Influence of Pre-Milling of Cr3C2-25 NiCr Spray Powder on the Fatigue Life of HVOF-Sprayed Coating on ASTM A516 Steel Substrate

Abstract

:1. Introduction

2. Materials and Methods

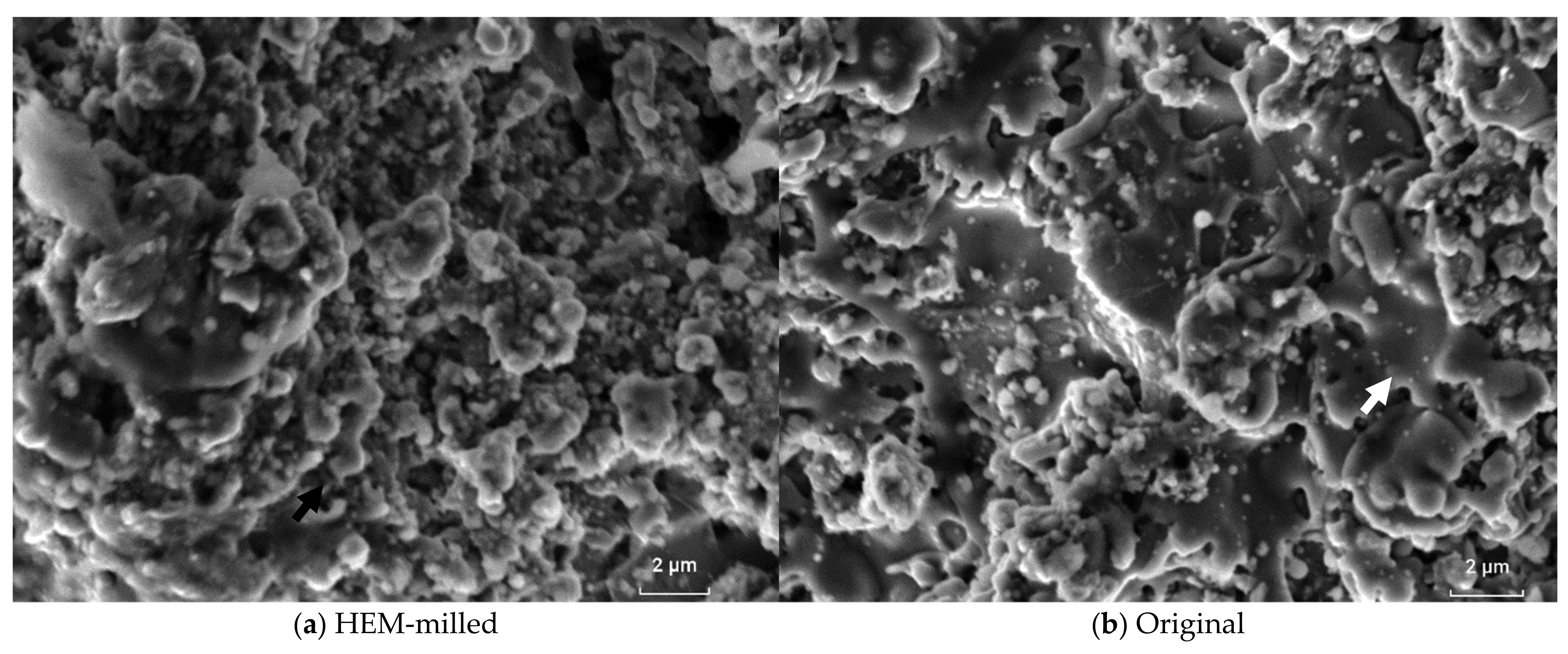

2.1. Spraying Powder Milling and Characterization

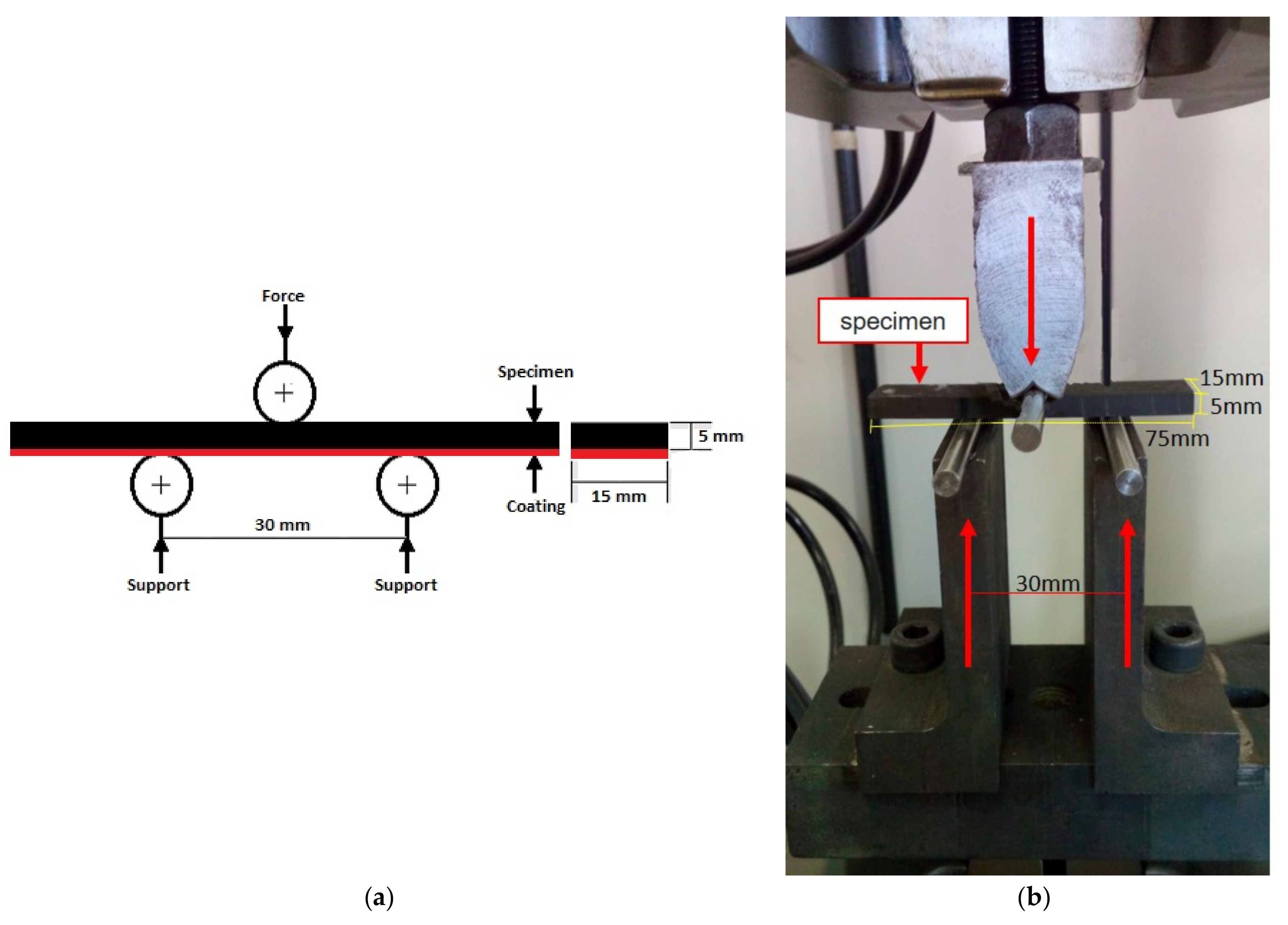

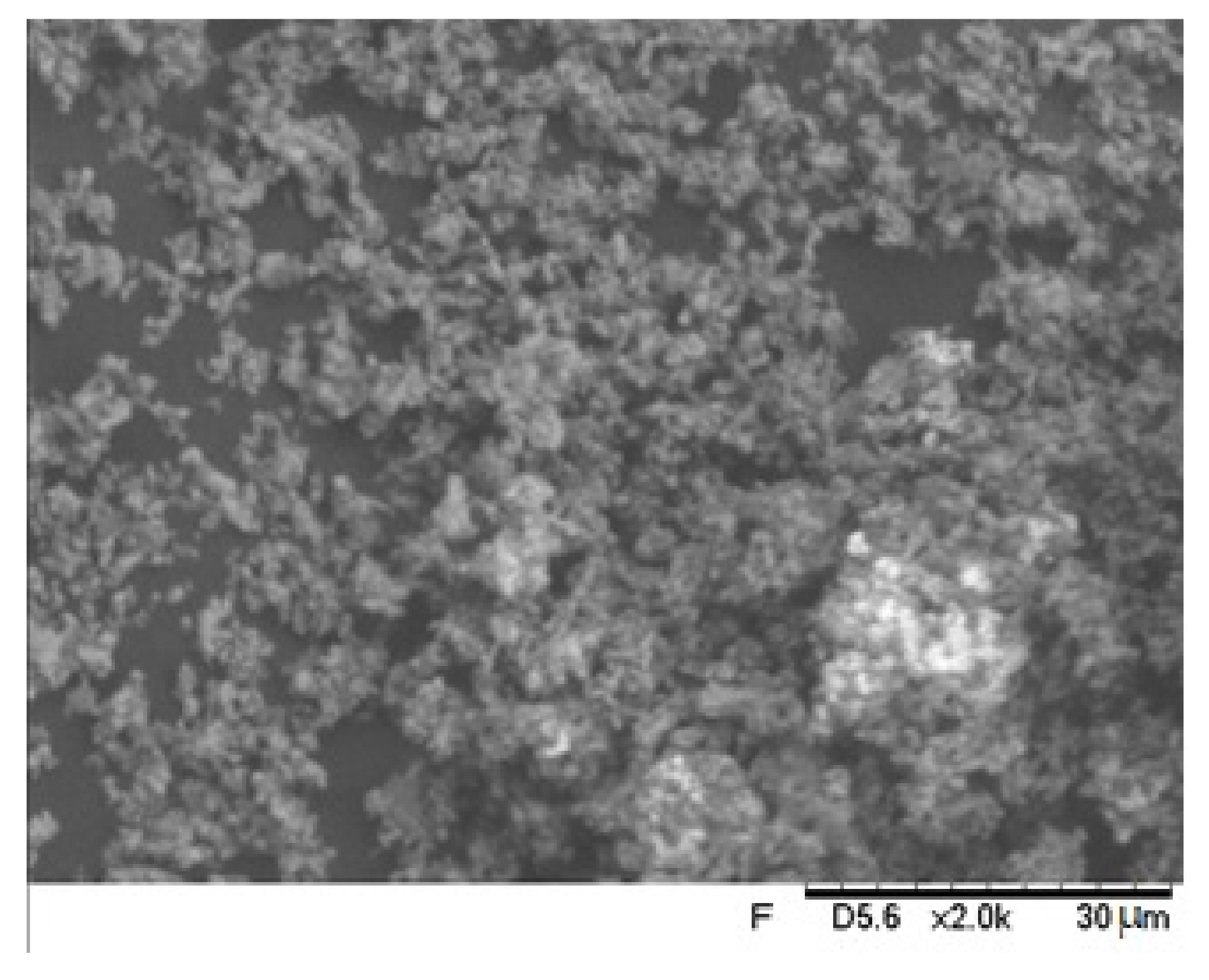

2.2. Spraying Process and Coating Characterization

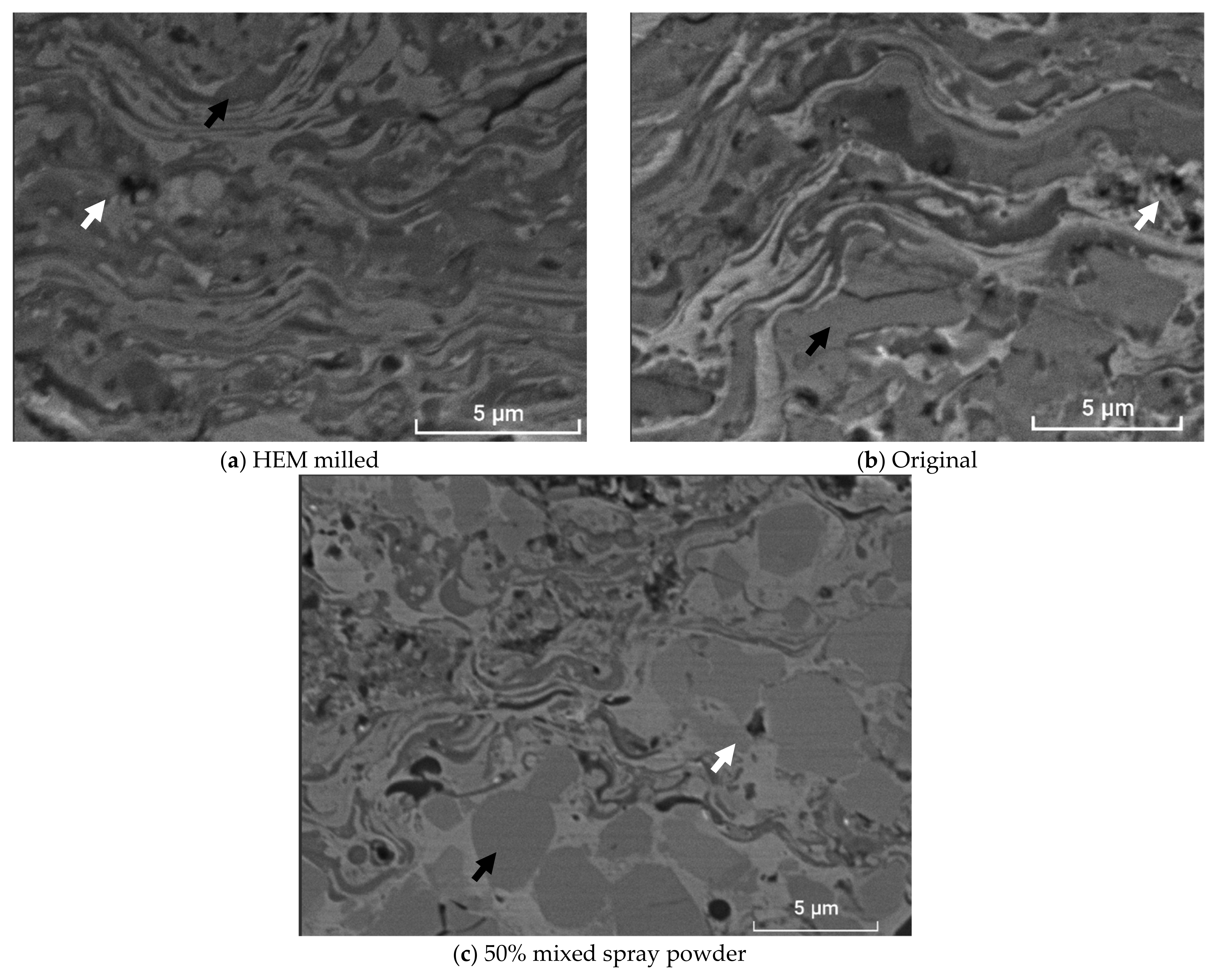

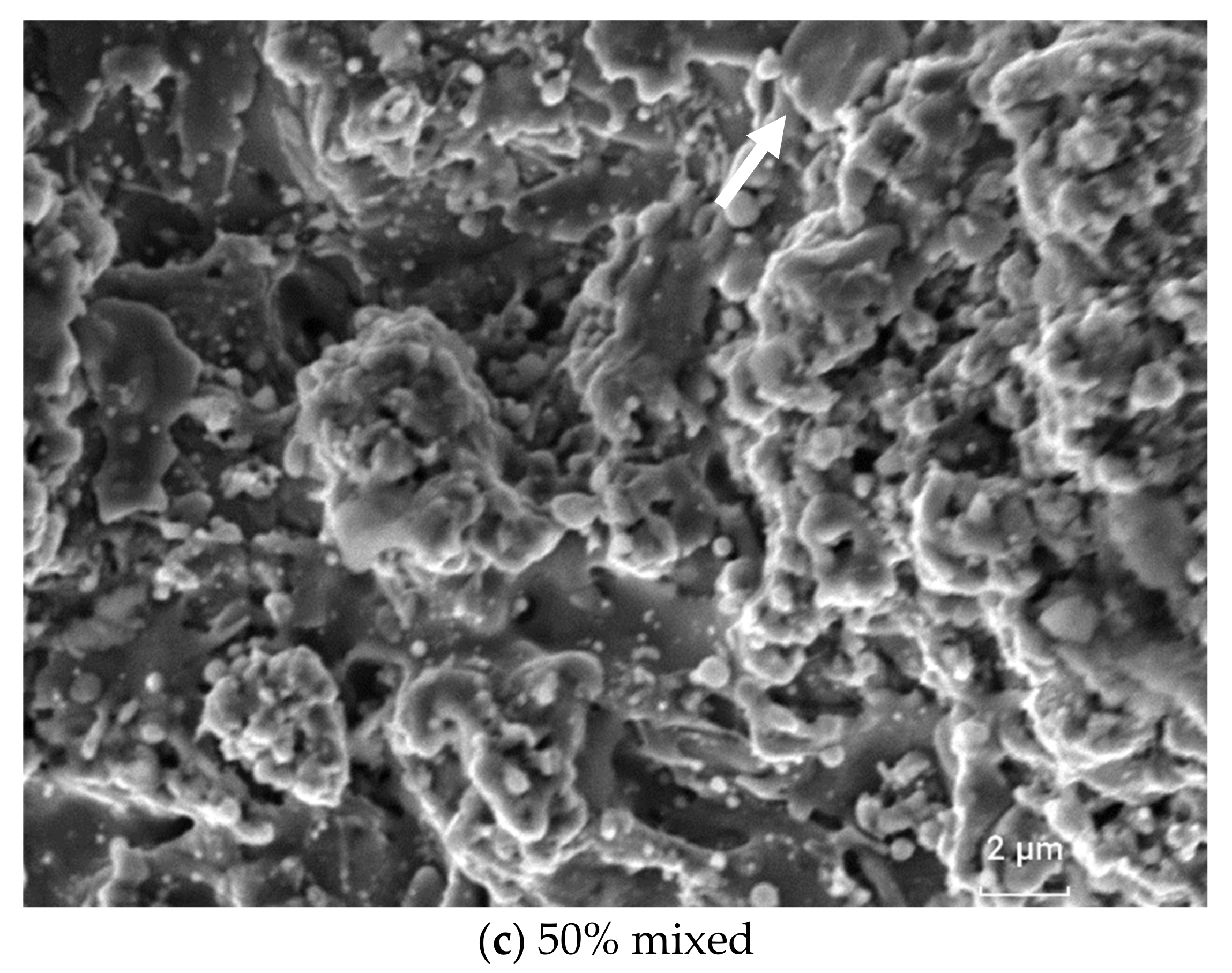

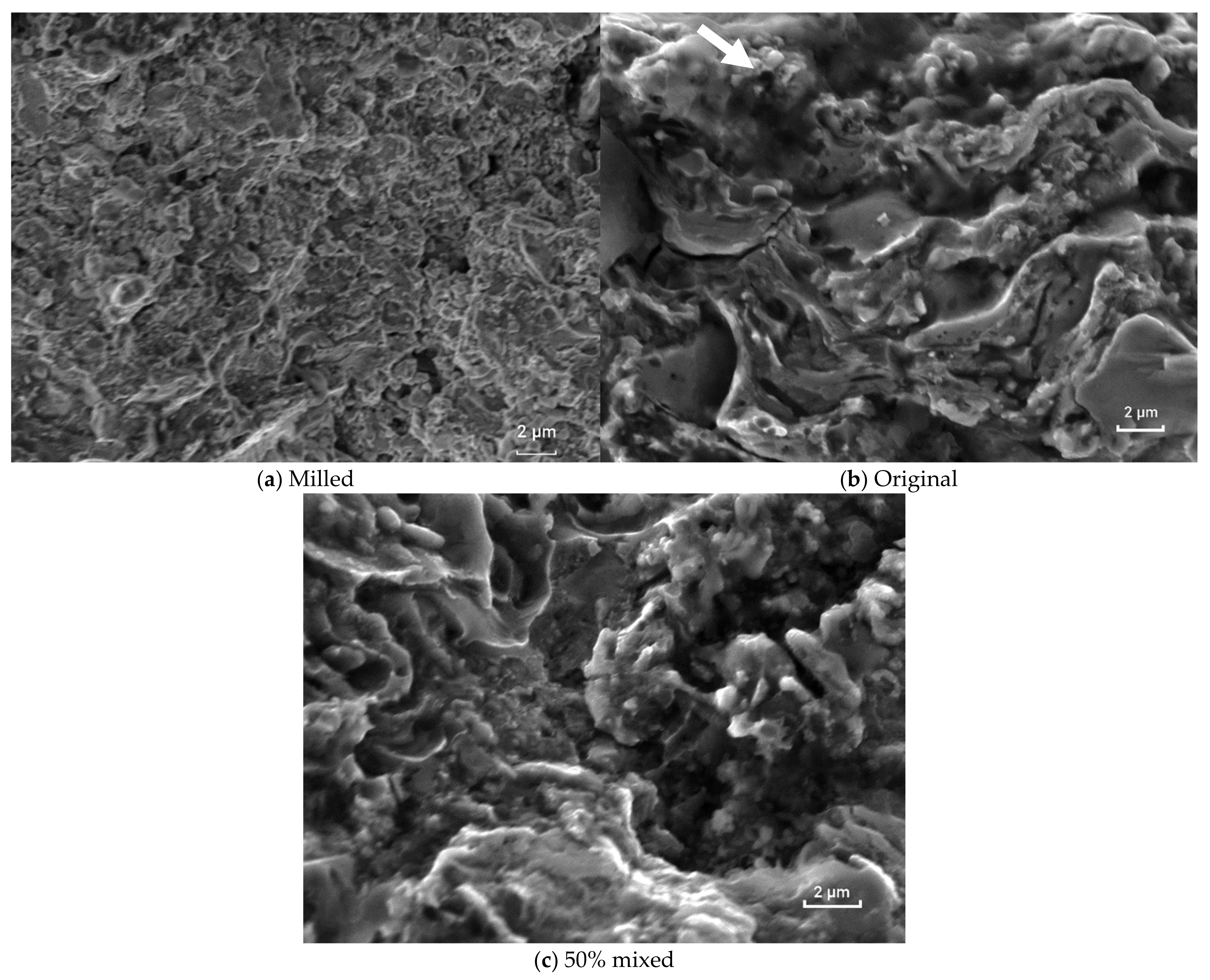

