Wooden Solar Evaporator Design Based on the Water Transpiration Principle of Trees

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Photothermal Evaporation Test

2.2.2. Microstructural Characterization Test

2.2.3. Fourier Transform Infrared Spectroscopy

2.2.4. X-ray Profile Density Test

3. Results

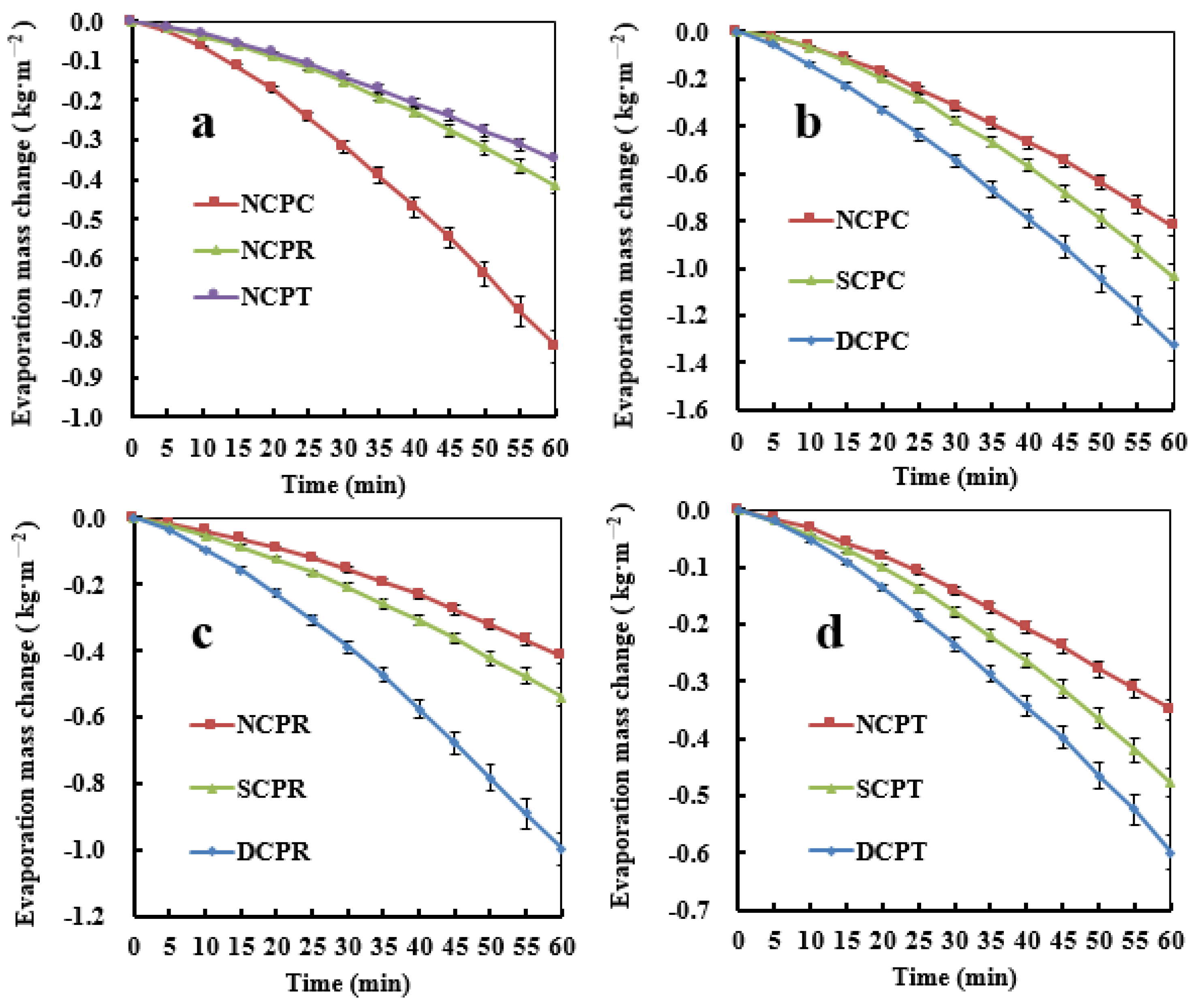

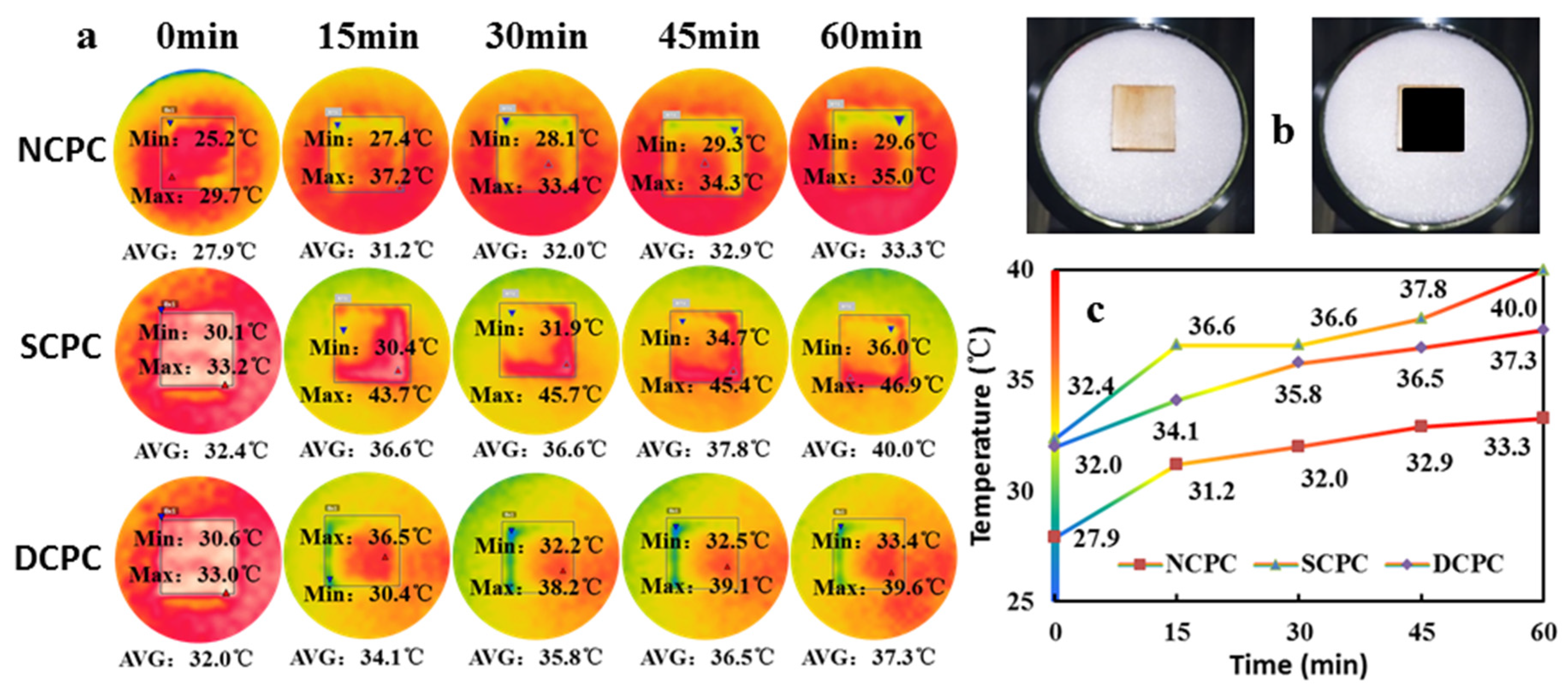

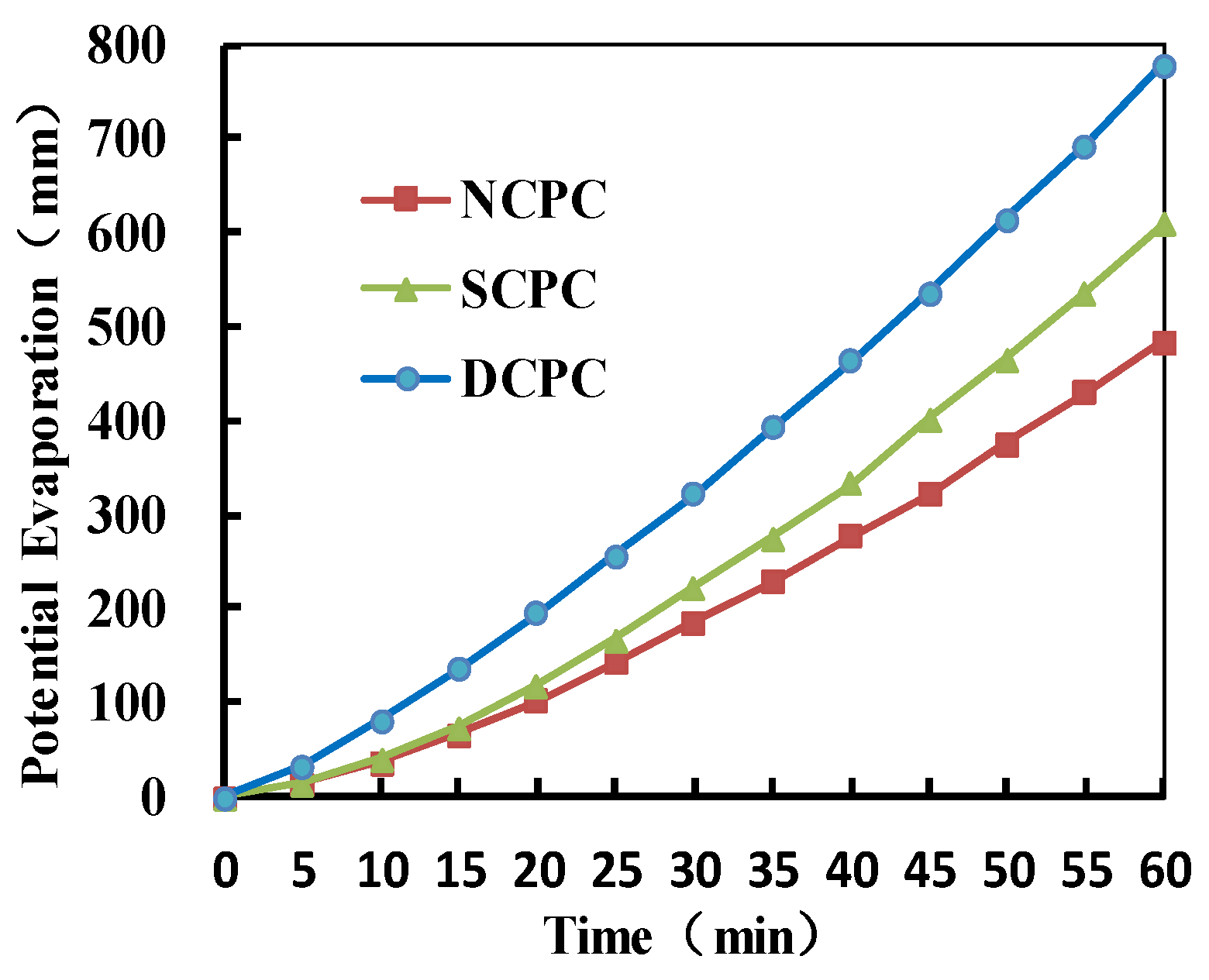

3.1. Estimation of Water Quality Change and Evaporation Force in Photothermal Evaporation

