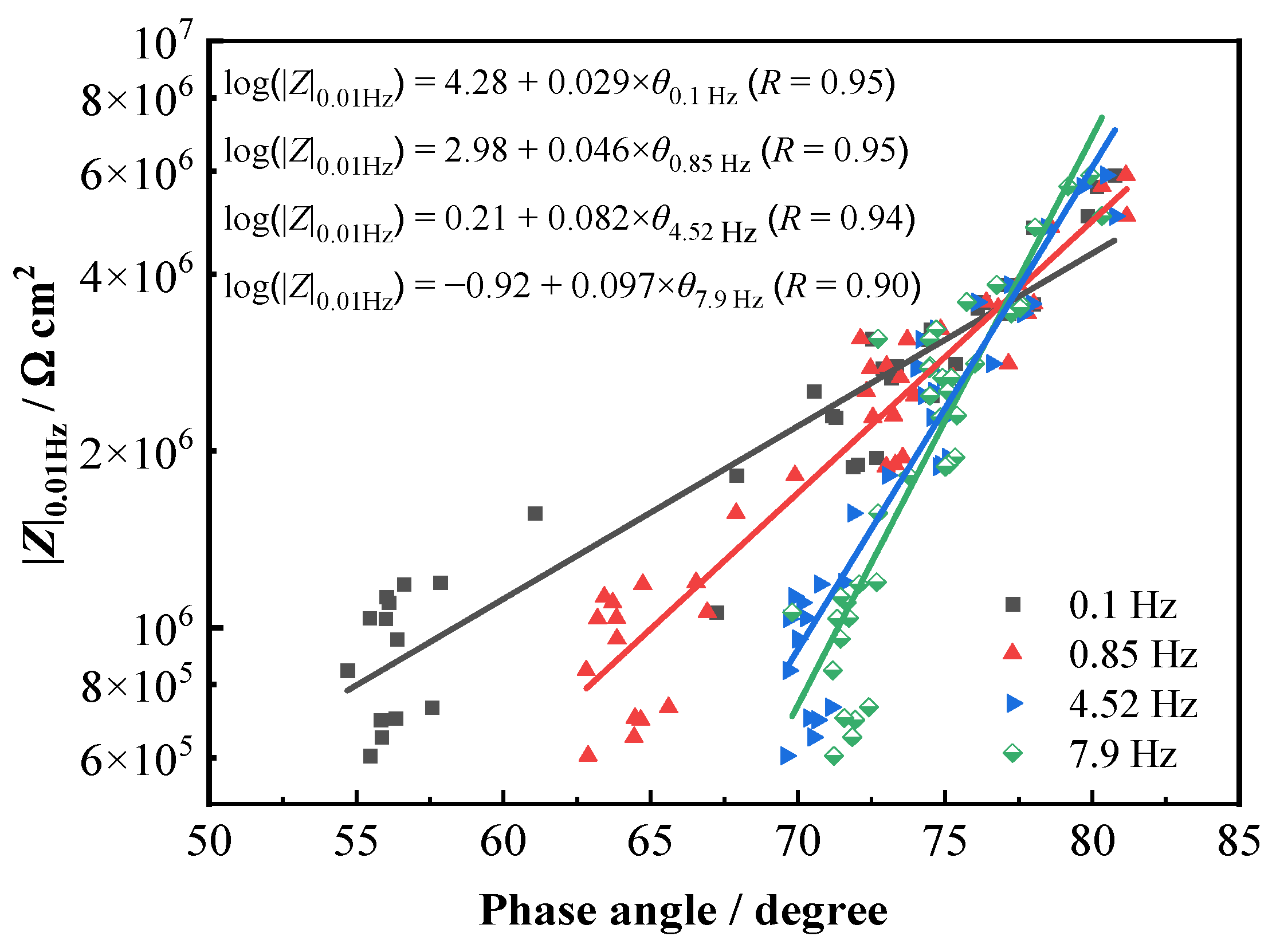

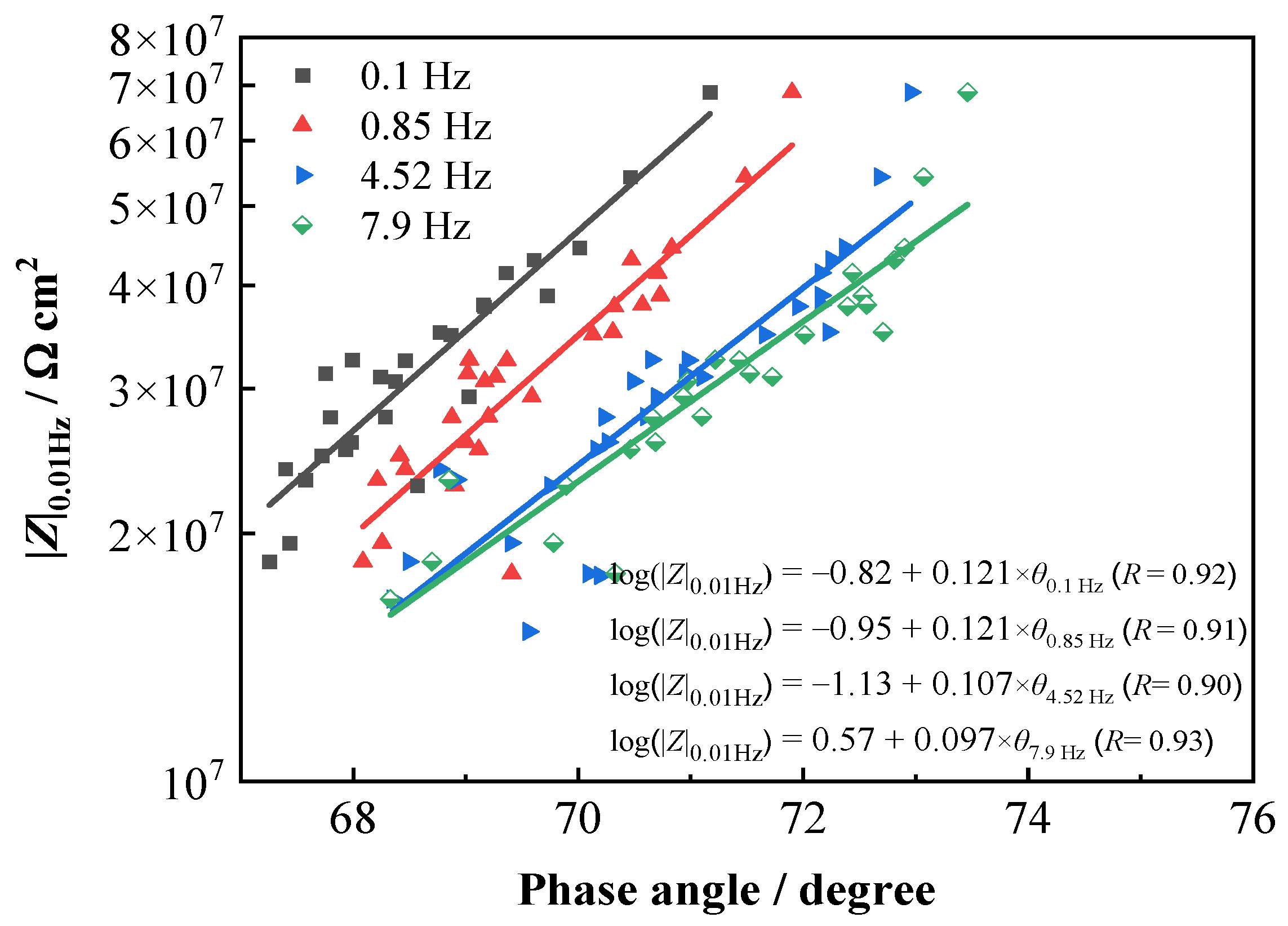

3.3. Evaluation of Degradation Performance of T700/VE Composites by Phase Angles in Middle Frequency

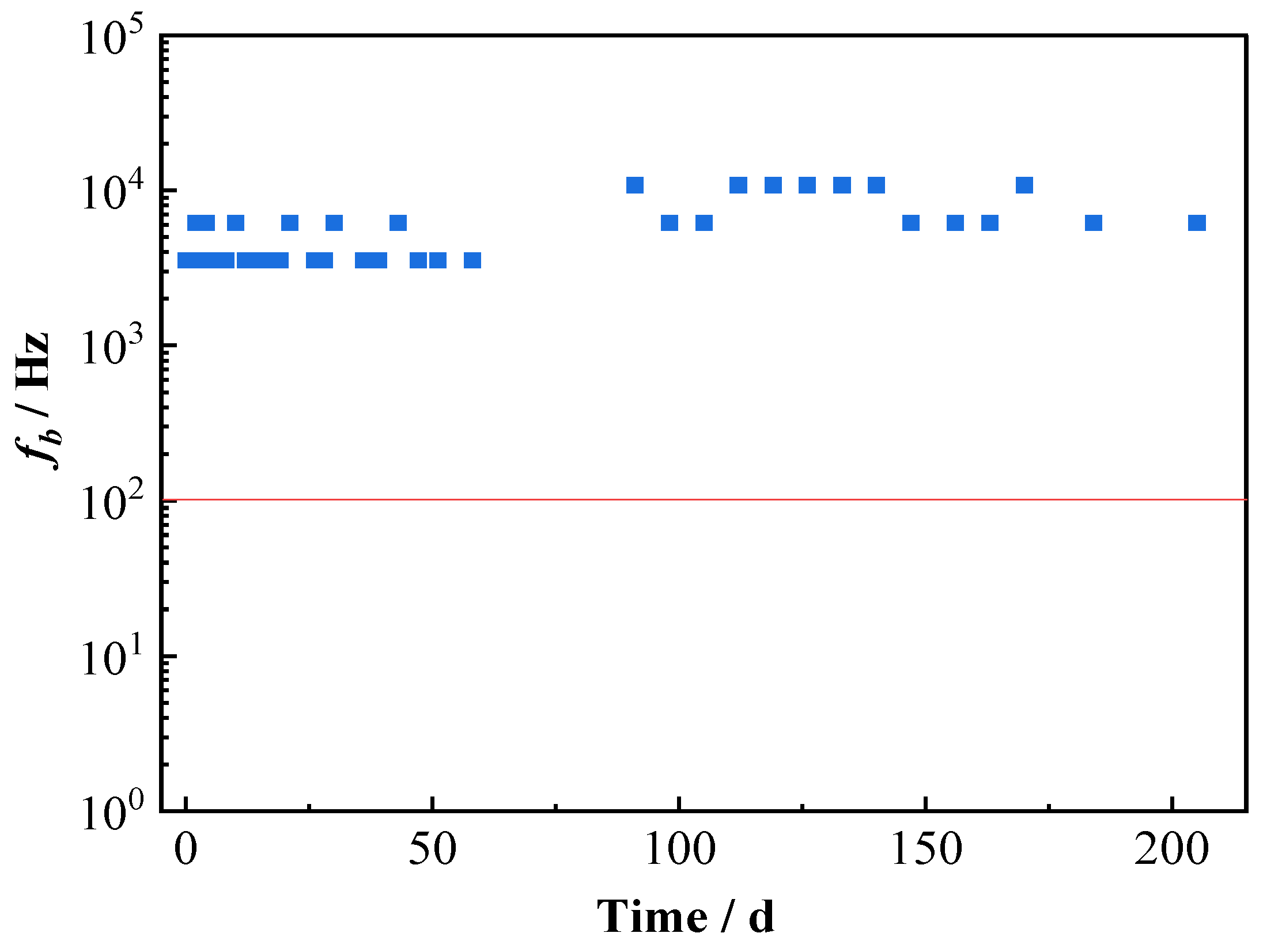

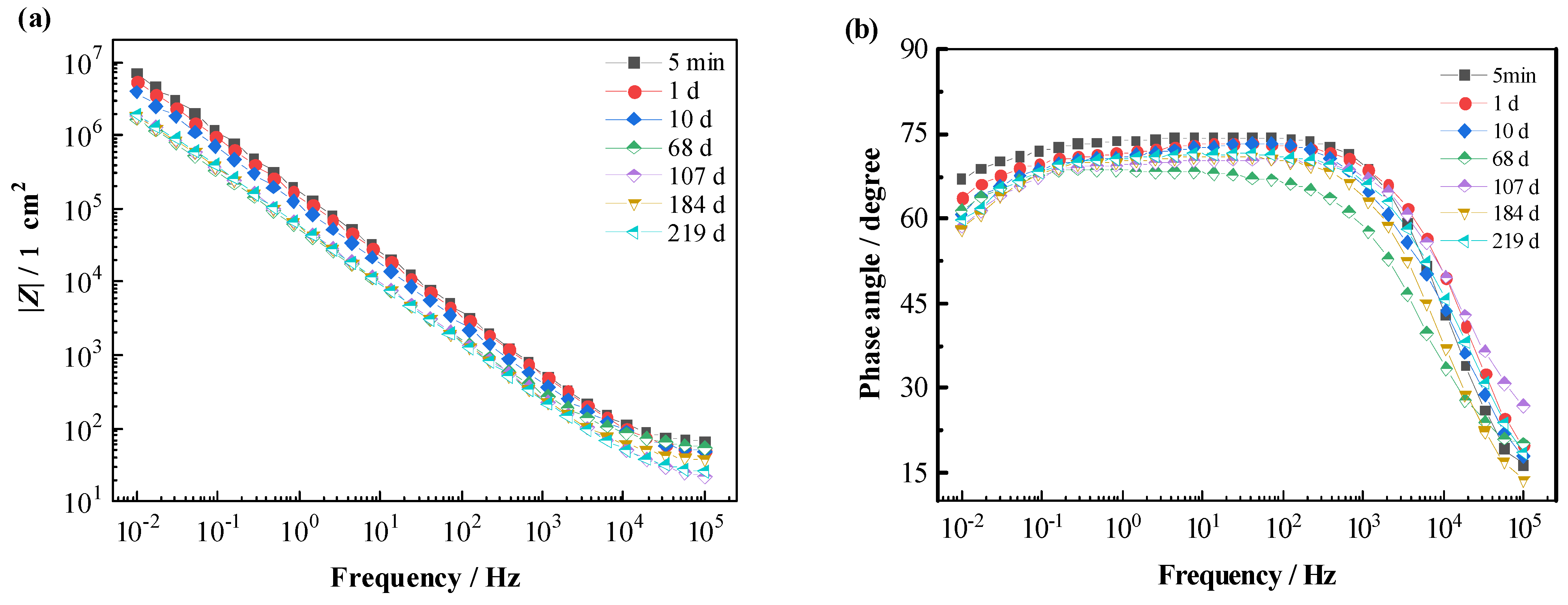

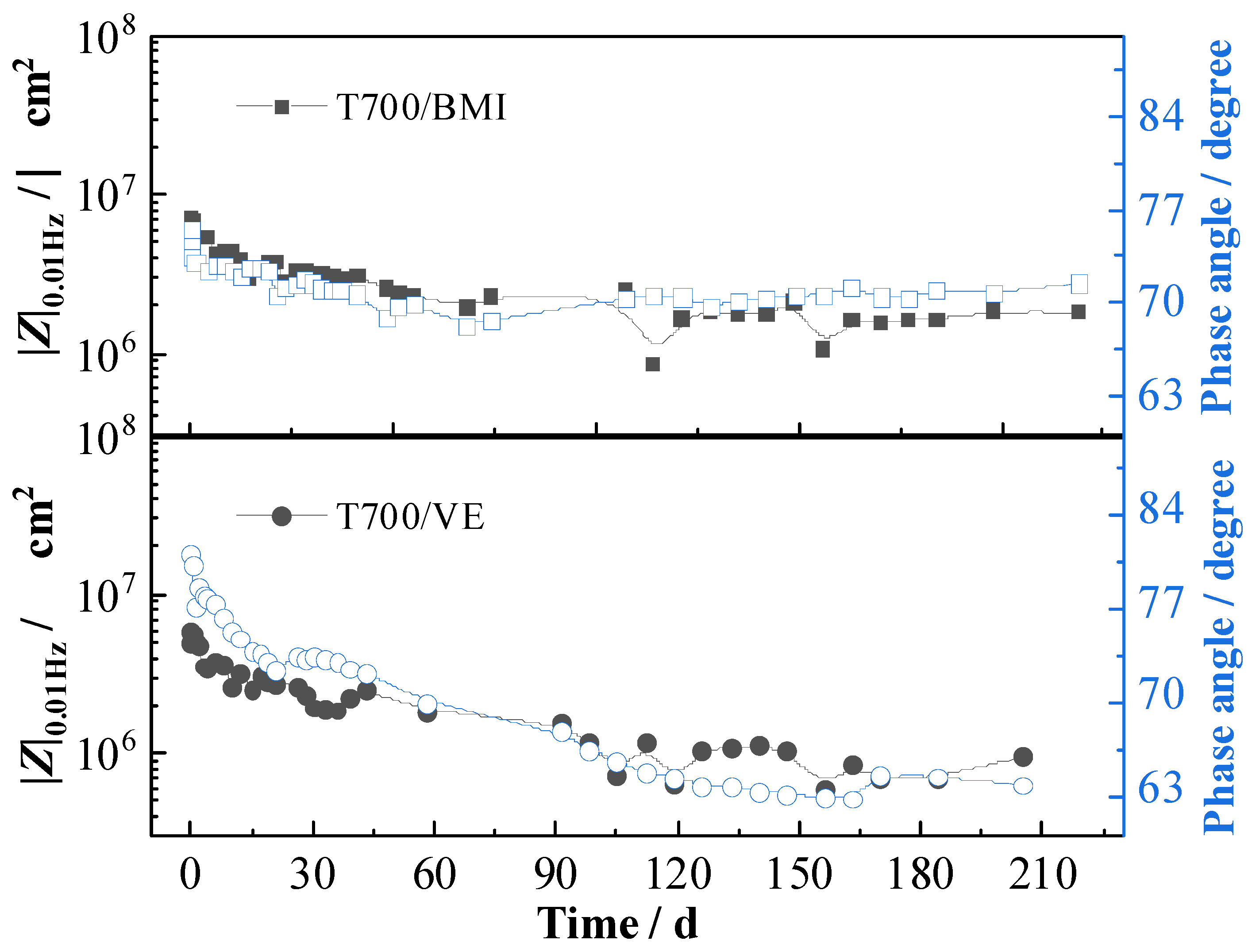

3.4. EIS spectra of T700/BMI Composite and Degradation Performance Evaluation by Phase Angles in Middle Frequency

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sloan, F.E.; Talbot, J.B. Corrosion of graphite-fiber-reinforced composites I—Galvanic coupling damage. Corrosion 1992, 48, 830–838. [Google Scholar] [CrossRef]