3. Results and Discussions

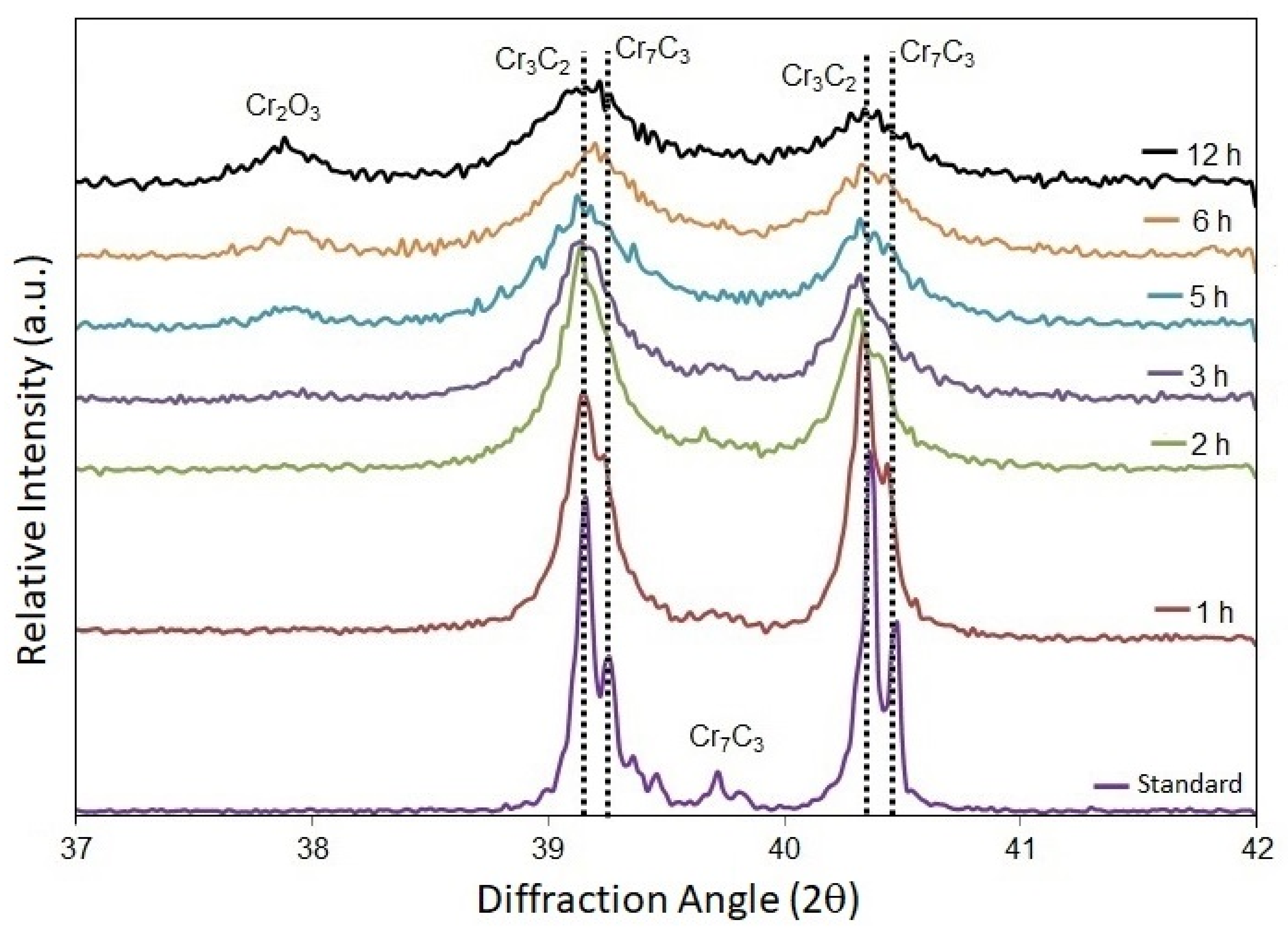

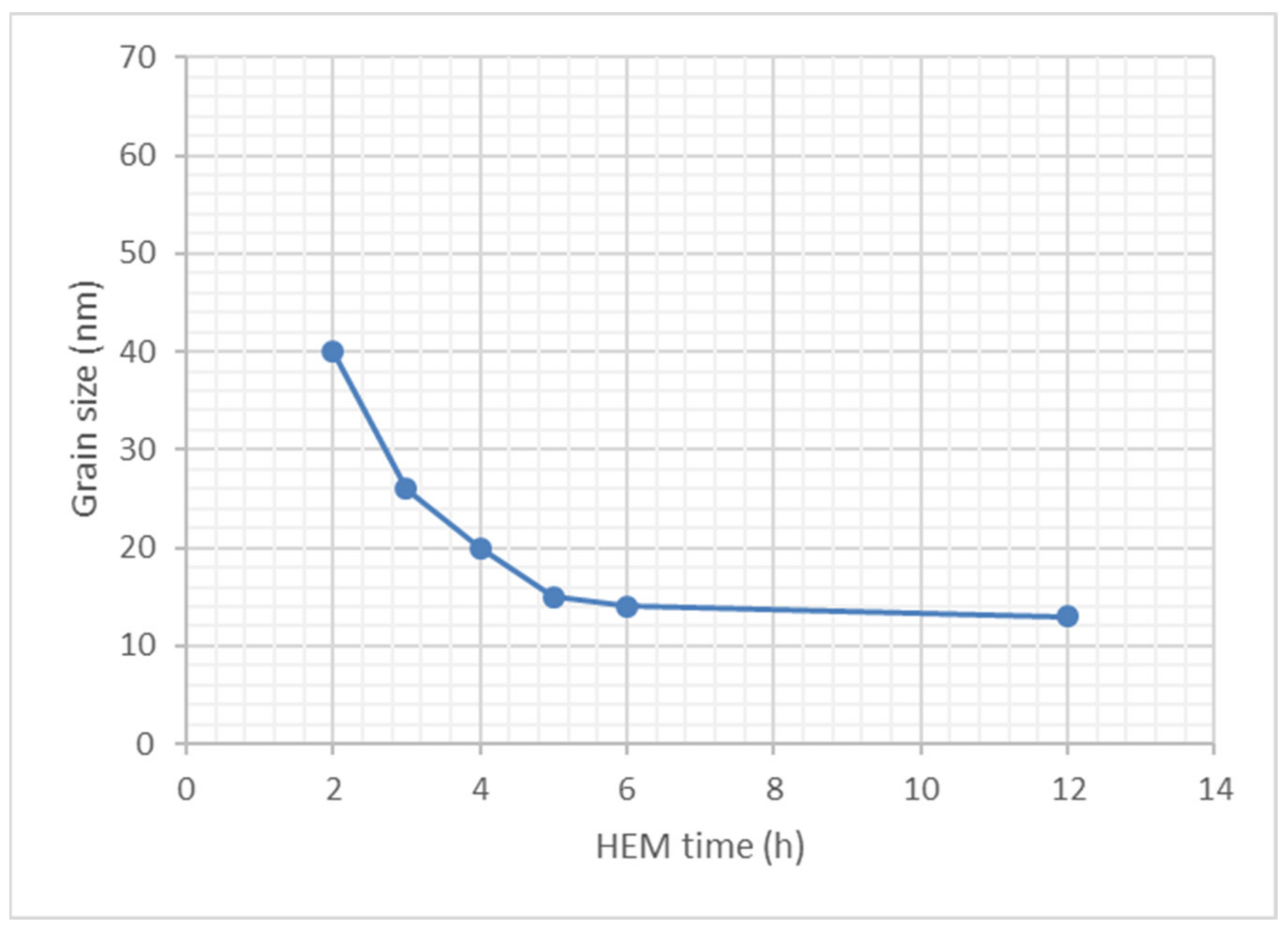

HEM Crystallite Size Reduction

4. Conclusions

- The milled coating presented lower roughness and more refined microstructure than the original and mixed coatings;

- The milled coatings exhibited a lower fatigue life above the fatigue limit and a higher fatigue limit than the original and mixed coatings;

- The coatings’ thickness and hardness did not denote significant differences among the coating