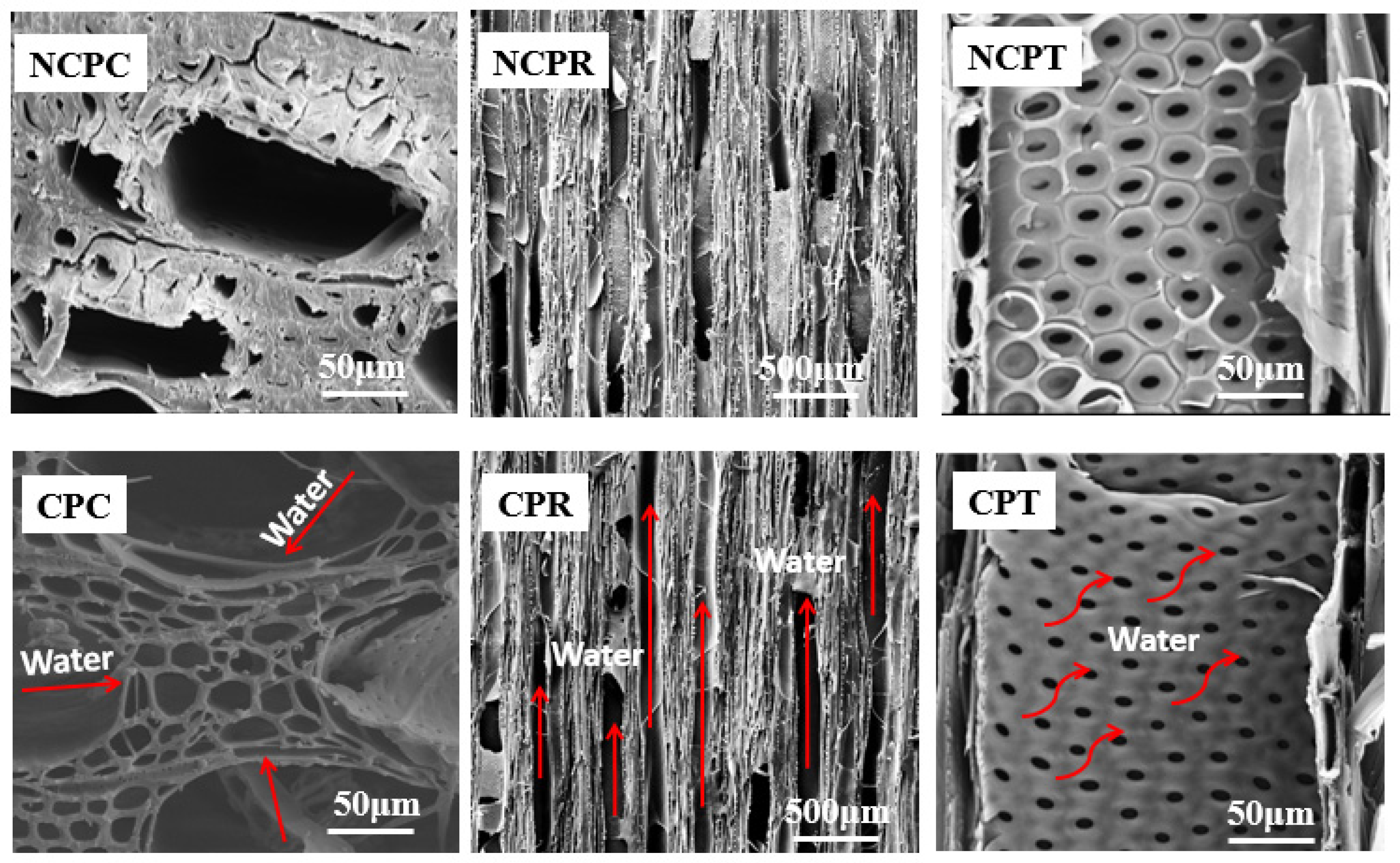

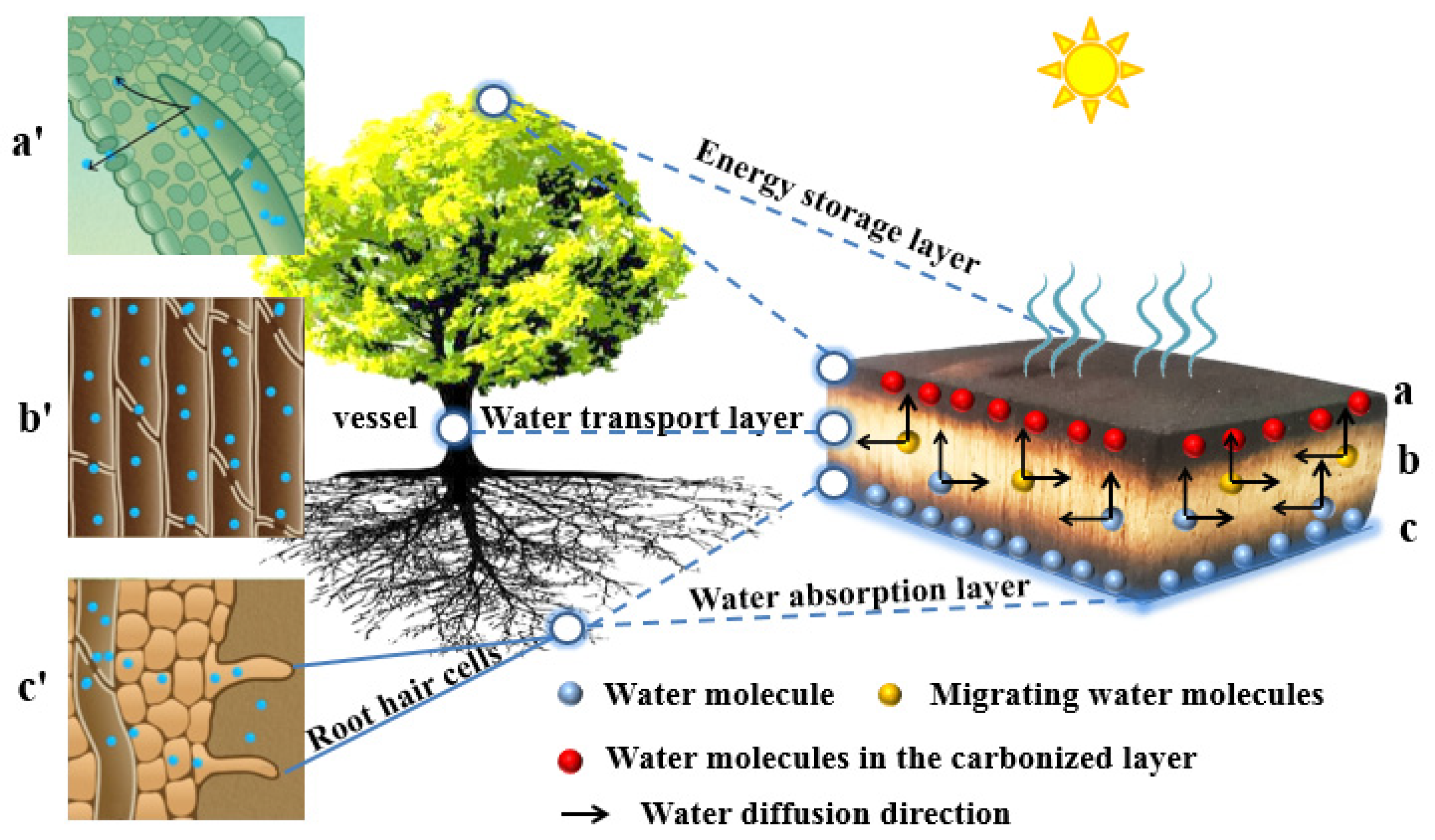

3.2. Moisture Migration Microstructure Characterization Analysis

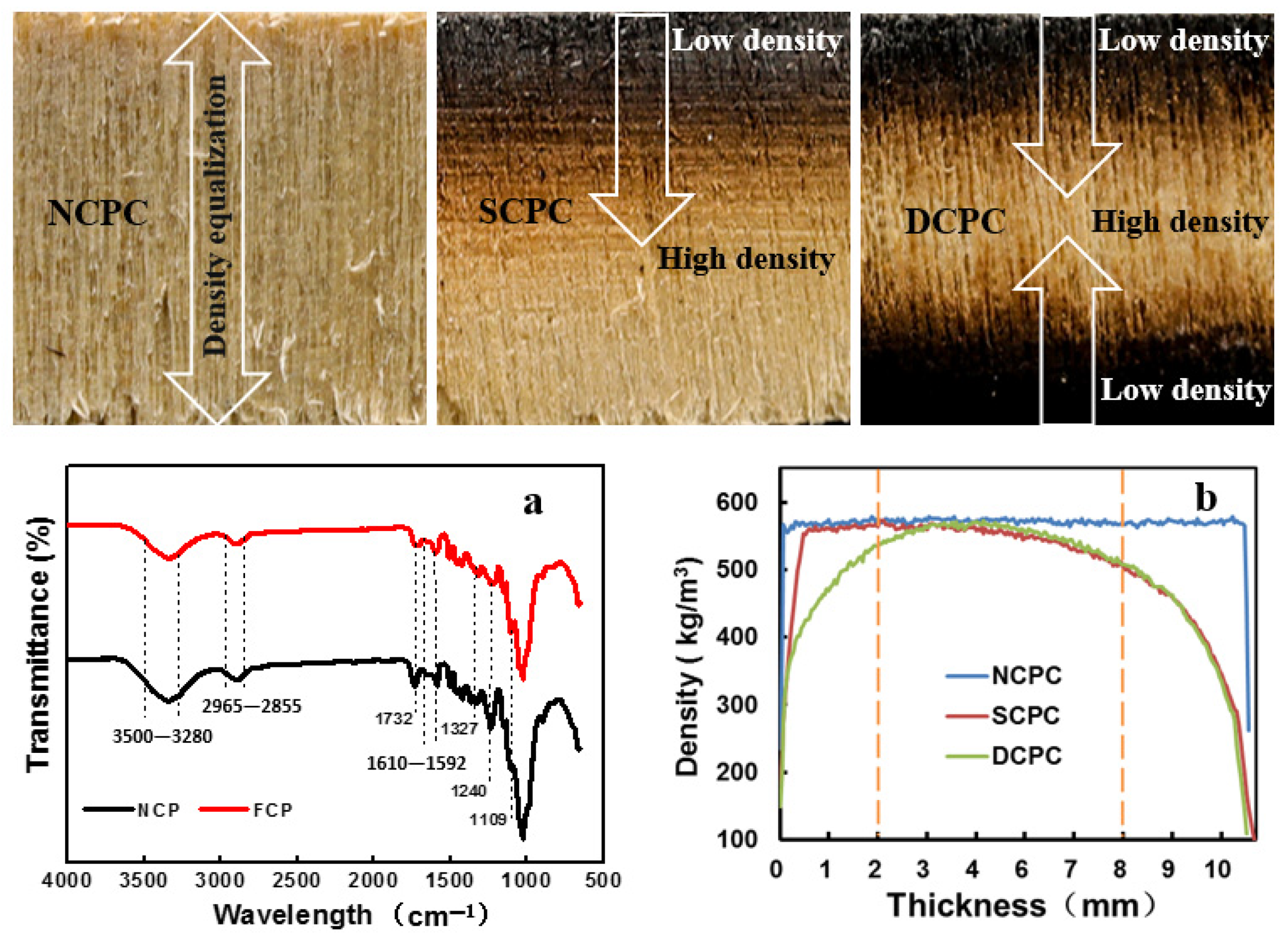

3.3. Profile Density and Composition Analysis

4. Conclusions

- The three-layer structure of double-sided carbonized poplar can better simulate the water transpiration mechanism of the roots, trunks, and leaves of trees. Driven by solar energy, the use of double-sided carbonized poplar significantly improved the water transpiration quality, and the water evaporation followed the trend of DCPC > SCPC > NCPC. Of these samples, NCPC had a photothermal evaporation capacity of 1.32 kg·m−2·h−1, which was 21.97% higher than SCPC and 37.88% higher than NCPC.