- Selzer, R.; Friedrich, K. Mechanical properties and failure behaviour of carbon fibre-reinforced polymer composites under the influence of moisture. Compos. Part A Appl. Sci. Manuf. 1997, 28, 595–604. [Google Scholar] [CrossRef]

- Antunes, R.A.; Lopes de Oliveira, M.C.; Ett, G. Investigation on the corrosion resistance of carbon black–graphite-poly(vinylidene fluoride) composite bipolar plates for polymer electrolyte membrane fuel cells. Int. J. Hydrogen Energy 2011, 36, 12474–12485. [Google Scholar] [CrossRef]

- Ofoegbu, S.U.; Ferreira, M.G.S.; Zheludkevich, M.L. Galvanically stimulated degradation of carbon-fiber reinforced polymer composites: A critical review. Materials 2019, 12, 651. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Wei, L.; Moahmoud, H.; Redaelli, E.; Xing, F.; Bertolini, L. Investigation on CFRP as dual-functional material in chloride-contaminated solutions. Constr. Build. Mater. 2017, 151, 127–137. [Google Scholar] [CrossRef]

- Marouani, S.; Curtil, L.; Hamelin, P. Ageing of carbon/epoxy and carbon/vinylester composites used in the reinforcement and/or the repair of civil engineering structures. Compos. Part B Eng. 2012, 43, 2020–2030. [Google Scholar] [CrossRef]

- Kootsookos, A.; Mouritz, A.P. Seawater durability of glass- and carbon-polymer composites. Compos. Sci. Technol. 2004, 64, 1503–1511. [Google Scholar] [CrossRef]

