Comparative Analysis of Waste, Steel, and Polypropylene Microfibers as an Additive for Cement Mortar

Abstract

1. Introduction

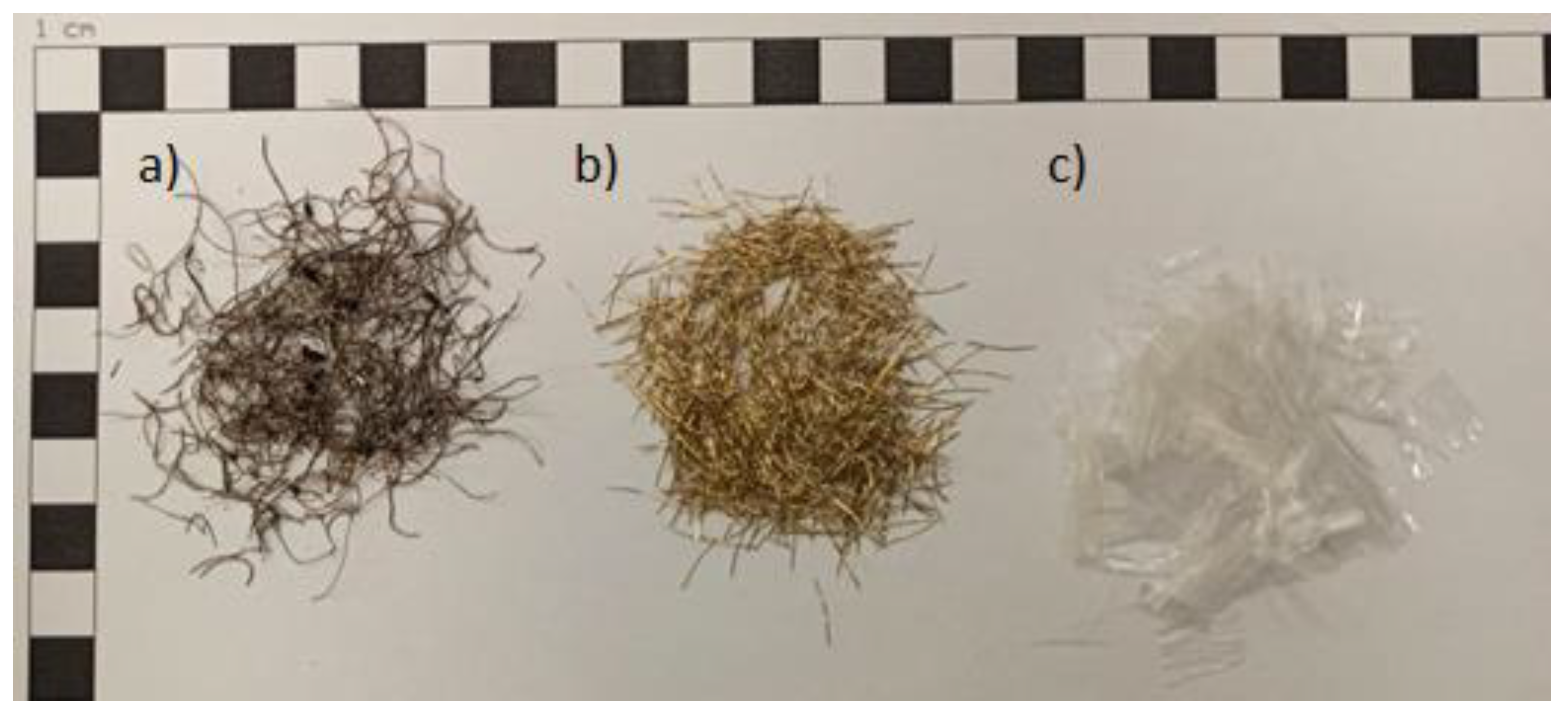

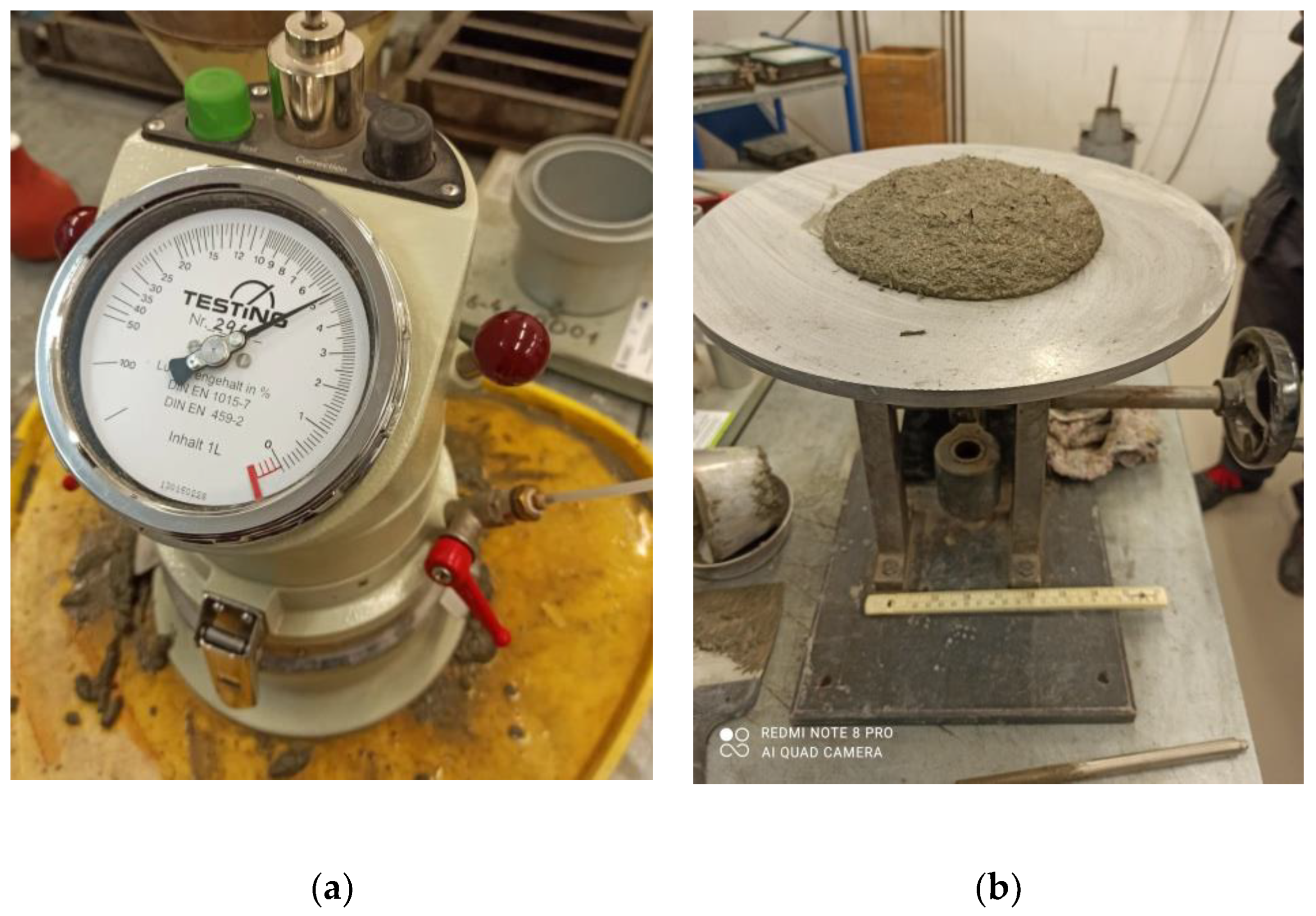

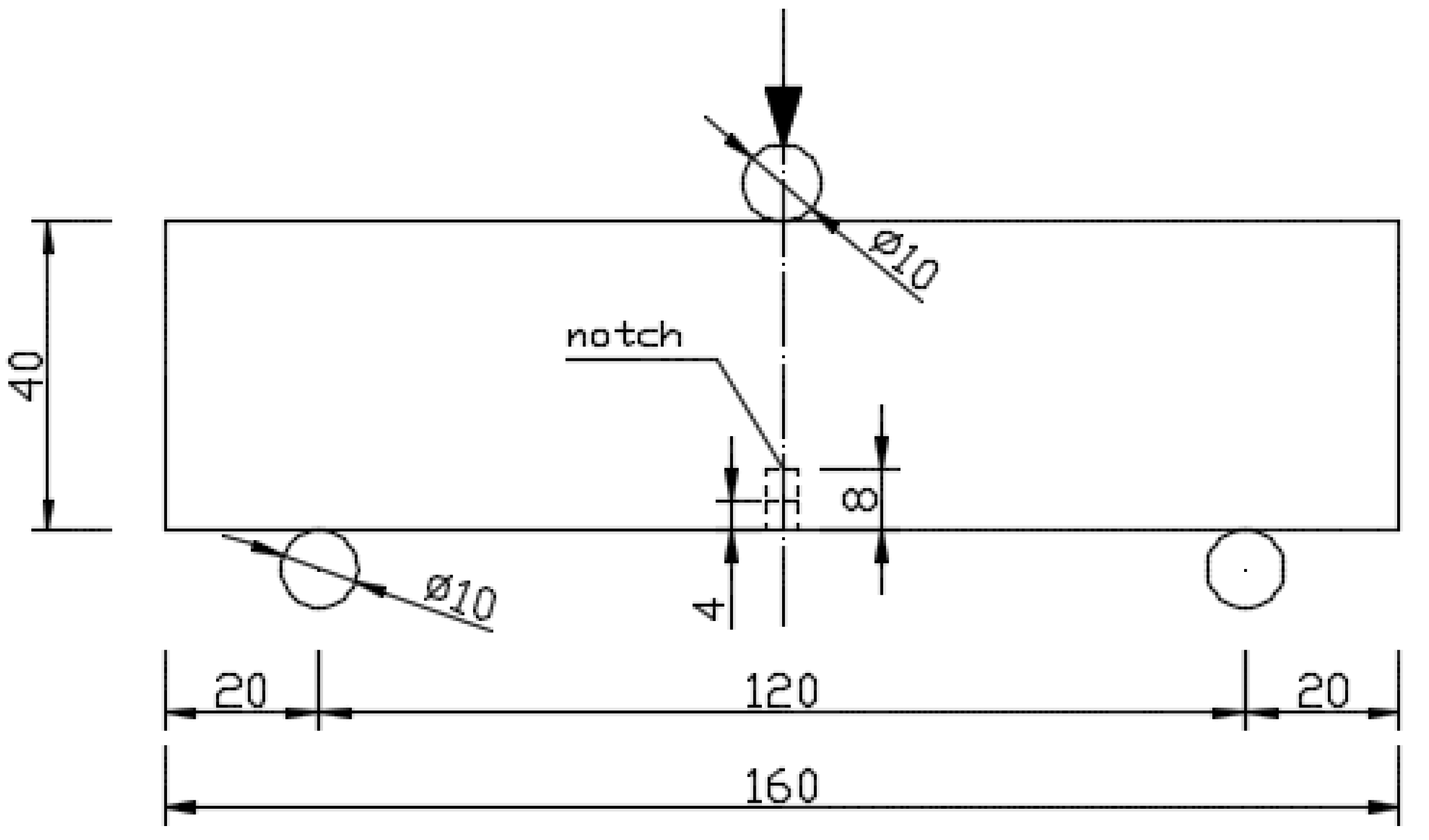

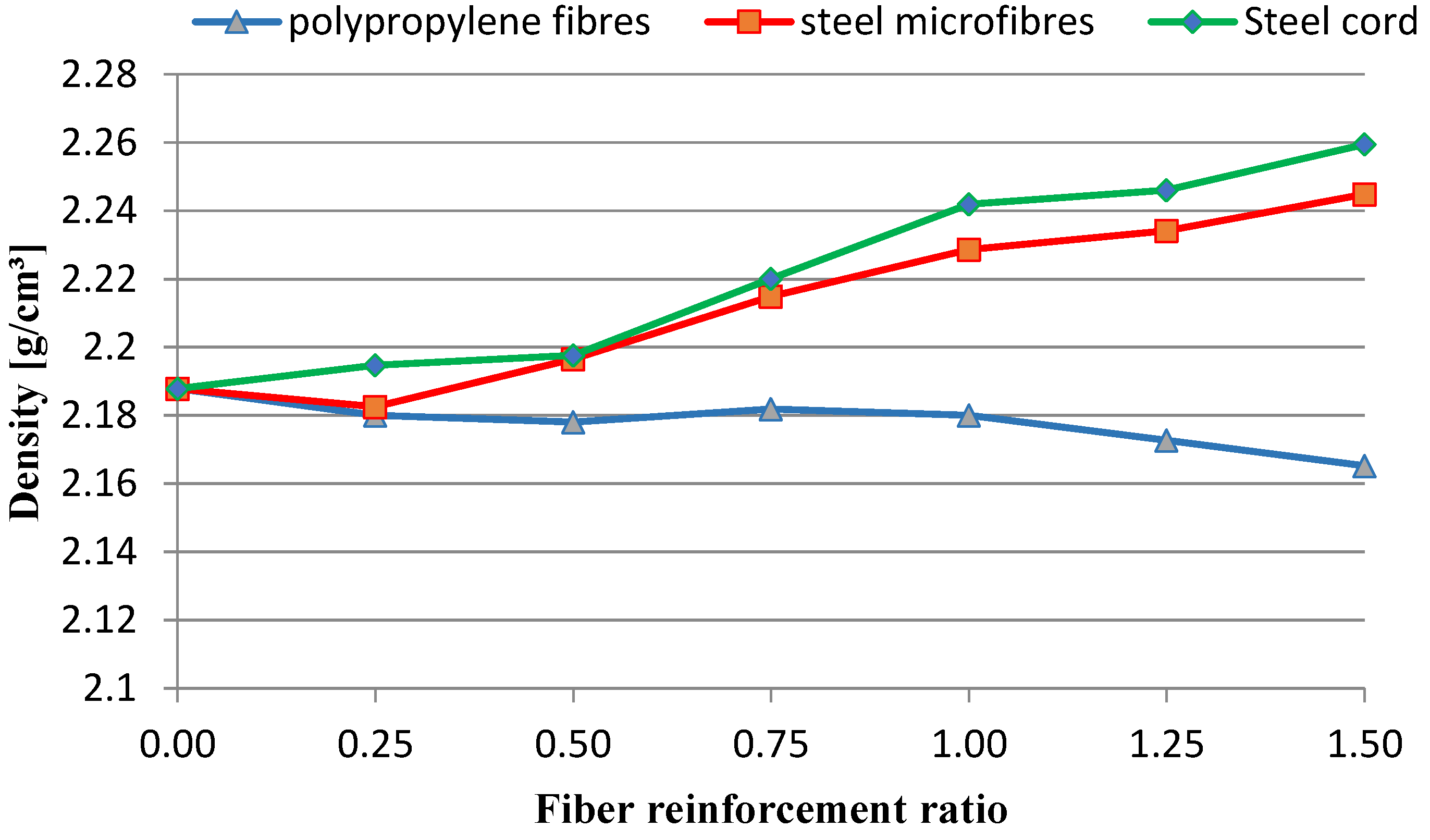

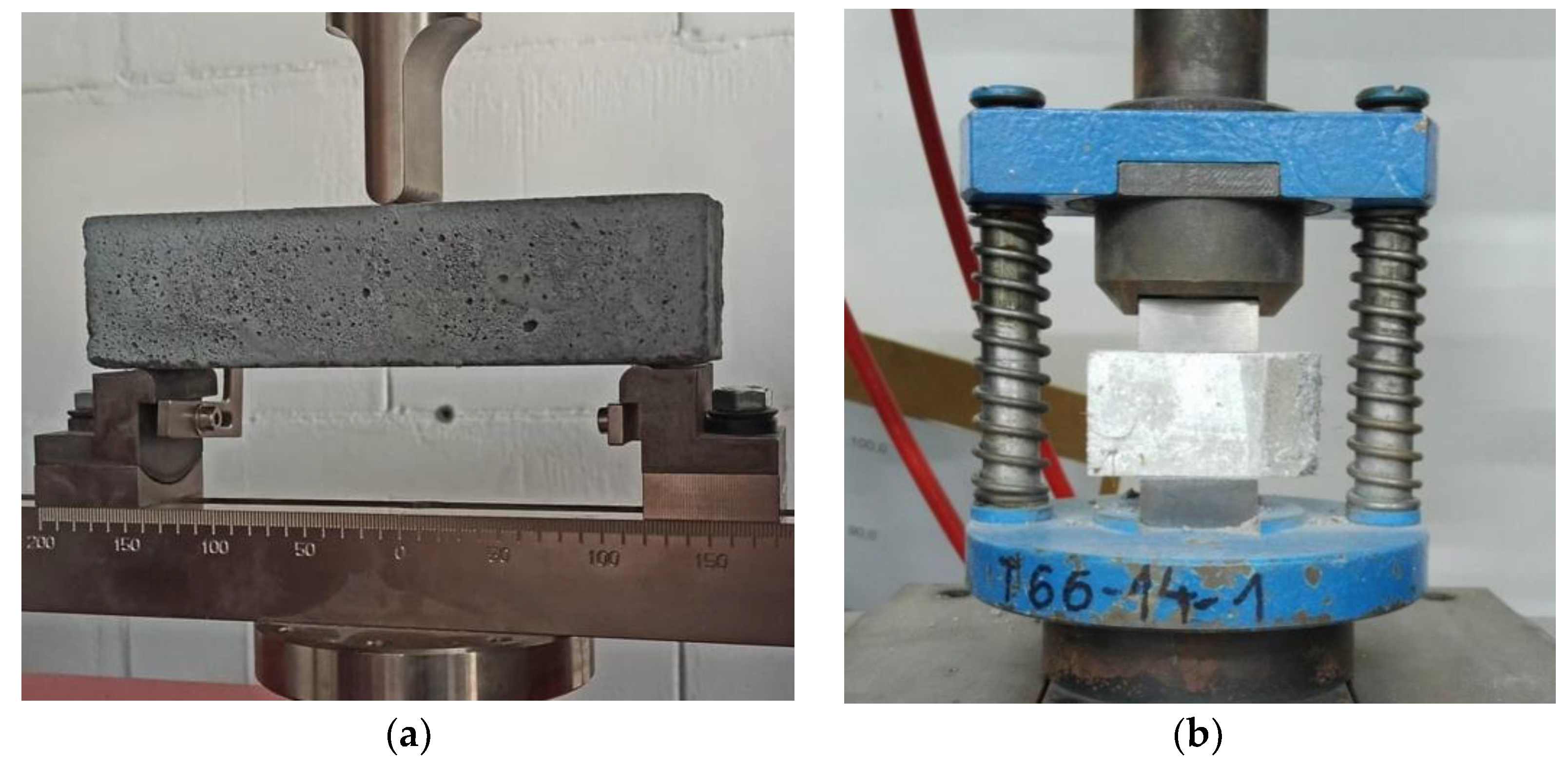

2. Materials and Methods

3. Experimental Results

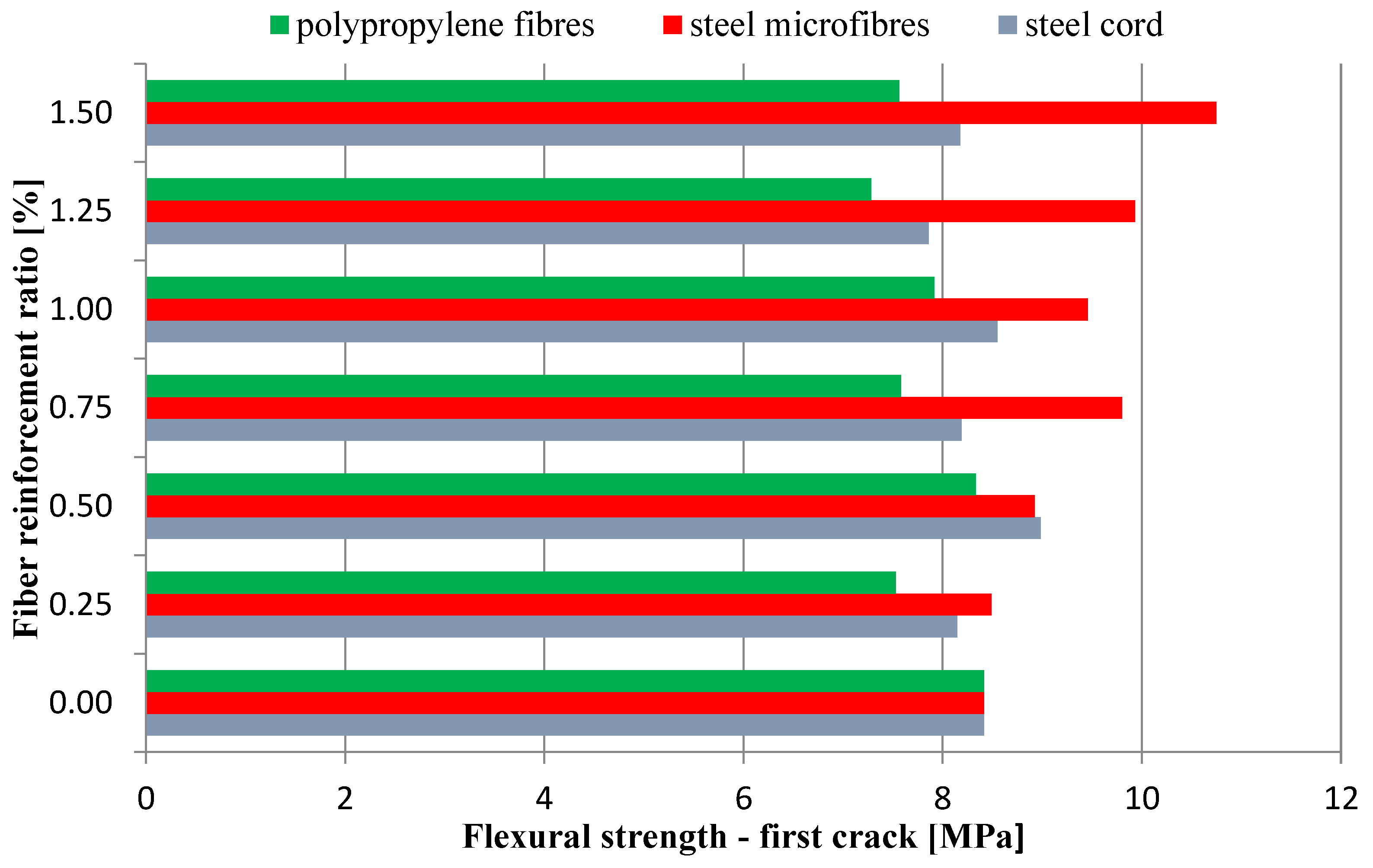

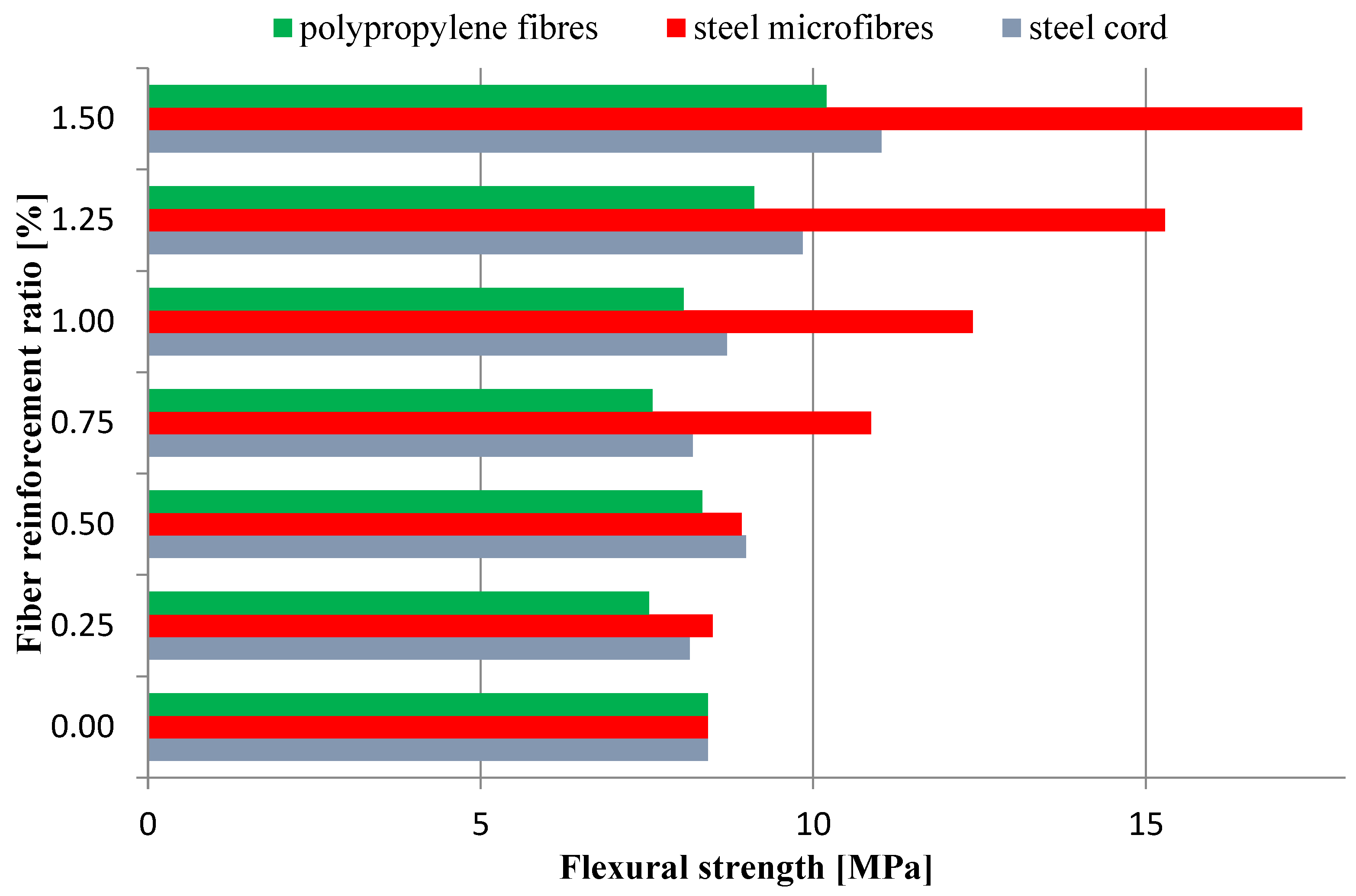

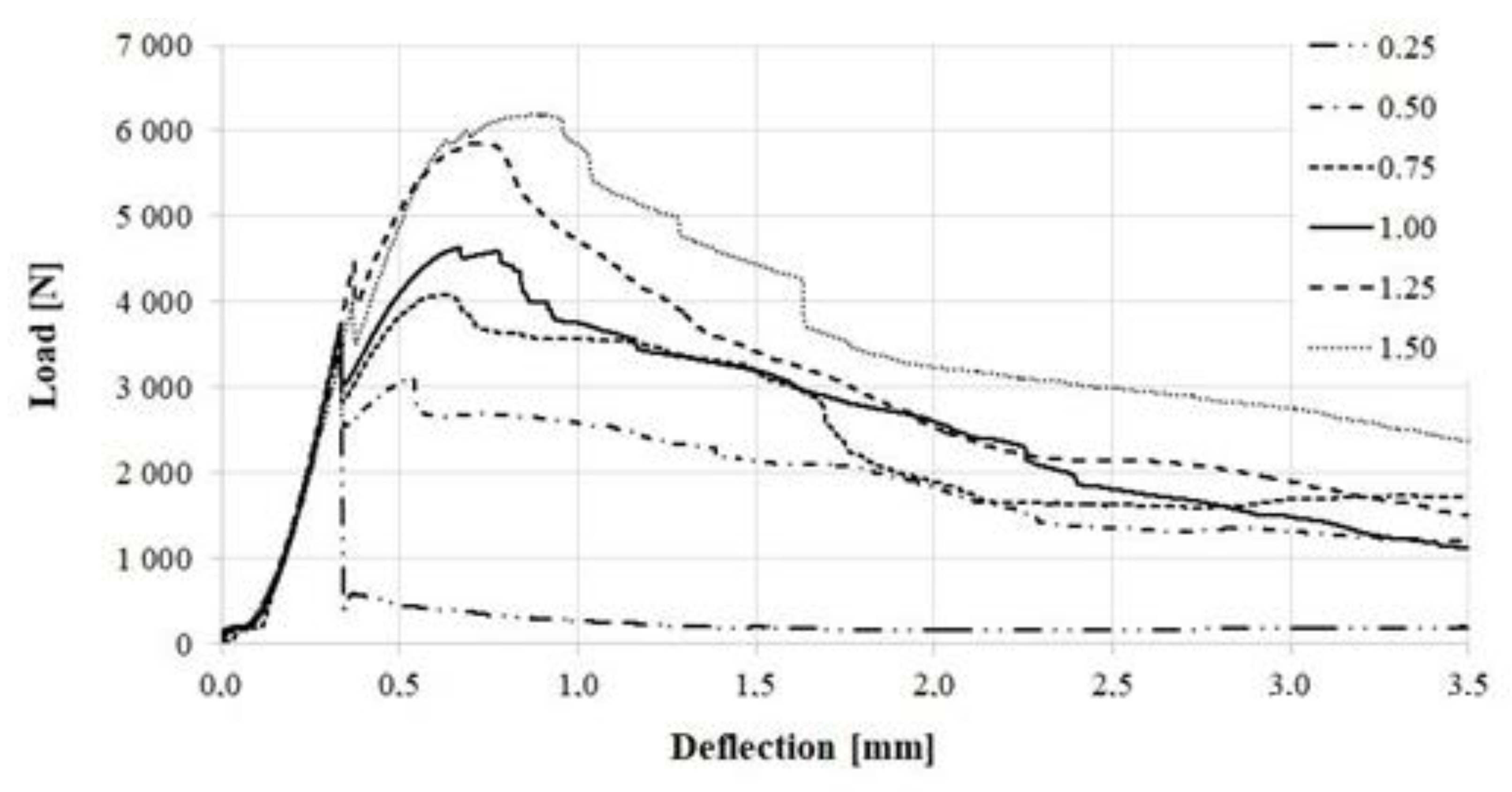

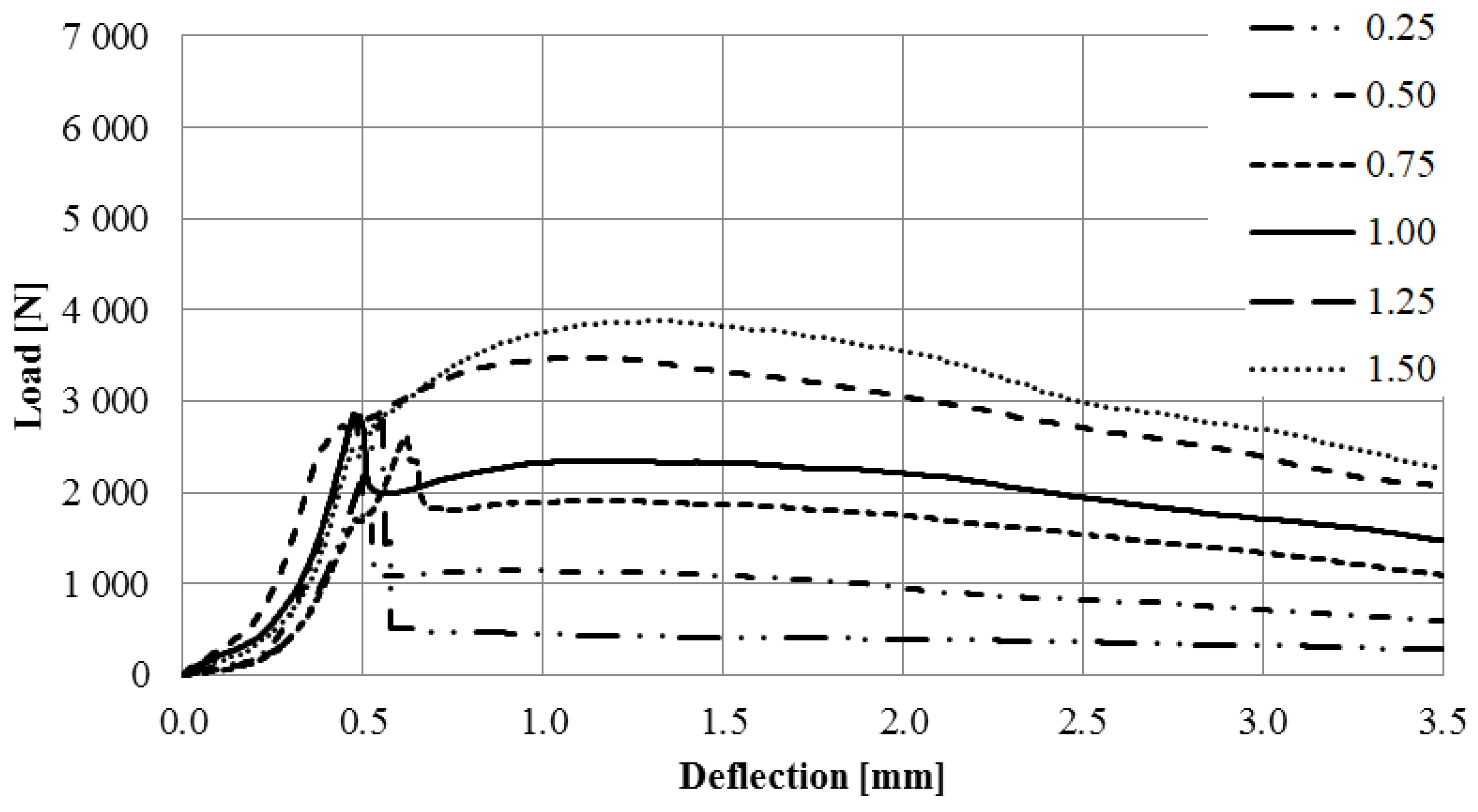

3.1. Flexural Strength

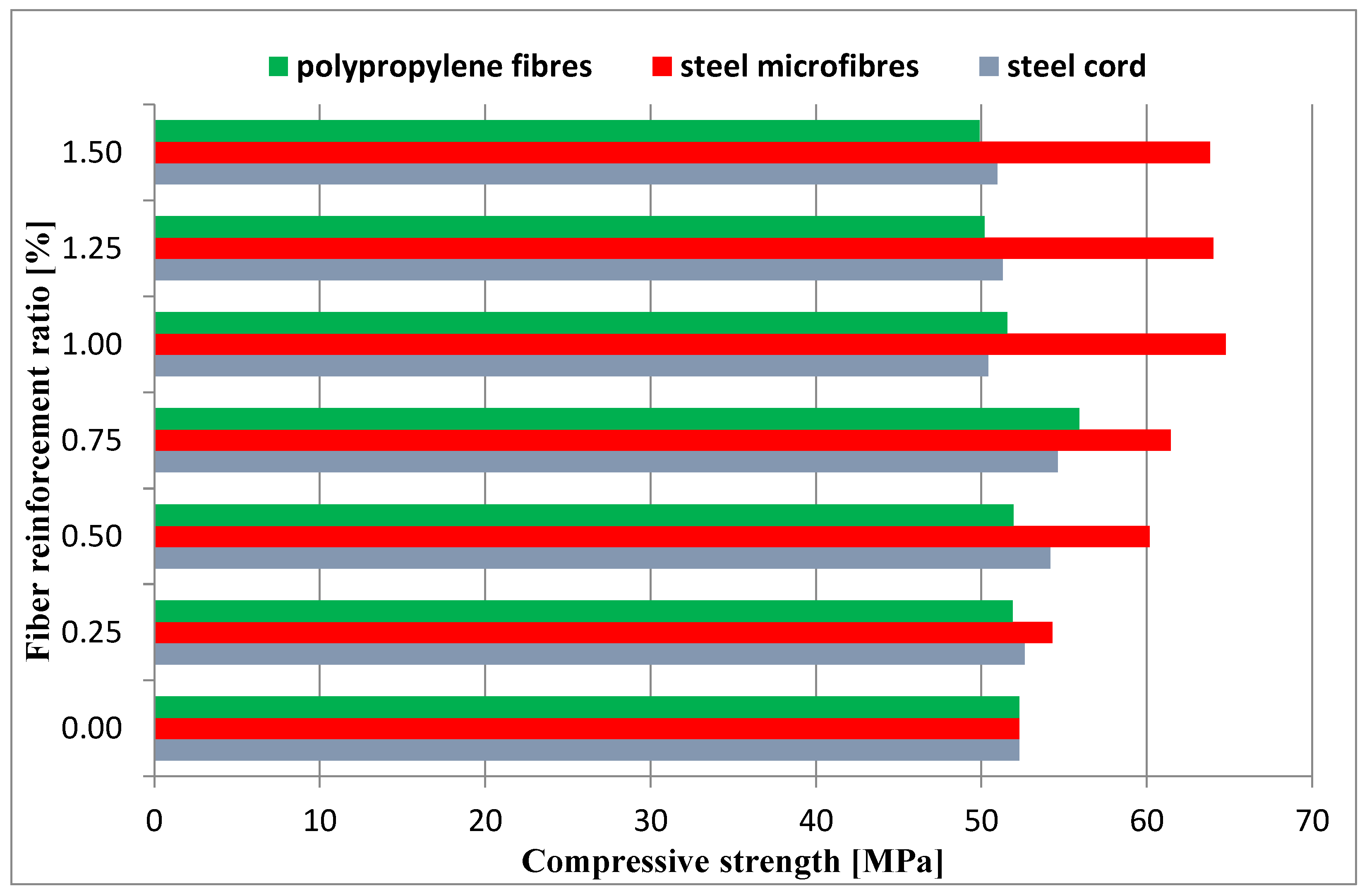