- Carbonized poplar had many micropores and transition pores on its surface, forming a high specific surface area. The tar material in the pores exhibited a good adsorption performance after exclusion. In addition, the longitudinal pipes were unobstructed; the pit tissue in the chord direction was affected by the high temperature, and the pit membrane was damaged, which made it easier for water to transmit laterally. Structural changes were carried out by wood physical treatment, but according to the existing literature, the transformation of the internal structure of the wood is an effective way to further improve the photothermal evaporation capacity.

- The evaporation force of the test piece was estimated by the experimental measurement of photothermal evaporation. This provides a certain reference value for estimating the water migration of xylem surfaces under photothermal conditions. In the future, the theory of molecular dynamics will be incorporated into the simulation analysis of the migration of water molecules in wood, which will have significance both on a microcosmic scale and in providing continuous guidance.

- As an absorber material, the mass of photothermal evaporation is also related to the tree species. In the photothermal evaporation test of a double-sided carbonized three-layer structure of spruce recently completed by the author, the maximum water evaporation was 0.94 kg·m−2·h−1, which was lower than the DCPC water evaporation of poplar (1.32 kg·m−2·h−1). This was due to the difference in the transporting molecules (tracheids and vessels) of the two kinds of wood. In the future, the selection of various kinds of wood for water purification is also a research direction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

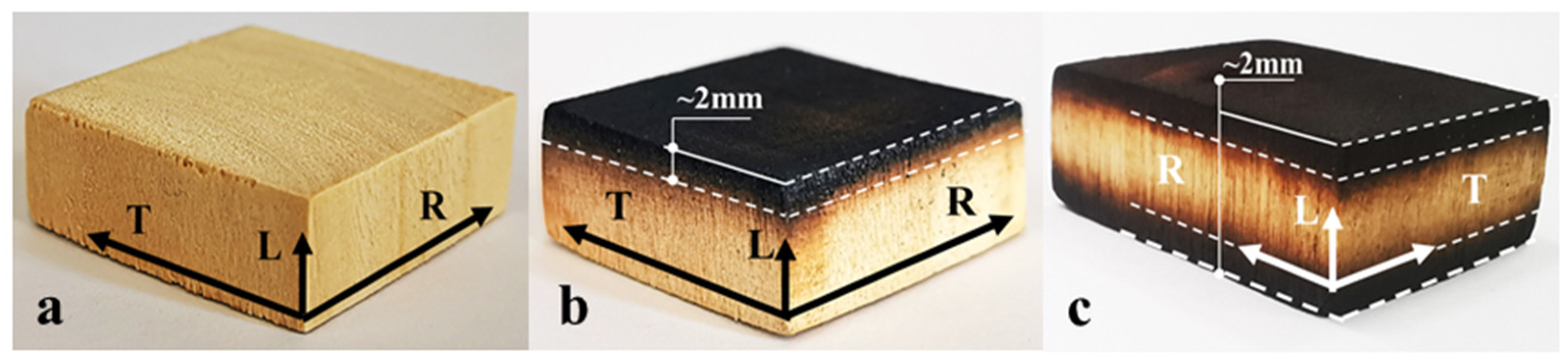

| L/C/R/T | Longitudinal, Cross-Section, Radial Section, and Tangential Section of Wood. |

| NCP/SCP/DCP/FCP | The uncarbonized poplar is expressed as NCP, single-sided carbonized poplar as SCP, double-sided carbonized poplar as DCP, and fully carbonized poplar as FCP. |

| NCPC/NCPR/NCPT | Cross-section, Radial section, and Tangential section of the uncarbonized poplar, Where N means uncarbonized. |

References

- Wei, T.; Li, X.; Li, J.; Zhou, L.; Zhu, S.; Zhu, J. Interfacial solar vapor generation. Chin. Sci. Bull. 2018, 63, 1404–1416. [Google Scholar] [CrossRef]

- Zhou, L.; Li, X.; Ni, G.W.; Zhu, S.; Zhu, J. The revival of thermal utilization from the Sun: Interfacial solar vapor generation. Natl. Sci. Rev. 2019, 6, 562–578. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Guo, Y.; Zhou, X.; Shi, W.; Yu, G. Materials for solar-powered water evaporation. Nat. Rev. Mater. 2020, 5, 388–401. [Google Scholar] [CrossRef]