- Afshar, A.; Liao, H.T.; Chiang, F.; Korach, C.S. Time-dependent changes in mechanical properties of carbon fiber vinyl ester composites exposed to marine environments. Compos. Struct. 2016, 144, 80–85. [Google Scholar] [CrossRef]

- Alias, M.N.; Brown, R. Damage to composites from electrochemical processes. Corrosion 1992, 48, 373–378. [Google Scholar] [CrossRef]

- Liu, S.; Chen, Y.; Chen, P.; Xu, D.; Xiong, X.; Wang, J. Properties of novel bismaleimide resins and thermal ageing effects on the ILSS performance of their carbon fibre–bismaleimide composites. Polym. Compos. 2019, 40, E1283–E1293. [Google Scholar] [CrossRef]

- Akay, M.; Spratt, G.R.; Meenan, B. The effects of long-term exposure to high temperatures on the ILSS and impact performance of carbon fibre reinforced bismaleimide. Compos. Sci. Technol. 2003, 63, 1053–1059. [Google Scholar] [CrossRef]

- Bao, L.R.; Yee, A.F. Effect of temperature on moisture absorption in a bismaleimide resin and its carbon fiber composites. Polymer 2002, 43, 3987–3997. [Google Scholar] [CrossRef]

- Li, B.; Wen, Y.Y.; Wang, Q.Z.; Gu, Y.Z.; Li, M.; Zhang, Z.G. Hygrothermal mechanical properties of domestic carbon fiber/bismaleimide resin composites for aviation application. J. Aeronaut. Mater. 2020, 40, 80–87. [Google Scholar] [CrossRef]