types after applying the parameters used in the study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peat, T.; Galloway, A.M.; Toumpis, A.I.; Harvey, D. Evaluation of the synergistic erosion-corrosion behaviour of HVOF thermal spray coatings. Surf. Coat. Technol. 2016, 299, 37–48. [Google Scholar] [CrossRef]

- Mengchuan, S.; Zhaolu, X.; Heping, L.; Zupeng, Y.; Xia, L.; Shihong, Z. High velocity oxygen fuel sprayed Cr3C2-NiCr coatings against Na2SO4 hot corrosion at different temperatures. Ceram. Int. 2020, 46, 23629–23635. [Google Scholar]

- Varis, T.; Suhonen, T.; Calonius, O.; Čuban, J.; Pietola, M. Optimization of HVOF Cr3C2 NiCr coating for increased fatigue performance. Surf. Coat. Technol. 2016, 305, 123–131. [Google Scholar] [CrossRef]

- Matthews, S.; Berger, L. Long-term Compositional/Microstructural Development of Cr3C2-NiCr Coatings at 500 °C, 700 °C and 900 °C. Int. J. Refract. Met. Hard Mater. 2016, 59, 1–18. [Google Scholar] [CrossRef]

- Somasundaram, B.; Kadoli, R.; Ramesh, M. Evaluation of Thermocyclic Oxidation