- Gao, M.; Zhu, L.; Peh, C.K.; Ho, G.W. Solar absorber material and system designs for photothermal water vaporization towards clean water and energy production. Energy Environ. Sci. 2019, 12, 841–864. [Google Scholar] [CrossRef]

- Li, Z.; Xu, X.; Sheng, X.; Lin, P.; Tang, J.; Pan, L.; Kaneti, Y.V.; Yang, T.; Yamauchi, Y. Solar-Powered Sustainable Water Production: State-of-the-Art Technologies for Sunlight-Energy-Water Nexus. ACS Nano 2021, 15, 12535–12566. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Gao, T.; Lu, Y.; Yang, X.; Chen, G.Y.; Owens, G.; Xu, H. Same materials, bigger output: A reversibly transformable 2D–3D photothermal evaporator for highly efficient solar steam generation. Nano Energy 2021, 79, 105477. [Google Scholar] [CrossRef]

- Wang, F.; Xu, N.; Zhao, W.; Zhou, L.; Zhu, P.; Wang, X.; Zhu, B.; Zhu, J. A high-performing single-stage invert-structured solar water purifier through enhanced absorption and condensation. Joule 2021, 5, 1602–1612. [Google Scholar] [CrossRef]

- Lu, Y.; Fan, D.; Wang, Y.; Xu, H.; Lu, C.; Yang, X. Surface Patterning of Two-Dimensional Nanostructure-Embedded Photothermal Hydrogels for High-Yield Solar Steam Generation. ACS Nano 2021, 15, 10366–10376. [Google Scholar] [CrossRef]

- Brongersma, M.L.; Halas, N.J.; Nordlander, P. Plasmon-induced hot carrier science and technology. Nat. Nanotechnol. 2015, 10, 25–34. [Google Scholar] [CrossRef]

- Han, P.; Jiang, C.; Zhang, X. Research progress of functional materials with photothermal conversion ability. Petrochem. Technol. 2019, 48, 522–528. [Google Scholar]

- Fang, J.; Liu, Q.; Zhang, W.; Gu, J.; Su, Y.; Su, H.; Guo, C.; Zhang, D. Ag/diatomite for highly efficient solar vapor generation under one-sun irradiation. J. Mater. Chem. A 2017, 5, 17817–17821. [Google Scholar] [CrossRef]

- Guler, U.; Shalaev, V.M.; Boltasseva, A. Nanoparticle plasmonics: Going practical with transition metal nitrides. Mater. Today 2015, 18, 227–237. [Google Scholar] [CrossRef]

- Ishii, S.; Sugavaneshwar, R.P.; Nagao, T. Titanium Nitride Nanoparticles as Plasmonic Solar Heat Transducers. J. Phys. Chem. C 2016, 120, 2343–2348. [Google Scholar] [CrossRef]

- Li, X.; Tong, Q.; Wang, N. Study on Preparation of CuS /rGO/PVA porous hydrogel with photothermal conversion performance. Shandong Chem. Ind. 2021, 50, 29–32. [Google Scholar]

- Fan, D.; Min, H.; Zhang, H.; Tang, Y.; Yang, X.; Lu, Y. Architecting a bifunctional solar evaporator of perovskite La0.5Sr0.5CoO3 for solar evaporation and degradation. J. Mater. Sci. 2021, 56, 18625–18635. [Google Scholar] [CrossRef]

- Hou, B.; Cui, Z.; Zhu, X.; Liu, X.; Wang, G.; Wang, J.; Mei, T.; Li, J.; Wang, X. Functionalized carbon materials for efficient solar steam and electricity generation. Mater. Chem. Phys. 2019, 222, 159–164. [Google Scholar] [CrossRef]

- Ren, P.; Li, J.; Zhang, X.; Yang, X. Highly efficient solar water evaporation of TiO2@TiN hyperbranched nanowires-carbonized wood hierarchical photothermal conversion material. Mater. Today Energy 2020, 18, 100546. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, L.; Dang, B.; Tao, J.; Li, S.; Zhao, S.; Li, W.; Li, J.; Chen, Z.; Liu, S. Nature-inspired design: P-toluenesulfonic acid-assisted hydrothermally engineered wood for solar steam generation. Nano Energy 2020, 78, 105322. [Google Scholar] [CrossRef]

- Zhu, M.; Li, Y.; Chen, F.; Zhu, X.; Dai, J.; Li, Y.; Yang, Z.; Yan, X.; Song, J.; Wang, Y.; et al. Plasmonic Wood for High-Efficiency Solar Steam Generation. Adv. Energy Mater. 2018, 8, 1701028. [Google Scholar] [CrossRef]