3.2. Compressive Strength

4. Discussion

5. Conclusions

- -

- The steel cord is a full-value, ecological replacement for polypropylene fibers. Steel cord provides better flexural strength and a greater flexural toughness factor.

- -

- The use of steel microfibers allows us to obtain better mixture properties than steel cord and polypropylene fibers.

- -

- The use of steel cord as dispersed reinforcement will allow for improved rational waste management and a reduction in energy consumption values required for remelting the steel cord.

- -

- The test conducted on small beams is a good method to determine the effect of fibers as an additive to concrete prior to starting tests in accordance with the standard EN 14651-2005.

- -

- The use of a plasticizer may improve the consistency of the mixtures with steel cord, and thus positively affect the parameters of mixtures with a higher fiber reinforcement ratio.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Halicka, A.; Ogrodnik, P.; Zegardlo, B. Using Ceramic Sanitary Ware Waste as Concrete Aggregate. Constr. Build. Mater. 2013, 48, 295–305. [Google Scholar] [CrossRef]

- Seitl, S.; Viszlay, V.; Domski, J.; Katzer, J. Fracture Mechanical Properties of Cement Based Composites with Various Amount of Waste Aggregates. Procedia Eng. 2017, 190, 345–351. [Google Scholar] [CrossRef]

- Lu, J.X.; Zheng, H.; Yang, S.; He, P.; Poon, C.S. Co-Utilization of Waste Glass Cullet and Glass Powder in Precast Concrete Products. Constr. Build. Mater. 2019, 223, 210–220. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.İ.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of Replacing Cement with Waste Glass on Mechanical Properties of Concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef] [PubMed]

- Çelik, A.I.; Özkılıç, Y.O.; Zeybek, Ö.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef] [PubMed]

- Domski, J.; Zakrzewski, M. Deflection of Steel Fiber Reinforced Concrete Beams Based on Waste Sand. Materials 2020, 13, 392. [Google Scholar] [CrossRef]

- Głodkowska, W.; Ziarkiewicz, M. Cracking Behavior of Steel Fiber Reinforced Waste Sand Concrete Beams in Flexure–Experimental Investigation and Theoretical Analysis. Eng. Struct. 2018, 176, 1–10. [Google Scholar] [CrossRef]

- Lehmann, M.; Głodkowska, W. Shear Capacity and Behaviour of Bending Reinforced Concrete Beams Made of Steel Fibre-Reinforced Waste Sand Concrete. Materials 2021, 14, 2996. [Google Scholar] [CrossRef]