Behavior of HVOF Sprayed (Cr3C2-35% NiCr) + 5% Si Coatings on Boiler Tube Steels. Procedia Mater. Sci. 2014, 5, 398–407. [Google Scholar] [CrossRef]

- Govande, A.R.; Chandak, A.; Sunil, B.R.; Dumpala, R. Carbide-based thermal spray coatings: A review on performance characteristics and post-treatment. Int. J. Refract. Met. Hard Mater. 2021, 103, 105772. [Google Scholar] [CrossRef]

- Fan, K.; Jiang, W.; Luzin, V.; Gong, T.; Feng, W.; Ruiz-Hervias, J.; Yao, P. Influence of WC Particle Size on the Mechanical Properties and Residual Stress of HVOF Thermally Sprayed WC–10Co–4Cr Coatings. Materials 2022, 15, 5537. [Google Scholar] [CrossRef] [PubMed]

- Vackel, A.; Sampath, S. Fatigue behavior of thermal sprayed WC-CoCr-steel systems: Role of process and deposition parameters. Surf. Coat. Technol. 2017, 315, 408–416. [Google Scholar] [CrossRef]

- Zishuan, F.; Shansong, W.; Zhengdong, Z. Microstructures and Properties of Nano-structural WC-12Co Coatings Deposited by AC-HVAF. Rare Met. Mater. Eng. 2017, 46, 923–927. [Google Scholar] [CrossRef]