- Li, T.; Liu, H.; Zhao, X.; Chen, G.; Dai, J.; Pastel, G.; Jia, C.; Chen, C.; Hitz, E.; Siddhartha, D.; et al. Scalable and Highly Efficient Mesoporous Wood-Based Solar Steam Generation Device: Localized Heat, Rapid Water Transport. Adv. Funct. Mater. 2018, 28, 1707134. [Google Scholar] [CrossRef]

- Shi, L.; Wang, Y.; Zhang, L.; Wang, P. Rational design of a bi-layered reduced graphene oxide film on polystyrene foam for solar-driven interfacial water evaporation. J. Mater. Chem. A 2017, 5, 16212–16219. [Google Scholar] [CrossRef]

- Li, W.; Li, X.; Liu, J.; Zeng, M.J.; Feng, X.; Jia, X.; Yu, Z.Z. Coating of Wood with Fe2O3-Decorated Carbon Nanotubes by One-Step Combustion for Efficient Solar Steam Generation. ACS Appl. Mater. Interfaces 2021, 13, 22845–22854. [Google Scholar] [CrossRef] [PubMed]

- Bian, Y.; Du, Q.; Tang, K.; Shen, Y.; Hao, L.; Zhou, D.; Wang, X.; Xu, Z.; Zhang, H.; Zhao, L.; et al. Carbonized Bamboos as Excellent 3D Solar Vapor-Generation Devices. Adv. Mater. Technol. 2018, 4, 1800593. [Google Scholar] [CrossRef]

- Xue, G.; Liu, K.; Chen, Q.; Yang, P.; Li, J.; Ding, T.; Duan, J.; Qi, B.; Zhou, J. Robust and Low-Cost Flame-Treated Wood for High-Performance Solar Steam Generation. ACS Appl. Mater. Interfaces 2017, 9, 15052–15057. [Google Scholar] [CrossRef]

- Wang, Z.; Yan, Y.; Shen, X.; Sun, Q.; Jin, C. Candle soot nanoparticle-decorated wood for efficient solar vapor generation. Sustain. Energy Fuels 2020, 4, 354–361. [Google Scholar] [CrossRef]

- He, F.; Han, M.; Zhang, J.; Wang, Z.; Wu, X.; Zhou, Y.; Jiang, L.; Peng, S.; Li, Y. A simple, mild and versatile method for preparation of photothermal woods toward highly efficient solar steam generation. Nano Energy 2020, 71, 104650. [Google Scholar] [CrossRef]

- Lu, Y.; Fan, D.; Shen, Z.; Zhang, H.; Xu, H.; Yang, X. Design and performance boost of a MOF-functionalized-wood solar evaporator through tuning the hydrogen-bonding interactions. Nano Energy 2022, 95, 107016. [Google Scholar] [CrossRef]

- Liu, H.; Chen, C.; Chen, G.; Kuang, Y.; Zhao, X.; Song, J.; Jia, C.; Xu, X.; Hitz, E.; Xie, H.; et al. High-Performance Solar Steam Device with Layered Channels: Artificial Tree with a Reversed Design. Adv. Energy Mater. 2018, 8, 1701616. [Google Scholar] [CrossRef]

- Wan, X.; Meng, P. Physiological and ecological mechanisms of long-distance water transport in plants: A review of recent issues. J. Plant Ecol. 2007, 31, 804–813. [Google Scholar]

- Jia, C.; Li, Y.; Yang, Z.; Chen, G.; Yao, Y.; Jiang, F.; Kuang, Y.; Pastel, G.; Xie, H.; Yang, B.; et al. Rich Mesostructures Derived from Natural Woods for Solar Steam Generation. Joule 2017, 1, 588–599. [Google Scholar] [CrossRef]

- Zhu, Z. Wood Drying; China Forestry Publishing House: Beijing, China, 1997; pp. 70–71. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, W.; Li, D. Wooden Solar Evaporator Design Based on the Water Transpiration Principle of Trees. Materials 2023, 16, 1628. https://doi.org/10.3390/ma16041628

Xiong W, Li D. Wooden Solar Evaporator Design Based on the Water Transpiration Principle of Trees. Materials. 2023; 16(4):1628. https://doi.org/10.3390/ma16041628

Chicago/Turabian StyleXiong, Wei, and Dagang Li. 2023. "Wooden Solar Evaporator Design Based on the Water Transpiration Principle of Trees" Materials 16, no. 4: 1628. https://doi.org/10.3390/ma16041628

APA StyleXiong, W., & Li, D. (2023). Wooden Solar Evaporator Design Based on the Water Transpiration Principle of Trees. Materials, 16(4), 1628. https://doi.org/10.3390/ma16041628