- Çelik, A.I.; Özkılıç, Y.O.; Zeybek, Ö.; Özdöner, N.; Tayeh, B.A. Performance Assessment of Fiber-Reinforced Concrete Produced with Waste Lathe Fibers. Sustainability 2022, 14, 11817. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Deifalla, A.F.; Aksoylu, C.; Arslan, M.H.; Ahmad, M.; Sabri Sabri, M.M. Improvement in Bending Performance of Reinforced Concrete Beams Produced with Waste Lathe Scraps. Sustainability 2022, 14, 12660. [Google Scholar] [CrossRef]

- Polek, K. Wpływ Włókien Stalowych Na Wybrane Właściwości Kompozytów Cementowych Na Bazie Regranulatu EPS. Mater. Bud. 2019, 1. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Aksoylu, C.; Sabri Sabri, M.M.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M. Flexural Behavior of Reinforced Concrete Beams Using Waste Marble Powder Towards Application of Sustainable Concrete. Front. Mater. 2022. [Google Scholar] [CrossRef]

- Mehta, A.; Ashish, D.K. Silica Fume and Waste Glass in Cement Concrete Production: A Review. J. Build. Eng. 2020, 29, 100888. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Chen, F.; Liu, C.; Chen, X. Utilization of Waste Clay Bricks as Coarse and Fine Aggregates for the Preparation of Lightweight Aggregate Concrete. J. Clean. Prod. 2018, 201, 706–715. [Google Scholar] [CrossRef]

- Edun, A.; Hachem-Vermette, C. Energy and Environmental Impact of Recycled End of Life Tires Applied in Building Envelopes. J. Build. Eng. 2021, 39, 102242. [Google Scholar] [CrossRef]

- Pilakoutas, K.; Neocleous, K.; Tlemat, H. Reuse of Tyre Steel Fibres as Concrete Reinforcement. Eng. Sustain. 2004, 157, 131–138. [Google Scholar] [CrossRef]

- Hylands, K.N.; Shulman, V. Civil Engineering Applications of Tyres; Viridis: Shanghai, China, 2003. [Google Scholar]

- Grammelis, P.; Margaritis, N.; Dallas, P.; Rakopoulos, D.; Mavrias, G. A Review on Management of End of Life Tires (Elts) and Alternative Uses of Textile Fibers. Energies 2021, 14, 571. [Google Scholar] [CrossRef]

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Çelik, A.İ.; Deifalla, A.F.; Ahmad, M.; Sabri Sabri, M.M. Performance Evaluation of Fiber-Reinforced Concrete Produced with Steel Fibers Extracted from Waste Tire. Front. Mater. 2022, 9, 692. [Google Scholar] [CrossRef]

- Chen, M.; Si, H.; Fan, X.; Xuan, Y.; Zhang, M. Dynamic Compressive Behaviour of Recycled Tyre Steel Fibre Reinforced Concrete. Constr. Build. Mater. 2022, 316, 125896. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental Investigation of Sound Transmission Loss in Concrete Containing Recycled Rubber Crumbs. Adv. Concr. Constr. 2021, 11, 447–454. [Google Scholar]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano Silica and Metakaolin Effects on the Behavior of Concrete Containing Rubber Crumbs. CivilEng 2020, 1, 264–274. [Google Scholar] [CrossRef]

- Augustino, D.S.; Kabubo, C.; Kanali, C.; Onchiri, R.O. The orientation effect of opening and internal strengthening on shear performance of deep concrete beam using recycled tyre steel fibres. Results Eng. 2022, 15, 100561. [Google Scholar] [CrossRef]

- Kruzel, R.; Ulewicz, M. Analysis of Fatigue Life of the Steel Cord Used in Tires in Unidirectional and Bidirectional Bending. Procedia Struct. Integr. 2018, 13, 1626–1631. [Google Scholar] [CrossRef]

- Simalti, A.; Singh, A.P. Comparative Study on Performance of Manufactured Steel Fiber and Shredded Tire Recycled Steel Fiber Reinforced Self-Consolidating Concrete. Constr. Build. Mater. 2021, 266, 121102. [Google Scholar] [CrossRef]

- Pająk, M. Concrete Reinforced with Various Amounts of Steel Fibers Reclaimed from End-of-Life Tires. MATEC Web Conf. 2019, 262. [Google Scholar] [CrossRef]

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Fiber-Reinforced Concrete with Low Content of Recycled Steel Fiber: Shear Behaviour. Constr. Build. Mater. 2018, 161, 141–155. [Google Scholar] [CrossRef]

- Pająk, M.; Janiszewski, J.; Kruszka, L. Laboratory Investigation on the Influence of High Compressive Strain Rates on the Hybrid Fibre Reinforced Self-Compacting Concrete. Constr. Build. Mater. 2019, 227, 116687. [Google Scholar] [CrossRef]

- Pawelska-Mazur, M.; Kaszynska, M. Mechanical Performance and Environmental Assessment of Sustainable Concrete Reinforced with Recycled End-of-Life Tyre Fibres. Materials 2021, 14, 256. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Aiello, M.A. Steel Fibers from Waste Tires as Reinforcement in Concrete: A Mechanical Characterization. Constr. Build. Mater. 2012, 36, 46–57. [Google Scholar] [CrossRef]

- Xu, C.; Cao, P.z.; Wu, K.; Lin, S.q.; Yang, D.g. Experimental Investigation of the Behavior Composite Steel-Concrete Composite Beams Containing Different Amounts of Steel Fibres and Conventional Reinforcement. Constr. Build. Mater. 2019, 202, 23–36. [Google Scholar] [CrossRef]

- Larsen, I.L.; Thorstensen, R.T. The Influence of Steel Fibres on Compressive and Tensile Strength of Ultra High Performance Concrete: A Review. Constr. Build. Mater. 2020, 256, 119459. [Google Scholar] [CrossRef]

- Isa, M.N.; Pilakoutas, K.; Guadagnini, M.; Angelakopoulos, H. Mechanical performance of affordable and eco-efficient ultra-high performance concrete (UHPC) containing recycled tyre steel fibres. Constr. Build. Mater. 2020, 255, 119272. [Google Scholar] [CrossRef]

- Paja̧k, M.; Ponikiewski, T. Investigation on Concrete Reinforced with Two Types of Hooked Fibers under Flexure. Procedia Eng. 2017, 193, 128–135. [Google Scholar] [CrossRef]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the Mechanical Response of Hybrid Fiber Reinforced Concrete with Recycled and Industrial Steel Fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Ramesh, R.B.; Mirza, O.; Kang, W.H. Mechanical Properties of Steel Fiber Reinforced Recycled Aggregate Concrete. Struct. Concr. 2019, 20, 745–755. [Google Scholar] [CrossRef]

- Meesala, C.R. Influence of Different Types of Fiber on the Properties of Recycled Aggregate Concrete. Struct. Concr. 2019, 20, 1656–1669. [Google Scholar] [CrossRef]

- Karalar, M.; Bilir, T.; Çavuşlu, M.; Özkiliç, Y.O.; Sabri Sabri, M.M. Use of Recycled Coal Bottom Ash in Reinforced Concrete Beams as Replacement for Aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- Ahmadi, M.; Farzin, S.; Hassani, A.; Motamedi, M. Mechanical Properties of the Concrete Containing Recycled Fibers and Aggregates. Constr. Build. Mater. 2017, 144, 392–398. [Google Scholar] [CrossRef]

- Karimipour, A.; Ghalehnovi, M.; de Brito, J. Mechanical and Durability Properties of Steel Fibre-Reinforced Rubberised Concrete. Constr. Build. Mater. 2020, 257, 119463. [Google Scholar] [CrossRef]

- Karimi, A.; Nematzadeh, M. Axial Compressive Performance of Steel Tube Columns Filled with Steel Fiber-Reinforced High Strength Concrete Containing Tire Aggregate after Exposure to High Temperatures. Eng. Struct. 2020, 219, 110608. [Google Scholar] [CrossRef]

- Kheddache, L.; Chahour, K.; Safi, B. Effect of Fiber Distribution on the Mechanical Behavior in Bending of Self-Compacting Mortars. Sel. Sci. Pap.-J. Civ. Eng. 2020, 15, 129–148. [Google Scholar] [CrossRef]

- Mustea, A.; Manea, D.L. Influence of Polypropylene Fibers upon the Mechanical Characteristics of Reinforced Composite Mortars. Procedia Eng. 2017, 181, 338–345. [Google Scholar] [CrossRef]