- Pavlacky, D.A.; Gelling, V.J.; Ulven, C.A. The use of electrochemical impedance spectroscopy to monitor delaminations in polymer matrix composites: A review. Int. J. Mater. Sci. 2011, 1, 23–29. [Google Scholar]

- Alias, M.N.; Brown, R. Corrosion behavior of carbon fiber composites in the marine environment. Corros. Sci. 1993, 35, 395–402. [Google Scholar] [CrossRef]

- Kaushik, D.; Alias, M.N.; Brown, R. An Impedance study of a carbon fiber/vinyl ester composite. Corrosion 1991, 47, 859–867. [Google Scholar] [CrossRef]

- Taylor, S.R.; Wall, F.D.; Cahen, G.L. The detection and analysis of electrochemical damage in bismaleimide/graphite fiber composites. J. Electrochem. Soc. 1996, 143, 449. [Google Scholar] [CrossRef]

- Mueller, Y.; Tognini, R.; Mayer, J.; Virtanen, S. Anodized titanium and stainless steel in contact with CFRP: An electrochemical approach considering galvanic corrosion. J. Biomed. Mater. Res. Part A 2007, 82, 936–946. [Google Scholar] [CrossRef]

- Zhang, C.; Zheng, D.; Song, G.L.; Guo, Y.; Liu, M.; Kia, H. Effect of the microstructure of carbon fiber reinforced polymer on electrochemical behavior. J. Electrochem. Soc. 2018, 165, C647. [Google Scholar] [CrossRef]

- Zhang, C.; Zheng, D.; Song, G.L.; Guo, Y.; Liu, M.; Kia, H. Influence of microstructure of carbon fibre reinforced polymer on the metal in contact. J. Mater. Res. Technol. 2020, 9, 560–573. [Google Scholar] [CrossRef]

- McIntyre, J.M.; Pham, H.Q. Electrochemical impedance spectroscopy; a tool for organic coatings optimizations. Prog. Org. Coat. 1996, 27, 201–207. [Google Scholar] [CrossRef]

- Hirayama, R.; Haruyama, S. Electrochemical impedance for degraded coated steel having pores. Corrosion 1991, 47, 952–958. [Google Scholar] [CrossRef]

- Tsai, C.H.; Mansfeld, F. Determination of coating deterioration with EIS: Part II. Development of a method for field testing of protective coatings. Corrosion 1993, 49, 726–737. [Google Scholar] [CrossRef]

- Mahdavian, M.; Attar, M.M. Another approach in analysis of paint coatings with EIS measurement: Phase angle at high frequencies. Corros. Sci. 2006, 48, 4152–4157. [Google Scholar] [CrossRef]

- Feng, Z.; Frankel, G.S. Evaluation of Coated Al Alloy Using the Breakpoint Frequency Method. Electrochim. Acta 2016, 187, 605–615. [Google Scholar] [CrossRef]

- Zuo, Y.; Pang, R.; Li, W.; Xiong, J.P.; Tang, Y.M. The evaluation of coating performance by the variations of phase angles in middle and high frequency domains of EIS. Corros. Sci. 2008, 50, 3322–3328. [Google Scholar] [CrossRef]

- Fu, T.; Tang, X.; Cai, Z.; Zuo, Y.; Tang, Y.; Zhao, X. Correlation research of phase angle variation and coating performance by means of Pearson’s correlation coefficient. Prog. Org. Coat. 2020, 139, 105459. [Google Scholar] [CrossRef]

- Bing, L.; Xu, A.; Liang, Y.; Huang, Z.; Qiao, Z.; Xia, D.; Zhang, S.; Li, Z.; Zhang, F.; Chen, P. Evaluation on protective performance of organic coatings by analyzing the change rate of phase angle at high frequency. Int. J. Electrochem. Sci. 2012, 7, 8859–8868. [Google Scholar]

- Xia, D.; Song, S.; Wang, J.; Bi, H.; Han, Z. Fast evaluation of degradation degree of organic coatings by analyzing electrochemical impedance spectroscopy data. Trans. Tianjin Univ. 2012, 18, 15–20. [Google Scholar] [CrossRef]

- Nardeli, J.V.; Snihirova, D.V.; Fugivara, C.S.; Montemor, M.F.; Pinto, E.R.P.; Messaddecq, Y.; Benedetti, A.V. Localised corrosion assessement of crambe-oil-based polyurethane coatings applied on the ASTM 1200 aluminum alloy. Corros. Sci. 2016, 111, 422–435. [Google Scholar] [CrossRef]