- Wang, K.; Hong, S.; Wei, Z.; Hu, N.; Cheng, J.; Wu, Y. Sprayed Cr3C2 e NiCr coatings in sulfide-containing 3.5 wt.% NaCl solution. J. Mater. Res. Technol. 2021, 15, 3122–3132. [Google Scholar] [CrossRef]

- Uściłowska, A.; Szczucka-Lasota, B.; Węgrzyn, T.; Szymczak, T.; Łazarz, B.; Kamińska, J. Numerical Simulations Based on a Meshfree Method for Nickel-Steel Welded Joint Manufactured by Micro-Jet Cooling. Materials 2022, 15, 8579. [Google Scholar] [CrossRef] [PubMed]

- Severiano, J.A.; Silva, A.S.; Sussushib, E.M.; Sant’anna, M.V.S.; Cunha, M.A.; Bergmann, C.P.; Griza, S. Corrosion damages of flow regulation valves for water injection in oil fields. Eng. Fail. Anal. 2019, 96, 362–373. [Google Scholar] [CrossRef]

- Ibrahim, A.; Lima, R.S.; Berndt, C.; Marple, B. Fatigue and mechanical properties of nanostructured and conventional titania (TiO2) thermal spray coatings. Surf. Coat. Technol. 2007, 201, 7589–7596. [Google Scholar] [CrossRef]

- Ham, G.-S.; Kreethi, R.; Kim, H.-J.; Yoon, S.-H.; Lee, K.-A. Effects of different HVOF thermal sprayed cermet coatings on tensile and fatigue properties of AISI 1045 steel. J. Mater. Res. Technol. 2021, 15, 6647–6658. [Google Scholar] [CrossRef]

- Guaglianoni, W.C.; Takimi, A.S.; Vicenzi, J.; Bergmann, C.P. Synthesis of WC-12 wt%Co Nanocomposites by High-energy Ball Milling and Their Morphological Characterization. Technol. Metall. Mater. Min. 2015, 12, 211–215. [Google Scholar] [CrossRef]

- Balbino, N.A.N.; Valeriano, L.d.C.; Correa, E.O.; Santos, J.N. Microstructural Characterization of the Powder and the Cemented Carbide WC-8Ni-2Mo2C. In Proceedings of the 23rd ABCM International Congress of Mechanical Engineering, Rio de Janeiro, Brazil, 6–11 December 2015; 1, pp. 1–8. [Google Scholar]

- Chen, W.; Mao, T.; Zhang, B.; Zhang, S.; Meng, X. Designs and preparation of advanced HVOF-PVD duplex coating by combination of HVOF and arc ion plating. Surf. Coat. Technol. 2016, 304, 125–133. [Google Scholar] [CrossRef]

- Jin, D.; Yang, F.; Zou, Z.; Gu, L.; Zhao, X.; Guo, F.; Xiao, P. A study of the zirconium alloy protection by Cr3C2–NiCr coating for nuclear reactor application. Surf. Coat. Technol. 2016, 287, 55–60. [Google Scholar] [CrossRef]

- Mayrhofer, E.; Janka, L.; Mayr, W.P.; Norpoth, J.; Ripoll, M.R.; Gröschl, M. Cracking resistance of Cr3C2-NiCr and WC-Cr3C2-Ni thermally sprayed coatings under tensile bending stress. Surf. Coat. Technol. 2015, 281, 169–175. [Google Scholar] [CrossRef]

- Verdi, D.; Garrido, M.; Múnez, C.; Poza, P. Cr3C2 incorporation into an Inconel 625 laser cladded coating: Effects on matrix microstructure, mechanical properties and local scratch resistance. Mater. Des. 2015, 67, 20–27. [Google Scholar] [CrossRef]

- Da Cunha, C.A.; Correa, O.V.; Sayeg, I.J.; Ramanathan, L.V. High Temperature Erosion-oxidation Resistance of Thermally Sprayed Nanostructured Cr3C2-25(Ni-20Cr) Coatings. Mater. Res. 2017, 20, 994–1002. [Google Scholar] [CrossRef]

- Hu, Q.; Ji, D.; Shen, M.; Zhuang, H.; Yao, H.; Zhao, H.; Hui, G.; Zhang, Y. Three-Body Abrasive Wear Behavior of WC-10Cr3C2-12Ni Coating for Ball Mill Liner Application. Materials 2022, 15, 4569. [Google Scholar] [CrossRef] [PubMed]

- Shabana, S.M.M.M.; Suman, K.N.S.; Kamaluddin, S. Tribological and Corrosion Behavior of HVOF Sprayed WC-Co, NiCrBSi and Cr3C2-NiCr Coatings and analysis using Design of Experiments. Mater. Today Proc. 2015, 2, 2654–2665. [Google Scholar] [CrossRef]

- Bolelli, G.; Berger, L.-M.; Börner, T.; Koivuluoto, H.; Matikainen, V.; Lusvarghi, L.; Lyphout, C.; Markocsan, N.; Nylén, P.; Sassatelli, P.; et al. Sliding and abrasive wear behaviour of HVOF- and HVAF-sprayed Cr3C2–NiCr hardmetal coatings. Wear 2016, 358–359, 32–50. [Google Scholar] [CrossRef]

- Kuffner, B.H.B.; Silva, G.; Rodrigues, C.A.; Rodrigues, G. Study of the AISI 52100 Steel Reuse Through the Powder Metallurgy Route Using High Energy Ball Milling. Mater. Res. 2017, 21, e20170546. [Google Scholar] [CrossRef]