- Suiffi, H.; el Maliki, A.; Cherkaoui, O.; Dalal, M. Influence of Polypropylene Fibers on the Ductility of Sand Concrete. Int. J. Mech. Eng. Technol. (IJMET) 2019, 10, 217–226. [Google Scholar]

- Blazy, J.; Blazy, R. Polypropylene Fiber Reinforced Concrete and Its Application in Creating Architectural Forms of Public Spaces. Case Stud. Constr. Mater. 2021, 14, e00549. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Nuaimi, N.; Rabie, M. The Role of Polypropylene Microfibers in Thermal Properties and Post-Heating Behavior of Cementitious Composites. Materials 2020, 13, 2676. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Characteristics of Recycled Polypropylene Fibers as an Addition to Concrete Fabrication Based on Portland Cement. Materials 2020, 13, 1827. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Xu, K. Size Effect in Fatigue Fracture of Concrete. ACI Mater. J. 1991, 88, 390–399. [Google Scholar]

- Spagnoli, A. Self-Similarity and Fractals in the Paris Range of Fatigue Crack Growth. Mech. Mater. 2005, 37, 519–529. [Google Scholar] [CrossRef]

- Bazant, Z.; Schell, W.F. Fatigue Fracture of High-Strength Concrete and Size Effect. ACI Mater. J. 1993, 90, 472–478. [Google Scholar] [CrossRef]

- Thienponta, T.; De Cortea, W.; Seitl, S. Self-compacting Concrete, Protecting Steel Reinforcement under Cyclic Load: Evaluation of Fatigue Crack Behavior. Procedia Eng. 2016, 160, 207–213. [Google Scholar] [CrossRef]

- Seitl, S.; Miarka, P.; Klusák, J.; Domski, J.; Katzer, J.; Šimonová, H.; Keršner, Z. Change of a Crack Propagation Rate in Fine-Grained Cement-Based Composites Due to Partial Replacement of Aggregate by Ceramic Waste. Key Eng. Mater. 2018, 761, 111–115. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled Fibers in Reinforced Concrete: A Systematic Literature Review. J. Clean. Prod. 2020, 248, 119207. [Google Scholar] [CrossRef]

- di Prisco, M.; Plizzari, G.; Vandewalle, L. Fibre Reinforced Concrete: New Design Perspectives. Mater. Struct. Mater. Constr. 2009, 42, 1261–1281. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Micelli, F.; Colonna, D.; Aiello, M.A. Concrete Reinforced with Recycled Steel Fibers from End of Life Tires: Mix-Design and Application. In Key Engineering Materials; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2016; Volume 711. [Google Scholar]

- Awolusi, T.F.; Oke, O.L.; Atoyebi, O.D.; Akinkurolere, O.O.; Sojobi, A.O. Waste Tires Steel Fiber in Concrete: A Review. Innov. Infrastruct. Solut. 2021, 6, 1–12. [Google Scholar] [CrossRef]

- Domski, J.; Katzer, J.; Zakrzewski, M.; Ponikiewski, T. Comparison of the Mechanical Characteristics of Engineered and Waste Steel Fiber Used as Reinforcement for Concrete. J. Clean. Prod. 2017, 158, 18–28. [Google Scholar] [CrossRef]

- EN 196-1; Methods of Testing Cement—Determination of Strength. European Committee for Standardization: Brussels, Belgium, 2016. Available online: https://www.cencenelec.eu (accessed on 1 February 2023).

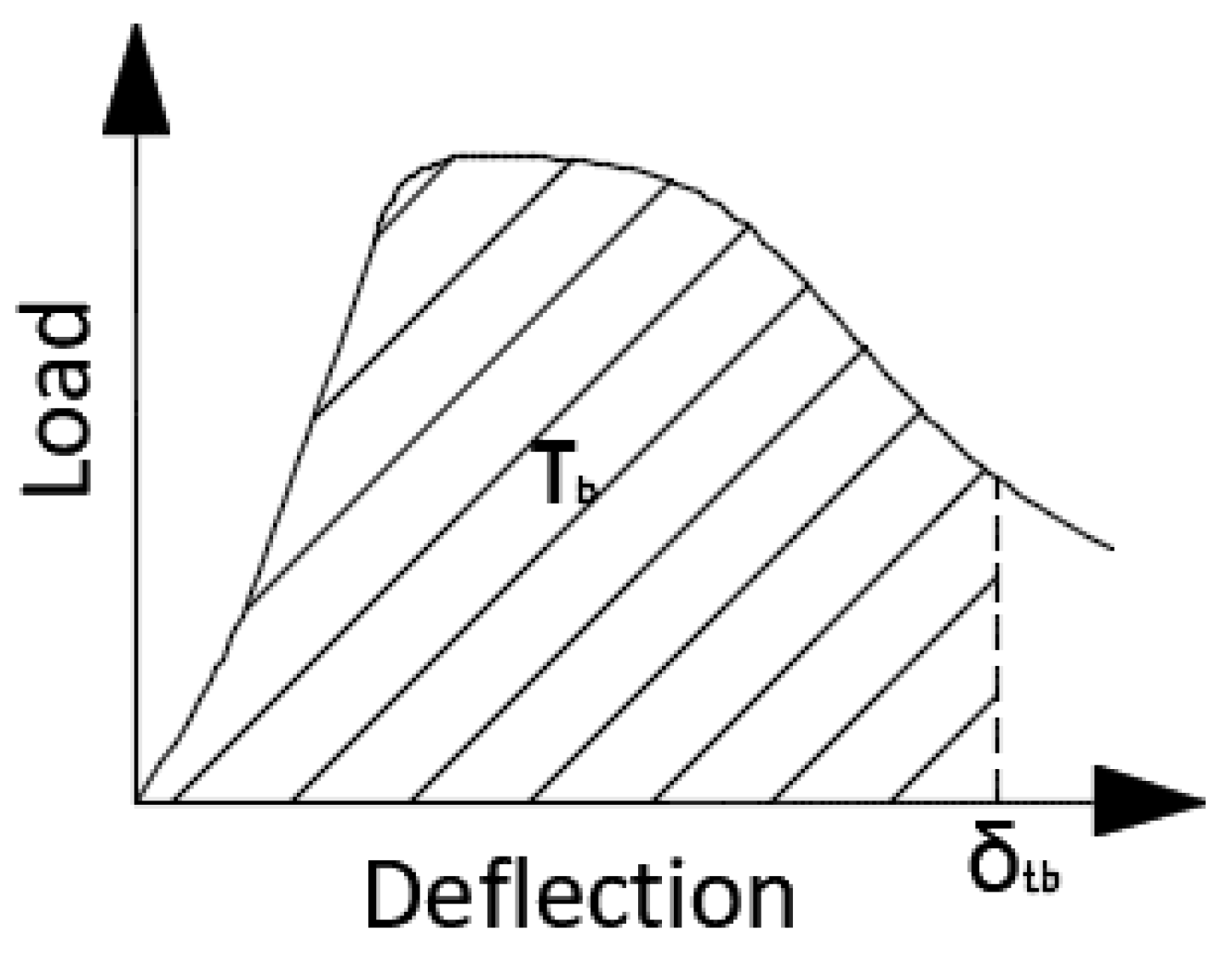

- JSCE-SF4; Method-of-Test-For-Flexural-Strength-and-Flexural-Toughness. Japan Society of Civil Engineers: Yotsuya, Japan, 1983. Available online: https://www.jsce-int.org (accessed on 1 February 2023).