- Chen, Z.; He, Z.; Yu, F.; Wang, Y. Study and application of electrochemical impedance spectroscopy for quickly evaluating the performance of coatings and predicting the failure time in the development of waterborne epoxy micaceous iron oxide coatings. Int. J. Electrochem. Sci. 2017, 12, 2798–2812. [Google Scholar] [CrossRef]

- Cai, G.; Wang, H.; Jiang, D.; Dong, Z. Impedance sensor for the early failure diagnosis of organic coatings. J. Coat. Technol. Res. 2018, 15, 1259–1272. [Google Scholar] [CrossRef]

- Fan, C.; Shi, J.; Dilger, K. Water uptake and interfacial delamination of an epoxy-coated galvanized steel: An electrochemical impedance spectroscopic study. Prog. Org. Coat. 2019, 137, 105333. [Google Scholar] [CrossRef]

- Tang, Y.; Hartt, W.; Granata, R.; Yu, H.; Farooq, M.U. Degradation of carbon/vinyl ester composites under cathodic polarization in seawater. J. Compos. Mater. 2012, 46, 3115–3120. [Google Scholar] [CrossRef]

- Mahfuz, H.; Powell, F.; Granata, R.; Hosur, M.; Khan, M. Coating of Carbon Fiber with Polyhedral Oligomeric Silsesquioxane (POSS) to Enhance Mechanical Properties and Durability of Carbon/Vinyl Ester Composites. Materials 2011, 4, 1619–1631. [Google Scholar] [CrossRef]

- Fazzino, P.D.; Reifsnider, K.L.; Majumdar, P. Impedance spectroscopy for progressive damage analysis in woven composites. Compos. Sci. Technol. 2009, 69, 2008–2014. [Google Scholar] [CrossRef]

- Montazeri, S.; Ranjbar, Z.; Rastegar, S.; Deflorian, F. A new approach to estimates the adhesion durability of an epoxy coating through wet and dry cycles using creep-recovery modeling. Prog. Org. Coat. 2021, 159, 106442. [Google Scholar] [CrossRef]

- Choi, S.; Choi, J.; Park, C. Multivariate analysis-based laser-induced breakdown spectroscopy for monitoring of laser paint cleaning. Appl. Phys. B 2023, 129, 8. [Google Scholar] [CrossRef]

| Sample | Matrix | Reinforcement and Volume Fraction |

|---|---|---|

| CF/VE | Vinyl ester resin | T700 carbon fiber (60%) |

| CF/BMI | 5428 Bismaleimide resin | T700 carbon fiber (55%) |

| Time | Rs (Ω cm2) | Rpo (Ω cm2) | Qc (Ω−1 sn cm−2) | nQc | Rct (Ω cm2) | Qdl (Ω−1 sn cm−2) | nQdl |

|---|---|---|---|---|---|---|---|

| 5 min | 4.177 | 6.09 × 106 | 2.06 × 10−5 | 0.8990 | |||

| 5 h | 4.209 | 1.30 × 107 | 2.24 × 10−5 | 0.8889 | |||

| 10 d | 3.128 | 8.09 × 106 | 3.43 × 10−5 | 0.8444 | |||

| 30 d | 2.886 | 2.01 × 106 | 4.38 × 10−5 | 0.8375 | |||

| 43 d | 2.267 | 1.56 × 106 | 4.05 × 10−5 | 0.8457 | 9.19 × 106 | 6.87 × 10−6 | 0.4170 |

| 58 d | 3.277 | 3.41 × 105 | 4.57 × 10−5 | 0.8292 | 1.99 × 106 | 7.61 × 10−6 | 0.8504 |

| 91 d | 1.593 | 2.87 × 105 | 5.08 × 10−5 | 0.8337 | 2.48 × 105 | 4.44 × 10−5 | 0.8543 |

| 133 d | 1.655 | 1.07 × 105 | 6.09 × 10−5 | 0.8113 | 2.05 × 105 | 8.93 × 10−5 | 0.8999 |

| 163 d | 2.586 | 1.20 × 105 | 6.38 × 10−5 | 0.7900 | 2.22 × 105 | 3.56 × 10−5 | 0.8129 |

| 205 d | 1.962 | 1.30 × 105 | 4.61 × 10−5 | 0.8437 | 5.37 × 105 | 4.04 × 10−5 | 0.6064 |