- Brupbacher, M.C.; Zhang, D.; Buchta, W.M.; Graybeal, M.L.; Rhim, Y.-R.; Nagle, D.C.; Spicer, J.B. Synthesis and characterization of binder-free Cr3C2 coatings on nickel-based alloys for molten fluoride salt corrosion resistance. J. Nucl. Mater. 2015, 461, 215–220. [Google Scholar] [CrossRef]

- Janka, L.; Berger, L.-M.; Norpoth, J.; Trache, R.; Thiele, S.; Tomastik, C.; Matikainen, V.; Vuoristo, P. Improving the high temperature abrasion resistance of thermally sprayed Cr3C2-NiCr coatings by WC addition. Surf. Coat. Technol. 2018, 337, 296–305. [Google Scholar] [CrossRef]

- Souza, R.; Voorwald, H.; Cioffi, M. Fatigue strength of HVOF sprayed Cr3C2–25NiCr and WC-10Ni on AISI 4340 steel. Surf. Coat. Technol. 2008, 203, 191–198. [Google Scholar] [CrossRef]

- Zhou, W.; Zhou, K.; Deng, C.; Zeng, K.; Li, Y. Hot corrosion behaviour of HVOF-sprayed Cr3C2-NiCrMoNbAl coating. Surf. Coat. Technol. 2017, 309, 849–859. [Google Scholar] [CrossRef]

- Karaoglanli, A.C.; Oge, M.; Doleker, K.M.; Hotamis, M. Comparison of tribological properties of HVOF sprayed coatings with different composition. Surf. Coat. Technol. 2017, 318, 299–308. [Google Scholar] [CrossRef]

- Chatha, S.S.; Sidhu, H.S.; Sidhu, B.S. Characterisation and Corrosion-Erosion Behaviour of Carbide based Thermal Spray Coatings. J. Miner. Mater. Charact. Eng. 2012, 11, 569–586. [Google Scholar] [CrossRef]

- Amin, M.; Daoxin, L.; Xiaohua, Z.; Guangyu, H.; Dan, L.; Chengsong, L.; Xingchen, X. The fretting fatigue performance of Ti-6Al-4V alloy influenced by microstructure of CuNiIn coating prepared via thermal spraying. Tribol. Int. 2020, 145, 106156. [Google Scholar]

- Baumann, I.; Hagen, L.; Tillmann, W.; Hollingsworth, P.; Stangier, D.; Schmidtmann, G.; Tolan, M.; Paulus, M.; Sternemann, C. Process characteristics, particle behavior and coating properties during HVOF spraying of conventional, fine and nanostructured WC-12Co powders. Surf. Coat. Technol. 2020, 405, 126716. [Google Scholar] [CrossRef]

- Padial, A.; Cunha, C.; Correa, O.V.; de Lima, N.B.; Ramanathan, L.V. Effect of Cr3C2-NiCr Powder Characteristics on Structure and Properties of Thermal Sprayed Nanostructured Coatings. Mater. Sci. Forum 2010, 660–661, 379–384. [Google Scholar] [CrossRef]

- Matikainen, V.; Koivuluoto, H.; Vuoristo, P. A study of Cr3C2-based HVOF- and HVAF-sprayed coatings: Abrasion, dry particle erosion and cavitation erosion resistance. Wear 2020, 446–447, 203188. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Oxygen pressure (PSI) | 150 |

| Oxygen flow (ft3/h) | 560 |

| Propane pressure (PSI) | 100 |

| Propane flow (ft3/h) | 160 |

| Air pressure (PSI) | 100 |

| Air flow (ft3/h) | 850 |

| Feeding rate (g/min) | 35 |

| Spraying distance (mm) | 230 |

| Number of passes | 01 |

| Spraying angle (°) | 90 |

| Feature | Coating | ||

|---|---|---|---|

| Milled | Original | 50% Mixed | |

| Hardness (HK) | 1166 (189) | 1081 (0) | 1177 (232) |

| Thickness (μm) | 42 (9) | 40 (8) | 50 (5) |

| Roughness Ra (μm) | 1.27 (0.03) | 1.41 (0.05) | 1.58 (0.04) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, R.d.P.S.; Cogo, G.R.; Nascimento, B.L.; Reis, M.M.S.; Takimi, A.; Griza, S.; Bergmann, C.P. Influence of Pre-Milling of Cr3C2-25 NiCr Spray Powder on the Fatigue Life of HVOF-Sprayed Coating on ASTM A516 Steel Substrate. Materials 2023, 16, 1593. https://doi.org/10.3390/ma16041593

Oliveira RdPS, Cogo GR, Nascimento BL, Reis MMS, Takimi A, Griza S, Bergmann CP. Influence of Pre-Milling of Cr3C2-25 NiCr Spray Powder on the Fatigue Life of HVOF-Sprayed Coating on ASTM A516 Steel Substrate. Materials. 2023; 16(4):1593. https://doi.org/10.3390/ma16041593

Chicago/Turabian StyleOliveira, Rosivânia da P. S., Gabriel R. Cogo, Brenno L. Nascimento, Matheus M. S. Reis, Antonio Takimi, Sandro Griza, and Carlos P. Bergmann. 2023. "Influence of Pre-Milling of Cr3C2-25 NiCr Spray Powder on the Fatigue Life of HVOF-Sprayed Coating on ASTM A516 Steel Substrate" Materials 16, no. 4: 1593. https://doi.org/10.3390/ma16041593

APA StyleOliveira, R. d. P. S., Cogo, G. R., Nascimento, B. L., Reis, M. M. S., Takimi, A., Griza, S., & Bergmann, C. P. (2023). Influence of Pre-Milling of Cr3C2-25 NiCr Spray Powder on the Fatigue Life of HVOF-Sprayed Coating on ASTM A516 Steel Substrate. Materials, 16(4), 1593. https://doi.org/10.3390/ma16041593