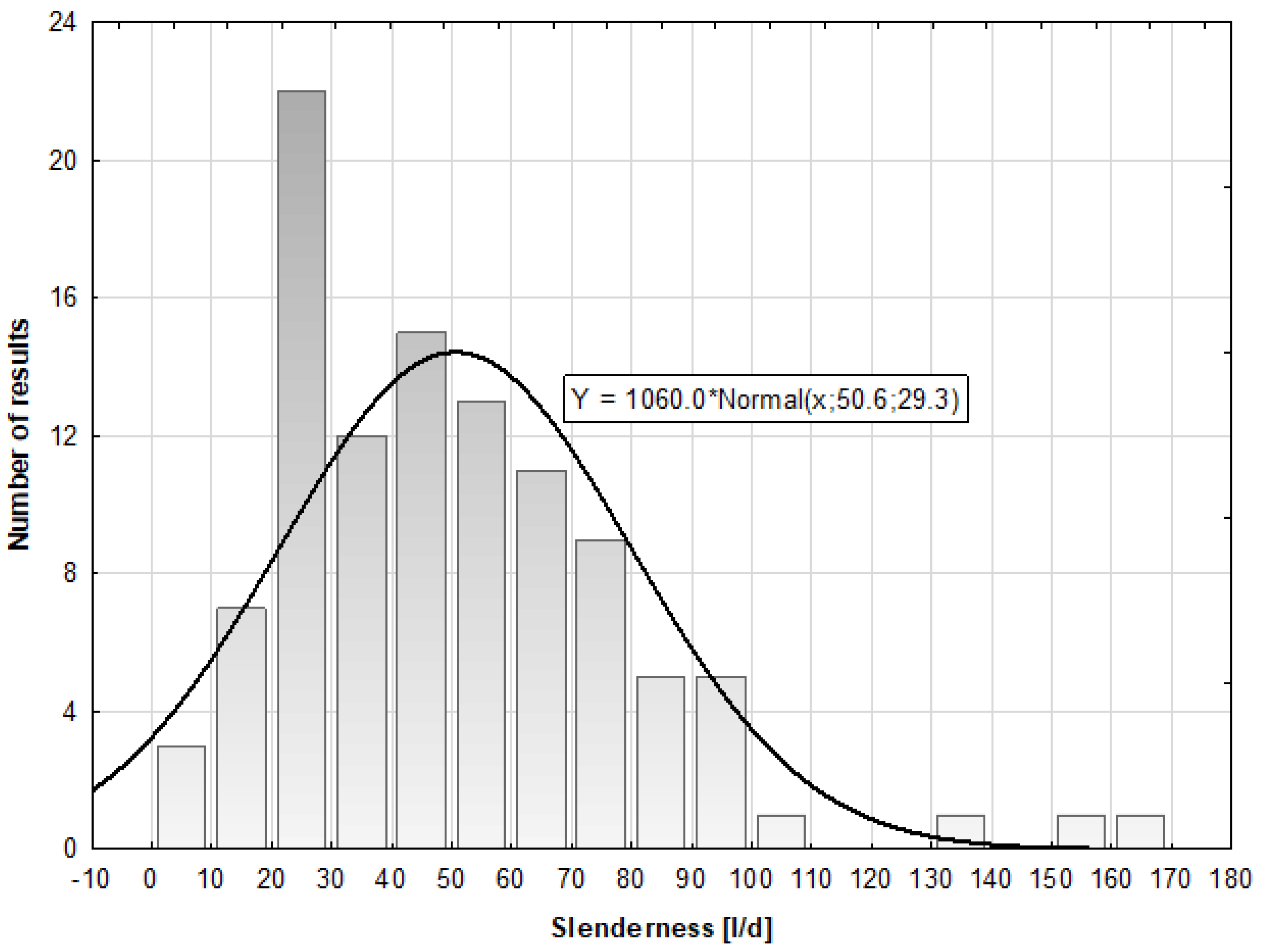

| Parameter | Average | Standard Deviation | Median | Minimum Value | Maximum Value |

|---|---|---|---|---|---|

| [mm] | [mm] | [mm] | [mm] | [mm] | |

| diameter | 0.31 | 0.18 | 0.25 | 0.05 | 1.35 |

| length | 13.29 | 5.80 | 12.57 | 2.90 | 27.90 |

| Diameter | Average Tensile Strength | Standard Deviation | Coefficient of Variation |

|---|---|---|---|

| [mm] | [MPa] | [MPa] | [%] |

| 0.30–0.35 | 1788.53 | 543.88 | 0.30 |

| Fiber Reinforcement Ratio | Steel Cord | Steel Microfibers | Polypropylene Fibers | |||

|---|---|---|---|---|---|---|

| [%] | Air Content | Consistency | Air Content | Consistency | Air Content | Consistency |

| [%] | [cm] | [%] | [cm] | [%] | [cm] | |

| 0.00 | 6.2 | 17,8 | 6.2 | 17,8 | 6.2 | 17,8 |

| 0.25 | 6.0 | 17.5 | 5.9 | 17.3 | 6.2 | 17.0 |

| 0.50 | 5.5 | 16.8 | 6.0 | 17.0 | 6.0 | 15.5 |

| 0.75 | 5.2 | 16.5 | 5.7 | 16.3 | 5.7 | 15.2 |

| 1.00 | 5.3 | 16.2 | 5.4 | 15.7 | 5.8 | 15.2 |

| 1.25 | 5.0 | 16.0 | 5.0 | 14.7 | 5.0 | 14.5 |

| 1.50 | 4.9 | 15.7 | 4.2 | 14.7 | 4.8 | 13.0 |

| Fiber Reinforcement Ratio | Steel Cord | Standard Deviation | Steel Microfibers | Standard Deviation | Polypropylene Fibers | Standard Deviation |

|---|---|---|---|---|---|---|

| [%] | [MPa] | [MPa] | [MPa] | [MPa] | [MPa] | [MPa] |

| 0.25 | 1.41 | 0.40 | 2.44 | 0.23 | 1.18 | 0.05 |

| 0.50 | 3.14 | 0.33 | 3.24 | 0.15 | 1.41 | 0.11 |

| 0.75 | 4.11 | 0.27 | 3.98 | 0.19 | 1.44 | 0.35 |

| 1.00 | 3.86 | 0.31 | 4.22 | 0.12 | 1.92 | 0.14 |

| 1.25 | 4.91 | 0.69 | 4.21 | 0.48 | 2.64 | 0.32 |

| 1.50 | 4.74 | 0.36 | 4.62 | 0.28 | 2.09 | 0.01 |

| Fiber Reinforcement Ratio | Fracture Toughness Steel Cord | Fracture Toughness Steel Microfibers | Fracture Toughness Polypropylene Fibers | |||

|---|---|---|---|---|---|---|

| notch | 4 mm | 8 mm | 4 mm | 8 mm | 4 mm | 8 mm |

| [%] | [MPa] | [MPa] | [MPa] | [MPa] | [MPa] | [MPa] |

| 0.00 | 0.809 | 1.085 | 0.664 | 1.082 | 0.647 | 1.056 |

| 0.25 | 0.804 | 1.173 | 0.708 | 1.123 | 0.573 | 1.090 |

| 0.50 | 0.768 | 1.121 | 0.819 | 1.313 | 0.625 | 1.050 |

| 0.75 | 0.885 | 1.392 | 1.084 | 1.437 | 0.694 | 1.077 |

| 1.00 | 0.991 | 1.356 | 1.366 | 2.040 | 0.651 | 1.124 |

| 1.25 | 1.523 | 1.704 | 1.616 | 2.006 | 0.679 | 1.174 |

| 1.50 | 1.470 | 1.438 | 1.655 | 1.846 | 0.706 | 1.111 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zakrzewski, M.; Gancarz, M.; Tvrdá, K.; Laskowska-Bury, J.; Domski, J. Comparative Analysis of Waste, Steel, and Polypropylene Microfibers as an Additive for Cement Mortar. Materials 2023, 16, 1625. https://doi.org/10.3390/ma16041625

Zakrzewski M, Gancarz M, Tvrdá K, Laskowska-Bury J, Domski J. Comparative Analysis of Waste, Steel, and Polypropylene Microfibers as an Additive for Cement Mortar. Materials. 2023; 16(4):1625. https://doi.org/10.3390/ma16041625

Chicago/Turabian StyleZakrzewski, Mateusz, Mateusz Gancarz, Katarína Tvrdá, Joanna Laskowska-Bury, and Jacek Domski. 2023. "Comparative Analysis of Waste, Steel, and Polypropylene Microfibers as an Additive for Cement Mortar" Materials 16, no. 4: 1625. https://doi.org/10.3390/ma16041625

APA StyleZakrzewski, M., Gancarz, M., Tvrdá, K., Laskowska-Bury, J., & Domski, J. (2023). Comparative Analysis of Waste, Steel, and Polypropylene Microfibers as an Additive for Cement Mortar. Materials, 16(4), 1625. https://doi.org/10.3390/ma16041625