| Before Immersion | 30 d | 60 d | 130 d | 205 d | |

|---|---|---|---|---|---|

| Ef/GPa | 740 | 764 | 754 | 129 | 123 |

| Reduction of Ef | −3.3% | −1.9% | 82.5% | 83.4% | |

| |Z|0.01Hz/Ω cm2 | 5.7 × 106 | 1.9 × 106 | 1.8 × 106 | 1.1 × 106 | 9.6 × 105 |

| Reduction of |Z|0.01Hz | 66.7% | 68.4% | 80.7% | 83.2% |

| Frequency/Hz | 0.01 | 0.1 | 0.85 | 4.52 | 7.9 | 13.7 | 23.9 | 127 | 1172 | 10,826 |

| r | 0.88 | 0.95 | 0.95 | 0.94 | 0.90 | 0.86 | 0.75 | 0.10 | −0.31 | −0.6 |

| Time | Rs (Ω cm2) | Rpo (Ω cm2) | Qc (Ω−1 sn cm−2) | nQc | Rct (Ω cm2) | Qdl (Ω−1 sn cm−2) | nQdl |

|---|---|---|---|---|---|---|---|

| 5 min | 59.52 | 4.40 × 107 | 1.28 × 10−6 | 0.8259 | |||

| 1 d | 41.51 | 2.85 × 107 | 1.56 × 10−6 | 0.8074 | |||

| 10 d | 44.17 | 1.63 × 107 | 2.11 × 10−6 | 0.8014 | |||

| 30 d | 87.7 | 1.06 × 107 | 2.43 × 10−6 | 0.7924 | |||

| 37 d | 66.22 | 1.19 × 107 | 2.56 × 10−6 | 0.7983 | 4.05 × 107 | 2.61 × 10−7 | 0.8309 |

| 68 d | 52.07 | 1.50 × 107 | 4.57 × 10−6 | 0.7574 | 8.26 × 106 | 4.10 × 10−6 | 0.7612 |

| 107 d | 17.84 | 6.90 × 106 | 4.00 × 10−6 | 0.7825 | 4.77 × 106 | 5.93 × 10−6 | 0.8090 |

| 149 d | 24.42 | 5.71 × 106 | 4.63 × 10−6 | 0.7718 | 1.17 × 106 | 4.55 × 10−6 | 0.7969 |

| 184 d | 35.08 | 5.74 × 106 | 4.00 × 10−6 | 0.7911 | 1.16 × 106 | 6.68 × 10−6 | 0.9584 |

| 219 d | 22.76 | 7.04 × 106 | 3.91 × 10−6 | 0.7940 | 1.65 × 106 | 6.76 × 10−6 | 0.8740 |

| Frequency/Hz | 0.01 | 0.1 | 0.85 | 4.52 | 7.9 | 13.7 | 23.9 | 127 | 1172 | 10,826 |

| r | 0.92 | 0.89 | 0.95 | 0.94 | 0.91 | 0.86 | 0.78 | 0.40 | 0.08 | −0.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Kong, F.; Dun, Y.; Chen, X.; Chen, Q.; Zhao, X.; Tang, Y.; Zuo, Y. Degradation of Carbon Fiber-Reinforced Polymer Composites in Salt Water and Rapid Evaluation by Electrochemical Impedance Spectroscopy. Materials 2023, 16, 1676. https://doi.org/10.3390/ma16041676

Zhang H, Kong F, Dun Y, Chen X, Chen Q, Zhao X, Tang Y, Zuo Y. Degradation of Carbon Fiber-Reinforced Polymer Composites in Salt Water and Rapid Evaluation by Electrochemical Impedance Spectroscopy. Materials. 2023; 16(4):1676. https://doi.org/10.3390/ma16041676

Chicago/Turabian StyleZhang, Hanlu, Fabao Kong, Yuchao Dun, Xueping Chen, Quankai Chen, Xuhui Zhao, Yuming Tang, and Yu Zuo. 2023. "Degradation of Carbon Fiber-Reinforced Polymer Composites in Salt Water and Rapid Evaluation by Electrochemical Impedance Spectroscopy" Materials 16, no. 4: 1676. https://doi.org/10.3390/ma16041676

APA StyleZhang, H., Kong, F., Dun, Y., Chen, X., Chen, Q., Zhao, X., Tang, Y., & Zuo, Y. (2023). Degradation of Carbon Fiber-Reinforced Polymer Composites in Salt Water and Rapid Evaluation by Electrochemical Impedance Spectroscopy. Materials, 16(4), 1676. https://doi.org/10.3390/ma16041676